Page 1

1-800-526-2400

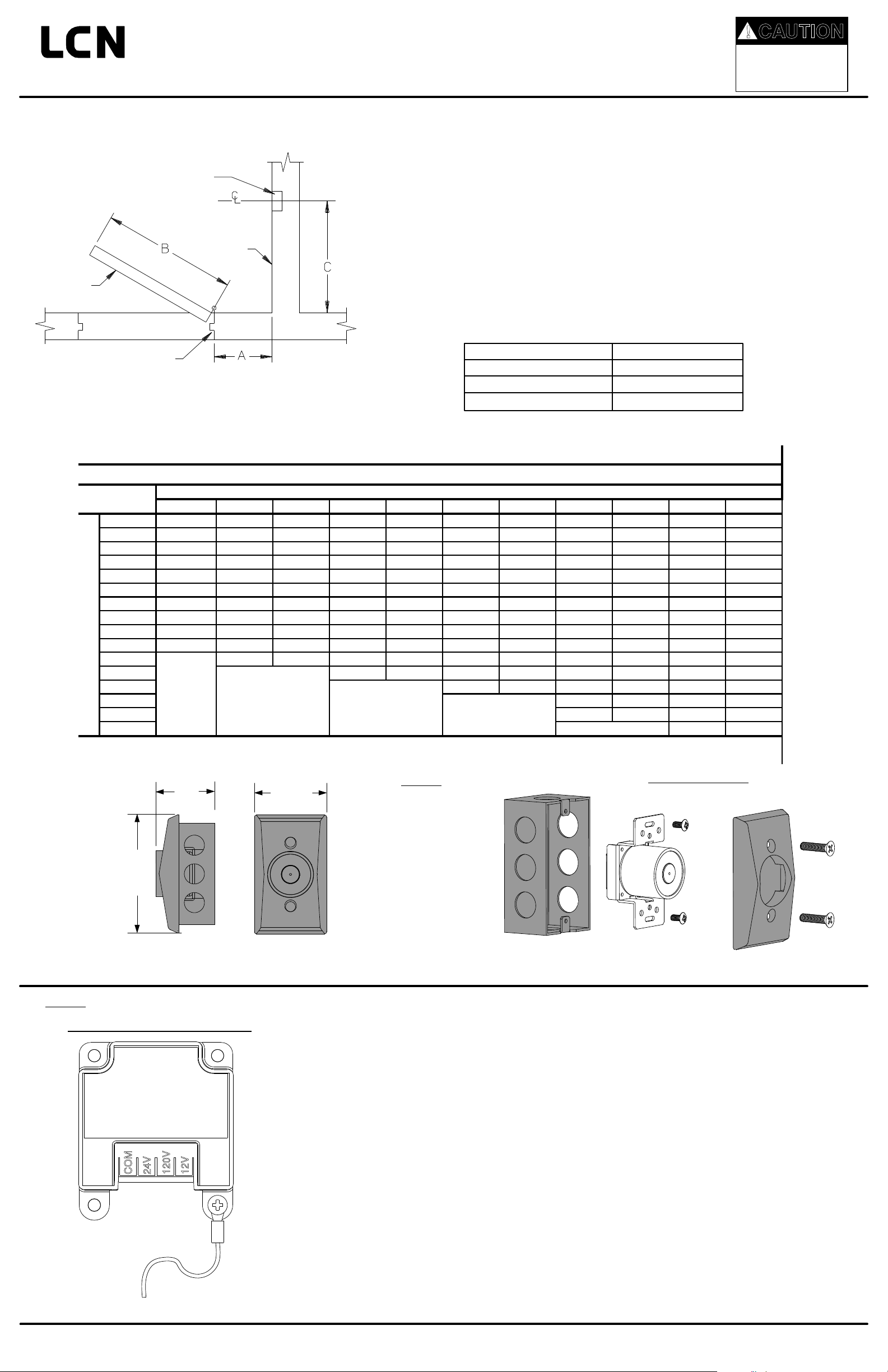

28 30 32 34 36 38 40 42 44 46 48

2 26 1/8 28 1/8 30 1/8 32 1/8 34 1/8 36 1/8 38 1/8 40 1/8 42 1/8 44 1/8 46 1/8

4 26 28 30 32 34 36 38 40 42 44 46

6 25 3/4 27 3/4 29 13/16 31 13/16 33 13/16 35 5/8 37 7/8 39 7/8 41 7/8 44 46

8 25 5/16 27 3/8 29 7/16 31 1/2 33 1/2 35 1/2 37 5/8 39 5/8 41 5/8 43 5/8 45 11/16

