Electronic Exposed

Teck

®

Flush Valves

Delta reserves the right (1) to make changes in specifications and materials, and (2) to change or discontinue models, both without notice or obligation.

Dimensions are for reference only. See current full-line price book or www.specselect.com for finish options and product availability.

DSP–81T201-WMS Rev. B

Refer to www.specselect.com for individual models. Note: Use this page as a product submittal sheet.

Engineer/Architect Approval

Model Specified:

Approval: Date:

81T201-WMSHW

Note: Measurements may vary ± 6mm (0.25'')

Note: For high and low pressure applications, please see page 7.C.18 High Water Pressure

note for more details.

Verify flow requirements with bowl manufacturer.

Approvals:

•

CSA certified

• Complies to ASSE 1037

•

ADA Compliant and meets Handicapped

Accessibility Standard ASME A117.1 of

less than 5 lbs. operating force.

•

IAPMO listed

(Contact Delta Representative for State

and/or Local Approvals.)

060704A 110 to 24VAC Class II 20VA

(for up to 5 Sensor Modules)

060771A 110 to 24VAC Class II 40VA

(up to 10 Sensor Modules)

060772A 110 to 24VAC Class II 100VA

(up to 25 Sensor Modules)

✔ TRANSFORMERS:

81T201-WMSHW

❏ 81T201-WMSHW

– Exposed Hard Wire Operated

1-1/2'' Top Inlet Closet Fixture

• Polished chrome plated vandal resistant metal cover with 4" wallmount sensor

• Right or left-hand supply installation

• ADA compliant, automatic operation hard wire powered

H2OPTICS

™

technology infrared sensor

• Infrared sensor range adjustment of 610mm-1422mm (24" - 56"), in 8" increments,

factory set at 40” (

±2")

• Hardwire adaptor

• Vandal resistant copper tube conduit

• 24 hour courtesy flush factory set to off

• 24 VAC input

• Electronic manual override button

• (110 to 24 VAC Transformer not included. See selection below for additional

part number.)

• Quiet action, Teck®exposed diaphragm flush valve

• Chloramine resistant diaphragm

• Forged brass diaphragm retainer

• Renewable seat

• Polished chrome plated finish

• External water conserving flush adjustment,

factory set at 60 PSI to 6 litre (1.6 US gal.) (except -48 and -6 models)

• 1" FIP/Copper sweat inlet adaptor, angle check stop with protecting cap

• Adjustable 121mm (4-3/4") plus or minus 11mm (7/16") inlet/valve outlet centers

• Vacuum breaker

• Cover tube, stainless steel wall flange, spud flange, concealed spud nut, and 292mm

(11-1/2") outlet tube

❏ 81T201-6-WMSHW

Same as 81T201-WMSHW,

but Not Field Adjustable

❏ 81T201-48-WMSHW

Same as 81T201-WMSHW, but factory set

at 60 PSI to 4.8 litre (1.27 US gal.),

Not Field Adjustable

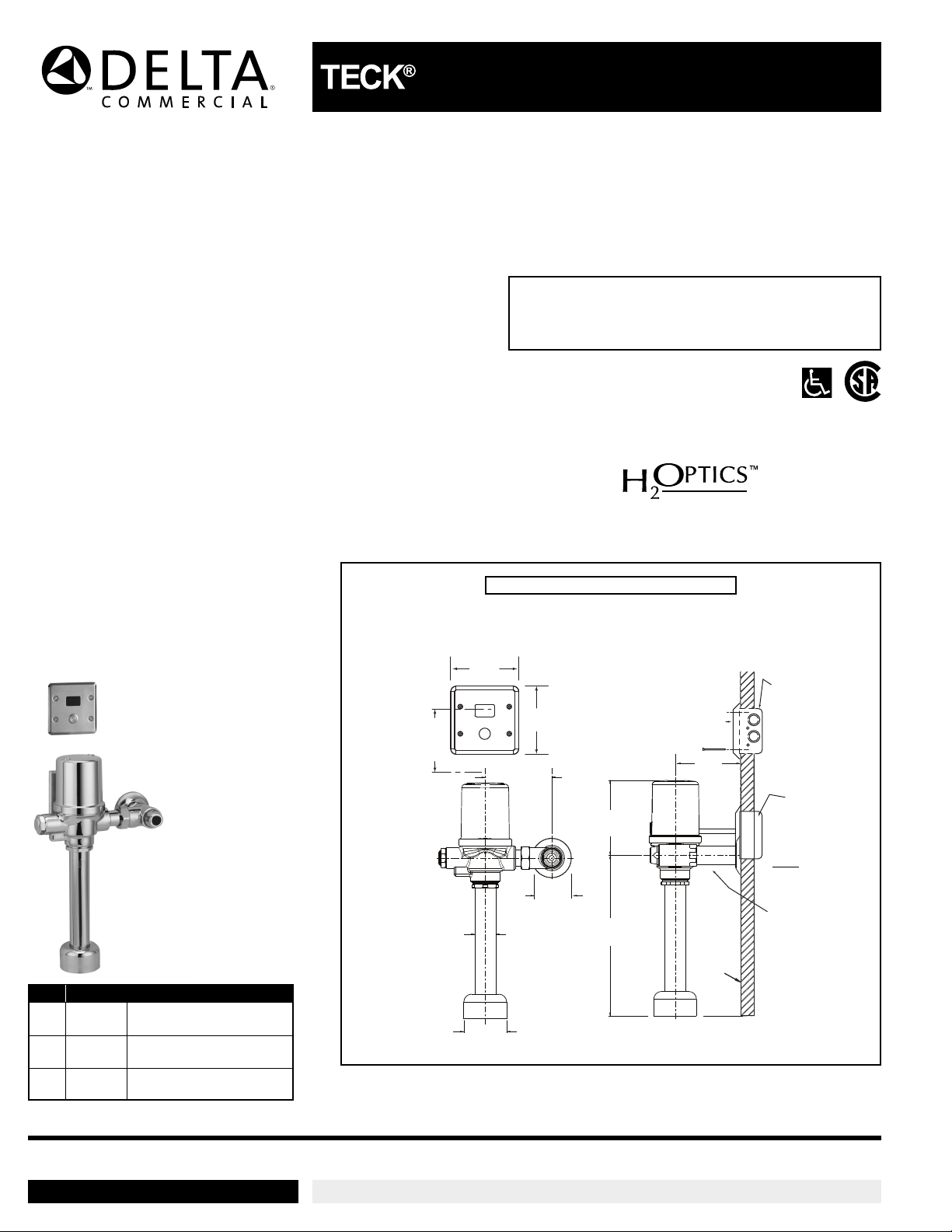

121mm ±13mm

(4.75" ±.44")

71mm

(2.81")

76mm

(3.0")

VACUUM

BREAKER

TUBE

38mm

(1.5")

38mm (1.5")

SLIP JOINT NUT

& WASHERS

SUPPLIED

124mm

(4.875")

292 mm (11.5”)

54mm

(2.13") MIN.

FINISHED

WALL

TOP OF FIXTURE

INLET:

25mm (1.0")

FIP OR

COPPER

SWEAT

W/ADAPTOR

(SUPPLIED)

* Note:

Recommended

height to sensor

from top of

fixture is

20-22" with

24" MAX.

* 76mm

to top

of open

seat cover

(3")

124mm

(4 1/2")

124mm

(4 1/2")

Stainless Steel

Coverplate

Sensor Box

102 x 102 x 51mm

(4" x 4" x 2")

Junction Box

51 x 102mm

(2" x 4")

Loading...

Loading...