Page 1

Installation and Owner’s Manual

Manual de Instrucciones y del Propietrario

Manuel D’Installation et D’Utilisation

EcoPower® Automatic Faucets

Grifos Automáticos EcoPower

®

Robinets Automatiques EcoPower

®

*NOTE: ASSE1070 supercedes ASSE1016 for non-shower point of use devices. Applies to TEL5 series models.

NSF/ANSI 61-9 applies to all models, except for Gooseneck Wall Mount and Integrated faucets.

*NOTA: El ASSE1070 sustituya al ASSE1016 para los dispositivos con punto de uso sin regadera. Aplica a los modelos serie

*NOTE: ASSE1070 remplace ASSE1016 pour des appareils différents des douches. Ceci s’applique aux modèles de séries

Warranty Registration and Inquiry

For product warranty registration, TOTO U.S.A. Inc. recommends online warranty registration. Please visit our web site http://www.totousa.com.

If you have questions regarding warranty policy or coverage, please contact TOTO U.S.A. Inc., Customer Service Department, 1155 Southern Road,

Morrow, GA 30260 (888) 295-8134 or (678) 466-1300 when calling from outside of U.S.A.

TEL5. NSF / ANSI 61-9 se aplica a todos los modelos, a excepción de cuello de cisne de montaje en pared y los

grifos integrados.

TEL5. NSF / ANSI 61-9 s’applique à tous les modèles, sauf pour Gooseneck Wall Mount et robinets intégrés.

Page 2

Page 3

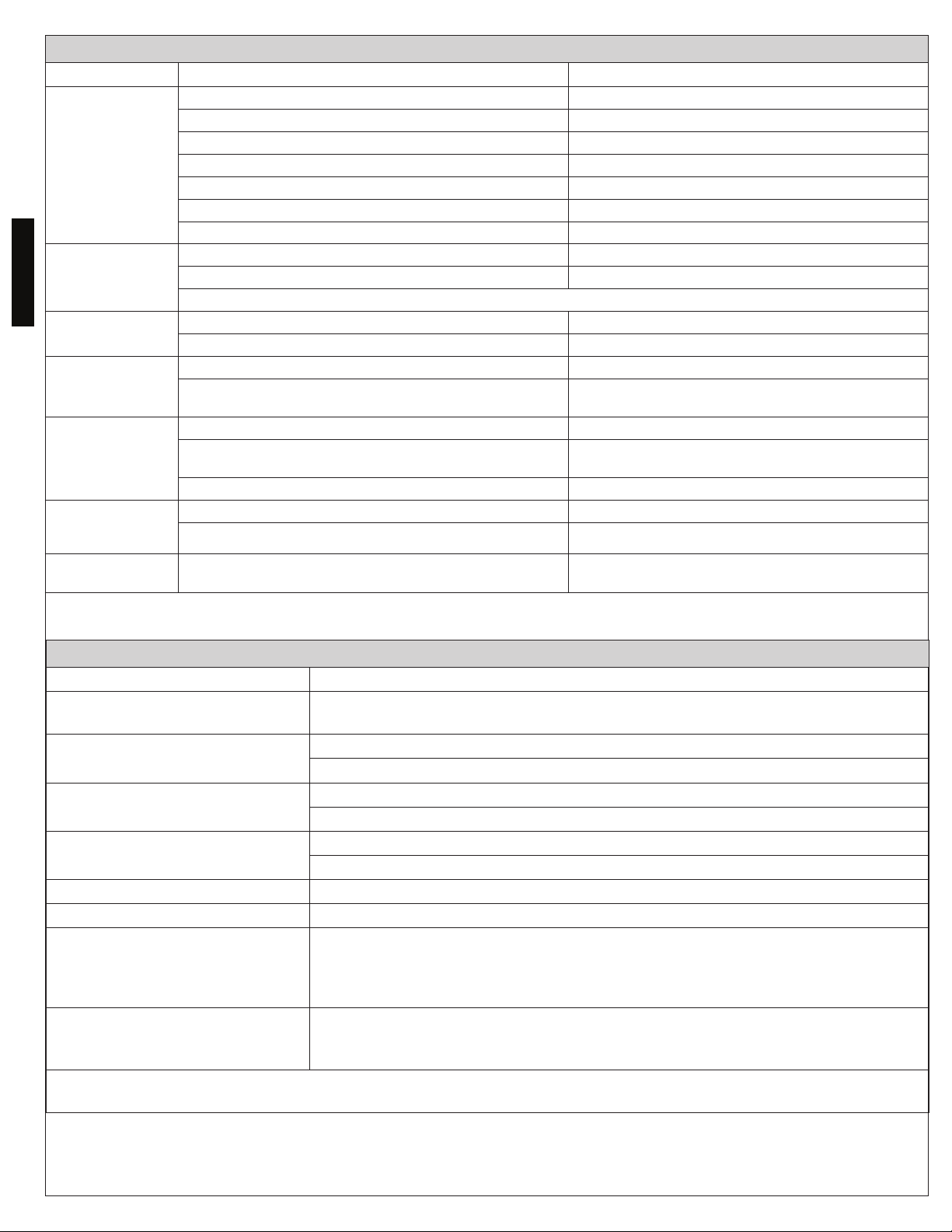

TABLE OF CONTENTS

Thanks for Choosing TOTO! ................................................................................................................................................................... 3

Included Parts ........................................................................................................................................................................................... 3

Warnings ...................................................................................................................................................................................................4

Before Installation ....................................................................................................................................................................................4

Installation Procedures ..........................................................................................................................................................................4-8

Care & Cleaning .......................................................................................................................................................................................8

Periodic Maintenance ..............................................................................................................................................................................9

Troubleshooting .....................................................................................................................................................................................10

Specifications .......................................................................................................................................................................................... 10

Warranty ..................................................................................................................................................................................................11

Rough-In Dimensions .......................................................................................................................................................................30-31

Spare Parts .........................................................................................................................................................................................32-34

THANKS FOR CHOOSING TOTO!

The mission of TOTO is to provide the world with healthy, hygienic and more comfortable lifestyles. We design every product

with the balance of form and function as a guiding principle. Congratulations on your choice.

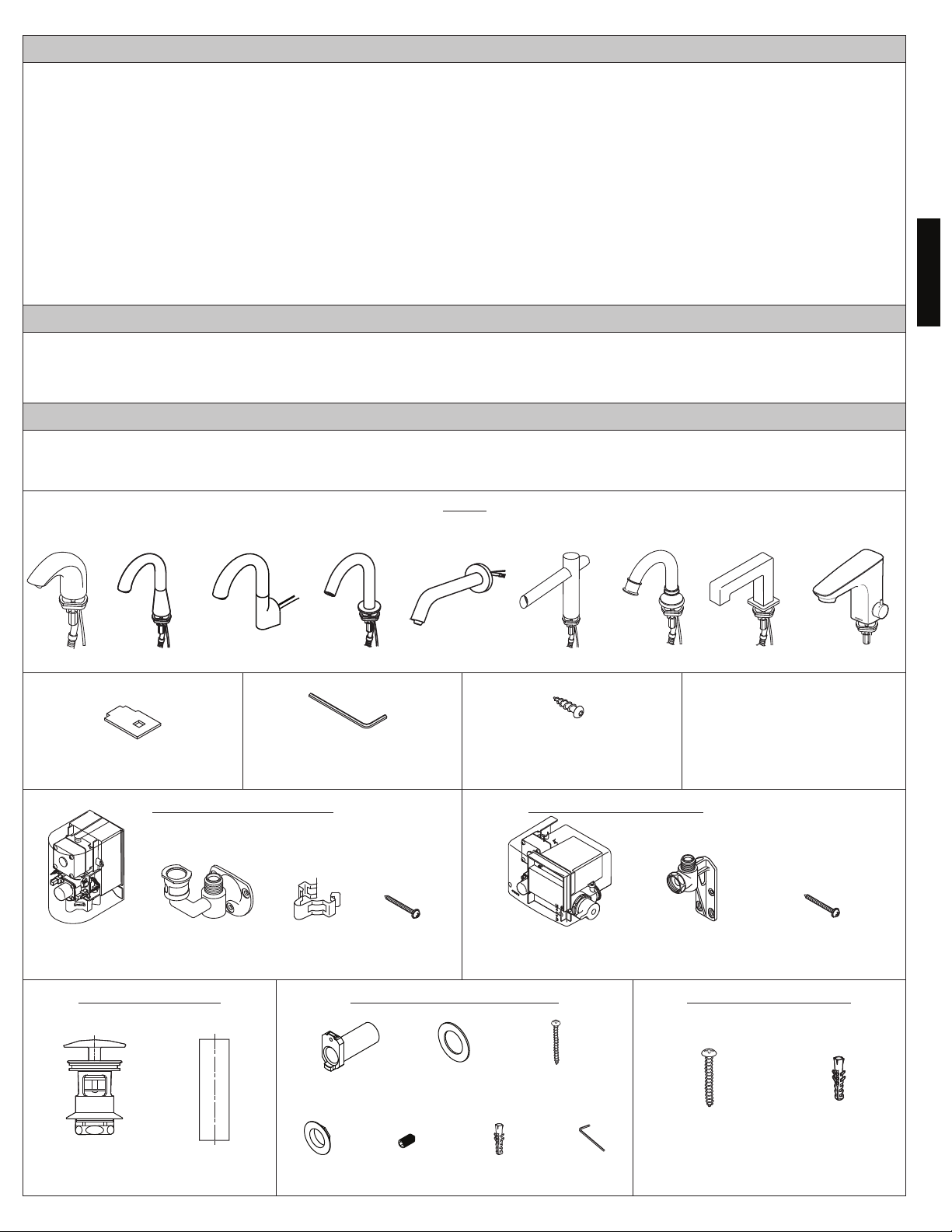

INCLUDED PARTS

Check to make sure you have all these parts from the package*:

(Appearance of some components may vary depending on the model)

ENGLISH

SPOUT:

Standard

TEL#GS/LS TEL#GG/LG TEL#GGW/LGW TEL#GC/LC TEL#GW/LW TEL#GT/LT TEL#GK/LK

Single Supply

Controller

(TN78-9Vxx)

Gooseneck

Nozzle/Strainer Tool

FOR SINGLE SUPPLY MODELS:

Gooseneck

Wall Mount

(TEL3 Series)

Water Inlet

Bracket

1/16” (2mm) Allen Wrench

Quick

Fastner

TM

Helix

Self-tapping

(ø 4.5mm x 38)

Screw (x3)

TM

Helix

Wall Mount

TM

Ryohan

TEL#GM

Screw (ø3mm x 10)

(except for Integrated)

FOR THERMAL MIX MODELS (except for Integrated):

Thermal Mixing

Controller

(TN78-10Vxx)

Fordham

TM

(TEL5 Series)

Water Inlet

Bracket (x2)

Axiom

TM

Integrated

TEL#LI

Self-tapping

Screw (x8)

(ø 4.5mm x 38)

RYOHAN MODEL ONLY: GOOSENECK WALL-MOUNT ONLY: HELIX WALL-MOUNT ONLY:

Drain

Drain Pipe

Brass

Nut (x2)

Mounting

Bracket

M5 Set

Screw

Washers

Brass (x1)

Rubber (x1)

Machine Screw

(ø M5mm x 30)

Wall Anchor

3

Allen

Wrench (x2)

Phillips Screw (x3)

(ø 4mm x 40)

Screw Anchor (x3)

Page 4

WARNINGS

This warning symbol appears in the installation instructions to alert you to the possibility of personal injury or damage to your

property if the instructions are not followed correctly.

No person other than a service engineer should disassemble, repair or modify this faucet, unless it is specifically

described in this manual. Failure to do so may result in electric shock or product malfunction.

Only set your faucet to the temperatures allowed in your local codes.

Do not use this faucet in a humid location where running water or condensation may collect on the surface, especially

in a sauna or steam room.

ENGLISH

Do not strike or kick the faucet or controller box, as this may damage the unit or cause a leak.

Do not touch the stop valve of the controller, as the surface may be very hot.

Disconnect the backup battery connector when the faucet is not in use for a long period of time.

Always close the stop valve(s) before cleaning the strainer.

Periodically check the piping for leaks.

If the room temperature drops to freezing, wrap the pipes with insulation.

Make sure the power cord does not come in contact with the hot-water supply pipe.

Avoid placing any objects within the detection range of the infrared sensor.

Occasionally turn the temperature control handle of the thermal mixing valve to prevent buildup or sticking.

