Page 1

I N C R E M E N T A L

Range

Analyze the application to make sure that

the proper encoder will be selected for the

machine.

To do this, bear in mind the following considerations

L i n e a r

n L i n e a r

Installation

Consider the physical length of the installation and the space

available for it.

These aspects are crucial to determine the type of linear

encoder to use (type of profile).

Accuracy

Each linear encoder comes with a graph showing its

accuracy along its measuring length.

Signal

Consider the following variables for selecting the type of

signal: Resolution, cable length and compatibility.

Resolution

The resolution of the control of machine-tools depends on the

linear encoder.

Cable length

The length of the cable depends on the type of signal.

Speed

The speed requirements for the application must be analyzed

before choosing the linear encoder.

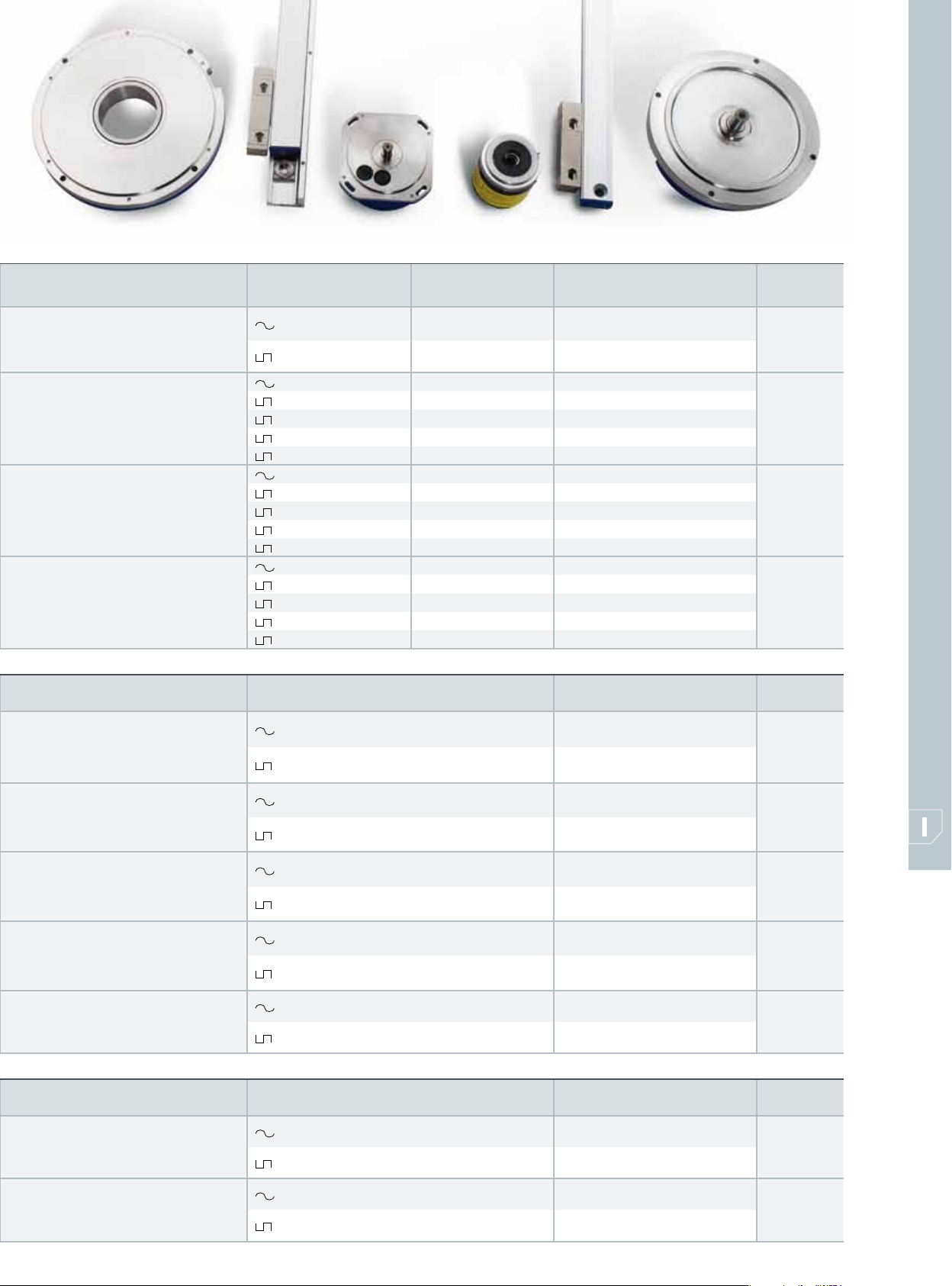

Series Section Measuring lengths Accuracy Signals

L

Long

G

Wide

S

Reduced

SV

Reduceds

400 mm to 60 m ± 5 µm

140 mm to 3 040 mm

70 mm to 1 240 mm

70 mm to 2 040 mm

A n g u l a r

Series Section Type of shaft Accuracy Signals Model Page

Shock and Vibration

Fagor linear encoders withstand vibrations of up to 20 g and

shocks of up to 30 g.

Alarm signal

Models SW / SOW / SSW and GW / GOW /GSW offer the

alarm signal AL.

n A n g u l a r

Installation

This point considers the physical dimensions of the

installation and the space available for it.

It is essential to determine its type of shaft: Hollow or solid.

Accuracy

Each encoder comes with a graph showing its accuracy

along its measuring length.

Alarm signal

