Page 1

User Guide for

FEBFAN7688SJXA_CP14U306

Evaluation Board

306 W/12 V PC Application

with 12 VSB Module

Evaluation Board

Featured Fairchild Product:

FAN7688

Direct questions or comments

about this evaluation board to:

“Worldwide Direct Support”

Fairchild Semiconductor.com

© 2015 Fairchild Semiconductor Corporation 1 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 2

Table of Contents

1. Introduction ............................................................................................................................... 3

1.1. Features ............................................................................................................................ 3

2. Evaluation Board Specifications ............................................................................................... 4

3. Photograph ................................................................................................................................ 4

4. Printed Circuit Board (PCB) ..................................................................................................... 5

5. Schematic .................................................................................................................................. 6

6. Bill of Materials ........................................................................................................................ 7

7. Transformer and Winding Specifications ............................................................................... 12

7.1. Main Transformer (TX1) ............................................................................................... 12

7.2. Resonant Inductor (L4) .................................................................................................. 13

7.3. Pulse Transformer (TX2) ............................................................................................... 14

7.4. Current Transformer (TX4) ............................................................................................ 15

7.5. PFC Inductor (L3) .......................................................................................................... 16

7.6. 12 V Standby Transformer (TX3) .................................................................................. 17

7.7. EMI Choke (L1, L2)....................................................................................................... 18

8. Test Conditions & Test Equipment......................................................................................... 19

8.1. Features .......................................................................................................................... 19

9. Performance of Evaluation Board ........................................................................................... 20

9.1. Current Harmonic Test: .................................................................................................. 20

9.2. AC Trim Up & Trim Down............................................................................................ 23

9.3. Efficiency ....................................................................................................................... 23

9.4. Output Transient Response ............................................................................................ 24

9.5. 390 V to 358 V && 358 V to 390 V at Loading ............................................................ 25

9.6. 390 V to 358 V && 358 V to 390 V at Vrms ................................................................ 25

9.7. Hold up Time ................................................................................................................. 25

9.8. AC Cycle Drop ............................................................................................................... 26

9.9. AC Transient .................................................................................................................. 26

9.10. Surge & ESD .................................................................................................................. 27

9.11. EMI Conduction ............................................................................................................. 27

10. Revision History ..................................................................................................................... 28

© 2015 Fairchild Semiconductor Corporation 2 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 3

This user guide supports the 306 W evaluation board for the 80Plus Platinum solution

based on a Continuous Conduction Mode (CCM) PFC and LLC convertor using the

FAN6982 with the FAN7688. It should be used in conjunction with the FAN7688

datasheet as well as Fairchild’s application notes and technical support team. Please visit

Fairchild’s website at www.fairchildsemi.com.

1. Introduction

The LLC converter in this Evaluation Board (EVB) is controlled by the FAN7688; it’s a

16-pin controller and locates in secondary side. The FAN7688 includes PFM and PWM

controls to optimization efficiency for all loading, its combine advantage SR control

improves efficiency. It employs a current mode control technique based on charge

control; this provides a better control-to-output and line-to-output transfer function of the

power stage, simplifying the feedback loop design while allowing true input power limit

capability. The PFC is controlled by the FAN6982, based on Continuous Conduction

Mode (CCM), which employs leading edge modulation for average current control and

has a number of advanced features for better performance and reliability.

1.1. Features

LLC:

Secondary Side PFM Controller with Synchronous Rectifier Control

Charge Current Control for better Transient Response and Simplified Feedback Loop

Design

Adaptive Synchronous Rectification Control with Dual Edge Tracking

Closed Loop Soft-Start

Green Functions to Improve Light Load Efficiency

- Symmetric PWM Control at Light Load to Limit the Switching Frequency while

Reducing Switching Losses

- Disabling SR During Light Load Operation

Complete Protection Functions with Auto-Restart

PFC:

Continuous Conduction Mode and Average-Current-Mode Control

Power-On Sequence Control

Brownout Protection

Fulfills Class-D Requirements of IEC 61000-3-2

Universal AC Input Voltage

Efficiency Optimization by External Output Voltage Adjustable Circuit

© 2015 Fairchild Semiconductor Corporation 3 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 4

Description

Symbol

Value

Comments

Output Power

PO

306 W

Efficiency

Eff, η

Meet 80PLUS Platinum

Input Voltage

VAC

90~264 V

Input Frequency

47~63 Hz

PFC Output Voltage

V

PFC

356 V / 392 V

Output Voltage

V

OUT

12 V

100% Load = 300 W

12 V Standby Output

V

12VSB

12 V

100% Load = 6 W

Brown-In / Out Voltage

VAC

85 V / 73 V

PFC Frequency

fSW

65 kHz

LLC Frequency

f

LLC

39 k~150 kHz

EVB Size

L * W * H

145 mm*122 mm*48 mm

Does not include the

metal case

PFC

LLC

Standby

AC Input

DC Ounput

2. Evaluation Board Specifications

All data for this table was measured at an ambient temperature of 25°C.

