Page 1

®

INSTALLATION INSTRUCTIONS

Toilet Flushometer Valve TMT1NNC

Toilet Flushometer Valve TMW1NNC

Toilet Flushometer Valve TMU1NNC

LIMITED WARRANTY

TOTO warrants its products to be made of first class materials, free from defects in material or workmanship,

under normal use, and to perform the service for which they are intended in a thoroughly reliable and

efficient manner when properly installed and serviced, for a period of three years from the date of purchase.

During this period TOTO will, at its option, repair or replace any part, or parts, which prove to be thus

defective if returned to TOTO, at the customer’s cost, and this shall be the sole remedy available under this

warranty. No claims will be allowed for labor, transportation, or other incidental costs. This warranty extends

only to persons or organizations who purchase TOTO’s products directly from TOTO for the purpose of

resale.

• THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE

HEREOF. IN NO EVENT IS TOTO RESPONSIBLE FOR ANY CONSEQUENTIAL DAMAGES OF ANY

MEASURE WHATSOEVER.

Page 2

PRIOR TO INSTALLATION

Prior to installing the Piston Flushometer Valve, install the items

listed below:

• Closet or urinal fixture

• Drain line

• Water supply line

The supply piping to these devices shall be securely anchored

to the building structure to prevent the installed device from

unnecessary movement when operated by the user. Care shall

be exercised when installing the device to prevent marring the

exposed significant surface.

1.

IMPORTANT:

• ALL PLUMBING IS TO BE INSTALLED IN ACCORDANCE WITH

APPLICABLE CODES AND REGULATIONS.

• WATER SUPPLY LINES MUST BE SIZED TO PROVIDE AN ADEQUATE VOLUME OF WATER FOR EACH FIXTURE.

•

FLUSH ALL WATERLINES PRIOR TO OPERATION.

The Piston Valve is designed to operate with water pressure as low as

10psi (69kPa). HOWEVER THE MINIMUM PRESSURE REQUIRED TO

OPERATE THE VALVE IS DETERMINED BY THE TYPE OF FIXTURE

SELECTED.

Pressure in excess of 100psi (690kPa) is not suitable for flushing any

plumbing fixture. Most codes mandate a maximum of 80psi; Please check

local code requirements.Protect the chrome or special finish of this

flushometer.

VICE THE VALVE.

Consult the fixture manufacturer for pressure requirements.

