Page 1

Installation and Owner’s Manual

Manual de Instrucciones y del Propietario

Manuel d’Installation et d’Utilisation

Single Handle lavatory Faucet 1.5gpm [ 5.7lpm ]

griFo de lavabo individual 1.5gpm [ 5.7lpm ]

obinet de lavabo à poignée unique 1.5gpm [ 5.7lpm ]

r

ENGLISH ESPAÑOL FRANÇAIS

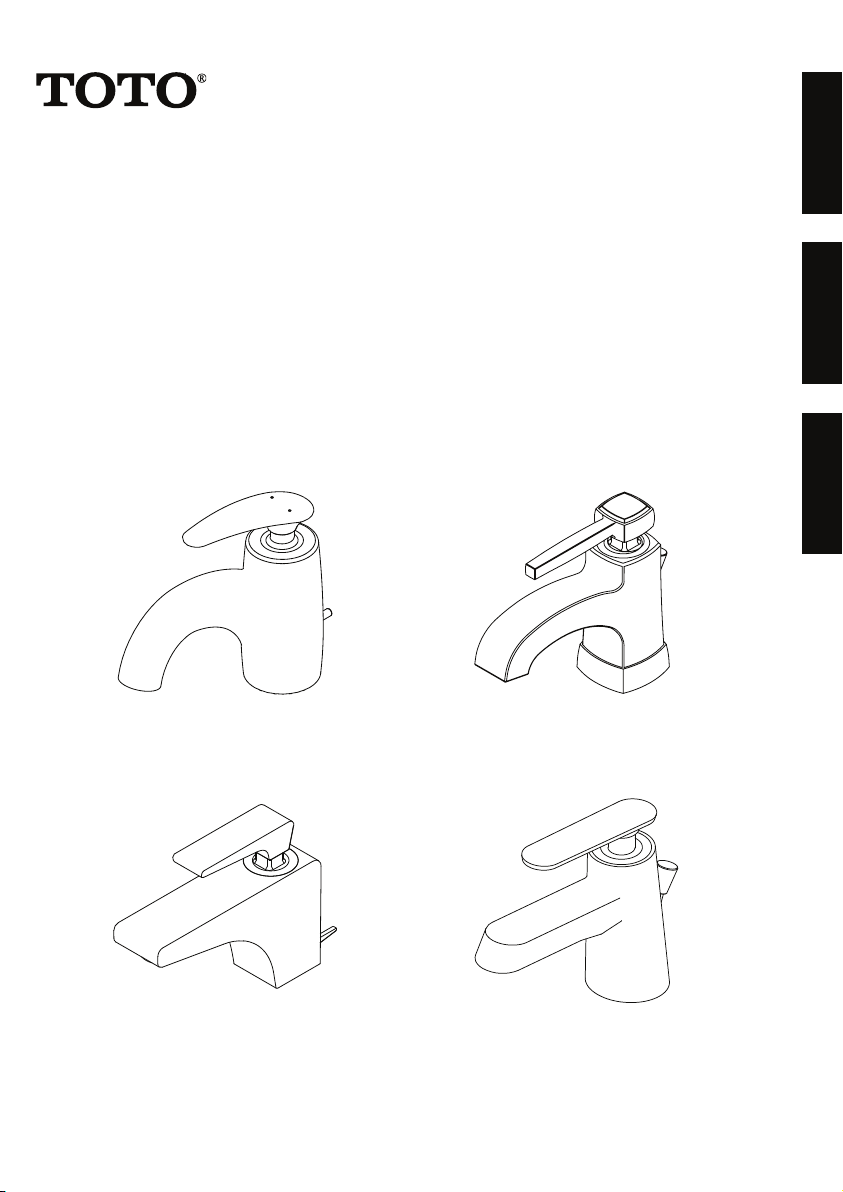

eThoS

TL660SDL

DeSign L

CoLLeCTion

TL670SDL

DeSign ni

®

TL680SDL

DeSign C

TL690SDL

DeSign nii

Page 2

TabLe of ConTenTS

THANKS FOR CHOOSING TOTO®! ...........................................................................2

CARE AND CLEANING ...............................................................................................2

ENGLISH

CAUTION .............................................................................................................. .........2

BEFORE INSTALLATION ................................................................................... .........3

TOOLS YOU WILL NEED ................................................................................... .........3

INSTALLATION PROCEDURE .......................................................................... .........4

TROUBLESHOOTING ......................................................................................... .........6

ROUGH IN ........................................................................................................... .........7

REPLACEMENT PARTS .................................................................................... .........11

WARRANTY ....................................................................................................... .........15

ThankS for ChooSing ToTo®!

TOTO’s® mission is to provide the world with healthy, hygienic and

more comfortable lifestyles. We design every product with the balance

of form and function as a guiding principle. Congratulations on your

choice.

Care anD CLeaning

Your new faucet is designed for years of trouble-free performance.

Keep it looking new by cleaning it periodically with mild soap, rinse

thoroughly with warm water and dry with a clean, soft cloth. Do not

use abrasive cleaners, steel wool or harsh chemicals as these will dull

the nish. Failure to follow these instructions may void your warranty.

CauTion

For safe operation of the faucet, please observe the following:

Operating pressure:

Minimum Pressure……..7psi [0.05MPa] (owing pressure)

Maximum Pressure…….108psi [0.75MPa] (non-owing pressure)

Do not reverse the hot and cold-water inlets

Hot water supply temperature must not exceed 185°F [85°C]

Do not use steam for hot water supply

Do not use the product at ambient temperature below 32°F (0°C).

Do not disassemble the ceramic valve

To ensure the product maintains its specied ow rate to meet EPA

standard, always use the manufacturer’s specied aerator for that faucet

2

Page 3

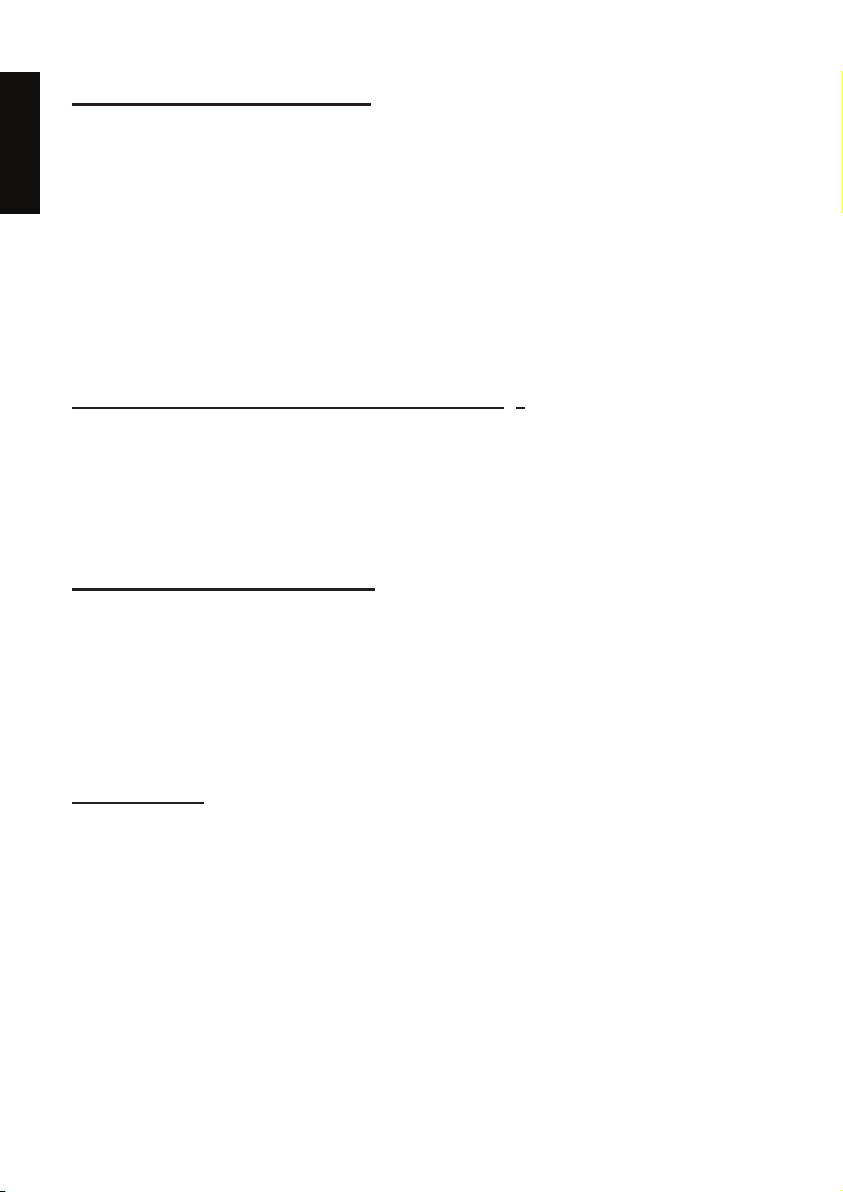

TooLS you wiLL neeD

ENGLISH

Pipe Tape Adjustable

Wrench

Adjustable

Pliers

Screwdrivers

Socket

Wrench

before inSTaLLaTion

Observe all local plumbing codes

Make sure water supply is shut off

Read these instructions carefully to ensure proper installation

TOTO® reserves the right to update product design without notice

Check to make sure you have the following parts indicated below

TL660SDL TL670SDL TL680SDL TL690SDL

Spout Unit

Aerator Key

1 piece

1 piece

Drain

Assembly

Pivot Rod &

Connection

Block

Repair Tool

Hex Wrench

1 piece

1 piece each

1 piece

1 piece

3

Page 4

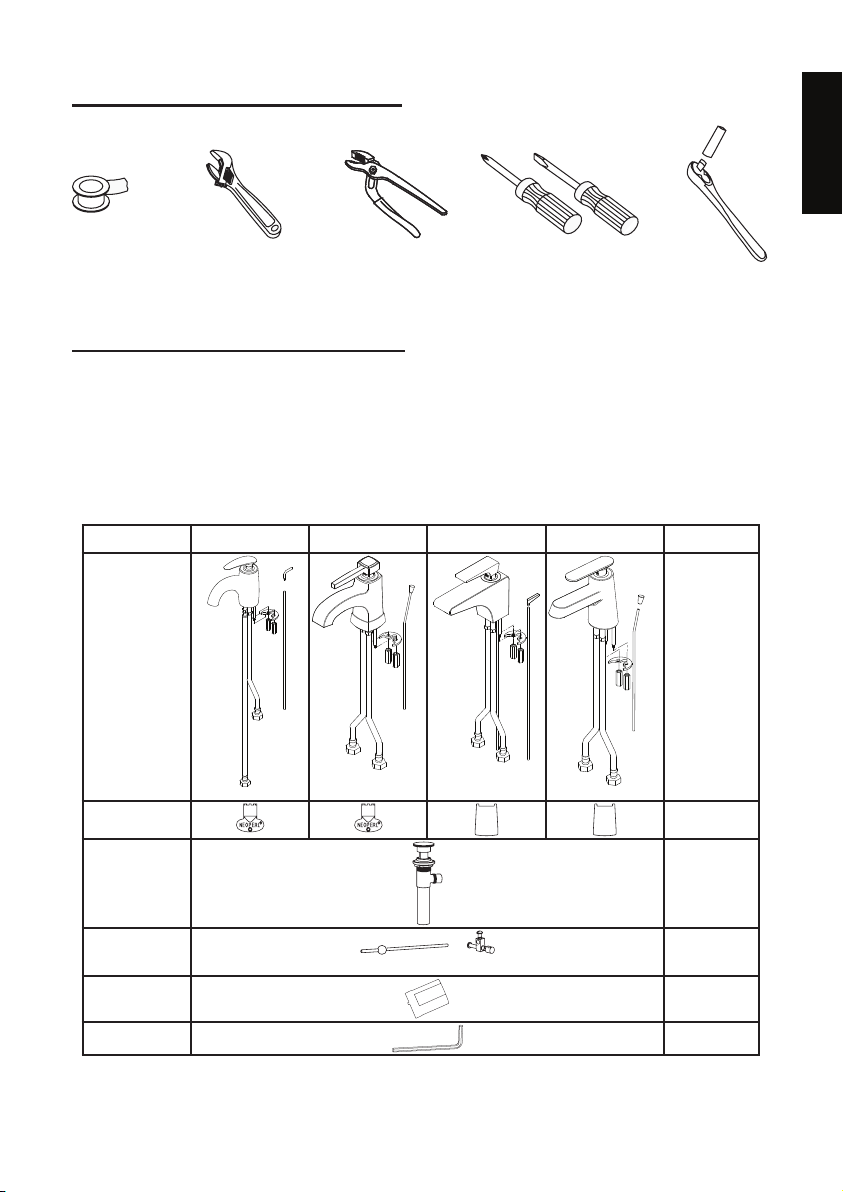

inSTaLLaTion ProCeDure

1. F

aucet body inStallation

ENGLISH

Insert exible hoses and

lift rod through the hole

on deck one at a time

If lift rod is not yet

installed, insert the lift

rod from underside of the

faucet and thread it into

the lift knob.