Table 1. Summary of Features and Performance

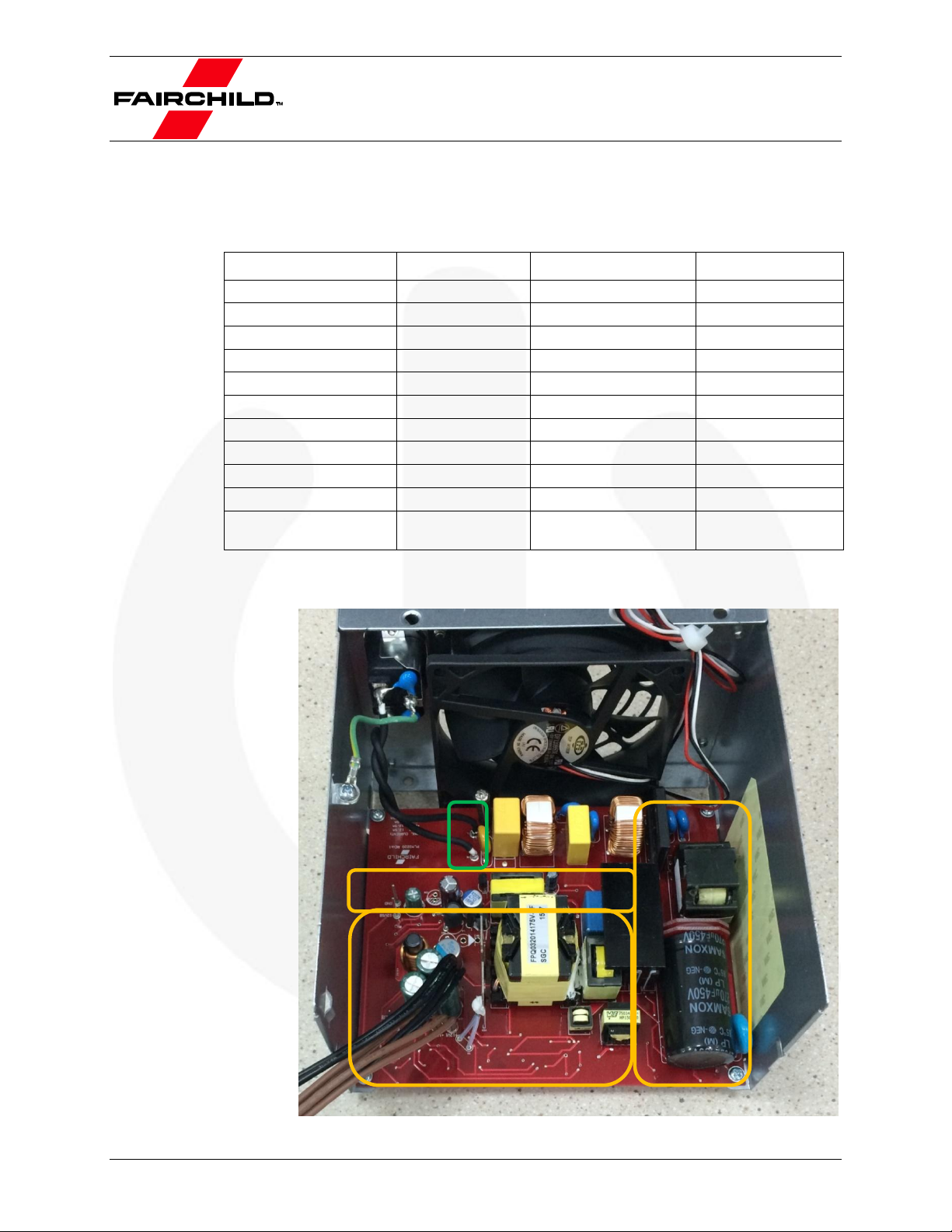

3. Photograph

© 2015 Fairchild Semiconductor Corporation 4 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Figure 1. Top View of Evaluation Board (EVB does not include the metal case)

Page 5

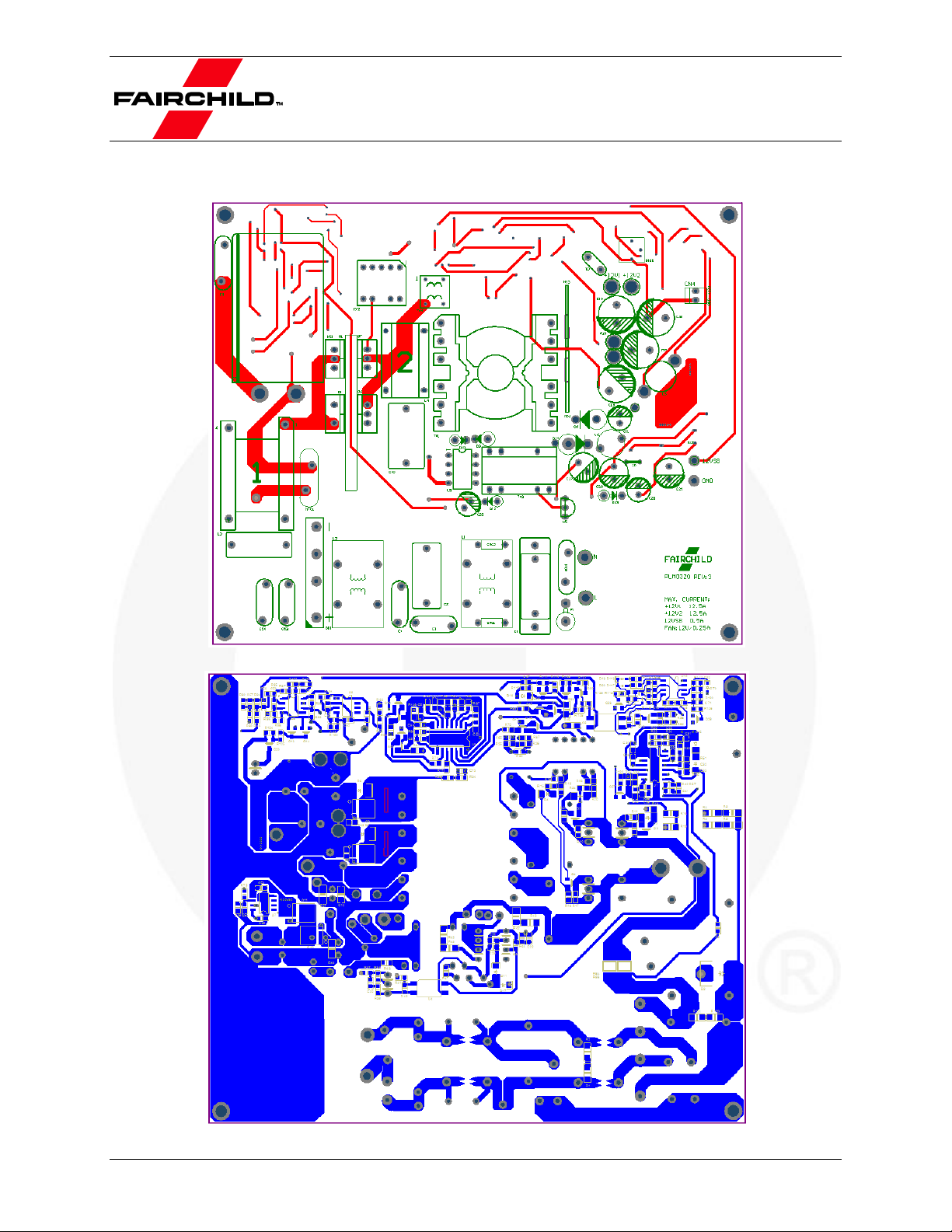

4. Printed Circuit Board (PCB)

Figure 2. Top Side of Evaluation Board

Figure 3. Bottom Side of Evaluation Board

© 2015 Fairchild Semiconductor Corporation 5 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 6

