Fagor Automation all products General Product Line Information

I N C R E M E N T A L

Technology

The incremental encoders provide direct

measure of machine position without using

any intermediate device. The positioning

errors originating from machine mechanics

are minimized as the encoder is directly

mounted to the machine surface and

the guide ways. The encoder sends the

real machine movement data to the CNC

and mechanical errors caused due to

thermal behavior of the machine, pitch

error compensation and backlash etc. are

minimized.

Measuring Methods

Fagor Automation uses two measuring methods in their

incremental encoders:

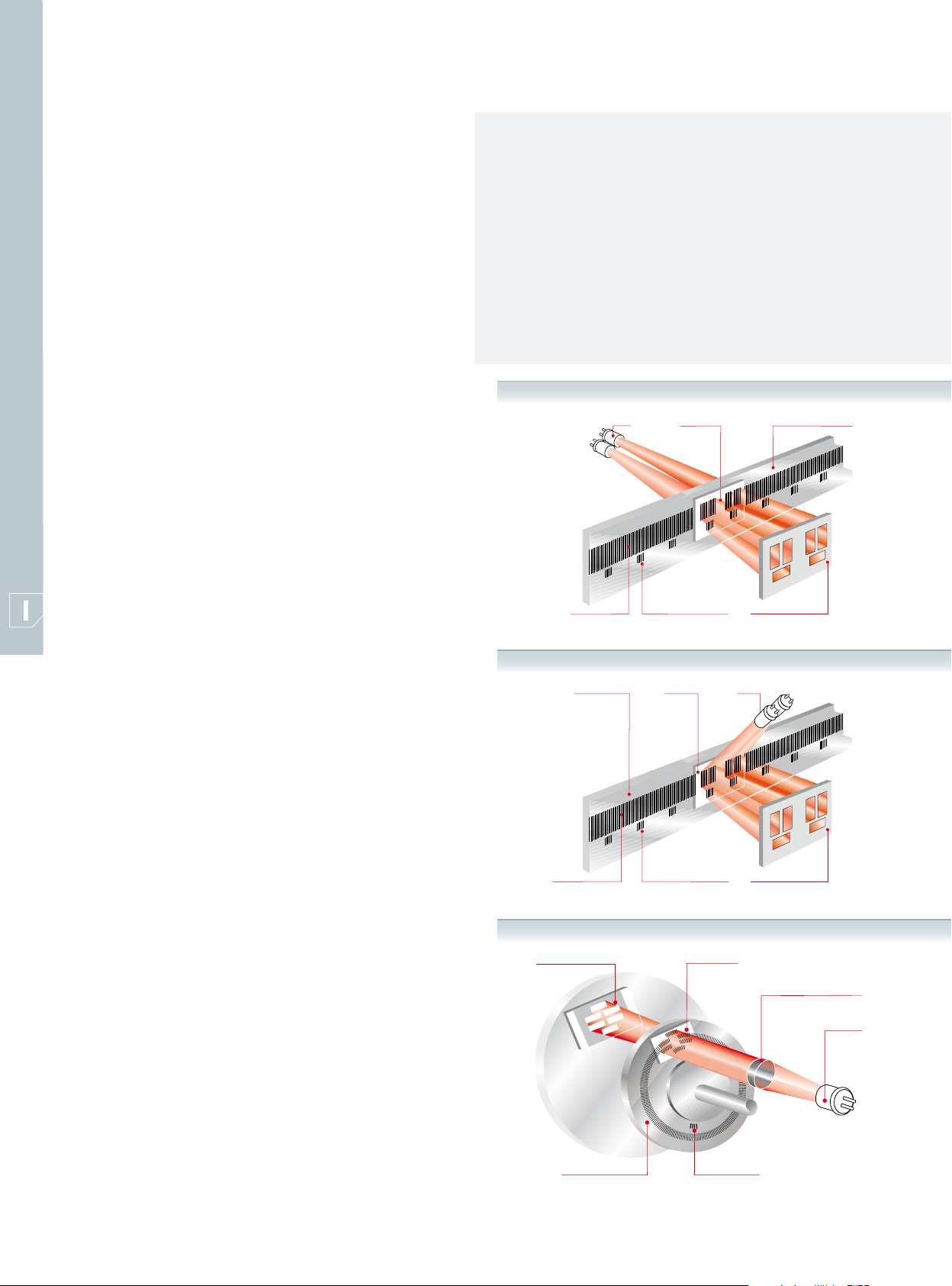

• Graduated glass: Linear encoders with a measuring

length of up to 3 040 mm use optical transmission. The

light from the LED goes through a graduated glass and a

reticule before reaching the receiving photo diodes. The

period of the generated electrical signals is the same as the

graduation pitch.

• Graduated steel: Linear encoders over 3 040 mm

measuring length use graduated steel tape and image

captured through diffused light as a measuring principle.

The reading system consists of an LED as a light source, a

mesh to make the image and a monolithic photo detector

element in the plane of the image specially designed and

patented by Fagor Automation.

Enclosed design

The robust aluminum profile encasing the graduated glass

provides the primary protection. The sealing lips provides

protection against contaminants and liquids as the reader

head travels along the profile. The reader head movement

along the graduated glass provides a perfectly balanced

system accurately capturing the machine movement. The

reader heard travels on precision bearings with minimum

contact with the profile hence minimizing the friction.

The optional air inlet at both ends of the encoder and at the

reader head provides increased protection levels against

contaminants and liquids.

