Technical Documentation

FAFNIR GmbH • Schnackenburgallee 149 c • 22525 Hamburg • Germany • Tel.: +49 /40 / 39 82 07-0 • Fax: +49 /40 / 390 63 39

TORRIX

The magnetostrictive level sensor

Edition: 2016-09

Version: 16

Art. no.: 207074

I Table of contents

Table of contents

1 Overview................................................................................................. 1

2 Safety instructions ................................................................................. 2

3 Design and function ............................................................................... 3

4 Installation .............................................................................................. 5

4.1 Installation with screw-in unit ............................................................................. 6

4.2 Installation with flange ....................................................................................... 7

4.3 Installation on the bypass ................................................................................... 7

5 Electrical connection .............................................................................. 9

5.1 Wiring diagram TORRIX ...................................................................................... 9

5.2 Wiring diagram TORRIX Ex ................................................................................. 9

5.3 Cable length .................................................................................................... 10

5.4 Wiring .............................................................................................................. 12

6 User configuration ............................................................................... 13

6.1 Measuring span at the level sensor ................................................................... 13

6.2 Current consumption in failure mode ............................................................... 15

7 Maintenance ......................................................................................... 16

7.1 Return shipment............................................................................................... 16

8 Technical data ....................................................................................... 16

8.1 Sensor .............................................................................................................. 16

8.2 Float ................................................................................................................ 18

9 List of figures ........................................................................................ 19

10 Annex .................................................................................................... 20

10.1 EC Declaration of Conformity ........................................................................... 20

10.2 SIL Certificate ................................................................................................... 21

10.3 EC type-examination certificate TÜV 01 ATEX 1772 X ....................................... 24

10.3.1 1st Supplement ................................................................................................ 27

Table of contents II

10.3.2 2nd Supplement ............................................................................................... 28

10.3.3 3rd Supplement ............................................................................................... 29

10.3.4 4th Supplement ............................................................................................... 30

10.4 Instructions ...................................................................................................... 34

© Copyright:

Reproduction and translation is permitted only with the written consent of the FAFNIR GmbH. The FAFNIR

GmbH reserves the right to carry out product alterations without prior notice.

Page 1/36 Overview

1 Overview

The high-precision TORRIX level sensor is designed to provide continuous gauging of

liquid media levels in tanks. The measuring principle used by the sensor exploits the

physical effect of magnetostriction and is largely unaffected by temperature. This method

is particularly ideal where level measurements are required to be extremely accurate, such

as in the chemical industry.

In this documentation, the TORRIX is described as the variant with cable gland. As

another option, the TORRIX with plug connector is available, see:

Technical documentation TORRIX M12, art. no. 350164

The TORRIX supplies a 4 ... 20 mA output signal which is configured using buttons in the

sensor head, or a digital output signal as HART® protocol. Probe lengths are possible from

100 mm to 6 m, as Flex version up to 10 m, as well as versions for different temperature

and pressure ranges.

It also comes in the following versions:

• TORRIX (with screw-in unit, welded or for stepless positioning)

• TORRIX flange (with process connection flange)

• TORRIX Flex (with flexible probe tube)

• TORRIX Bypass (for installation on a bypass with magnetic float)

• TORRIX 90 (with 90° angled sensor head)

• TORRIX 6 (with 6 mm probe tube)

• TORRIX 6B (with 6 mm probe tube and short cable gland)

For the description of communication with the HART® protocol, see:

Technical documentation TORRIX Hart, art. no. 207095

To install the TORRIX Flex version see:

TORRIX Flex Installation Guide multilingual, art. no. 350118

The TORRIX versions can also be supplied as Ex version:

The level sensor TORRIX Ex … with Ex approval (ATEX, IECEx) can be installed in

potentially explosive areas which require equipment protection level Ga (Ex Zone 0),

Ga/Gb (Ex Zone 0/1) or Gb (Ex Zone 1) for electrical equipment.

Safety instructions Page 2/36

2 Safety instructions

The purpose of the TORRIX level sensor is to gauge liquid levels in tanks. The level sensor

must be used exclusively for this purpose. The manufacturer accepts no liability for any

form of damage resulting from improper use!

The level sensor has been developed, manufactured and tested in accordance with the

latest good engineering practices and generally accepted safety standards. Nevertheless,

hazards may arise from its use. For this reason, the following safety information must be

observed:

• Do not change or modify the level sensor or add any equipment without the prior

consent of the manufacturer.

• The installation, operation and maintenance of the level sensor must be carried

out only by expert personnel. Specialised knowledge must be acquired by regular

training.

• Operators, fitters and service technicians must observe all applicable safety regu-

lations. This also applies to any local safety and accident prevention regulations

which are not stated in these operating instructions.

The safety instructions in this manual are marked as follows:

If these safety instructions are not observed, it may result in the risk of

accident or damages to the TORRIX level sensor.

Useful information designed to ensure continued and correct operation of

the TORRIX level sensor or helpful advice to make your work easier.

Page 3/36 Design and function

3 Design and function

The design of the TORRIX level sensor is illustrated in the version with screw-in unit (see

following figure).

Inside sensor head (1) of the level sensor, concealed by cap (2), are the protected terminal

clamps and configuration buttons. The electrical connection is established by an

M16 x 1.5 screwed cable gland (3) or M12 plug-in connection at the top of the sensor

head and by earth connector (4) at the bottom of the sensor head (see chapters

“Installation” and “User configuration”).

