Page 1

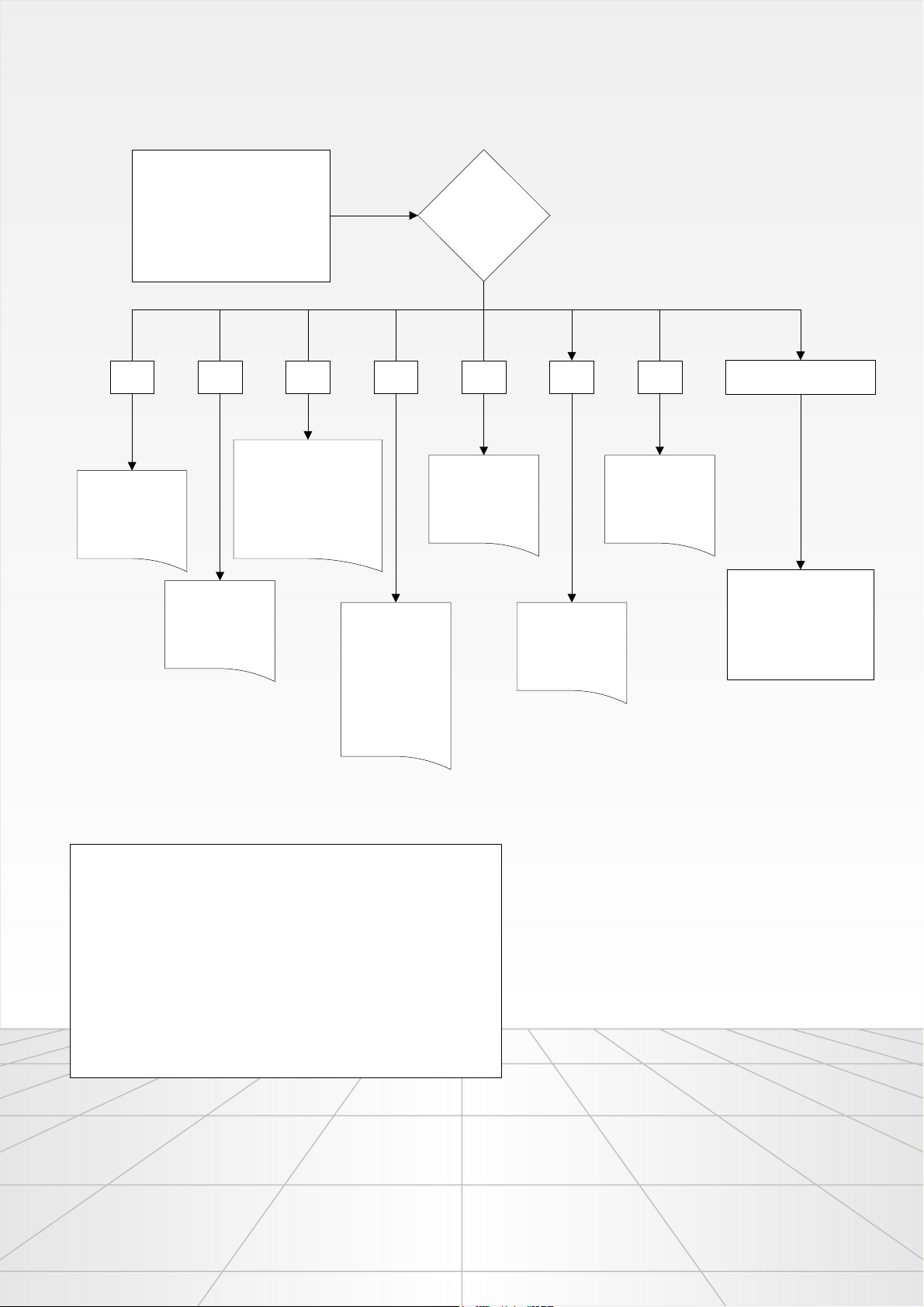

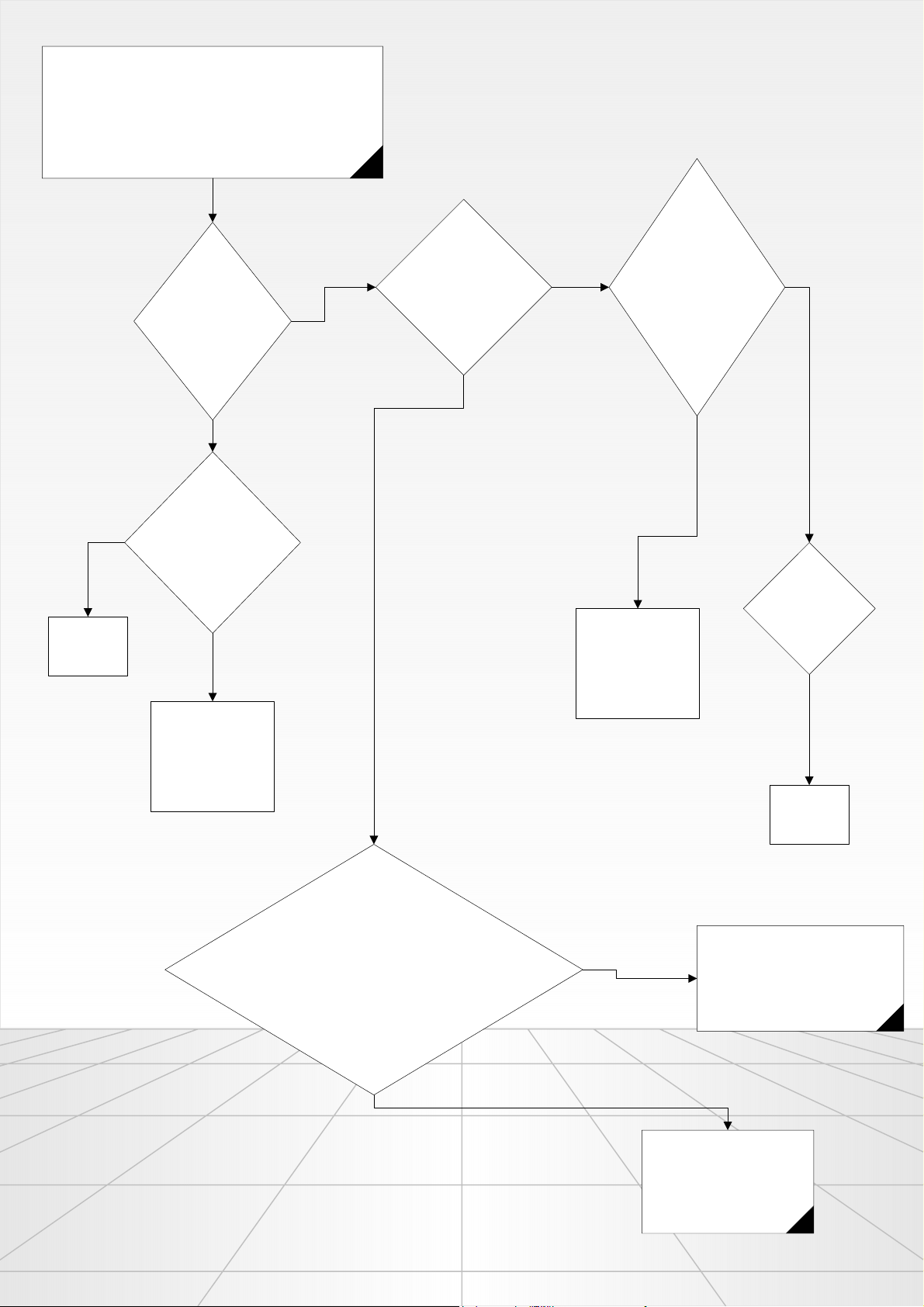

Jump Failure Finding Flow-charts

Check the failure code (Can be

observed at the beginning of

“functional test mode” or “failure

code observing mode”)

100 101110010 001 None111011

Heater always on

NTC short circuit

or open circuit

problem. Follow

“no heating” flow-

chart

Heater open

circuit problem.

Follow “no

heating” flow-chart

problem. Start draining

program. If heating is

observed, change the

electronic card group

Valve triac short

circuit problem.

After checking

wiring(is there a

problem in cable

orders), change

the electronic card

if the valve always

on failure is

actually seen.

Go to the

algorithm

related with the

error code

Pump open circuit

or pump short-

circuit problem.

See no-draining

flow-chart

Water level sensor

Motor triac short-

circuit failure. See

spinning at a

washing step flow-

chart

problem. See no

water filling flow-

chart

Go to the flow-chart

which defines the

problem you observe.

FAILURE CODE OBSERVING MODE

Press the first auxiliary function button from the left for 6 seconds. “Run/

Pause/Cancel” led will start blinking and the program followers will start

blinking as an error code for 3 seconds if any failure routine has run.

After 3 seconds, the machine will return to the selection mode.

After entering the failure code observing mode, pressing and holding “Run/

Pause/Cancel” button for a short time will erase the error code from the

memory. After you complete your inspection, if you are not sure that you

have solved the problem and if you are going to change the electronic card

group, do not erase the error code. For else cases, you may erase the error

Entrance:

Deletion of the error code:

code.

