Page 1

1-800-526-2400

Input Voltage Current Draw Max.

120VAC, 60Hz .02A

24VAC, 60Hz/24VDC .02A

12VDC .03A

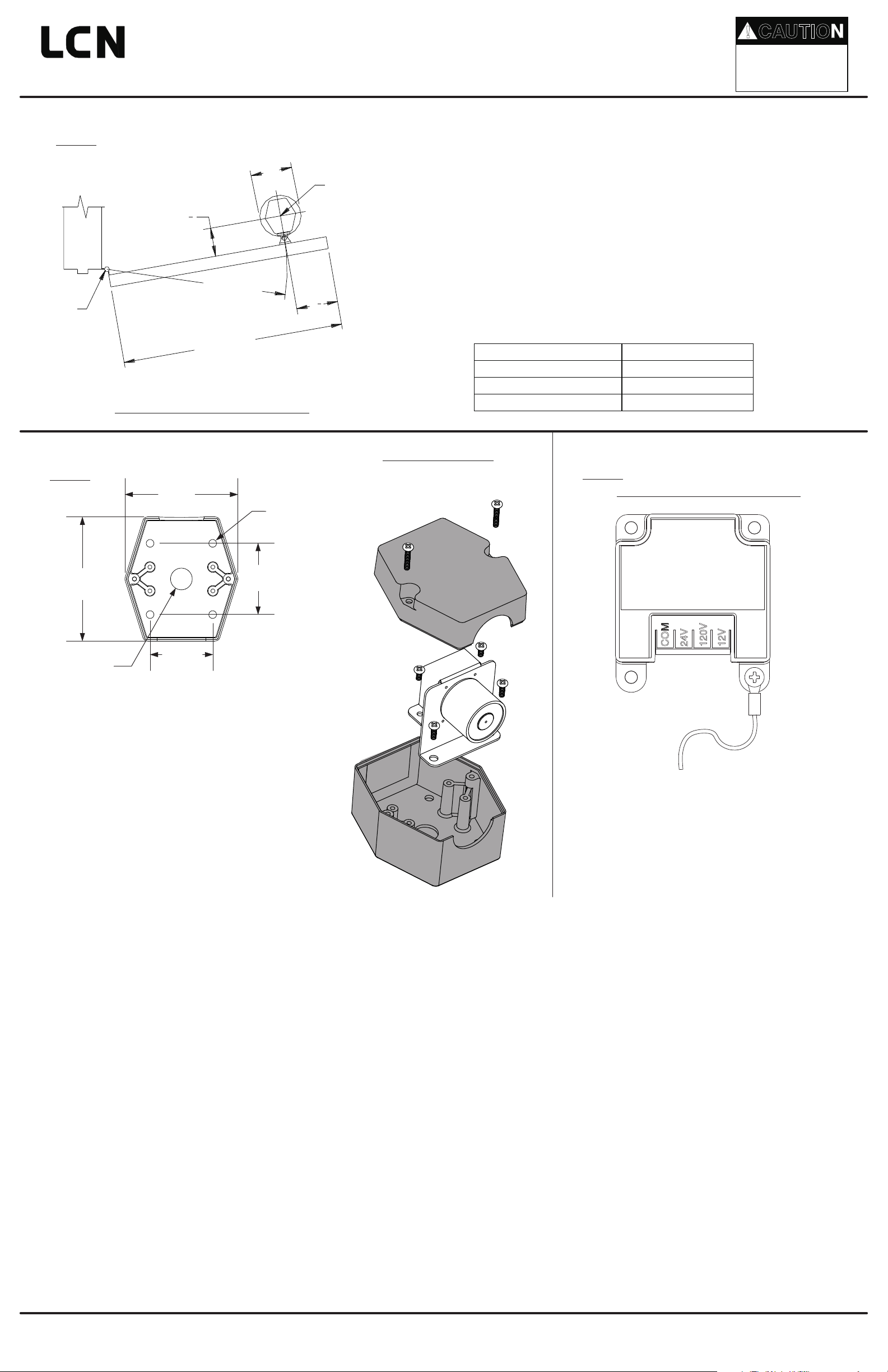

Fig. 1

WALL

DOOR PIVOT

POINT

®

1

4

4

ARC LENGTH

DOOR WIDTH

(INCHES)

CLEARANCE FOR SEM7820

FLOOR PORTION

6”

DIA.

SEM 7820

Sentronic Electro-Magnetic

®

Single Door Holder Floor Mounted

Step 1: Plan the Installation

A. Measure the door width.

B. Calculate the arc length by subtracting 5 5/8 from the door width.

Draw an arc at the calculated length using the door pivot point as

LOCATION OF

CONDUIT

the center point. String and a pencil could be used to draw the arc

on the floor.

