Page 1

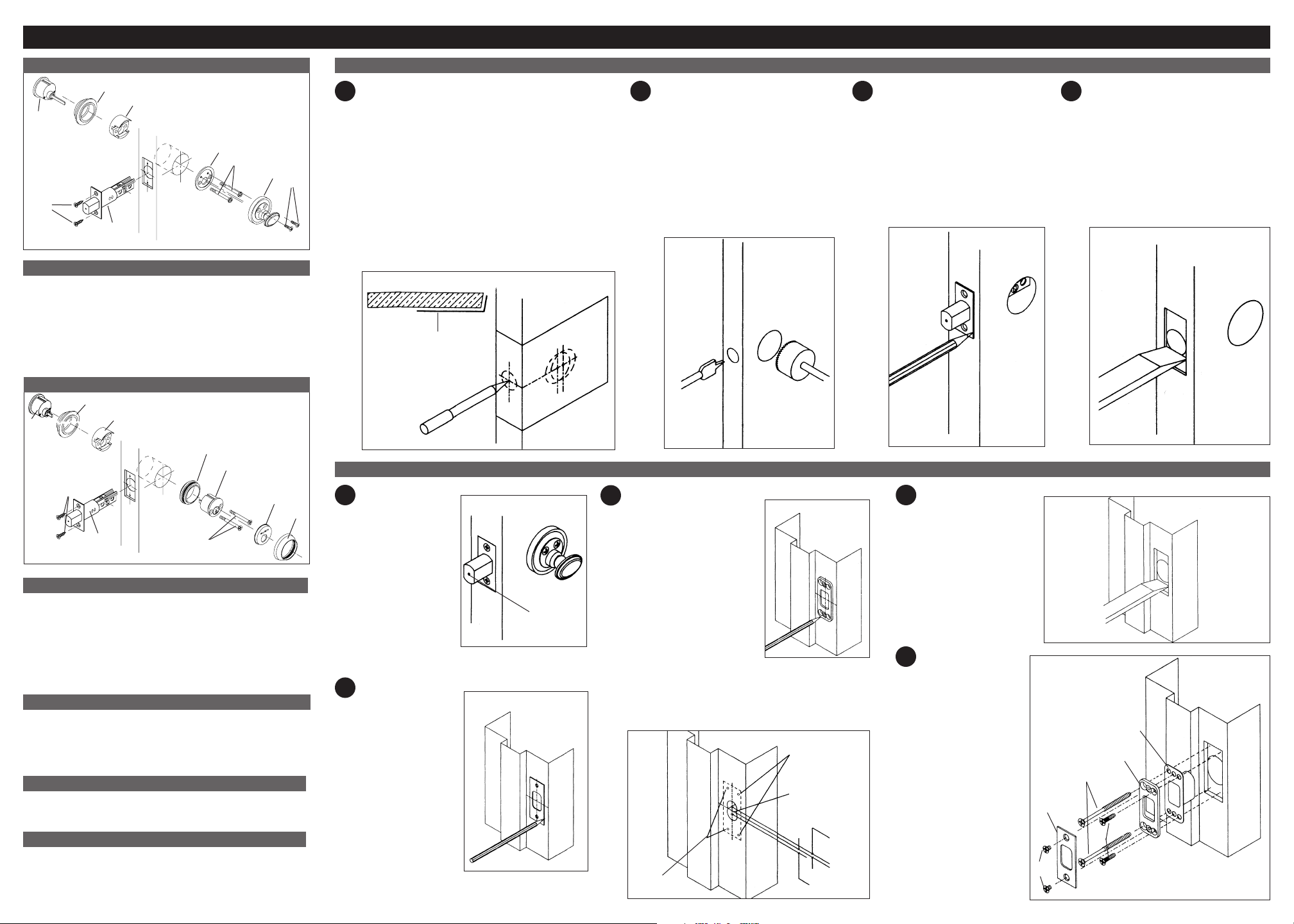

Deadbolt Installation/Single Cylinder and Double Cylinder

Exploded View Single Cylinder Deadbolt

7.

9.

8.

4.

6.

5.

Parts Enclosed

1. 2 each #8-32 x 5/8” Oval Head

Machine Screws

2. 1 Turnpiece Trim

3. 2 each #10-32 x 1-7/8” Pan Head

Machine Screws

4. 1 Turnpiece Mounting Plate

Note: See Strike Installation section for strike parts listing.

5. 1 Adjustable Backset Deadbolt

6. 4 each #8-3/4” Flathead

Combination Screws

7. 1 Outside Cylinder Collar

8. 1 Outside Cylinder

9. Screw Guide

Exploded View Double Cylinder Deadbolt

8.

