1

© 2007-07-13 FAG Industrial Services

From software version 3.2.0

2

Table of Contents

............................................................................ 7

1 Welcome

............................................................................ 9

2 General

.............................................................................................................. 92.1 About this documentation

.............................................................................................................. 9

2.2 Mode of functioning

.............................................................................................................. 12

2.3 Intended use

.............................................................................................................. 13

2.4 Scope of delivery

.............................................................................................................. 15

2.5 Characteristic values

.............................................................................................................. 17

2.6 Statement of Conformance to electrical safety and EMI requirements

............................................................................ 18

3 Trendline 3

.............................................................................................................. 183.1 Program installation

................................................................................................. 18

System requirements 3.1.1

................................................................................................. 19

Trendline software installation 3.1.2

................................................................................................. 22

Detector Flash Updater installation 3.1.3

................................................................................................. 24

MSDE installation 3.1.4

..................................................................................................... 27

Registering databases at the MSDE/SQL server3.1.4.1

................................................................................................. 29

Uninstalling3.1.5

.............................................................................................................. 30

3.2 User interface

................................................................................................. 30

Main window 3.2.1

................................................................................................. 31

Menu bar 3.2.2

................................................................................................. 33

Toolbar3.2.3

.............................................................................................................. 34

3.3 First steps

................................................................................................. 34

Adding a sensor 3.3.1

................................................................................................. 36

Installing USB-serial converter 3.3.2

................................................................................................. 38

Balancing activation 3.3.3

................................................................................................. 40

Register new detector 3.3.4

.............................................................................................................. 42

3.4 Setting up configuration

................................................................................................. 42

Enter system tree 3.4.1

................................................................................................. 43

Automatic assignment of RFID tags to measuring points 3.4.2

................................................................................................. 45

Create a measuring point 3.4.3

................................................................................................. 50

Setting characteristic values 3.4.4

................................................................................................. 52

Editing / deleting sensors 3.4.5

................................................................................................. 52

Managing measurement comments 3.4.6

................................................................................................. 53

Add balancing configuration 3.4.7

................................................................................................. 61

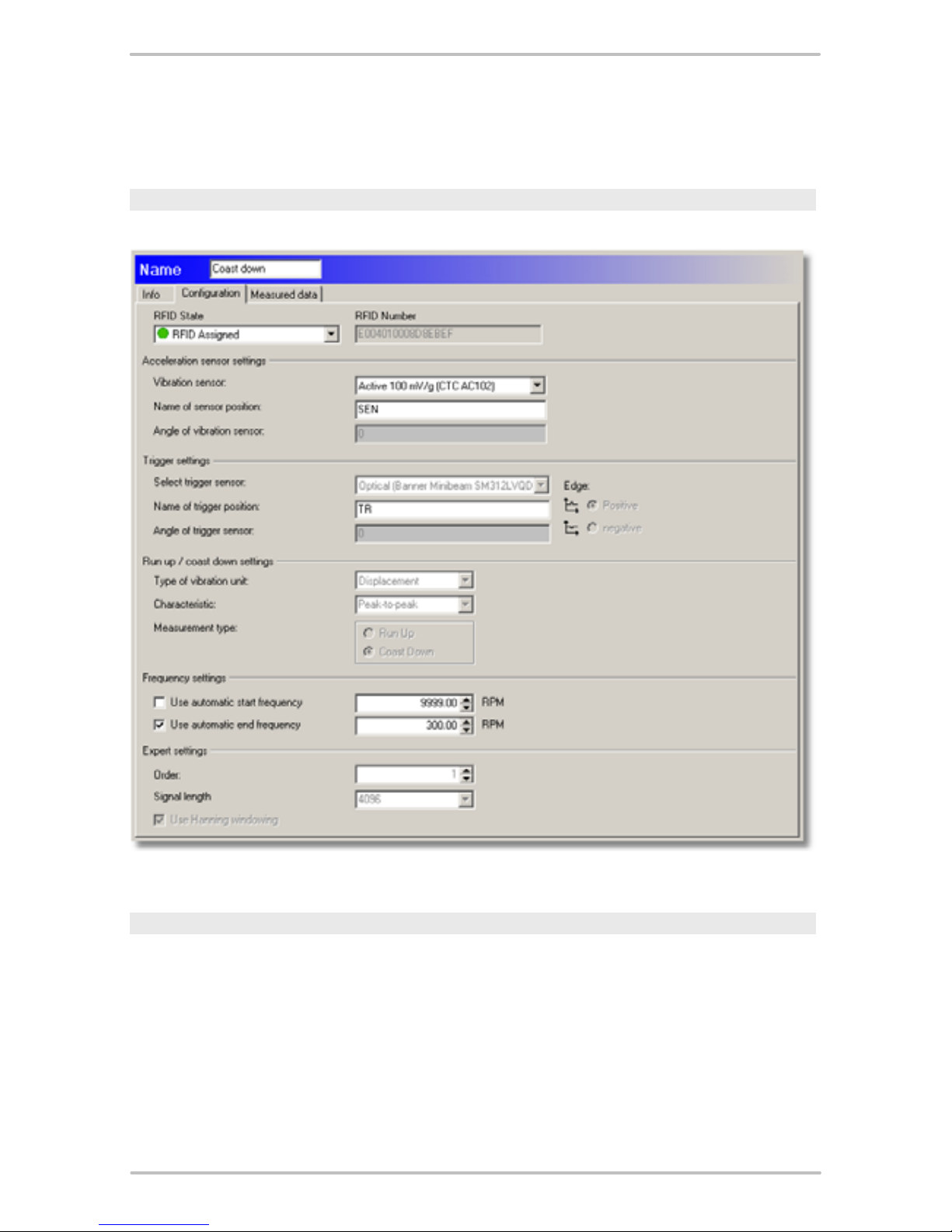

Setting up run up/coast down 3.4.8

3

Table of Contents

................................................................................................. 65Change alarm levels automatically 3.4.9

................................................................................................. 67

Send configuration 3.4.10

................................................................................................. 68

Deleting the Trendline database 3.4.11

.............................................................................................................. 68

3.5 Bearing database

................................................................................................. 69

Search bearing 3.5.1

................................................................................................. 71

Add bearing 3.5.2

................................................................................................. 72

Edit / delete bearings 3.5.3

................................................................................................. 74

Exporting / importing bearings 3.5.4

................................................................................................. 75

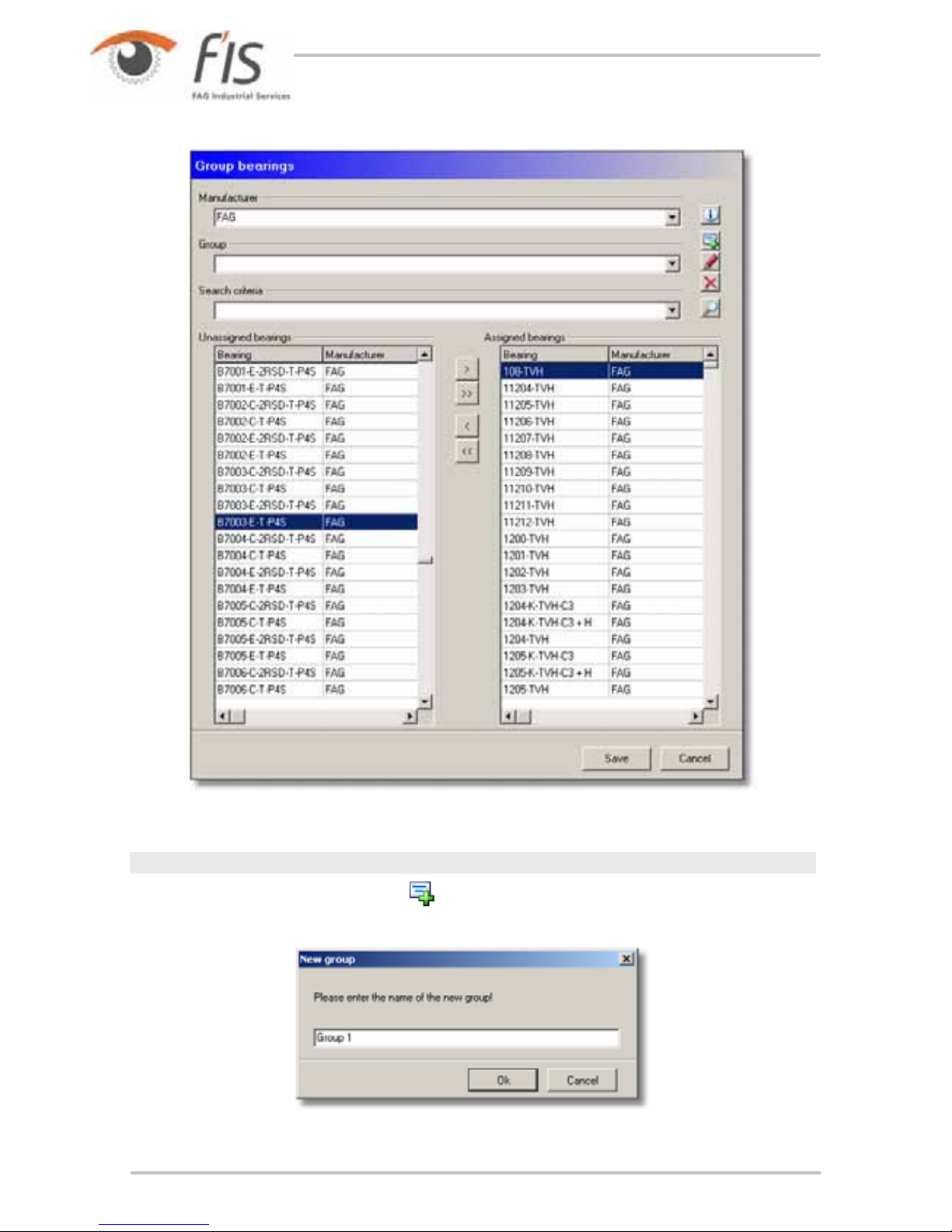

Manage groups 3.5.5

................................................................................................. 78