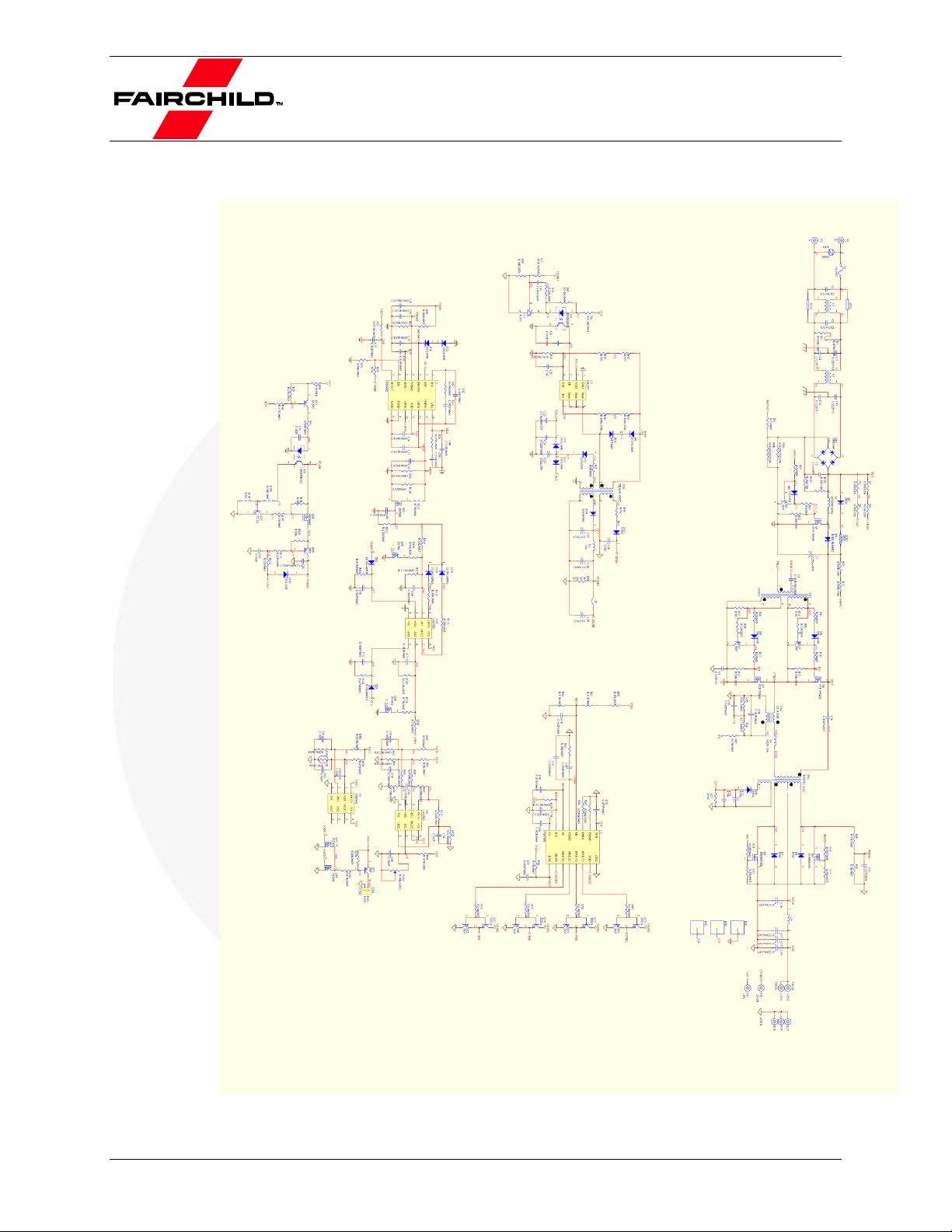

5. Schematic

Figure 4. Evaluation Board Schematic

© 2015 Fairchild Semiconductor Corporation 6 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 7

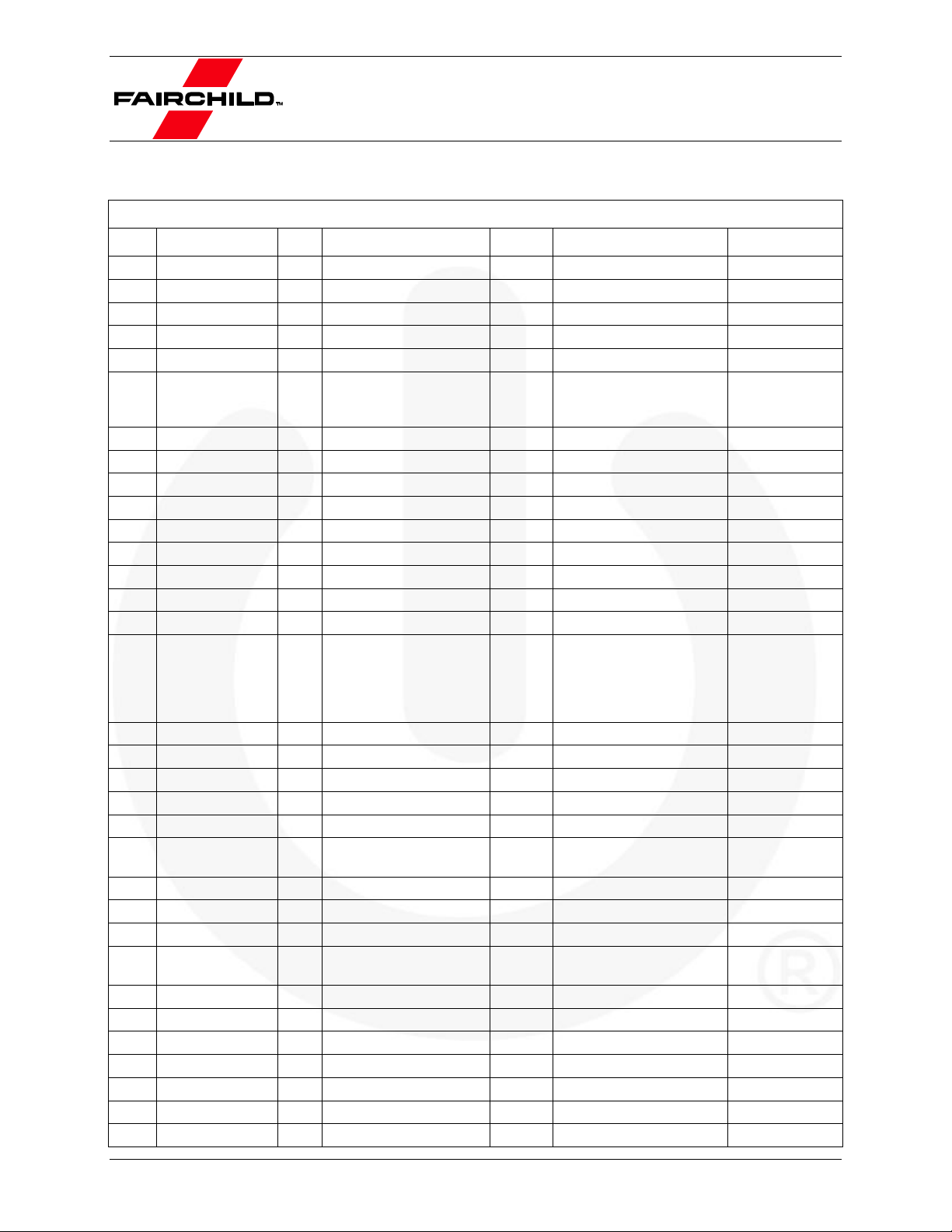

FEBFAN7688SJXA_CP14U306 BOM (PLM0320 REV.3)

Item

Reference

Qty.

Part No.

Value

Description

Manufacturer

1

JP

1

JUMPER WIRE 0.6ψ

2

C13

1 47 pF

C0603 X7R ±10% 50 V

3 C42

1 100 pF

C0603 X7R ±10% 50 V

4 C38

1 470 pF

C0603 X7R ±10% 50 V

5

C51

1 680 pF

C0603 X7R ±10% 50 V

6

C21, C35, C46,

C50, C64, C65,

C66, C67, C73

9 1 nF

C0603 X7R ±10% 50 V

7

C24

1 2.2 nF

C0603 X7R ±10% 50 V

8

C40, C41

2 3.3 nF

C0603 X7R ±10% 50 V

9 C47

1 4.7 nF

C0603 X7R ±10% 50 V

10

C31, C52

2 47 nF

C0603 X7R ±10% 50 V

11

C33, C34

2 10 nF

C0603 X7R ±10% 50 V

12

C39

1 22 nF

C0603 X7R ±10% 50 V

13

C20, C36, C37

3 100 nF

C0603 X7R ±10% 50 V

14

C48

1 220 nF

C0603 X7R ±10% 50 V

15

C32, C49

2 470 nF

C0603 X7R ±10% 16 V

16

C57, C58, C59,

C60, C61, C62,

C63, C68, C69,

C70, C71, C72,

C74

13 1 μF

C0603 X7R ±10% 50 V

17

C8

1 1 μF

C0805 X7R ±10% 50 V

18

C23

1 10 μF

C0805 X7R ±10% 25 V

19

C43

1 22 μF

C0805 X7R ±10% 25 V

20

R11, R16, R21

3 0 Ω

R0603 ±1%

21

R30, R31

2 2.2 Ω

R0603 ±1%

22

R10, R15, R20,

R58

4 10 Ω

R0603 ±1%

23

R26

1 17.4 Ω

R0603 ±1%

24

R25

1 42.2 Ω

R0603 ±1%

25

R8

1 51 Ω

R0805 ±1%

26

R69, R70, R71,

R72

4 100 Ω

R0603 ±1%

27

R19, R24, R112

3 220 Ω

R0603 ±1%

28

R107

1 330 Ω

R0603 ±1%

29

R41

1 1.24 KΩ

R0603 ±1%

30

R63

1 1.5 KΩ

R0603 ±1%

31

R90, R93

2 2 KΩ

R0603 ±1%

32

R111

1 2.2 KΩ

R0603 ±1%

33

R34

1 3 KΩ

R0603 ±1%

6. Bill of Materials

© 2015 Fairchild Semiconductor Corporation 7 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 8