9.

10.

Door Preparation

1

To position template fold enclosed template on line and

locate on door at desired height (usually 5 ½” above

center of latchset.) If you have a new door that is not

3.

2.

1.

already cut-out, please follow these instructions. If your

door is pre-bored, please proceed to Single Cylinder

& Double Cylinder Deadbolt Installation-Step 1. If the

door is beveled, place the folded edge on low side

of bevel as shown in the illustration. Determine door

2 4

Drill the 1-5/8” diameter face bore

(A) through the door and 1” diameter

edge bore (B) 3-1/2” deep for a 2-3/8”

backset or 3-7/8” deep for a 2-3/4”

backset. The bolt accommodates both

3

Insert deadbolt into edge of door.

While holding faceplate, trace outline

of the faceplate onto the door edge.

Mark screw hole centers and drill with

a 1/8”drill.

size backsets.

Caution: Re-check hole locations

before drilling.

Chisel out the area marked for the

faceplate to a depth of 5/32” or until

faceplate is flush with door edge.

Proceed now to the Strike Installation.

thickness and backset (2-3/8” or 2-3/4”). Mark the door

for face and edge bores.

Top view of door

A

Template

A

B

B

Edgebore

Facebore

5.

4.

7.

6.

3.

2.

Parts Enclosed

1. 1 Inside Collar

2. 1 Cylinder Cover

3. 2 each #10-32 x 2-1/4” Flat Head

Machine Screws

4. 1 Inside Cylinder

5. 1 Threaded Collar

Note: See Strike Installation section for strike parts listing.

6. 1 Adjustable Backset

7. 4 each #8-3/4” Flathead

Combination Screws

8. 1 Outside Cylinder Collar

9. 1 Outside Cylinder

10. Screw Guide

Tools Needed: Only Required for Doors Without Cutout

If your door is not pre-bored, see reverse side of instructions

for door preparation.

1. Pencil 3. 1/2” or 3/4” wood chisel

2. 1-5/8” diameter hole saw 4. Drill and assorted bits: 1/8”, 5/32” and 1”

Tools Needed: Doors Prepared with 1-5/8” Cutout

1. No. 2 and No. 3 phillips screwdrivers 3. Two pliers for Double Cylinder

2. Measuring device 4. Flathead Screwdriver

Optional Deadbolt Accessories for 1-3/8” Doors

When installing deadbolts on 1-3/8” thick doors, optional Cylinder Collar

Spacers are required (No. 8097). Consult your Baldwin distributor for

further details.

TEAR HERE FOR ENGLISH. TEAR HERE FOR ENGLISH.

Strike Installation

1

1.

Close door and

extend deadbolt

FIG. 1

several times

against door frame.

Strike centering

indicator will leave

a center mark on

the door frame

(Fig. 1).

2

Position strike plate

FIG. 2

Centering

indicator

on center mark.

Align and trace

outside of strike and

mounting screws

onto the door frame

(Fig. 2).

3

Using reinforcing strike

as a template, mark

locations for reinforcing

screws (Fig 3). Drill two

5/32” dia. pilot holes for

the 3” long screws and

two 1/8” dia. pilot holes

for the #8 x 3/4” screws.

Mark drill points 5/16”

above and below

centering point. Bore

two 1” dia. holes 1-1/4”

deep at these points.

Chisel out holes for dust

box (Fig. 4).

FIG. 4

Drill 5/32” dia. pilot

holes for 3” screws.

FIG. 3

Drill 1/8” dia. pilot

holes for # 8 screws.

Bore 1” dia. hole

above and below

centering point.

5/16” above

center point.

center line

5/16” below center point.

4

Mortise 7/32” deep

or until the strike box,

reinforcing strike and

strike plate fits inside

mortise and flushwith the

door frame (Fig. 5).

5

Install strike as

illustrated.

1. Dust Box

2. Reinforcing Strike

3. #8 x 3/4” Combination

6. Screws (2)

4. 3” Reinforcing

6. Screws* (2)

5. Strike Plate

6. #8-32 x 1/4”

6. Machine Screws (2)

FIG. 5

* Note: Lubricant

recommended

when installing 3”

reinforcing screws.