Add manufacturer 3.5.6

................................................................................................. 78

Edit / delete manufacturer 3.5.7

................................................................................................. 80

Select a different bearing database 3.5.8

.............................................................................................................. 82

3.6 Create a route

................................................................................................. 82

Create a new route 3.6.1

................................................................................................. 83

Create template 3.6.2

................................................................................................. 84

Send route 3.6.3

.............................................................................................................. 85

3.7 Download data from Detector

................................................................................................. 86

Sorting Wizard 3.7.1

.............................................................................................................. 88

3.8 Viewing measuring data

................................................................................................. 88

Measured values 3.8.1

................................................................................................. 91

Graphic3.8.2

.............................................................................................................. 92

3.9 Reset Alarm Status

.............................................................................................................. 93

3.10 Delete measured data

.............................................................................................................. 94

3.11 EService

................................................................................................. 94

Before starting 3.11.1

................................................................................................. 94

Send data 3.11.2

.............................................................................................................. 95

3.12 Create reports

................................................................................................. 96

Measurement report 3.12.1

................................................................................................. 100

Alarm Report 3.12.2

................................................................................................. 102

Route report 3.12.3

................................................................................................. 102

Balancing report 3.12.4

................................................................................................. 104

Creating a run up/coast down report 3.12.5

.............................................................................................................. 105

3.13 Importing and exporting data

................................................................................................. 105

Importing data from a Trendline 3.x database 3.13.1

................................................................................................. 105

Export wizard 3.13.2

................................................................................................. 106

Export a measuring point 3.13.3

................................................................................................. 110

Import and export between different workstations 3.13.4

.............................................................................................................. 110

3.14 Program settings

................................................................................................. 110

General3.14.1

................................................................................................. 111

Database3.14.2

4

................................................................................................. 111Report3.14.3

................................................................................................. 112

E-mail3.14.4

................................................................................................. 113

Data view 3.14.5

................................................................................................. 113

Automatic export 3.14.6

............................................................................ 114

4 The FIS-Viewer

.............................................................................................................. 1144.1 The working interface

................................................................................................. 114

Interface areas 4.1.1

................................................................................................. 115

Toolbar4.1.2

................................................................................................. 116

Tools4.1.3

................................................................................................. 122

Diagram display 4.1.4

................................................................................................. 123

Cursor and measuring information 4.1.5

................................................................................................. 125

The diagram information bar 4.1.6

.............................................................................................................. 128

4.2 Working with the Viewer

................................................................................................. 128

Displaying several diagrams simultaneously4.2.1

................................................................................................. 128

Modifying the appearance of a diagram 4.2.2

................................................................................................. 132

Using the mouse to control the cursor or zoom function 4.2.3

................................................................................................. 132

Zoom tools 4.2.4

................................................................................................. 137

Cursor tools 4.2.5

................................................................................................. 144

Positioning of base cursor 4.2.6

................................................................................................. 145

Modifying the cursor properties 4.2.7

................................................................................................. 151

Other tools 4.2.8

................................................................................................. 152

Using the diagram information bar 4.2.9

................................................................................................. 160

Exporting data via the clipboard 4.2.10

................................................................................................. 160

Viewer settings 4.2.11

.............................................................................................................. 171

4.3 Keyboard shortcuts

............................................................................ 174

5

Detector III

.............................................................................................................. 1745.1 Detector display

.............................................................................................................. 174

5.2 Keyboard

.............................................................................................................. 175

5.3 Explanation of the symbols

.............................................................................................................. 176

5.4 Connectors

.............................................................................................................. 176

5.5 Accumulator

.............................................................................................................. 178

5.6 Switching on and off

.............................................................................................................. 178

5.7 Main menu

.............................................................................................................. 181

5.8 Data transfer

.............................................................................................................. 182

5.9 Measuring procedure

.............................................................................................................. 182

5.10 CM-measurement

................................................................................................. 183

Selection of measuring point 5.10.1

................................................................................................. 185

Measuring procedure 5.10.2

5

Table of Contents

................................................................................................. 185Display of values measured 5.10.3

................................................................................................. 186

Viewing time signals on the Detector display 5.10.4

................................................................................................. 187

Display of the FFT on the Detector display 5.10.5

................................................................................................. 188

Repeated measurements 5.10.6

................................................................................................. 188

Measuring with temperature sensor 5.10.7

................................................................................................. 189

Using the headset 5.10.8

.............................................................................................................. 189

5.11 Balancing measurement

................................................................................................. 194

Measuring rotational speed 5.11.1

................................................................................................. 194

Reference run 5.11.2

................................................................................................. 195

Trial run 5.11.3

................................................................................................. 197

Display coefficients and apply balance weights 5.11.4

................................................................................................. 198

Trim run 5.11.5

.............................................................................................................. 199

5.12 Determining the resonance range of a machine

.............................................................................................................. 201

5.13 Free measurement

.............................................................................................................. 205

5.14 System messages and their meaning

.............................................................................................................. 208

5.15 Update firmware

............................................................................ 211

6 Special information

.............................................................................................................. 2116.1 Time signals

.............................................................................................................. 212

6.2 Frequency selective characteristic values

.............................................................................................................. 213

6.3 Dynamic memory management

.............................................................................................................. 214

6.4 Analog branches in the Detector III

.............................................................................................................. 214

6.5 Establishing a data connection

............................................................................ 216

7 Appendix

.............................................................................................................. 2167.1 General information on vibration monitoring

................................................................................................. 216

Introduction7.1.1

................................................................................................. 217

Frequency analysis 7.1.2

................................................................................................. 218

Demodulation analysis 7.1.3

................................................................................................. 227

Vibration characteristic values 7.1.4

..................................................................................................... 228

Arithmetic mean value7.1.4.1

..................................................................................................... 228

Peak values (peak, peak to peak)7.1.4.2

..................................................................................................... 228

Root mean square (RMS)7.1.4.3

..................................................................................................... 229

Broad band RMS value7.1.4.4

..................................................................................................... 229

Selective RMS value7.1.4.5

................................................................................................. 230

Bibliography7.1.5

.............................................................................................................. 231

7.2 Principles of non-contact temperature measurement

................................................................................................. 231

Introduction7.2.1

................................................................................................. 231

Advantages of using IR thermometers 7.2.2

................................................................................................. 232

Infrared measuring system 7.2.3

6

................................................................................................. 232Target7.2.4

................................................................................................. 236

Handling the pyrometer 7.2.5

..................................................................................................... 236

Distance to spot size ratio7.2.5.1

..................................................................................................... 237

Emissivity7.2.5.2

..................................................................................................... 237

Measurement considerations7.2.5.3

................................................................................................. 237

Bibliography7.2.6

............................................................................ 239

8

Technical data

Index

............................................................................239

7

Welcome

1 Welcome

Overview

The FAG Detector III

is a vibration measuring device, data collector and

operational balancing device in one. Together with the Trendline 3

software,

the device allows improved planning of maintenance and increased machine

availability.

Machine vibrations are a good indicator of a machine's condition. With the aid of

Detector III, you can monitor machine vibrations according to ISO 10816 and roller

bearing condition by means of the demodulation detection method. The base

curve and demodulation signals stored in the system can then be used to analyze

the signals in the time and frequency range. This permits detection of alignment

errors and imbalance as reliably as roller bearing damage or gearing problems.

Other process parameters that can be recorded are temperature and rotational

speed.

Applications

Measuring and analyzing machine condition

The FAG Detector III records vibration signals at pre-defined measuring points by

means of a sensor and then calculates the effective values for velocity,

acceleration and demodulation. These characteristic values

describe the

condition of the machine and component.

You can define and monitor frequency bands of any frequency width in the range

from 0.1 Hz to 20 kHz. FAG Detector III can save up to 1600 measuring points and

up to 270 time signals. Once a measuring round has been finished, all data

recorded are transferred to the Trendline software, where they are evaluated,

analyzed and displayed.

174

18

15

8

Balancing with the Detector III (available as accessory function)

There are many and diverse reasons for unscheduled machine standstills.

However, a considerable number of these is due, directly or indirectly, to

imbalance or alignment errors. During operation, imbalance may cause severe

vibrations, that can lead to consequential damage, for example premature bearing

wear or fatigue-induced breaks. The result is machine failure and thus

unscheduled production downtime.

The FAG Detector III is a tool with which you can not only detect but also remedy

such conditions easily and efficiently. The easy user interface provides good

support during the balancing process. Step by step, the device software guides the

user through the balancing process. The user can create a configuration for each

balancing process with the Trendline software. Furthermore, he can define

templates that can be adapted on site on the machine. The balancing results are

sent to the Trendline software. You can display them there in table form or as a

diagram.