DO NOT USE TOOTHED TOOLS TO INSTALL OR SER-

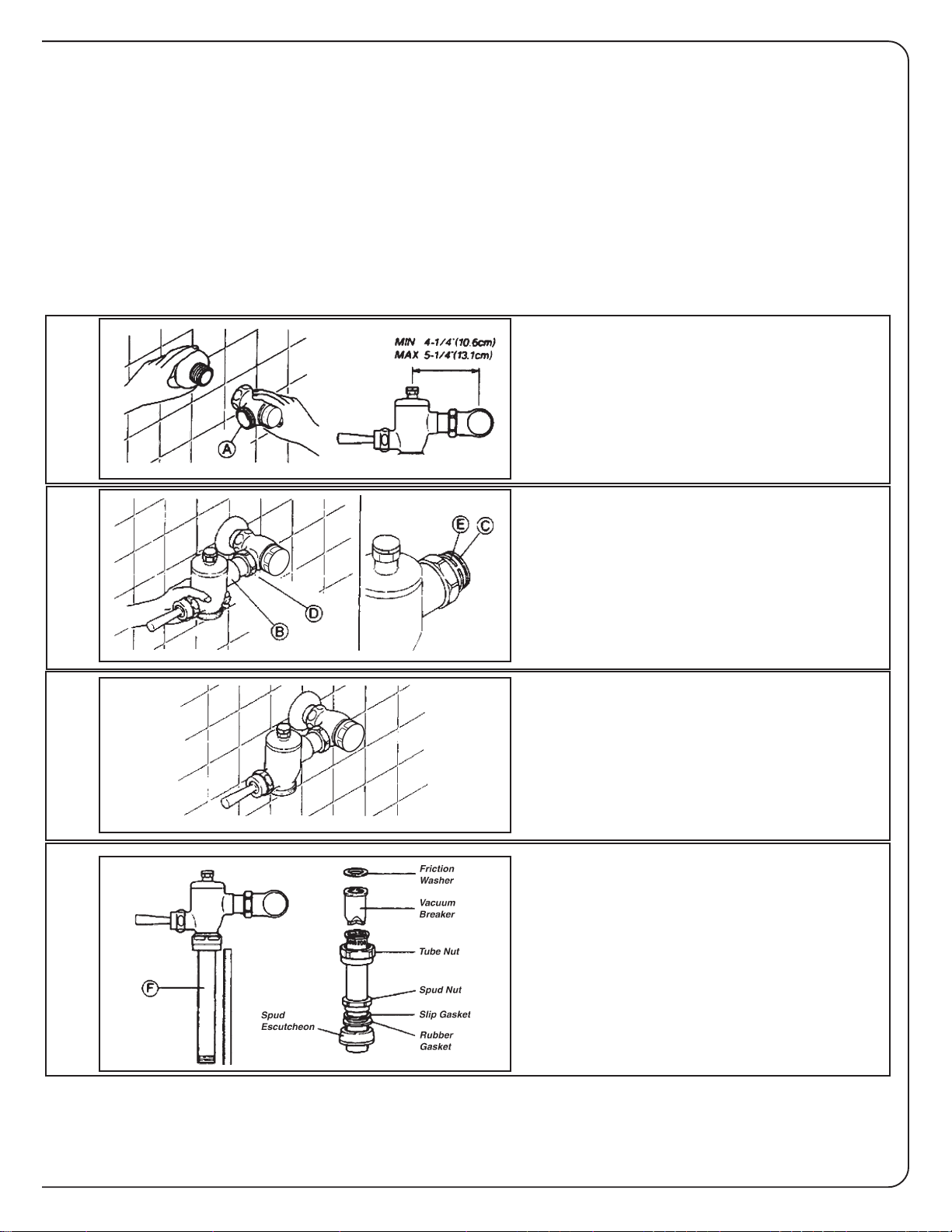

Install stop valve assembly A and wall flange.

Refer to shown rough in dimension. Thread

sealing compounds should be used on male

NPT threads only.

For sweat solder refer to instructions in the

sweat solder kit.

2.

3.

4.

Prior to inserting the flushometer valve tailpiece

B into the stop valve, be certain that the O-ring

seal C is located in the O-ring seal groove at

the end of the tailpiece, and the locking nut D

and locking snap ring E are located as shown.

Care should be taken not to damage the O-ring

when inserting the tailpiece into the stop valve.

If lubrication is needed, wetting the O-ring with

water will be sufficient.

Insert the flushometer valve tailpiece B into

the stop valve A and hand tighten the lock

nut D to the stop valve. Plumb the entire

unit.

Determine the length of vacuum breaker tube

F required to join the flushometer valve and

fixture spud. Cut the vacuum breaker tube, if

required, to this length. Assemble the vacuum

breaker tube assembly and spud nut assembly to the flushometer valve and fixture spud.

Page 3

Hand tighten the spud nut and vacuum breaker tube nut to the fixture and flushometer valve. Align and plumb

5.

the valve assembly. Tighten the fixture spud nut, vacuum breaker tube nut, and lock nut with a wrench.

6.

6a.

Before the water supply is turned on, be sure all

stop valves to the flush valves are closed off tightly.

The stop valves can be opened and closed by

using the adjustment screw located at the center

of the stop valve cap G, behind the adjustment

screw cover if already installed. Stop valve adjustments can only be made by using the adjustment screw. If for any reason, it becomes necessary to remove the stop valve cap G, be certain

that the water is shut off at the main supply valve.