BEFORE INSTALLATION

Observe all local and plumbing codes.

Check the cold and hot water supply pressure.

Make sure the cold water supply pressure is higher or equal to the hot water supply pressure. When the water supply

pressure is higher than 125 psi (826 kPa), be sure to reduce the pressure within a range of 20 to 80 psi by using a pressurereducing valve (sold separately). The working pressure range is between 15 psi and 80 psi (100 kPa and 551 kPa).

Check the temperature of the hot water supply (thermal mixing only).

Never use steam as a hot water supply.

The recommended temperature range: HOT supply 120°F - 180°F (49°C - 82°C) and COLD supply 39°F - 80°F

(4°C - 27°C)

Flush all water lines prior to installation.

Other precautions before you begin:

Pay special attention so that the sensor surface is not flawed or scratched during the installation process.

Make sure that all pipework, stop valves, and connection lines are installed according to local codes.

Do not place other devices that use an inverter or infrared sensor near the faucet, as this may cause the faucet to

malfunction.

* Water pressures over 80 psi are not recommended for most plumbing fixtures. Check your local plumbing code for details.

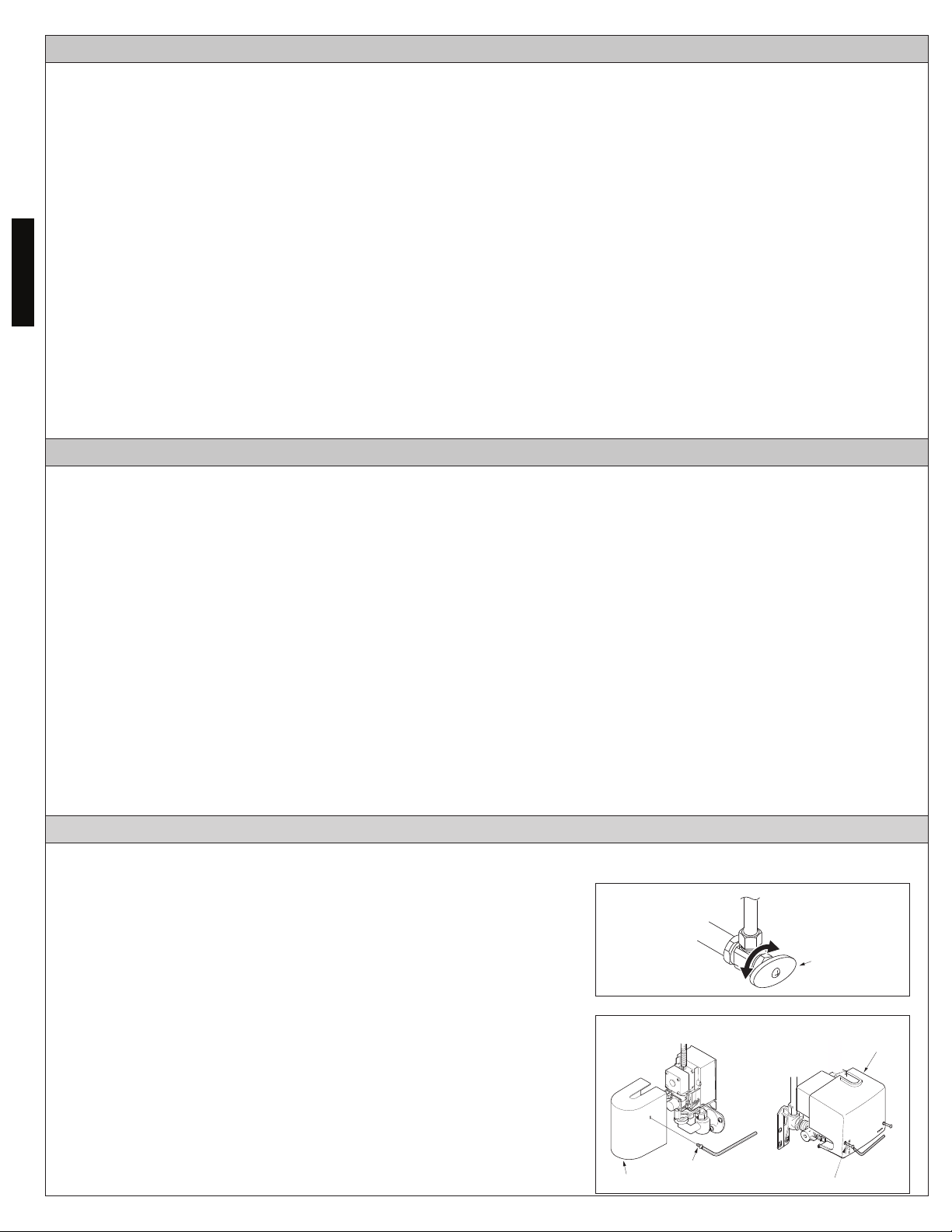

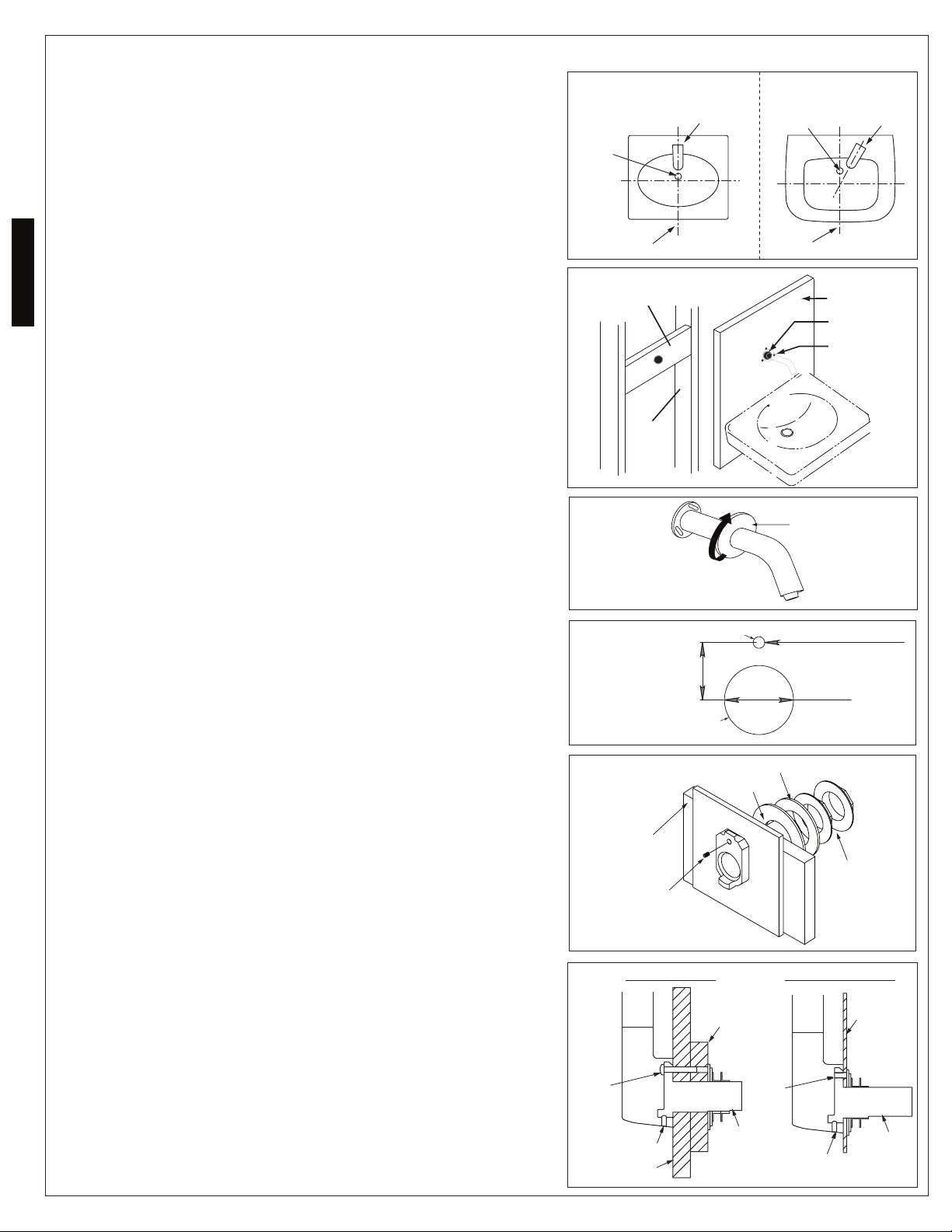

INSTALLATION PROCEDURE

Install the Controller

NO TE: Before installing the faucet, be sure to thoroughly

flush the supply pipes of dirt and debris. Shut off the

water supply at the stop valves after flushing (see Ill. 1).

1. See the roughin dimension page to determine the

proper location for the controller.

1. Remove the screws on the front of the controller cover

and pull to remove (see Ill. 2).

Ill. 1

Close

Stop Valve

Open

Ill. 2

Screw

Cover

4

Screws

Cover

Page 5

Install the Controller (continued)

3. Mount the water inlet bracket(s) on the wall,

using wall anchors (not included) if necessary and

temporarily tighten the screws. Hold the controller in

place on the bracket(s) to check for any obstructions

that may interfere with the controller or connections.

Once the bracket position is confirmed, tighten the

mounting screws (see Ill. 3).

NO TE: For the thermal mixing controllers, the water

inlet brackets MUST be mounted 3-¾” (95mm)

apart (center to center) to allow for proper

connection to the controller.

IMPORTANT!

Be sure to mount each water inlet bracket in the

correct upright direction as shown. Otherwise, the

strainer on the water inlet bracket will be inaccessible

for cleaning.

4. Connect the hot/cold water supply lines to the water

inlet bracket(s). For the thermal mixing controllers,

ensure that the hot water supply is connected to the

left water inlet bracket (see Ill. 4).

5. Connect the controller to the water inlet bracket:

For Single Supply Controller: Push the controller into

the water inlet bracket until it is fully seated, and

secure it with the included quick fastner.

For Thermal Mixing Controller: Check that the rubber

gaskets are located in the water inlet brackets.

Hold the controller in place and tighten the nuts

on the inlet brackets to secure it.

To install Integrated Deck Mount Models (III.1):

NOTE: 1-3/8” (35mm) faucet hole and 1-3/8” (35mm) min.

gap between finished wall and back of the spout is highly

recommended so that an Allen wrench can be placed behind

the spout (see the image below) for service/maintenance.

1. Install the spout with gasket into the center hole in deck

or lavatory.

2. Install strainers and flex hoses onto HOT and COLD

supply stops.

3. Tighten the 3/8” compression nuts to supply stops first;

then place the strainers and tighten the adapters.

