Page 1

Is Now Part of

To learn more about ON Semiconductor, please visit our website at

ON Semi conductor an d the ON Semico nductor logo a re trademar ks of Semicon ductor Comp onents Indus tries, L LC dba ON Semico nductor or it s subsidiari es in the United S tates and /or other coun tries. ON Se miconducto r owns the righ ts to a number

of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent coverage may be accessed at www.onsemi.com/site/pdf/Patent-Marking.pdf. ON Semiconductor reserve s the right

to make changes without f urther noti ce to any produc ts herein. ON S emicon ductor makes no warran ty, representat ion or guar antee regar ding the suitability of its pro ducts for any partic ular purpose, n or does ON Semic onductor as sume any liabilit y

arisin g out of the applica tion or us e of any product o r circui t, and specific ally dis claims any and all lia bilit y, includin g witho ut limit ation sp ecial, c onsequential or incidental da mages . Buye r is responsib le for it s products and a pplica tions us ing ON

Semic onductor pr oducts, inc luding complia nce with all law s, regulati ons and safet y requirem ents or stan dards, rega rdless of an y support or ap plications in formation p rovided by ON S emiconduc tor. “Typical ” parameter s which may be pr ovided in ON

Semic onductor data s heet s and/or s pecificatio ns can and do vary in diff erent a pplica tions an d actual perf ormance may var y over time. All o perat ing parameter s, including “Typical s” must b e validated for e ach cus tomer ap plicat ion by customer’s

techni cal exper ts. ON Semic onductor do es not conve y any license un der its pate nt rights no r the rights o f others. ON S emiconduc tor produc ts are not des igned, inte nded, or autho rized for use a s a critical c omponent in lif e support s ystems or an y FDA

Clas s 3 medical devi ces or medica l devices wit h a same or similar c lassificat ion in a foreign j urisdictio n or any device s intended for im plantation in t he human body. Sho uld Buyer pur chase or use ON S emiconduct or products f or any such unint ended

or unaut horized appli cation, Buy er shall indemn ify and hold O N Semiconduc tor and its of ficers, e mployees , subsidiari es, affilia tes, and dis tributor s harmless ag ainst all claim s, costs , damages, an d expenses , and reason able attorn ey fees aris ing out

of, dire ctly or indire ctly, any claim o f personal inj ury or death as sociated w ith such unint ended or unauth orized use, e ven if such claim a lleges that ON S emiconduc tor was neglig ent regardin g the design or ma nufacture o f the part. ON S emiconduct or

is an Equa l Oppor tunity/Affirm ative Action E mployer. This li terature is s ubject to all applicable c opyright la ws and is no t for resale in any manner.

www.onsemi.com

Page 2

User Guide for

FEBFAN9611_S01U300A

Evaluation Board

FAN9611 300W Interleaved Dual-BCM,

Low-Profile, PFC Evaluation Board

Featured Fairchild Product:

FAN9611

Direct questions or comments

about this evaluation board to:

“Worldwide Direct Support”

Fairchild Semiconductor.com

© 2012 Fairchild Semiconductor Corporation 1 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 3

Table of Contents

1. Overview of the Evaluation Board ............................................................................................. 3

2. Key Features ............................................................................................................................... 5

3. Specifications ............................................................................................................................. 6

4. Test Procedure ............................................................................................................................ 7

4.1. Safety Precautions .............................................................................................................7

5. Schematic ................................................................................................................................... 9

6. Boost Inductor Specification .................................................................................................... 10

7. Four-Layer PCB and Assembly Images ................................................................................... 11

8. Bill of Materials (BOM) ........................................................................................................... 14

9. Inrush Current Limiting ............................................................................................................ 16

10.Test Results ............................................................................................................................. 18

10.1.Startup .............................................................................................................................18

10.2.Steady State Operation ....................................................................................................20

10.3.Line Transient .................................................................................................................24

10.4.Load Transient ................................................................................................................25

10.5.Brownout Protection .......................................................................................................27

10.6.Phase Management .........................................................................................................28

10.7.Efficiency ........................................................................................................................30

10.8.Harmonic Distortion and Power Factor ..........................................................................32

10.9.EMI .................................................................................................................................33

11.References ............................................................................................................................... 34

12.Ordering Information .............................................................................................................. 34

13.Revision History ..................................................................................................................... 34

© 2012 Fairchild Semiconductor Corporation 2 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 4

The following user guide supports the FAN9611 300W evaluation board for interleaved

boundary-conduction-mode power-factor-corrected supply. It should be used in

conjunction with the FAN9611 datasheet, Fairchild application note AN-6086 —Design

Considerations for Interleaved Boundary-Conduction Mode PFC Using FAN9611 /

FAN9612

and FAN9611/12 PFC Excel®-based Design Tool.

1. Overview of the Evaluation Board

The FAN9611 interleaved, dual Boundary-Conduction-Mode (BCM), Power-FactorCorrection (PFC) controllers operate two parallel-connected boost power trains 180º out

of phase. Interleaving extends the maximum practical power level of the control

technique from about 300W to greater than 800W. Unlike the Continuous Conduction

Mode (CCM) technique often used at higher power levels, BCM offers inherent zerocurrent switching of the boost diodes (no reverse-recovery losses), which permits the use

of less expensive diodes without sacrificing efficiency. Furthermore, the input and output

filters can be smaller due to ripple current cancellation between the power trains and

doubling of effective switching frequency.

The advanced line feed-forward with peak detection circuit minimizes the output voltage

variation during line transients. To guarantee stable operation with less switching loss at

light load, the maximum switching frequency is clamped at 525kHz. Synchronization is

maintained under all operating conditions.

Protection functions include output over-voltage, over-current, open-feedback, undervoltage lockout, brownout, and redundant latching over-voltage protection. FAN9611 is

available in a lead-free, 16-lead, Small-Outline Integrated-Circuit (SOIC) package.

This FAN9611 evaluation board uses a four-layer Printed Circuit Board (PCB) designed

for 300W (400V/0.75A) rated power. The maximum rated power is 350W and the

Maximum On-Time (MOT) power limit is set to 360W. The FEBFAN9611_S01U300A

is optimized to demonstrate all the FAN9611 efficiency and protection features in a lowprofile height form factor less than 18mm.

© 2012 Fairchild Semiconductor Corporation 3 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 5

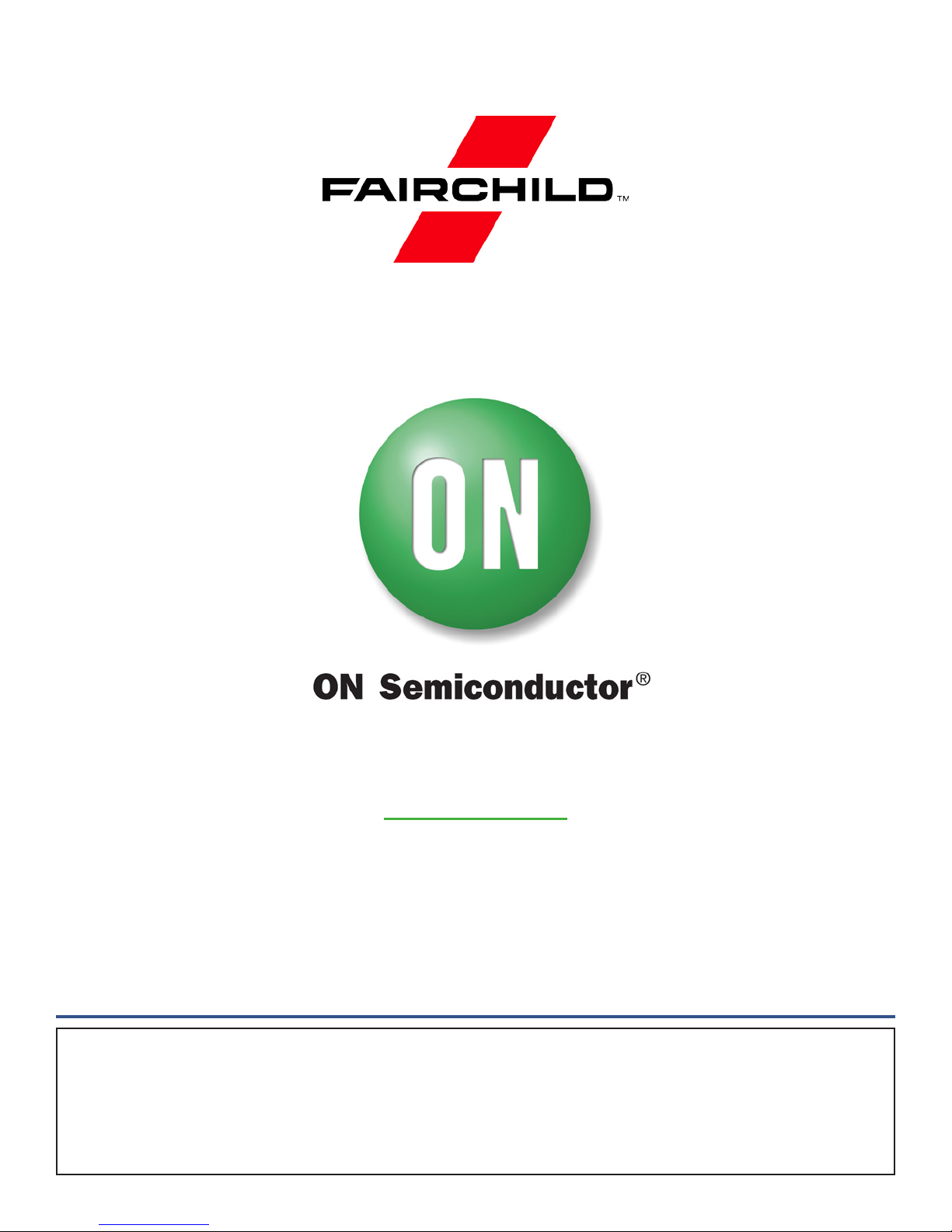

Figure 1. FEBFAN9611_S01U300A, Top View, 152mm x 105mm

Figure 2. FEBFAN9611_S01U300A, Side View (Low Profile), Cross Section=18mm

Figure 3. FEBFAN9611_S01U300A, Bottom View, 152mm x 105mm

© 2012 Fairchild Semiconductor Corporation 4 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 6