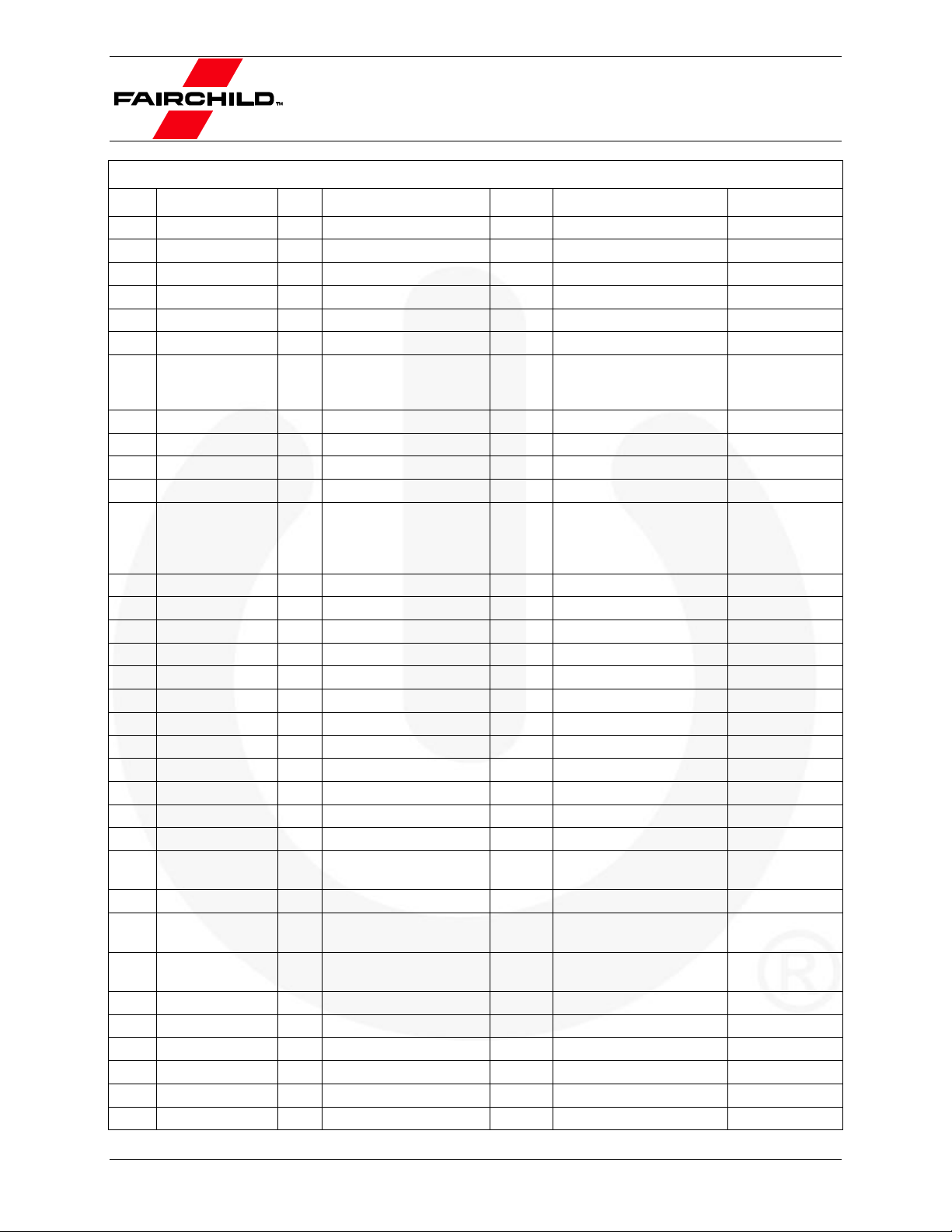

FEBFAN7688SJXA_CP14U306 BOM (PLM0320 REV.3)

Item

Reference

Qty.

Part No.

Value

Description

Manufacturer

34

R64

1 3.3 KΩ

R0603 ±1%

35

R60, R105

2 4.7 KΩ

R0603 ±1%

36

R95, R96

2 4.99 KΩ

R0603 ±1%

37

R40

1 5.1 KΩ

R0603 ±1%

38

R55

1 6.98 KΩ

R0603 ±1%

39

R92, R94

2 8.25 KΩ

R0603 ±1%

40

R38, R65, R87,

R108, R117,

R118

6 10 KΩ

R0603 ±1%

41

R89

1 12 KΩ

R0603 ±1%

42

R120

1 12.4 KΩ

R0603 ±1%

43

R115

1 13.3 KΩ

R0603 ±1%

44

R88, R106, R114

3 15 KΩ

R0603 ±1%

45

R12, R17, R22,

R32, R33, R39,

R54, R57, R102,

R104, R110

11 20 KΩ

R0603 ±1%

46

R68, R101

2 24.9 KΩ

R0603 ±1%

47

R59, R119

2 27 KΩ

R0603 ±1%

48

R52

1 27.4 KΩ

R0603 ±1%

49

R51

1 36 KΩ

R0603 ±1%

50

R37

1 38.3 KΩ

R0603 ±1%

51

R44

1 43.2 KΩ

R0603 ±1%

52

R103

1 47 KΩ

R0603 ±1%

53

R66

1 51 KΩ

R0603 ±1%

54

R129

1 73.2 KΩ

R0603 ±1%

55

R122, R126

2 75 KΩ

R0603 ±1%

56

R125

1 91 KΩ

R0603 ±1%

57

R99

1 147 KΩ

R0603 ±1%

58

R67, R97, R98,

R127

4 200 KΩ

R0603 ±1%

59

R56

1 357 KΩ

R0603 ±1%

60

R130 (Parallel

with R55)

1 1 MΩ

R0603 ±5%

61

R113, R116,

R121, R128

4 4.3 MΩ

R0603 ±5%

62

R47

1 0 Ω

R0805 ±1%

63

R61

1 10 KΩ

R0805 ±1%

64

R50

1 200 KΩ

R0805 ±1%

65

R49

1 3 KΩ

R1206 ±1%

66

R45, R46

2 100 KΩ

R1206 ±1%

67

R1, R2

2 470 KΩ

R1206 ±1%

© 2015 Fairchild Semiconductor Corporation 8 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