4. Tighten the flex hoses securely to the adapters.

Top Cover

Set Screw

Allen wrench

IN

Wall Anchors

(not included)

Ill. 3

SINGLE SUPPLY

MODELS

Water

Inlet

Bracket

HOT IN

COLD IN

OUT

3-3/4”

(95mm)

Controller

Quick Fastener

Wall Anchors

(not included)

THERMAL MIXING

MODELS

Self-Tapping Screw

SINGLE SUPPLY MODELS

Ill. 4

Flexible Hose

(not included)

Nut

Gasket

Self-Tapping Screw

OUT

Copper Tube

(not included)

Nut

Friction Ring

Cone Washer

THERMAL MIXING MODELS

Flexible Hose

(not included)

Nut

Gasket

Controller

Water Inlet

Bracket

(Copper tube may be used in place of flexible hose)

III. 1

adapter

strainer

3/8”

compression nut

Supply Stop

min. 1-3/8”

(35mm)

Mounting

Bracket

Water

Inlet

Bracket

gasket

Mounting

nut

Gasket

Water Inlet

Bracket -

Side View

Water Inlet

Bracket -

Side View

Nut

Water Inlet

Bracket

Spout

gasket

Flex hose

Faucet Hole

1-3/8” (35mm)

Lock

Washer

ENGLISH

5

Page 6

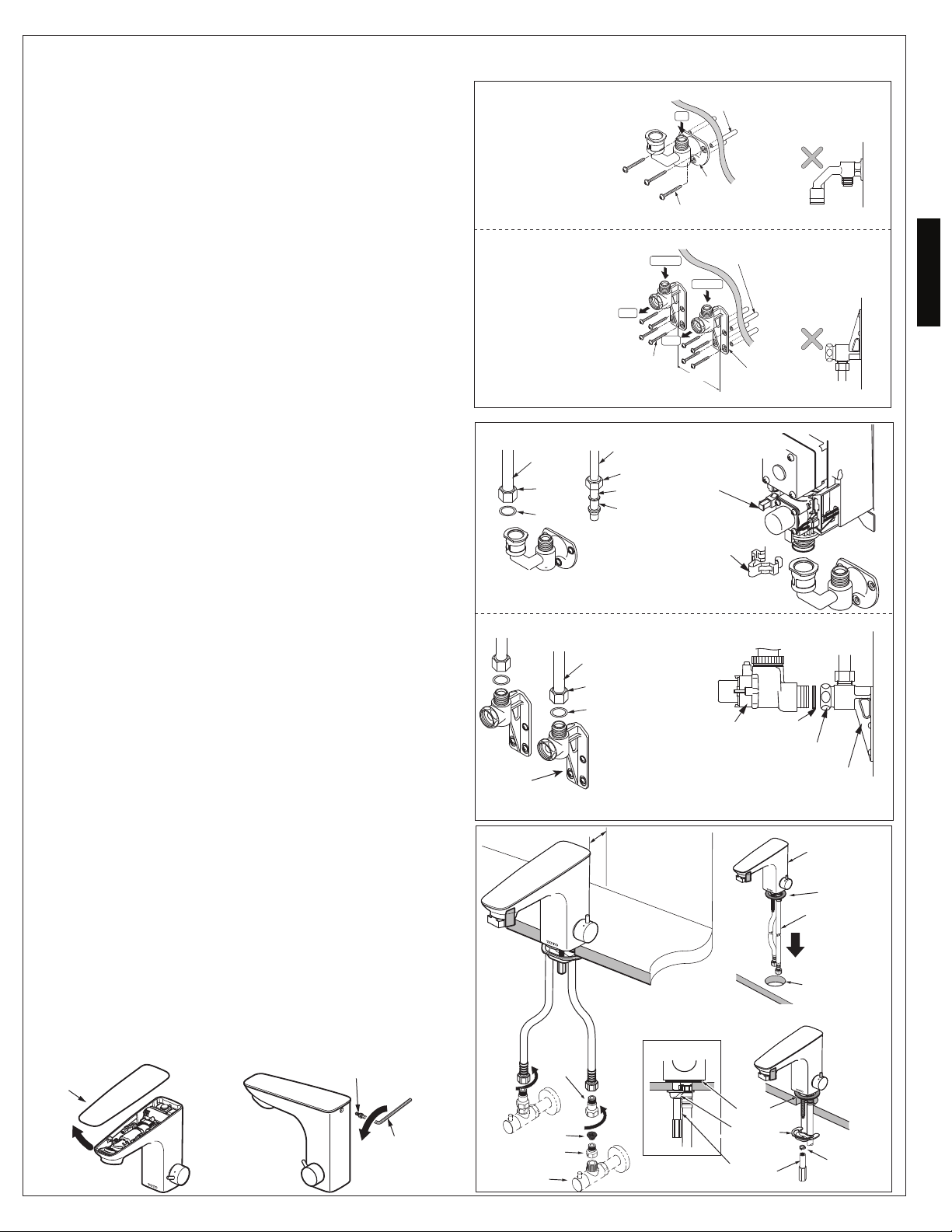

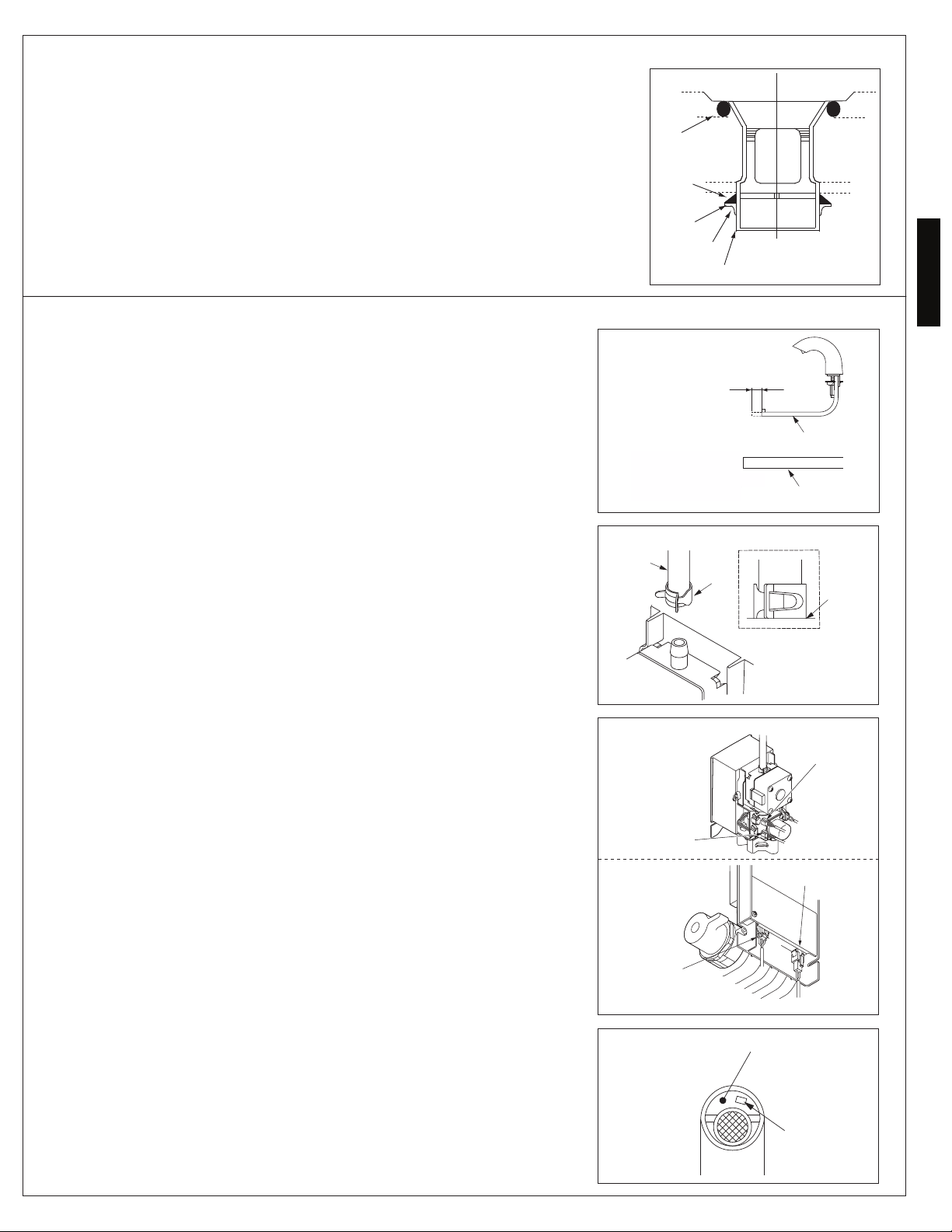

Install the Spout (continued)

STEP 8

To Install Deck-Mounted Models (Ill. 2):

Secure the spout to the countertop with the included

bracket and hexagonal nut. Make sure that the spout is

mounted with the tip directed towards the center of the

basin.

To Install Helix Wall-Mounted Models (Ill. 3 & 4):

NO TE: The addition of a 2 x 6” framing behind the

ENGLISH

marked locations and install the included wall

anchors. Fasten the spout securely to the wall

anchors with the provided Phillips screws.

spout installation location is highly recommended.

1. Drill a ¾” (19mm) diameter hole at the spout

mounting location for the supply hose and sensor cord to pass through.

2. Feed the supply hose and sensor cord through

the drilled hole and hold the mounting bracket

against the wall in the desired position. Mark

the location of the mounting bracket holes and

remove the spout.

3. Drill a 3/16” (5mm) diameter holes at the

4. Tighten the 3 small Phillips screws that secure

the spout to the mounting bracket, then handtighten the escutcheon to the bracket.

Ill. 2

Ill. 3

Ill. 4

SPOUT POSITION

IN THE CENTER

Drain

Basin Center

2 x 6

Framing

2 x 4

Studs

Spout

SPOUT POSITION

ON THE RIGHT

Drain

Basin Center

Finished Wall

3/4” Diameter

Hole for Anchors

3/16” Diameter

Holes for Anchors

Escutcheon

Spout

To Install Gooseneck Wall-Mounted Models (Ill. 5, 6 & 7):

NO TE: The addition of a 1 x 6” or plywood

bracing behind the mounting location is highly

recommended for drywall/hollow wall installations.

The overall maximum wall thickness is 2” (50mm).

1. Drill a 1-1/8” (29 mm) hole at the desired loca-

tion for the mounting bracket. Put the mounting

bracket through a hole in the wall with the set

screw hole located at 12 o’clock. Mark the location of the set screw hole on the wall and remove

the mounting bracket.

For sheet metal surface: Drill a 3/16” (4.8 mm) hole at

the marked location.

NO TE: Drill bits (not supplied) for hard materials

may be required.

For a drywall/hollow wall surface: Drill a 1/4”

(6.5 mm) hole at the marked location, and install the

included wall anchors.

NO TE: Confirmation of wall strength is highly

recommended before drilling.

2. Install the mounting bracket using the rubber

washer, brass washer, and both brass nuts

on back side of the installation surface.

Install the included set screw (for sheet metal

installation) or 30 mm machine screw (for drywall

installations).

3. Pass the hose and sensor cord through the

mount¬ing bracket, slide the spout base over

the mounting bracket and tighten the set screw

to secure the spout to the mounting bracket.

Hole for set screw/machine

Ill. 5

screw and wall

anchor

Hole for mounting bracket

Ill. 6

Plywood

(not required for sheet

metal installation)

Set Screw

(Sheet metal) or

Machine Screw

(Drywall/ Hollow

Wall)

Ill. 7

M5x30

Machine

Screw

and

Wall

Anchor

Set Screw

Drywall

15/16"

Brass Washer

Rubber Washer

1x6 or Plywood

Bracing

M5 Set

Screw

Mounting

Bracket

Ø 3/16” (sheet metal surface)

Ø 1/4” (drywall/hollow wall)

Ø 1-1/8"

Nuts (2)

Sheetmetal InstallationDrywall Installation

Thin Wall

(Sheet

Metal

Surface)

Mounting

Set Screw

Bracket

6

Page 7

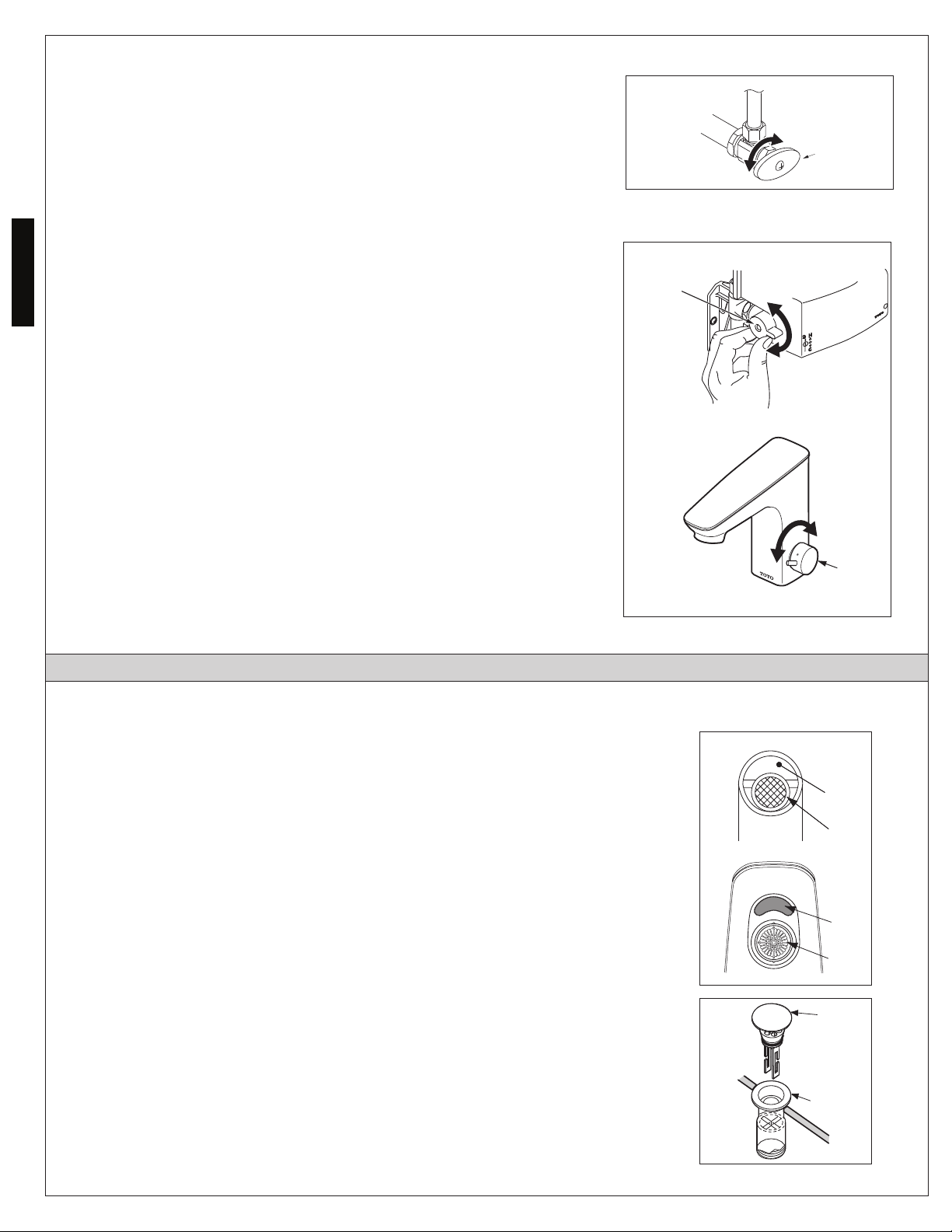

Install the Spout (continued)

To Install the Drain Assembly (Ryohan model only):

1. Install the main drain body, gasket, washer, and lock nut

in that order.