Analyzing data with the Trendline bearing database

The integrated bearing database (approx. 20,000 bearings from various

manufacturers) simplifies and speeds up analysis of measured data in

combination with the FIS-Viewer

. It allows you to detect any irregularities at

first glance and assign the appropriate components. You can save multiple

bearings per measuring point. This allows you to check multiple bearing ball-pass

frequencies at a measuring point. Every user can add new entries to the bearing

database to suit individual needs.

114

9

General

2 General

2.1 About this documentation

This documentation describes the functionality of the Detector III and the Trendline

software. It explains:

· how to create configurations

or measuring routes on a computer and

transfer these to the Detector;

· how to use the device to record measuring data;

· how to transfer data from the Detector to the computer and

· how data can be analyzed and stored.

The appendix also contains an introduction to the basic principles of vibration

monitoring

and a brief description of the subject "Temperature measurement

with the Detector III

".

Safety information symbols

DANGER

Safety symbol

This safety symbol warns you of material damage and dangers to

health, life-threatening injuries and death.

General information symbols

This symbol indicates

· helpful additional information and

· device settings or application tips that help you perform tasks

more efficiently.

Cross-reference symbol : This symbol indicates a page in the manual with more

detailed information. If you are reading the manual on screen in PDF format, you

can jump to this page by clicking the word to the left of the cross-reference symbol.

2.2 Mode of functioning

Detector III is a hand-held measuring instrument with data recording function for

offline monitoring of systems and machinery (condition monitoring). For this

purpose, the instrument senses vibrations at pre-determined measuring points

using a detector and works out the RMS values of vibration velocity, acceleration

in vibration and demodulation, the so-called characteristic values, for

characterizing machine or component condition. In addition, Detector can measure

42 82

216

216

9

10

temperatures using an infra-red sensor.

· Once a measuring round is finished, the measured characteristic values and any

recorded time signals are transferred to a computer where they are evaluated,

analyzed and graphically depicted using the Trendline software

.

· The exact location of the measuring point within the system to be monitored is

stored in the configuration

. There, the sensor sensitivity for each measuring

point and the threshold values for main or preliminary alarm are stored as well.

The configuration is created using the Trendline software

and transferred to

the Detector prior to measuring.

· For measuring, the vibration sensor is fixed to a pre-determined measuring point

with the help of a magnet footing. If this is not possible due to the housing

material (e.g. aluminum), attach an iron plate or a washer the size of the

magnetic at the measuring point. This is easiest done with the help of a fastcuring superglue (e.g. cyan acrylate glue).

· The configuration of the measuring point is selected on the Detector and the

measuring started. Detector records the sensor signals broadband and works

out the characteristic values. These characteristic values are stored and

transferred to the computer once the measuring round is finished.

· For each measuring point, the newly measured characteristic values are

compared with the threshold values determined for this measuring point for a

main alarm and pre-alarm. The Detector (main alarms) and the Trendline

software (main and pre-alarms) display the threshold events. New characteristic

values are stored. You can depict them graphically in the Trendline software

depending on time of measuring.

In addition to the condition monitoring measurement (subsequently referred to as

CM measurement

) the Detector III also masters what is known as operation

balancing. During this process the Detector helps you find the optimum position of

balancing weights when carrying out the balancing measurement

. These

weights serve to compensate for imbalances in rotating parts and therefore extend

their service life.

18

42

18

182

189

11

General

Before you start

Ferrit modules will reduce electromagnetic fields from the device which could

otherwise affect other electronic devices in the vicinity.

You will receive three ferromagnetic modules with the RFID-Kit or the

RFID-Detector. The ferrit modules have to be fasten to the three sensor cables

(cable for the acceleration sensors as well as for the trigger sensor) of the

Detector.

Ferrit module

Proceed as follows:

1.

Put the sensor cable into the groove of the ferrit.

2.

Adjust the cable so that the rim of the ferrit modul is placed addording to the

picture. Please note that the ferrit module should be placed as close as possible

to the Detector.

3.

Close the retractable ferrit module enclosing the cable firmly till it engages.

Ferrits fasten at the sensor cables

12

2.3 Intended use

Disposal information

Neither the Detector not the associated components may be disposed of via

domestic waste as they contain electronic components and NiMH accumulators

that must be disposed of in the proper manner. Please return them to us so that

we can ensure disposal in keeping with legal and environmental requirements.

Returning used devices is an important contribution to environmental protection.

Information to the user

Changes or modifications not expressly approved by the party responsible for

compliance could void the user's authority to operate the equipment.

Note: This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the

interference at his own expense.

Industry Canada

This Class A digital apparatus complies with Canadian ICES-003.

13

General

2.4 Scope of delivery

DETECT3-KIT

· Base unit with accumulator

· Accelerometer with magnetic foot

· Infrared temperature sensor

· Battery charger with travel adapter

· PC data cable (serial/USB)

· Manual

· Protective bag with temperature sensor holder

· Trendline PC software

· Case

14

DETECT3.BALANCE-KIT

· Acceleration sensor with magnetic foot and sensor cable

· Trigger sensor (optical and inductive)

· Scales

· Magnetic holder for trigger sensor

· Extension stick for magnetic holder

· Cable for trigger sensor (length 10 m)

· Reflex mark for optical trigger sensor

· Dongle for activating the balancing function

· Case

15

General

RFID KIT

· Base unit with accumulator and RFID reader

· 5 RFID tags

· Accelerometer with magnetic foot

· Infrared temperature sensor

· Battery charger with travel adapter

· PC data cable (serial/USB)

· Manual

· Protective bag with temperature sensor holder

· Trendline PC software

· Case

Accessories

Sensor extension cable (5m and 15m length), sensor bases and rail magnet

available on request.

2.5 Characteristic values

Detector III can store up to 4 different (or same just as well) characteristic values

per measuring point. The following characteristic values can be selected:

Characteristic

value

Meaning

ISO 10816

RMS value of vibration velocity

Frequency range: 10 Hz to 1 kHz

Unit: mm/s

v

sel

RMS value of vibration velocity with freely selectable upper and lower limiting frequency

Frequency range: 0.3 Hz to 20 kHz (depending on the lowpass frequency)

Unit: mm/s

a

eff

RMS value of acceleration in vibration

Frequency range: 2 Hz to 20 kHz (depending on the lowpass frequency)

Unit: g

a

sel

RMS value of acceleration in vibration with freely selectable upper and lower limiting frequency

Frequency range: 0.1 Hz to 20 kHz (depending on the lowpass frequency)

Unit: g

d

eff

Demodulation signal of acceleration in vibration with switchable low-pass

Frequency range: 0.1 Hz to 20 kHz (depending on the lowpass frequency)

Unit: g

d

sel

RMS value of demodulation in vibration with freely selectable upper and lower limiting frequency

Frequency range: 0.1 Hz to 20 kHz (depending on the lowpass frequency)

16

Characteristic

value

Meaning

Unit: g

T

Temperature

Range: -20°C to +550°C

Unit: °C

Crest factor

Ratio between peak value and RMS value (Crest factor = peak value / RMS value)

In addition to the aforementioned characteristic values, you can

also measure rotational speed.

17

General

2.6 Statement of Conformance to electrical safety and EMI

requirements

Declaration of conformity as per the Radio and Telecommunication

Transmitter Devices Act (FTEG) and Directive 1999/5/EC (R&TTE)

The manufacturer:

F'IS, FAG Industrial Services GmbH

Kaiserstraße 100

D-52134 Herzogenrath Germany

declares that the product:

Detector III

Radio installation

Purpose:

RFID application

Device category: Category 1

corresponds to the basic requirements of §3 and the other relevant provisions o

f

FTEG (article 3 of R&TTE) if used for the intended purpose.

Health and safety as per § 3 (1) 1. (article 3 (1) a))

Harmonised standards used: EN 60950-1: 2001, EN 50364: 2001

Protection requirements with regard to EMC § 3 (1) 2, article 3 (1) b))

Harmonised standards applied: ETSI EN 301 489-3 V1.4.1

Measures for efficient use of the radio frequency spectrum

Harmonised standards applied: ETSI EN 300 330-2 V1.3.1.

This statement of conformance is issued based on testing the EMC aspects of a

representative product sample of the above mentioned product in conformance

with the following standards:

ETSI EN 301 489 ETSI EN 300 330 EN 61000-6-2

EN 61000-6-4 EN 60950-1 FCC Part 15

Measuring device identifier: CE

Herzogenrath, 22.06.2007

18

3 Trendline 3

The Trendline software is the server-based program for the Detector III. The

Detector itself is designed only for the recording of measured values. All data

organization and evaluation tasks are carried out by the Trendline software.

The monitoring of a system is configured using the software which also evaluates,

analyses, and stores the measuring data delivered by the Detector.

Further, Trendline 3 manages the exchange of data between the server on which

the software is running and the Detector.

3.1 Program installation

In addition to the application program, the Trendline software requires the MSDE

database server. It must be installed either on the local computer or on a network

server. If you are already using an MSDE database server, you can register the

databases with this.

Please note that you need Administrator permissions for your

computer to install the Trendline software completely. If you do not

have these permissions, ask your system administrator. For

example, you can install the software with Administrator

p

ermissions and then switch back to a normal user.

3.1.1 System requirements

In order to use the Trendline software in an optimum way, the following minimum

requirements must be met:

General system requirements

· Pentium III PC with 500 MHZ (recommended: 1 GHz)

· at least 512 MB RAM (recommended: 1 GB)

· Screen resolution: 1024x768 (pixels)

Operating systems

· with MSDE 2000: Windows 2000, Windows Server 2003, Windows XP

Please note that the Trendline software does not yet run on

Windows Vista.