Probe tube (5) features a screw-in unit (6) (cutting ring fitting or ferrule fitting) for height

adjustment capability or a flange (not shown) for fixed installation. Float (7) is the key

component for continuous gauging of the product filling level or boundary layer and is

held on the probe tube by a guard ring (8).

The TORRIX Bypass version is supplied without a process connection and a float.

Figure 1: TORRIX level sensor

1

4

5

6 7 2 3 8

Design and function Page 4/36

The measuring principle illustrated in the following figure exploits the physical effect of

magnetostriction and is largely unaffected by temperature. The probe tube contains a

tensioned wire (1) made of magnetostrictive material. The sensor electronics transmit

current pulses (2) through the wire, which generate a circular magnetic field (3). A

magnet (4) contained in the float acts as the filling level sensor. Its magnetic field applies

an axial magnetic field to the wire. The superposition of the two magnetic fields produces

a torsional wave (5) at the float position, which then propagates along the wire in both

directions. One wave propagates directly to the sensor head, the other propagates down

to the bottom of the probe tube and is reflected. The time between the current pulse

being transmitted and the wave arriving at the sensor head is measured. From these

propagation times, it is possible to determine the current position of the float.

Figure 2: Operating principle of the TORRIX level sensor

2

3

5

4

1

5

Page 5/36 Installation

4 Installation

When installing and maintaining the level sensor in potentially explosive

areas, the national rules must be observed (Explosion Protection Regulations,

Industrial Health and Safety Regulations, Equipment Safety Regulations and

specific conditions of the EC-type examination certificates). The generally

accepted rules of engineering and these operating instructions must be observed.

All applicable local safety and accident prevention regulations not included

in these operating instructions must also be observed.

This section describes how to install the level sensor depending on the type (see the

following figure).

TORRIX screw-in unit TORRIX flange TORRIX Bypass

Figure 3: TORRIX versions

Probe length

Sensor head

Sensor head

Screew-in

unit

Probe tube

ø 12

Probe tube

ø 12

Float

Guard ring

Guard ring

Float

Flange

Neck tube

Probe length

Installation length

112

∅ 50

∅ 50

∅

50

112

116

88

Installation Page 6/36

During installation, take great care not to bend the probe tube, and

protect the float from shock and impact loads.

Installing a level sensor in areas exposed to a powerful external magnetic

field is not permitted because this could impair gauging.

The level sensor can also be fitted into the tank from underneath.

If the float is removed during installation, it must be slid back onto the

probe tube afterwards with the “TOP” marking oriented towards the sensor head end, to enable correct measurements to be made.

4.1 Installation with screw-in unit

Figure 4: Installation with screw-in unit

Removal of the float is necessary only if the float does not fit through the

installation opening in the tank. Otherwise, please proceed directly to steps

3, 6 and, if applicable, 7.

