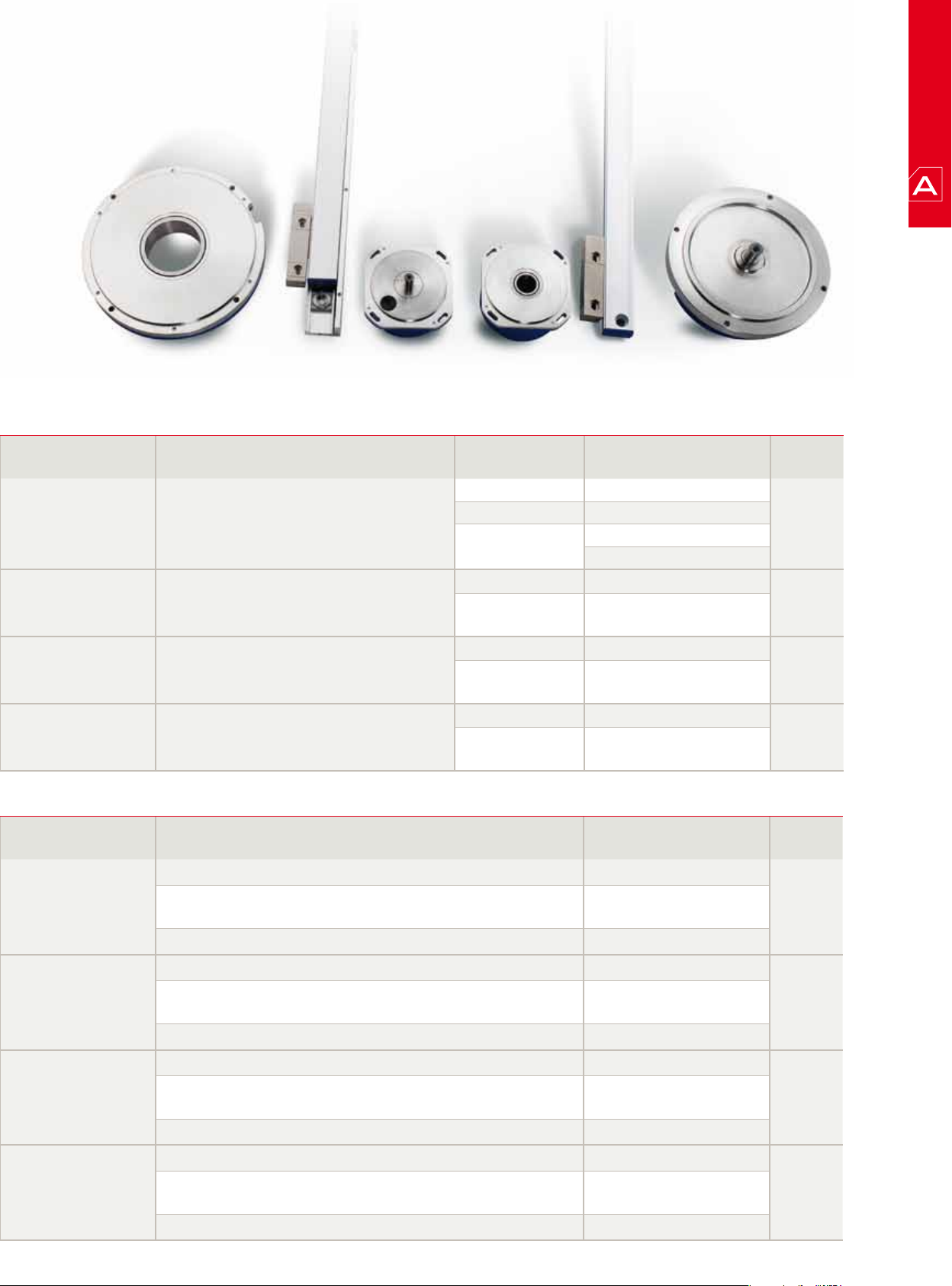

A B S O L U T E

Range

Analyze the application to make sure that

the proper encoder will be selected for the

machine.

To do this, bear in mind the following considerations

n L i n e a r

Installation

Consider the physical length of the installation and the space

available for it.

These aspects are crucial to determine the type of linear

encoder to use (type of profile).

Accuracy

Each linear encoder comes with a graph showing its

accuracy along its measuring length.