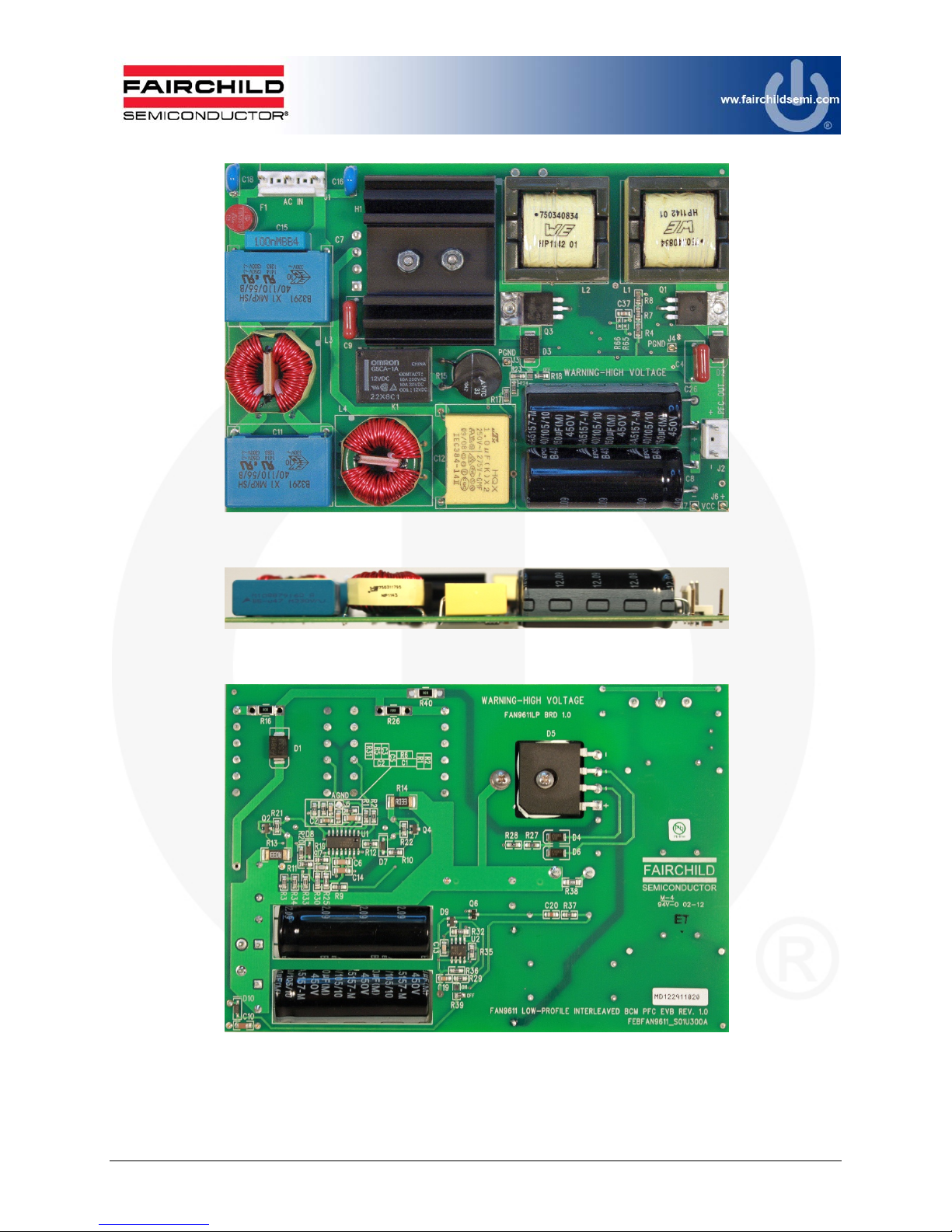

2. Key Features

180° Out-of-Phase Synchronization

Automatic Phase Disable at Light Load

1.8A Sink, 1.0A Source, High-Current Gate Drivers

Transconductance (g

Voltage-Mode Control with (V

Closed-Loop Soft-Start with Programmable Soft-Start Time for Reduced Overshoot

Minimum Restart Timer Frequency to Avoid Audible Noise

Maximum Switching Frequency Clamp

Brownout Protection with Soft Recovery

Non-Latching OVP on FB Pin and Second-Level Latching Protection on OVP Pin

Open-Feedback Protection

Over-Current and Power-Limit Protection for Each Phase

Low Startup Current: 80µA Typical

Works with DC input or 50Hz to 400Hz AC Input

) Error Amplifier for Reduced Overshoot

M

)2 Feed-Forward

IN

ZCD1

ZCD2

5VB

MOT

AGND

SS

COMP

FB

1

2

3

4

5

6

3V

7

8

VALLEY DETECTOR

VALLEY DETECTOR

5V

I

MOT

1.25V

REF

CHANNEL 1

CHANNEL 2

V

5V

BIAS

K1 VINI

K1 VINI

5V

5µA

16

0.2V

2µA

15

14

13

12

11

10

9

CS1

CS2

VDD

DRV1

DRV2

PGND

VIN

OVP

0.195V

0.195V

AB

PROTECTION LOGIC

(Open FB, Brownout Protec tion,

OVP, Latched OVP)

UVLO

S

S

INPUT VOLTAGE SENSE

(Input Voltage Squarer,

Input UVLO, Brownout)

V

DD

QQR

A

QQR

B

SYNCHRONIZATION

RESTART TIMERS

FREQUENCY CLAMPS

DD

5V

2

MOT

2

MOT

gm

A

5V

B

Phase

Management

Figure 4. Block Diagram

© 2012 Fairchild Semiconductor Corporation 5 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 7