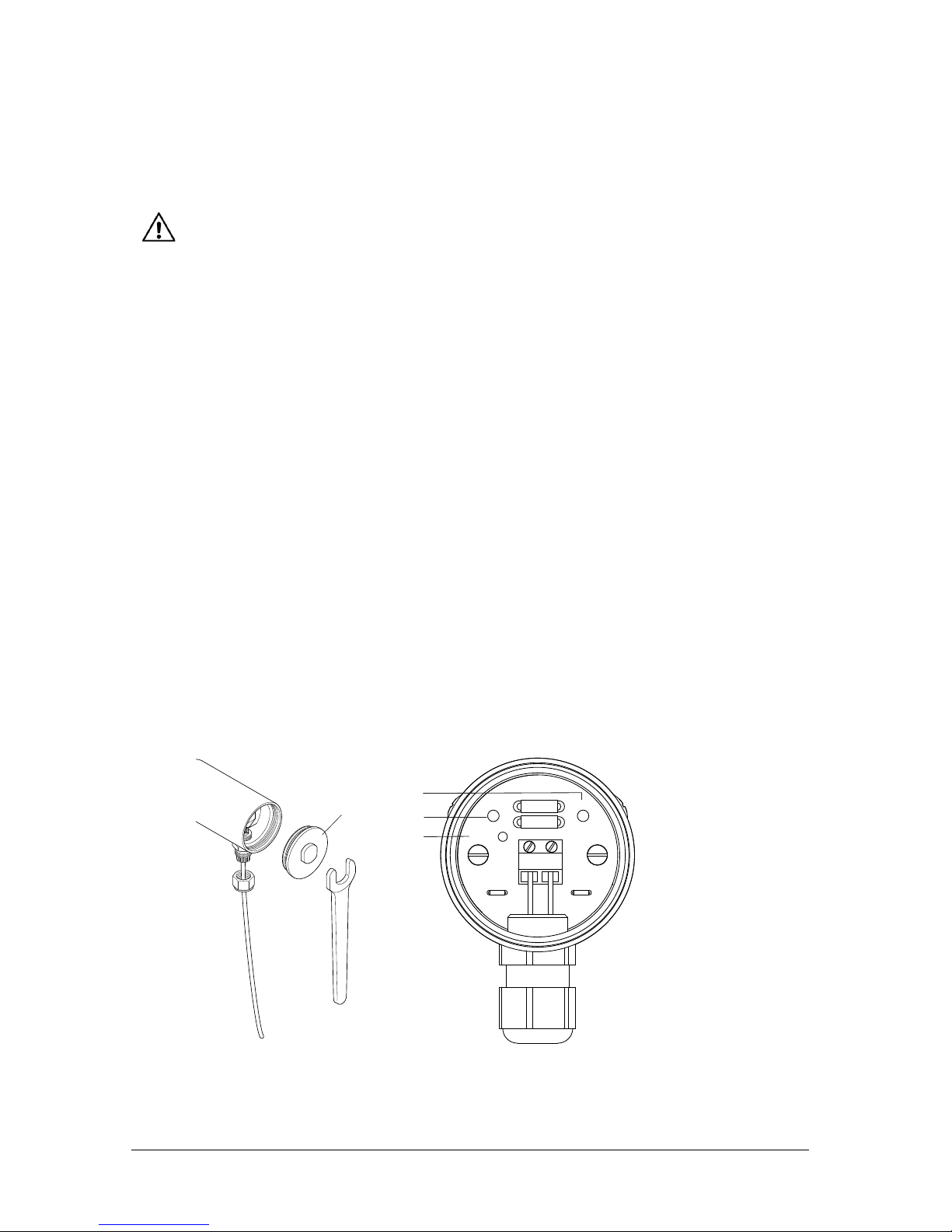

Insert the level sensor into the tank (see Figure 4):

(1) Loosen both set screws, remove guard ring (1) and remove float (2) from probe

tube (3).

(2) If necessary, slot screw-in unit (4) onto the probe tube.

(3) Insert the level sensor into the tank, provide screw-in unit thread (4) with a

suitable sealing material, screw it in and tighten.

(4) Slide float (2) back onto probe tube (3).

For correct gauging, the float must be slid onto the probe tube with the

“TOP” marking oriented towards the sensor head end, to enable correct

measurements to be made.

(5) Refit guard ring (1) on the tube, align the set screws with the groove and tighten.

1 2 3 4 5

Page 7/36 Installation

(6) Adjust the height of the process connection and fix the union nut (5) by hand

finger-tight.

(7) Fix the union nut (5) with a wrench by a 1¼ clockwise turn (see following figure).

Figure 5: Compression fitting fixing

4.2 Installation with flange

The probe tube is permanently welded to the flange, which means that the installation

length cannot be altered.

Secure the flange using the flange screws.

If the float does not fit through the installation opening, see installation instructions

chapter 4.1.

4.3 Installation on the bypass

The level sensor is mounted at the side of the bypass tube using suitable non-magnetic

fasteners.

To ensure reliable gauging, the probe tube must be fitted with no

deformation on the outside.

The distance between the probe and bypass tubes must be as small as possible.

Only floats approved by FAFNIR can be used.

5

Installation Page 8/36

Figure 6: Installation on the bypass

montiert (unverformt)

Magnetposition

min.

max.

Magnetposition

Magnet

position

Bypassr

ohr

T

ORRIX Bypass

S

ondenrohr spannungsfrei

Bypass-Schwimmer

70 mi

n.

Messberei

ch

Schwimmermitte: max. Abst

and

abhängig vom Bypass-Schwimmer

Abstand Sondenrohr zu

50 m

in.

S

ondenl

äng

e

A

A

SCHNITT A-A

Abstandshalter

Sondenbefestigung

(unmagneti

sch

)

Distance between probe tube

and float centre: max. distance

depends on the bypass float

Bypass float

Probe tube tension-

free

mounted (undeformed)

Bypass tube

Magnet position

Spacer

Probe fixture

(non-magnetic)

Probe length

max.

Magnet position

min.

Magnet position

Measuring range

Section A-A

TORRIX Bypass

Page 9/36 Electrical connection

5 Electrical connection

5.1 Wiring diagram TORRIX

The level sensor without Ex approval is installed in accordance with the following wiring

diagram:

Figure 7: Wiring diagram TORRIX

Power supply: U

max

= 30 V DC

Minimum supply voltage: U

min

= 8 V

Total resistance (including cable resistance and load): ΣR = (U - U

min

) / 0,0215 A

To connect the cable, see chapter 5.4

5.2 Wiring diagram TORRIX Ex

The level sensor with Ex approval is installed in accordance with the following wiring

diagram:

Figure 8: Wiring diagram for TORRIX in a potentially explosive atmosphere

Power supply: U

max

= 30 V DC

Minimum supply voltage: U

min

= 8 V

Total resistance (including cable resistance and load): ΣR = (U - U

min

) / 0,0215 A

+

+

_

Y

I

R1

R2

R3

U

TORRIX

Spannungsquelle

Leitungswiderstände

Bürde

U = 30 V

max

U = 8 V

min

Y

I

+

-

R1

R2

TORRIX (Ex-Ausführung)

Leitungswiderstände

Trennverstärker (Beispiel)

Hilfsenergie

4...20 mA

+

-

4...20 mA

8...30 V

Power supply

Line resistance

Load

Isolation amplifier

(example)

Line resistance

Power supply

(Ex version)

Electrical connection Page 10/36

The intrinsically safe version of the TORRIX Ex level sensor, when installed in

a potentially explosive atmosphere, is permitted to be connected only to

isolation amplifiers that have been certified by a recognised inspection authority and offer electrical outputs that meet the following conditions:

U0 ≤ 30 V

I0 ≤ 200 mA

P0 ≤ 1 W

Further data can be found in the EC type-examination certificate (refer to the Appendix).