Hard disk memory for installing the Trendline software

· Trendline software 3.2 (without database and database server): 62 MB

19

Trendline 3

· Detector Flash Updater: 4 MB

· Demo database and bearing database: 20 MB

Hard disk memory for installing the database server

· MSDE 2000: 50 MB

Hard disk memory for the database

· MSDE 2000: at least 2 GB (recommended: 6 GB)

Other requirements

· Microsoft Internet Explorer 6.0 SP1 or later

3.1.2 Trendline software installation

Please insert the Installation CD. If you do not have a CD, you can download the

current version of Trendline from our website (www.fis-services.de).

If the installation program does not start automatically you can start it manually

using Windows Explorer:

1.

Open My computer.

2.

Under Equipment with removable media click the right-hand mouse button on

the CD-ROM drive then click Open.

3.

Start the Trendline installation file (Trendline-Setup-3.2.exe) by doubleclicking

on it.

4.

Please select the language to install the Trendline software. You can change the

language settings

at any time after installing.

The Setup Wizard guides you through the rest of the installation:

110

20

5.

Select the directory where you want to install the software and click Next.

6.

Select the Start menu directory to create the program link. Click on Continue.

21

Trendline 3

7.

Optionally, you can select other components of the Trendline software to install.

To do so, check the checkbox next to the option

a)

Flash Updater to update the Detector firmware

b)

Database installations to install the demo database and/or bearing database

and click Continue.

208

22

Please note that the Trendline software requires MSDE (Microsoft

SQL Server 2000 Desktop Engine)!

8.

In the next window check your settings and click Install or Back to correct your

settings.

This installs the Trendline software.

3.1.3 Detector Flash Updater installation

If you selected Flash Updater when you installed the Trendline software, the

Setup Wizard automatically starts installation:

1.

Select the directory where you want to install the software and click Next.

23

Trendline 3

2.

Optionally, you can add program icons on the desktop or to the quick launch

bar. To do so, check the checkbox next to the option

a)

Create a desktop icon to add a shortcut on your desktop

b)

Create a Quick Launch icon to add a symbol to the Quick Launch bar next

to the Start button

and click on Next.

3.

In the next window check your settings and click Next to install the Detector

24

Flash Updater or Back to correct your settings.

This installs the Detector Flash Updater.

3.1.4 MSDE installation

If you selected Database installation when you installed the Trendline software,

the Setup Wizard automatically starts installation:

1.

Please select whether you want to

a)

install MSDE and register database,

b)

only install MSDE or

c)

register databases with an existing MSDE/SQL server

and click Continue.

25

Trendline 3

If you selected Register databases with MSDE/SQL server, please continue

with registration

.

2.

Select the directory in which you want to install the database server. Click on

Continue.

3.

Select the directory in which you want to install the MSDE database. Click on

Continue.

27

26

4.

Optionally, you can select additional databases to install. To do so, check the

checkbox next to the option

a)

bearing database

to install the most common bearings in a database

b)

demo Trendline database to install a database with demo data

and click Continue.

This installs the Microsoft SQL Server 2000 Desktop Engine (MSDE) with the

selected databases.

68

27

Trendline 3

5.

Click Finish to close the Setup Wizard.

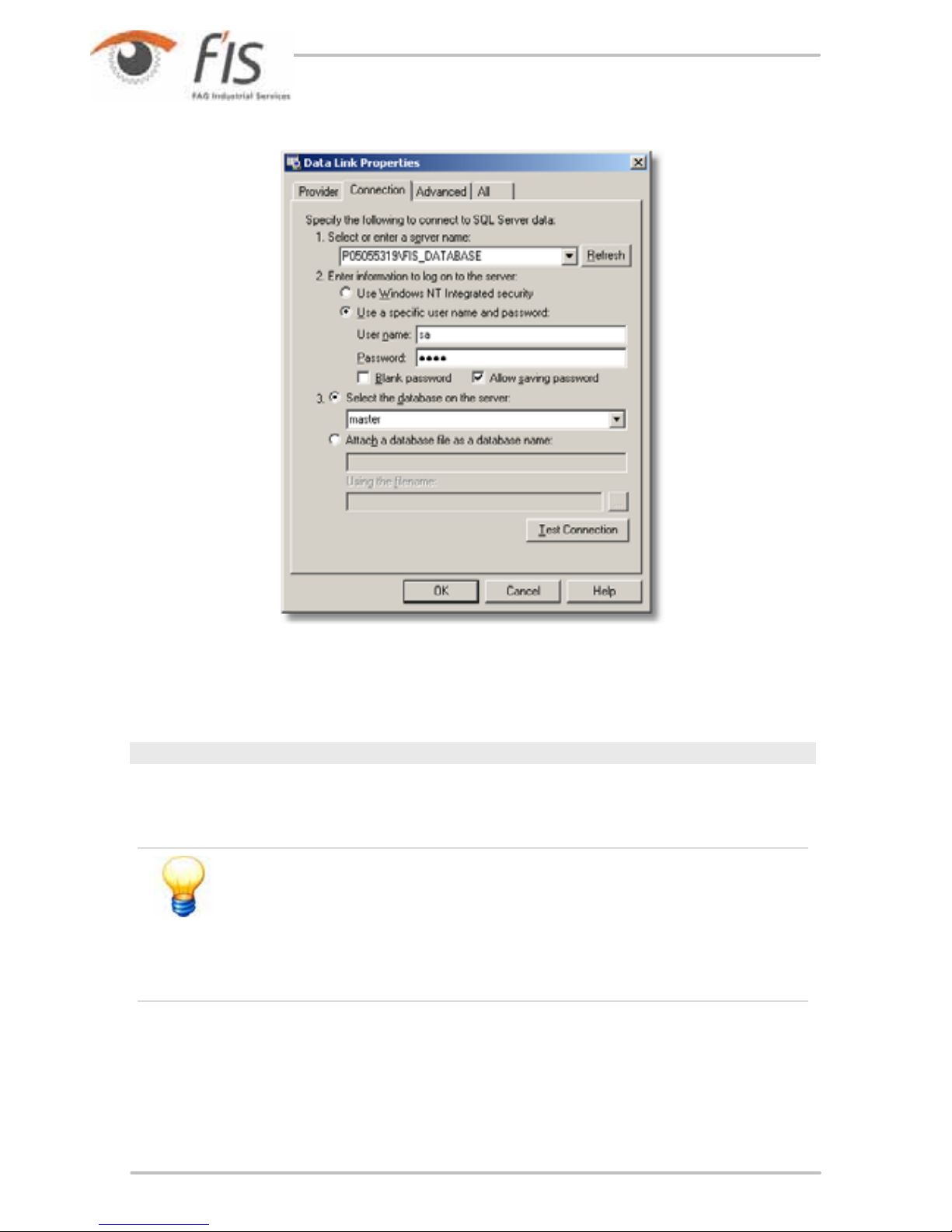

3.1.4.1 Registering databases at the MSDE/SQL server

If you selected Register databases with the MSDE/SQL server, you must

connect the databases (Trendline and bearing database) to the MSDE/SQL server:

Registering Trendline databases at the MSDE/SQL server

1.

Select the database server that contains the database from the server list or

enter the server in the input field in the upper area of the window. Click on

Refresh to display the list of available servers.

If you do not find any entries in the server list due to restricted user

p

ermissions, enter "Computer name\FIS_DATABASE" manually (if

the name of your computer, for example, is "peters_laptop", the

server name would be "peters_laptop\FIS_DATABASE"). You can

find your computer's name in the Windows Explorer drives. If you

are not sure about your computer's name, ask your administrator.

2.

Select Use a specific user name and password and enter your user name

and password to log-on to the database. If you select a database server that

was installed during a Trendline installation (contains FIS_DATABASE in its

name), the user name is sa and the password is sql8. Make sure to enable

Allow Password Save to save the password.

28

3.

Select the database master from the list.

4.

Click on OK.

Registering a bearing database at the MSDE/SQL server

1.

Select the database server that contains the database from the server list or

enter the server in the input field in the upper area of the window. Click on

Refresh to display the list of available servers.

If you do not find any entries in the server list due to restricted user

p

ermissions, enter "Computer name\FIS_DATABASE" manually (if

the name of your computer, for example, is "peters_laptop", the

server name would be "peters_laptop\FIS_DATABASE"). You can

find your computer's name in the Windows Explorer drives. If you

are not sure about your computer's name, ask your administrator.

2.

Select Use a specific user name and password and enter your user name

and password to log-on to the database. If you select a database server that

was installed during a Trendline installation (contains FIS_DATABASE in its

name), the user name is sa and the password is sql8. Make sure to enable

Allow Password Save to save the password.

29

Trendline 3

3.

Select the database master from the list.

4.

Click on OK.

If you want to register the database later on, please select

bearingDB instead of masterDB.

3.1.5 Uninstalling

To uninstall the Trendline software, please click Programs > FIS > Trendline 3.2

Uninstall Trendline in the Start menu. This uninstalls the Trendline software and

its components.

Please note that configuration and export files are left on your computer. For your

safety, the database is not deleted either. To completely uninstall, you must delete

these files manually.

30

3.2 User interface

3.2.1 Main window

The layout of the main Trendline 3 software window is based on standards which

have developed for user interfaces in the meantime.

At the top edge of the main window you will find the menu bar , where you can

call up the functions of the program via the menu items. Frequently used functions

can also be activated using the buttons in the toolbar

.