Rev.02 _ 060604 1

Page 2

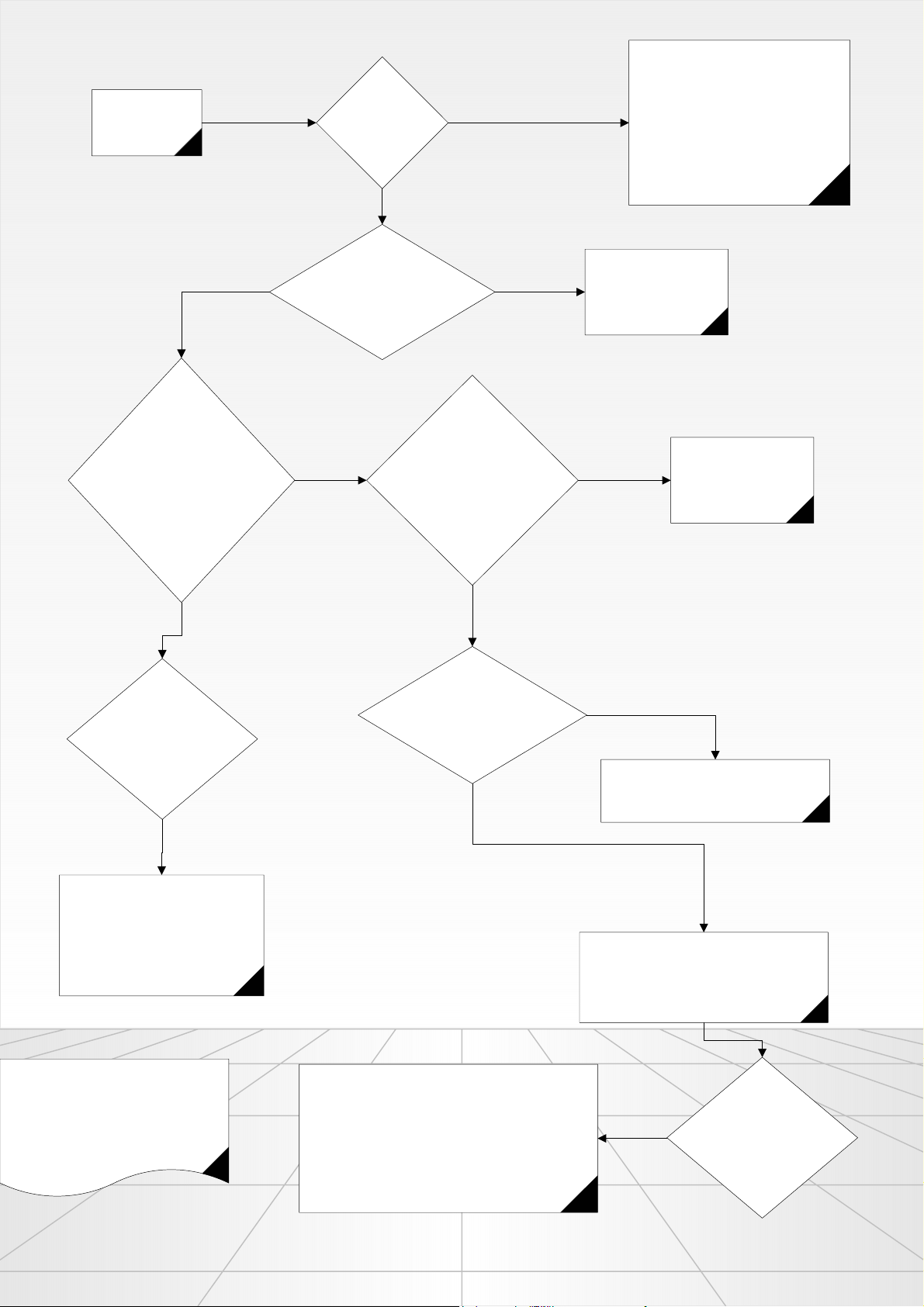

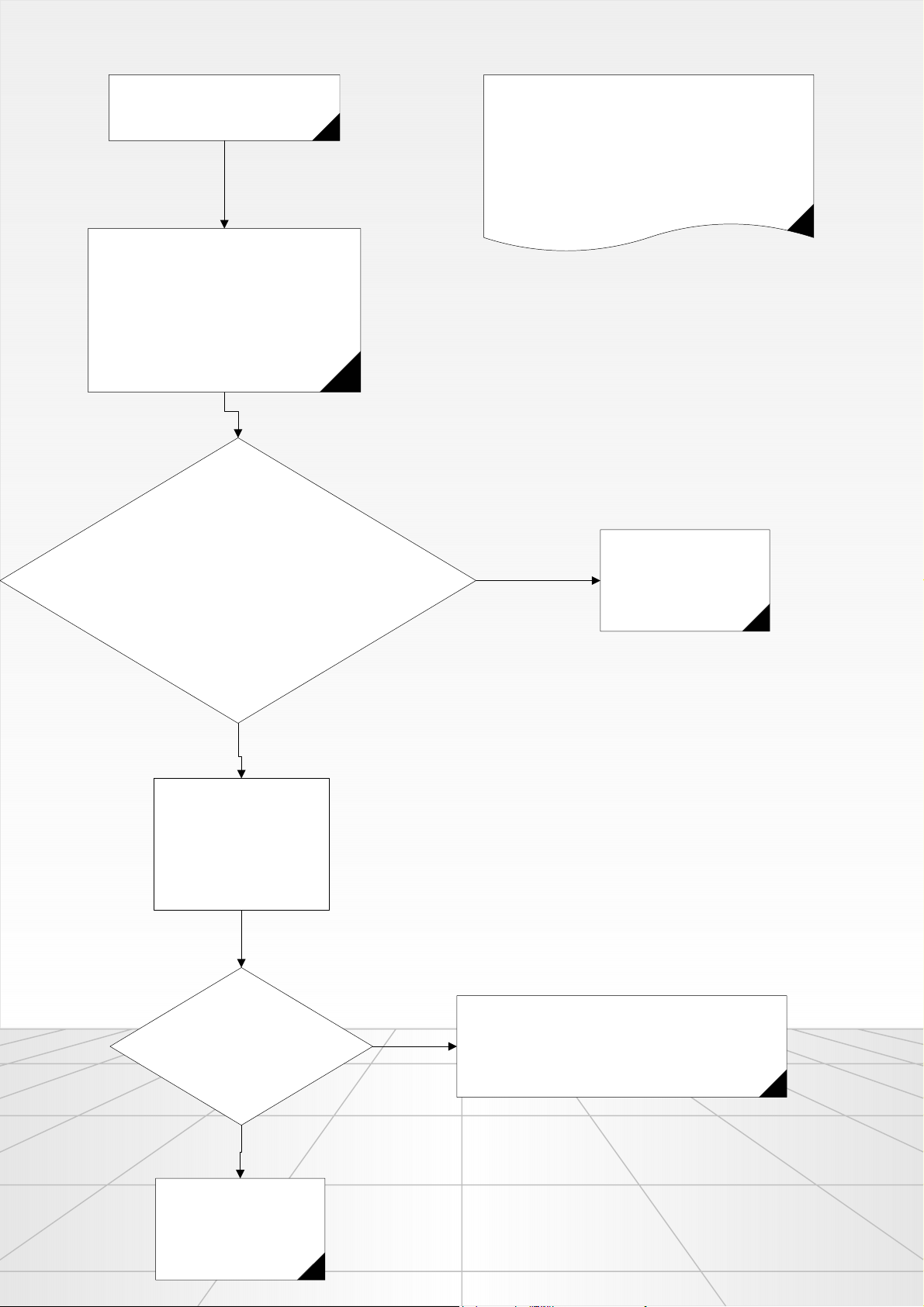

Jump Failure Finding Flow-charts

WM does not work

No

Is “Start/Pause/Cancel” led

illuminating after “Start/Pause/

Cancel” button is pressed.

Is “Ready”

(“door” led in

some models)

blinking

No

Is the door locked?

(If the door is locked, “Ready”

led {“door” led in some models}

No

must be off)

Can you sense the “tact”

feeling of the tact switch

while you press “Start/

Pause/Cancel” button?

Yes

Yes

Check if the program selector is in a

position between two programs. If the

blinking of Ready continues even if

you have seen that the selector is not

in between any adjacent positions,

change the control card group.

See “no water filling”

flow-chart

No

Check if the card is

assembled correctly to

front panel or not.

Yes

Measure the voltage

between the pins 1 and 3 of

door-lock. Is it 230 V AC?

Yes

Change the door-lock

Yes

Measure the voltage between the

pins 1 and 2 of the filter (brown

and blue cables). Is it 230 V AC?

Yes

No

Check the power cord and fuses.

Change the power cord if you see a

problem there.

Check the cable connections of the On/Off.

If there is no problem at the wiring, change

the On/Off switch.

Important Note:

WM does not work failure means, none

of the functions of the machines can be

done. In this condition, WM will not take

any water, will not do any washing,

draining or spinning.

If “Ready” led (“Door” Led in some models) is not

active, door is not locked and 230 V AC is measured

between L and N terminals of the On/Off switch;

change the electronic card group.

Yes

Do you still observe the

problem?