C. Open the door to the desired position. On the pull side of the door,

put a mark on the arc 4 from the door. This is the center of the

conduit hole.

D. Drill and install conduit as needed. Maximum conduit size is .

Maximum conduit height above the floor is 1 .

5

5

8

E. Pull wire in accordance with applicable codes, standards, and

authorities having jurisdiction. Electrical specifications are

shown below.

¼”

CAUTION

!

IMPROPER INSTALLATION MAY

RESULT IN PERSONAL INJURY OR

PROPERTY DAMAGE. FOLLOW ALL

INSTRUCTIONS CAREFULLY. FOR

QUESTIONS, CALL LCN AT

800 - 526 - 2400

”

”

½”

Fig. 2

5”

127mm

CONDUIT

HOLE

SINGLE DOOR INSTALLATION

4 9/16”

116mm

2 17/32”

64mm

MOUNTING

HOLES

2 7/8”

73mm

FLOOR PORTION

Cover

Magnet

Bracket

Assembly

Fig. 3

Back view of magnet assembly

COM

24V

120V

12V

Earth Ground

Base

Step 2: Install the Magnet

A. The magnet is shipped partially assembled for protection. Unscrew the cover from the base, then unscrew the magnet bracket

assembly from the base. Keep the screws for later reattachment.

B. Guide the conduit through the hole in the base and snug up the conduit nut. Square up the base to the door, with the door

opened to the desired position, as shown in Fig.1.

C. See Fig. 2. Using the base as a template, mark the four mounting hole locations on the floor.

D. Remove the base and drill 3/8” holes in the floor at 1 1/4” deep. Install the cement anchors provided into the drilled holes,

threaded ends up.

E. Reposition the base, aligning the mounting holes with the floor holes and the magnet opening facing the door.

Tighten the conduit nut. Install (2) mounting screws that are furthest away from the magnet opening into the cement anchors.

The magnet assembly must first be connected to power supply wires before the other two base housing mounting screws can be

installed.

F. See Fig. 3. Connect the supply earth ground wire to the green wire on the magnet assembly bracket. Connect the power supply

common wire to the screw terminal marked COM. If the supply voltage is 24V, connect the power supply hot wire to the screw

terminal marked 24V. If the supply voltage is 120V, connect the power supply hot wire to the screw terminal marked 120V. If the

supply voltage is 12V, connect the power supply hot wire to the screw terminal marked 12V. Polarity is important on the 12V input.

There are protective plastic tabs over the terminal screws. Break off the two tabs that protect COM and the desired voltage so that

the screw heads are exposed.

G. See Fig. 2. With the magnet wired, position the magnet bracket assembly over the two base mounting holes and the two base

post holes. Insert (2) -20 base mounting screws and the (2) 10-24 shorter screws from step 2A into

the post holes. Tighten firmly. Attach the cover using the (2) 10-24 longer screws from step 2A.