Signal

The signal selection considers the communication protocols

compatible with the main CNC manufacturers.

Resolution

The resolution of the control of machine-tools depends on the

linear encoder.

Cable length

The length of the cable depends on the type of signal.

Compatibility

The signal must be compatible with the control system.

Speed

The speed requirements for the application must be analyzed

before choosing the linear encoder.

Shock and Vibration

Fagor linear encoders withstand vibrations of up to 20 g and

shocks of up to 30 g.

n A n g u l a r

L i n e a r

Series Section Measuring lengths Accuracy Signals

LA

Long

GA

Wide

SA

Reduced

SVA

Reduced

440 mm to 50 m ± 5 µm

140 mm to 3 040 mm

70 mm to 1 240 mm

70 mm to 2 040 mm

A n g u l a r

Series Section Type of shaft Accuracy Signals Model Page

Installation

This point considers the physical dimensions of the

installation and the space available for it.

It is essential to determine its type of shaft: Hollow or solid.

Accuracy

Each encoder comes with a graph showing its accuracy

along its measuring length.

14

HA-D200

HA-D90

SA-D170

SA-D90

Hollow shaft ± 2” and ±1”

Hollow shaft ± 5” and ±2,5”

Solid shaft ± 2”

Solid shaft ± 5” and ±2,5”

± 5 µm and

± 3 µm

± 5 µm and

± 3 µm

± 5 µm and

± 3 µm

SSI + 1 Vpp FAGOR

SSI + 1 Vpp SIEMENS

®

FANUC

SIEMENS

/ MITSUBISHI® / PANASONIC® / FAGOR

®

(*)

®

(*)

SSI +1 Vpp FAGOR / SIEMENS

®

FANUC

SIEMENS

/ MITSUBISHI® / PANASONIC® / FAGOR

®

(*)

SSI +1 Vpp FAGOR / SIEMENS

®

FANUC

SIEMENS

/ MITSUBISHI® / PANASONIC® / FAGOR

®

(*)

SSI +1 Vpp FAGOR / SIEMENS

®

FANUC

SIEMENS

/ MITSUBISHI® / PANASONIC® / FAGOR

®

(*)

Pitch

Resolution up to Model Page

0.1 µm LA

1 µm LAS

0.01 µm

®

(*)

0.1 µm GA / GAS

0.01 µm

®

(*)

0.1 µm SA / SAS

0.01 µm

®

(*)

0.1 µm SVA / SVAS

0.01 µm

LAF / LAM / LAP / LAD

LAD + EC-PA-DQ

GAF / GAM / GAP / GAD

GAD + EC-PA-DQ

SAF / SAM / SAP / SAD

SAD + EC-PA-DQ

SVAF / SVAM / SVAP / SVAD

SVAD + EC-PA-DQ

16 and 17

18 and 19

20 and 21

22 and 23

SSI +1 Vpp FAGOR / SIEMENS

®

/ MITSUBISHI® / PANASONIC® / FAGOR

SIEMENS

(*) HAD-D200 + EC-PA-DQ

SSI +1 Vpp FAGOR / SIEMENS

®

/ MITSUBISHI® / PANASONIC® / FAGOR

SIEMENS

(*) HAD-D90 + EC-PA-DQ

SSI +1 Vpp FAGOR / SIEMENS

®

/ MITSUBISHI® / PANASONIC® / FAGOR

SIEMENS

(*) SAD-D170 + EC-PA-DQ

SSI +1 Vpp FAGOR / SIEMENS

®

/ MITSUBISHI® / PANASONIC® / FAGOR

SIEMENS

* SIEMENS®: valid for family Solution Line.

(*) SAD-D90 + EC-PA-DQ

®

(*) HA-D200/ HAS-D200

HAF-D200 / HAM-D200 /

HAP-D200 / HAD-D200

®

(*) HA-D90 / HAS-D90

HAF-D90 / HAM-D90 /

HAP-D90 / HAD-D90

®

(*) SA-D170 / SAS-D170

SAF-D170 / SAM-D170 /

SAP-D170 / SAD-D170

®

(*) SA-D90 / SAS-D90

SAF-D90 / SAM-D90 /

SAP-D90 / SAD-D90

24FANUC

25FANUC

26FANUC

27FANUC

15

Loading...

Loading...