Rev.02 _ 060604 2

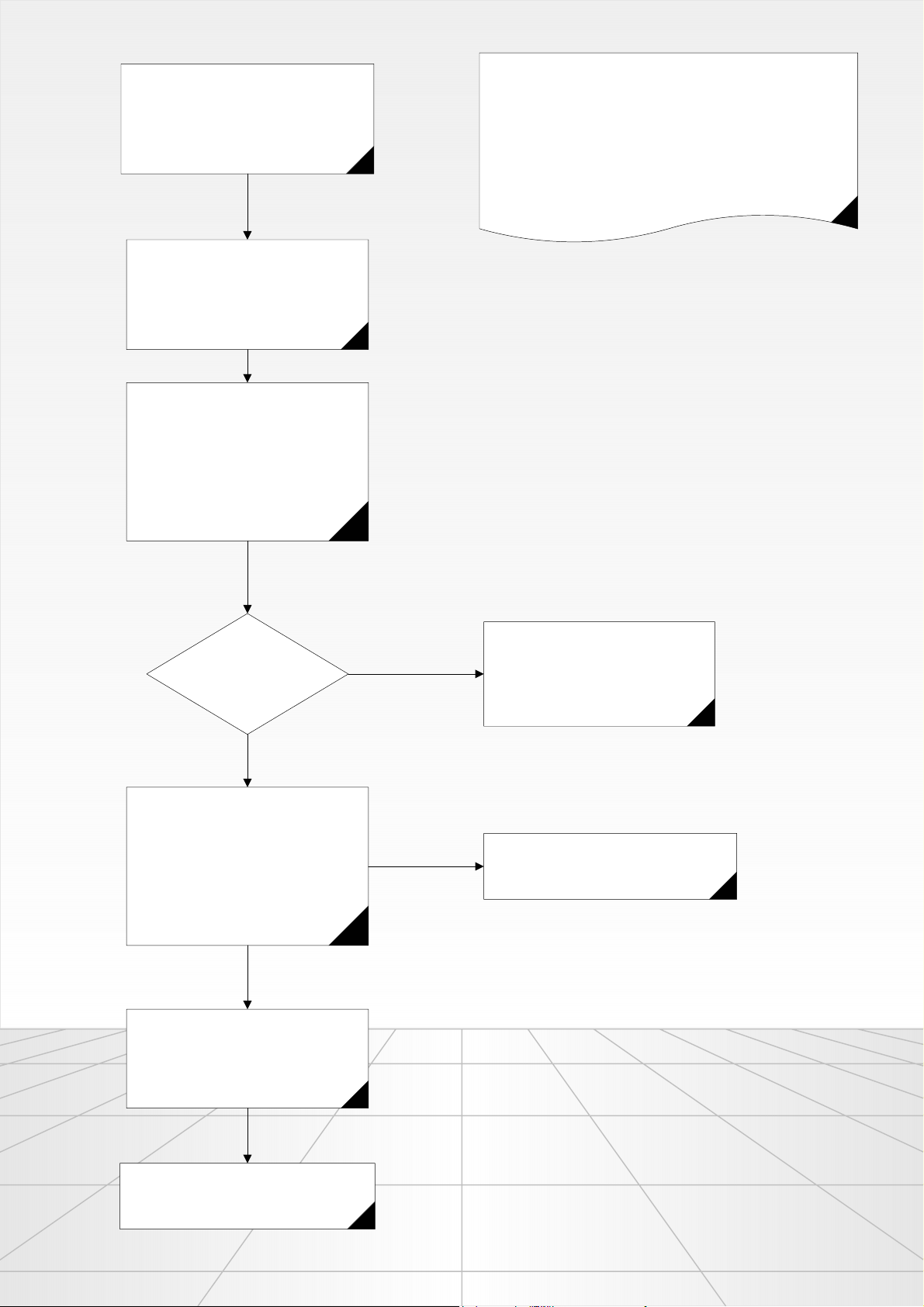

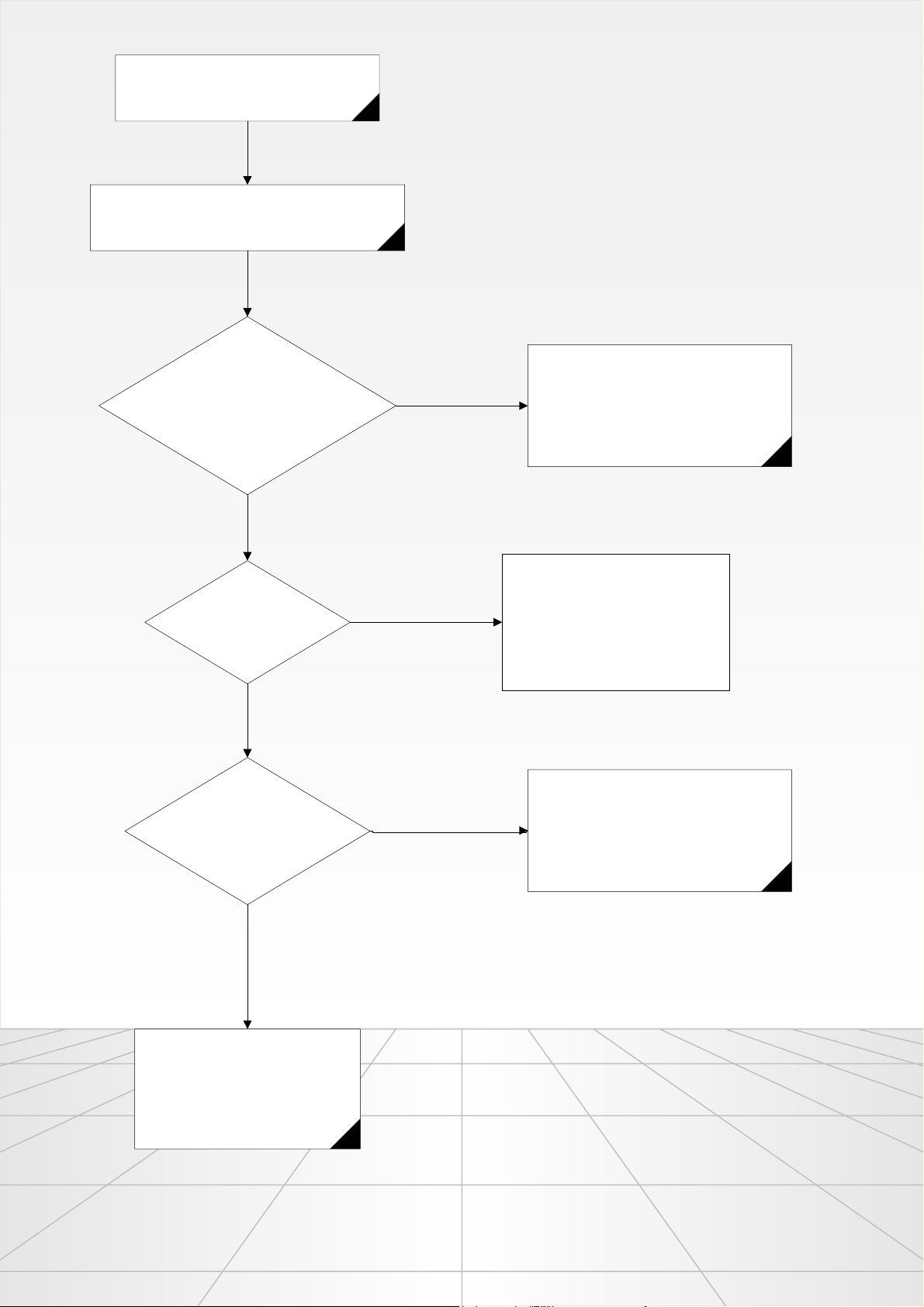

Page 3

WM does not work.

(There is water filling)

Jump Failure Finding Flow-charts

REMARK

Right after the machine finishes water filling step, if the motor does

non start working or if any motion data is not sensed (Tacho

failures) the electronic card makes 8 take-off trials, waits 120 sec.

between each take-off trial, and if the failure is still detected, the

motor is stopped, and draining starts. Right after draining, the

machine turns to the selection mode.

Make sure the machine completes water

filling step.