Slide the bracket into

place and secure the spout

with locknuts

Adjust the spout to face

forward. Hold the spout

in place. Tighten locknuts

Connect ex hoses to

supply lines. Make sure

the left hose connects to

the hot supply line and the

right hose connects to the

cold supply line

Handle

Flex Hose

Lift Knob

Bracket

Locknut

Lift Rod

Hot

Inlet

4

Cold

Inlet

Page 5

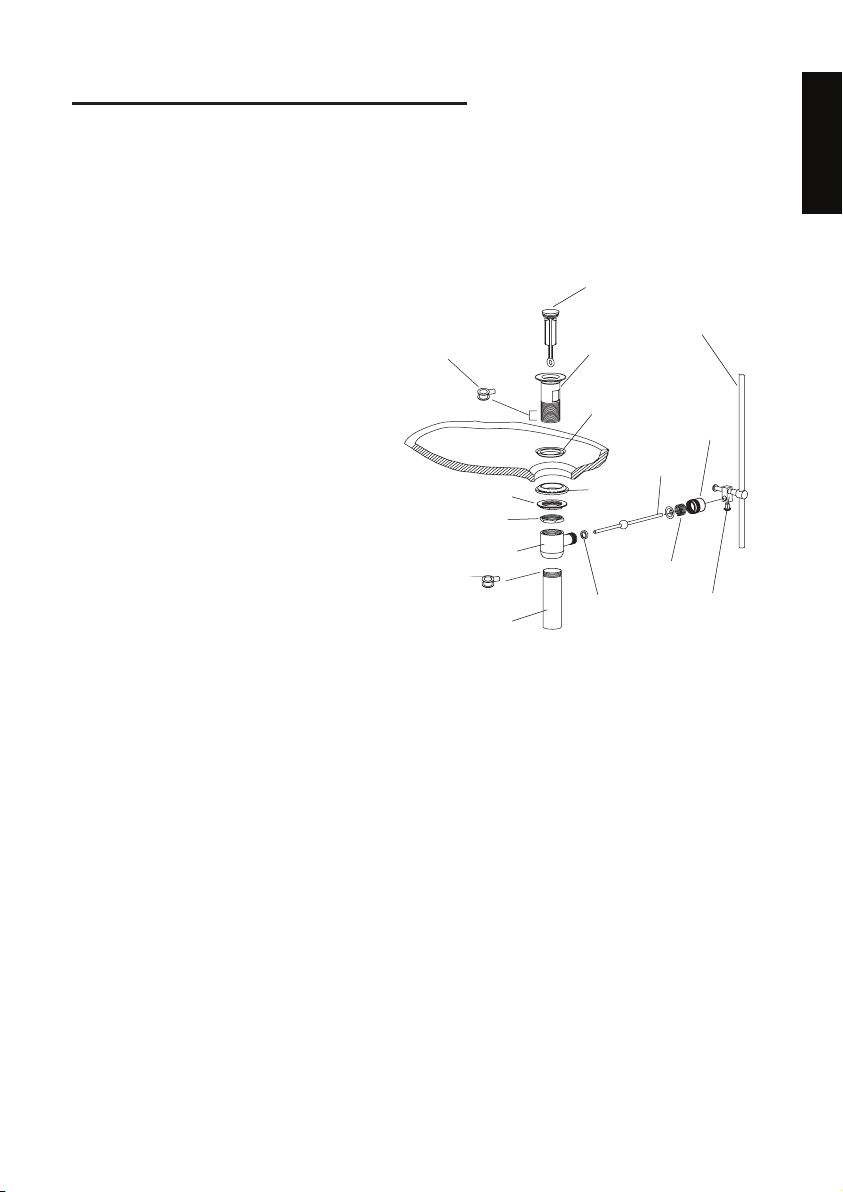

inSTaLLaTion ProCeDure

rain inStallation

2. d

Apply pipe tape to the

ange threads

Insert ange into the

drain hole

Assemble the gasket,

ange nut, and lock

nut

Install the drain body

onto the ange

Secure the drain

assembly by tightening

the ange nut and

locknut

Apply pipe tape to

the threads of the tail

piece and install the

tail piece to the drain

body

Insert the drain stopper

into the ange

Assemble the pivot

rod as shown in the

diagram

Insert the pivot rod

into the drain stopper

hole. Tighten the lock

nut

Insert the lift rod and

pivot rod into the

connecting block.

Tighten both rods with

screwdriver

Pipe Tape

Flange Nut

Locknut

Drain Body

Tail Piece

Drain Stopper

Flange

Gasket

Gasket

Seal

ENGLISH

Lift Rod

Nut

Pivot Rod

Spring

Connecting

Block

5

Page 6

TroubLeShooTing

1

2

If you have followed the instructions carefully and your

ENGLISH

3. Valve lock nut

Is it properly tightened?

faucet still does not work properly, take these corrective

action steps

Problem AreA to InsPect

low wAter Flow 6

l

oose HAndle 1, 2, 3

l

oose sPout 7

l

eAkAge 3, 4, 5, 8,

1. Set Screw

Is it properly tightened?

2. Screw

Is it properly tightened?

4. Cartridge

Is it damaged or dirty

5.Gasket/O-ring

Is it damaged or dirty

6. Aerator

Is it damaged or dirty

8. Flex hose

Is it properly tightened?

Locknuts

7. Is it properly tightened?

To access cartridge with

valve lock nut removal tool

6

Page 7

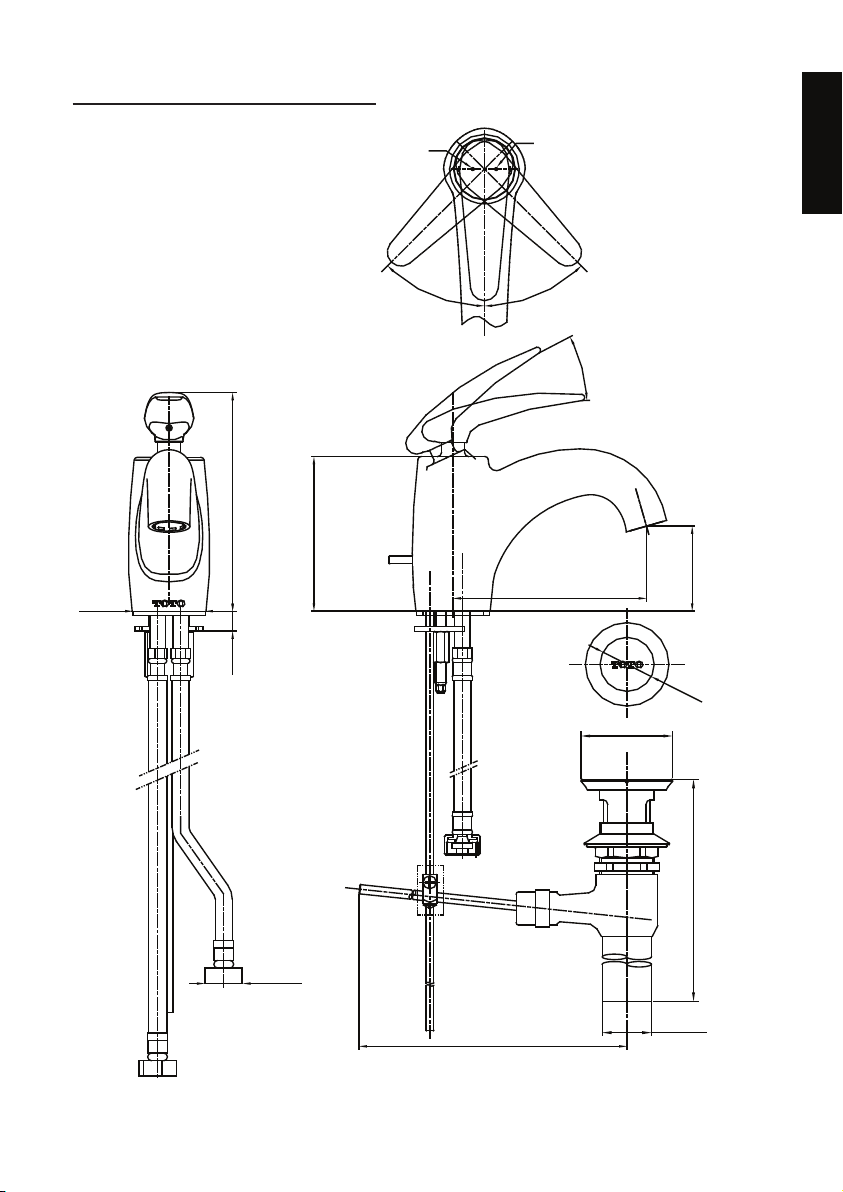

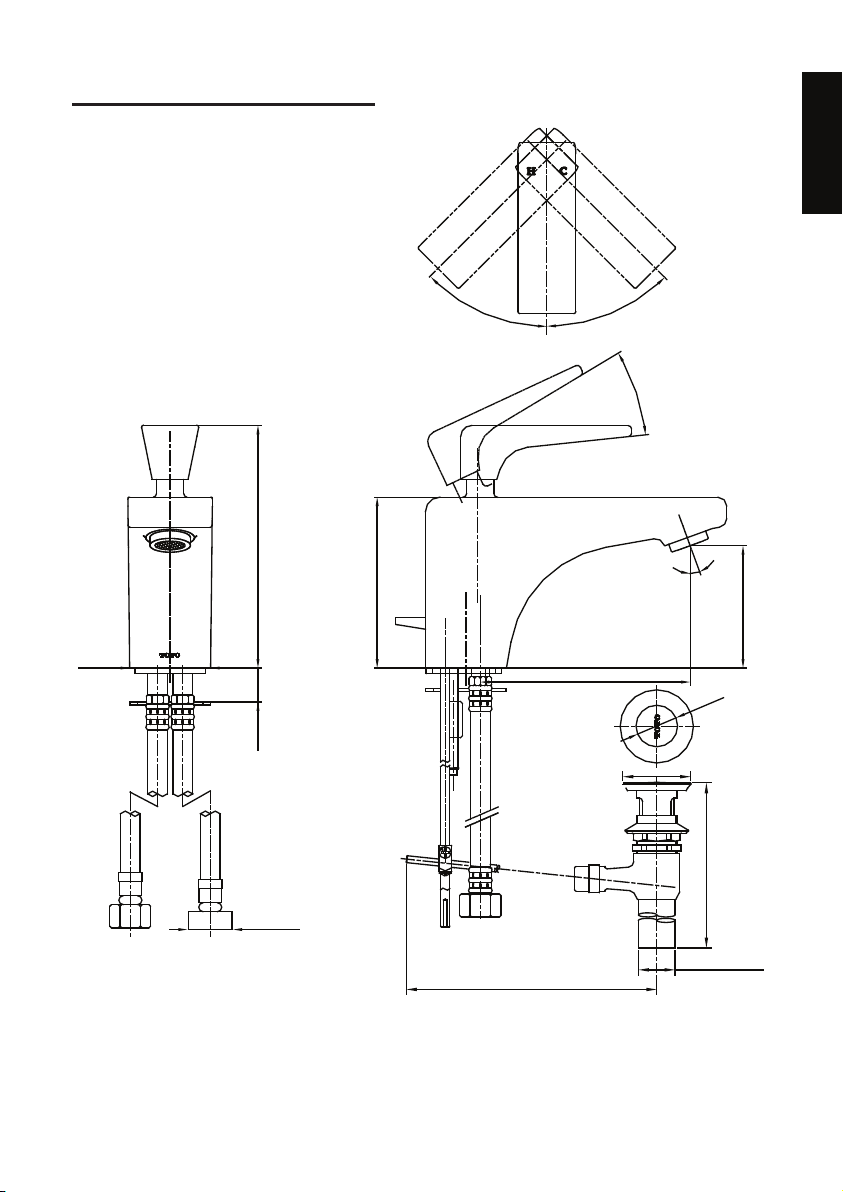

rough in (TL660SDL)

