Technical Documentation

THE COOL ONE

The calorimetric level sensor

08/2000

Issue: 1

FAFNIR GmbH • Bahrenfelder Str. 19 • D-22765 Hamburg • Phone: +49 (0)40-39 82 07-0 • Fax: +49 (0)40-3 90 63 39

© Copyright:

Reproduction and translation only with the written consent of the company FAFNIR.

FAFNIR reserves the right to carry out product alterations without prior notice.

Art. Nr. 207042

2

THE COOL ONE

Tabel of Contents

1 Characteristic features of the level sensor

THE COOL ONE ................................................ 4

2 Safety instructions .......................................... 5

3 Structure and mode of operation .................. 7

4 Installation .......................................................9

5 Technical data ................................................ 13

THE COOL ONE

3

1 Characteristic features of the level sensor

THE COOL ONE

The level sensor THE COOL ONE operates according to the

calorimetric measuring principle and serves the purpose of

monitoring liquids in tanks and other containers as well as in

conduits and pipes. It is used in many different industrial sectors

such as the machine and plant construction industry or the

chemical and pharmaceutical industry as an overflow protection,

level monitoring, min. and max. detection, dry running

protection, tank control and overflow safety device.

The evaluating electronics unit of this level sensor is integrated

in its probe tube, which makes this sensor a more compact and

space-saving device when compared with other liquidmonitoring systems equipped with an external evaluating unit.

The level sensor THE COOL ONE is extremely suitable for

monitoring liquids, the viscosity of which increases with rising

temperatures, and also for monitoring oil-containing liquids and

fats, as well as aggressive media.

The evaluating electronics unit controls two PNP open collector

outputs that provide the option of making the connection to a

PLC, valve, relay or lamp.

With the two or three different versions of the level sensor,

individual sensor or installation lengths can be adjusted

according to each type of container.

4

THE COOL ONE

2 Safety instructions

The level sensor THE COOL ONE serves the purpose of

monitoring liquids in tanks and other containers as well as in

conduits and pipes. Use the sensor for this purpose only. The

manufacturer shall not be liable for any form of damage

resulting from improper use!

The level sensor was developed, manufactured and inspected in

accordance with state-the-art technology and with recognised

technical safety rules and regulations. Nevertheless, hazards may

arise from the use of this sensor. Therefore, observe the

following safety instructions.

Do not change or modify the system or add any equipment

without the prior consent of the manufacturer.

The installation, operation and maintenance of the level sensor

is only allowed to be carried out by expert, authorised

personnel. Only experienced electricians are allowed to install

and service the level sensor. Specialised knowledge must be

obtained by undergoing regular training.

Operators, installers and service personnel must observe all

applicable safety regulations. This also applies to the local safety

regulations and accident prevention regulations not mentioned

in this manual of operating instructions.

For the installation of the level sensor, the response point must

not be located in areas of intensive gas flow.

Following the installation work and when changing the bearing

liquid, an inspection with respect to determining proper

installation and perfect operation must be carried out by an

expert of the specialised company or the owner-operator.

Electric circuits for horns and lamps that cannot be switched

according to the quiescent current principle must be easy to

check with respect to their operability.

Prior to putting the level sensor into service, all the devices of

the limit value indicator must be checked with respect to correct

connection and proper operation. The electrical power supply,

including the supply of the downstream devices, must be

checked.

THE COOL ONE

5

Not inspected system parts of the overfilling safety device must

comply with the requirements of the certification principles

specified for overfilling safety devices.

For overfilling safety devices, the specialised company or the

owner-operator of the level sensor is only allowed to use those

system parts without inspection symbols that comply with the

General Design Principles and with the Special Design Principles

of the design and inspection principles specified for overfilling

safety devices.

In case of failure of the auxiliary power supply (exceeding or

dropping below the limit values) or in case of interruption of

the connecting lines between the system parts, overfilling safety

devices must report these malfunctions or indicate the maximum

filling level.