Disconnect the J5 and J6 motor

connectors from the main board and

measure the resistance values of motor

windings. Measured vaues must be as

given below:

STATOR IN - COMMUN = 0,5 - 1,5 Ohms

STATOR MP - COMMUN = 0,5 - 1 Ohm

ROTOR1 - ROTOR2 = 0,5 - 1 Ohm

TACHO = 50 - 60 Ohms

Are motor windings OK?

No

First check the motor wiring connections

between the motor and the electronic

card. If there is no problem at the wiring,

change the motor.

Yes

Connect a voltmeter (AC) to J6 (Tacho)

connector on electronic card and rotate

the drum manually. When the drum is

rotating, a voltage value related to the

rotation speed must be seen on the

voltmeter and this walue must be 0V(AC)

when the drum is stopped.

Yes

Make sure that the J5 and J6 connectors

are connected properly to the mainboard.

The terminals of the connector may be

coming out of the plastic body. If there if a

problem at the connector or teminals, try

fixing it.

If the failure still exists, change the electronic

card group.

No

If there is a problem at motor tacho

magnets, change the tacho.

Rev.02 _ 060604 3

Page 4

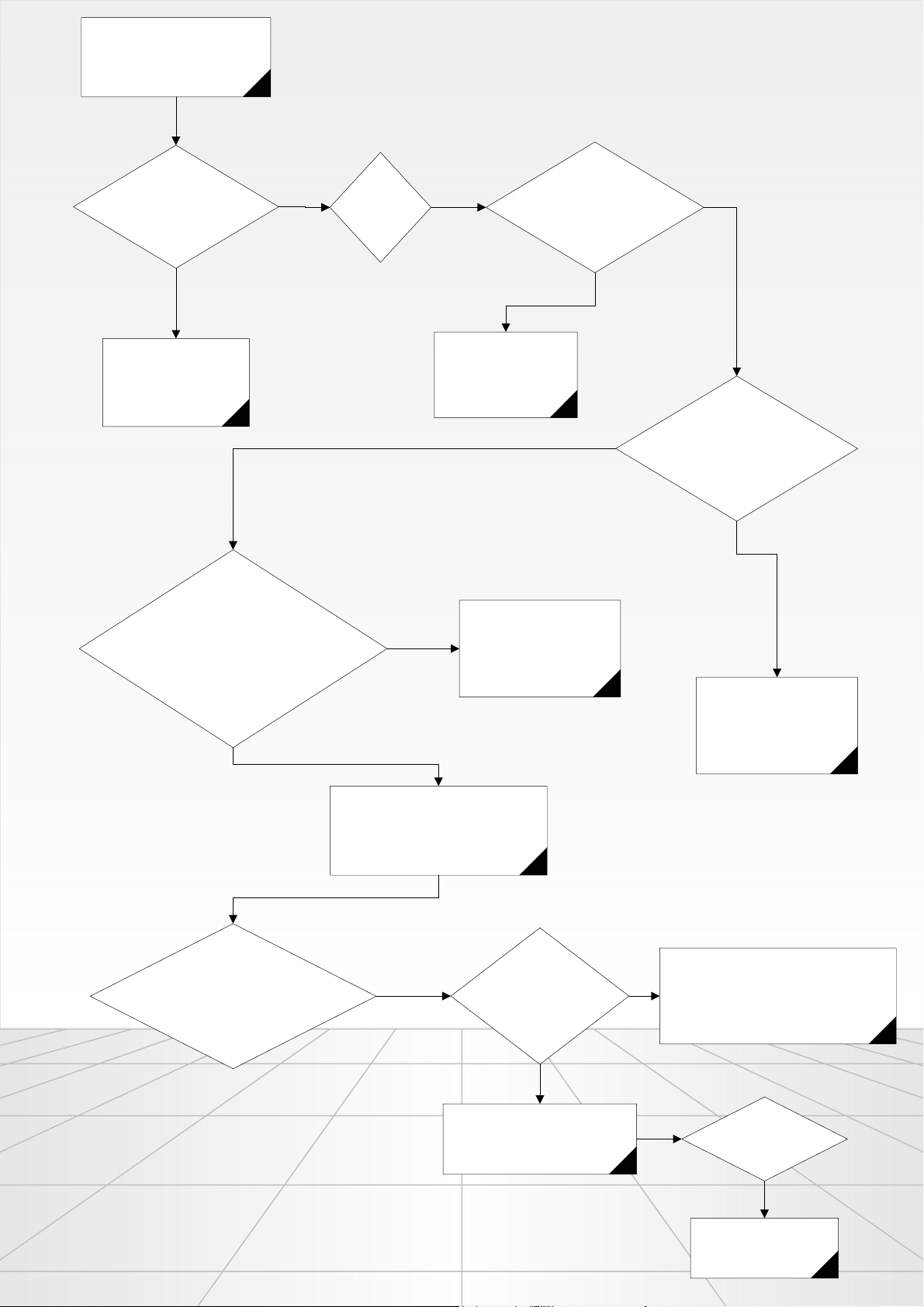

No water filling

Jump Failure Finding Flow-charts

Yes Yes

Is the door locked?

No

See WM does not work

flow-chart

Can you measure 230 V AC between the

terminals of the relevant valve?

Also check the voltage values on J3 and J4

connectors, too.

EVCOLD2 - NEUTRAL=230V (PW)

EVCOLD1 - NEUTRAL =230V (MW)

Is washing

led blinking?

Yes

Open the taps and try

again.

No

Yes

Change the valve

Check if the water taps are

open or not. If they are closed,

open them. Are the taps open?

No

Check the valve filter. Filter may be

congested. Are the filters

congested?

Yes

Check the connections between water

level sensor and the electronic card. Are

the connections OK?

No

Check the wiring between the control

card and the valves.

Yes

Can you measure 5 V

(DC) between the water

level sensors terminals 1

and 2?

Change the water level sensor.

Yes

Change the filter and try

The terminals of the connector on the

No

water level sensor or the electronic card

may not be connecting properly to their

pairs on the wiring. Check the

connections of each pair.

Is the problem solved?

again.

No

Change the electronic

card group.

Rev.02 _ 060604 4

Page 5

Water filling from wrong compartment.

No

Is the failure; water

filling from softener

compartment,

when this is not

expected?

Jump Failure Finding Flow-charts

Is the failure; filling is

done from other

compartment, when it

is expected to be

done from softener

compartment?

Yes

Is there a problem at

J4.2 EVCOLD1-

prewash

and J4.3-EVCOLD2

mainwash

connections? (230 V

AC must be

measured from both

valves terminals.)

230 V AC is

not seen at

least at one

of the pre-

wash and

main wash

terminals.

Yes

Change the

electronic

card

Yes

Measure the voltages

on prewash and

mainwash valves.

Can you measure

230 V AC on both

valve terminals?

No

Change the valve. If

the problem still

exists, chance the

detergent dispenser

assembly.