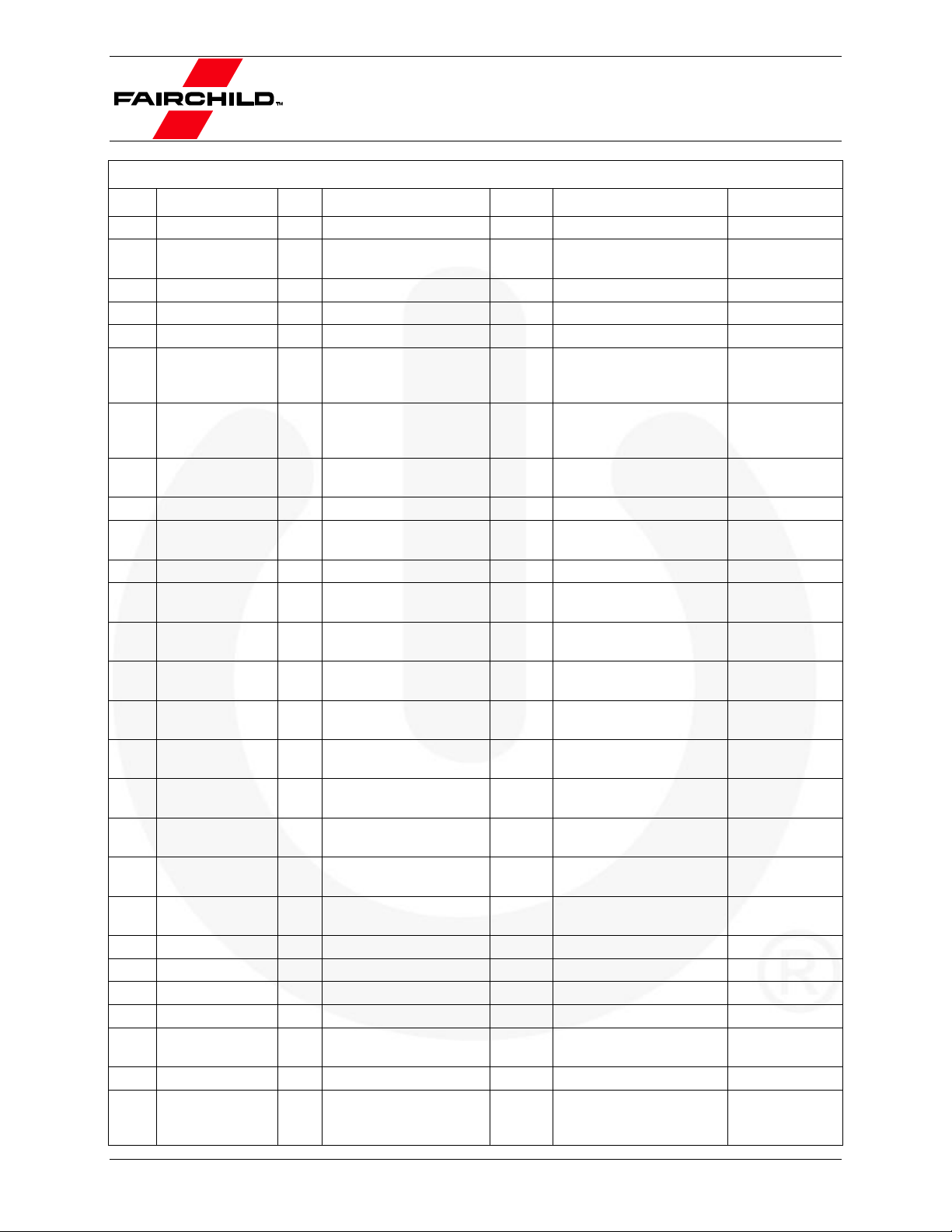

Page 9

FEBFAN7688SJXA_CP14U306 BOM (PLM0320 REV.3)

Item

Reference

Qty.

Part No.

Value

Description

Manufacturer

68

R13, R14

2 499 KΩ

R1206 ±1%

69

R3, R4, R123,

R124

4 1 MΩ

R1206 ±5%

70

R5, R6

2 3 MΩ

R1206 ±5%

71

R9A, R9B

2 0.15 Ω

R2512 ±1% 2 W

72

R100

1 10 KΩ

VR

73

C1

1 0.68 μF

X2 Capacitor 275 V ±10%

(11.5*19.5*17.5 mm

Pitch=15 mm)

74

C2

1 0.47 μF

X2 Capacitor 275 V ±10%

(18*8.5*16.5 mm,

Pitch=15 mm)

75

C53, C54

2

CD12-E2GA222MYASA

2.2 pF

Y1 Capacitor 250 V ±20%

UNIVERSE

CONDENSER

76

C3, C4

2 0.22 pF

Y1 Capacitor 250 V ±20%

77

C9

1 4.7 pF

Y1 Capacitor 250 V ±20%

(19x8x10 mm)

78

C10

1

MP3S104J0630DB1151H

0.1 μF

MP3S Capacitor DC630V

FUH BANG

79

C25

1 22 μF

Electrolytic Capacitor 50 V

105°C 5*11 mm LHK

HONJU

80

C29

1 220 μF

Electrolytic Capacitor 16 V

105°C 6.3*11 mm GF

SAMXON

81

C7

1 270 μF

Electrolytic Capacitor

450 V 105°C 25*45 mm LP

SAMXON

82

C27

1 470 μF

Solid Capacitor 16 V

8*11.5 mm ULR

HE SHEN TANG

83

C28

1 1000 μF

Electrolytic Capacitor 16 V

105°C 8*18 mm

84

C17, C18, C19

3 2200 μF

Electrolytic Capacitor 16 V

105°C 10*25 mm

85

C16

1 470 μF

Solid Capacitor 16 V

10*11.5 mm PSF

HE SHEN TANG

86

C5

1

TF105K2Y159L270D9R

1 μF

MTF Capacitor 450 V

±10%

KENJET

TECHNOLOGY

87

BD1

1

DFB2560

Bridge 25 A/600 V

TS-6P

Fairchild

88

D1

1

ISL9R860P2

Diode 8 A/600 V TO-220

Fairchild

89

D10

1

UF4007

Diode 1 A/1000 V DO-41

Fairchild

90

D12

1

1N4935

Diode 1 A/200 V DO-41

Fairchild

91

D14

1

EGP30D Diode 3 A/200 V

Fairchild

92

D19, D20, D21,

D22

4

1N4148WS

Diode SOD-32F

Fairchild

93

D2

1

S3J Diode 3 A/600 V SMC

Fairchild

94

D3, D4, D5, D11,

D15, D16, D17,

D18

8

LL4148

Diode 200 mA/100 V

SOD80

Fairchild

© 2015 Fairchild Semiconductor Corporation 9 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 10

FEBFAN7688SJXA_CP14U306 BOM (PLM0320 REV.3)

Item

Reference

Qty.

Part No.

Value

Description

Manufacturer

95

D9

1

P6KE200A TVS

Fairchild

96

Q1, Q6, Q7

3

FCP170N60

MOS 22 A/ 600 V TO-220

Fairchild

97

Q13, Q14, Q27,

Q28, Q29

5

2N7002 SOT-23

Fairchild

98

Q15, Q17, Q19,

Q21, Q25

5

MMBT2222A SOT-23

Fairchild

99

Q24

1

NDS0605

-0.18 A/ -60 V SOT-23

Fairchild

100

Q3, Q4, Q5, Q12,

Q16, Q18, Q20,

Q22, Q23, Q26

10

MMBT2907A SOT-23

Fairchild

101

Q8, Q9

2

FDMS8320L

100 A /40 V, Power56

Fairchild

102

U1

1

FAN6982MY

IC SO-14L

Fairchild

103

U2

1

FAN7688SJX IC

Fairchild

104

U3

1

FSL137MRIN

MDIP 8L

Fairchild

105

U4, U6

2

FODM121C MFP 4L

Fairchild

106

U5

1

KA431LZTA TO-92R

Fairchild

107

U8, U9, U10

3

LM358M SO-8L

Fairchild

108

L1, L2

2

SN20128A EMI Choke

FORMOSA

SHING GA

109

L3

1

Inductor QP2920H 420 μH

YUJING

110

L4

1

102Q553

Inductor EQ20 120 μH

SUMIDA

111

L5

1

Inductor 0.75 μH

SHOWWELL

112

TX1

1

FPQ032014175V-PF

Transformer

PQ3230 (PC44)