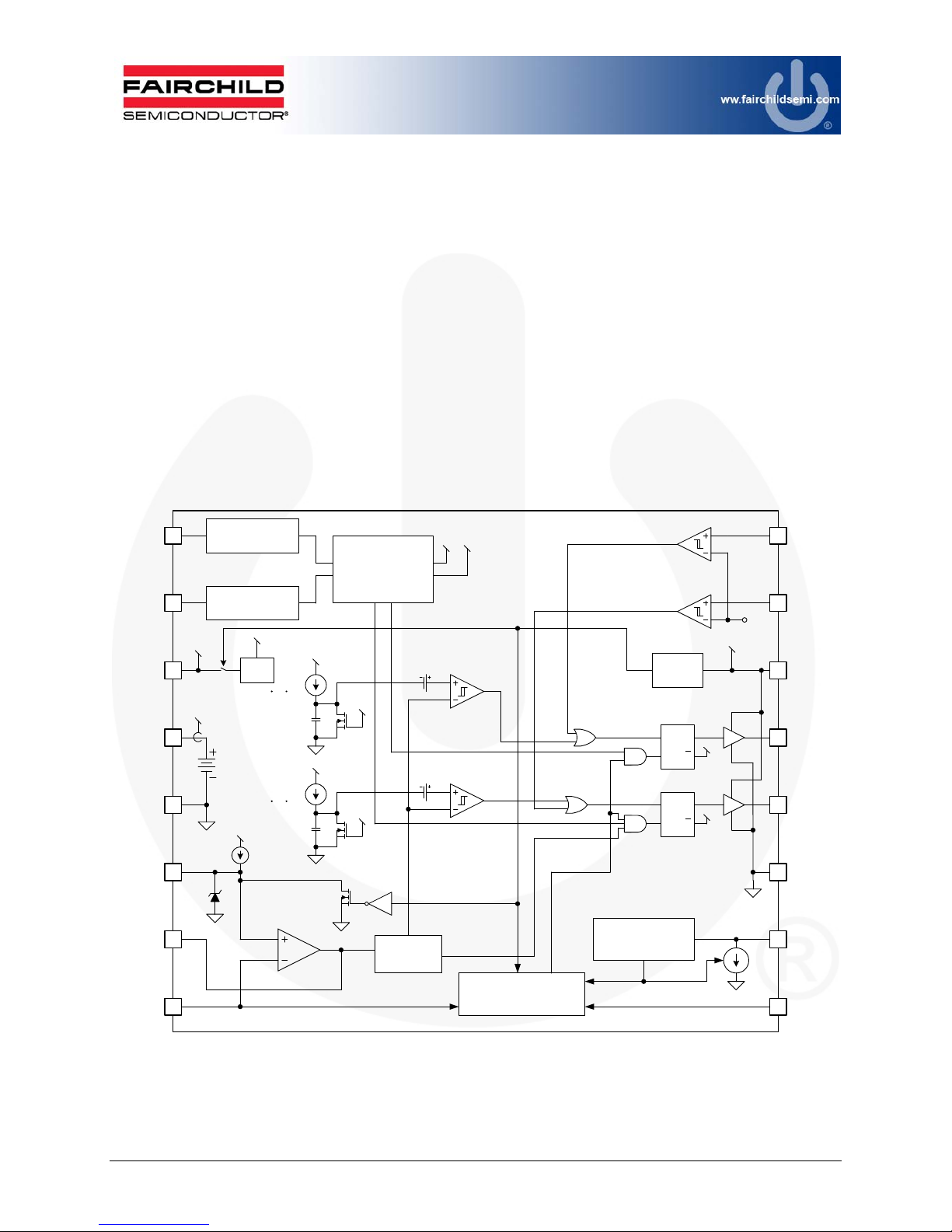

3. Specifications

This evaluation board has been designed and optimized for the conditions in Table 1.

Table 1. Electrical and Mechanical Requirements

Min. Typ. Max.

V

80V 120V 265V

IN_AC

P

P

V

V

V

OUT_PFC_RIPPLE

P

OUT_PFC(MOT LIMIT)

t

SOFT_START

t

ON_OVERSHOOT

>30%P

OUT

>30%P

OUT

90V

IN_AC(ON)

IN_AC(OFF)

f

50Hz 60Hz 65Hz

VIN_AC

V

395V 400V 405V

OUT_PFC

P

300W 350W

OUT_PFC

f

18kHz 300kHz

SW_P FC

t

20ms

HOLD_UP

250ms 300ms

_PFC_120V

OUT(TYP)

_PFC_230V

OUT(TYP)

PF

0.991

_120V

PF

0.980

_230V

Height 18mm

JC

80V

10V 11V

360W

10V

96% 96.5%

95% 98%

Mechanical and Thermal

60⁰C

The trip points for the built-in protections are set as below in the evaluation board.

The line UVLO (brownout protection) trip point is set at 80V

(10VAC hysteresis).

AC

The pulse-by-pulse current limit for each MOSFET is set at 6A.

The current-limit function can be observed by measuring the individual inductor current

waveforms while operating at 85V

power limit is set at ~120% of the rated output power. The power-limit function can be

observed while operating at >115V

operating in power limit, the output voltage drops and the COMP voltage is saturated, but

the AC line current remains sinusoidal. The phase-management function permits phase

shedding / adding ~18% of the nominal output power for high line (230V

can be increased by modifying the MOT resistor (R6) as described in Fairchild

Application Note AN-6086 —Design Considerations for Interleaved Boundary-

Conduction Mode PFC Using FAN9611 / FAN9612.

© 2012 Fairchild Semiconductor Corporation 6 FEBFAN9611_S01U300A • Rev. 0.0.1

and increasing the load to 360W. The maximum

AC

and increasing the load beyond 360W. When

AC

). This level

AC

Page 8

4. Test Procedure

Before applying power to the FEBFAN9611_S01U300A evaluation board; the DC bias

supply for V

should be connected to the board as shown in Figure 5.

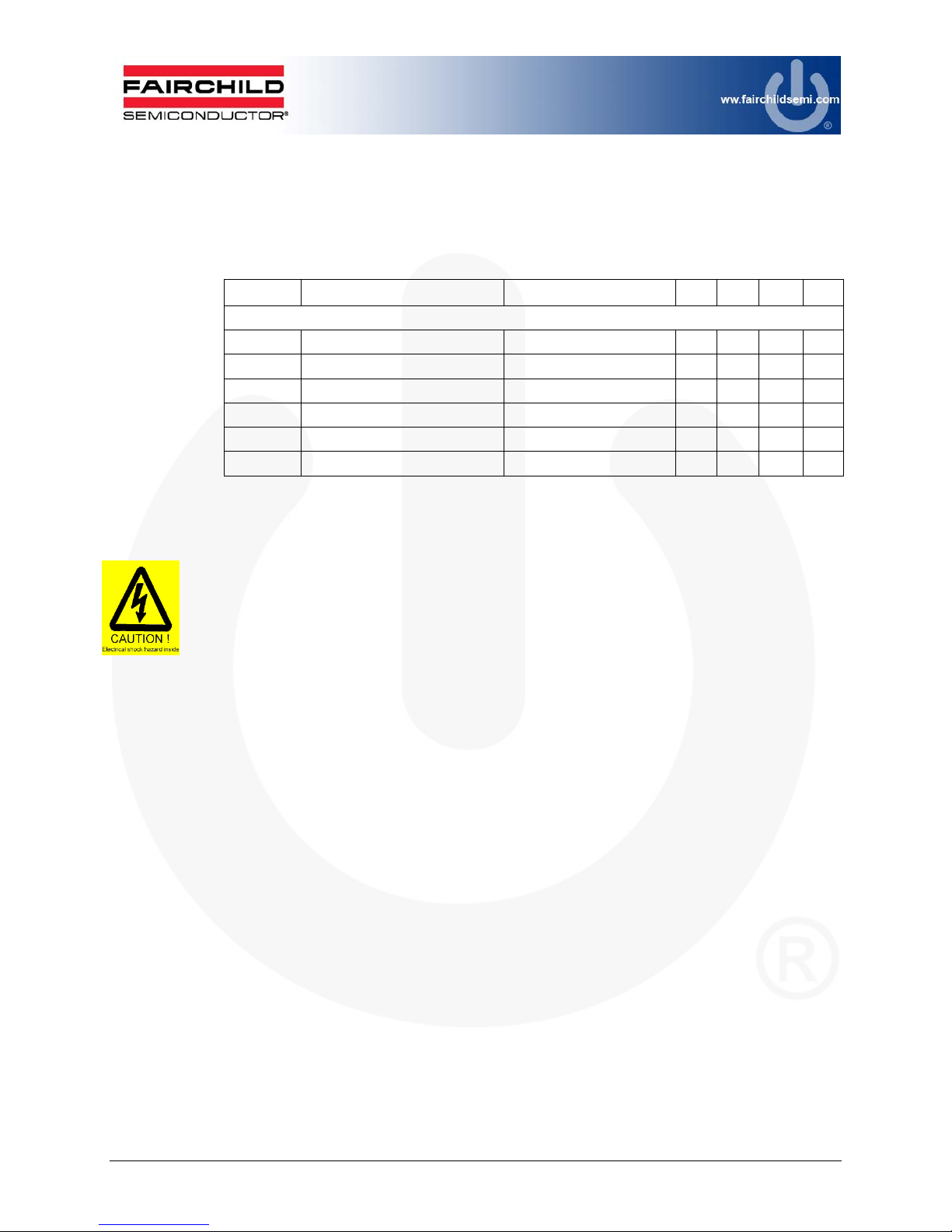

Table 2. Specification Excerpt from FAN9611 Datasheet

Symbol Parameter Conditions Min. Typ. Max. Unit

Supply

I

STARTUP

IDD

I

DD_DYM

VON

V

OFF

V

HYS

4.1. Safety Precautions

The FEBFAN9611_S01U300A evaluation module produces lethal voltages and the bulk

output capacitors store significant charge. Please be extra careful when probing and

handling the module and observe a few precautions:

, AC voltage supply for line input, and DC electronic load for output

DD

Startup Supply Current VDD = VON – 0.2V

Operating Current Output Not Switching

Dynamic Operating Current fSW = 50kHz; C

UVLO Start Threshold VDD Increasing

UVLO Stop Threshold Voltage VDD Decreasing

UVLO Hysteresis V

ON

– V

OFF

80 110 µA

3.7 5.2 mA

= 2nF

LOAD

4 6 mA

9.5 10.0 10.5 V

7.0 7.5 8.0 V

2.5 V

Start with a clean working surface, clear of any conductive material.

Be careful while turning on the power switch to the AC source.

Never probe or move a probe on the DUT while the AC line voltage is present.

Ensure the output capacitors are discharged before disconnecting the test leads. One

way to do this is to remove the AC power with the DC output load still switched on.

The load then discharges the output capacitors and the module is safe to disconnect.

Power-On Procedure

1. Supply V

specification for V

2. Connect the AC voltage (90~265V

FAN9611 has brownout protection, any input voltage less than the designed

minimum AC line voltage triggers brownout protection. FEBFAN9611_S01U300A

does not start until the AC input voltage is greater than 90V

3. Change load current (0~0.75A) and check the operation

4. Verify the output voltage is regulating between 395V

for the control chip first. It should be higher than 10.5V (refer to the

DD

turn-on threshold voltage in Table 2).

DD

) to start the FAN9611 evaluation board. Since

AC

.