Gasket

Gasket

Washer

Lock Nut

Main Drain Body

Connect the Spout to the Controller

1. If the spout connecting hose is too long,

cut it to the appropriate length, making sure the end

is square. Do not cut the hose more than 4 inches

(see Ill. 1).

2. Push the spout connecting hose onto the outlet barb

of the controller and secure it with the hose clamp

(see Ill. 2). Make sure that the hose clamp is placed

fully against the controller.

3. Connect the backup battery connector (white) to the

controller (see Ill. 3).

IMPORTANT!

Wait 2 minutes before proceeding to the next step to

allow the internal circuitry to stablize.

Make sure there are no obstructions between the

sensor and the basin, then connect the spout sensor

connector (green) to the controller (see Ill. 3 & 4).

4. Confirm that the connections have been properly

made.

• The faucet will begin an automatic sensing range

adjustment immediately after the sensor connector

is plugged into the controller. During this process,

the red sensor light near the spout outlet will flash.

• Do not place your hands or other objects in front of

the sensor while the sensor light is flashing, as it will

interfere with the range adjustment process.

• If the sensor light continues to ash for more than

20 seconds, the spout direction will need to be

readjusted for proper operation. If adjustment is

necessary, you must do it within 10 minutes or the

adjustment process will end. To restart the process,

unplug the sensor connector for 10 seconds, then

reconnect it.

Ill. 1

Ill. 2

Spout

Connecting

Hose

Ill. 3

SINGLE

SUPPLY

MODELS

THERMAL

MIXING

MODELS

Sensor

Connector

(Green)

Cutting Length

Flexible Tube

Clamp

Sensor

Connector

(Green)

ENGLISH

90°

Spout Connecting

Hose

Spout Connecting

Hose

Hose

Clamp flush

with

controller

Backup Battery

Connector (White)

Backup Battery

Connector (White)

5. Double-check all connections, then reinstall the

controller cover, securing it with the screws.

WARNING: Draw the sensor cord from the bottom of the

controller while installing the controller cover to ensure

that the cord is not pinched.

Ill. 4

7

Sensor

Sensor

Light

Page 8

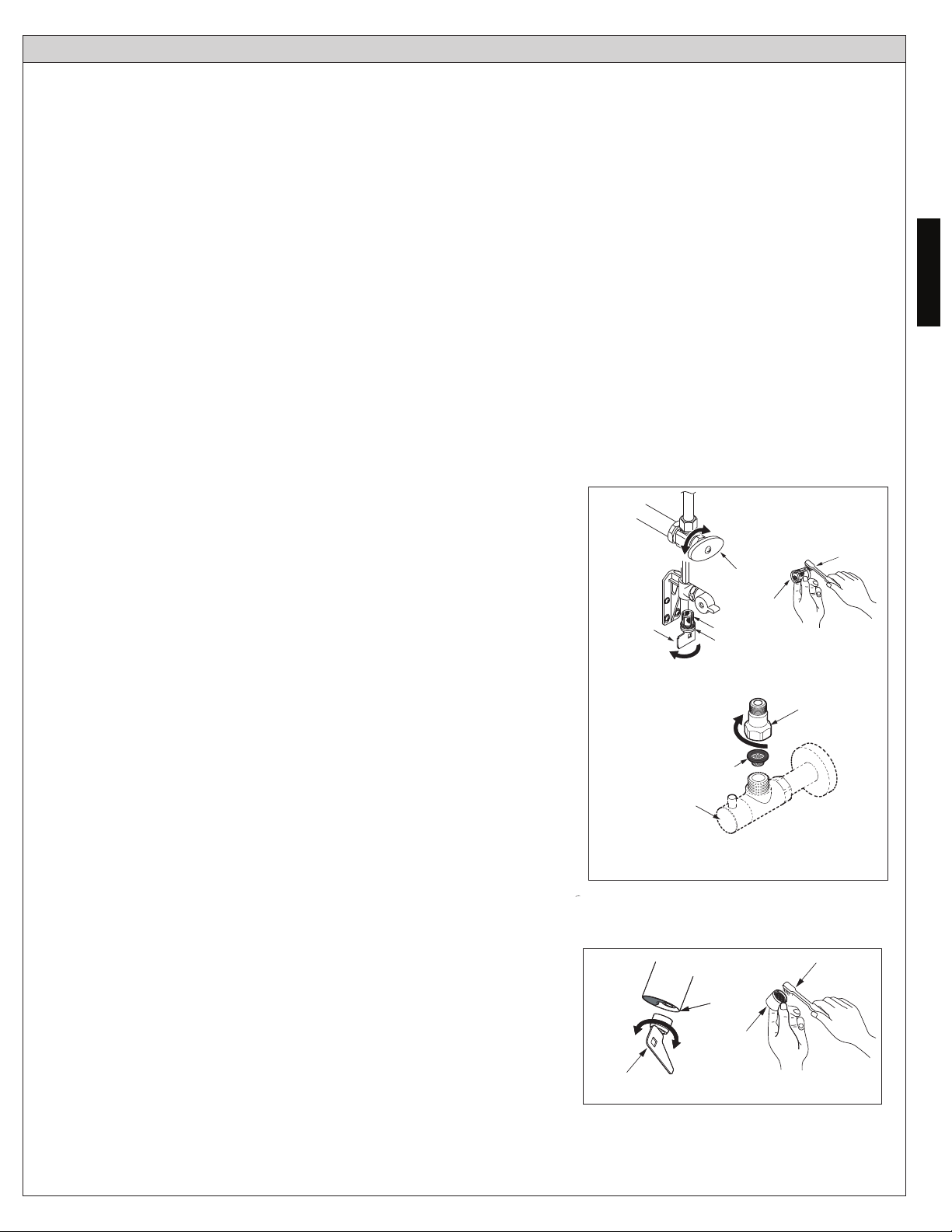

Testing and Adjustment

Turn on the water supply.

Turn on the water supply at the stop valves and inspect all the

Flow Rate Adjustment.

IMPORTANT: The EcoPower Automatic Faucets must be used

ENGLISH

If flowrate adjustment is necessary because the wash basin

Temperature Adjustment (thermal mixing models only).

The water temperature has been factory set at 100°F (38°C,

NOTE: If turning the temperature control handle changes the

connections for any leaks (see Ill. 1).

with the stop valves fully opened whenever possible. Insufficient flow rate will result in power shortage and consumption of

the built-in backup battery.

is too small or the water pressure is too high, turn the stop

valve(s) clockwise to limit the flow. Confirmation of wash basin

specifications is highly recommended before installation of the

Automatic Faucet.

Max: 42°C ± 3°C). Depending on the supply water pressure and

other local conditions, the water temperature may not be kept

as specified. In such a case, adjust the temperature by turning

the temperature control handle (see Ill. 2).

temperature opposite of the direction indicated, make sure the

hot water supply is connected to the left inlet bracket.

Ill. 1

Ill. 2

Temperature

Control

Handle

Close

Stop Valve

Open

Hot

Cold

Hot

CARE & CLEANING

Spout and Sensor

IMPORTANT! Do not scratch the sensor when cleaning the

spout (see Ill. 1).

Avoid using any cleaning materials that may scratch the spout

surface.

Never use polishing powder, detergent that includeds coarse

particles, thinners, benzene, acids, alkaline detergents, or nylon

scrub brushes, as they can damage the surface of the spout.

To safely clean the surface, wipe it using a dampened soft cloth

with diluted dishwashing detergent and dry it with another soft

cloth. If this does not adequately clean the surface, wipe the

area with a neutral detergent and wet cloth.

Drain (Ryohan only)

To remove the drain cup for cleaning (see Ill. 2):

1. Pull the drain cup unit firmly to the drain part, then release it.

2. Turn the drain cup unit clockwise 45 degrees.

3. Pull the drain cup upwards and out.

NO TE: If the drain cup unit does not come out, put it back and

while turning it clockwise once again, slowly pull it out.

Ill. 1

Ill. 2

Cold

Temperature

Control

Handle

Sensor

Area

Outlet

Sensor

area

Outlet

Drain

Cup

Unit

Main

Drain

Body

8

Page 9

PERIODIC MAINTENANCE

Check your faucet at least once a month for the following potential problems and to do the following maintenance procedures:

Inspect for Leakage

• Check all water connections for signs of leakage.

Tighten the Spout

• If the spout is loose, tighten the hexagonal nut underneath the spout for deck-mounted models.

• To tighten the Helix Wall-Mounted Spout:

1. Unscrew the escutcheon, tighten the three screws securing the mounting bracket to the wall and the three screws securing the spout to the mounting bracket.

2. Reinstall escutcheon.

• To tighten the Gooseneck Wall-Mounted Spout:

1. Turn off the water supply at the stop valves and disconnect the spout connecting hose from the controller.

2. Remove the spout from the mounting bracket by removing the set screw on the bottom of the spout base.

3. Tighten the set screw on the back of the spout, then reinstall the spout on the mounting bracket.

4. As required, ensure the set screw on the mounting bracket and mounting nuts behind the sink/wall (refer to “Install the

Spout” section) are tight.

Adjust the Temperature

• For thermostatic mixing models, turn the temperature control handle a few times a year. Buildup may form inside the

valve, resulting in impaired performance if maintenance is not regularly performed.

Ill. 1

Cleaning the Inlet Strainer and Nozzle

• When the inlet strainer is clogged, the ow rate will decrease. Decreased

flow rate can lead to insufficient power generation, which will deplete the

backup battery quickly.

• To clean the strainer (see Ill. 1):

1. Turn the water off at the stop valves.

2. Remove the strainer cover with the provided tool.

3. Pull out the strainer and clean it with a brush.

4. Re-install the clean strainer and open the stop valves.

Open

included

Tool

For Integrated Faucets

Close

Valve

Strainer

Strainer

Cover

Stop

Strainer

Brush

Adapter

ENGLISH

• To clean the nozzle (see Ill. 2):

1. Remove the nozzle from the spout with the suppplied tool.

2. Clean the nozzle with a soft brush to remove any dirt from the screen.

3. Re-install the nozzle in the spout.

9

Ill. 2

Open

Included

Tool

Stop

Valve

Close

Strainer

Brush

Spout

Nozzle

Spout

Nozzle

Page 10

Water won’t begin

ENGLISH

Water won’t stop

Low flow rate.

Water temperature

is too high.

Water temperature

Water temperature

is not controlled

Short detection

TROUBLESHOOTING

Problem Cause Solution

The surface of the sensor is dirty. Clean the surface of the sensor.

There is an obstruction in front of the sensor. Remove the obstruction.

The stop valve is turned off. Turn on the valve.

running.

running.

is too low.

properly.

range.

Backup battery connector is disconnected. Connect the backup battery connector.