On the left-hand side of the window the structure of the configuration for the

system to be monitored is depicted in the form of a directory tree. The

“Configurations”, which are splitting in descending order into the levels “Section”,

“Machine” and “Measuring Point”, are the highest classification element. That way,

a measuring point within a configuration is clearly defined by it’s denomination as

well as the specification and location of the machine the measuring place is to be

found at.

Next to the denomination of each element of the configuration and system

structure you will find a field marked in color. It indicates the alarm condition for

this part of the system following the table below.

31

33

31

Trendline 3

Color

Meaning

For this level of the system structure no alarm is recorded.

For this level of the system structure preliminary alarm is recorded.

For this level of the system structure main alarm is recorded.

An RFID tag has been assigned to this measuring point.

An RFID tag in this part of the system has been marked as defective.

On the right-hand side next to the configuration and system structure you can

insert an image. At the highest level you will find the tabsheets, where you can

adjust the settings of the individual measuring points.

The dividing line between the image of the configuration and system structure can

be shifted towards the right or left by dragging with the mouse.

In the configuration structure, always one element is marked. The

p

roperties of this element are depicted in the right-hand part of the

window.

3.2.2 Menu bar

The menu bar allows access to the following functions of the Trendline 3 software:

Menu

Menu items and their functions

File

New Creates a new database.

Open Opens an existing database.

Import Loads records exported with Trendline.

Export Exports part of a current measuring point structure using the export wizard

or export a single measuring point .

Recently used

databases

Trendline displays recently used databases at this point in the menu. You

can specify the number in the program settings

.

Close Quits the Trendline software.

System

To root level Takes you from your current position in the tree right back to the

beginning, all the time.

Rename Rename currently selected element.

New item Inserts an element of the configuration structure in the same level as

currently displayed.

New subitem Inserts an element of the configuration structure in the level below the

current.

Add balancing

configuration

Inserts a balancing configuration.

105 106

111

53

53

32

Menu

Menu items and their functions

Add run up/coast

down configuration

Creates a run up/coast down configuration.

Expand selection Flaps up all elements under the current element.

Collapse selection Closes the complete tree structure.

Cut Cuts out the current element of the tree.

Copy Copies the current element of the tree.

Paste Pastes the element on the clipboard into the current position in the tree.

This is only possible in the tree level above that of the copied element, e.

g. when copying a machine, this can only be pasted into the plant level of

the tree.

Delete entry Deletes the current entry at the tree with all sub-entries.

Delete measured

data

Deletes measured data from the current position.

Reset alarm status Reset all alarms for the element of the configuration and system structure

selected.

Adjust alarm levels Automatic adjustment of the alarm levels.

Detector

Send configuration Send all measuring points from currently selected element downwards to

detector.

Send route Sends one of the pre-selected routes to the detector.

Load data from

Detector

Opens a connection to the detector and downloads all data stored in the

detector.

Configure Detector Allows to set all options to the detectors registered.

Balancing activation Enables the balancing function on the Detector.

Sensor

Adds , edits and deletes sensors.

Comment selection

list

Create and edit a list of comments.

Planning

Route Creates out and edits routes.

Template Defines and edits configuration templates that can be used for ad-lib.

measurements.

Service

EService Sends selected data for further analysis.

Measurement report Creates a measurement report.

Alarm Report Creates an alarm report.

Route report Creates a route report.

Balancing report Creates a balancing report.

Run up/coast down

Report

Creates a run up/coast down report.

61

93

92

65

38

34

52

96

33

Trendline 3

Menu

Menu items and their functions

Tools

Options Program settings

Bearing DB

Opens the bearing database .

?

Contents Contents of the online help.

Index Search index for the online help.

First steps Start using the Trendline Software.

Menu bar Explains all menus of the Trendline Software.

Toolbar Explains all icons in the toolbar.

About Trendline Information about the Trendline Software.

3.2.3 Toolbar

Frequently used functions of Trendline software can be used via the toolbar.

Toolbar

Go to root element Paste

Create new item Delete

Create new sub-item Reset Alarm Status

Add balancing configuration Send configuration to detector

Add run up/coast down configuration Send route to detector

Expand tree entries Download data from detector

Close selected element Alarm Report

Cut EService

Copy

68

34

3.3 First steps

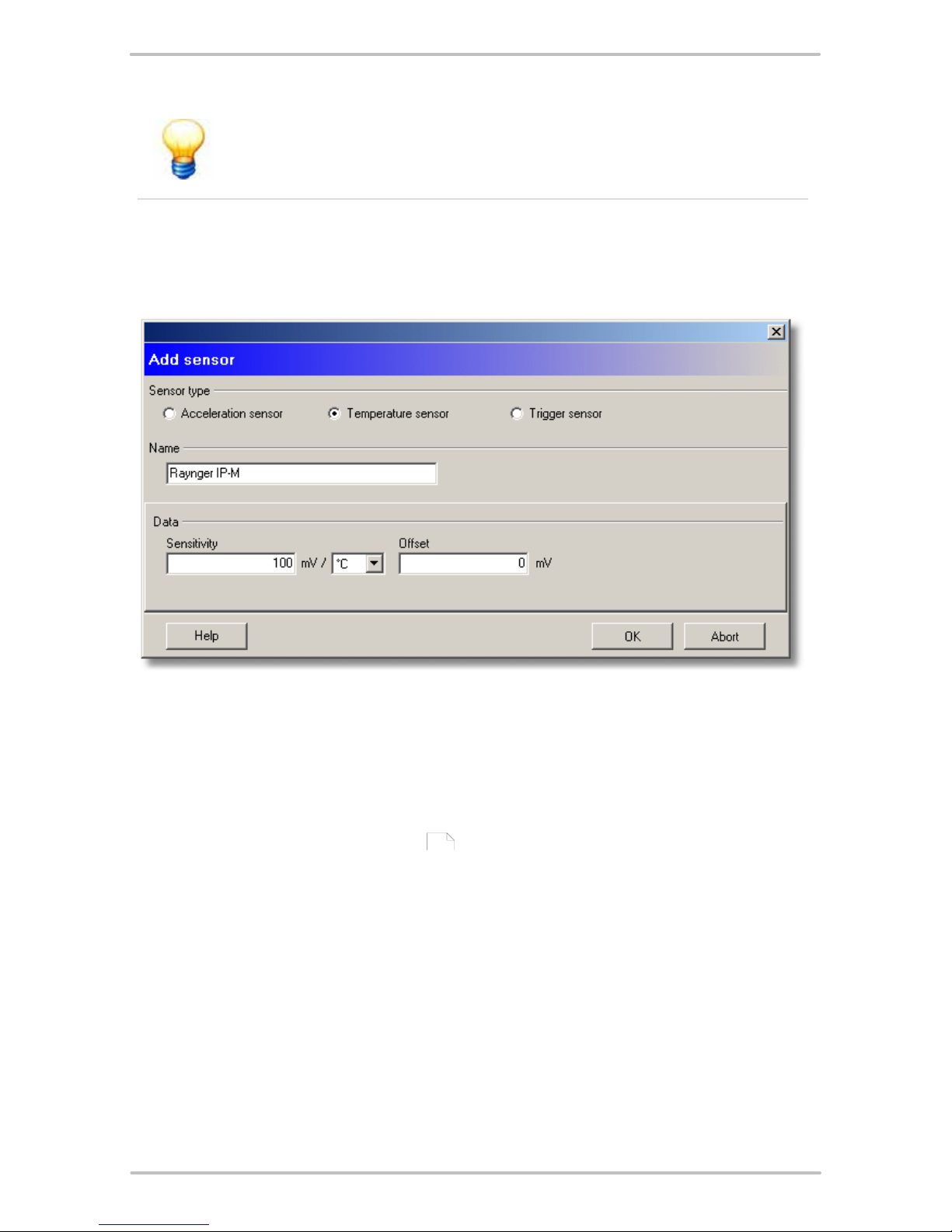

3.3.1 Adding a sensor

Before you can set up configurations, you must define the sensors you want to

use. Detector III is delivered with all necessary sensors. They are pre-defined in

the Trendline software.

Proceed as follows to add new sensors:

· In the Detector menu click Sensor > Add.

· In Sensor type choose from Acceleration, Temperature or Trigger sensor.

· In the Name field, enter a name for the sensor, e.g. "IMI 627".

Acceleration sensor

· Enter sensor sensitivity in mV/g in the Sensitivity field. Sensitivity is printed on

the sensor or indicated in the enclosed specifications.

· When you add an active sensor, select Active sensor and enter minimum and

maximum bias voltage in the appropriate input boxes. On the one hand, this

activates sensor supply voltage in the Detector before the measurement is

performed and activates a high pass to filter the supply voltage out of the

measuring signal. On the other hand, the Detector checks whether sensor bias

voltage is within the set thresholds. Minimum bias voltage must be at least 3,

maximum bias voltage must not be greater than 17. The difference between the

two values must not be less than 10.

35

Trendline 3

If you want to measure on a power supply unit, Active sensor must

not be enabled.

· Click OK to save the new sensor.

Temperature sensor

· Enter sensor sensitivity in mV/°C, mV/°F or mV/K and the offset in mV.

· Click OK to save the new sensor.

Trigger sensor

The trigger sensor serves to measure rotational speed and is used in operational

balancing to start the measurement

.

189

36

· Select the Supply voltage: External, 5V, 12V.

· Click OK to save the new sensor.