10 24 3/4 26 13/16 29 31 33 35 1/8 37 3/16 39 1/4 41 1/4 43 5/16 45 3/8

12 24 26 28 1/4 30 3/8 32 1/2 34 9/16 36 11/16 38 3/4 40 13/16 42 7/8 45

14 23 25 3/16 27 3/8 29 5/8 31 3/4 33 15/16 36 38 1/8 40 1/4 42 5/16 44 3/8

16 21 5/8 24 26 3/8 28 5/8 30 7/8 33 35 1/4 37 7/16 39 9/16 41 11/16 43 13/16

18 20 1/8 22 3/4 25 1/8 27 1/2 29 13/16 32 1/8 34 3/8 36 9/16 38 3/4 41 43

20 18 1/4 21 23 11/16 26 3/16 28 5/8 31 33 5/16 35 9/16 37 13/16 40 42 1/4

22 19 22 24 5/8 27 3/16 29 11/16 32 34 7/16 36 3/4 39 41 5/16

24 22 3/4 25 1/2 28 1/8 30 11/16 33 1/8 35 3/16 38 40 1/4

26 26 3/8 29 31 11/16 34 5/8 36 5/8 39

28 30 32 5/8 35 3/16 37 11/16

30 28 30 7/8 33 9/16 36 3/16

32 31 11/16 34 1/2

A = Dimension of door jamb to wall (Inch)

Nearest Whole

Number

B = dimension of door width (Inch)

Magnetic Door Holder Placement Chart

7840/50

DOOR

®

JUNCTION

BOX

WALL LINE

SEM 7840/7850

Sentronic Electro-Magnetic

®

Single Door Holder Concealed Wall Mount

Step 1: Locate the Junction Box (Not Provided)

See Fig. 1. Measure dimensions A and B. Find the intersection of those two dimensions in

A.

Table 1.The intersection is dimension C, the centerline of the surface mount box location.

(For 180° installations, take B dimension and subtract 5 5/8” to find the centerline of junction

box. Note: Optional extensions maybe needed.)

If dimension A or B is not shown on the chart, interpolate to find dimension C as follows.

B.

If dimension A is 11” and dimension B is 36”, then:

dimension C = 33 - ((33 - 32 1/2)/2) = 32 3/4

If dimension A is 12” and dimension B is 35”, then:

dimension C = 32 1/2 - ((32 1/2 - 30 3/8)/2) = 31 7/16

If dimension A or B is beyond those listed in Table 1 or if they intersect in a blank area in

Table 1, use optional extensions as needed to align contact plate and magnet.

See Fig. 2. The center of the junction box should be located about 5” from the top of the

C.

door. Install junction box to withstand at least a 50 pound pull.

Pull wire in accordance with applicable codes, standards, and authorities having jurisdiction.

D.

Electrical specifications are shown below.

CAUTION

!

IMPROPER INSTALLATION MAY

RESULT IN PERSONAL INJURY OR

PROPERTY DAMAGE. FOLLOW ALL

INSTRUCTIONS CAREFULLY. FOR

QUESTIONS, CALL LCN AT

800 - 526 - 2400

DOOR JAMB

Table 1

Input Voltage

120VAC, 60Hz

24VAC, 60Hz/24VDC

12VDC

Current Draw Max.

.02A

.02A

.03A

Fig. 2

2 ½”

64mm

4 5/8”

117mm

Fig. 3

Back view of magnet assembly

2/07 © 2007 SCHLAGE LOCK Company. All rights reserved D.P. # 29352r2

COM

24V

120V

12V

Earth Ground

2 13/16”

70mm

Junction

Box

Step 2: Install the Magnet

A. The magnet is shipped partially assembled for protection. Unscrew the cover from the

magnet bracket assembly. Keep the screws for later reattachment.