3/8" Comp

1-15/16”

(50 mm)

(25 mm)

1” (max)

(141 mm)

3-7/8”

(99 mm)

5-1/2”

2-3/16”

(55 mm)

(130 mm)

5-1/8”

Off

25º

On

45º

Cold

Hot

45º

Red

Blue

ø1-5/16”

(ø34 mm)

ø2-1/8”

(ø54 mm)

7-3/8”

(187 mm)

ø1-1/4”

ø31 mm (T=1)

(265 mm)

10-7/16”

ENGLISH

7

Page 8

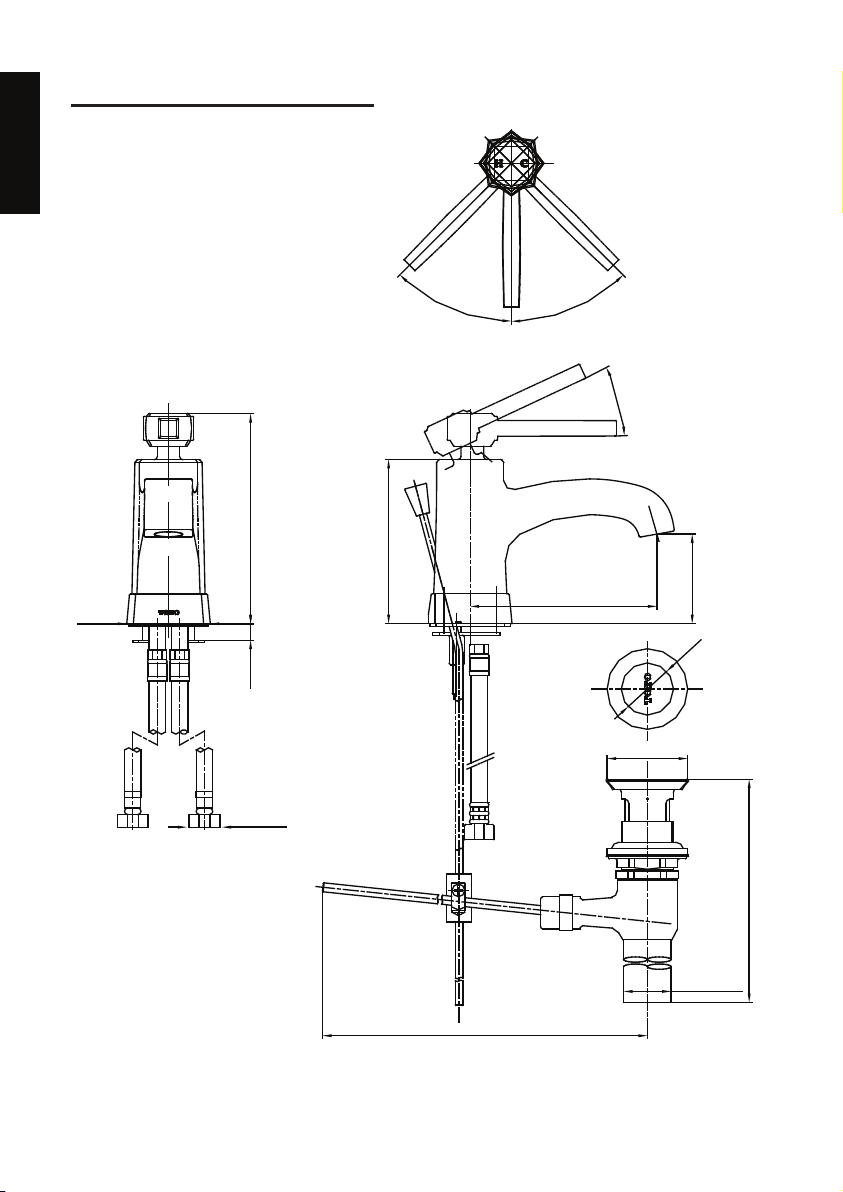

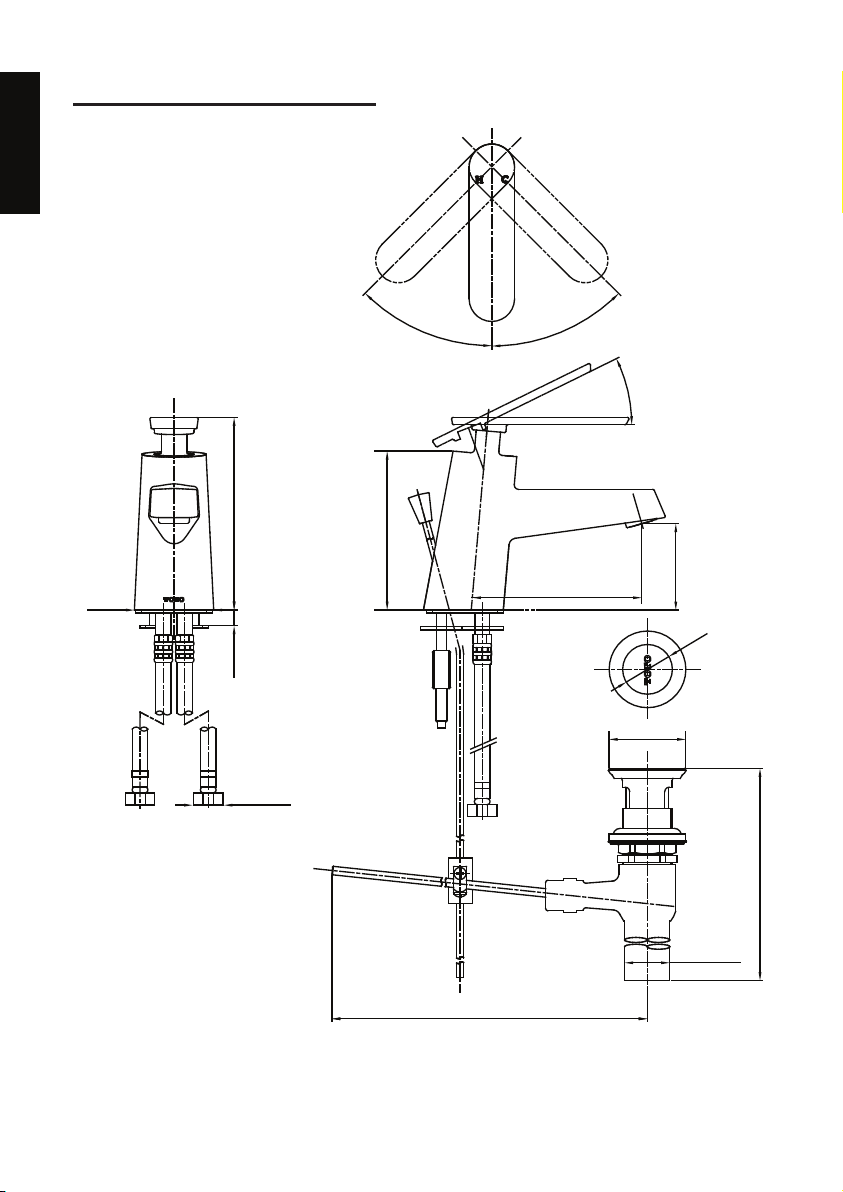

rough in (TL670SDL)

3/8” Comp

(25 mm)

1” (max)

2-3/16”

(56 mm)

5-9/16”

(141 mm)

45º

Cold

45º

Hot

On

Off

25º

2-3/8”

(60 mm)

4-7/8”

(125 mm)

(109 mm)

4-5/16”

ø1-5/16”

(ø34 mm)

ø2-1/8”

(ø54 mm)

(187 mm)

7-3/8”

ø1-1/4” (T=1.0)

ø31 mm (T=1.0)

(265 mm)

10-7/16”

ENGLISH

8

Page 9

rough in (TL680SDL)

3/8” Comp

1” (max)

(125 mm)

(134 mm)

5-1/4”

1-3/4"

(45 mm)

3-3/4”

(95 mm)

(67 mm)

2-5/8”

7-3/8”

(187 mm)

(265 mm)

10-7/16"

ø31 mm (T=1)

ø1-1/4” (T=1)

ø2-1/8” (ø54 mm)

(ø34 mm)

ø1-5/16”

4-5/8”

(118 mm)

20º

Off

On

25º

50º

50º

Cold

Hot

ENGLISH

9

Page 10

rough in (TL690SDL)

1” (max)

(25.5 mm)

2-1/4”

(56.2 mm)

5-9/16”

(136 mm)

45

º

45

º

Cold

Hot

On

Off

25

º

(60 mm)

2-1/4”

(121 mm)

4-3/4”

(112 mm)

4-7/16”

(

ø

34 mm)

ø

1-5/16

”

(ø54 mm)

ø2-1/8”

7-3/8”

(187 mm)

ø31 mm (T=1.0)

ø1-1/4”

(265 mm)

10-7/16”