If the level sensor is to be used in a potentially explosive atmosphere, always

make sure that the permissible capacitance and inductance of the isolation

amplifier are not exceeded (refer to the electrical data in the EC typeexamination certificate).

Used in an explosion-proof application, the connecting cable to the isolation amplifier

must be marked, preferably as a blue cable for intrinsically safe electric circuits.

To connect the cable, see chapter 5.4

5.3 Cable length

The maximum cable length depends on the total resistance (see Chap. 5.1 / 5.2),

composed of the line resistances and the load of connected devices.

The cable (length and cross-section) must be chosen so that the supply

voltage will not fall below the sensor-specific minimum voltage (8 V) in the

event of a maximum current consumption (21.5 mA) .

If the level sensor is to be used in a potentially explosive atmosphere, always

make sure that the permissible capacitance and inductance of the associated equipment are not exceeded (refer to the electrical data in the EC typeexamination certificate).

Because of the voltage drop of 12 V the connection housing HPH Ex d and

the safety barrier SB1 can be used with TORRIX only at a supply voltage

higher than 20 volts.

Page 11/36 Electrical connection

The following table shows the maximum total resistances at different supply voltages, and

cable resistances at various cross-sections:

Supply

voltage [V]

Max. total

resistance [Ω]

Cable cross-

section

[mm²]

Cable resistance

per m copper

-

cable [Ω/m]

For connection

housing HPH Ex d

suitable (yes/no)

12 (-5%)

158

0.5

0.0356

no

1.0

0.0178

no

1.5

0.0119

no

24 (-5%)

688

0.5

0.0356

yes

1.0

0.0178

yes

1.5

0.0119

yes

The max. cable length is calculated as follows:

L = (((U – U

min

) / I

max

) – RB) / RQ

L = Cable length [m]

U = Supply voltage [V] (with negative tolerance value -5%)

U

min

= Minimum supply voltage [V] = 8 V

I

max

= Maximum power consumption [A] = 0.0215 A

RB = Load

RQ = cable resistance copper cable per m [Ω/m] for cable cross-section Q [mm²]

Example:

Supply voltage: 12 V (± 5%)

Supply voltage U = 11.4 V (12 V - 5%)

Minimum supply voltage U

min

= 8 V

Highest power consumption I

max

= 0.0215 A

Load RB = 86.8 Ω

Cable resistance RQ = 0.0356 Ω/m at cable cross-section Q = 0.5 mm²

L = (((11,4 – 8) / 0,0215) - 86,8) / 0,0356 = 2000 m

Thus a cable with forward and return line (2-wire) can be up to 1000 m long.

Electrical connection Page 12/36

5.4 Wiring

The wiring is not required for the variant TORRIX with M12 connector.

Assignment of the M12 connector: Pin 1 = brown (+), Pin 3 = blue (-)

For the wiring of the level sensor, proceed as follows:

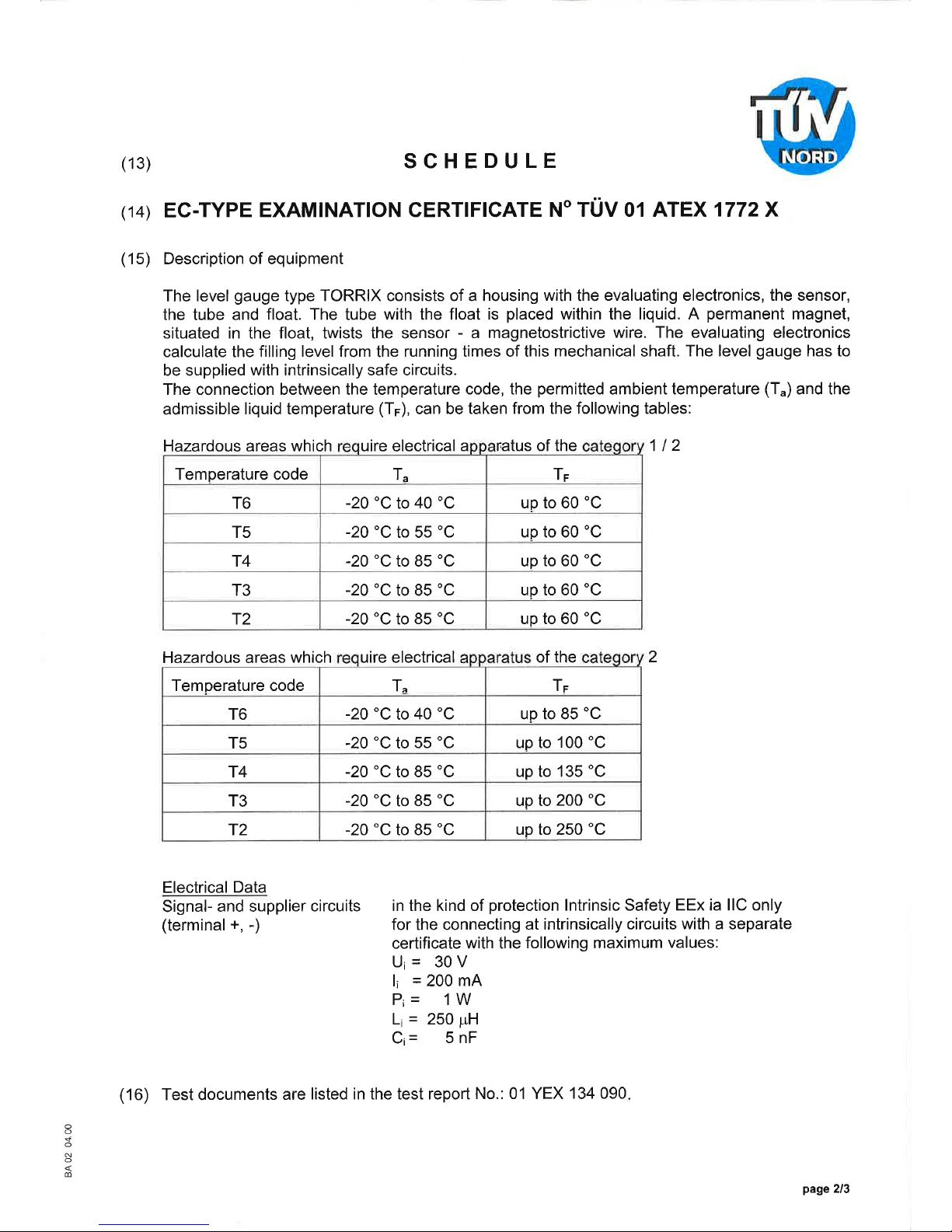

(1) Unscrew sensor head cap (1) using an open-ended spanner.

(2) Loosen union nut (2) of screwed cable gland (3).

Figure 9: Wiring

Figure 10: Removable screw terminal

(3) Feed the two-core cable (4) into the union nut (2) and tighten the nut.

The external diameter must be 5 to 10 mm.

(4) Remove screw terminal (5).

(5) Connect the two-core cable to the (+) and (–) marked pols of the screw terminal (5).

(6) Plug the screw terminal (5) back on. The cable must have no traction.

(7) Configuration of reference points if necessary (see chapter 6.1 )

(8) Screw sensor head cap (1) back on.

1

3

2

4

C

al/Er

r

+

4 mA 20 mA

–

3

2

4

5

5

Page 13/36 User configuration

The earth connector on the underside of the sensor head can be used for earthing or

equipotential bonding.

Protect the sensor head against the ingress of water. An external cable

diameter of 5 to 10 mm ensures reliable sealing of the cable entry. Make

sure that the cable gland is screwed tight, and close the sensor head cap

firmly.

6 User configuration

Versions that support the HART® protocol enable the adjustments carried

out remotely without the sensor head having to be opened.

6.1 Measuring span at the level sensor

To enable configuration of the 4 mA and 20 mA points at the TORRIX level sensor, two

buttons and an LED (light emitting diode) are provided near the terminals inside the

sensor head.

By default, the level sensor is set to maximum measuring span with 4 mA at the sensor

base and 20 mA at the sensor head. The measuring span is configurable for adaptation to

the tank concerned. However, a minimum clearance of 10 mm must be observed.

If this minimum clearance is not observed, the display direction of the level sensor will be

reversed automatically (ullage measurement).

Through configuration, it is also possible to have the measured value output inverted: e.g.

the level sensor can be set to maximum measuring span with 4 mA at the sensor head

and 20 mA at the sensor base.

Figure 11: Adjustment of the measuring span

1

+

4 mA

20 mA

–

3

4

Cal/Err

2

User configuration Page 14/36

(1) Unscrew sensor head cap (1) using an open-ended spanner.

(2) Press and hold 4 mA button (2) or 20 mA button (3) for at least 3 seconds. The

green LED begins to flash.

(3) The level sensor is now in configuration mode. The current consumption of the

level sensor is 12 mA. If no button is pressed again, the level sensor remains in

configuration mode for 20 seconds before reverting to measuring mode and discarding any changes. In configuration mode, the 4 mA or 20 mA reference point,

or both, can be modified in any order.

To define a reference point:

(4) Move the float to the desired reference point and

− briefly press (0.1 to 2 seconds) “4 mA” button (2) to define a current consump-

tion of 4 mA at this position

− briefly press (0.1 to 2 seconds) “20 mA” button (3) to define a current consump-

tion of 20 mA at this position

When the “4 mA” button is pressed, the LED goes out for 5 seconds. When the

“20 mA” button is pressed, the LED lights up permanently for 5 seconds.

The sensor then remains in configuration mode for a further 15 seconds before storing

the change and reverting to measuring mode.

The new measuring range configuration is not stored until the level sensor

reverts automatically from adjustment mode to configuration mode and the

LED goes out. The new configuration is retained even if the level sensor is

subsequently disconnected from the power supply.

For “dry” settings to be possible in the case of bypass sensors, a magnetic

system with spacer bracket will need to be obtained from the manufacturer

of the bypass. Configuration can then be carried out even with the sensor

removed.

Page 15/36 User configuration

6.2 Current consumption in failure mode

If a malfunction is preventing the level sensor from recording a plausible float position,

i.e. the measured level is incorrect, the sensor will enter failure mode after a short time.