Models H-D200, H-D90, S-D170, S-1024-D90 and S-D90

offer the alarm signal AL.

n R o t a r y

Installation

This point considers the physical dimensions of the

installation and the space available for it.

It is essential to determine its type of shaft: Hollow or solid.

H-D200

H-D90

S-D170

S-1024-D90

S-D90

Hollow shaft

Hollow shaft

Solid shaft

Solid shaft

Solid shaft

R o t a r y

Series Section Type of shaft Accuracy Signals Model Page

H

S

Hollow shaft ± 1/10 of the pitch

Solid shaft ± 1/10 of the pitch

36

Page 2

Pitch

Resolution up to Model Page

± 5 µm and

± 3 µm

± 5 µm and

± 3 µm

± 5 µm and

± 3 µm

± 2”

(arc-seconds)

1 Vpp

TTL

1 Vpp

TTL

TTL

TTL

TTL

1 Vpp

TTL

TTL

TTL

TTL

1 Vpp

TTL

TTL

TTL

TTL

1 Vpp

TTL

0.1 µm LP / LOP

1 µm LX / LOX

0.1 µm GP / GOP / GSP

1 µm GX / GOX / GSX

0.5 µm GY / GOY / GSY

0.1 µm GW / GOW / GSW

0.05 µm GZ / GOZ / GSZ

0.1 µm SP / SOP / SSP

1 µm SX / SOX / SSX

0.5 µm SY / SOY / SSY

0.1 µm SW / SOW / SSW

0.05 µm SZ / SOZ / SSZ

0.1 µm SVP / SVOP / SVSP

1 µm SVX / SVOX / SVSX

0.5 µm SVY / SVOY / SVSY

0.1 µm SVW / SVOW / SVSW

0.05 µm SVZ / SVOZ / SVSZ

HP-D200 / HOP-D200

H-D200 / HO-D200

38 and 39

40 and 41

42 and 43

44 and 45

46

± 5”, ± 2,5”

(arc-seconds)

± 2”

(arc-seconds)

± 5”

(arc-seconds)

± 5”, ± 2,5”

(arc-seconds)

1 Vpp

TTL

1 Vpp

TTL

1 Vpp (dual feedback)

TTL (dual feedback)

1 Vpp

TTL

1 Vpp

TTL

1 Vpp

TTL

HP-D90 / HOP-D90

H-D90 / HO-D90

SP-D170 / SOP-D170

S-D170 / SO-D170

SP/SOP 18000-1024-D90

S/SO 18000-1024-D90

S/SO 90000-1024-D90

SP-D90 / SOP-D90

S-D90 / SO-D90

HP

H / HA

SP

S

47

48

49

50

52 and 53

52 and 53

37

Loading...

Loading...