1

2

4*

5

3

6

Page 2

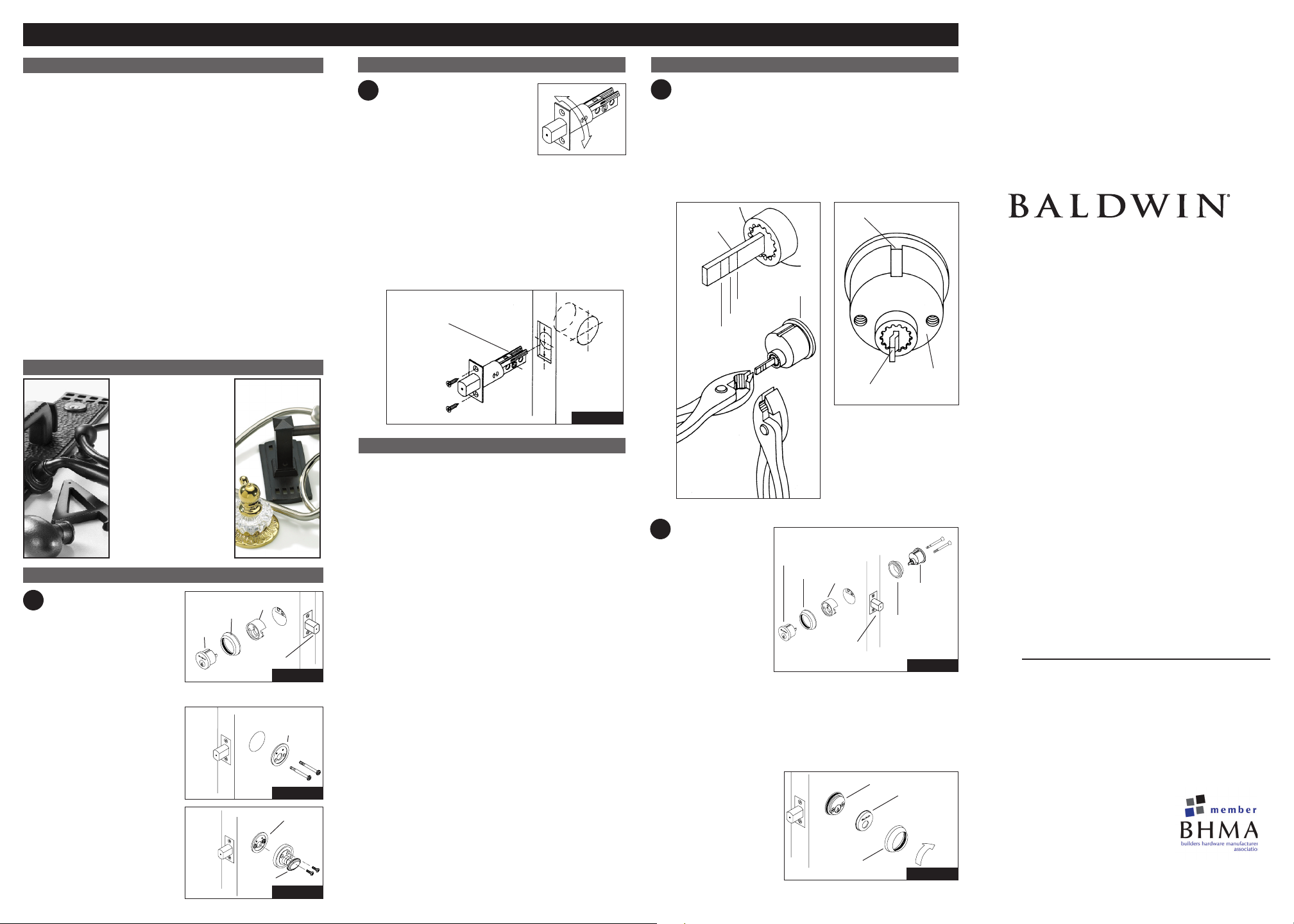

1-5/8” Deadbolt Preparation

Congratulations!

With your purchase of The Images Collection solid brass deadbolt, you’re

among a group of discerning individuals who know the intrinsic value of

selecting the finest – Baldwin.

Images entrance locksets, interior latchsets, and deadbolts coordinate beautifully,

enabling you to carry a specific design theme throughout your home.

Our step-by-step installation instructions will help guide you through your

project quickly and easily.

Before you begin your installation, read and understand the installation

instructions and marking templates. If you have any questions, please do not

hesitate to contact our Baldwin Technical Services Department at

1-800-566-1986. We’re here to help!

NOTE: Failure to use all recommended components will void Grade 1 rating.

We thank you for your Baldwin purchase and wish you the fullest

enjoyment of your Baldwin Handleset.

Technical Services Support

1-800-566-1986

Hours: 8 a.m. to 8 p.m. E.S.T. – Monday - Friday

10 a.m. to 6 p.m. E.S. T. – Saturday

Remember Baldwin

With the completion of

your project, remember that

Baldwin quality hardware

products are available for

all your decorating and

remodeling needs. Matching

knob and leversets for

interior doors, beautiful bath

accessories, and a complete

selection of cabinet and door

enhancing hardware are all

available from your Baldwin

retailer.