3/8” Comp

ENGLISH

10

Page 11

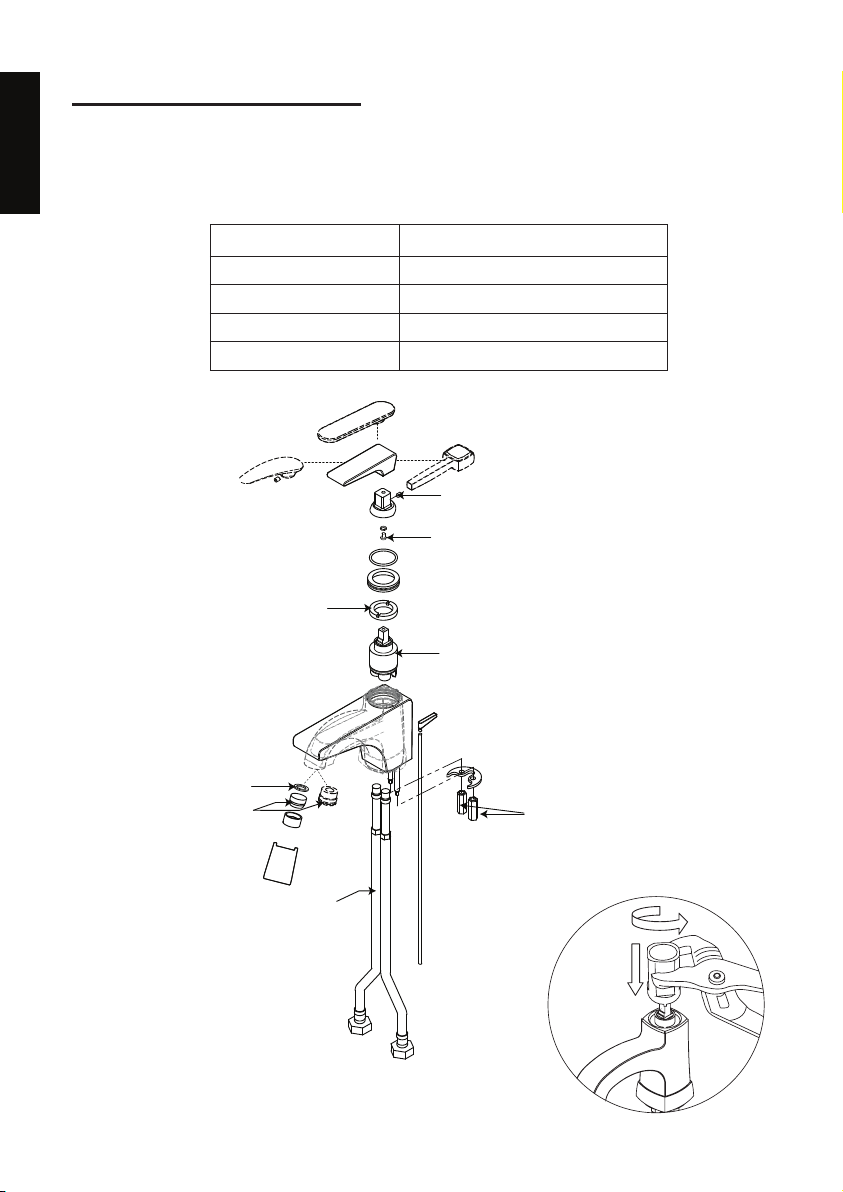

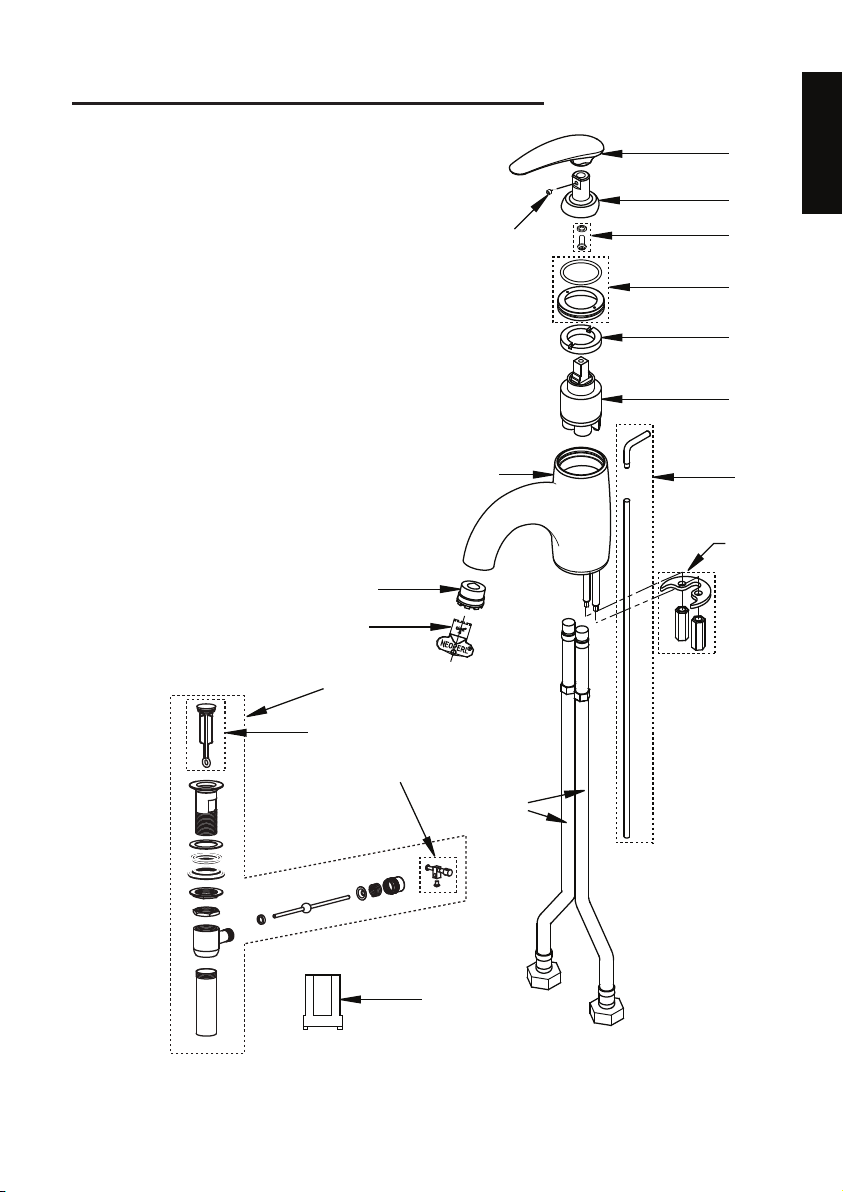

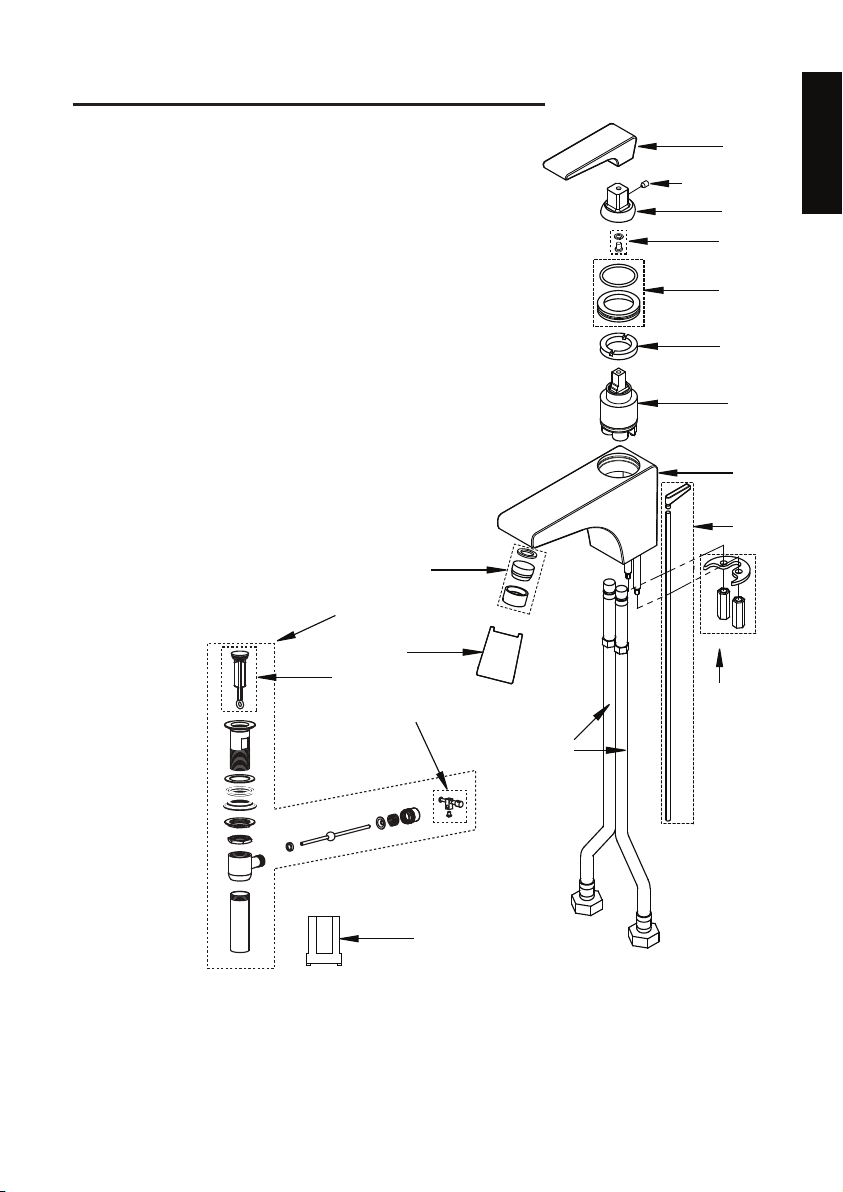

rePLaCemenT ParTS (TL660SDL)