SHOWWELL

113

TX2

1

750342754

Transformer EE13

Würth Elektronik

114

TX3

1

078Q561

Transformer EQ20

SUMIDA

115

TX4

1

750342753

Transformer EE8.3

Würth Elektronik

116

L6

1

TRN-00199

117

TR

1

TTC104

100 KΩ

NTC 5ψ

118

FAN

1

Connect WAFER

(2530HHS) 2P 2.5 mm

180°

119

F1

1

FUSE GLASS 7 A/250 V

QUICK 5*20 mm

120

MOV1

1

TVR10471KSY

Varistor ATOM MOV

121

NTC1

1

SCK132R56MYS

NTC 13ψ SCK2R56

122

HS1

1

MCH0146 Heat Sink

123

HS2, HS3

2

Heat Sink

124 2

Power Cable

1007#16AWG +3.2ψ

HOOK

YIYI

125

12VSB, GND

2

Test Pin

© 2015 Fairchild Semiconductor Corporation 10 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 11

FEBFAN7688SJXA_CP14U306 BOM (PLM0320 REV.3)

Item

Reference

Qty.

Part No.

Value

Description

Manufacturer

126 1

Heat Shrinkable Tubing

3*15 mm

127 1

Heat Shrinkable Tubing

6*20 mm

128 3

MCH0040 Bead Core C8B

3.5*3.2*1.0

129 4

Bushing TO220 602M

130 4

Silicone Sheet TO-220

131 2

Screws 3ψ12 mm

132 6

Nut 3ψ

133 4

Copper Tube M3

6.5*6 mm

134 1

CANADA Silicone

ES2482W 333 ml

135 2

Heat Shrinkable Tubing

3*7.5 mm (for YS-201M)

136

SPG1, SPG2

2

Surge Absorber

YS-201M

© 2015 Fairchild Semiconductor Corporation 11 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 12

No.

Winding

Pin (S → F)

Wire

Turns

Winding Method

1

N1

5 → 4

0.7φ×1

20

Solenoid Winding

2

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

3

N2

10 → 9

Copper foil

0.3 mm (3T),

W=15 mm

Copper Foil to

Pin, 0.7φ*2

3

N2, N3 are the same

copper foil

4

N3

9 → 11, 12

3

5

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

6

N4

4 → 3

0.7φ×1

20

Solenoid Winding

7

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

8

0.8T Open loop shielding to PIN2

9

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

10

1.2T Close loop shielding on outside to PIN2

11

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

Pins

Specifications

Inductance

3 - 5

1.75 mH ±5%

10

5

3

11, 12

N2

N1

N4

4

N3

9

7. Transformer and Winding Specifications

7.1. Main Transformer (TX1)

Core: PQ3230 (PC44)

Bobbin: 12 Pins

Figure 5. Transformer Specifications of TX1

Table 2. Winding Specifications

Table 3. Electrical Characteristics

© 2015 Fairchild Semiconductor Corporation 12 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 13

No.

Winding

Pin (S → F)

Wire

Turns

Winding Method

1

N1

1 → 5

0.1φ×40

24

Solenoid Winding

Pins

Specifications

Inductance

1 - 5

120 μH ±5%

1

Top View

Cut off

N1

12345

109876

5

7.2. Resonant Inductor (L4)

Core: EQ20 (TP5)

Bobbin: 10 Pins

Table 4. Winding Specifications

Figure 6. Transformer Specifications of L4

Table 5. Electrical Characteristics

© 2015 Fairchild Semiconductor Corporation 13 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 14

No.

Winding

Pin (S → F)

Wire

Turns

Winding Method

1

N1

3 → 5

0.2φ×1

15

Solenoid Winding

2

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

3

N2

9 → 10

0.15φ×1

18

Solenoid Winding

Transformer Triple

Wire

4

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

5

N2

7 → 6

0.2φ×1

18

Solenoid Winding

6

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

Pins

Specifications

Inductance

3 – 5

>200 μH

9

3

6

N2

N1

5

N3

10

7

Top View

Cut off

12345

109876

7.3. Pulse Transformer (TX2)

Core: EE13 (3C90)

Bobbin: 10 Pins

Table 6. Winding Specifications

Figure 7. Transformer Specifications of TX2

Table 7. Electrical Characteristics

© 2015 Fairchild Semiconductor Corporation 14 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 15

No.

Winding

Pin (S → F)

Wire

Turns

Winding Method

1

N1

4 → 3

0.1φ×50

0.75

Solenoid Winding

2

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

3

N2

2 → 1

0.15φ×1

80

Solenoid Winding

4

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

Pins

Specifications

Inductance

1 – 2

> 4 mH

2

4

N2

N1

3

1

Top View

Cut off

12

43

7.4. Current Transformer (TX4)

Core: EE8.3 (3C90)

Bobbin: 4 Pins

Figure 8. Transformer Specifications of TX4

Table 8. Winding Specifications

Table 9. Electrical Characteristics

© 2015 Fairchild Semiconductor Corporation 15 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 16

No.

Winding

Pin (S → F)

Wire

Turns

Winding Method

1

N1

1 → 3

0.1φ×50

40

Solenoid Winding

2

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

Pins

Specifications

Inductance

1 – 2

420 μH ± 5%

1

N1

3

Bottom View

7.5. PFC Inductor (L3)

Core: QP2920H (3C94)

Bobbin: 4 Pins

Table 10. Winding Specifications

Figure 9. Transformer Specifications of L3

Table 11. Electrical Characteristics

© 2015 Fairchild Semiconductor Corporation 16 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 17

No.

Winding

Pin (S → F)

Wire

Turns

Winding Method

1

N1

10 → 8

0.2φ×1

49

Solenoid Winding

2

Insulation: Polyester Tape t = 0.025 mm, 2-Layer

3

N2

6 → 7

0.25φ×2

11

Solenoid Winding

Transformer Triple

Wire

4

Insulation: Polyester Tape t = 0.025 mm, 2-Layer

5

N2

8 → 9

0.2φ×1

22

Solenoid Winding

6

Insulation: Polyester Tape t = 0.025 mm, 2-Layer

7

N2

2 → 1

0.15φ×1

15

Solenoid Winding

8

Insulation: Polyester Tape t = 0.025 mm, 2-Layer

9

N2

5 → 4

0.2φ×1

16

Solenoid Winding

10

Insulation: Polyester Tape t = 0.025 mm, 2-Layer

11

1.2T Close loop shielding on outside to PIN1

12

Insulation: Polyester Tape t = 0.025 mm, 3-Layer

Pins

Specifications

Inductance

10 – 9

820 μH ± 5%

9

1

Bottom View

N4 2 7

N2

N1

12345

109876

N3

8

N5

5

4

Cut off

10

6

7.6. 12 V Standby Transformer (TX3)

Core: EQ20 (TP5)

Bobbin: 10 Pins

Figure 10. Transformer Specifications of TX3

Table 12. Winding Specifications

Table 13. Electrical Characteristics

© 2015 Fairchild Semiconductor Corporation 17 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 18

7.7. EMI Choke (L1, L2)

Figure 11. Transformer Specifications of L1 and L2

© 2015 Fairchild Semiconductor Corporation 18 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 19

Test Mode

FEBFAN7688SJXA_CP14U306

Test Date

May 29, 2015

Test Temperature

Ambient 25ºC

Test Equipment

AC Source: EXTECH 6800

AC/DC Electronic Load: Chroma 63030

Power Meter: Chroma 6630

Oscilloscope: Lecroy 24MXs-B

Test Items

1. Current Harmonic

2. AC Trim up & Trim down

3. Efficiency

4. Output Transient Response

5. 392 V to 354 V && 354 V to 392 V @Loading

6. 392 V to 354 V && 354 V to 392 V @Vrms

7. Hold-up time

8. AC Cycle Drop

9. AC Transient

10. SURGE & ESD

11. EMI

Test Loading

306 W (Loading shown in Amps)

Loading

12V1

12V2

12Vsb

100%

12.5

12.5

0.5

50%

6.25

6.25

0.25

20%

2.5

2.5

0.1

Min.