The power generator and sensor connector is disconnected. Securely attach the connector(s).

Water supply is suspended. Wait until the water supply is restored.

The strainer or the regulating screen is clogged. Clean the strainer and the regulating screen.

The surface of the sensor is dirty. Clean the surface of the sensor.

There is an obstruction in front of the sensor. Remove the obstruction.

If the water continues to run after attempting the above solutions, turn off the stop valve.

The stop valve is not fully opened. Open the stop valve fully.

The strainer or the regulating screen is clogged. Clean the strainer and the regulating screen.

The temperature control handle is set at “H”. Set the temperature control handle to the middle point.

The stop valve connected to the cold-water supply is not fully

opened.

The temperature control handle is set at “C”. Set the temperature control handle to the middle point.

The stop valve connected to the hot water supply is not fully

opened.

The hot water supply temperature is lower than 120°F. Set the hot water supply temperature to 120°F.

One side of the stop valve is not fully opened. Open the stop valve fully.

The strainer or the regulating screen is clogged. Clean the strainer and the regulating screen.

The self-adjusting sensor may not work properly when strained

or blocked by water droplets.

Open the cold-water stop valve fully.

Open the hot water stop valve fully.

Clean the sensor surface.

SPECIFICATIONS

Power supply Hydropower Generation

Sensor Detection Range 5-1/8’”~ 7-7/8” (130~200mm)

Sensor is self-adjusting.

Water Supply Pressure

Water Supply Connection

Inlet Temperature range

Ambient Temperature 32~104°F (0~40°C)

Humidity Max. 90% RH

VARIED : 1.06 gallon per minute (4 L/min.), 0.8 gallon per minute (3 L/min.) and

Flow Rate*

Duration Time of Water Discharge* 10 seconds

*Refer to Price Book or consult with a TOTO Rep. for model numbers, flow rate and water discharge duration of each model.

**Check your local plumbing codes.

Minimum required water pressure: 15 psi (100 kPa) (Flowing)

Maximum water pressure: 80 psi (551 kPa)

1/2” NPSM

3/8” Compression (for Integrated Faucets only)

HOT: 120~180**°F (49~82°C)

COLD: 39~80°F (4~27°C)

0.5 gallon per minute (2 L/min.)

TEL5LI15 MODEL: minimum flow rate: 0.46 gpm (1.74 lpm)

water consumption: 0.15 gallon/cycle

15 seconds

60 seconds

10

Page 11

WARRANTY

1. TOTO® warrants its electronic flush valves, faucets and soap dispensers (“Product”) to be free from defects in materials and

workmanship during normal use when properly installed and serviced, for a period of three (3) years from date of purchase.

This limited warranty is extended only to the ORIGINAL PURCHASER of the Product and is not transferable to any third

party, including but not limited to any subsequent purchaser or owner of the Product. This warranty applies only to TOTO

Product purchased and installed in North, Central and South America.

2. TOTO’s obligations under this warranty are limited to repair, replacement or other appropriate adjustment, at TOTO’s

option, of the Product or parts found to be defective in normal use, provided that such Product was properly installed, used

and serviced in accordance with instructions. TOTO reserves the right to make such inspections as may be necessary in

order to determine the cause of the defect. TOTO will not charge for labor or parts in connection with warranty repairs or

replacements. TOTO is not responsible for the cost of removal, return and/or reinstallation of the Product.

3. This warranty does not apply to the following items:

a. Damage or loss sustained in a natural calamity such as fire, earthquake, flood, thunder, electrical storm, etc.

b. Damage or loss resulting from any accident, unreasonable use, misuse, abuse, negligence, or improper care, cleaning,

or maintenance of the Product.

c. Damage or loss resulting from sediments or foreign matter contained in a water system.

d. Damage or loss resulting from improper installation or from installation of the Product in a harsh and/or hazardous en-

vironment, or improper removal, repair or modification of the Product.

e. Damage or loss resulting from electrical surges or lightning strikes or other acts which are not the fault of TOTO or

which the Product is not specified to tolerate.

f. Damage or loss resulting from normal and customary wear and tear, such as gloss reduction, scratching or fading over

time due to use, cleaning practices or water or atmospheric conditions, including but not limited to, the use of bleach,

alkali, acid cleaners, dry (powder) cleaners or any other abrasive cleaners or the use of metal or nylon scrubbers.

4. In order for this limited warranty to be valid, proof of purchase is required. TOTO encourages warranty registration upon

purchase to create a record of Product ownership at http://www.totousa.com. Product registration is completely voluntary

and failure to register will not diminish your limited warranty rights.

5. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS. YOU MAY HAVE OTHER RIGHTS WHICH VARY FROM STATE TO

STATE, PROVINCE TO PROVINCE OR COUNTRY TO COUNTRY.

6. To obtain warranty repair service under this warranty, you must take the Product or deliver it prepaid to a TOTO service

facility together with proof of purchase (original sales receipt) and a letter stating the problem, or contact a TOTO distributor

or products service contractor, or write directly to TOTO U.S.A., INC., 1155 Southern Road, Morrow, GA 30260 (888) 295

8134 or (678) 466-1300, if outside the U.S.A. If, because of the size of the Product or nature of the defect, the Product

cannot be returned to TOTO, receipt by TOTO of written notice of the defect together with proof of purchase (original

sales receipt) shall constitute delivery. In such case, TOTO may choose to repair the Product at the purchaser’s location or

pay to transport the Product to a service facility.

ENGLISH

THIS WRITTEN WARRANTY IS THE ONLY WARRANTY MADE BY TOTO. REPAIR, REPLACEMENT OR OTHER APPROPRIATE

ADJUSTMENT AS PROVIDED UNDER THIS WARRANTY SHALL BE THE EXCLUSIVE REMEDY AVAILABLE TO THE ORIGINAL

PURCHASER. TOTO SHALL NOT BE RESPONSIBLE FOR LOSS OF THE PRODUCT OR FOR OTHER INCIDENTAL, SPECIAL

OR CONSEQUENTIAL DAMAGES OR EXPENSES INCURRED BY THE ORIGINAL PURCHASER, OR FOR LABOR OR OTHER

COSTS DUE TO INSTALLATION OR REMOVAL, OR COSTS OF REPAIRS BY OTHERS, OR FOR ANY OTHER EXPENSE NOT

SPECIFICALLY STATED ABOVE. IN NO EVENT WILL TOTO’S RESPONSIBILITY EXCEED THE PURCHASE PRICE OF THE

PRODUCT. EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW, ANY IMPLIED WARRANTIES, INCLUDING THAT

OF MERCHANTABILITY OR FITNESS FOR USE OR FOR A PARTICULAR PURPOSE, ARE EXPRESSLY DISCLAIMED. SOME

STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS, OR THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION AND EXCLUSION MAY NOT APPLY

TO YOU.

11

Page 12

ÍNDICE

¡Gracias Por Elegir TOTO! .................................................................................................................................................................. 12

Incluía Partes .........................................................................................................................................................................................12

Precaución.............................................................................................................................................................................................13

Antes de la Instalación ......................................................................................................................................................................... 13

Procedimiento de Instalación .........................................................................................................................................................13-17

Cuidado y Limpieza ..............................................................................................................................................................................17

Mantenimiento Periódico .................................................................................................................................................................... 18

Resolución de Problemas .................................................................................................................................................................... 19

Especificaciones ................................................................................................................................................................................... 19

Garantía .................................................................................................................................................................................................20

Bosquejo .........................................................................................................................................................................................30-31

Piezas de Repuesto .........................................................................................................................................................................32-34

¡GRACIAS POR ELEGIR TOTO!

La misión de TOTO es dar al mundo estilos de vida más saludables, higiénicos y cómodos. Diseñamos cada producto guiándonos

por el principio del equilibrio entre forma y función. Felicitaciones por su elección.

INCLUÍA PARTES

Asegúrese que todas estas partes estén incluidas en su empacado*:

(La apariencia de algunos componentes puede variar dependiendo del modelo)

ESPAÑOL

Standard

TEL#GS/LS TEL#GG/LG TEL#GGW/LGW

Herramienta Boquilla/Filtro

Controlador de

Suministro Único

(TN78-9Vxx)

Gooseneck

PARA MODELOS DE SUMINISTRO ÚNICO:

Soporte de

la Entrada de

Gooseneck

Wall Mount

(Serie TEL3)

Agua

TM

Helix

TEL#GC/LC TEL#GW/LW TEL#GT/LT TEL#GK/LK

1/16” (2mm) Llave Allen

Cierre

Rápido

Tornillo Autor-

roscante (x3)

(ø 4.5mm x 38)

SURTIDOR:

TM

Helix

Wall Mount

TM

Ryohan

TEL#GM

Tornillo (ø3mm x 10)

(excepto por lo Integrado)

PARA MODELOS DE MEZCLA TÉRMICA (excepto por lo Integrado):

Controlador de

Mezclado Térmico

(TN78-10Vxx)

Fordham

TM

(Serie TEL5)

Soporte de

la Entrada de

Agua (x2)

Axiom

TM

Tornillo Autor-

roscante (x8)

(ø 4.5mm x 38)

Integrated

TEL#LI

SÓLO MODELO RYHOAN: SÓLO GOOSENECK WALL-MOUNT: SÓLO HELIX WALL-MOUNT:

Desagüe

Tubería de

Desagüe

Soporte para

Montaje

Tuerca de

Latón (x2)

Arandelas

M5 Tornillo

de Fijación

Latón (x1)

Hule (x1)

12

Taquete

Tornillo para

Máquina

(ø M5mm x 30)

Llave Allen

(x2)

Tornillo Phillips (x3)

(ø 4mm x 40)

Taquete de

Tornillo (x3)

Page 13

PRECAUCIÓN

Es el símbolo que aparece en las instrucciones de instalación para que le avise de la posibilidad de lesiones personales o

daños a su propiedad si las instrucciones no se siguen correctamente.

Ninguna persona que no sea un ingeniero de servicios debe desensamblar, reparar o modificar este grifo, a menos que

se describa específicamente en este manual. No hacer lo anterior puede resultar en un malfuncionamiento del producto.

Fije las temperaturas del grifo únicamente a las permitidas en sus códigos locales.

No utilice este grifo en una ubicación húmeda donde se pueda acumular agua corriente o condensación en la superficie,

especialmente en un sauna o vapor.

No golpee o patee el grifo o la caja del controlador, ya que puede dañar la unidad o causar fugas.

No toque la válvula de cierre del responsable del tratamiento, ya que la superficie puede estar muy caliente.

Desconecte el conector de la batería de respaldo cuando el grifo no esté en uso por un largo periodo de tiempo.

Siempre cierre la(s) válvula(s) de suspensión al limpiar el filtro.

Revise periódicamente la tubería para verificar que no haya fugas.

Si la temperatura ambiente cae drásticamente, envuelva la tubería con aislante.

Asegúrese de que el cable de energía no entre en contacto con la tubería de suministro de agua caliente.

Evite colocar cualquier objeto dentro del rango de detección del sensor infrarrojo.

Ocasionalmente gire la manija de control de temperatura de la válvula de mezclado térmico para evitar acumulaciones o

que se atore.

ANTES DE LA INSTALACIÓN

Siga todos los códigos locales de plomería y construcción.

Revise la presión del suministro de agua fría y caliente.

Asegúrese que la presión del suministro de agua fría sea más alta o igual a la presión del suministro de agua caliente.

Cuando la presión del suministro de agua es mayor a 125 psi (826 kPa), asegúrese de reducir la presión dentro de un

intervalo de 20 a 80 psi utilizando una válvula reductora de presión (se vende por separado). El intervalo óptimo para la

presión de trabajo es entre 15 psi y 80 psi (100 kPa y 551 kPa).

Revise la temperatura del suministro de agua caliente (mezclado térmico únicamente).

Nunca utilice vapor como un suministro de agua caliente.

El intervalo de temperatura recomendado del suministro de agua caliente es entre 140°F - 185°C (60°C - 80°C).

Descargue todas las líneas de agua antes de su instalación.

Otras precauciones antes de comenzar:

Ponga especial atención para que la superficie del sensor no se dañe o raye durante el proceso de instalación.

Asegúrese que toda la tubería, válvulas de suspensión y líneas de conexión estén instaladas de acuerdo con los códigos

locales.

No coloque otros dispositivos que utilicen un inversor o sensor infrarrojo cerca del grifo, ya que puede causar un

malfuncionamiento del grifo.