Failure mode signalling conforms to the NAMUR NE43 recommendation. The failure

current is set by default to 21.5 mA but this value can also be set to 3.6 mA.

To configure current consumption in failure mode (see Figure 11)

(1) Unscrew sensor head cap (1) using an open-ended spanner.

(2) Press and hold both the “4 mA” (2) and “20 mA” (3) simultaneously for at least

3 seconds.

Green LED (4) “Cal/Err” flashes rapidly.

The current consumption of the level sensor is 16 mA. After 5 seconds, the LED

stops flashing and indicates the selected failure current consumption for 2.5 seconds. If the LED is on permanently, I

failure

is 21.5 mA; if the LED turns off, I

failure

is

3.6 mA.

If no button is pressed then, the level sensor remains in failure mode for a further

2.5 seconds before reverting to measuring mode and discarding the change.

(3) To set a current consumption

− of 3.6 mA during the dwell time (10 sec) in the fault mode, briefly press the

"4 mA" (2) button (0.1 … 2 seconds).

− of 21.5 mA during the dwell time (10 sec) in the fault mode, briefly press the

"20 mA" (3) button (0.1 … 2 seconds).

The new measuring range configuration is not stored until the level sensor

reverts automatically from adjustment mode to configuration mode and the

LED goes out. The new configuration is retained even if the level sensor is

subsequently disconnected from the power supply.

(4) Screw sensor head cap (1) back on.

If, during operation, the level sensor detects that the level cannot be output

correctly due to an insufficient supply voltage, it enters failure mode and

sets current consumption to 3.6 mA (regardless of any failure current settings).

Maintenance Page 16/36

7 Maintenance

7.1 Return shipment

Before returning any FAFNIR equipment the returned goods authorization by the FAFNIR

customer care is required. Please contact your account manager or the customer care to

get the instructions for the return of goods.

The return of FAFNIR equipment is possible only with authorization by the

FAFNIR customer care.

8 Technical data

8.1 Sensor

Electrical connection

Two-line terminal

4 to 20 mA (3.8 ... 20.5 mA) current consumption for level display

21.5 mA (3.6 mA) current consumption in failure mode

Supply voltage:

TORRIX

TORRIX EX

8 ... 30 V DC

8 ... 30 V DC

Process connection Screw-in unit with possibility of variable height adjustment

Standard G ½ (cutting ring coupling)

Flange on request

For material, see probe tube

Bypass assembly

Sensor head Height 112 mm, Bypass version 116 mm

IP68 (in accordance with TÜV NORD test report 13 993 1204 83 of

02.09.2013)

Material: stainless steel

Cable diameter 5 to 10 mm

Temperature -40 ... +85 °C

Probe tube Length 200 to 6,000 mm (to order)

Length TORRIX Flex 1.5 m ... 10 m

Diameter 12 mm (other diameters on request)

Material: 1.4571 standard

(Hastelloy, or other materials on request)

Measuring range freely configurable (> 10 mm)

Normal temperature (NT) -40 °C … +125 °C

High temperature (HT) -40 °C … +250 °C

Ultra high temperature (HHT) -40 °C … +450 °C

Low temperature (LT) -65 °C … +125 °C

Communication HART® protocol (available)

Page 17/36 Technical data

Accuracy

NT/LT digital component

Linearity better than ±0.2 mm or ±0.01 %,

better than ±0.001 % per K

Repetition accuracy better than 0.05 mm

Resolution better than 10 µm

Accuracy

HT/HHT digital component

Linearity better than ±0.5 mm or ±0.025 %,

better than ±0.01 % per K

Repetition accuracy better than 0.1 mm

Resolution better than 50 µm

Accuracy

Bypass digital component

Linearity better than ±0.5 mm or ±0.025 %,

better than ±0.001 % per K

Repetition accuracy better than 0.05 mm

Resolution better than 10 µm

Accuracy

HT/HHT Bypass digital

component

Linearity better than ±2 mm or ±0.1 %,

better than ±0.01 % per K

Repetition accuracy better than 0.5 mm

Resolution better than 50 µm

Accuracy

Analogue component

Linearity better than ±0.01 %

Temperature drift better than ±0.01 % per K

Resolution better than 0.5 µA (16 bit)

Technical data Page 18/36

8.2 Float

The float is a key component of the level sensor that must be matched to the medium in

respect of density, pressure resistance and material durability.

The following floats are exchangeable and are available to order separately. Other float

types and materials are available on request.

The density and magnet position of floats of the same type may vary

slightly, in which case readjustment may be required.

All floats are also suitable for use at a pressure of -1 bar (vacuum).

Excerpt from available float range:

min. medium

density [g/cm³]

Material

max. operating pressure

[bar] at 20 °C *)

Shape

[mm]

0.5

0.6

0.7

0.7

0.7

0.85

0.95

Titanium

1.4571 / 316 Ti

1.4571 / 316 Ti

C276

1.4571 / 316 Ti

1.4571 / 316 Ti

1.4571 / 316 Ti

20

20

16

10

40

20

50

Ball ø 50

Ball ø 52

Cylinder ø 53

Cylinder ø 46

Ball ø 52

Ball ø 43

Ball ø 43

*) above 50 °C the maximum operating pressure decreases

Pressure resistance is guaranteed for undamaged floats only. Even the most

minor and invisible dents, which can occur if, for example, the float is

dropped from a bench onto a stone floor, are sufficient to cause a significant deterioration in pressure resistance.