Graduated glass encoder

LED’s Graduated glassGrid

Incremental graduation

Graduated steel encoder

Graduated steel Grid

Reference marks

Receiving photo-diodes

LED’s

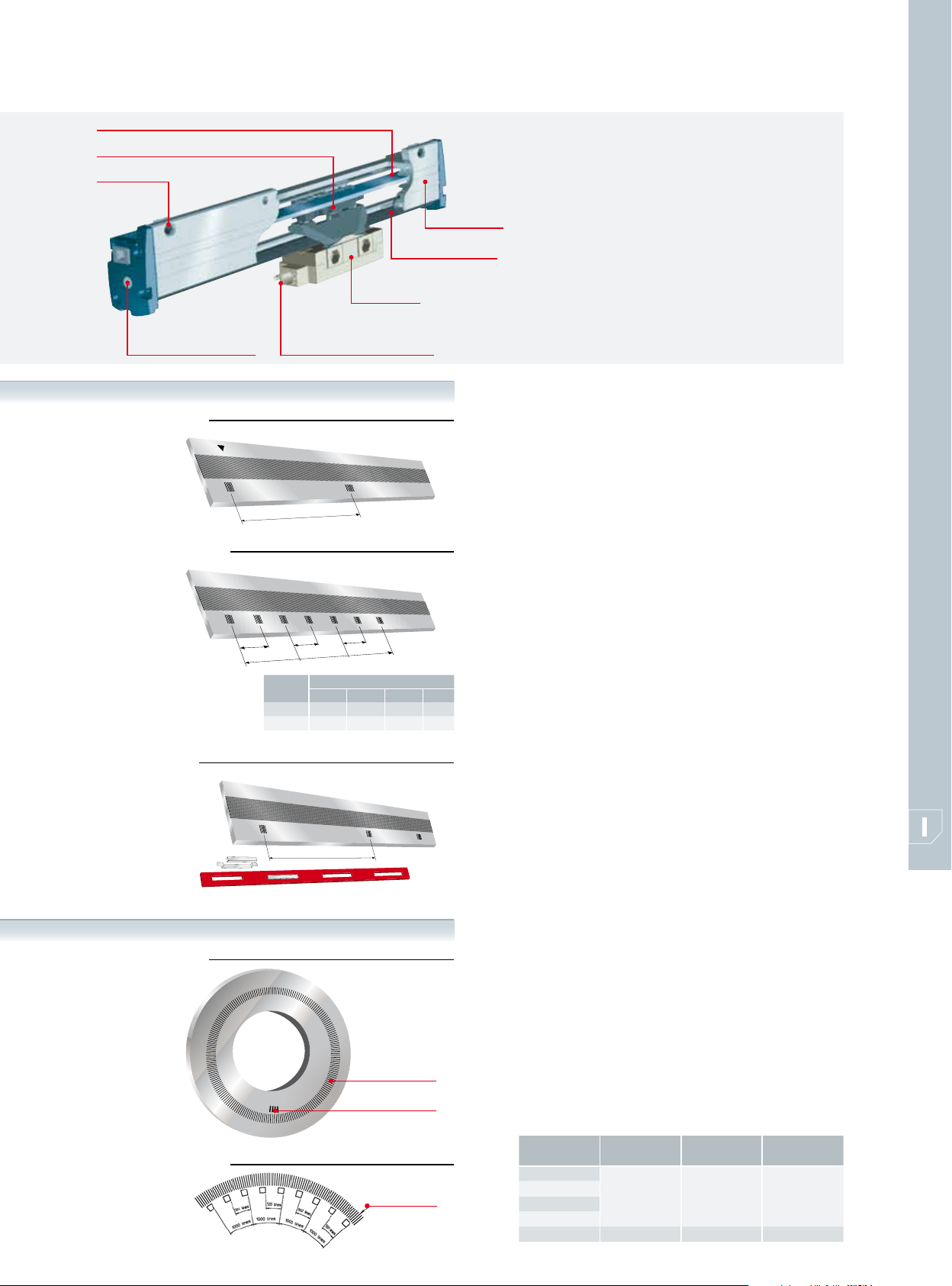

Types of incremental encoders

• Linear encoder: Ideal for milling, grinding, lathe and

boring mill applications requiring federates of up to

120 m/min and vibrations of up to 20 g.

• Angular encoder: Used as an angular movement sensor

on machines/devices requiring high resolution and

accuracy. Fagor Angular encoders offer from 18 000 to

360 000 pulses/turn and accuracy levels of

±

and

2” depending on the model.

• Rotary encoder: Used as a measuring sensor for rotary

movements, angular speeds and also linear movement

when connected to a mechanical device like ball screw.

They are also used on various types of machine tools and

robotic applications.

±

±

5”,

2.5”

Incremental graduation

Graduated glass disk

Receiving photo-diodes

Reference marks

Receiving photo-diodes

Grid

Flat convex lens

LED

32

Graduated glass disk

Reference marks

d

a

b

c

d

d

Graduated glass /steel tape

Cursor

Thermal Determined Mounting System

TM

(TDMS

)

Aluminum profile

Sealing lips

Reader head

Air intake at both ends

Incremental

Distance-coded

Selectable

Air intake on the reader head

Linear encoder

50

a

b

d

Series

L 40.04 40.08 40.12 80

G and S 10.02 10.04 10.06 20

c

d

d

Distances

a b c d

50

Reference signals (I0)

It is a reference signal etched on a graduation and when

scanned by the measuring system generates a pulse.

Reference marks are used to validate and restore the

machine zero position specially after turning on the machine

power.

Fagor Automation encoders have three types of reference

marks

I

:

0

• Incremental: The reference signal obtained is

synchronized with the feedback signals to ensure perfect

measuring repeatability.

Linear: One every 50 mm of travel.

Angular and rotary: One signal per turn

• Distance-coded: Both on linear and angular encoders

each distance coded reference signal is graduated in a non

linear way based on the predefined mathematical function.

The machine position value can be restored by moving

through two consecutive reference signals. The machine

movement needed to know the real position is always

very small and this is a very useful feature for large travel

machines.

• Selectable: With selectable linear encoders the customer

can select one or more reference points and ignore the

rest by simply inserting a magnet at the selected point or

points.

Incremental

Distance-coded

Angular encoder

etching

reference signals

reference signals

Series

H-D90

S-D90

S-D170

H-D200

H-D200 36

Nr. of

lines

18

000 36 20º

000 72 10º

Nr. of

references

Angle

33

Loading...

Loading...