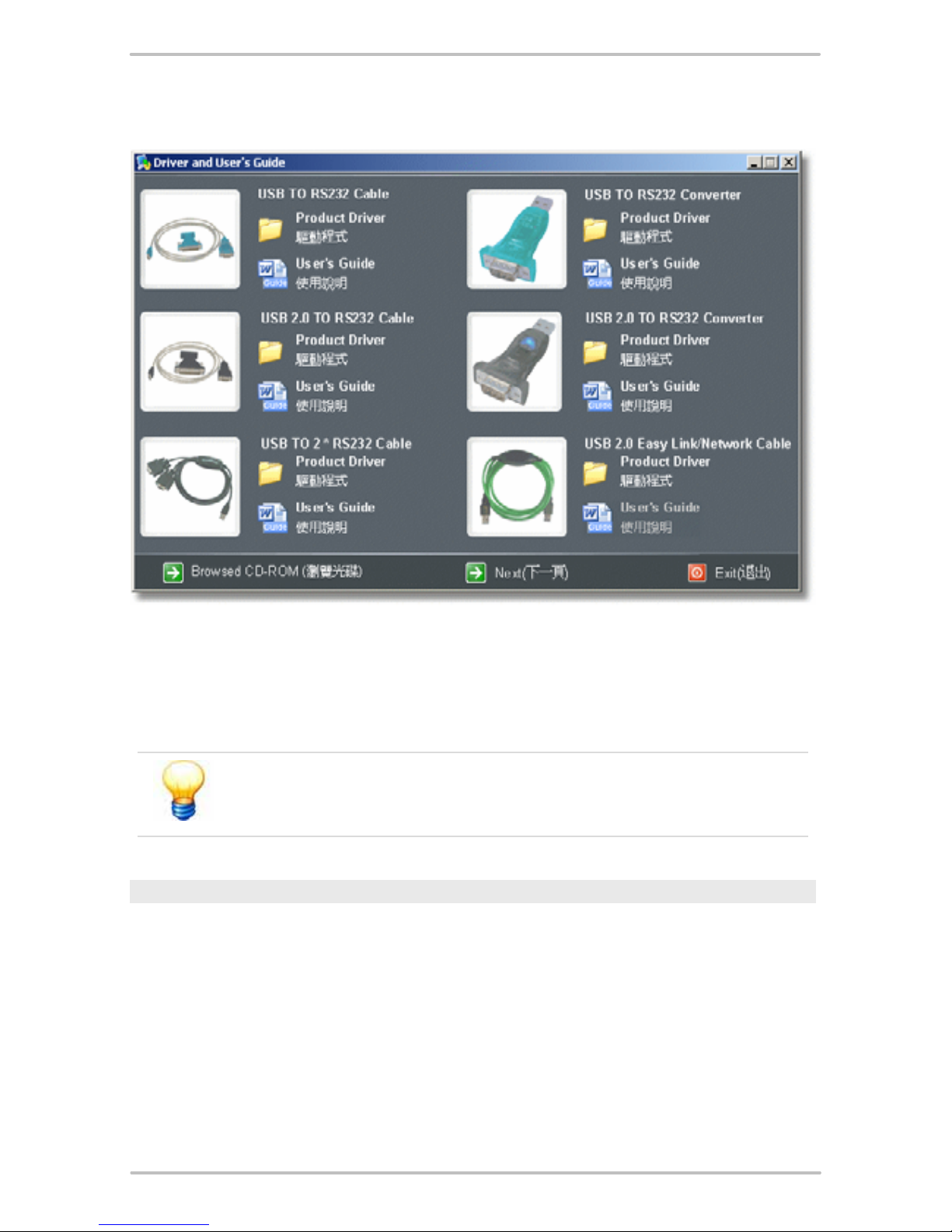

3.3.2 Installing USB-serial converter

A USB serial adapter is supplied with the Detector which you can use to connect

the Detector to computers with USB interfaces.

When installing the adapter software make sure you have the adapter and the

installation CD provided to hand.

Installation of the adapter software

To install the adapter software proceed as follows:

· Insert the supplied CD. The installation program should start automatically.

If the installation program does not start automatically you can start it manually

using Windows Explorer:

1.

Open My computer.

2.

Under Equipment with removable media click the right-hand mouse button on

the CD-ROM drive then click Open.

3.

Double click to launch autorun.exe.

4.

At USB TO RS232 Converter, click the folder icon next to Product Driver.

37

Trendline 3

5.

Select the win_98se_me_2000_xp folder.

6.

Click on Setup.exe.

This launches the installation wizard which guides you through the installation.

If you are already using other devices that use a Prolific USB to

Serial chip, please uninstall the drivers for the old devices first as

this may result in conflicts.

Checking serial interface settings

To make sure that communication between the Trendline software and the

Detector works smoothly, you can check the USB serial adapter settings for the

serial interface:

1.

Click the right mouse button on My computer then click on Properties.

2.

Click Hardware then Device manager. The adapter should be displayed as

"Prolific USB-to-Serial Bridge" under Connections (COM and LPT).

38

3.

Close the Device manager.

Removing the adapter software

The adapter software can be removed as follows:

1.

Click on Start, click on Control panel and then click on Software.

2.

Click on Modify or remove program then click on PL-2303-USB-to-Serial.

3.

Click on Modify/remove to uninstall the software.

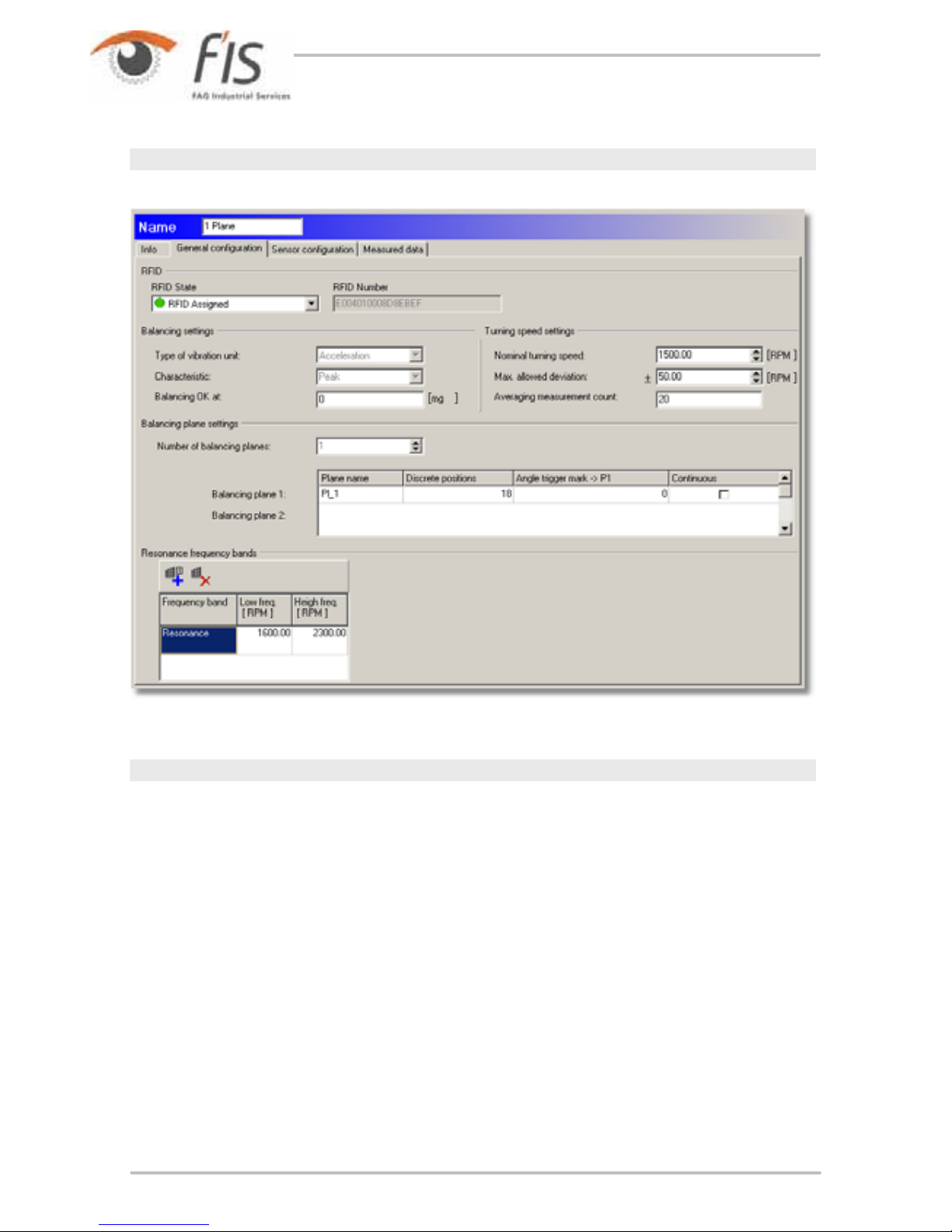

3.3.3 Balancing activation

The Detector III is supplied ex works with the balancing functionality switched off.

You can enable this function if you have purchased a Detector III balancing kit.

The balancing kit contains a USB dongle which can be used to enable one unit

only.

Dongle

This activation is essentially carried out as follows:

· A dongle is supplied with the balancing kit that has not previously been used.

· You can use this dongle to enable the balancing functionality for only one

Detector which can be selected at will.

· Once enabled, the serial number of the Detector is saved on the dongle. From

this point onwards the dongle may only be used with this specific Detector.