14

15

16

1

2

3

4

5

6

7

9

10

8

11

12

13

17

1 tHP4272 * desIgn l sIngle HAndle

2 tHP4276 * HAndle AdAPter

3 tHP4263 screw & wAsHer

4 tHP4167 set screw

5 tHP4264 * o-rIng cAP

6 tHP4265 VAlVe lock nut

7 tHP4004 cerAmIc cArtrIdge

8 tHP4273 * desIgn l sPout body

9 tHP4184 * lIFt rod

10 tHP4007 brAcket & lock nuts

11 9Au4248 AerAtor kIt

12 tHP4182 AerAtor key

13 tHP4404 Flex Hoses

14 tHP4207 * drAIn Assembly

15 tHP4011 * drAIn Plunger

16 tHP4012 lIFt rod connector

17 tHP4271 VAlVe lock nut remoVAl tool

ENGLISH

*PleAse IndIcAte FInIsH code wHen PlAcIng order

11

Page 12

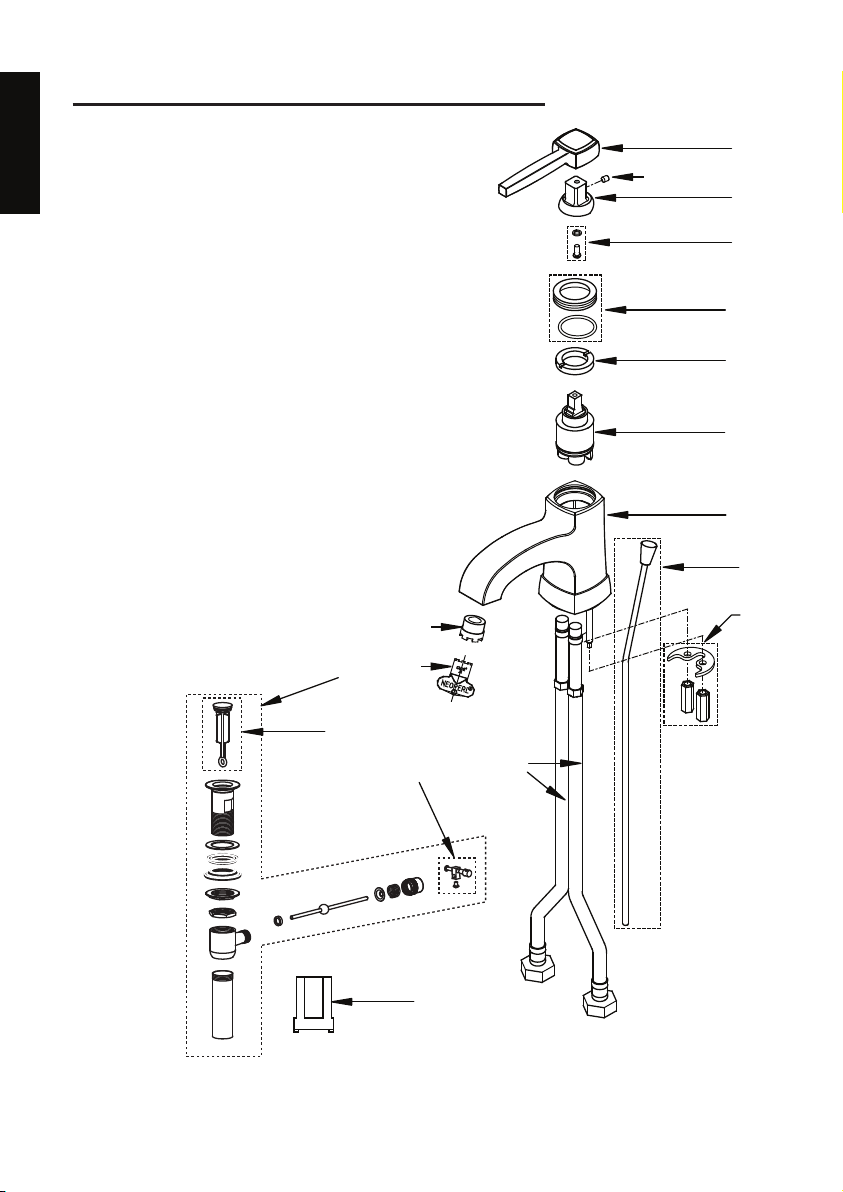

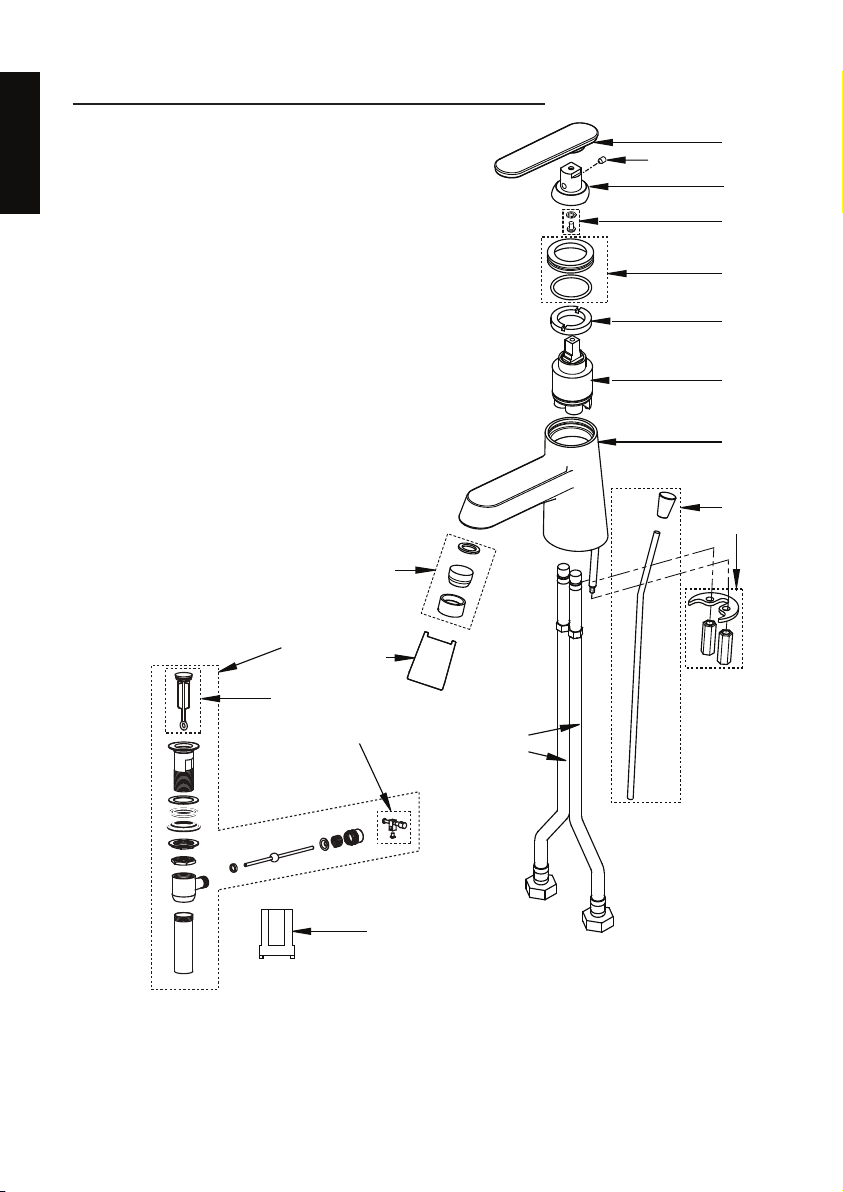

rePLaCemenT ParTS (TL670SDL)

14

15

16

12

8

1

3

2

4

5

6

7

9

10

11

13

17

1 tHP4277 * desIgn nI sIngle HAndle

2 tHP4262 * HAndle AdAPter

ENGLISH

3 tHP4263 screw & wAsHer

4 tHP4167 set screw

5 tHP4264 * o-rIng cAP

6 tHP4265 VAlVe lock nut

7 tHP4004 cerAmIc cArtrIdge

8 tHP4278 * desIgn nI sPout body

9 tHP4279 * lIFt rod

10 tHP4007 brAcket & lock nuts

11 9Au4249 AerAtor kIt

12 tHP4193 AerAtor key

13 tHP4404 Flex Hoses

14 tHP4207 * drAIn Assembly

15 tHP4011 * drAIn Plunger

16 tHP4012 lIFt rod connector

17 tHP4271 VAlVe lock nut remoVAl tool

*PleAse IndIcAte FInIsH code wHen PlAcIng order

12

Page 13

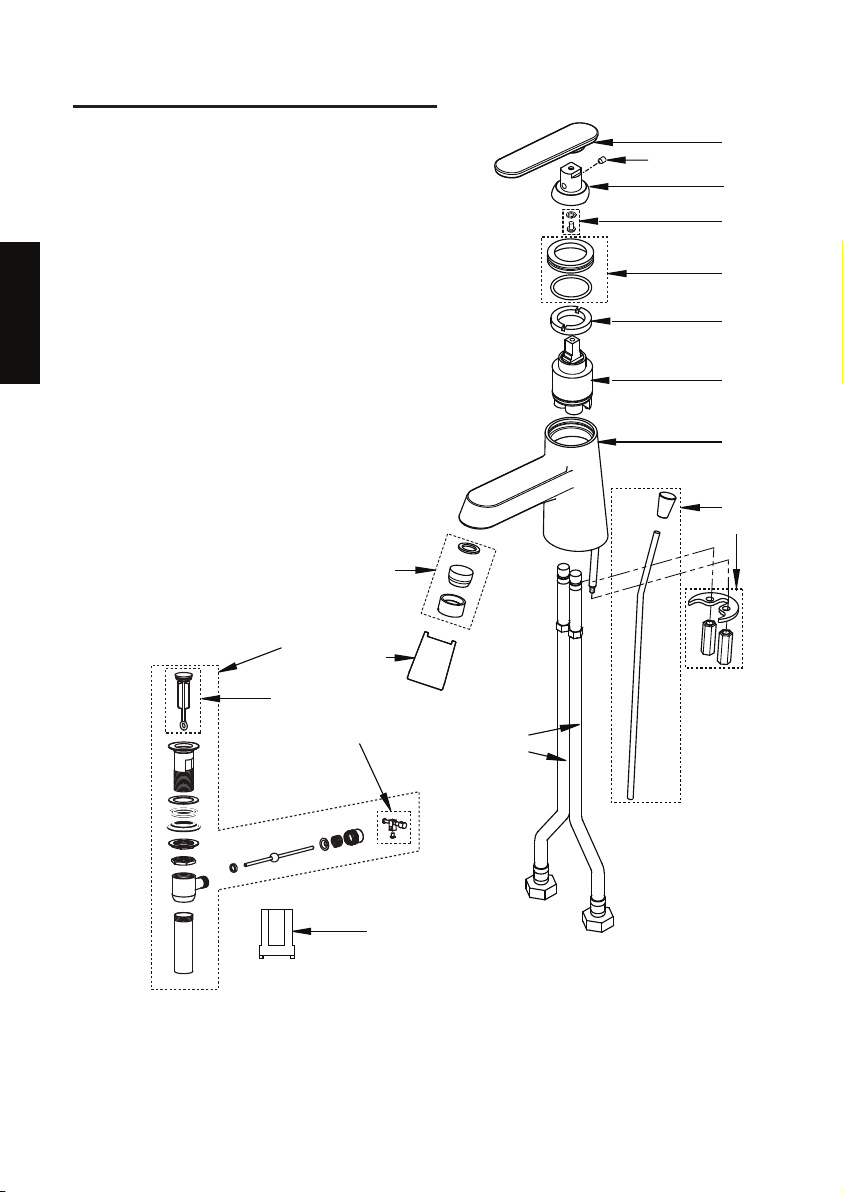

rePLaCemenT ParTS (TL680SDL)

2

8

9

3

5

6

4

1

7

10

11

13

12

14

15

16

17

1 tHP4261 * desIgn c sIngle HAndle

2 tHP4262 * HAndle AdAPter

3 tHP4263 screw & wAsHer

4 tHP4167 set screw

5 tHP4264 * o-rIng cAP

6 tHP4265 VAlVe lock nut

7 tHP4004 cerAmIc cArtrIdge

8 tHP4266 * desIgn c sPout body

9 tHP4267 * lIFt rod

10 tHP4007 brAcket & lock nuts

11 tHP4406 * AerAtor kIt

12 tHP4101 sPout key

13 tHP4423 Flex Hoses

14 tHP4207 * drAIn Assembly

15 tHP4011 * drAIn Plunger

16 tHP4012 lIFt rod connector

17 tHP4271 VAlVe lock nut remoVAl tool

ENGLISH

*PleAse IndIcAte FInIsH code wHen PlAcIng order

13

Page 14

rePLaCemenT ParTS (TL690SDL)

14

15

16

1

2

3

5

4

8

7

6

9

11

10

13

12

17

1 tHP4280 * desIgn nII sIngle HAndle

2 tHP4281 * HAndle AdAPter

ENGLISH

3 tHP4282 screw & wAsHer

4 tHP4167 set screw

5 tHP4264 * o-rIng cAP

6 tHP4265 VAlVe lock nut

7 tHP4004 cerAmIc cArtrIdge

8 tHP4283 * desIgn nII sPout body

9 tHP4279 * lIFt rod

10 tHP4007 brAcket & lock nuts

11 tHP4406 * AerAtor kIt

12 tHP4101 sPout key

13 tHP4404 Flex Hoses

14 tHP4207 * drAIn Assembly

15 tHP4011 * drAIn Plunger

16 tHP4012 lIFt rod connector

17 tHP4271 VAlVe lock nut remoVAl tool

*PleAse IndIcAte FInIsH code wHen PlAcIng order

14

Page 15

warranTy

LIFETIME LIMITED WARRANTY

Warranty applies to selected residential faucets only.

1. TOTO® warrants its faucets (“Product”) to be free from defects in materials and workmanship

during normal residential use for as long as the original consumer end-user purchaser owns their

home. This limited lifetime warranty is extended only to the original consumer end-user purchaser

and only so long as the Product remains in use by the original consumer end-user purchaser in its

original place of installation in the purchaser’s residence. This warranty applies only to Product

purchased and installed in North America.

2. TOTO

of Product or parts found to be defective in normal residential use, provided that such Product was

properly installed and used in accordance with the owner’s manual. TOTO

make such inspections as may be necessary in order to determine the cause of the defect.

3. This warranty does not apply to the following items:

a) Damage or loss sustained in a natural calamity such as re, earthquake, ood,

thunder, electrical storm, etc.

b) Damage or loss resulting from any accident, unreasonable use, misuse, abuse,

negligence, or improper care, cleaning or maintenance of the Product.

c) Damage or loss resulting from sediments or foreign matter contained in a water

system.

d) Damage or loss resulting from improper installation or from installation of the

Product in a harsh and/or hazardous environment, or improper removal, repair or

modication of the Product.

e) Damage or loss resulting from the use of an abrasive cleanser.

4. If the Product is used commercially, TOTO

defects in materials and workmanship for one (1) year from the date the Product is

installed, with all other terms of this warranty applicable except the duration of the

warranty.

5. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE

OTHER RIGHTS, WHICH VARY FROM STATE TO STATE OR PROVINCE TO

PROVINCE.

6. To obtain warranty repair service under this warranty, you must take the Product

or deliver it prepaid to a TOTO

receipt) together with a letter stating the problem, or contact a TOTO® distributor or

products service contractor, or write directly to TOTO

road, Morrow, Georgia 30260, (888) 295-8134. If, because of the size of the Product

or nature of the defect, the Product cannot be returned to TOTO

of written notice of the defect together with proof of purchase (original sales receipt)

shall constitute delivery. In such case, TOTO

purchaser’s location or pay to transport the Product to a service facility.

THIS WRITTEN WARRANTY IS THE ONLY WARRANTY MADE BY TOTO®.

REPAIR, REPLACEMENT OR OTHER APPROPRIATE ADJUSTMENT AS

PROVIDED UNDER THIS WARRANTY SHALL BE THE EXCLUSIVE REMEDY

AVAILABLE TO THE ORIGINAL PURCHASER. TOTO

RESPONSIBLE FOR LOSS OF THE PRODUCT OR FOR OTHER INCIDENTAL,

SPECIAL OR CONSEQUENTIAL DAMAGES OR EXPENSES INCURRED BY

THE ORIGINAL PURCHASER, OR FOR LABOR OR OTHER COSTS DUE TO

INSTALLATION OR REMOVAL, OR COSTS OF REPAIRS BY OTHERS, OR

FOR ANY OTHER EXPENSE NOT SPECIFICALLY STATED. IN NO EVENT

WILL TOTO

PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW,

ANY IMPLIED WARRANTIES, INCLUDING THAT OF MERCHANTABILITY

OR FITNESS FOR USE OR FOR A PARTICULAR PURPOSE, ARE EXPRESSLY

LIMITED TO THE DURATION OF THIS WARRANTY. SOME STATES AND

PROVINCES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS, OR THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION AND

EXCLUSION MAY NOT APPLY TO YOU.

®

obligations under this warranty are limited to repair or replacement, at TOTO®’s option,

®

reserves the right to

®

warrants the Product to be free from

®

service facility with proof of purchase (original sales

®

U.S.A., INC., 1155 Southern

®

, receipt by TOTO®

®

may choose to repair the Product at the

®

SHALL NOT BE

®

’S RESPONSIBILITY EXCEED THE PURCHASE PRICE OF THE

ENGLISH

15

Page 16

ConTeniDo

GRACIAS POR ELEGIR TOTO®! ..............................................................................16

CUIDADO Y LIMPIEZA ............................................................................................. 16

PRECAUCIÓN ............................................................................................................. 16

ANTES DE LA INSTALACIÓN .................................................................................. 17

HERRAMIENTAS NECESARIAS .............................................................................. 17

PROCEDIMIENTO DE INSTALACIÓN .................................................................... 18

RESOLUCIÓN DE PROBLEMAS .............................................................................. 20

BOSQUEJO .................................................................................................................. 21

REPUESTOS ................................................................................................................ 25

ESPAÑOL

GARANTÍA .................................................................................................................. 29

graCiaS Por eLegir ToTo®!