Page 19/36 List of figures

9 List of figures

Figure 1: TORRIX level sensor .......................................................................................... 3

Figure 2: Operating principle of the TORRIX level sensor .................................................. 4

Figure 3: TORRIX versions ................................................................................................ 5

Figure 4: Installation with screw-in unit ........................................................................... 6

Figure 5: Compression fitting fixing ................................................................................. 7

Figure 6: Installation on the bypass .................................................................................. 8

Figure 7: Wiring diagram TORRIX .................................................................................... 9

Figure 8: Wiring diagram for TORRIX in a potentially explosive atmosphere ...................... 9

Figure 9: Wiring ............................................................................................................ 12

Figure 10: Removable screw terminal ............................................................................ 12

Figure 11: Adjustment of the measuring span ............................................................... 13

Page 1/3

FAFNIR GmbH Bahrenfelder Str. 19 22765 Hamburg Telephone: +49 / (0) 40 / 39 82 07-0 Fax: +49 / (0) 40 / 390 63 39

IIIInstructions

nstructionsnstructions

nstructions

TÜV 01 ATEX 1772 X

Level Sensor

Level SensorLevel Sensor

Level Sensor TORRIX

TORRIXTORRIX

TORRIX Ex

ExEx

Ex ………… Edition: 07.2011

IIII Range of application

Range of applicationRange of application

Range of application

The intrinsically safe equipment TORRIX Ex ... is used for the continuous measurement of liquid levels. The

magnetostrictive measurement system detects the filling level by means of a float and the water level in

case of a second float. These move up and down the probe tube.

II

IIII

II Standards

StandardsStandards

Standards

See EC-type examination certificate including supplements.

IIIIII

IIII

II Instructions for safe

Instructions for safeInstructions for safe

Instructions for safe …………

IIIIII

IIII

II....aaaa ………… use

useuse

use

The sensor is designed as intrinsically safe apparatus and is approved for use in potentially explosive areas.

The level sensor can be installed in Ex Zone 0 and is suitable for all gas groups (IIA, IIB and IIC).

A plastic float for LPG tanks can be used, as inside LPG tanks no explosive atmosphere is present.

The approval applies for all types TORRIX Ex ...

III.b

III.bIII.b

III.b …

… …

… assembling and dismantling

assembling and dismantlingassembling and dismantling

assembling and dismantling

TORRIX Ex … (without process connection)

If the level sensor is supplied without process connection, the installer is responsible for compliance

with the Ex requirements.

With a riser installation the plastic centring aid is plugged onto the sensor head. Then let the sensor slide in the riser until it stands firmly on the bottom.

TORRIX Ex E …

Seal the threads of the screw in unit with a suitable sealing material, screw it into the existing

socket and tighten it.

In the case of installation with a cutting ring coupling, it is no longer possible to alter the position

of the level sensor after the union nut has been tightened.

TORRIX Ex F … and TORRIX Ex TAG-…

The probe tube is permanently fixed to the flange, which means that the installation length cannot

be altered. Seal the flange with a suitable sealing and fix it with flange bolts or nuts.

TORRIX Ex … Flex …

This type can be manufactured with different probe feet, which are used to stabilize the probe. A

foot can be a magnetic base. The magnet is then encapsulated in an electrically conductive plastic

and may therefore be used in explosion hazardous areas.

General remark (see also EN 60079-26, clause 4.6):

Attention must be paid, if the level sensor is built into the boundary wall between Zone 0 and Zone 1,

that a protection class of at least IP67 is achieved after installation.

Page 2/3

FAFNIR GmbH Bahrenfelder Str. 19 22765 Hamburg Telephone: +49 / (0) 40 / 39 82 07-0 Fax: +49 / (0) 40 / 390 63 39

IIIIII

IIII

II.c

.c.c

.c ………… Installation

InstallationInstallation

Installation

All wiring operations must solely be carried out with the power disconnected. The special regulations

including EN 60079-14 and local installation regulations must be observed.

TORRIX Ex … (4 … 20 mA) and TORRIX Ex … HART …

The level sensor has a two-pole electrical connector. The level signal is included in the supply current. In addition, using TORRIX Ex ... HART ... it can be communicated with the sensor via HART

protocol.

TORRIX Ex … SC …

The level sensor has a four-pole electrical connector. The level signal is transmitted in a digital, serial communication.

TORRIX Ex TAG-…

The level sensor has a two-pole electrical connector. The level signal is transmitted in accordance

with the standard EN 14116.

Via the connector, the sensor is powered and the level signal is forwarded simultaneously to the parent

measurement converter. The wiring from the sensor to the measurement converter shall be carried out

using a two- or four-wire cable (preferably blue). The terminals on the sensor must be connected to the

same terminals on the transducer.

For integration into the equipotential bonding a PA terminal is present at the sensor head.

III.

III.III.

III.dddd …

… …

… putting into service

putting into serviceputting into service

putting into service

Before putting into service, all devices must be checked of right connection and fitting. The power supply,

as well of connected devices, must be checked.

III.

III.III.