· You can also deactivate the balancing functionality in the Detector once again

39

Trendline 3

using the corresponding dongle. The serial number on the dongle is then

deleted and you can now use it to enable any other Detector of your choice. This

is useful, for example, if you are sending a Detector to the manufacturer for

calibration and want to use the balancing function on a different Detector in the

meantime.

To activate the balancing function on the Detector, start the Trendline software.

Connect the Detector to the PC using the serial cable. Plug the dongle into a free

USB port. Switch on the Detector and select the Trendline menu item Detector >

balancing activation. The following window is now displayed:

The serial number of the connected Detector and the dongle identified are

displayed at the top and bottom respectively. The identified version should start

with "3" in the case of Detector III. The serial number of the Detector for which this

dongle has already been used or, if the dongle has not yet been used, <Empty> is

displayed in the Used for Detector: column. Now select the required dongle from

the Type column (should be displayed as "<Empty>" in the "Used for Detector"

column). You can now enable the balancing functionality via Activate balancing

for connected Detector. A new line Balancing should now be visible and the

serial number of the Detector is displayed in the dongle line.

40

· The first time the dongle is used Windows detects the driver that

was previously installed with the Trendline software. If Windows

asks for a driver select the automatic search option.

· If the dongle is not displayed or a previously used dongle

appears in the list, please click Refresh dongle list.

· If the dongle is correctly identified by Windows but this is not

displayed in the Trendline dongle list you may have an old driver

installed on your system. You can check this in the device

manager under USB controller -> CBUSB Ver 2.0. If Version 1.x

is displayed, uninstall this driver and install the up-to-date driver

on the Trendline CD in the CbSetup directory. In this case select

the CRYPTO-BOX USB.

3.3.4 Register new detector

The Trendline software holds a database for administrating all detectors you use

with your program. Prior to sending data to the Detector for the first time, it has to

be registered to Trendline software. To do that, you connect the Detector to a

serial interface of your computer using the data cable supplied and switch on the

Detector.

The Detector which has just been connected to the computer is

normally automatically detected by the system and registration of

this is not compulsory.

How to register a new Detector:

· Click on Detector > Configure Detector.

41

Trendline 3

· Connect the Detector to your PC and switch it on. Click on Search for new

Detector to register the new Detector on to the program.

· You may give the Detector a name, which will be displayed in the default display

when switching on the instrument.

· You can select the language for the Detector. Nevertheless it still can be

changed at the Detector.

· You can set the time of the Detector either by entering the correct time and date

(to do this, click on the figure you want to change) or by clicking Send system

date to the Detector (that way the detector is set to the same time and date as

your PC).

· Here, you can select the baud rate of the Detector. Under normal

circumstances, you should select the highest possible (57,6 kbps). In case of

problems with communication (e.g. the connection breaks down at times) you

may select the lower baud rate of 38,4 kbps.

· After completing all settings, click on OK to send the changes to the Detector.

Make sure that the Detector is switched on when clicking OK, because

otherwise no communication is possible.

42

3.4 Setting up configuration

3.4.1 Enter system tree

Each configuration is subdivided into three levels, e.g. section – machine –

measuring point.

Setting up configuration elements

In order to create a new configuration, carry out the following steps:

· Click on System > New item (or on

).

· Name the entry, e.g. "Cement Plant 1”.

· Add the new sub-entry by clicking on System > New sub-item or click on

.

That way, you add a new section to the configuration. Name that e.g. "Section

1".

· Exactly as with the section, add another machine (“Machine 1”) and a new

measuring point (“Measuring Point 1”) by following the sequence via New sub-

item.

Moving or copying configuration elements

You can only move configuration elements if the target is on a higher level, i.e. you

can

· move or copy a measuring point (level 3) to another machine (level 2), and

· move or copy a machine (level 2) to a different section (level 1).

If the target already contains sub-elements, the moved/copied

element is always appended to the end of the list.

Moving an element

· Left-click on the element, keep the mouse button pressed, and drag the element

onto the target element.

· Release the mouse button to insert the element.

Copying an element

· Left-click on the element while pressing the CTRL key, keep the mouse button

and CTRL pressed, and drag the element onto the target element.

· Release the mouse button and CTRL to copy the element.

or:

· Right-click on the element and select Copy.

· Right-click on the target element and select Paste.

43

Trendline 3

or:

· Right-click on the element, keep the mouse button pressed, and drag the

element onto the target element. A pop-up menu displays.

· Select Move.

3.4.2 Automatic assignment of RFID tags to measuring points

In order to simplify allocation of measuring points in the Trendline configuration to

measuring point in your system, you can add RFID tags to them. The Detector can

read existing RFID tags at the measuring points and automatically assign the

measured values to the correct measuring point in the Trendline software.

If you transfer a configuration with RFID settings to a Detector

without an RFID reader, it displays an error after data transfer and

ignores the RFID settings.

Assigning an RFID tag to a measuring point

Before using, you must assign the RFID tags placed on the measuring points. You

can do this immediately before a CM or balancing measurement. Select the

measuring points wither in the Trendline software or in the on-site Detector:

Selection in the Trendline software

1.

Select a measuring point in the Trendline configuration.

2.

Click on the Configuration tab.

3.

In the RFID Status box select Assign RFID.

4.

Repeat this procedure for all measuring points to which you wish to assign RFID

tags.

5.

Send

the configuration to the Detector.

6.

During the round, select the appropriate measuring point in the Detector (see

Selection of measuring point

).

a)

Select Start measurement. The Detector reads the RFID tag on site and

assigns it to the measuring point.

b)

If you do not want to perform a measurement but just want to assign the RFID

tag, select Assign RFID at the appropriate measuring point on the Detector.

7.

Load the data from the Detector in Trendline. The RFID status of the measuring

points is now set to "RFID assigned" and the green RFID icon is displayed in

front of the measuring point in the configuration tree.

67

183

44

You can set the status of all measuring points of an element (e.g. a

machine) to "RFID assigned". To do so, right-click the element and

select Assign RFIDs globally. On the next round with the Detector

you can assign the RFID tags placed here to all the appropriate

measuring points.

Selection in Detector

1.

If you have not assigned an RFID tag to a measuring point yet, you can also

assign one on the Detector. You can assign it immediately before a CM/

balancing measurement or before a run up/coast down test. Select the

measuring point on the Detector and then the Assign RFID command. You can

then perform a measurement.

2.

Load the data from the Detector in Trendline. The RFID status of the measuring

points is now set to "RFID assigned".

Removing the assignment of an RFID tag

1.

Select a measuring point with an RFID tag assigned in the Trendline.

2.

Click on the Configuration tab.

3.

In the RFID Status box select Delete RFID.

4.

Send

the configuration to the Detector.

5.

During the round, select the appropriate measuring point in the Detector (see

Selection of measuring point

).

6.

Select Start measurement. The Detector prompts you to delete the tag.

Delete the tag and select Tag deleted.

If you do not delete the tag, select Tag stays.

7.

Continue measuring.

8.

Load the data from the Detector in Trendline. The RFID status of the measuring

point is set to "No RFID" if the tag was deleted.

You can globally delete all RFID tag assignments to measuring

p

oints of an element (e.g. a machine) in the configuration. To do so,

right-click the element and select Delete RFIDs globally. On the

next round, confirm deletion of the RFID tag assignment for each

measuring point before the measurement.

Changing the assignment of an RFID tag

To change the assignment of an RFID tag to a measuring point: First change the

RFID status in the Trendline configuration and transfer the modified configuration

to the Detector. On the next round with the Detector, you can then import the new

RFID tag.

67

183

45

Trendline 3

1.

Select the measuring point in the Trendline configuration.

2.

Click on the Configuration tab.

3.

In the RFID Status box select Edit RFID.

4.

Send

the configuration to the Detector.

5.

During the round, select the appropriate measuring point in the Detector (see

Selection of measuring point

).

6.

Select Start measurement. The Detector prompts you to delete the tag.

a)

Delete the tag and select Tag deleted. You can now assign the new RFID

tag.

b)

If you do not delete the tag, select Tag stays.

7.

Continue measuring.

8.

Load the data from the Detector in Trendline. The new RFID tag is assigned in

the measuring point in the system configuration.

Exchanging a defective RFID tag

If communication with the RFID tag at a measuring point does not work, the user

can mark it as "defective" in the Detector and then continue measuring. After the

next data synchronization with the Trendline software, the RFID status "RFID

defective" is displayed at the measuring point and recursively up to the top level in

the configuration tree. You can then assign a different RFID tag to the measuring

point.

1.

The Detector cannot read the RFID tag at the measuring point. Select RFID tag

defective in the Detector.

2.

The program displays "Is the tag defective?". Select Yes.

3.

Delete the RFID tag from the measuring point.

4.

Load the data from the Detector in Trendline. The RFID status of the measuring

points is now set to "RFID defective".

5.

You can now assign a different RFID tag to the measuring point.

Additional information

· You can abort Detector RFID tag assignment handling functions by pressing

Esc. This preserves the previous state of the assignment.

· If the Detector recognizes an RFID tag that is not in the configuration, it displays

the error message: "At least one configuration does not exist".