1.25

1.25

0.05

8. Test Conditions & Test Equipment

8.1. Features

Table 14. Test Conditions & Test Equipment

© 2015 Fairchild Semiconductor Corporation 19 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 20

Figure 12. Input Current Waveform and THD Test Result in 115 V

AC

75 W Load, 100 V/50 Hz

Figure 13. Input Current Waveform and THD Test Result in 115 VAC, Mid. Load

Input Voltage

Condition

PF

THD (%)

Class D

100 V/50 Hz

Input 75 W

0.983

14.170

Pass

Mid. Load

0.980

13.390

Pass

100% Load

0.992

8.310

Pass

230 V/50 Hz

Input 75 W

0.879

17.330

Pass

Mid. Load

0.939

16.410

Pass

100% Load

0.976

11.560

Pass

9. Performance of Evaluation Board

9.1. Current Harmonic Test:

Test Condition:

Measure input current power factor (PF) and total harmonic distortion (THD, IEC610003-2, Class D) at various line and output loading.

A PF less than 0.95 in 230 V/50 Hz can cause a fast response of PFC voltage loop in

some test requirement; it can be fine tuned to meet PF > 0.95 when it is needed.

Test Results:

© 2015 Fairchild Semiconductor Corporation 20 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 21

Figure 14. Input Current Waveform and THD Test Result in 115 VAC, 100% Load

Figure 15. Input Current Waveform and THD Test Result in 230 V

AC,

75 W Load,

230 V/50 Hz

© 2015 Fairchild Semiconductor Corporation 21 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 22

Figure 16. Input Current Waveform and THD Test Result in 230 VAC, Mid. Load

Figure 17. Input Current Waveform and THD Test Result in 230 VAC, 100% Load

© 2015 Fairchild Semiconductor Corporation 22 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 23

90 V264 V

264 V 90 V

50% Load

50% Load

Pass

Pass

Ch1:12Vo, Ch2: Iin, Ch3: VAC, Ch4:Vbulk

90 V264 V

264 V90 V

Input

Watts

(W)

Output Watts (W)

12V

FAN

Efficiency

Standard

12V1

12V2

12Vsb

When VIN= 115 V,

at 100% Load

344.00

152.31

152.28

6.00

ON

90.28%

> 89%

When VIN= 115 V,

at 50% Load

167.30

76.37

76.39

3.01

OFF

93.10%

> 92%

When VIN= 115 V,

at 20% Load

69.00

30.63

30.67

1.21

OFF

90.59%

> 90%

When VIN= 230 V,

at 100% Load

336.80

152.31

152.31

6.00

ON

92.22%

> 91%

When VIN= 230 V,

at 50% Load

165.30

76.37

76.39

3.01

OFF

94.23%

> 94%

When VIN= 230 V,

at 20% Load

68.50

30.63

30.66

1.21

OFF

91.24%

> 90%

9.2. AC Trim Up & Trim Down

Test Condition:

Switch the input voltage from 90 V to 264 V or from 264 V to 90 V. The output voltages

should be normal and the output of PFC bus should be less than 450 V.

Test Results:

Figure 18. Test Waveform of AC Trim Up & Trim Down

9.3. Efficiency

Test Condition:

Measure input current Power Factor (PF) and Total Harmonic Distortion (THD, Class D)

at various line and output loading.

Test Results:

© 2015 Fairchild Semiconductor Corporation 23 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 24

VIN=115 V

0~7.2 A (mV)

4.8~12 A (mV)

12V1

448

462

12V2

452

465

12V1, 0~7.2 A

12V1, 4.8~12 A

12V2, 0~7.2 A

12V2, 4.8~12 A

9.4. Output Transient Response

Test Condition:

Figure 19 summarizes the expected output transient step sizes for each output. Input

=115 VAC; IO= 0~7.2 A or IO= 4.8~12 A. The transient load slew rate is = 1.0 A/µS.

Test Result:

© 2015 Fairchild Semiconductor Corporation 24 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Figure 19. Test Waveform of Output Transient Response

Page 25

Input Voltage

Loading (A)

Loading (%)

115 V / 60 Hz 390 V to 358 V

15.37

61.5

230 V / 60 Hz 390 V to 358 V

16.09

64.4

115 V / 60 Hz 358 V to 390 V

17.9

71.6

230 V / 60 Hz 358 V to 390 V

18.7

74.8

Loading & Bulk Voltage

Input Voltage

Loading = 100% 390 V to 358 V

235 V

Loading = 100% 358 V to 390 V

253 V

Hold up Time

90 V/60 Hz

264 V/50 Hz

100% Load

50% Load

20% Load

100% Load

50% Load

20% Load

17.09 ms

23.56 ms

66.51 ms

17.61 ms

68.59 ms

134.68 ms

Vbulk 395 V

Vbulk 352 V

Vbulk 352 V

Vbulk 395 V

Vbulk 395 V

Vbulk 395 V

Ch2: VAC, Ch3:12Vo, Ch4:Vbulk

90 V / 60 Hz, 100% Load

264 V / 50 Hz, 100% Load

9.5. 390 V to 358 V && 358 V to 390 V at Loading

Test Condition:

Load: 100% load, during the loading-point to change, the PFC bulk voltage steps up to

390 V from 358 V or steps down to 358 V from 390 V.

Test Results:

9.6. 390 V to 358 V && 358 V to 390 V at Vrms

Test Condition:

Load: 100%. Load, during the AC input to change, the PFC bulk voltage steps up to

390 V from 358 V or steps down to 358 V from 390 V.

Test Results:

9.7. Hold up Time

Test Condition:

After AC power off, the output voltages should stay at nominal value for at least 17 ms.

Test Results:

© 2015 Fairchild Semiconductor Corporation 25 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Figure 20. Test Waveform of Hold up Time

Page 26

9.8. AC Cycle Drop

115 V0 V115 V

230 V0 V230 V

100% Load

100% Load

Pass

Pass

Ch1: 12Vo, Ch2: Iin, Ch3: VAC, Ch4: Vbulk

115 V0 V115 V, Max. Load

230 V0 V230 V, Max. Load

115 V80 V115 V

230 V160 V230 V

100% Load

100% Load

Pass

Pass

Ch1: 12VO, Ch2: Iin, Ch3: VAC, Ch4: Vbulk

115 V80V115 V, Max. Load

230 V160 V230 V, Max. Load

Test Condition:

After AC input drop 0.5 cycle, check system to ensure that no damage occurred and

behavior is correct. If the AC drop time increases to 1 cycle, the Vbulk will drop too

much to make the 12 V VO also drop. So, it’s also about min. frequency of controller.