AC

DC<VOUT

<405VDC

© 2012 Fairchild Semiconductor Corporation 7 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 9

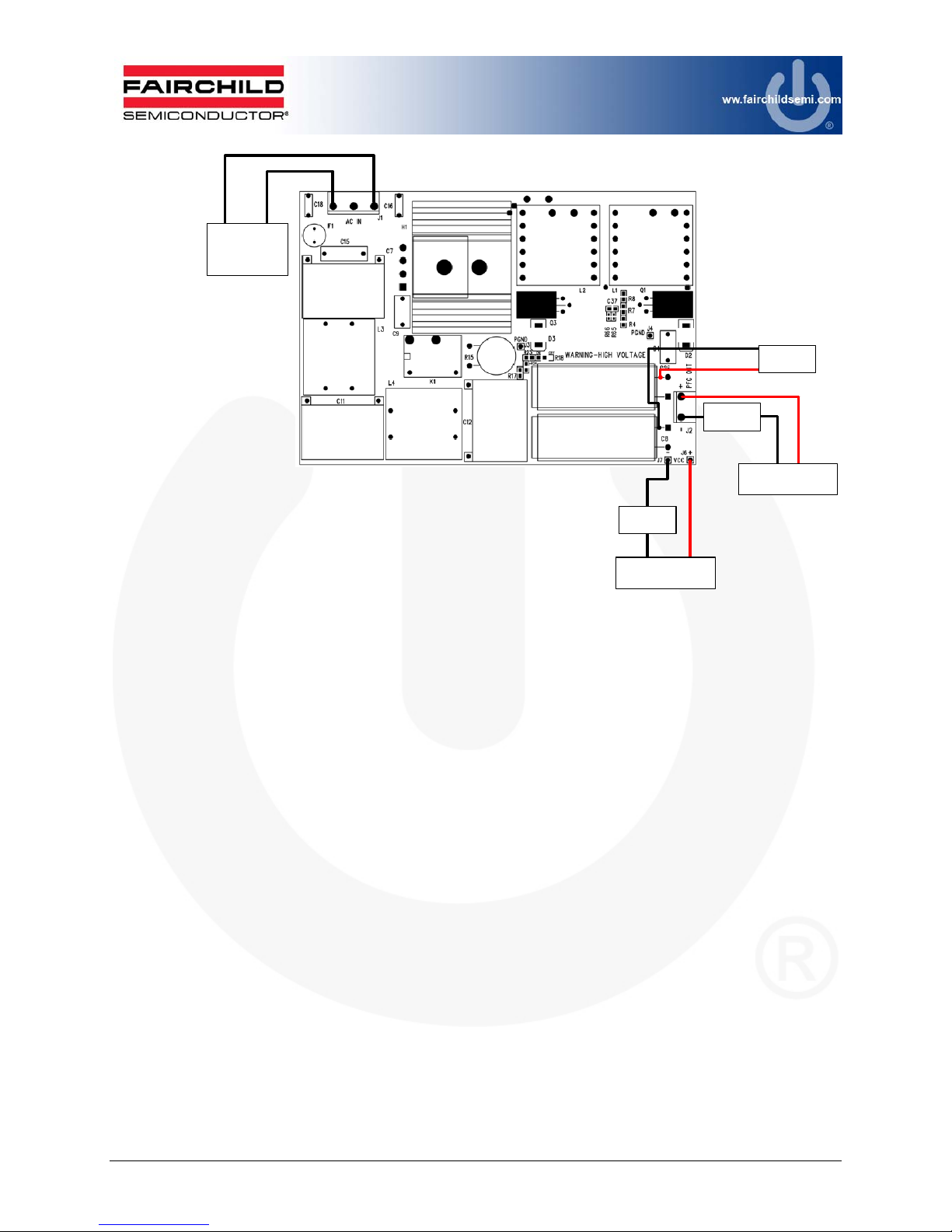

AC Source

PF, THD, P

0-265V

AC

IN

DVM

Voltage

DVM

Current

Electronic Load

400V, 0-1A

DVM

Current

DC Bias Supply

0-12V

Figure 5. Recommended Test Set-Up

All efficiency data shown in this document was taken using the test set up shown in

Figure 5 with the output voltage being measured directly at the output bulk capacitors

(not through the output connector (J2)).

Power-Off Procedure

1. Make sure the electronic load is set to draw at least 100mA of constant DC current.

2. Disconnect (shut down) AC line voltage source.

3. Disconnect (shut down) 12V DC bias power supply.

4. Disconnect (shut down) DC electronic load last to ensure that the output capacitors

are fully discharged before handling the evaluation module.

© 2012 Fairchild Semiconductor Corporation 8 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 10

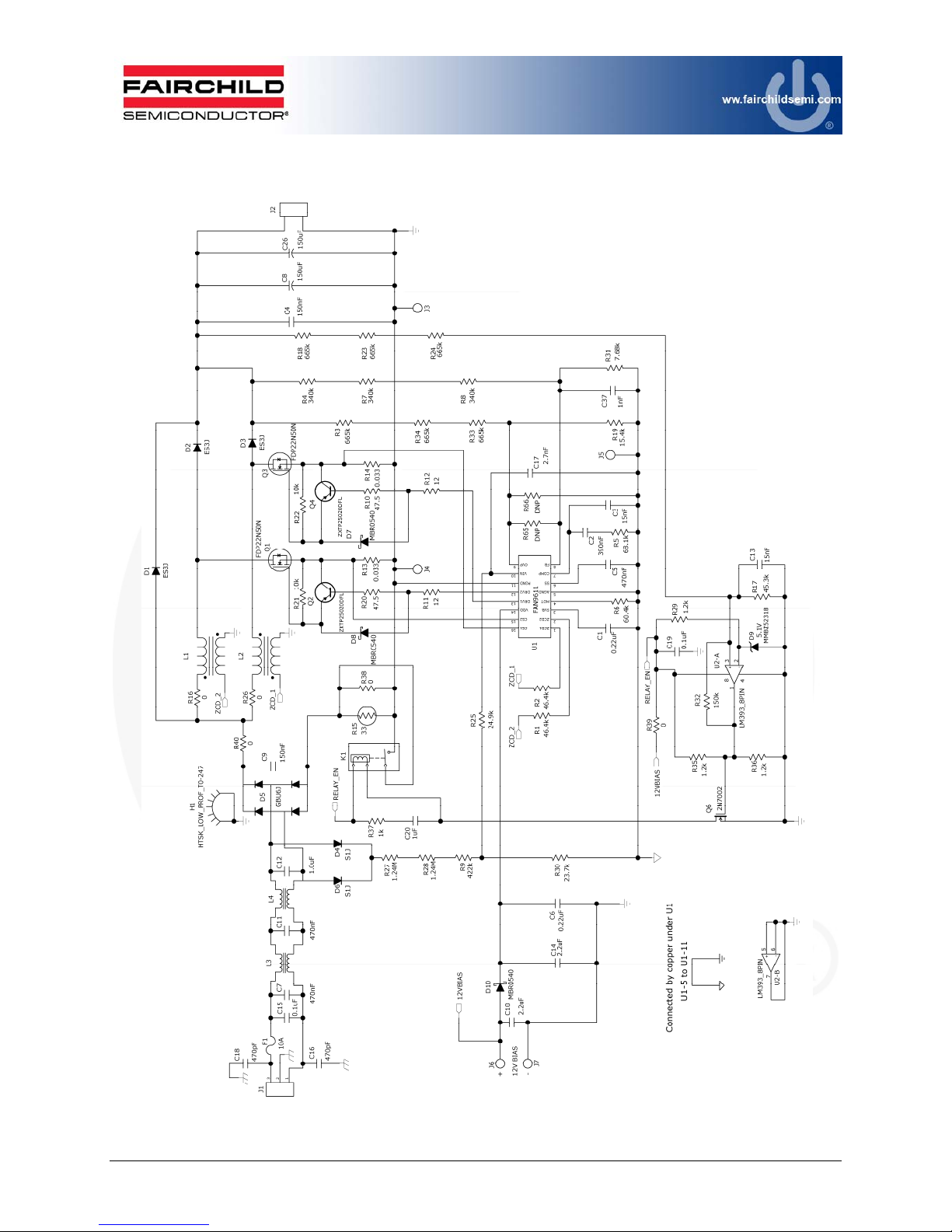

5. Schematic

Figure 6. FEBFAN9611_S01U300A 300W Evaluation Board Schematic

© 2012 Fairchild Semiconductor Corporation 9 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 11