No, the failure is

not related with

the softener

compartment.

No Problem about

measuring 230 V

(AC) at both valves.

(prewash and

mainwash)

Change the valve. If

the problem still

exists, chance the

detergent dispenser

assembly.

Is there a

problem at

wiring?

No

Change the

electronic

card group

J4.3 EVCOLD2–Prewash valve

Are

J4.2 EVCOLD1–Mainwash valve

J4.1 EVHOT–Hotwater valve

connections made properly?

Yes

No

Check and correct the connections

and test again by starting a washing

program.

Change the control card

Rev.02 _ 060604 5

Page 6

Jump Failure Finding Flow-charts

No heating, heater does not initiate.

Check the NTC connections and wiring. Make

sure the connectors are plugged well.

Also make sure that the water level sensor’s

hose is not punctured or congested.

Remark:

In cases of NTC open / short circuit or heater open circuit,

washing machine performs cold washing without activating

the heater.

Measure the NTC resistance from J2 connector’s NTC-5V terminals. Is

this resistance approximately 4700 Ohms at 25ºC temperature? (The

measurement must be a value different than Open or Short circuit)

NOTE: Before doing the measurement, make sure that the scale

setting of your ohmmeter is set correct.

Yes

Make sure that the heater

wiring and connections are

proper and the connectors

are plugged well. Continue

following the flow-chart if the

problem still exists.

No

Measure the NTC after

seperating it from wiring; If

you measure the NTC as

open or short circuit, change

it.

Unplug one of the heaters connectors

and measure the heater resistance. Is

it about 20-30 Ohms?

Yes

Change the electronic card.

No

Change the heater

Rev.02 _ 060604 6

Page 7

Jump Failure Finding Flow-charts

No Draining

Select Pump program and start the program.

Is the pump active? (can be understanded

by touching the filter cover)

No

Yes

Is the machine filling water?

No

Can you measure 230 V AC voltage

between pump teminals?

Also check J3 connector

PUMP-NEUTRAL voltage. Is it

230V AC ?

Yes

Yes

* Check and Clean the pump filter

* Drain hose level should be between 0,5

and 1 meter from the floor

* Check the drain hose , it ishould not be

banded or broken

If the water temperature in the tub is

higher than 50C, the machine makes

water filling to decrease this

temperature. If the “no draining”

problem still exists after water filling,

check the NTC resistance value.

Pump motor windings are open circuit, change

the pump.

No

Check the wiring and connections

between the electronic card and wires.

Fix if you see any disconnections. If

you don’t see any problem at the wiring

and the connections, change the

electronic card group.

Rev.02 _ 060604 7

Page 8

Jump Failure Finding Flow-charts

WM is spinning at a washing

step.

If the motor triac is short-circuit, motor

will make 2 take-off trials at spinning

step; and pauses 40 sec between these

trials. After these 2 trials the water in the

tub will be discharged by draining.

Un plug the J6 connector and

measure the tacho resistance.

Is it open circuit?

No

Check the wiring and

connections between the

electronic card and J6

connector. Keep following the

flow-chart if the problem still

exists.

Connect a voltmeter (AC) to J6 (Tacho)

connector on electronic card and rotate

the drum manually. When the drum is

rotating, a voltage value related to the

rotation speed must be seen on the

voltmeter and this walue must be 0V(AC)

when the drum is stopped.

Yes

Change the motor. (In tacho open

circuit condition; WM makes 8 trials

and pauses 120 seconds between

each trial. The machine returns to the

selection mode if the tacho resistance

is not normal after these trials.

Are your measurements as

expected above?

No

Change the motor

Yes

Change the electronic card.

Rev.02 _ 060604 8

Page 9

Jump Failure Finding Flow-charts

Program follower LED blinking

Is “Ready” Led

blinking?

No

Yes

Check if the program selector is in a

position between two programs. If the

blinking of Ready continues even if

you have seen that the selector is not

in between any adjacent positions,

change the control card group.

Is “Washing” Led blinking?

Yes

See no water filling flow-chart

Rev.02 _ 060604 9

Page 10

Jump Failure Finding Flow-charts

THE ERROR CODES WHICH CAN BE OBSERVED AT FUNCTIONAL TEST AND FAILURE

H1 : NTC OPEN OR SHORT CIRCUIT ( 100 )

H2 : HEATER OPEN CIRCUIT ( 010 )

H3 : HEATER ALWAYS ON ( 110 )

H4 : VALVE TRIAC SHORT CIRCUIT ( 001 )

H5 : PUMP OPEN OR SHORT CIRCUIT ( 101 )

H6 : MOTOR TRIAC SHORT CIRCUIT ( 011 )

H7 : WATER LEVEL SENSOR FAILURE ( 111 )

CODE OBSERVING MODES

PS : THE ERROR CODES GIVEN ABOVE DOES NOT ALWAYS MEAN REASON FOR THE

FAILURE IS THE DEFINED COMPONENT

ALWAYS CHECK THE CONNECTORS AND WIRING FIRST TO SEE IF THE CAUSE OF

THE FAILURE IS A DISCONNECTION OR SOMETHING SIMILAR.

FAILURE CODE OBSERVING MODE

Press the first auxiliary function button from the left for 6 seconds. “Run/

Pause/Cancel” led will start blinking and the program followers will start

blinking as an error code for 3 seconds if any failure routine has run.

After 3 seconds, the machine will return to the selection mode.

After entering the failure code observing mode, pressing and holding “Run/

Pause/Cancel” button for a short time will erase the error code from the

memory. After you complete your inspection, if you are not sure that you

have solved the problem and if you are going to change the electronic card

group, do not erase the error code. For else cases, you may erase the error

Entrance:

Deletion of the error code:

code.

Rev.02 _ 060604 10

Page 11

Jump Failure Finding Flow-charts

JUMP Functional Test Program

Entrance to the test mode:

1. Turn off the machine from On/Off Button

2. Turn on the W/M from the main switch, while pressing “start/pause/cancel” button. Start icon will start to blink within 3

seconds. At the moment, you can see the code of failure in follower LEDs

3. After seeing the failure, erase the failure by pressing start/pause/cancel button 3 seconds without losing any time

4. After erasing the failure code, you will be in functional test mode. Each push to the start / pause / cancel button will

represent one function.

Functional Test Sequence:

1. All LEDs on the board will start to blink after the door is locked.

2.For the softwares before 32A, 3-6-9 time delay leds will be on in different combinations , related to the spin

potantiometer position.( For max spin 3-9 leds will be on , for no spin no led will be on)

For 32A and following softwares , 1 and 2 auxilary function leds will be on in 4 different combinations, related to the

spin potantiometer position.