The safety instructions in this instructions manual are labelled as

follows:

If you do not observe these safety instructions, risk of an

accident exists or the level sensor THE COOL ONE could be

damaged.

Useful information that will guarantee proper function of

the sensor or facilitate your work.

6

THE COOL ONE

3 Structure and mode of operation

The level sensor THE COOL ONE consists of an encapsulated PTC

thermistor and a probe tube, the height of which can be

adjusted using a clampable screw-in body, or which is

permanently installed using a fixed screw-in piece. The electrical

connection of the level sensor is made via the integrated

connection plug M12. (see Fig. 1)

For the detection of the liquid level, the encapsulated PTC

thermistor serves this purpose in the form of a varying resistance

at the response point of the level sensor, the resistance value of

which increases with rising temperatures (see Fig. 1).

Since liquids possess better thermal conduction values than

gases, the PTC thermistor heats up in air or gas spaces. In case of

submergence of the PTC thermistor in liquid, e.g. upon reaching

the liquid level, the PTC thermistor cools off and the resistance

value drops. The signal current is so limited that a re-heating of

the PTC thermistor in its submerged state is not possible. In a

gaseous environment, the heating-up time of the PTC thermistor

ranges from 15 seconds (at +80 °C ambient temperature) to two

minutes (at -25 °C ambient temperature).

THE COOL ONE

The evaluating electronics unit converts the resistance changes

of the PTC thermistor into a binary signal and controls two PNP

open collector outputs for connection to a PLC, valve, relay or

lamp.

On a optional basis, the level sensor is equipped with an

integrated testing function in accordance with AK3 which

checks the proper functional efficiency of the overfilling safety

device. This verification is carried out in the emerged state of

the level sensor using a magnet.

For the inspection of the overfilling safety device, the

sensor must be in its emerged and heated-up state.

7

The level sensor THE COOL ONE is available in three different

versions (types 1–3) (see Fig. 1).

Types 1 and 2 have a clampable screw-in body (thread 3/4), with

which the individual response length for each container can be

adjusted by moving the probe tube in the screw-in body. These

two types are highly suitable for installation above the liquid

level. (see Fig. 1 and Chap. 4 "Installation")

Type 3 is intended for installation laterally and below a liquid

level. This level sensor has a fixed screw-in piece (thread 3/8),

and the response length cannot be varied. (see Fig. 1)

probe length

response length

10

Type 1

Ø16

M12 plug

probe length

impressed

wrench size 27

thread 3/4

probe tube

PTC thermistor

response point

probe length

response length

2

Type 2

Ø16

M12 plug

probe length

impressed

wrench size 27

thread 3/4

probe tube

PTC thermistor

response point

Type 3

M12 plug

Ø16

12234

probe tube

wrench size 22

thread 3/8

PTC thermistor

response point

Fig. 1: THE COOL ONE (types 1–3) – structure

8

THE COOL ONE

4 Installation

For all work performed on the level sensor, observe the

national safety regulations and accident prevention

regulations as well as all the safety instructions in this

manual of operating instructions.

For the installation and operation of the level sensor, the

regulations of the equipment safety law as well as the

generally recognised rules and regulations of technology

and this manual of operating instructions shall prevail.

For the installation of the level sensor, make sure that the

response point is not located in areas of intensive gas

flow.

The installation position of the level sensor in the container

must be selected so that neither splashes of liquid nor excessive

gas flow can result in premature response of the level sensor.

The level sensor should be installed as perpendicularly as

possible so that any residual liquid can drop down from the

detector.

With the permissible filling degree in the container, you define

the response height (A) of the level sensor (types 1 and 2) (see

Fig. 2). The response length of the level sensor type 3 is not variable (see Chap. 6 "Technical data").

When using the level sensor as an overfilling safety device,

the permissible filling degree is calculated according to

TRbF (technical rules and regulations for flammable liquids)

280, Section 2.2. Take into account the switching delay

time (see Chap. 6 "Technical data").