ESPAÑOL

PROCEDIMIENTO DE INSTALACIÓN

Instale el Controlador

NO TA: Antes de instalar el grifo, asegúrese de descargar

perfectamente las tuberías de suministro de suciedad

o desechos. Cierre el suministro de agua en las válvulas

de suspensión después de descargarlas (ver III. 1).

1) Vea la página de dimensiones en borrador para determinar la ubicación adecuada para el controlador.

2) Retire los tornillos en la parte de enfrente de la cubierta

del controlador y jale para retirarla (ver III. 2).

13

Ill. 1

Ill. 2

Cubierta

Tornillo

Abrir

Cerrar

Válvula de

Suspensión

Cubierta

Tornillos

Page 14

Instale el Controlador (continuación)

3) Monte el(los) soporte(s) de la entrada de agua en la

pared, utilizando taquetes de pared (no incluidos)

si es necesario y apriete temporalmente los tornillos. Sostenga el controlador en su lugar en el(los)

soporte(s) para verificar cualquier obstrucción que

pudiera interferir con el controlador o las conexiones.

Una vez que la posición del soporte sea confirmada,

apriete los tornillos de montaje (ver III. 3).

NO TA: Para los controladores de mezclado térmico,

los soportes de la entrada de agua DEBEN estar

montados 3-3/4” (95 mm) aparte (centro a centro)

para permitir una adecuada conexión al controlador.

¡IMPORTANTE!

Asegúrese de montar cada soporte de la entrada de

agua en la posición vertical correcta, tal y como se

muestra. De otra manera, el filtro en el soporte de la

entrada del agua será inaccesible para la limpieza.

ESPAÑOL

4) Conecte las líneas de suministro de agua caliente/

fría al (los) soporte(s) de entrada de agua. Para los

controladores de mezclado térmico, asegúrese que el

suministro de agua caliente esté conectado al soporte

de entrada de agua izquierdo (ver III. 4).

Ill. 3

MODELOS DE

SUMINISTRO

ÚNICO

Tornillo Autorroscante

MODELOS DE

MEZCLA TÉRMICA

OUT

Tornillo Autorroscante

MODELOS DE SUMINISTRO ÚNICO

Ill. 4

Tubo Flexible

(no está incluido)

Tuerca

Junta

Copper Tube

(no está incluido)

Nut

Anillo de

Fricción

Arandela

Cónica

(no está incluido)

IN

Soporte

de la

Entrada

de Agua

HOT IN

COLD IN

OUT

3-3/4”

(95mm)

Controller

Quick Fastener

Taquetes

Taquetes

(no está incluido)

Soporte de

la Entrada

de Agua

Soporte de la

Entrada de Agua -

Vista Lateral

Soporte de la

Entrada de Agua -

Vista Lateral

5) Conecte el controlador al soporte de entrada de agua

(ver III. 5):

Para el Controlador de Suministro Único: Empuje el

controlador hacia el soporte de entrada de agua

hasta que esté completamente acomodado y

asegúrelo con el cierre rápido incluido.

Para el Controlador de Mezclado Térmico: Revise que

las juntas de hule sean colocadas en los soportes

de la entrada de agua. Sostenga el controlador

en su lugar y apriete las tuercas en los soportes

de la entrada para asegurarlo.

Para instalar los modelos con cubierta montada:

NOTA: Se recomienda ampliamente dejar un orificio

para el grifo de 1-3/8” (35mm) y un espacio de 1-3/8”

(35mm) entre la pared terminada y la parte posterior del

surtidor (véase la siguiente imagen) para servicio/mantenimiento. 1) Instale el surtidor con junta en el orificio

central dentro de la cubierta o lavabo. 2) Instale los filtros

y mangueras flexibles a los frenos de suministro CALIENTE y FRÍO. 3) Apriete las tuercas de compresión de 3/8”

a los frenos de suministro primero; después coloque los

filtros y apriete los adaptadores. 4) Apriete las mangueras flexibles de manera segura a los adaptadores

MODELOS DE MEZCLA TÉRMICA

Tubo Flexible

(no está incluido)

Tuerca

Junta

Controlador

Soporte de

la Entrada de

Agua

El tubo de cobre puede utilizarse en lugar de la manguera flexible

III. 1

min. 1-3/8”

(35mm)

Tuerca

Junta

Soporte de la Entrada

de Agua

Del Surtidor

Junta

Flex hose

Tubo Flexible

Faucet Hole

1-3/8” (35mm)

La cuiberta

Top Cover

Tornillo de Fijación

Set Screw

Allen wrench

Llave Allen

3/8”

compression nut

Supply Stop

14

adapter

strainer

Junta

del Soporte

Mounting

de Montaje

Bracket

Mounting

nut

Lock

Washer

Page 15

Instale el Surtidor

Para Instalar Modelos Montados en el Mostrador (III. 2):

Asegure el surtidor a la parte superior del mostrador con el so-

porte incluido y la tuerca hexagonal. Asegúrese de que el surtidor

sea montado con la punta apuntando hacia el centro del lavabo

Para Instalar Modelos Montados en la Pared de Hélice (III. 3 y 4):

NO TA: La adición de un marco de 2 x 6” detrás de la ubicación

de la instalación del surtidor es altamente recomendable.

1) Perfore un orificio de 3/4” (19 mm) de diámetro en la ubicación

de montaje del surtidor para que la manguera de suministro y

el cable del sensor pasen a través de él.

2) Pase la manguera de suministro y el cable del sensor a través

del orificio perforado y sostenga el soporte de montaje contra

la pared en la posición deseada. Marque la ubicación de los

orificios del soporte de montaje y retire el surtidor.

3) Perfore orificios de 3/16” (5mm) de diámetro en las ubicaciones marcadas e instale los taquetes incluidos. Apriete el

surtidor fuertemente a los taquetes con los tornillos Phillips

proporcionados.

4) Apriete los 3 tornillos pequeños Phillips que aseguran el surtidor al soporte de montaje, después apriete con la mano el

escudete al soporte.

Para Instalar los Modelos Montados en Pared Cuello de Ganso

(Ill. 5, 6 & 7):

NO TA: La adición de un contrachapado de recubrimiento de 1 x

6” detrás de la ubicación de montaje es altamente recomendable para las instalaciones en pared laminada/pared hueca. El

grosor de pared máximo total es de 2” (50mm).

1) Perfore un orificio de 1-1/8” (29 mm) en la ubicación deseada

para el soporte de montaje. Ponga el soporte de montaje a

través de un orificio en la pared con el orificio del tornillo de

fijación ubicado a las 12 en punto. Marque la ubicación del

orificio del tornillo de fijación en la pared y retire el soporte de

montaje.

Para una superficie de hoja de metal: Perfore un orificio de

3/16” (4.8 mm) en la ubicación marcada.

NO TA: Se pueden necesitar brocas de taladro (no propor-

cionadas) para materiales duros.

Para una superficie de pared laminada/pared hueca: Perfore

un orificio de 1/4” (6.5 mm) en la ubicación marcada e

instale los taquetes incluidos.

NO TA: Es altamente recomendable la confirmación de la

resistencia de la pared antes de perforar.

2) Instale el soporte de montaje utilizando una arandela de

hule, arandela de latón y ambas tuercas de latón en la

parte posterior de la superficie de instalación. Instale el

tornillo de fijación incluido (para la instalación en hoja metálica) ó tornillo de máquina de 30 mm (para instalaciones

en pared laminada).

3) Pase la manguera y el cable del sensor a través del soporte

de montaje, deslice la base del surtidor sobre el soporte

de montaje y apriete el tornillo de fijación para asegurar el

surtidor al soporte de montaje.

Ill. 2

POSICIÓN DEL SURTI-

DOR EN EL CENTRO

Desagüe

Centro del Lavabo

Ill. 3

Marco de

2 x 6

2 x 4

Montantes

Ill. 4

Orificio para el tornillo de

Ill. 5

fijación/tornillo de máquina

y anclaije de pared

Orificio para el surtidor al

soporte de montaje

Ill. 6

Contrachapado

(no se requiere para

la instalación en hoja

metálica)

Tornillo de Fijación

(Hoja Metálica) or Tornillo

de Máquina (pared lami-

nada/pared hueca)

Ill. 7

Tornillo de

Máquina

Taquetes

Tornillo de Fijación

Instalación en Pared

Laminada

M5x30

y

Pared Laminada

Surtidor

15/16"

Arandela de

Goma

1x6 o Contra-

chapado de

Recubrimiento

Tornillo de

Soporte de

Montaje

POSICIÓN DEL SURTIDOR

DEL LADO DERECHO

Desagüe

Centro del Lavabo

Pared Terminada

Orificio de 3/4” de Diá-

Diámetro para Taquetes

Escudete

Ø 3/16” (Superficie de la

hoja metálica)

Ø 1/4” (superficie de pared

laminada/pared hueca)

Ø 1-1/8"

Arandela de Latón

Instalación en Hoja

M5

Fijación

Tornillo de

Fijación

metro para Taquetes

Orificio de 3/16” de

Surtidor

Tuercas (2)

Metálica

Delgada

(Superficie

de la Hoja

Metálica)

Soporte de

ESPAÑOL

Pared

Montaje

15

Page 16

Instale el Surtidor (continuación)

Para instalar el montaje del desagüe (modelo Ryohan

únicamente):

1) Instale el cuerpo principal de desagüe, junta, arandela

y contratuerca en ese orden.

Conecte el Surtidor al Controlador

Junta

Junta

Arandela

Contratuerca

Cuerpo Principal de Desagüe

1) Si la manguera que conecta el surtidor es demasiado larga,

córtela a la longitud adecuada, asegurándose que el extremo

esté cuadrado. No corte la manguera más de 4 pulgadas.

2) Empuje la manguera que conecta el surtidor en la lengüeta

de salida del controlador y asegúrela con la abrazadera de

la manguera (ver III. 2). Asegúrese que la abrazadera de la

ESPAÑOL

manguera esté perfectamente colocada contra el controlador.

3) Conecte el conector de la batería de respaldo (blanco) al

controlador (ver III. 3).

¡IMPORTANTE!

Espere 2 minutos antes de proceder al siguiente paso para

permitir que el circuito interno se estabilice.

Asegúrese que no haya obstrucciones entre el sensor y el

lavabo, después conecte el conector del sensor del surtidor

(verde) al controlador (ver III. 3 y 4).

4) Confirme que las conexiones se hayan realizado

adecuadamente.

• El grifo iniciará un ajuste automático del rango sensor

inmediatamente después de que el conector del sensor se

haya conectado al controlador. Durante este proceso, la luz

roja del sensor cerca de la salida del surtidor parpadeará.

• No coloque sus manos u otros objetos enfrente del sensor

mientras la luz del sensor esté parpadeando, ya que puede

interferir con el proceso de ajuste del rango.

• Si la luz del sensor sigue parpadeando por más de 20

segundos, se deberá reajustar la dirección del surtidor para

una operación adecuada. Si el ajuste es necesario, debe

hacerlo dentro de los siguientes 10 minutos o el proceso

de ajuste terminará. Para reiniciar el proceso, desconecte el

conector del sensor 10 segundos y vuélvalo a conectar.

5) Vuelva a revisar todas las conexiones, después reinstale la

cubierta del controlador, asegurándola con los tornillos.

Ill. 1

Largo de Corte

Ill. 2

Manguera

que Conecta

el Surtidor

Ill. 3

MODELOS DE

SUMINISTRO

ÚNICO

Conector del

Sensor (Verde)

MODELOS

DE MEZCLA

TÉRMICA

Conector del

Sensor (Verde)

Abrazadera de la

Manguera

90°

Manguera que Conecta

el Surtidor

Manguera que Conecta

el Surtidor

Abrazadera

con

Controlador

Conector de la

Batería de Respaldo

(Blanco)

Conector de la

Batería de Respaldo

(Blanco)

ADVERTENCIA: Lleve el cable del sensor a la parte inferior del

controlador mientras instala la cubierta del controlador para

asegurarse que el cable no quede atrapado.

16

Ill. 4

Sensor

Luz del Sensor

Page 17

Pruebas y Ajuste

Encienda el suministro de agua.

Encienda el suministro de agua en las válvulas de suspensión

e inspeccione todas las conexiones para verificar que no haya

fugas (ver III. 1).

Ajuste de la velocidad del flujo.