3. Take in water from pre-wash compartment

4. Take in water from main wash compartment

5. Take in water from softener compartment (Both PW and MW valves are active)

6. Take in water from main wash compartment if the W/M has a hot valve option (If not this step will be skipped)

7. The heater will be ON. If the water level inside the tub is not enough for the heater to switch on then all valves will be

turn on to fill the level.

8. Clockwise motor rotation with 52 rpm

9. Counterclockwise motor rotation with 52 rpm

10. Draining and after draining is finished spinning up to maximum speed.

11. Turn on all the valves to fill a certain level in a short time for water leakage test on the production line.

12. End

13. You can get off the test mode by turning the WM off.

Rev.02 _ 060604 11

Page 12

COMPONENTS

Mechanical Parts (Dynamic System):

The tub is made of special plastic material that has high strength, is able to decrease

noise level and no corrosion problem. The tub cover is also made of plastic used in

YOÇ and is attached to the tub with special fixing clamps. Truva tub is made of 2

tubs connected each other by PT screw. The main motor is attached to the tub with

two rubber grommets and a bolt in YOÇ series. On the other hand, motors are

connected by 4 arms Positioned behind the tub, on the right, left and top, are

transport security bolt connection slots. There are also two concrete counterbalance

weights one on top of, and one underneath the tub. The tub group is hooked onto the

cabinet at each side by two springs. There are two horizontal shock absorbers at the

bottom, the functions of the springs and the shock absorbers is to dampen the

vibrations caused by tub movement and to reduce motion and noise. The drum is

made of stainless steel.

Shock Absorber System:

Tub group is hooked onto the cabinet at each side by two springs. Furthermore, it is

fixed to the cabinet by two shock absorbers. Springs and shock absorbers defeat

high noise level and the movement of the machine transmitting vibration to the

cabinet. Shock absorbers are connected to chassis and tub with plastic pins instead

of nuts.

Electronic Control and Display Card:

Wash programs, wash and spin motor profiles, protection algorithms and

components (motor, heater, pump, valves, door lock, NTC, pressure sensor, rotary

switch, spin/temperature potentiometer) are controlled by double-phase design

control and display card produced by INVENSYS.

There are connection terminals of smps, motor and other component control circuitstriacs and relays- on the front face of the card. On the other face there are, microchip,

auxillary function and time delay button and led, as well as program follower.

Wash operation is started due to the signals from the auxillary function, time delay,

assembly rotary switch, spin /temperature potentiometer.

Auxillary function, spin/temperature and time delay options can be selected from

electronic card.

Door lock:

A PTC door-lock is used. When the door is closed, the PTC disk is heated up and

locks the door. After the program is terminated, the PTC is cooled down and after

max. 120 seconds the door is unlocked. Thus the door is prevented from opening

during operation. If there is a fault with the door lock, then washing machine will not

operate.

Page 13

Nominal Voltage: 250V 50-60Hz

Current: 10-50mA

PTC Resistance: Min.>=50Ohm

Lock time: <=8sn

Unlock time: 35…70sn

Main motor:

The main motor is a universal series motor. It is controlled by a card. The motor spin

is adjusted as the triggering angle is altered by the triac on the electronic card

module depending on the tachometer. Universal motor is composed of stator and

rotor. Stator and rotor are in series connection by collector and brush. Cycle of the

motor is controlled by electronic card. Motor triac on card adjusts the motor/drum

cycle by changing the triac alert angle according to signals from taco. There is a fuse

that prevents extreme heating of bandage on motor.

Nominal Voltage: 220-240V 50-60Hz

Current: 6A max (wash)/ 3A(spin)

Start Power: 300/450W

Start current: 5…8A(wash)/10A max (spin)

Taco generator technical data:

Number of Double Pole: 8

Taco Voltage at 300rpm: >0,9V

Taco Voltage at 1650rpm: <45V

Heater:

A 1900-watt heater is used. There are two thermofuses on the heater. If the heater

runs without enough water, one of the thermofuse goes off, and thus this heater

cannot be used again. The heater is energized only when there is enough water

inside the washing machine. When the desired temperature is reached, electronic

control card reads the resistance of NTC and if the prescribed resistance (and hence

temperature) is reached, the heater is switched off. In order to prevent the heater

operating without water, “heater safety level” is introduced to microchip. Heater is out

of operation when water level is under the heater level.

Nominal Voltage: 230V 50-60Hz

Nominal Power:1900W (±%5)

Valves:

There are double water inlet valves at single water inlet models and double and

additional single valves at hot water inlet models. Valves are operated by triac.

Nominal Voltage 220-240V 50-60Hz

Nominal Power 5-8W

Coil Resistance 3400-4500 Ohm

Flow Rate 10lt/min

Page 14

Drain Pump:

It is a synchronize motor that has single phased, double pole and magnetic rotor.

Triac runs during drain step. Impedance is protected against the rotor blockage and

continuous operation.

Nominal Voltage 220-240V 50Hz

Resistance 145 Ohm

Current <02A

Flow Rate >14lt/min

Starting Performance <=4sn(160V)

NTC:

As the temperature of the surrounding of NTC increases, its resistance decreases. At

fixed temperature, NTC will always have a specified resistance within the tolerances.

With the aid of this principle it becomes possible to have an operation without using a

mechanical thermo-stop. The heater operates until the desired temperature is

reached. In this way, the selected program completes properly each time in

accordance with the program set and auxiliary functions selection and is nor

influenced by water temperature etc. Thus a considerable time can be saved at low

temperature washes.

No mechanical thermostat or timer is used on these washing machines and the

heater is completely driven by the relay.

Pressure Sensor:

An analog pressure sensor (5V) that gives frequency output is used. At each water

level, the pressure sensor gives a specified frequency output within the tolerances.

With this property of the pressure sensor, it is possible to check and control the water

lever precisely. It is driven by micro.

DISASSEMBLY

1- Top plate:

- Remove two screws that attach the top lid to the body.

- Top plate is pulled back and then upwards and taken off.

2- Back cover:

- Remove five screws that attach the back cover to the body.

- The cover is laid 90º to the body and lifted up and out of its retaining slot.

3-Kickplate:

The plastic screws that attach the kick plate to the body are turned 90º

counter-clockwise and the kick plate unclipped

4-Front panel:

- Door is opened by pulling the handle towards yourself.

- The door hood clamp that fixes the door hood to the front panel is removed

by using the special pliers (shown below) or a suitable alternative.

- The door hood is released from the front panel

Page 15

- Remove two screws that attach the safety lock to the front panel.

- Kick plate is disassembled.

- Remove the screws that attach the front panel to the body.

5-) Front Door (Single Axis):

-Open the front door

-Hinge holder screws, the connection between hinge and front door, are unscrewed

and front door is separated from hinge.