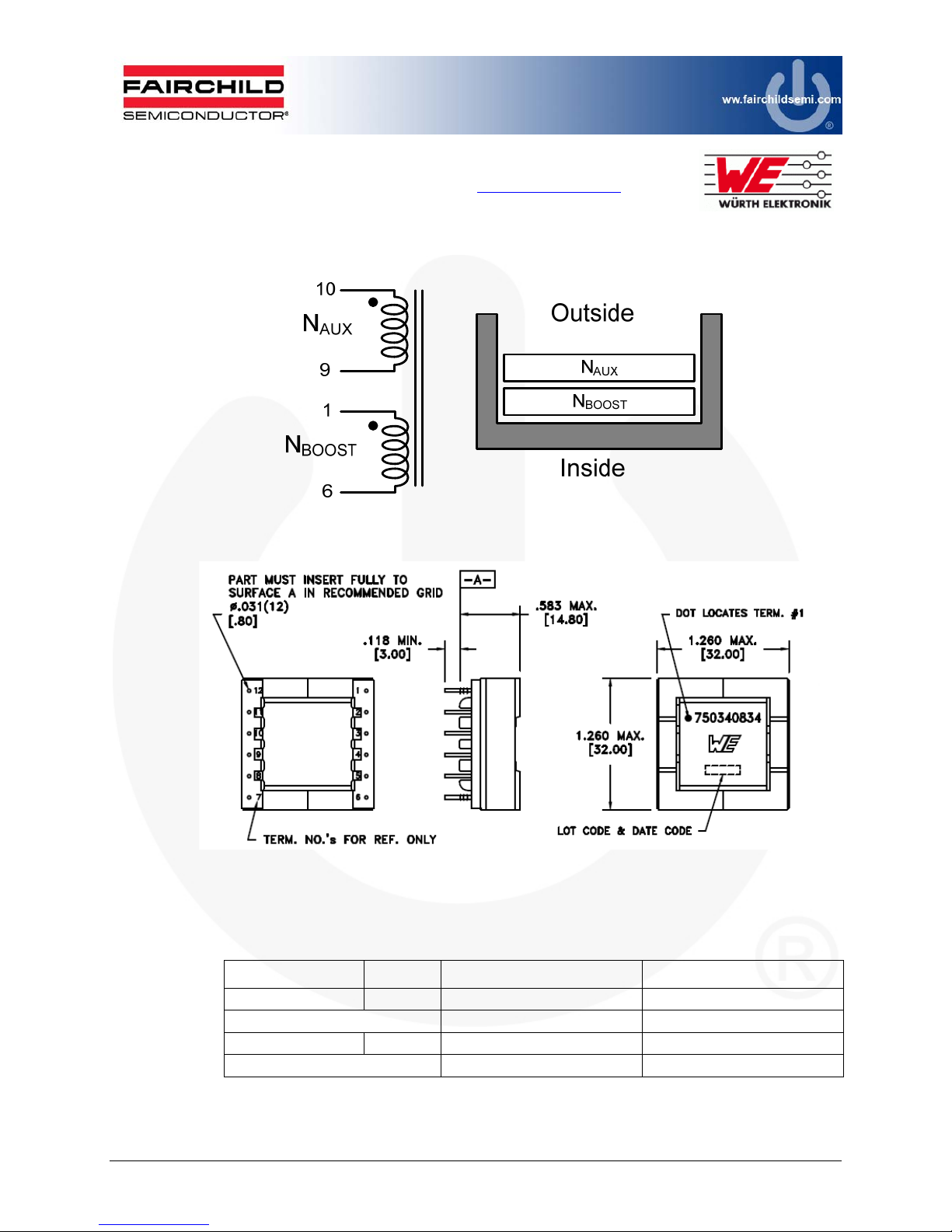

6. Boost Inductor Specification

750340834 from Wurth Electronics (www.we-online.com)

Core: EFD30 (A

=69mm2)

e

Bobbin: EFD30

Inductance : 270H

Figure 7. Boost Inductor (L1, L2) in the Evaluation Board

Figure 8. Wurth 750340834 Mechanical Drawing

Table 3. Inductor Turns Specifications

Pin Turns Wire

N

1 6 69 (3 Layers) 30xAWG#38 Litz

BOOST

Insulation Tape

N

10 9 7 AWG#28

AUX

Insulation Tape

© 2012 Fairchild Semiconductor Corporation 10 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 12

7. Four-Layer PCB and Assembly Images

Figure 9. Layer 1 – Top Layer

© 2012 Fairchild Semiconductor Corporation 11 FEBFAN9611_S01U300A • Rev. 0.0.1

Figure 10. Layer 2 – Internal Layer

Page 13

Figure 11. Layer 3 – Internal Layer

© 2012 Fairchild Semiconductor Corporation 12 FEBFAN9611_S01U300A • Rev. 0.0.1

Figure 12. Layer 4 – Bottom Layer

Page 14

Figure 13. Top Assembly

© 2012 Fairchild Semiconductor Corporation 13 FEBFAN9611_S01U300A • Rev. 0.0.1

Figure 14. Bottom Assembly

Page 15

8. Bill of Materials (BOM)

Item Qty. Reference Part Number Value Description Manufacturer Package

1 2 C1, C6

2 1 C2

3 2 C3, C13

4 2 C4, C9 ECW-F2W154JAQ 150nF Cap, 450V, 5%, Polypropylene Panasonic Thru-Hole

5 1 C5

6 2 C7, C11 B32914A3474 470nF

7 2 C8, C26 B43041A5157M 150µF Cap, Alum, Elect. EPCOS Thru-Hole

8 2 C10, C14

9 1 C12 B32914A3105K 1µF

10 1 C15 PHE840MB6100MB05R17 0.1µF

11 2 C16, C18 CS85-B2GA471KYNS 470pF

12 1 C17

13 1 C19

14 1 C20 1µF CAP, SMD, Ceramic,50V, X5R STD 805

15 1 C37

16 3 D1-3 ES3J

17 2 D4, D6 S1J

18 1 D5 GBU6J

19 3 D7-8, D10 MBR0540

20 1 D9 MMBZ5231B 5.1V Diode, Zener, 5V, 350mW

21 1 F1 37421000410 10A

22 1 H1 7-345-2PP-BA Heatsink, Low Profile, T0-247 CTS Thru-Hole

23 1 J1 1-1318301-3 Header, 3 Pin, 0.312 Spacing TE Connectivity Thru-Hole

24 1 J2 1-1123724-2 Header, 2 Pin, 0.312 Spacing TYCO Thru-Hole

25 5 J3-7 3103-2-00-21-00-00-08-0 Test pin, Gold, 40mil, Mill-Max Thru-Hole

26 1 K1 G5CA-1A DC12

27 2 L1-2 750340834/NP1138-01 280µH Inductor, Coupled Wurth Thru-Hole

28 2 L3-4 750311795 9mH Common Mode Choke, 9mH Wurth Thru-Hole

29 2 Q1, Q3 FDP22N50N

0.22µF

390nF

15nF

470nF

2.2µF

2.7nF

0.1µF

1nF

CAP, SMD, Ceramic, 25V,

CAP, SMD, Ceramic, 25V,

CAP, SMD, Ceramic, 25V,

CAP, SMD, Ceramic, 25V,

CAP, SMD, Ceramic, 25V,

Cap, Ceramic, 250V

CAP, SMD, Ceramic, 25V,

CAP, SMD, Ceramic, 25V,

CAP, SMD, Ceramic, 25V,

Diode, 600V, 3A, Ultra-Fast

Diode, General Purpose, 1A,

Diode, Bridge, 6A, 1000V

Diode, Schottky,40V, 500mA

Fuse, 374 Series, 5.08mm

RELAY PWR SPST-NO 10A

MOSFET, NCH, UniFET,

X7R

X7R

X7R

X7R

Cap, 330VAC, 10%,

Polypropylene

X7R

Cap, 330V

Polypropylene

Cap, X Type, 10%,

Polypropylene

Y5P,

X7R

X7R

X7R

Recovery

600V

Spacing

12VDC PCB

500V, 11.5A, 0.18

, 10%,

AC

STD 1206

STD 805

STD 805

STD 805

EPCOS Thru-Hole

STD 1206

Epcos Thru-Hole

KEMET Thru-Hole

, 10%,

AC

TDK Corporation Thru-Hole

STD 805

STD 805

STD 805

Fairchild

Semiconductor

Fairchild

Semiconductor

Fairchild

Semiconductor

Fairchild

Semiconductor

Fairchild

Semiconductor

Littlefuse Radial

Omeron

Electronics, Inc.