Single Cylinder Assembly

Collar

Screw

Guide

Extended

Deadbolt

Turnpiece

Trim

OUTSIDE

Mounting

Plate

INSIDE

Mounting Plate

INSIDE

A. Extend deadbolt using

1

flathead screwdriver. Keeping

tailpiece vertical, insert cylinder

through collar and screw guide

into deadbolt. The arrow on

the screw guide must be on the

outside and pointing up. Hold in

place. Do not insert key during

this procedure (Fig. 1).

B. Place turnpiece mounting

plate on inside of door as shown.

Attach cylinder using two #1032 x 1-7/8” pan head machine

screws. Insert screws through

mounting plate, deadbolt, screw

guide and collar into the cylinder.

Tighten all screws (Fig. 2).

C. Place turnpiece trim over

mounting plate. Insert tailpiece

into turn piece. Attach trim to

mounting plate with two #8-32

x 5/8” oval head machine

screws. Tighten screws

(Fig 3).

TEAR HERE FOR ENGLISH.

FIG. 1

Cylinder

FIG. 2

FIG. 3

Installing Deadbolt

A. The deadbolt supplied with this

1

unit has an adjustable backset

feature. It will be set at 2-3/8”

backset. To adjust to 2-3/4” backset,

grasp body and twist faceplate/

bolthead assembly 180° until it stops. Unit is now ready

for installation in a 2-3/4” backset configuration.

B. Insert deadbolt. Install with two #8 x 3/4” flat head combination screws provided (see diagram for proper positioning).

Ensure deadbolt head is extended throughout installation

procedure.

Install deadbolt with both long slots

on latch body in upper position.

INSIDE

Warranty Information

Limited Lifetime Mechanical Warranty – Baldwin warrants

that each Baldwin product shall be free from mechanical defects at

the time of delivery and for the lifetime of the product or as long as

you own your home.

Limited Lifetime Finish™ Warranty – The Baldwin Lifetime

Finish™ uses advanced finishing technology (physical vapor

deposition) to create a finish highly resistant to the effects of

weather and normal wear and tear. The Limited Lifetime Finish

Warranty on Lifetime Finish™ products covers the original

purchaser for as long as you own your home.

Limited Finish Warranty – The finish on Baldwin products

(excluding Lifetime Finish and living finish products) is protected by

a durable topcoat designed to maintain the beauty and quality of the

Baldwin product. The Baldwin Limited Finish Warranty covers the

original purchaser for five years from date of purchase for interior

use and one year for exterior use.

Living Finishes – Due to the nature of Baldwin living finish

products, they will wear over time and may already have begun the

process before reaching your home. No finish warranty is offered

on living finish products, which are designed to age and improve

over time. Living finishes include raw brass, oil rubbed bronze,

stainless steel, and other non-lacquered or non-PVD finishes.

Refer to www.baldwinhardware.com for a complete warranty

statement.

Double Cylinder Assembly

1

A. Carefully break off cylinder

tailpiece at required mark for

your door thickness.

Caution; use two pairs of pliers

B. Align tailpiece with slot.

Keep tailpiece vertical and

curved toward right side of

the hole as illustrated.

as shown or tailpiece will be

damaged.

Tailpiece

Cylinder

1-3/4”

2”

2-1/4”

A. Extend deadbolt

2

using flathead

screwdriver.

Keeping tailpiece

FIG. 4

Outside Cylinder

Collar

vertical and toward

the right side of

hole, insert outside

cylinder through

collar and into the

deadbolt. Align

slot of inside cylinder with notch in threaded collar. Keeping

tailpiece vertical and curved toward the right side of hole, insert

inside cylinder with threaded collar into the deadbolt. Attach

cylinders using two #10-32 x 2-1/4” flat head machine screws.

Tighten screws. Do not insert key during this procedure. (Fig.4)

B. Align cylinder cover

over inside cylinder.

Screw on decorative

cylinder collar.

Congratulations! Your

installation is now

complete!

Slot

Tailpiece

Screw

Guide

Extended

deadbolt

Cylinder collar

Threaded

Collar

Inside Cylinder

TEAR HERE FOR ENGLISH.

Cylinder

Inside

Cylinder

OUTSIDE

Cylinder

cover

INSIDE

1-5/8” Collar

Auxiliary Deadbolt

Installation Instructions

©2009 Baldwin Hardware Corporation

Reading, PA 19611

PK-1092-T (1/09)

Loading...

Loading...