3.4.3 Create a measuring point

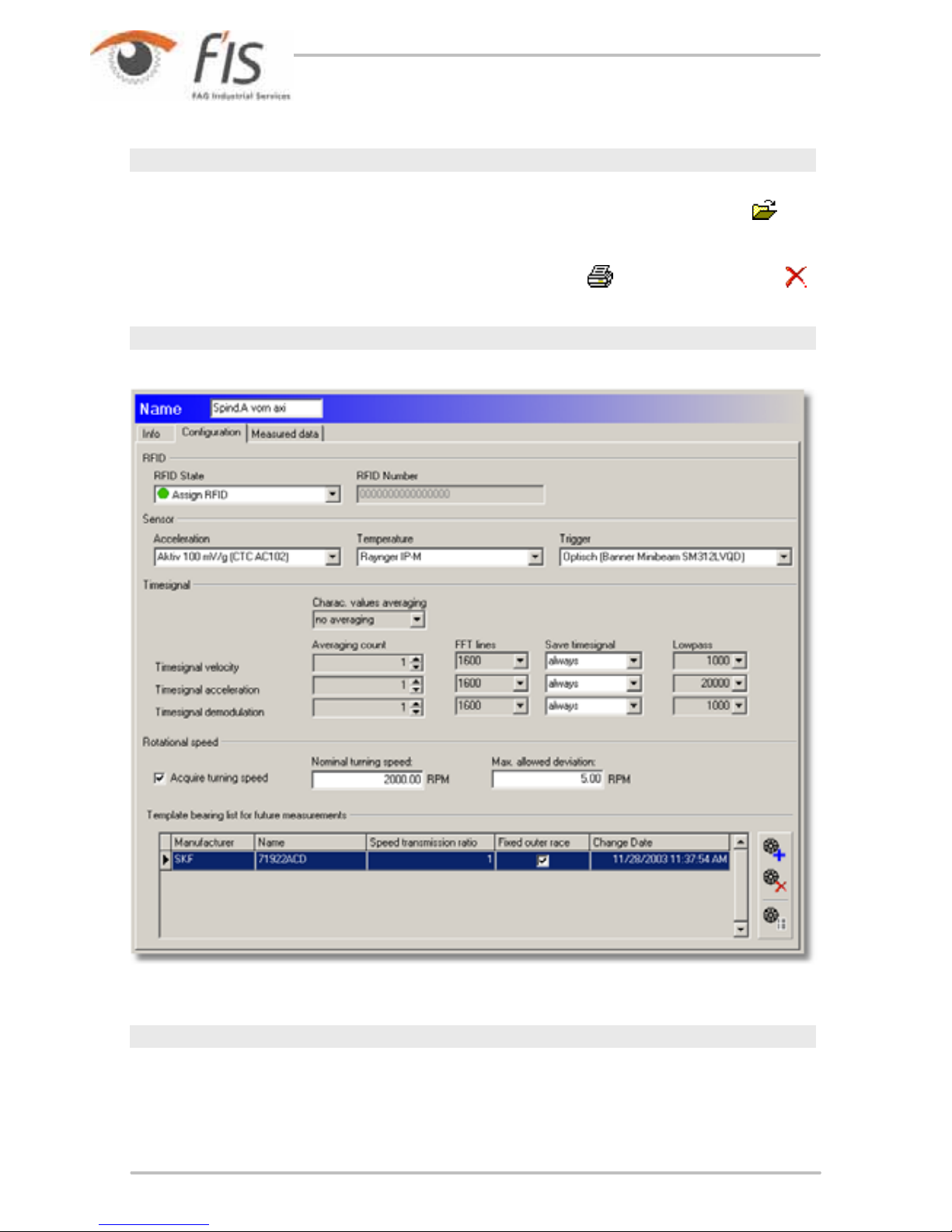

The settings for the measuring point can now be made. Three tabs are assigned to

each measuring point in the right-hand window: Information

, Configuration

and Measured values .

67

183

46 46

88

46

Info

Comments on this measuring point may be entered in the field provided in the

Information tab. It is also possible to insert an picture. To do this, click

and

select the desired picture in the file dialogue. Please observe that these pictures

should not be larger then 100kB, otherwise the program will run more slowly with a

lot of large pictures. You can print out the picture using

and remove it using .

Configuration

RFID status

In this section you can display and edit the status of an RFID tag assigned to the

measuring point:

· No RFID No RFID tag is assigned to the measuring point.

47

Trendline 3

· Assign RFID This option instructs the Detector to assign an RFID tag placed on

the machine to this measuring point during the next round.

· RFID assigned An RFID tag is assigned to the measuring point. The unique ID

is displayed in the RFID number field.

· Delete RFID This option instructs the Detector to cancel the RFID tag

assignment to the measuring point during the next round.

· RFID defective The Detector has marked the assigned RFID tag as defective.

· Change RFID This option tells the Detector to replace the assigned RFID tag.

During the next round, you must delete the tag and assign a new one before you

can perform the measurement at this measuring point.

You can only select the statuses that are accessible as a follow-up

status of the current status.

See also

Automatic assignment of RFID tags to measuring points

.

Sensor

You can adjust the vibration measurement sensors and the temperature at Sensor

. Only the sensors that were previously entered in the sensor database will be

available for selection (see Add sensor

). You can select a sensor for

Acceleration, Temperature and Trigger from the sensor database.

Time signal

In this area you can specify how the Detector should handle time signals

, FFTs

and characteristic values.

· Charac. value averaging: the FFTs or characteristic values calculated from the

time signals are averaged. If the average of four values is determined, for

example, four values are recorded in succession, the FFT is calculated and the

(frequency selective) characteristic values are produced. The time signals

stored for the purposes of an averaged measurement are always the last time

signals measured. Select FFT to determine the mean values of the FFTs

calculated from the time signals and select Char. values to apply the average

determined for the characteristic values calculated from the FFTs.

· You can set the resolution of the spectrum under FFT lines. Select 1600

(corresponds to 4096 samples) or 3200 FFT lines (corresponds to 8192

samples).

· You can use Save time signal to specify when a time signal should be saved:

never, always or on alarm (a main alarm).

43

34

211

48

· At Lowpass you can select a low pass frequency for the frequency band to be

measured from a predefined list. The sample rate in this case is always 2.56

times the selected low pass frequency.

Note that the filter calculation in the software is performed at the

200 Hz and 500 Hz settings and is therefore slower than at the

other frequencies. Therefore, you should only select this high

frequency if you really need it. Otherwise, select a greater number

of FFT lines: For example, it is faster to measure at 1 kHz / 3200

FFT lines than at 500 Hz / 1600 FFT lines, although both

measurements are performed at the same resolution.

A

part from Save time signal the time signal settings can no longer

be changed after the first measurement as otherwise it would no

longer be possible to compare characteristic values.

Rotational speed

If the rotational speed also needs to be determined by the Detector during the

measurement select the Acquire turning speed option. The nominal rotational

speed as well as the maximum permissible deviation in RPM should also be

entered in the appropriate input fields. If the rotational speed deviates from the

rotational speed band defined here during measurement, the Detector issues an

error message but still performs the measurement.

Bearing list template

In this section you can assign bearings from the bearing database

to the

measuring point or delete an assignment. The associated kinematic frequencies of

the selected bearing are then also displayed in the evaluation diagram in the FISViewer. Both when making assignments and deleting assignments you can choose

whether

· to only apply bearing data in future

· for all measurements already performed, or

· only for measurements from a certain period

Specify the bearing assignment at measuring point level in the

configuration. You can also assign bearing data directly to individual

measured values. For more information refer to Measured values

.

68

88

49

Trendline 3

Add bearing

· Click and select the bearing from the bearing database.

· Selecting measurements:

o If you only want to apply the bearing information for future measurements,

click Do not add this bearing to any measurement of this measuring

point.

o If you want to apply the bearing information to all saved measurements, click

Add this bearing to all existing measurements of this measuring point.

o To apply the bearing information to measurements in a certain time range,

click Add this bearing to all measurements of following timerange and

select the time range.

· In the Bearing configuration section enter the speed transmission ratio and

select whether the bearing has a fixed outer race.

Disable bearing

· Click on the bearing to delete and then

.

50

· Selecting measurements:

o To keep the bearing information for the existing measurements of this

measuring point, click Do not disable the bearing for any measurement of

this measuring point.

o To delete the bearing information from all saved measurements of this

measuring point, click Disable the bearing for all existing measurements

of this measuring point.

o To delete the bearing information from measurements in a certain time range,

click Deactivate bearing for all measurements of following timerange and

select the time range.

Displaying bearing information

· Click on the desired bearing and then

. This displays the bearing information

in the bearing database.

Measured values

In the Measured data section you can display the acquired data numerically and

graphically. For more information refer to Measured values

.

3.4.4 Setting characteristic values

You can create the following characteristic values per measuring point:

· ISO 10816

· A

sel

and A

eff

,

88

51

Trendline 3

· D

sel

and D

eff

,

· Temperature,

· V

sel

,

· Crest factor.

Please also observe the information in the "Frequency selective characteristic

values

" section.

Characteristic values can be changed until they have been sent to

the Detector for the first time. After that the characteristic values

turn grey in the tree and cannot be altered anymore. Otherwise, the

measuring results could not be compared.

To add a new characteristic value, right-click the measuring point the characteristic

value is meant for and, after that, on New sub-item. Alternatively, you can do it via

System > New sub-item or via

. Now, the following window opens.

Under Type various characteristic values can be selected, which can be measured

with the detector. With selective characteristic values (e.g. a

sel

) the upper and

lower cut-off frequency can be set in Frequency min. and Frequency max.,

between which the characteristic value will be calculated. More information to that

you will find in Frequency selective characteristic values

. For the other

characteristic values (ISO 10816, a

eff

and d

eff

) the cut-off frequencies are pre-set.

In the Alarm section you can set a threshold value for each characteristic value. If

this is exceeded by a measurement, both Detector and Trendline software show