-Hinge holder screws, the connection between hinge and front panel, are unscrewed

and hinge is separated from front panel.

Page 16

External Front Door:

-Screws that connect internal front door to external front door are unscrewed

-External front door is pulled from internal door.

Inner Front Door:

-Disassemble the front door group. Disassemble the subassemblies.

-Collect with the new internal door

External Front Door Glass:

- Disassemble the front door group

- Disassemble the front door

- Separate outer front door glass from the ratchets of internal door

-Assemble new glass (Be careful not to break the ratchets during assembly of the

glass)

Hook:

-Disassemble external front door

-Unscrew 2 screws that hold hook on the internal door

Door Push and Door Push Spring:

-Disassemble the external door.

-Remove the ratchets of door push

Hinge:

-Disassemble the front door.

-Unscrew the 4 screws that connect hinge to the internal door and then remove the

hinge

Page 17

-Assemble the 4 plastic hinge sleeve, taken from the old hinge, to the new hinge.

New hinge is assembly to the internal door.

-Screw the hinge holder to the hinge, screw external door to the internal door.

-Screw front door group to the front panel.

6-) Rotary Switch:

-Push the ratchets of button from the inner face panel and then remove the button.

7-) Drawer panel:

-Drawer is pulled back from the detergent box.

-The piece INDICATED by the arrow is pressed and the drawer is pulled back

-Drawer is turned upside down in order to release the drawer front cover panel

Page 18

8-) Panel

-Drawer is removed from the detergent box

-Remove the screw that attaches the panel to the panel holder

-Remove 2 screws that attach the panel to the panel holder

-Panel is released from the snaps on the panel holder

9-) Program Card:

-Remove the sockets of program control card

-Unscrew the 2 screws of on the display holder

-Separate display holder from ratchets

Page 19

-Unscrew 2 screws and remove on-off switch. Separate the on-off switch from panel

by pushing from lamp holder ratchets.

10-) Program Control Card:

-Remove the card from card holder

11-Pressure Sensor:

- Disassemble front panel

- Remove 2 screws that attach the pressure switch

Page 20

12- On-off Switch (Not Illuminated):

-Disassemble on-off switch cables

-Disassemble 2 PT screws from the switch holder

13-Interference Suppressor:

-Disassembled top plate

-Disconnect interference suppressor cables

-Remove two screws that are in the terminal box behind the body that fixes the

interference suppressor to the terminal group.

-Hold the interference suppressor with one hand and the M8 nut is unscrewed with

an appropriate spanner or socket.

14-Water Inlet Valve

-Disassemble top plate

-Disconnect single valve cables

-Release single valve hose clamp and move up the hose.

-Remove hose from the end of the valve

-Turn the valve counter-clockwise

15-Double Valve:

-Disassemble top plate

-Disconnect double valve cables

-Release single valve hose clamp

-Remove the hose

-Unscrew the 2 screws that connect valve to the cabinet

16-Door Safety lock:

-Hold the front door handle and pull the door towards yourself.

-Remove the clamp that fixes the door hood to the front panel

-Disassemble door hood from the front panel

-Remove two screws that attach the safety lock to the body

-Remove front panel

Page 21

-Disconnect cables

17-Heater:

-Disassemble front panel

-Disconnect heater cables

- Loosen heater M6 bolt and release heater through the tub cover

(When re-fitting the heater ensure element engages correctly in the heater holder clip

which is fixed to the tub)

18-Pump:

-Disassemble front panel

-Disconnect pump cables

-Release tub filter hose from the pump

-Release outlet hose

-Remove the screw that attaches the pump to the body

-Separate pump from the body

Page 22

Connection

hose

Pump cables

Drain hose

connection

Pump screws

19-Tub Gasket:

Disassembling:

-Disassemble front panel

-Grab the door hood and pull with force. The hood and the spring clamp will release

from the tub.

Assembling

-Assembly should be done on the freestanding tub cover. For that reason

disassemble the tub cover by taking out the clips one by one.

-Then find the water drainage hole on the tub gasket. It should be placed at 6 o’clock

position of the tub front cover. Begin from 6 o’clock position and remount the door

hood on the peripheral of the tub opening. Rear tongue should be placed in the tub

side and the front tongue should be placed in the front canal at the same time.

-After positioning the tub gasket, fix it with the spring clamp.

Page 23

20-Water inlet hose:

-Remove front panel

-Loosen the wire clamp on the detergent box connection and release the water inlet

hose

-Pull off the other end of the water inlet hose and release the tub cover by hand.

21- Poly-V Belt:

-Remove back cover

-Pull off Poly-V belt while turning over the pulley

22- Pulley:

-Remove back cover

-Remove poly-V belt

-Unscrew the bat connects the pulley to the drum shaft

-Pull off pulley from the drum shaft.

Page 24

23-Motor:

-Remove back cover

-Plug out motor socket

-Remove poly-V belt

-Unscrew the bolt that attach the motor to the tub (there are 4bolts, in order to

unscrew the bolts use end 40)

-Release motor from the grommet.

24-Power supply cord:

-Release terminal group cover from the snaps at both sides

-Loosen cable holder screw

-Remove power supply cord terminal from the interference suppressor

Page 25

25- Upper counterweight:

-Remove top plate

-Unscrew upper counterweight fixture screws and pull off counterweight

26-Lower Counterweight:

-Disassemble front panel

-Lower counterweight fixture screws are unscrewed and counterweight pulled off.

(Torque value during assembly of lower and upper counterweight should be

2100Ncm)

IMPORTANT:

Transportation bolts should be used in the case of laying the machine to the front

part. Whenever laying of the machine is not required, lower counterweight bolts

should not be screwed.

A 25 Torks end is required in order to separate tub connections.

27-Tub seal:

-Disassemble the front panel

-Loosen the lower counterweight to improve access to tub clips.

-Screw that connects pressure sensor pipe to the tub is unscrewed, so that

unscrewing process becomes easy.

-Remove heater

-Remove NTC

-Release tub cover clips

-Pull off tub cover and turn upside down

-Removed tub seal.

(When re-fitting, ensure that the seal and cover fit into the tub securely. Assembly of

the tub group requires 450Ncm torque with –50Ncm tolerances)

28-Drum group:

-Disassemble front panel

-Remove tub cover

-Disassemble back cover

-Disassemble pulley

-Pull off drum from the tub

Page 26

29-Shock absorber:

-Disassemble back cover

-Pull off damper pin at the tub pressing on the snaps at the sharp end

-Pull off damper pin at the body

30- Outlet hose:

-Remove front panel

-Loosen the clamp at the pump entry of the outlet hose and slid back.

-Pull off outlet hose from the pump

-Release the hose from the snaps at the back of the body

-Release hose from the front of the machine.

Loading...

Loading...