Test Results:

9.9. AC Transient

Test Condition:

AC Transient in 115 V80 V115 V and 230 V160 V230 V conditions, check

system to ensure that no damage occurred and behavior is correct.

Test Results:

Figure 21. Test Waveform of AC Cycle Drop

© 2015 Fairchild Semiconductor Corporation 26 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Figure 22. Test Waveform of AC Transient

Page 27

L-PE ±3k V

N-PE ±3k V

L-N ±1k V

AIR ±16k V

Contact ±8k V

Pass

Pass

Pass

Pass

Pass

115 V / 60 Hz CONDUCTION-L

115 V / 60 Hz CONDUCTION-N

230 V / 50 Hz CONDUCTION-L

230 V / 50 Hz CONDUCTION-N

1 P K

CLR WR

2 A V

CLR WR

TDF

6DB

dBµ V dBµ V

15 0 kH z

30 M Hz

MT

1 0 ms

RB W

9 k Hz

PR EA MP

OF F

At t

1 0 dB

PRN

1 MH z

10 M Hz

0

10

20

30

40

50

60

70

80

90

100

EN 55 02 2A

EN 55 02 2Q

Da te : 1 7.MA R.20 15 16:3 5:11

1 P K

CLR WR

2 A V

CLR WR

TDF

6DB

dBµ V dBµ V

15 0 kH z

30 M Hz

MT

1 0 ms

RB W

9 k Hz

PR EA MP

OF F

At t

1 0 dB

PRN

1 MH z

10 M Hz

0

10

20

30

40

50

60

70

80

90

100

EN 55 02 2A

EN 55 02 2Q

Da te : 1 7.MA R.20 15 16:3 2:05

1 P K

CLR WR

2 A V

CLR WR

TDF

6DB

dBµ V dBµ V

15 0 kH z

30 M Hz

MT

1 0 ms

RB W

9 k Hz

PR EA MP

OF F

At t

1 0 dB

PRN

1 MH z

10 M Hz

0

10

20

30

40

50

60

70

80

90

100

EN 55 02 2A

EN 55 02 2Q

Da te : 1 7.MA R.20 15 16:3 7:27

1 P K

CLR WR

2 A V

CLR WR

TDF

6DB

dBµ V dBµ V

15 0 kH z

30 M Hz

MT

1 0 ms

RB W

9 k Hz

PR EA MP

OF F

At t

1 0 dB

PRN

1 MH z

10 M Hz

0

10

20

30

40

50

60

70

80

90

100

EN 55 02 2A

EN 55 02 2Q

Da te : 1 7.MA R.20 15 16:3 9:31

9.10. Surge & ESD

9.11. EMI Conduction

Test Condition:

EMI conduction test in 100% Load.

Test Results:

Figure 23. Test Waveform of EMI

Figure 24 shows, this EVB is design and test with the metal case. If the user wants to

perform an EMI conduction test, connect power earth (PE) to secondary ground point and

flowing point of Y-cap C9.

Figure 24. Setting of EMI Test

© 2015 Fairchild Semiconductor Corporation 27 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Page 28

Rev.

Date

Description

1.0.0

May 2015

Initial release

1.1

September 2015

Correct Output power, page 4 306 kW to 306 W

10. Revision History

WARNING AND DISCLAIMER

Replace components on the Evaluation Board only with those parts shown on the parts list (or Bill of Materials) in the Users’ Guide. Contact an

authorized Fairchild representative with any questions.

This board is intended to be used by certified professionals, in a lab environment, following proper safety procedures. Use at your own risk. The

Evaluation board (or kit) is for demonstration purposes only and neither the Board nor this User’s Guide constitute a sales contract or create any kind

of warranty, whether express or implied, as to the applications or products involved. Fairchild warrantees that its products meet Fairchild’s published

specifications, but does not guarantee that its products work in any specific application. Fairchild reserves the right to make changes without notice to

any products described herein to improve reliability, function, or design. Either the applicable sales contract signed by Fairchild and Buyer or, if no

contract exists, Fairchild’s standard Terms and Conditions on the back of Fairchild invoices, govern the terms of sale of the products described herein.

DISCLAIMER

FAIRCHILD SEMICONDUCTOR RESERVES THE RIGHT TO MAKE CHANGES WITHOUT FURTHER NOTICE TO ANY PRODUCTS HEREIN TO

IMPROVE RELIABILITY, FUNCTION, OR DESIGN. FAIRCHILD DOES NOT ASSUME ANY LIABILITY ARISING OUT OF THE APPLICATION OR

USE OF ANY PRODUCT OR CIRCUIT DESCRIBED HEREIN; NEITHER DOES IT CONVEY ANY LICENSE UNDER ITS PATENT RIGHTS, NOR

THE RIGHTS OF OTHERS.

LIFE SUPPORT POLICY

FAIRCHILD’S PRODUCTS ARE NOT AUTHORIZED FOR USE AS CRITICAL COMPONENTS IN LIFE SUPPORT DEVICES OR SYSTEMS

WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE PRESIDENT OF FAIRCHILD SEMICONDUCTOR CORPORATION.

As used herein:

1. Life support devices or systems are devices or systems which, (a)

are intended for surgical implant into the body, or (b) support or

sustain life, or (c) whose failure to perform when properly used in

accordance with instructions for use provided in the labeling, can be

reasonably expected to result in significant injury to the user.

ANTI-COUNTERFEITING POLICY

Fairchild Semiconductor Corporation's Anti-Counterfeiting Policy. Fairchild's Anti-Counterfeiting Policy is also stated on our external website,

www.fairchildsemi.com, under Sales Support.

Counterfeiting of semiconductor parts is a growing problem in the industry. All manufacturers of semiconductor products are experiencing

counterfeiting of their parts. Customers who inadvertently purchase counterfeit parts experience many problems such as loss of brand reputation,

substandard performance, failed applications, and increased cost of production and manufacturing delays. Fairchild is taking strong measures to

protect ourselves and our customers from the proliferation of counterfeit parts. Fairchild strongly encourages customers to purchase Fairchild parts

either directly from Fairchild or from Authorized Fairchild Distributors who are listed by country on our web page cited above. Products customers buy

either from Fairchild directly or from Authorized Fairchild Distributors are genuine parts, have full traceability, meet Fairchild's quality standards for

handling and storage and provide access to Fairchild's full range of up-to-date technical and product information. Fairchild and our Authorized

Distributors will stand behind all warranties and will appropriately address any warranty issues that may arise. Fairchild will not provide any warranty

coverage or other assistance for parts bought from Unauthorized Sources. Fairchild is committed to combat this global problem and encourage our

customers to do their part in stopping this practice by buying direct or from authorized distributors.

EXPORT COMPLIANCE STATEMENT

These commodities, technology, or software were exported from the United States in accordance with the Export Administration Regulations for the

ultimate destination listed on the commercial invoice. Diversion contrary to U.S. law is prohibited.

U.S. origin products and products made with U.S. origin technology are subject to U.S Re-export laws. In the event of re-export, the user will be

responsible to ensure the appropriate U.S. export regulations are followed.

2. A critical component is any component of a life support device or

system whose failure to perform can be reasonably expected to

cause the failure of the life support device or system, or to affect its

safety or effectiveness.

© 2015 Fairchild Semiconductor Corporation 28 FEBFAN7688SJXA_CP14U306 • Rev. 1.1

Loading...

Loading...