III.eeee …

… …

… mmmmaintenance, overhaul and repair

aintenance, overhaul and repairaintenance, overhaul and repair

aintenance, overhaul and repair

Generally the device is maintenance-free. In case of a defect it must be send back to FAFNIR or one of his

representations.

IIIIVVVV Marking

MarkingMarking

Marking

1 Manufacturer: FAFNIR GmbH, Hamburg

2 Type designation: TORRIX Ex …

3 Serial number: Ser. N°: …

4 Certificate number: TÜV 01 ATEX 1772 X

5 Ex marking:

II 1 G Ex ia IIC/IIB T4 Ga

II 1/2 G Ex ia IIC/IIB T6 Ga/Gb

II 2 G Ex ia IIC/IIB T6 Gb

6 CE marking: 0044

7 Electrical data: Ui ≤ 30 V

Ii ≤ 200 mA

Pi ≤ 1 W

Li < 50 µH

Ci < 5 nF

Electrical data for the level sensor TORRIX Ex … SC …

Ui ≤ 15 V

Ii ≤ 60 mA

Pi ≤ 100 mW

Ci < 10 nF

L

i

< 100 µH

Page 3/3

FAFNIR GmbH Bahrenfelder Str. 19 22765 Hamburg Telephone: +49 / (0) 40 / 39 82 07-0 Fax: +49 / (0) 40 / 390 63 39

VVVV Tec

TecTec

Techhhhni

nini

niccccal

alal

al Da

DaDa

Dattttaaaa

The following safety-related values are defined with:

Input voltage: Ui ≤ 30 V (15 V)*

Input current: Ii ≤ 200 mA (60 mA)*

Input power: Pi ≤ 1 W (100 mW)*

The externally effective capacitance and inductance are:

Internal capacitance: Ci < 5 nF (10 nF)*

Internal inductance: L

i

< 50 µH (100 µH)*

When used in potentially explosive atmospheres, the maximum temperatures depending on the temperature classes and categories can be found in the table.

Temperatur

TemperaturTemperatur

Temperatureeee cccclass

lasslass

lass TTTT

aaaa

TTTT

FFFF

Equipment protection level

Equipment protection levelEquipment protection level

Equipment protection level Ga

Ga Ga

Ga resp

respresp

resp.

. .

. ccccategor

ategorategor

ategoryyyy 1 (

1 (1 (

1 (level senso

level sensolevel senso

level sensorrrr entirely

entirelyentirely

entirely erected

erected erected

erected in Zone

in Zonein Zone

in Zone 0000))))

T4, T3, T2, T1 -20 °C … +60 °C

Equipment protection level

Equipment protection levelEquipment protection level

Equipment protection level Ga/Gb

Ga/Gb Ga/Gb

Ga/Gb resp.

resp.resp.

resp. category

categorycategory

category 1/

1/1/

1/2 (probe tube erected in

2 (probe tube erected in 2 (probe tube erected in

2 (probe tube erected in Zone

ZoneZone

Zone 0, sensor head ere

0, sensor head ere0, sensor head ere

0, sensor head erecccct-

t-t-

t-

ed in

ed in ed in

ed in Zone

ZoneZone

Zone 1)

1)1)

1)

T6 -40 °C … +40 °C (+50 °C)*

-20 °C … +60 °C

T5 -40 °C … +55 °C (+65 °C)*

T4, T3, T2, T1 -40 °C ... +85 °C (+75 °C)*

Equipment protection level

Equipment protection levelEquipment protection level

Equipment protection level Gb

Gb Gb

Gb resp.

resp.resp.

resp. category

categorycategory

category 2 (level sensor entirely erected in

2 (level sensor entirely erected in 2 (level sensor entirely erected in

2 (level sensor entirely erected in ZZZZoooone

nene

ne 1)

1)1)

1)

T6 -40 °C … +40 °C (+50 °C)* -40 °C ... +85 °C

T5 -40 °C … +55 °C (+65 °C)* -40 °C ... +100 °C

T4

-40 °C ... +85 °C (+75 °C)*

-40 °C ... +135 °C

T3 -40 °C ... +200 °C

T2 -40 °C ... +300 °C

T1 -40 °C ... +450 °C

*

It must be ensured through appropriate measures that at no point on the sensor head the temperature

(Ta) for the respective temperature class is exceeded.

General remark (see also EN 60079-0, clause 1):

Zone 0 is given only under atmospheric conditions:

Temperature range: -20 °C … +60 °C

Pressure range: 0.8 bar … 1.1 bar

Oxidants: Air (oxygen content of about 21 %)

VI

VIVI

VI Special conditions

Special conditionsSpecial conditions

Special conditions

1. If titanium floats are used, care must be taken during the installation and the operation that these

floats cannot cause any frictional and impact sparks.

2. The level gauge isn't signed with the permitted ambient temperature and the liquid temperature. The

relation between the temperature code, the permitted ambient temperature (Ta) and the permitted

liquid temperature (TF) shows the above tables or the EC-Type Examination Certificate.

*Values in parentheses are valid for level sensor TORRIX Ex … SC …

FAFNIR GmbH

Schnackenburgallee 149 c

22525 Hamburg

Germany

Tel.: +49 / 40 / 39 82 07–0

Fax: +49 / 40 / 390 63 39

E-mail: info@fafnir.com

Web: www.fafnir.com

Loading...

Loading...