Each probe length (Z) is permanently impressed at the top end

of the probe. The probe length is provided as a distance

dimension between this mark and the response point of the

level sensor. (see Fig. 2)

THE COOL ONE

9

In order to adjust the response length (L) as a distance between

the hexagon support of the screw-in body and the marking

groove of the protective sleeve of the detector at the bottom

end of the level sensor, proceed as follows (see Fig. 2):

• Calculate the response length (L) depending on the container

dimensions and the response height (A).

L = (H – A) + S

• Adjust the calculated response length (L) on the level sensor.

When the level sensor has been installed, the correct

adjustment of the response length (L) can be checked,

without removing the sensor, by means of the reference

dimension (Y) (= distance between the top end of the probe tube and hexagon support of the screw-in body and the

impressed probe length.

L = Z – Y

probe length impressed

Z

10

HS

ALY

Fig. 2: Adjustment dimensions

In order to lock the probe tube in place, proceed as follows:

• Tighten the gland bolt of the screw-in body firmly and lock it

by tightening down the locking screw.

• Provide the screw-in threads with suitable, resistant sealing

material and the screw the threads into the tank muff.

The electrical connection of the level sensor is made using an

M12 plug-in connector (see Fig. 1).

THE COOL ONE

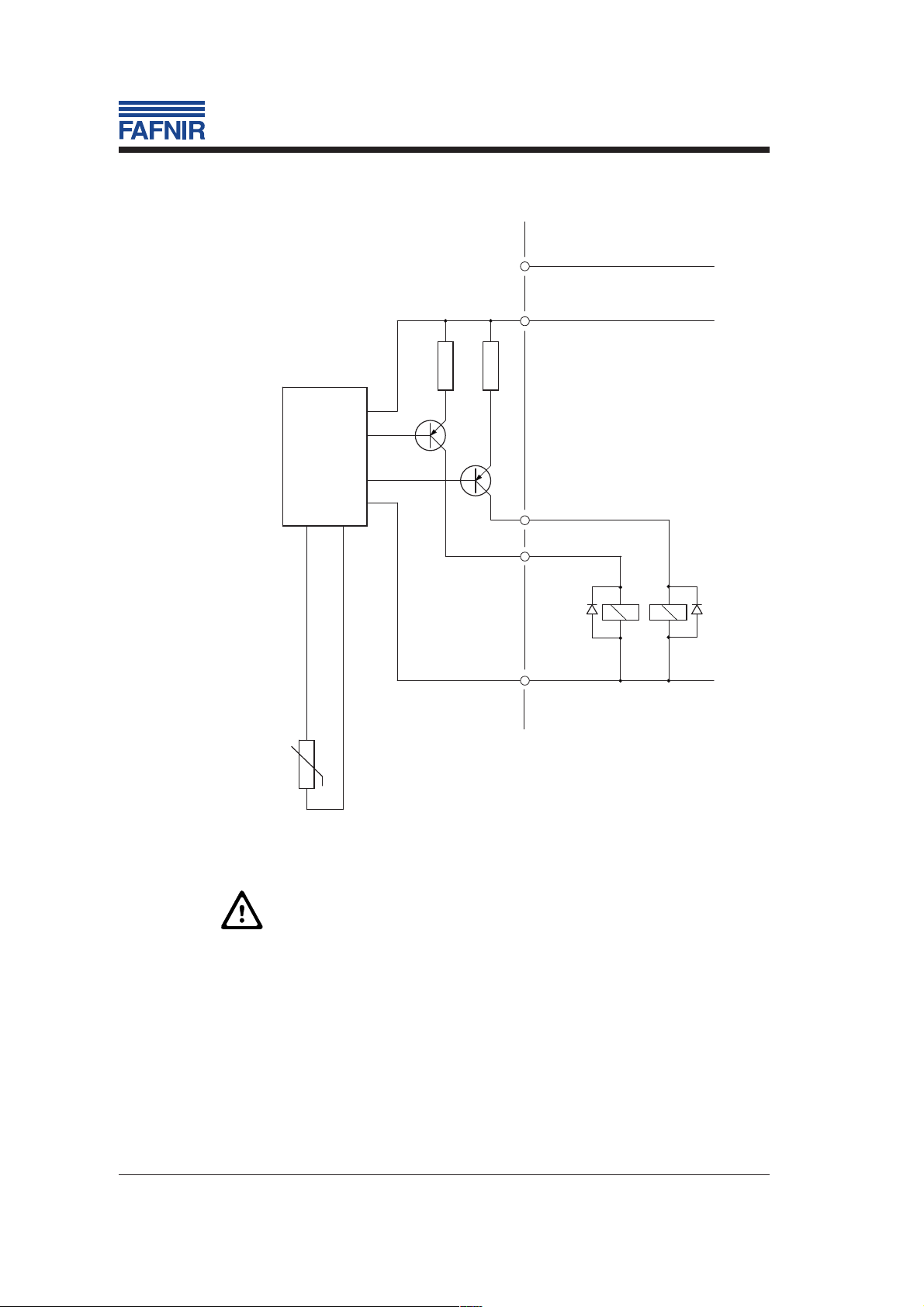

Fig. 3a and 3b each show an example of a terminal connection

diagram for a connection coupling with LEDs or relays (optional).

THE COOL ONE

measurement

evaluation unit

LED1

green

green/yellow

white

1,5 k

1,5 k

LED2

yellow

brown

black

1,5 k

LED3

yellow

blew

+

-

5

1