Fairchild

Semiconductor

Continued on the following page…

SMC

SMA

Thru-Hole

SOD-123

SOT-23

Thru-Hole

TO-220

© 2012 Fairchild Semiconductor Corporation 14 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 16

Item Qty. Reference Part Number Value Description Manufacturer Package

30 2 Q2, Q4 ZXTP25020DFL Transistor, PNP, 20V, 1.5A Zetex SOT-23

31 1 Q6 2N7002 MOSFET, NCH, 60V, 300mA Philips SOT-23

32 2 R1-2 46.4k RES, SMD, 1/8W STD 805

33 6

34 3 R4, R7-8 340k RES, SMD, 1/8W STD 805

35 1 R5 68.1k RES, SMD, 1/8W STD 805

36 1 R6 60.4k RES, SMD, 1/8W STD 805

37 1 R9 422k RES, SMD, 1/8W STD 805

38 2 R10, R20 47.5 RES, SMD, 1/8W STD 805

39 2 R11-12 12 RES, SMD, 1/8W STD 805

40 2 R13-14 0.033 RES, SMD, 1W STD 2512

41 1 R15 B57237S0330M000 33 Thermistor Epcos Inc. Thru-Hole

42 3

43 1 R17 45.3k RES, SMD, 1/8W STD 805

44 1 R19 15.4k RES, SMD, 1/8W STD 805

45 2 R21-22 10k RES, SMD, 1/8W STD 805

46 1 R25 24.9k RES, SMD, 1/4W STD 1206

47 2 R27-28 1.24M RES, SMD, 1/8W STD 805

48 3 R29, R35-36 1.2k RES, SMD, 1/8W STD 805

49 1 R30 23.7k RES, SMD, 1/4W STD 1206

50 1 R31 7.68k RES, SMD, 1/8W STD 805

51 1 R32 150k RES, SMD, 1/4W STD 1206

52 1 R37 1k RES, SMD, 1/8W STD 805

53 1 R38 0 RES, SMD, 1/4W STD 1206

54 1 R39 0 RES, SMD, 1/8W STD 805

55 2 R65-66 DNP RES, SMD, 1/10W STD 603

56 1 U1 FAN9611

57 1 U2 LM393M

58 2 SC1, SC2 PMSSS 440 0050 PH

59 2 W1, W2 INT LWZ 004

60 2 N1, N2 HNZ440 NUT HEX 4-40 ZINC PLATED STD Hardware

61 1 PWB

Notes:

1. DNP = Do Not Populate

2. STD = Standard Components

R3, R18,

R23-24 R33-

34

R16, R26,

R40

665k RES, SMD, 1/8W STD 805

0 RES, SMD, 1/2W STD 2010

Interleaved, Dual, BMC, PFC

Dual, Differential Comparator

SCREW MACHINE PHIL 4-

WASHER LOCK INT TOOTH

4 Layer, FR4, FAN9611 LOW-

PROFILE PWB - REV. 1.0

Controller

40X1/2 SS

#4 ZINC

Fairchild

Semiconductor

Fairchild

Semiconductor

STD Hardware

STD Hardware

Fairchild

Semiconductor

SOIC-16

SOIC-8

PCB

© 2012 Fairchild Semiconductor Corporation 15 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 17

9. Inrush Current Limiting

The evaluation board includes an inrush current limiting circuit comprised of the highlighted

components shown in

Figure 15.

Since the inrush current limiting circuit has a negative impact on light-load efficiency and may not

be required by all offline applications, the evaluation board is configured with the inrush circuit

fully populated, but disabled, as shown in Figure 15. R18 and R39 are installed on the PCB;

purposely electrically open. To enable and test the inrush current limiting circuit, rotate R18 and

R39 to complete the proper series connection shown in the schematic. Remove R38 to allow the

33Ω NTC thermistor (R15) to limit the inrush current during startup. Input current measurements

can be made by removing the R16, 0Ω jumper and installing a loop of wire connected to the holes

provided within the R16 PCB pad locations. A current probe can then be connected to the wire

loop. The effectiveness of the inrush current limiting function is shown below in Figure 16.

© 2012 Fairchild Semiconductor Corporation 16 FEBFAN9611_S01U300A • Rev. 0.0.1

Figure 15. Inrush Current Limiting Circuit

Page 18

AC Input Current

(Inrush Enabled)

AC Input Current

(Inrush Disabled)

AC Input Peak

Current (Zoom)

(Inrush Disabled)

33 NTC

M2: AC Line Current (5A/div), CH3: AC Line Current (5A/div), Time (50ms/div)

Figure 16. Full-Load Startup at 115V

AC

Table 4. Inrush Current Limiting Circuit Effectiveness Comparison

Input Line

Voltage

VIN=115V

VIN=230V

Output

Power

300W 22.50A

AC

300W 26.9A

AC

Peak Line Current

(Inrush Circuit Disabled)

Peak Line Current

(Inrush Circuit Enabled)

8.45APK 62.40%

PK

11.5APK 57.3%

PK

% Inrush

Current

Reduction

© 2012 Fairchild Semiconductor Corporation 17 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 19

10. Test Results

10.1. Startup

Figure 17 and Figure 18 show the startup operation at 115VAC line voltage for no-load

and full-load condition, respectively. Due to the closed-loop soft-start, almost no

overshoot is observed for no-load startup and full-load startup.

DRV1

COMP

V

OUT

Line

Current

CH1: Gate Drive 1 Voltage (20V/div), CH2: COMP Voltage (2V/div),

CH3: Output Voltage (200V/div), CH4: Line Current (5A/div), Time (100ms/div)

Figure 17. No-Load Startup at 115V

AC

DRV1

COMP

V

OUT

Line

Current

CH1: Gate Drive 1 Voltage (20V/div), CH2: COMP Voltage (2V/div),

CH3: Output Voltage (200V/div), CH4: Line Current (5A/div), Time (200ms/div)

Figure 18. Full-Load Startup at 115V

AC

© 2012 Fairchild Semiconductor Corporation 18 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 20

Figure 19 and Figure 20 show the startup operation at 230V

line voltage for no-load

AC

and full-load conditions, respectively. Due to the closed-loop soft-start, almost no

overshoot is observed for no-load startup and full-load startup.

DRV1

COMP

V

OUT

Line

Current

CH1: Gate Drive 1 Voltage (20V/div), CH2: COMP Voltage (2V/div),

CH3: Output Voltage (200V/div), CH4: Line Current (10A/div), Time (100ms/div)

Figure 19. No-Load Startup at 230VAC

DRV1

COMP

V

Line

Current

OUT

CH1: Gate Drive 1 Voltage (20V/div), CH2: COMP Voltage (2V/div),

CH3: Output Voltage (200V/div), CH4: Line Current (10A/div), Time (100ms/div)

Figure 20. Full-Load Startup at 230V

AC

© 2012 Fairchild Semiconductor Corporation 19 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 21

10.2. Steady-State Operation

Figure 21 and Figure 22 show the two inductor currents and the sum of the two inductor

currents operating at full load for 90V

inductor currents has relatively small ripple due to the ripple cancellation of interleaving.

IL2

I

L1

I

+ IL2

L1

and 230VAC line voltage. The sum of the

AC

CH3: Inductor L2 Current (5A/div), CH4: Inductor L1 Current (5A/div),

CH2: Sum of Two Inductor Currents (5A/div), Time (2ms/div, zoom to 10s/div)

Figure 21. Zoom of Inductor Current Waveforms at Full-Load and 90V

AC

IL2

I

L1

I

+ IL2

L1

CH3: Inductor L1 Current (2A/div), CH4: Inductor L2 Current (2A/div),

CH2: Sum of Two Inductor Current (2A/div), Time (2ms/div)

Figure 22. Zoom of Inductor Current Waveforms at Full-Load and 230V

AC

© 2012 Fairchild Semiconductor Corporation 20 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 22

V

DS(Q3)

DRV1

ZCD1

I

L2

CH1: DRV1 (20V/div), CH2: VDS(Q3) (100V/div)

CH3: ZCD1 (1V/div), CH4: Inductor L2 Current (5A/div)

Figure 23. Zero Valley Switching at Full Load, 115V

AC

V

DS(Q3)

DRV1

ZCD1

IL2

Figure 24. Zero Valley Switching at Full Load, 230V

CH1: DRV1 (20V/div), CH2: VDS(Q3) (100V/div)

CH3: ZCD1 (1V/div), CH4: Inductor L2 Current (5A/div)

AC

© 2012 Fairchild Semiconductor Corporation 21 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 23

V

DS(Q3)

I

L2

DRV1

CH1: DRV1 (20V/div), CH2: VDS(Q3) (100V/div)

CH4: Inductor L2 Current (5A/div)

Figure 25. Zoom of Valley Switching at Full Load, 230V

AC

CS1

CS2

IL2

I

L1

Figure 26. Current-Sense Waveforms at Full Load, 90VAC

CH1: FAN9611, Pin 16 (100mV/div), CH2: FAN9611, Pin 15 (100mV/div)

CH3: Inductor L2 Current (5A/div), CH4: Inductor L1 Current (5A/div)

© 2012 Fairchild Semiconductor Corporation 22 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 24

IL1

I

L2

CH1: Inductor L1 Current (2A/div), CH2: Inductor L2 Current (2A/div)

Figure 27. Inductor Current Waveforms at 360W, 85V

, Over-Current Operation

AC

IL1

IL2

Line

Current

V

OUT

CH1: Inductor L1 Current (5A/div), CH2: Inductor L2 Current (5A/div)

CH3: Output Voltage (100V/div), CH4: Line Current (5A/div), Time (20ms/div)

Figure 28. MOT Power Limit, 0.5A to 1.3A Load Transient, 115VAC

© 2012 Fairchild Semiconductor Corporation 23 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 25

10.3. Line Transient

V

V

Figure 29 and Figure 30 show the line transient operation and minimal effect on output

voltage due to the line feed-forward function. When the line voltage changes from

230V

observed. When the line voltage changes from 115V

nominal output voltage) voltage overshoot is observed.

to 115VAC, about 20V (5% of nominal output voltage) voltage undershoot is

AC

Rectified

Line

Voltage

OUT

COMP

Line

Current

to 230VAC, about 6V (1.5% of

AC

CH1: Rectified Line Voltage (200V/div), CH2: Output Voltage (20V/div, AC),

CH3: COMP Voltage (2V/div), CH4: Line Current (5A/div), Time (50ms/div)

Figure 29. Line Transient Response at Full-Load Condition (230VAC 115VAC)

Rectified

Line

Voltage

OUT

COMP

Line

Current

CH1: Rectified Line Voltage (200V/div), CH2: Output Voltage (10V/div, AC),

CH3: COMP Voltage (2V/div), CH4: Line Current (5A/div), Time (50ms/div)

Figure 30. Line Transient Response at Full-Load Condition (115V

230VAC)

AC

© 2012 Fairchild Semiconductor Corporation 24 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 26

10.4. Load Transient

V

V

Figure 31 and Figure 32 show the load-transient operation. When the output load changes

from 100% to 0%, 20V (5% of nominal output voltage) voltage overshoot is observed.