IMPORTANTE: Los grifos automáticos EcoPower deben ser uti-

lizados con la válvulas de suspensión completamente abiertas

siempre que sea posible. Una velocidad de flujo insuficiente

tendrá como resultado una escasez de energía y consumo de la

batería de respaldo incorporada.

Si el ajuste de la velocidad del flujo es necesaria debido a que

el lavabo es muy pequeño o la presión del agua es muy alta,

gire la(s) válvula(s) de suspensión en el sentido de las manecillas del reloj para limitar el flujo. La confirmación de la especificaciones del lavabo es altamente recomendable antes de la

instalación del grifo automático.

Ajuste de la Temperatura (modelos de mezclado térmico

únicamente).

La temperatura del agua fue configurada en la fábrica a 100°F

(38°C, Máx: 42°C ± 3°C). Dependiendo de la presión de agua

del suministro y otras condiciones locales, la temperatura del

agua puede no guardarse como se especifica. En tal caso,

ajuste la temperatura girando la manija del control de temperatura (ver III. 2).

NOTA: Si al girar la manija del control de temperatura se

cambia la temperatura a la dirección opuesta de la indicada,

asegúrese que el suministro de agua caliente esté conectado al

soporte de entrada izquierdo.

Ill. 1

Ill. 2

Manija del

Control de

Temperatura

Abrir

Cerrar

Válvula de

Cierre

Abrir

Cerrar

ESPAÑOL

CUIDADO Y LIMPIEZA

Surtidor y Sensor

¡IMPORTANTE! No raye el sensor al limpiar el surtidor (ver III.

1).

Evite utilizar cualquier material de limpieza que pueda rayar la

superficie del surtidor.

Nunca utilice polvo para pulir, detergente que incluya partícu-

las corrosivas, thinners, benceno, ácidos, detergentes alcalinos

ni estropajos de nylon, ya que pueden dañar la superficie del

surtidor.

Para limpiar la superficie con seguridad, límpiela con un trapo

remojado en detergente para trastes diluido y séquelo con otro

trapo. Si esto no limpia adecuadamente la superficie, límpiela

con un detergente neutro y un trapo mojado.

Desagüe (Ryohan únicamente)

Para retirar el embudo de desagüe para limpiarlo (ver III. 2):

1) Jale la unidad del embudo de desagüe firmemente a la

parte del desagüe, después suéltela.

2) Gire la unidad del embudo de desagüe en sentido de las

manecillas del reloj 45 grados.

3) Jale el embudo de desagüe hacia arriba y hacia afuera.

Ill. 1

Ill. 2

Sensor

Area

Outlet

Sensor

area

Outlet

Unidad

del Embudo

de Desagüe

Cuerpo

Principal de

Desagüe

NO TA: Si la unidad del embudo de desagüe no sale, póngalo

otra vez en su lugar y mientras lo gira en sentido de las

manecillas del reloj otra vez, lentamente jálelo hacia afuera.

17

Page 18

MANTENIMIENTO PERIÓDICO

Revise su grifo al menos una vez al mes para los siguientes problemas potenciales y para realizar los siguientes procedimientos de mantenimiento:

Inspeccione Para ver si Hay Fugas

• Revise todas las conexiones de agua para ver si hay signos de fugas.

Apriete el Surtidor

• Si el surtidor está ojo, apriete la tuerca hexagonal debajo del surtidor para los modelos montados en el mostrador.

• Para apretar el Surtidor Montado en la Pared de Helix:

1) Desatornille el escudete, apriete los tres tornillos que aseguran el soporte de montaje a la pared y los tres tornillos que aseguran

el surtidor al soporte de montaje.

2) Reinstale el escudete.

• Para apretar el Surtidor Montado en la Pared Cuello de Ganso:

1) Cierre el suministro de agua en las válvulas de suspensión y desconecte la manguera que conecta el surtidor del controlador.

2) Retire el surtidor del soporte de montaje quitando el tornillo de fijación en la parte inferior de la base del surtidor.

3) Apriete el tornillo de fijación en la parte posterior del surtidor, después reinstale el surtidor en el soporte de montaje.

4) Según se requiera, asegure el tornillo de fijación en el soporte de montaje y las tuercas de fijación detrás del lavabo/pared (consulte la sección “Instale el surtidor”) están apretadas.

Ajuste la Temperatura

• Para los modelos de mezclado térmico, gire la manija del control de temperatura algunas veces en el año. Se pueden

formar acumulaciones dentro de la válvula, teniendo como resultado un desempeño dañado si no se lleva a cabo el

ESPAÑOL

mantenimiento regularmente.

Limpiando el Filtro de Entrada y la Boquilla

• Cuando el ltro de entrada esté tapado, la velocidad de ujo disminuirá.

Una disminución en la velocidad del flujo puede llevar a una generación

de energía insuficiente, que agotará la batería de respaldo rápidamente.

• Para limpiar el ltro (ver III. 1):

1) Cierre el agua en las válvulas de suspensión.

2) Retire la cubierta del filtro con la herramienta proporcionada.

3) Jale el filtro hacia afuera y límpielo con un cepillo.

4) Reinstale el filtro limpio y abra las válvulas de suspensión.

• Para limpiar la boquilla (ver III. 2):

1) Retire la boquilla del surtidor con la herramienta proporcionada.

2) Limpie la boquilla con un cepillo suave para retirar toda la suciedad de la

pantalla.

3) Reinstale la boquilla en el surtidor.

Ill. 1

Abrir

Herramienta

Incluida

Para grifos integrados

Stop

Valve

Ill. 2

Abrir

Cerrar

Herramienta

Incluida

Cerrar

Cepillo

Válvula de

Suspensión

Filtro

Filtro

Strainer

Cover

Adapter

Strainer

Cepillo

Boquilla del

Surtidor

Boquilla del

Surtidor

18

Page 19

RESOLUCIÓN DE PROBLEMAS

Problema Causa Solución

La superficie del sensor está sucia. Limpie la superficie del sensor.

Hay una obstrucción enfrente del sensor. Retire la obstrucción.

La válvula de suspensión está apagada. Abra la válvula.

El agua no empieza

a correr.

El agua no sigue

corriendo.

Velocidad del flujo

baja.

La temperatura del

agua es demasiado

alta.

La temperatura del

agua es demasiado

baja.

La temperatura

del agua no está

controlada adecua-

damente.

Rango de detección

corto.

El conector de la batería de respaldo está desconectada. Conecte el conector de la batería de respaldo.

El generador de energía y el conector del sensor están desco-

nectados.

El suministro de agua está suspendido. Espere a que el suministro de agua se restablezca.

El filtro o la pantalla reguladora está tapado. Limpie el filtro y la pantalla reguladora.

La superficie del sensor está sucia. Limpie la superficie del sensor.

Hay una obstrucción enfrente del sensor. Retire la obstrucción.

Si el agua continúa corriendo después de intentar las soluciones anteriores, cierre la válvula de suspensión.

La válvula de suspensión no está completamente abierta. Abra la válvula de suspensión completamente.

El filtro o la pantalla reguladora está tapado. Limpie el filtro y la pantalla reguladora.

La manija del control de temperatura está fija en “H”. Fije la manija del control de temperatura en el punto

La válvula de suspensión conectada al suministro de agua fría

no está completamente abierta.

La manija del control de temperatura está fija en “C”. Fije la manija del control de temperatura en el punto

La válvula de suspensión conectada al suministro de agua caliente no está completamente abierta.

La temperatura del suministro de agua caliente es menor a 120F. Fije la temperatura del suministro de agua caliente en 120F.

Un lado de la válvula de suspensión no está completamente

abierto.

El filtro o la pantalla reguladora está tapado. Limpie el filtro y la pantalla reguladora.

El sensor de ajuste automático puede no funcionar adecuadamente cuando está tapado o bloqueado por gotitas de agua.

Fije perfectamente el (los) conector(es).

medio.

Abra la válvula de suspensión de agua fría completamente.

medio.

Abra la válvula de suspensión de agua caliente completa-

mente.

Abra la válvula de suspensión completamente.

Limpie la superficie del sensor.

ESPAÑOL

ESPECIFICACIONES

Suministro de Energía Generación de Hidroenergía

Rango de Detección del Sensor 5-1/8’”~ 7-7/8” (130~200mm)

El sensor tiene ajuste automático.

Presión del Suministro de Agua

Conexión del Suministro de Agua 1/2” NPSM

Temperatura Ambiente 32~104°F (0~40°C)

Humedad Max. 90% RH

Velocidad del Flujo

Tiempo de Duración de la Descarga

de Agua

Consulte el Libro de precios o con un representante de TOTO para conocer los números de modelo y velocidad de flujo y la

duración de descarga de agua de cada modelo.

Presión del agua mínima requerida: 15 psi (100 kPa) (fluyendo)

Presión del agua máxima: 80 psi (551 kPa)

Compresión de 3/8” (únicamente para grifos integrados)

1.06 galón por minuto (4 L/minuto)

0.8 galón por minuto (3 L/minuto)

0.5 galón por minuto (2 L/minuto)

10 segundos

60 segundos

Varía de acuerdo al modelo. Determinado por el controlador.

19

Page 20

GARANTÍA

1. TOTO® garantiza que sus válvulas de descarga, grifos y dispensadores de jabón automáticos (“Producto”) no tienen defectos en los materiales y mano de obra durante su uso normal, cuando son adecuadamente instalados y cuidados, por un

periodo de tres (3) años a partir de la fecha de compra. Esta garantía limitada se extiende únicamente al COMPRADOR

ORIGINAL del Producto y no es transferible a ninguna tercera persona, incluyendo, pero sin limitarse a, cualquier comprador o dueño subsecuente del Producto. Esta garantía aplica únicamente al Producto TOTO adquirido e instalado en

América del Norte, Central y del Sur.

2. Las obligaciones de TOTO bajo esta garantía se limitan a reparar, reemplazar u otro ajuste adecuado, a elección de TOTO,

del Producto o partes que estén defectuosas con el uso normal, dado que dicho Producto haya sido adecuadamente instalado, utilizado y cuidado de acuerdo con las instrucciones. TOTO se reserva el derecho de hacer dichas inspecciones, ya

que pueden ser necesarias con el fin de determinar la causa del defecto. TOTO no cobrará por el trabajo o partes relacionados con las reparaciones o cambios de la garantía. TOTO no es responsable por el costo de remoción, devolución y/o

reinstalación del Producto.

3. Esta garantía no aplica a los siguientes puntos:

a. Daño o pérdida ocurridos en una calamidad natural, tal como un incendio, terremoto, inundación, truenos, tormenta

eléctrica, etc.

b. Daño o pérdida resultado de cualquier accidente, uso no razonable, mal uso, abuso, negligencia o cuidado, limpieza o

mantenimiento inadecuado del Producto.

c. Daño o pérdida resultado de sedimentos o materia extraña contenidos en un sistema de aguas.

d. Daño o pérdida resultado de una instalación inadecuada o de la instalación del Producto en un ambiente riguroso y/o

ESPAÑOL

peligros, o la remoción, reparación o modificación inadecuada del Producto.

e. Daño o pérdida resultado de sobrecarga eléctrica o rayos u otros actos que no sean culpa de TOTO o que el Producto

no esté especificado para tolerar.

f. Daño o pérdida resultado del desgaste normal y acostumbrado, tal como reducción del brillo, rayado u opacamiento en

el tiempo debido al uso, prácticas de limpieza o agua o condiciones atmosféricas, incluyendo pero sin limitarse a, el uso

de cloro, limpiadores alcalinos o ácidos, limpiadores secos (talco) u otros limpiadores abrasivos o el uso de estropajos

de metal o nylon.

4. Con el fin de que esta garantía limitada sea válida, se requiere una prueba de compra. TOTO le aconseja el registro de la

garantía al momento de la compra para crear un registro de la propiedad del Producto en http://totousa.com. El registro

del Producto es completamente voluntario y no hacerlo no disminuirá los derechos de su garantía limitada.

5. ESTA GARANTÍA LE OTORGA DERECHOS LEGALES ESPECÍFICOS. USTED PUEDE TENER OTROS DERECHOS QUE PU-

EDEN VARIAR ENTRE ESTADOS, PROVINCIAS O PAÍSES.