¼-20

into the cement anchors¼

12/06 © 2006 SCHLAGE LOCK Company. All rights reserved D.P. # 29350

Page 2

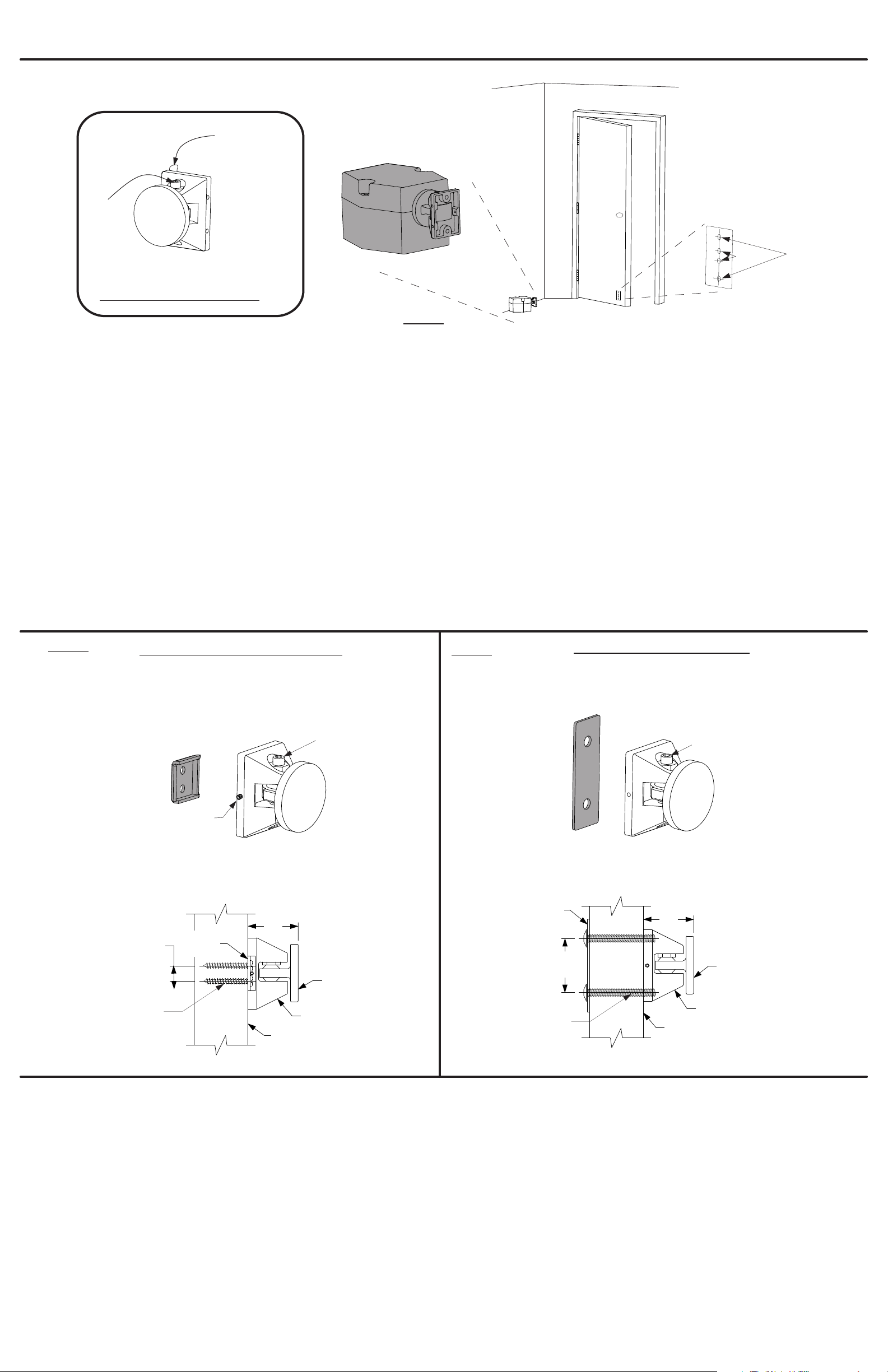

Locking

Screw

For drill hole template,

remove paper from

the back to reveal

sticky back of template.

Wood

Screws

Thru

bolts

Fig. 4 Door Armature

Fig. 5

Step 3: Install the Door Armature

A. See Fig. 4. Slightly loosen the contact plate locking screw using a 5/32” Allen wrench so the contact plate can rotate with some

resistance. Remove the protective paper from the drill template sticky-back label on the back of the door armature.

B. See Fig. 5. Place the armature against the floor magnet. This is best done with power applied to the magnet. If power is not available,

hold the armature in place by hand. The armature contact plate must fully cover the magnet. If the contact plate is not centered and

flat on the magnet, reduced holding force will result.

C. With the armature against the magnet, open the door and press it against the armature and magnet. Pull the door away to transfer

the drill template to the door. Template may need assistance with transferring to door, using a flat blade screwdriver on the

template tab that sticks out and push it onto the door while pulling the door away.

D. See Fig. 6 and 7. Determine if the armature will be mounted using the wood screw kit or the thru bolt kit. The thru bolt kit is

recommended for 1 ¾” hollow metal, hollow core, or composite-type wood doors. If using the wood screw kit, drill the center two

holes on the template using a 1/8” bit by 1 ¼” deep. If using the thru bolt kit, drill the outer two holes on the template using a 5/16”

bit all the way through the door. Remove the template after the holes are drilled.

E. Attach the armature to the door using the appropriate plate and screws. If using the wood screws and backup plate, tighten the

armature set screw against the backup plate as the last step using the 1/16” Allen wrench provided.

Fig. 6

WOOD SCREW MOUNTING

FOR SOLID WOOD CORE DOORS

This view shows the contact plate

locking screw accessible from the top.

Rotate backup plate 180° for underside access.

½”

13mm

Backup

Plate

Backup

Plate

Set

Screw

Armature

1 5/8”

41mm

Contact Plate

locking screw

Contact

Plate

Fig. 7

THRU BOLT MOUNTING

RECOMMENDED FOR

HOLLOW METAL, HOLLOW CORE

OR COMPOSITE TYPE WOOD DOORS

Contact Plate

locking screw

Door

Plate

Door

Plate

1 3/4”

44mm

Armature

1 5/8”

41mm

Contact

Plate

(2) #10 x 1 ½”

Armature

Pull Side

of Door

(2) 1/4-20 x 2”

Armature

Pull Side

of Door

Loading...

Loading...