R1 4,7 Ω

T1

R2 4,7 Ω

T2

4

2

3

THE COOL ONE

PIN 2 = LED 2 (yellow) illuminated in submerged state

PIN 4 = LED 3 (yellow) illuminated in emerged state

+T

PTC

Output: max. 80 mA

Fig. 3a: Terminal connection diagram – example

11

THE COOL ONE

5 green/yellow

measurement

evaluation unit

PIN 2 = relay 1 pulled up in submerged state

PIN 4 = relay 2 pulled up in emerged state

+T

PTC

Output: max. 80 mA

1 brown

R1 4,7 Ω

R2 4,7 Ω

T1

T2

black

4

white

2

relay 1

D1 D2

3

blue

relay 2

+

-

12

Fig. 3b: Terminal connection diagram – example

Prior to putting the level sensor into service, all the

possible devices of the limit value indicator must be

checked to determine correction connection and proper

operation. In addition, the electrical power supply of the

downstream devices must also checked.

THE COOL ONE

5 Technical data

Auxiliary power: 24 V DC (±10 %)

Power input: < 2 W

Temperature range: media

Pressure range: 0 to 2 bar

Media compatibility: Materials of media-contacted parts

Type 1 brass: 2.0332

-25 °C to +50 °C

environment

-25 °C to +80 °C

stainless steel: 1.4301 to 1.4571 (DIN 17440)

spring steel: 1.248, galvanised (DIN 17222)

soldering tin: L-Sn 40 Pb

Viton: FPM

linear polyester: Ultradur

Type 2 stainless steel: 1.4301 to 1.4571 (DIN 17440)

Viton: FPM

Type 3 stainless steel: 1.4301 to 1.4571 (DIN 17440)

Submergence

switching delay: < 2 seconds

Heating-up/release time

Ambient temperature: at -25 °C < 2 min

at +80 °C < 15 sec

Housing protective

system: IP 67

Outputs: 2 x PNP open collector, max. 80 mA

Dimensions: tube diameter: 16 x 1.5

probe length (types 1 and 2): 200 to

3,000 mm, standard up to 1,000 mm

response length (type 3): 34 mm

THE COOL ONE

13

14

THE COOL ONE

Loading...

Loading...