La misión de TOTO’s® es proporcionar estilos de vida saludables,

higiénicos y más cómodos. Diseñamos cada producto con el equilibro

de forma y función como principio rector. Felicitaciones por su elección.

CuiDaDo y LimPieza

Su nuevo grifo está diseñado para funcionar sin problemas durante

muchos años. Si desea que luzca como nuevo, límpialo periódicamente

con jabón suave, enjuáguelo bien con agua tibia y séquelo con un paño

suave y limpio. No use limpiadores abrasivo, lana de acero o sustancias

químicas ásperas, ya que opacarán el acabado. El incumplimiento de

estas instrucciones puede anular su garantía.

PreCauCión

Para la segura operación del grifo, tenga en cuenta lo siguiente:

Presión de operación:

Presión mínima ……………..7 psi (presión de ujo)

Presión máxima …………….108 psi (presión sin ujo)

No invierta las entradas de agua caliente y fría.

No use vapor para el suministro de agua caliente.

No use el producto a temperatura ambiente inferior a 32 ºF (0 ºC).

No desarme la válvula de cerámica.

Para asegurar que el producto mantiene su caudal especicado

para cumplir la norma EPA, utilice siempre el especicado por el

fabricante igual de aireacion para que el grifo.

16

Page 17

herramienTaS neCeSariaS

Cinta de

Tuberia

Llave de Tuercas

Ajustable

Alicates

Ajustable

Destornilladores

Llave

de cubo

anTeS De La inSTaLaCión

Cumpla con todos los códigos de plomería locales

Asegúrese que el suministro de agua esté cerrado

Lea estas instrucciones detenidamente para asegurar una instalación

adecuada

TOTO® se reserva el derecho de actualizar el diseño del producto sin

previo aviso

Asegúrese de tener todas las partes que se muestran a continuación

TL660SDL TL670SDL TL680SDL TL690SDL

Unidad del

surtidor

1 unidad

ESPAÑOL

Llave del

aireador

Ensamblaje

de drenaje

Varilla de

pivote y

bloque de

conexión

Herramienta

de reparación

Llave

hexagonal

17

1 unidad

1 unidad

1 unidad

cada una

1 unidad

1 unidad

Page 18

ProCeDimienTo De inSTaLaCión

1. inSTaLaCión DeL CuerPo DeL grifo

ESPAÑOL

Introduzca las mangueras

exibles a través del oricio

una a la vez.

Introduzca la varilla

elevadora por debajo del

grifo y pásela por el gancho

de elevación.

Deslice el soporte a su lugar

y asegure el surtidor con

tuercas.

Ajuste el surtidor para

que mire hacia adelante.

Mantenga el surtidor en su

lugar. Ajuste las tuercas.

Conecte las mangueras

exibles a las líneas

de suministro de agua.

Asegúrese de que la

manguera izquierda esté

conectada a la línea de

suministro de agua caliente

y la manguera derecha esté

conectada a la línea de

suministro de agua fría.

Manija

Manguera

exible

Gancho de

elevación

Ménsula

Contra tuerca

Varilla

elevadora

Entrada

caliente

Entrada

fría

18

Page 19

ProCeDimienTo De inSTaLaCión

2. inSTaLaCión DeL DrenaJe

Aplique cinta de tubería a

las roscas de la brida.

Introduzca la brida en el

oricio de drenaje.

Ensamble la junta, la tuerca

de brida y la contratuerca.

Instale el cuerpo de drenaje

en la brida.

Asegure el conjunto de

drenaje ajustando la tuerca

de brida y la contratuerca.

Aplique cinta de tubería

a las roscas de la pieza

posterior e instale esta pieza

en el cuerpo de drenaje.

Introduzca el tapón de

drenaje en la brida.

Ensamble la varilla pivote

como se muestra en el

diagrama.

Introduzca la varilla pivote

en el oricio del tapón de

drenaje. Ajuste la tuerca.

Introduzca la varilla

elevadora y la varilla pivote

en el bloque de conexión.

Ajuste ambas varillas con

un destornillador

Cinta de

tubería

Tuerca de

brida

Contra tuerca

Cuerpo de

drenaje

Pieza posterior

Tapon de drenaje

Brida

Junta

Junta

Sello

elevadora

Varilla

pivote

Resorte

Bloque de

ESPAÑOL

Varilla

Tuerca

conexión

19

Page 20

reSoLuCión De ProbLemaS

1

2

Si usted siguió las instrucciones con atención y aun así el grifo

no funciona correctamente, siga estos pasos como medida

correctiva.

ProblemA AreA A InsPeccIonAr

Flujo de AguA InsuFIcIente 6

mAngo Flojo 1, 2, 3

surtIdor Flojo 7

ESPAÑOL

3. Contratuerca de la válvula

¿Está bien apretada?

goteo 3, 4, 5, 8,

1. Tornillo de jación

¿Está bien apretado?

2. Tornillo

¿Está bien apretado?

4. Cartucho

¿Está sucio o dañado?

5. Junta/Anillo en O

¿Está sucio o dañado?

6. Aireador

¿Está sucio o dañado?

8. Manguera exible

¿Está bien apretada?

7. Contratuerca

¿Está bien apretada?

Para acceder al cartucho con

la herramienta para quitar la

contratuerca de la válvula

20

Page 21

boSqueJo(TL660SDL)

3/8" Comp

1-15/16”

(50 mm)

(25 mm)

1” (max)

(141 mm)

3-7/8”

(99 mm)

5-1/2”

2-3/16”

(55 mm)

(130 mm)

5-1/8”

Off

25º

On

45º

Cold

Hot

45º

Red

Blue

ø1-5/16”

(ø34 mm)

ø2-1/8”

(ø54 mm)

7-3/8”

(187 mm)

ø1-1/4”

ø31 mm (T=1)

(265 mm)

10-7/16”

rojo Azul

cAlIente

FríA

ESPAÑOL

21

Page 22

boSqueJo(TL670SDL)

3/8” Comp

(25 mm)

1” (max)

2-3/16”

(56 mm)

5-9/16”

(141 mm)

45º

Cold

45º

Hot

On

Off

25º

2-3/8”

(60 mm)

4-7/8”

(125 mm)

(109 mm)

4-5/16”

ø1-5/16”

(ø34 mm)

ø2-1/8”

(ø54 mm)

(187 mm)

7-3/8”

ø1-1/4” (T=1.0)

ø31 mm (T=1.0)

(265 mm)

10-7/16”

ESPAÑOL

cAlIente

FríA

22

Page 23

boSqueJo(TL680SDL)

3/8” Comp

1” (max)

(125 mm)

(134 mm)

5-1/4”

1-3/4"

(45 mm)

3-3/4”

(95 mm)

(67 mm)

2-5/8”

7-3/8”

(187 mm)

(265 mm)

10-7/16"

ø31 mm (T=1)

ø1-1/4” (T=1)

ø2-1/8” (ø54 mm)

(ø34 mm)

ø1-5/16”

4-5/8”

(118 mm)

20º

Off

On

25º

50º

50º

Cold

Hot

cAlIente

FríA

ESPAÑOL

23

Page 24

boSqueJo(TL690SDL)

1” (max)

(25.5 mm)

2-1/4”

(56.2 mm)

5-9/16”

(136 mm)

45

º

45

º

Cold

Hot

On

Off

25

º

(60 mm)

2-1/4”

(121 mm)

4-3/4”

(112 mm)

4-7/16”

(

ø

34 mm)

ø

1-5/16

”

(ø54 mm)

ø2-1/8”

7-3/8”

(187 mm)

ø31 mm (T=1.0)

ø1-1/4”

(265 mm)

10-7/16”

3/8” Comp

ESPAÑOL

cAlIente

FríA

24

Page 25

rePueSToS(TL660SDL)

14

15

16

1

2

3

4

5

6

7

9

10

8

11

12

13

17

1 tHP4272 * mAnIjA IndIVIduAl, dIseño l

2 tHP4276 * AdAPtAdor de lA mAnIjA

3 tHP4263 tornIllo y ArAndelA

4 tHP4167 tornIllo de FIjAcIón

5 tHP4264 * tAPA del AnIllo en o

6 tHP4265 contrAtuercA de lA VálVulA

7 tHP4004 cArtucHo de cerámIcA

8 tHP4273 * cuerPo del surtIdor, dIseño l

9 tHP4184 * VArIllA de eleVAcIón

10 tHP4007 ménsulA y contrAtuercAs

11 9Au4248 AIreAdor

12 tHP4182 llAVe del AIreAdor

13 tHP4404 mAnguerAs FlexIbles

14 tHP4207 * ensAmblAje del drenAje

15 tHP4011 * tAPón del drenAje

16 tHP4012 conector de lA VArIllA de

eleVAcIón

17 tHP4271 HerrAmIentA PArA quItAr lA

contrAtuercA de lA VálVulA

ESPAÑOL

*IndIque el códIgo de termInAcIón cuAndo HAgA un PedIdo

25

Page 26

rePueSToS(TL670SDL)

14

15

16

12

8

1

3

2

4

5

6

7

9

10

11

13

17

1 tHP4277 * mAnIjA IndIVIduAl, dIseño nI

2 tHP4262 * AdAPtAdor de lA mAnIjA

3 tHP4263 tornIllo y ArAndelA

4 tHP4167 tornIllo de FIjAcIón x2

5 tHP4264 * tAPA del AnIllo en o

6 tHP4265 contrAtuercA de lA VálVulA

7 tHP4004 cArtucHo de cerámIcA

8 tHP4278 * cuerPo del surtIdor, dIseño nI

9 tHP4279 * VArIllA de eleVAcIón

10 tHP4007 ménsulA y contrAtuercAs

11 9Au4249 AIreAdor

ESPAÑOL

12 tHP4193 llAVe del AIreAdor

13 tHP4274 mAnguerAs FlexIbles

14 tHP4207 * ensAmblAje del drenAje

15 tHP4011 * tAPón del drenAje

16 tHP4012 conector de lA VArIllA de

eleVAcIón

17 tHP4271 HerrAmIentA PArA quItAr lA

contrAtuercA de lA VálVulA

*IndIque el códIgo de termInAcIón cuAndo HAgA un PedIdo

26

Page 27

rePueSToS(TL680SDL)

1

2

8

9

3

5

6

4

7

10

11

13

12

14

15

16

17

1 tHP4261 * mAnIjA IndIVIduAl, dIseño c

2 tHP4262 * AdAPtAdor de lA mAnIjA

3 tHP4263 tornIllo y ArAndelA

4 tHP4167 tornIllo de FIjAcIón x2

5 tHP4264 * tAPA del AnIllo en o

6 tHP4265 contrAtuercA de lA VálVulA

7 tHP4004 cArtucHo de cerámIcA

8 tHP4266 * cuerPo del surtIdor, dIseño en c

9 tHP4267 * VArIllA de eleVAcIón

10 tHP4007 ménsulA y contrAtuercAs

11 tHP4406 * kIt del AIreAdor

12 tHP4101 llAVe del surtIdor

13 tHP4423 mAnguerAs FlexIbles

14 tHP4207 * ensAmblAje del drenAje

15 tHP4011 * tAPón del drenAje

16 tHP4012 conector de lA VArIllA de

eleVAcIón

17 tHP4271 HerrAmIentA PArA quItAr lA

contrAtuercA de lA VálVulA

ESPAÑOL

*IndIque el códIgo de termInAcIón cuAndo HAgA un PedIdo

27

Page 28

rePueSToS(TL690SDL)

14

15

16

1

2

3

5

4

8

7

6

9

11

10

13

12

17

1 tHP4280 * mAnIjA IndIVIduAl, dIseño nII

2 tHP4281 * AdAPtAdor de lA mAnIjA

3 tHP4282 tornIllo y ArAndelA

4 tHP4167 tornIllo de FIjAcIón x2

5 tHP4264 * tAPA del AnIllo en o

6 tHP4265 contrAtuercA de lA VálVulA

7 tHP4004 cArtucHo de cerámIcA

8 tHP4283 * cuerPo del surtIdor, dIseño nII

9 tHP4279 * VArIllA de eleVAcIón

10 tHP4007 ménsulA y contrAtuercAs

11 tHP4406 * kIt del AIreAdor

ESPAÑOL

12 tHP4101 llAVe del surtIdor

13 tHP4404 mAnguerAs FlexIbles

14 tHP4207 * ensAmblAje del drenAje

15 tHP4011 * tAPón del drenAje

16 tHP4012 conector de lA VArIllA de el-

17 tHP4271 HerrAmIentA PArA quItAr lA

eVAcIón

contrAtuercA de lA VálVulA

*IndIque el códIgo de termInAcIón cuAndo HAgA un PedIdo

28

Page 29

garanTÍa

GARANTÍA LIMITADA DURANTE LA VIDA ÚTIL DEL PRODUCTO

La garantía se apLica a grifos y accesorios residenciaLes seLeccionados soLamente.