For new installations, we recommend the following steps:

Shut off stop valve and remove flushometer cover.

Lift out the piston valve. Install the flushometer

cover and open the stop valve to flush the line of

any debris and sediment.

After completion, shut off the stop valve, remove

the flushometer cover and reinstall the piston

valve. Reinstall the flushometer cover securely.

Open the stop valve and activate the flushometer

valve.

7.

8.

Flushometer valves are preset for fixture volume

as marked on the valve cartons. The valve does

not require adjustment for variations in water

pressure within its operating range. To set the

flushometer valve for proper operation, open the

stop valve completely by turning the adjustment

screw and flush the Flushometer valve several

times. Gradually adjust the stop valve down, using the adjustment screw, so that the rate of water flow into the fixture is not excessive, yet is

sufficient to adequately evacuate the waste. The

final setting for urinals should be such that the

fixture will not overflow when the valve is actuated several times in succession.

The stop cap screw cover should be replaced

and tightly secured after final adjustments have

been made.

Page 4

Specifications

Flush volume: TMT1NNC - 6.0LPF (1.6GPF) TMW1NNC - 13.3LPF (3.5GPF) TMU1NNC - 3.8LPF (1.0GPF)

Protect the Chrome or Special finish of the flushometer. DO NOT USE TOOTHED TOOLS TO INSTALL OR SERVICE THE VALVE.

A non-hold open feature is standard on these valves.

Sweat Solder Adapter Installation Instructions

Step No. 1

Measure distance from finished wall to center line of

fixture spud; cut water supply pipe 1-1/4" shorter

than this measurement. Chamfer O.D. and I.D.

OF FIXTURE

C

SPUD

11/4"

WATER SUPPLY PIPE

FINISHED WALL

Step No. 2

Slide threaded adapter onto supply pipe

until shoulder stops on end of pipe. Then

sweat-solder the adapter to water supply pipe.

SWEAT ADAPTER

Step No. 3

Measure from finished wall to first thread

of adapter for length of chrome tube. Cut

chrome tube at this length "x"".

'x'

Step No. 4

Slide wall escutcheon over chrome

tube and slide both chrome tube and

wall escutcheon over supply pipe

pushing the wall escutcheon all the

way to the wall.

CHROME TUBE

WALL ESCUTCHEON

CONTROL

STOP

FINISHED WALL

Troubleshooting Guide

PROBLEM CAUSE SOLUTION

Valve will not operate.

Valve does not shut off.

Not enough water to fixture.

Too much water for fixture;

noisy flush.

Water supply is shut off.

Dirt in Piston bypass hole.

Dirt or debris at valve seat or sealing-area.

Wrong flushometer valve unit

installed.

Control stop improperly adjusted.

Piston is damaged.

Piston Stroke is too short.

Wrong flushometer valve unit

installed.

Control stop improperly adjusted.

Turn on water supply and open control stop.

Clean bypass groove by flushing awat debris.

Clean valve seat and clean piston.

replace seat seal if needed.

Check fixture requirements.

Install proper flushometer valve unit.

Adjust control stop

Replace Piston.

Turn Piston Adjustment Screw counter-clockwise.

Check fixture requirements.

Install proper flushometer valve unit.

Adjust control stop by turning the screw clockwise.

Step No. 5

Screw control stop onto water

supply pipe adapter.

.

Lever assembly leaks.

bypass groove

Piston Stroke is too long.

Lever nut is loose.

Fiber washer is damaged.

U-packing is dirty.

Turn Piston Adjustment Screw clockwise.

Tighten nut.

Replace washer.

Disassemble lever & clean U-packing.

U.S, Subsidiary: TOTO U.S.A., Inc. 1155 Southern Road, Morrow, GA 30260

Tel. (800) 877-1541 Fax (770) 961-9646 Printed in the U.S.A. by TOTO LTD. 04/04

0GU3001 04/04

Loading...

Loading...