When the output load changes from 0% to 100%, 34V (8.5% of nominal output voltage)

voltage undershoot is observed.

Rectified

Line

Voltage

OUT

COMP

Line

Current

CH1: Rectified Line Voltage (100V/div), CH2: Output Voltage (20V/div, AC),

CH3: COMP Voltage (2V/div), CH4: Line Current (5A/div), Time (50ms/div)

Figure 31. Load Transient Response at 115VAC (Full Load No Load)

Rectified

Line

Voltage

OUT

COMP

Line

Current

Figure 32. Load Transient Response at 115V

© 2012 Fairchild Semiconductor Corporation 25 FEBFAN9611_S01U300A • Rev. 0.0.1

CH1: Rectified Line Voltage (100V/div), CH2: Output Voltage (20V/div, AC),

CH3: COMP Voltage (2V/div), CH4: Line Current (5A/div), Time (50ms/div)

(No Load Full Load)

AC

Page 27

V

V

Rectified

Line

Voltage

OUT

COMP

Line

Current

CH1: Rectified Line Voltage (100V/div), CH2: Output Voltage (20V/div, AC),

CH3: COMP Voltage (5V/div), CH4: Line Current (5A/div), Time (50ms/div)

Figure 33. Load Transient Response at 230VAC (Full Load No Load)

Rectified

Line

Voltage

OUT

COMP

Line

Current

CH1: Rectified Line Voltage (100V/div), CH2: Output Voltage (20V/div, AC),

CH3: COMP Voltage (5V/div), CH4: Line Current (5A/div), Time (50ms/div)

Figure 34. Load Transient Response at 230V

(No Load Full Load)

AC

© 2012 Fairchild Semiconductor Corporation 26 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 28

10.5. Brownout Protection

Figure 35 shows the startup operation while slowly increasing the line voltage. The

power supply starts up when the line voltage reaches around 90V

shutdown operation while slowly decreasing the line voltage. The power supply shuts

down when the line voltage reaches around 80V

Line

Voltage

DRV1

Line

Current

AC

. Figure 36 shows the

AC

.

CH1: Line Voltage (100V/div), CH2: Gate Drive 1 Voltage (10V/div),

CH4: Line Current (5A/div), Time (200ms/div)

Figure 35. Startup Slowly Increasing the Line Voltage

Line

Voltage

DRV1

Line

Current

CH1: Line Voltage (100V/div), CH2: Gate Drive 1 Voltage (10V/div),

CH4: Line Current (5A/div), Time (20ms/div)

Figure 36. Shutdown Slowly Decreasing the Line Voltage

© 2012 Fairchild Semiconductor Corporation 27 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 29

10.6. Phase Management

Figure 37 and Figure 38 show the phase-shedding waveforms. As observed, when the

gate drive signal of Channel 2 is disabled, the duty cycle of Channel 1 gate drive signal is

doubled to minimize the line current glitch and guarantee smooth transient.

DRV1

DRV2

I

L1

I

L2

CH1: Gate Drive 1 Voltage (20V/div), CH2: Gate Drive 2 Voltage (20V/div),

CH3: Inductor L1 Current (1A/div), CH4: Inductor L2 Current (1A/div), Time (5ms/div)

Figure 37. Phase-Shedding Operation

DRV1

DRV2

I

L1

I

L2

CH1: Gate Drive 1 Voltage (20V/div), CH2: Gate Drive 2 Voltage (20V/div),

CH3: Inductor L1 Current (1A/div), CH4: Inductor L2 Current (1A/div), Time (5µs/div)

Figure 38. Phase-Shedding Operation (Zoomed-in Timescale)

© 2012 Fairchild Semiconductor Corporation 28 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 30

Figure 39 and Figure 40 show the phase-adding waveforms. As observed, just before the

Channel 2 gate drive signal is enabled, the duty cycle of Channel 1 gate drive signal is

reduced by 50% to minimize the line current glitch and guarantee smooth transient. In

Figure 40, the first pulse of gate drive 2 during the phase-adding operation is skipped to

ensure 180° out-of-phase interleaving operation during transient.

DRV1

DRV2

I

L1

I

L2

CH1: Gate Drive 1 Voltage (20V/div), CH2: Gate Drive 2 Voltage (20V/div),

CH3: Inductor L1 Current (1A/div), CH4: Inductor L2 Current (1A/div), Time (5ms/div)

Figure 39. Phase-Adding Operation

DRV1

DRV2

I

L1

I

L2

CH1: Gate Drive 1 Voltage (20V/div), CH2: Gate Drive 2 Voltage (20V/div),

CH3: Inductor L1 Current (1A/div), CH4: Inductor L2 Current (1A/div), Time (5µs/div)

Figure 40. Phase-Adding Operation (Zoomed-in Timescale)

© 2012 Fairchild Semiconductor Corporation 29 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 31

10.7. Efficiency

A

A

A

A

Figure 41 and Figure 42 show the measured efficiency of the 300W evaluation board

with R

threshold on the test evaluation board is approximately 15% of the nominal output power.

The threshold can be adjusted upwards to achieve a more desirable efficiency profile by

increasing the MOT resistor. Figure 43 and Figure 44 show the light-load efficiency

improvement that can be achieved when the threshold is adjusted to 30% by increasing

the MOT resistor to 120kΩ.

Since phase shedding reduces the switching loss by effectively decreasing the switching

frequency at light load, greater efficiency improvement is achieved at 230V

switching losses dominate. Relatively less improvement is obtained at 115V

MOSFET is turned on with zero voltage and switching losses are negligible. The

efficiency measurements include the losses in the EMI filter, cable loss and power

consumption of the control IC.

=60.4kΩ at input voltages of 115VAC and 230VAC. The phase management

MOT

, where

AC

, since the

AC

100%

95%

Efficiency(% )

90%

(115VAC,400VDCOutput,R

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Efficiencyvs.Load

=60.4KΩ,NoInrushCircuit)

MOT

OutputPower(%)

Figure 41. Efficiency vs. Load (115V

100%

(115VAC,400VDCOutput,R

95%

Efficiency (%)

Efficiencyvs.Load

=120KΩ,NoInrushCircuit)

MOT

100%

95%

Efficiency(% )

90%

) Figure 42. Efficiency vs. Load (230V

C

100%

95%

Efficiency (%)

(230VAC,400VDCOutput,R

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

(230VAC,400VDCOutput,R

Efficiencyvs.Load

Efficiencyvs.Load

=60.4KΩ,NoInrushCircuit)

MOT

OutputPower(%)

=120KΩ,NoInrushCircuit)

MOT

)

C

90%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

OutputPower(%)

Figure 43. Efficiency vs. Load (115V

© 2012 Fairchild Semiconductor Corporation 30 FEBFAN9611_S01U300A • Rev. 0.0.1

90%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

) Figure 44. Efficiency vs. Load (230V

C

OutputPower(%)

)

C

Page 32

A

A

Figure 45 and Figure 46 show a direct comparison of light-load efficiency benefit gained

when increasing the MOT resistor. For R

=120kΩ, the phase threshold is adjusted

MOT

upward from 18% to approximately 30% of nominal maximum output power. It is not

recommended to adjust the phase threshold near the 50% nominal maximum output

power, since each individual BCM PFC channel is optimally designed to process 50%

(plus 20% margin) of the total output power required by the load.

100%

Efficiency(% )

(115VAC,400VDCOutput,R

95%

90%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Efficiencyvs.Load

Comparison,NoInrushCircuit)

MOT

OutputPower(%)

RMOT=60.4KΩ

RMOT=120KΩ

Figure 45. Efficiency vs. Load (115V

The FEBFAN9611_S01U300A evaluation board is configured with R

sets the maximum output power limit to about 360W. Because of the highly optimized,

low-profile cross-section of this design; the EFD30 inductors are not rated to process

more than 200W each (400W total output power). When the MOT resistor is increased to

120kΩ, the maximum allowable output power is also increased to greater than 400W. To

fully protect the power stage, a simple voltage divider and PNP clamp should be applied

to the FAN9611 COMP voltage (pin 7) as detailed in AN-6086

100%

95%

Efficiency(% )

90%

) Figure 46. Efficiency vs. Load (230V

C

(230VAC,400VDCOutput,R

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Efficiencyvs.Load

Compare,NoInrushCircuit)

MOT

OutputPower(%)

=60.4kΩ, which

MOT

, Figure 15.