1. toto

durante eL uso residenciaL normaL siempre que eL comprador, usuario finaL y consumidor

originaL sea dueño de su casa. esta gar antía Limitada dur ante La vida útiL deL producto se

extiende soLamente aL comprador usuario finaL consumidor originaL y únicamente si eL producto

sigue siendo utiLizando por eL comprador, usuario finaL y consumidor originaL en su Lugar

de instaLación originaL en La residencia deL comprador. esta garantía se apLica soLamente aL

p

2. l

reemPlAzo A oPcIón de toto

deFectuosAs en uso resIdencIAl normAl, sIemPre que el Producto se HAyA InstAlAdo

bIen y se HAyA usAdo según el mAnuAl del ProPIetArIo. toto

de eFectuAr dIcHAs InsPeccIones según seA necesArIo A FIn de determInAr lA cAusA del

deFecto.

3. e

4. s

de materiaLes y fabricación durante un (1) año a partir de La fecha en que se instaLó eL producto,

con Los demás términos de esta garantía apLicabLes excepto La duración de La misma.

5. esta garantía Le da derechos LegaLes específicos. usted puede tener

otros derechos que varían de un estado a otro o de una provincia a

otra.

6. p

previo pago deL franqueo a una instaLación de servicio de toto

de venta originaL) junto con una carta indicando eL probLema, o ponerse en contacto con un

distribuidor de toto

a toto

debido aL tamaño deL producto o a La natur aLeza deL defecto, eL producto no puede devoLverse

a toto

de ventas originaL) debe constituir entrega. en dicho caso, toto

p

servicio.

esta garantía por escrito es La única garantía dada por toto

ajuste apropiado según esta garantía debe ser eL remedio excLusivo disponibLe para eL comprador

originaL. toto

emergentes o concomitantes incurridos por eL comprador originaL, o por mano de obra u otros

costos debidos a La instaLación o aL desmontaje, o costos o reparaciones por otros, o por cuaLquier

otro gasto que no se indique específicamente. La responsabiLidad de toto

caso eL precio de compra deL producto. excepto en La medida que Lo prohíba La Ley correspondiente,

cuaLquier garantía impLícita, incLuida La de comerciaLización o idoneidad para un uso o un fin

particuLar, se Limita expresamente a La duración de esta garantía. aLgunos estados y provincias no

permiten Limitaciones sobre La duración de una garantía impLícita, o La excLusión o Limitación de

daños emergentes o concomitantes, de modo que es posibLe que La Limitación y La excLusión anteriores

no se Limiten a usted.

®

garantiza que sus grifos (“producto”) carecen de defectos de materiaLes y fabricación

roducto comprado e instaLado en norte américa.

As oblIgAcIones de toto

sta garantía no se apLica a Los artícuLos siguientes:

®

según estA gArAntíA se lImItAn A lA rePArAcIón o Al

®

, del Producto o PIezAs que se comPruebe que son

®

se reserVA el derecHo

a) Daños o pérdidas debidas a una calamidad natural tal como un incendio,

terremoto, inundación, tormenta eléctrica, etc.

b) Daños o pérdidas debidas a un accidente, uso no razonable, uso indebido, abuso,

negligencia o cuidados indebidos, limpieza o mantenimiento del producto.

c) Daños o pérdidas debidas a sedimentos o materias extrañas contenidas en un

sistema de agua.

d) Daños o pérdidas debidas a la instalación indebida o a la instalación del Producto

en un entorno riguroso o peligroso, o desmontaje, reparación o modicación

indebida del Producto.

e) Daños o pérdidas debidas al uso de un limpiador abrasivo.

i eL producto se usa comerciaLmente, toto

ara obtener un servicio de reparación de garantía, debe LLevar eL producto o entregarLo

®

®

u.sa. inc., 1155 southern road, morrow, georgia 30260, (888) 295-8134. si

®

, eL recibo de toto® deL aviso escrito deL defecto junto con La prueba de compra (recibo

roducto en eL Lugar deL comprador o pagar para transportar eL producto a una instaLación de

®

no debe ser responsabLe de La pérdida deL producto o de otros daños especiaLes,

o contratista de ser vicio de productos. también puede escribir directamente

®

garantiza que eL producto no tenga defectos

®

con La prueba de compra (recibo

®

puede decidir entre reparar eL

®

. La reparación, eL reempLazo u otro

®

no excederá en ningún

ESPAÑOL

29

Page 30

Sommaire

MERCI D’AVOIR CHOISI TOTO® ! ................................................................... ........30

ENTRETIEN EN NETTOYAGE.......................................................................... ........30

ATTENTION ........................................................................................................ ........30

AVANT L’INSTALLATION ................................................................................. ........31

ES OUTILS DONT VOUS AVEZ BESOIN ........................................................ ........31

PROCÉDURE D’INSTALLATION .............................................................................32

DÉPANNAGE ..............................................................................................................34

ROBINETTERIE .................................................................................................. ........35

PIÈCES DÉTACHÉES ......................................................................................... ........39

GARANTIE .......................................................................................................... ........43

merCi D’aVoir ChoiSi ToTo® !

La mission de TOTO® est d’apporter au monde entier un style de vie

sain, hygiénique et plus confortable. Nous créons tous nos produits avec

un principe de base à l’esprit : équilibrer forme et fonction. Félicitations

pour votre choix.

FRANÇAIS

enTreTien en neTToyage

Votre nouveau robinet est conçu pour fonctionner des années sans vous

causer de souci. Gardez-le comme neuf en le nettoyant régulièrement

avec un détergent léger, rincez-le soigneusement à l’eau tiède et séchezle à l’aide d’un chiffon doux et propre. N’utilisez pas de nettoyant

abrasif, de paille de fer ou de détergent agressif, car cela ternirait

le revêtement. Ne pas suivre ces instructions pourrait annuler votre

garantie.

aTTenTion

Pour utiliser convenablement votre robinet, veuillez suivre les instructions cidessous:

Pression de fonctionnement

Pression minimum ……………..7 psi (pression d’écoulement)

Pression maximum …………….108 psi (pression de rétention)

N’inversez pas les entrées d’eau chaude et d’eau froide.

N’utilisez pas de vapeur pour l’arrivée d’eau chaude.

N’utilisez pas ce produit à des températures ambiantes inférieures à 0°C.

Ne démontez pas la valve en céramique.

Pour assurer le produit maintient sa specie debit pour repondre a la norme

EPA, toujours utiliser le constructeur specie que aerateur pour robinet.

30

Page 31

eS ouTiLS DonT VouS aVez beSoin

Ruban

adhésif de

plomberie

Clé á

molette

Pince

Réglable

Tournevis Clé à Douilles

aVanT L’inSTaLLaTion

Observez tous les codes locaux de plomberie

Assurez-vous que l’alimentation en eau est coupée

Lisez ces instructions attentivement an d’assurer l’installation

adéquate

TOTO® se réserve le droit de modier le design de son produit sans

préavis

Assurez-vous d’avoir toutes les pièces indiquées ci-dessous

TL660SDL TL670SDL TL680SDL TL690SDL

L`unité du

Bec

1 pièce

FRANÇAIS

Clé d’aérateur 1 pièce

Assemblage

de drain

Tige de

pivotage

et Bloc de

connexion

Outils de

Dépannage

Hex Wrench

31

1 pièce

1 pièce

chacune

1 pièce

1 piece

Page 32

ProCÉDure D’inSTaLLaTion

1. inSTaLLaTion Du CorPS Du robineT

FRANÇAIS

Insérez les tuyaux exibles

dans le trou, un par un

Insérez la tige du bouchon

en-dessous du robinet et

vissez-la dans son bouton

Faites glisser la cale en

place et xez le col à

l’aide des écrous.

Ajustez le col et le bec

pour qu’ils soient tournés

vers l’avant. Maintenez

le col en place. Serrez

l’écrou.

Connectez les tuyaux

exibles aux conduites

d’alimentation. Vériez

que le tuyau de gauche

est bien connecté à la

conduite d’eau chaude

et que le tuyau de droite

est bien connecté à l’eau

froide.

Poignée

Tuyau exible

Bouton de la

tige

Support

Contre-écrou

Tige de levage

32

Entrée d`eau

Chaude

Entrée d`eau

Froide

Page 33

ProCÉDure D’inSTaLLaTion

2. inSTaLLaTion Du Tuyau D’ÉCouLemenT

Placez de l’adhésif de

plomberie sur le letage de

la bride.

Insérez la bride dans le trou

du tuyau d’écoulement.

Assemblez l’anneau,

l’écrou de la bride et le

Ruban adhésif

de plomberie

contre-écrou.

Installez le corps du tuyau

d’écoulement sur la bride.

Fixez le système

d’écoulement en serrant

l’écrou de la bride et le

contre-écrou.

Contre-écrou

Corps du tuyau

d’écoulement

Appliquez de l’adhésif de

plomberie sur le letage

de l’about et installez

l’about sur le système

d’écoulement.

Insérez le bouchon

d’écoulement dans la bride.

Assemblez la tige pivot

comme indiqué su le

schéma.

Insérez la tige pivot

dans le trou du bouchon

d’écoulement. Serrez

l’écrou.

Insérez la tige du bouchon

et la tige-pivot dans le

bloc de raccord. Serrez les

deux tiges à l’aide d’un

tournevis.

Écrou de la

bride

About

Bouchon

d’écoulement

Bride

Anneau

Anneau

Joint

Tige pivot

Ressort

Tige du

bouchon

Écrou

Bloc

Raccord

FRANÇAIS

33

Page 34

1

2

DÉPannage

Si vous avez bien suivi toutes les instructions et que votre

robinet ne fonctionne pas convenablement, suivez la procédure

de dépannage ci-dessous.

Problème zone á InsPecter

débIt d’eAu troP FAIble 6

PoIgnée troP lâcHe 1, 2, 3

col troP lâcHe 7

FuIte 3, 4, 5, 8,

FRANÇAIS

3. Contre-écrou de l`obsturateur

Est-il bien serré?

1. Ensemble des Vis

Est-il bien serré?

2. Vis

Est-il bien serré?

4. Cartouche

Est-elle endommagée ou sale?

5.Joint statique/

Joint Torique

Est-il endommagé ou sale?

6. Aérateur

Est-il endommagé

ou sale?

8. Boyau Flexible

Est-il bien serré?

7. Contre-écrous

Est-il bien serré?