B. See Fig. 3. Connect the supply earth ground wire to the green wire on the magnet bracket assembly. Connect

the power supply common wire to the screw terminal marked COM. If the supply voltage is 24V, connect the

power supply hot wire to the screw terminal marked 24V. If the supply voltage is 120V, connect the power

supply hot wire to the screw terminal marked 120V. If the supply voltage is 12V, connect the power supply

hot wire to the screw terminal marked 12V. Polarity is important on the 12V input. There are protective plastic

tabs over the terminal screws. Break off the two tabs that protect COM and the desired voltage so that the

screw heads are exposed.

C. See Fig. 2. With the magnet wired, position the magnet bracket assembly into the junction box and attach it

to the box using the (2) 6-32 screws. Tighten firmly. Attach the cover housing using the (2) 10-24 screws from

step 2A.

WALL PORTION

Magnet

Bracket

Assembly

Cover

Page 2

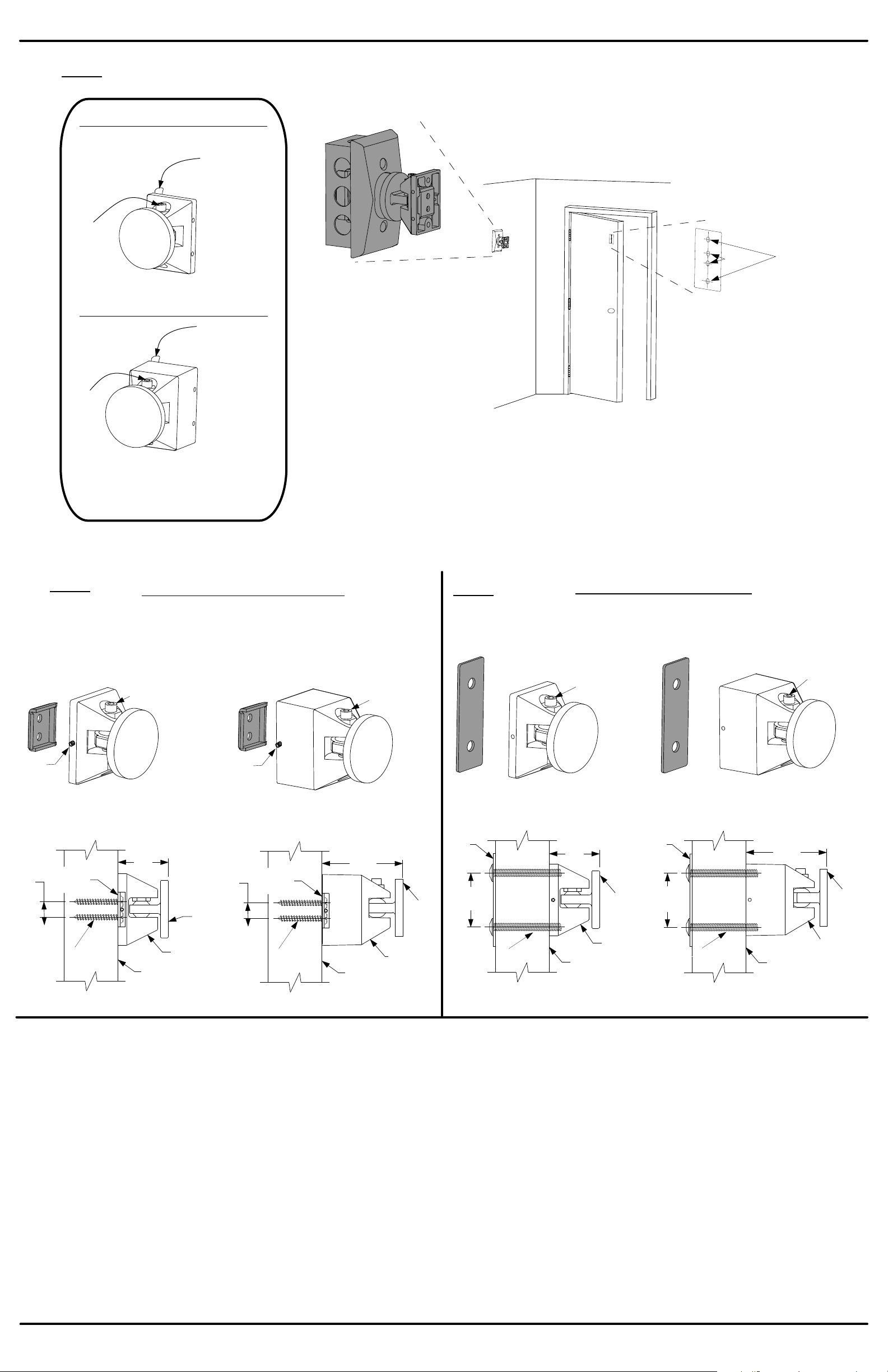

Fig. 4

Install Armature for 7840

For drill hole template,

remove paper from

the back to reveal

sticky back of template.

Locking

Screw

Install Armature for 7850

For drill hole template,

remove paper from

the back to reveal

sticky back of template.

Locking

Screw

Wood

Screws

7840SEM show, 7850SEM can be mounted in the same fashion.

*

Thru

bolts

Fig. 5

Backup

Plate

Set

Screw

SEM 7840 Armature

Backup

½”

13mm

Plate

WOOD SCREW MOUNTING

FOR SOLID WOOD CORE DOORS

This view shows the contact plate

locking screw accessible from the top.

Rotate backup plate 180° for underside access.

½”

13mm

Backup

Plate

Set

Screw

SEM 7850 Armature

Backup

Plate

Contact Plate

locking screw

1 5/8”

41mm

Contact

Plate

Contact Plate

locking screw

2 5/8”

67mm

Contact

Plate

Fig. 6

Door

Plate

Door

Plate

1 3/4”

44mm

THRU BOLT MOUNTING

HOLLOW METAL, HOLLOW CORE

OR COMPOSITE TYPE WOOD DOORS

Contact Plate

locking screw

SEM 7840 Armature

1 5/8”

41mm

RECOMMENDED FOR