RMOT=60.4KΩ

RMOT=120KΩ

)

C

© 2012 Fairchild Semiconductor Corporation 31 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 33

A

A

r

10.8. Harmonic Distortion and Power Factor

Figure 47 and Figure 48 compare the measured harmonic current with EN61000 Class D

and Class C, respectively, at input voltages of 115V

TV and PC power, while Class C is applied to lighting applications. As can be observed,

both regulations are met with sufficient margin.

and 230VAC. Class D is applied to

AC

EN61000‐3‐2,115VAC,300W

1.2

1

0.8

0.6

Harmonic

Current(A)

0.4

0.2

0

3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

HarmonicNumber

Measur edHarmonic Current

ClassCLimit

ClassDLimit

Figure 47. Harmonic Current, 115V

PowerFacto rvs.Load

1.00

0.95

0.90

0.85

PowerFactor

0.80

0.75

0.70

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

(400VDCOutput ,300W)

230Vac

115Vac

OutputPower(%)

EN61000‐3‐2,230VAC,300W

1.2

1

0.8

0.6

Harmonic

Current(A)

0.4

0.2

0

3 5 7 9 11 13 15 17 19 21 23 25 27 29 31 33 35 37 39

HarmonicNumber

C

Figure 48. Harmonic Current, 230V

Tota l HarmonicDistortionvs.Load

30%

25%

20%

15%

THD(%)

10%

5%

0%

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

(400VDCOutput,300W)

OutputPower(%)

Measure dHarmonic Current

ClassCLimit

ClassDLimit

C

230Vac

115Vac

Figure 49. Measured Power Facto

Figure 49 shows the measured power factor at input voltage of 115V

observed, high power factor above 0.95 is obtained from 100% to 50% load. Figure 50

shows the total harmonic distortion at input voltages of 115V

© 2012 Fairchild Semiconductor Corporation 32 FEBFAN9611_S01U300A • Rev. 0.0.1

Figure 50. Measured Total Harmonic Distortion

and 230VAC. As

AC

and 230VAC.

AC

Page 34

10.9. EMI

V

K

M

V

M

K

M

V

M

K

M

V

M

K

M

V

M

EN55022 CISPR, Class B

RBW 9 kHz

MT 10 ms

dBµV dBµV

100

90

1 P

AXH

80

2 A

AXH

70

EN55022Q

60

EN55022A

50

40

30

20

10

0

150 kHz 30 MHz

1 MHz 10 MHz

Figure 51. 115VAC, Line

dBµV dBµV

100

90

1 P

AXH

80

2 A

AXH

70

EN55022Q

60

EN55022A

50

40

30

20

10

0

150 kHz 30 MHz

1 MHz 10 MHz

Figure 53. 230

PREAMP OFFAtt 10 dB

RBW 9 kHz

MT 10 ms

PREAMP OFFAtt 10 dB

, Line Figure 54. 230VAC, Neutral

AC

RBW 9 kHz

MT 10 ms

dBµV dBµV

100

90

1 P

AXH

80

2 A

TDF

AXH

70

EN55022Q

PRN

6DB

60

EN55022A

50

40

30

20

10

0

150 kHz 30 MHz

1 MHz 10 MHz

Figure 52. 115VAC, Neutral

dBµV dBµV

100

90

1 P

AXH

80

2 A

TDF

AXH

70

EN55022Q

PRN

6DB

60

EN55022A

50

40

30

20

10

0

150 kHz 30 MHz

1 MHz 10 MHz

PREAMP OFFAtt 10 dB

RBW 9 kHz

MT 10 ms

PREAMP OFFAtt 10 dB

TDF

PRN

6DB

TDF

PRN

6DB

© 2012 Fairchild Semiconductor Corporation 33 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 35

11. References

[1] FAN9611 / FAN9612 — Interleaved Dual BCM PFC Controllers

[2] AN-6086 — Design Considerations for Interleaved Boundary-Conduction Mode

PFC Using FAN9611 / FAN9612

12. Ordering Information

Orderable Part Number Description

FEBFAN9611_S01U300A FAN9611 300W Evaluation Board

13. Revision History

Date Revision Description

February 2012 0.0.1 Initial release

WARNING AND DISCLAIMER

Replace components on the Evaluation Board only with those parts shown on the parts list (or Bill of Materials) in the Users’ Guide. Contact an

authorized Fairchild representative with any questions.

This board is intended to be used by certified professionals, in a lab environment, following proper safety procedures. Use at your own risk. The

Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this User’s Guide constitute a sales contract or create any kind

of warranty, whether express or implied, as to the applications or products involved. Fairchild warrantees that its products meet Fairchild’s published

specifications, but does not guarantee that its products work in any specific application. Fairchild reserves the right to make changes without notice to

any products described herein to improve reliability, function, or design. Either the applicable sales contract signed by Fairchild and Buyer or, if no

contract exists, Fairchild’s standard Terms and Conditions on the back of Fairchild invoices, govern the terms of sale of the products described herein.

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO

IMPROVE RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR

USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR

THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems which, (a)

are intended for surgical implant into the body, or (b) support or

sustain life, or (c) whose failure to perform when properly used in

accordance with instructions for use provided in the labeling, can be

reasonably expected to result in significant injury to the user.

ANTI-COUNTERFEITING POLICY

Fairchild Semiconductor Corporation's Anti-Counterfeiting Policy. Fairchild's Anti-Counterfeiting Policy is also stated on our external website,

www.fairchildsemi.com, under Sales Support.

Counterfeiting of semiconductor parts is a growing problem in the industry. All manufacturers of semiconductor products are experiencing

counterfeiting of their parts. Customers who inadvertently purchase counterfeit parts experience many problems such as loss of brand reputation,

substandard performance, failed applications, and increased cost of production and manufacturing delays. Fairchild is taking strong measures to

protect ourselves and our customers from the proliferation of counterfeit parts. Fairchild strongly encourages customers to purchase Fairchild parts

either directly from Fairchild or from Authorized Fairchild Distributors who are listed by country on our web page cited above. Products customers buy

either from Fairchild directly or from Authorized Fairchild Distributors are genuine parts, have full traceability, meet Fairchild's quality standards for

handling and storage and provide access to Fairchild's full range of up-to-date technical and product information. Fairchild and our Authorized

Distributors will stand behind all warranties and will appropriately address any warranty issues that may arise. Fairchild will not provide any warranty

coverage or other assistance for parts bought from Unauthorized Sources. Fairchild is committed to combat this global problem and encourage our

customers to do their part in stopping this practice by buying direct or from authorized distributors.

EXPORT COMPLIANCE STATEMENT

These commodities, technology, or software were exported from the United States in accordance with the Export Administration Regulations for the

ultimate destination listed on the commercial invoice. Diversion contrary to U.S. law is prohibited.

U.S. origin products and products made with U.S. origin technology are subject to U.S Re-export laws. In the event of re-export, the user will be

responsible to ensure the appropriate U.S. export regulations are followed.

2. A critical component is any component of a life support device or

system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect its

safety or effectiveness

© 2011 Fairchild Semiconductor Corporation 34 FEBFAN9611_S01U300A • Rev. 0.0.1

Page 36

ON Semiconductor and are trademarks of Semiconductor Components Industries, LLC dba ON Semiconductor or its subsidiaries in the United States and/or other countries.

ON Semiconductor owns the rights to a number of patents, trademarks, copyrights, trade secrets, and other intellectual property. A listing of ON Semiconductor’s product/patent

coverage may be accessed at www.onsemi.com/site/pdf/Patent−Marking.pdf

ON Semiconductor makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does ON Semiconductor assume any liability

arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental damages.

Buyer is responsible for its products and applications using ON Semiconductor products, including compliance with all laws, regulations and safety requirements or standards,

regardless of any support or applications information provided by ON Semiconductor. “Typical” parameters which may be provided in ON Semiconductor data sheets and/or

specifications can and do vary in different applications and actual performance may vary over time. All operating parameters, including “Typicals” must be validated for each customer

application by customer’s technical experts. ON Semiconductor does not convey any license under its patent rights nor the rights of others. ON Semiconductor products are not

designed, intended, or authorized for use as a critical component in life support systems or any FDA Class 3 medical devices or medical devices with a same or similar classification

in a foreign jurisdiction or any devices intended for implantation in the human body. Should Buyer purchase or use ON Semiconductor products for any such unintended or unauthorized

application, Buyer shall indemnify and hold ON Semiconductor and its officers, employees, subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and

expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of personal injury or death associated with such unintended or unauthorized use, even if such

claim alleges that ON Semiconductor was negligent regarding the design or manufacture of the part. ON Semiconductor is an Equal Opportunity/Affirmative Action Employer. This

literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

19521 E. 32nd Pkwy, Aurora, Colorado 80011 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: orderlit@onsemi.com

© Semiconductor Components Industries, LLC

. ON Semiconductor reserves the right to make changes without further notice to any products herein.

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5817−1050

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

www.onsemi.com

1

www.onsemi.com

Loading...

Loading...