Pour acceder à la cartouche à

l`aide de l`outil d’extraction du

contre-écrou de l’obturateur

34

Page 35

robineTTerie(TL660SDL)

3/8" Comp

1-15/16”

(50 mm)

(25 mm)

1” (max)

(141 mm)

3-7/8”

(99 mm)

5-1/2”

2-3/16”

(55 mm)

(130 mm)

5-1/8”

Off

25º

On

45º

Cold

Hot

45º

Red

Blue

ø1-5/16”

(ø34 mm)

ø2-1/8”

(ø54 mm)

7-3/8”

(187 mm)

ø1-1/4”

ø31 mm (T=1)

(265 mm)

10-7/16”

cHAud

rouge

bleu

FroId

FRANÇAIS

35

Page 36

robineTTerie(TL670SDL)

3/8” Comp

(25 mm)

1” (max)

2-3/16”

(56 mm)

5-9/16”

(141 mm)

45º

Cold

45º

Hot

On

Off

25º

2-3/8”

(60 mm)

4-7/8”

(125 mm)

(109 mm)

4-5/16”

ø1-5/16”

(ø34 mm)

ø2-1/8”

(ø54 mm)

(187 mm)

7-3/8”

ø1-1/4” (T=1.0)

ø31 mm (T=1.0)

(265 mm)

10-7/16”

FRANÇAIS

cHAud

FroId

36

Page 37

robineTTerie(TL680SDL)

3/8” Comp

1” (max)

(125 mm)

(134 mm)

5-1/4”

1-3/4"

(45 mm)

3-3/4”

(95 mm)

(67 mm)

2-5/8”

7-3/8”

(187 mm)

(265 mm)

10-7/16"

ø31 mm (T=1)

ø1-1/4” (T=1)

ø2-1/8” (ø54 mm)

(ø34 mm)

ø1-5/16”

4-5/8”

(118 mm)

20º

Off

On

25º

50º

50º

Cold

Hot

cHAud

FroId

FRANÇAIS

37

Page 38

robineTTerie(TL690SDL)

1” (max)

(25.5 mm)

2-1/4”

(56.2 mm)

5-9/16”

(136 mm)

45

º

45

º

Cold

Hot

On

Off

25

º

(60 mm)

2-1/4”

(121 mm)

4-3/4”

(112 mm)

4-7/16”

(

ø

34 mm)

ø

1-5/16

”

(ø54 mm)

ø2-1/8”

7-3/8”

(187 mm)

ø31 mm (T=1.0)

ø1-1/4”

(265 mm)

10-7/16”

3/8” Comp

FRANÇAIS

cHAud

FroId

38

Page 39

PiÈCeS DÉTaChÉeS(TL660SDL)

14

15

16

1

2

3

4

5

6

7

9

10

8

11

12

13

17

1 tHP4272 * PoIgnée sImPle de style l

2 tHP4276 * AdAPtAteur de PoIgnée

3 tHP4263 VIs et rondelle

4 tHP4167 VIs de réglAge

5 tHP4264 * cAPucHon de joInt torIque

6 tHP4265 contre-écrou de l’obturAteur

7 tHP4004 cArtoucHe de cérAmIque

8 tHP4273 * bec Verseur de style l

9 tHP4184 * tIge de leVAge

10 tHP4007 suPPort et contre-écrous

11 9Au4248 brIse jet

12 tHP4182 clé d’AérAteur

13 tHP4404 boyAux FlexIbles

14 tHP4207 * AssemblAge de drAIn

15 tHP4011 * déboucHoIr du drAIn

16 tHP4012 tIge de leVAge du connecteur

17 tHP4271 outIl d’extrActIon du contre-

écrou de l’obturAteur

FRANÇAIS

* PrIère d`IndIquer le code de FInItIon lors de lA commAnde

39

Page 40

PiÈCeS DÉTaChÉeS(TL670SDL)

14

15

16

12

8

1

3

2

4

5

6

7

9

10

11

13

17

1 tHP4277 * PoIgnée sImPle de style nI

2 tHP4262 * AdAPtAteur de PoIgnée

3 tHP4263 VIs et rondelle

4 tHP4167 VIs de réglAge x2

5 tHP4264 * cAPucHon de joInt torIque

6 tHP4265 contre-écrou de l’obturAteur

7 tHP4004 cArtoucHe de cérAmIque

8 tHP4278 * bec Verseur de style nI

9 tHP4279 * tIge de leVAge

10 tHP4007 suPPort et contre-écrous

11 9Au4249 brIse jet

12 tHP4193 clé d’AérAteur

13 tHP4404 boyAux FlexIbles

14 tHP4207 * AssemblAge de drAIn

15 tHP4011 * déboucHoIr du drAIn

16 tHP4012 tIge de leVAge du connecteur

17 tHP4271 outIl d’extrActIon du contre-

écrou de l’obturAteur

FRANÇAIS

*PrIère d`IndIquer le code de FInItIon lors de lA commAnde

40

Page 41

PiÈCeS DÉTaChÉeS(TL680SDL)

1

2

8

9

3

5

6

4

7

10

11

13

12

14

15

16

17

1 tHP4261 * PoIgnée sImPle de style c

2 tHP4262 * AdAPtAteur de PoIgnée

3 tHP4263 VIs et rondelle

4 tHP4167 VIs de réglAge x2

5 tHP4264 * cAPucHon de joInt torIque

6 tHP4265 contre-écrou de l’obturAteur

7 tHP4004 cArtoucHe de cérAmIque

8 tHP4266 * bec Verseur de style c

9 tHP4267 * tIge de leVAge

10 tHP4007 suPPort et contre-écrous

11 tHP4406 * trousse de brIse-jet

12 tHP4101 clé de bec

13 tHP4423 boyAux FlexIbles

14 tHP4207 * AssemblAge de drAIn

15 tHP4011 * déboucHoIr du drAIn

16 tHP4012 tIge de leVAge du connecteur

17 tHP4271 outIl d’extrActIon du contre-

écrou de l’obturAteur

FRANÇAIS

* PrIère d`IndIquer le code de FInItIon lors de lA commAnde

41

Page 42

PiÈCeS DÉTaChÉeS(TL690SDL)

14

15

16

1

2

3

5

4

8

7

6

9

11

10

13

12

17

1 tHP4280 * PoIgnée sImPle de style nII

2 tHP4281 * AdAPtAteur de PoIgnée

3 tHP4282 VIs et rondelle

4 tHP4167 VIs de réglAge x2

5 tHP4264 * cAPucHon de joInt torIque

6 tHP4265 contre-écrou de l’obturAteur

7 tHP4004 cArtoucHe de cérAmIque

8 tHP4283 * bec Verseur de style nII

9 tHP4279 * tIge de leVAge

10 tHP4007 suPPort et contre-écrous

11 tHP4406 * trousse de brIse jet

12 tHP4101 clé de bec

13 tHP4404 boyAux FlexIbles

14 tHP4207 * AssemblAge de drAIn

15 tHP4011 * déboucHoIr du drAIn

16 tHP4012 tIge de leVAge du connecteur

17 tHP4271 outIl d’extrActIon du contre-

écrou de l’obturAteur

FRANÇAIS

* PrIère d`IndIquer le code de FInItIon lors de lA commAnde

42

Page 43

garanTie

GARANTIE LIMITÉE À VIE

A gArAntIe est APPlIcAble à certAIns robInets et AccessoIres résIdentIels seulement.

l

1. toto

mAtérIAu et de FAbrIcAtIon PendAnt l’utIlIsAtIon résIdentIelle normAle, tAnt que

l’AcHeteur utIlIsAteur FInAl Possède sA mAIson. cette gArAntIe lImItée à VIe est

oFFerte unIquement à l’AcHeteur utIlIsAteur FInAl et seulement tAnt que le ProduIt

est utIlIsé PAr celuI-cI à son emPlAcement d’InstAllAtIon InItIAle, dAns lA résIdence

de l’AcHeteur. cette gArAntIe n’est APPlIcAble qu’Aux ProduIts AcHetés et InstAllés

en AmérIque du nord.

2. l

lA réPArAtIon ou Au remPlAcement, Au cHoIx de toto

déFectueuses en serVIce résIdentIel normAl, PourVu qu’un tel ProduIt AIt été InstAllé

et utIlIsé conFormément Aux InstructIons du mAnuel d’utIlIsAtIon. toto

le droIt de FAIre les InsPectIons jugées nécessAIres Pour détermIner lA cAuse du

déFAut.

3. c

A) dommAge ou Perte cAusé PAr une cAlAmIté nAturelle, telle qu’IncendIe,

tremblement de terre, InondAtIon, Foudre, orAge électrIque, etc.

b) dommAge ou Perte résultAnt d’un AccIdent, d’une utIlIsAtIon AbusIVe, d’une

mAuVAIse utIlIsAtIon, de néglIgence ou de mAuVAIs soIns, nettoyAge ou entretIen du

ProduIt.

c) dommAge ou Perte résultAnt de sédIments ou d’objets étrAngers contenus dAns un

système d’eAu.

d) dommAge ou Perte résultAnt d’une mAuVAIse InstAllAtIon ou d’une InstAllAtIon du

ProduIt dAns un enVIronnement AgressIF ou dAngereux, une mAuVAIse mAnIPulAtIon,

réPArAtIon ou modIFIcAtIon du ProduIt.

e) dommAge ou Perte résultAnt de l’utIlIsAtIon de ProduIts de nettoyAge AbrAsIFs.

4. s

déFAuts de mAtIère et de FAbrIcAtIon PendAnt une PérIode d’un (1) An à comPter de

lA dAte d’InstAllAtIon du ProduIt, AVec toutes les Autres condItIons de lA gArAntIe

APPlIcAble, sAuF lA durée de lA PérIode de gArAntIe.

5. cette gArAntIe donne des droIts sPécIFIques. Il est PossIble

que l’AcHeteur AIt d’Autres droIts quI VArIent d’une

ProVInce à l’Autre.

6. P

doIt lIVrer à un centre de réPArAtIon de toto

reçu de cAIsse orIgInAl), AVec une lettre exPlIquAnt le Problème ou contActer

(

un dIstrIbuteur de toto

dIrectement à toto

295-8134. s

renVoyer le ProduIt à toto

AVec PreuVe d’AcHAt (reçu de cAIsse orIgInAl) constItue lIVrAIson. dAns un tel cAs,

toto® Peut cHoIsIr de réPArer le ProduIt cHez l’AcHeteur ou de PAyer le trAnsPort

du ProduIt à un centre de réPArAtIon.

cette gArAntIe écrIte est lA seule gArAntIe FAIte PAr toto

lA réPArAtIon, le remPlAcement ou tout Autre Ajustement

APProPrIé selon les termes de cette gArAntIe est le seul

recours de l’AcHeteur InItIAl. toto

de lA Perte du ProduIt ou de tout Autre dommAge IndIrect,

sPécIAl ou secondAIre ou des déPenses encourues PAr

l’AcHeteur InItIAl nI de lA mAIn-d’oeuVre ou Autres FrAIs

AssocIés à l’InstAllAtIon ou lA mAnIPulAtIon, ou les FrAIs

de réPArAtIon PAr des tIers, nI Pour tous Autres FrAIs PAs

sPécIFIquement mentIonnés. en Aucun cAs, lA resPonsAbIlIté

de toto

quAnd InterdIte PAr une loI APPlIcAble, toute gArAntIe sousentendue, y comPrIs celle de VendAbIlIté ou d’APPlIcAtIon

Pour un usAge PArtIculIer, est exPressément lImItée PAr lA

durée de cette gArAntIe. PuIsque certAInes ProVInces ne

Permettent PAs lA lImItAtIon de lA longueur d’une gArAntIe

sous-entendue, ou l’exclusIon ou lA lImItAtIon des dommAges

IndIrects ou secondAIres, Il est donc PossIble que cette

lImItAtIon et exclusIon ne s’APPlIquePAsà

un cAs sPécIFIque.

®

gArAntIt ses robInets et AccessoIres (« ProduIt ») contre tout déFAut de

es oblIgAtIons de toto

ette gArAntIe n’est PAs APPlIcAble Aux ArtIcles suIVAnts :

I le ProduIt est utIlIsé commercIAlement. toto

our obtenIr une réPArAtIon selon les termes de cette gArAntIe, l’AcHeteur

I, à cAuse de sA tAIlle ou de lA nAture du déFAut, Il n’est PAs PossIble de

®

ne Peut déPAsser le PrIx d’AcHAt du ProduIt. sAuF

®

selon les termes de cette gArAntIe sont lImItées à

®

ou un entrePreneur de réPArAtIon du ProduIt ou écrIre

u.s.A., Inc., soutHern roAd, morrow, géorgIe 30260, (888)

®

, lA récePtIon PAr toto

®

, des ProduIts ou des PIèces

®

se réserVe

®

gArAntIt le ProduIt contre les

®

, Port PAyé, AVec PreuVe d’AcHAt

®

d’un AVIs écrIt du déFAut,

®

n’est PAs resPonsAble

®

.

FRANÇAIS

43

Page 44

toto® u.S.a., inc. 1155 soutHern roAd, morrow, georgIA 30260

tel: 888-295-8134 FAx: 800-699-4889

www.totousA.com

TOTO USA

REV 01/2009

0GU4105

Loading...

Loading...