6. Para obtener un servicio de reparación por garantía bajo esta garantía, debe llevar el Producto o enviarlo prepagado a las

instalaciones de servicio TOTO junto con su prueba de compra (recibo de venta original) y una carta declarando el problema, o póngase en contacto con un distribuidor de TOTO o contratista de servicio de productos, o escriba directamente

a TOTO U.S.A., INC., 1155 Southern Road, Morrow, GA 30260 (888) 295 8134 ó (678) 466-1300, si está fuera de los Estados

Unidos. Si, debido al tamaño del Producto o naturaleza del defecto, el Producto no puede devolverse a TOTO, la recepción

de TOTO del aviso por escrito del defecto junto con la prueba de compra (recibo de venta original) constituirá el envío. En

tal caso, TOTO puede elegir entre reparar el Producto en la ubicación del comprador o pagar el transporte del Producto a

unas instalaciones de servicio.

ESTA GARANTÍA ESCRITA ES LA ÚNICA GARANTÍA HECHA POR TOTO. LA REPARACIÓN, CAMBIO U OTRO AJUSTE ADECUADO, SEGÚN LO ESTIPULADO EN ESTA GARANTÍA, SERÁ EL ÚNICO REMEDIO DISPONIBLE PARA EL COMPRADOR

ORIGINAL. TOTO NO SERÁ RESPONSABLE DE LA PÉRDIDA DEL PRODUCTO O DE OTROS DAÑOS INCIDENTALES, ESPECIALES O CONSECUENCIALES O GASTOS INCURRIDOS POR EL COMPRADOR ORIGINAL, O PARA EL TRABAJO U OTROS

COSTOS DEBIDO A LA INSTALACIÓN O REMOCIÓN, O COSTOS DE REPARACIONES HECHAS POR TERCEROS, O POR

CUALQUIER OTRO GASTO NO DECLARADO ESPECÍFICAMENTE ARRIBA. EN NINGÚN CASO, LA RESPONSABILIDAD DE

TOTO EXCEDERÁ EL PRECIO DE COMPRA DEL PRODUCTO. EXCEPTO AL GRADO PROHIBIDO POR LA LEY APLICABLE,

CUALQUIER GARANTÍA IMPLÍCITA, INCLUYENDO LA DE COMERCIABILIDAD O ADECUACIÓN PARA SU USO O PARA UN

PROPÓSITO EN PARTICULAR, SE DECLARARÁ EXPRESAMENTE. ALGUNOS ESTADOS NO PERMITEN LAS LIMITACIONES

EN LA DURACIÓN DE UNA GARANTÍA IMPLÍCITA, O LA EXCLUSIÓN O LIMITACIÓN DE LOS DAÑOS INCIDENTALES O

CONSECUENCIALES, POR LO QUE LA LIMITACIÓN O INCLUSIÓN ANTERIORES PUEDE NO APLICAR PARA USTED.

20

Page 21

TABLE DES MATIÈRES

Merci d’Avoir Choisi TOTO! ................................................................................................................................................................ 21

Pièces Incluses ...................................................................................................................................................................................... 21

Prudence ............................................................................................................................................................................................... 22

Avant de Commencer .......................................................................................................................................................................... 22

Procédure d’Installation ..................................................................................................................................................................22-26

Entretien et Nettoyage ........................................................................................................................................................................ 26

Maintenance Périodique .....................................................................................................................................................................27

Dépannage ........................................................................................................................................................................................... 28

Caractéristiques ....................................................................................................................................................................................28

Garantie.................................................................................................................................................................................................29

Robinetterie Brute ..........................................................................................................................................................................30-31

Pièces de Rechange .......................................................................................................................................................................32-34

MERCI D’AVOIR CHOISI TOTO!

La mission de TOTO est d’offrir au monde entier un style de vie sain, hygiénique et plus confortable. comme principe de base,

nous concevons chaque produit avec un équilibre entre la forme et la fonction. félicitations pour votre choix..

PIÈCES INCLUSES

Vérifiez que toutes les pièces sont inclues dans votre paquet:*:

(l’apparence de certains éléments pourrait varier en fonction du modèle)

Standard

TEL#GS/LS TEL#GG/LG TEL#GGW/LGW

Embout/ Outil de Crépine

Contrôleur à

Source Unique

(TN78-9Vxx)

Gooseneck

POUR LES MODÈLES À SOURCE UNIQUE:

Gooseneck

Wall Mount

1/16” (2mm) Clé Allen

(Séries TEL3)

Support

d’Entrée

d’Eau

BEC:

TM

TM

Helix

TEL#GC/LC TEL#GW/LW TEL#GT/LT TEL#GK/LK

Attache

Rapide

Vis Auto Tarau-

deuse (x3)

(ø 4.5mm x 38)

Helix

Wall Mount

Vis (ø3mm x 10)

(sauf pour l`Intégré)

POUR LES MODÈLES À MELANGE THERMIQUE (sauf pour l`Intégré):

Contrôleur de Mé-

lange Thermique

(TN78-10Vxx)

Ryohan

TEL#GM

TM

Fordham

TM

(Séries TEL5)

Support

d’Entrée

d’Eau (x2)

Axiom

TM

Vis Auto Tarau-

deuse (x8)

(ø 4.5mm x 38)

Integrated

TEL#LI

FRANÇAIS

MODÈLE RYOHAN SEULEMENT: GOOSENECK WALL-MOUNT SEULEMENT: HELIX WALL-MOUNT SEULEMENT:

Évacuation

Tuyau

d’Évacuation

Support de

Montage

Écrou en

Laiton (x2)

Caoutchouc (x1)

M5 Vis de

Fixation

Rondelles

Laiton (x1)

Ancrage Mural

21

Vis de Machine

(ø M5mm x 30)

Clé Allen (x2)

Vis Phillips (x3)

(ø 4mm x 40)

Ancrage à Vis (x3)

Page 22

PRUDENCE

Ce symbole d’avertissement apparaît dans les instructions d’installation pour vous alerter de la possibilité de blessures ou de

dommages à votre propriété si les instructions ne sont pas suivies correctement.

Personne d’autre qu’un ingénieur de service ne devrait démonter, réparer ou modifier ce robinet, à moins que ce ne soit

décrit spécifiquement dans ce manuel. Le non-respect de ces recommandations pourrait causer le dysfonctionnement

du produit.

Réglez votre robinet seulement aux températures autorisées dans vos codes locaux.

N’utilisez pas ce robinet dans des endroits humides où l’eau courante ou de la condensation pourrait s’accumuler à la

surface, particulièrement dans un sauna ou un hammam.

Ne pas frapper ou botter le robinet ou la boîte du contrôleur, car ceci pourrait endommager l’unité ou provoquer une

fuite.

Ne pas toucher la vanne d’arrêt de l’automate, que la surface peut être très chaude.

Débranchez le connecteur de la batterie de secours lorsque le robinet n’est pas utilisé pendant une longue période de

temps.

Assurez vous de toujours fermer la valve d’arrêt avant de nettoyer l’épurateur.

Vérifiez régulièrement les tuyaux pour détecter les fuites.

Si la température de la pièce dminue au point de congélation, enveloppez les tuyaux avec un isolant.

Assurez vous que le cordon d’alimentation n’entre pas en contact avec le tuyau d’alimentation d’eau chaude.

Évitez de placer tout objet dans la zone de détection du capteur infrarouge.

Tournez occasionnellement la poignée de contrôle de la température de la valve de mélange thermique afin d’empêcher

toute accumulation ou collage.

AVANT DE COMMENCER

Respecter tous les codes locaux de plomberie et de construction

Vérifiez la pression des sources d’eau froide et chaude.

Assurez vous que la pression de la source d’eau froide soit plus élevée que celle de la source d’eau chaude. Lorsque la

pression de la source d’eau est plus élevée que 125psi (826kPa), soyez sure de réduire la pression dans une fourchette

de 20 à 80 psi en utilisant un détendeur (vendu séparément). La fourchette de pression de travail optimale se situe

entre 15 psi et 80 psi (100 kPa et 551 kPa).

Vérifiez la température de la source d’eau chaude (pour mélange thermique seulement).

N’utilisez jamais la vapeur comme source d’eau chaude.

La fourchette de température recommandée pour la source d’eau chaude est entre 140°F - 185°F (60°C - 85°C).

FRANÇAIS

Rincez toutes les conduites d’eau avant l’installation.

Autres précautions à prendre avant de commencer:

Portez une attention particulière afin que la surface du capteur ne soit pas défectueuse ou rayée pendant le processus

d’installation.

Assurez vous que toute la tuyauterie, les valves d’arrêt, et les lignes de connexion sont installées en accordance avec les

codes locaux.

Ne placez pas d’autres appareils qui utilisent un onduleur ou un capteur infrarouge près du robinet, car ceci pourrait

causer le dysfonctionnement du robinet.

PROCÉDURE D’INSTALLATION

Installez le Contrôleur

NO TE: Avant d’installer le robinet, soyez sûr de rincer

soigneusement les tuyaux d’alimentation pour éliminer

toute saleté et débris. Fermez la source d’eau aux valves

d’arrêt après le rinçage (voir III. 1).

1) Voir le sommaire de la page des dimensions pour déterminer l’emplacement approprié pour le contrôleur.

2) Enlevez les vis à l’avant de la couverture du contrôleur et

tirez pour enlever (voir III. 2).

22

Ill. 1

Ill. 2

Couverture

Fermer

Valve d’Arrêt

Ouvrir

Couverture

Vis

Vis

Page 23

Installez le Contrôleur (suite)

3) Montez le support(s) d’entrée d’eau sur le mur, en

utilisant les chevilles (non inclus) si nécessaire et serrez

provisoirement les vis. Maintenez le contrôleur en

place sur le support (s) pour détecter tout obstacle

qui pourrait interférer avec le contrôleur ou les connexions. Dès que la position du contrôleur est confirmée, serrez les vis de montage (voir III. 3).

NO TE: Pour les contrôleurs de mélange thermiques,

les supports d’entrée d’eau DOIVENT être montés

à 3-¾” (95mm) à part (d’un centre à l’autre) pour

permettre une connexion appropriée au contrôleur.

IMPORTANT!

Soyez sûr de monter chaque support d’entrée d’eau

dans la direction verticale correcte, comme indiqué.

Sinon, le filtre sur le support d’entrée d’eau ne sera

pas accessible pour le nettoyage.

4) Connectez les lignes pour source d’eau chaude/froide

au(x) support d’entrée d’eau. Pour les contrôleurs

de mélange thermiques, assurez-vous que la source

d’eau chaude est connectée au support d’entrée

d’eau à gauche (voir III. 4).

5) Connectez le contrôleur au support d’entrée d’eau

(voir III. 5):

Ill. 3

MODÈLES À

SOURCE UNIQUE

Vis Auto Taraudeuse

MODÈLES À

MELANGE

THERMIQUE

Vis Auto Taraudeuse

MODÈLES À SOURCE UNIQUE

Ill. 4

Flexible Hose

(pas inclus)

Écrou

Joint

d’Étanchéité

IN

HOT IN

OUT

OUT

3-3/4”

(95mm)

Tube en Cuivre

(pas inclus)

Écrou

Anneau de

Frottement

Rondelle

Conique

Ancrages Mural

(pas inclus)

Support

d’Entrée

d’Eau

Ancrages Mural

(pas inclus)

COLD IN

Contrôleur

Attache

Rapide

Support d’Entrée

d’Eau -

vue de côté

Support d’Entrée

d’Eau -

vue de côté

Support

d’Entrée

d’Eau

Pour un contrôleur à source unique: Poussez le con-

trôleur dans le support d’entrée d’eau jusqu’à ce

qu’il soit bien en place, et fixez le avec la fermeture rapide inclue.

Pour les contrôleurs de mélange thermique: Vérifiez

que les joints d’étanchéité en plastique sont

placés dans le support d’entrée à eau. Maintenez

le contrôleur en place et serrez les écrous sur les

supports d’entrée à eau pour le garder en place.

Pour installer les modèles à plate-forme montée :

NOTE: Un trou de robinet 1-3/8 “(35mm) et un espace de

1-3/8 po (35 mm) min. entre le mur fini et le dos du bec est

fortement recommandé de sorte qu’une clé Allen puisse

être placée derrière le bec (voir l’image ci-dessous) pour le

service / maintenance.

1) Installez le bec avec le joint dans le trou central du

comptoir ou de la toilette.

2) Installez les filtres et les tuyaux flexibles sur les arrêts d

‘alimentation CHAUD ET FROID.

3) Serrez les écrous à compression de 3/8” aux arrêts

d’alimentation en premier, puis placez les filtres et serrez les

adaptateurs.

4) Serrez les tuyaux flexibles de manière sécurisée aux

adaptateurs