Door

Plate

Door

Plate

Contact

Plate

1 3/4”

44mm

Contact Plate

locking screw

SEM 7850 Armature

2 5/8”

67mm

Contact

Plate

(2) #10 x 1 ½”

Armature

Pull Side

of Door

(2) #10 x 1 ½”

Pull Side

of Door

Armature

(2) 1/4-20 x 2”

Pull Side

of Door

Armature

(2) 1/4-20 x 2”

Armature

Pull Side

of Door

Step 3: Install the Door Armature

A. See Fig. 4. Slightly loosen the contact plate locking screw using a 5/32 Allen wrench so the contact plate can rotate with some

”

resistance. Remove the protective paper from the drill template sticky-back label on the back of the door armature.

B. Place the armature against the floor magnet. This is best done with power applied to the magnet. If power is not available, hold

the armature in place by hand. The armature contact plate must fully cover the magnet. If the contact plate is not centered and

flat on the magnet, reduced holding force will result.

C. With the armature against the magnet, open the door and press it against the armature and magnet. Pull the door away to transfer

the drill template to the door.

Template may need assistance with transferring to door, using a flat blade screwdriver on the

template tab that sticks out and push it onto the door while pulling the door away.

D. See Fig. 5 and 6. Determine if the armature will be mounted using the wood screw kit or the thru bolt kit. The thru bolt kit

is recommended for 1 hollow metal, hollow core, or composite-type wood doors. If using the wood screw kit, drill the center

two holes on the template using a 1/8 bit by 1 deep. If using the thru bolt kit, drill the outer two holes on the template using

a 5/16 bit all the way through the door. Remove the template after the holes are drilled.

”

¾”

” ¼”

E. Attach the armature to the door using the appropriate plate and screws. If using the wood screws and backup plate, tighten the

armature set screw against the backup plate as the last step using the 1/16 Allen wrench provided.

”

Loading...

Loading...