Facit N4000 User Manual

Facit N4000

Punch/Reader-Punch

User's Manual

C o n t e n t s P a g e

1 I n t r o d u c t i o n / H o w t o g e t s t a r t e d 3

2 D e s i g n a n d C o n s t r u c t i o n 1 1

3 O p e r a t i o n 1 5

4 K e y b o a r d C o n t r o l s 1 9

5 P r o g r a m M o d e 2 3

6 I n t e r f a c e c o n n e c t i o n s 3 3

7 T e c h n i c a l S p e c i fi c a t i o n 3 5

Appendix 1 (C o n v e r s i o n c h a r t , A S C I I to Tel e x )

Appendix 2 (C o n v e r s i o n c h a r t , A S C I I to Tel e x )

Appe n dix 3 (Conver s ion ch a rt,ASC I I to EI A)

App endix 4 (C onve rsion cha rt,AS CII to RS 358)

Appendix 5 (Code co nve rsi on)

Appe ndix 6 (Tel ex Tape F ormat t ing)

Appendix 7 (Test Mode)

Copyright, Facit AB Sweden, 1989.01/3500

1 Introduction

The Facit N4000 comes in two versions, a paper

tape punch and a reader/punch combination.

The paper tape punch, punches 5 to 8 track tapes.

Five track is normally used to punch telextapes

and eight track mostly for punching NC-programs.

The punching speed is 30, 62 or 75 characters

per second, operator selectable.

The reader/punch combination can read and punch 5

to 8 track tapes.

The reading speed is 200/500 characters per

second, operator selectable.

Both units are designed as stand alone units for

table top mounting. Two standard I/O ports are

available with CCITT V.24/RS-232-C serial

interface.

Facit N4000 has a buffer of~ 9 K capacity.

Code conversion can be performed. The codes

included are the two used NC codes ISO and EIA and

the national versions of the telexcode.

A small keyboard and status display are

inc orpor ated at th e top of the unit; with this all

operating system parameters may be quickly and

easily entered with no necessity to change PC

board DIP switch settings. The status display

clearly indicates the u n i t ' s c u r r e n t ope r a t i n g

status, and also shows simple error messages.

How to get started

Mains connection

- Check that the mains voltage selector on the

rear panel, see Fig. 6.1, shows the actual

mains vo ltage.

- Connect the mains cord to rear panel mains inlet

and to the mains.

- Switch the ON/OFF switch on the rear panel to

ON.

- Check that the status display, see Fig. 4.1,

shows OFF.

Punching

Punch tape loading

Load the tape according to section 1.2 Punch Tape

Loading.

Punching instruction

- Connect the NC/Computer cable plug to the

CHANNEL 1 I/O PORT connector on the rear panel,

see Fig.6.1.

- Depress the key ON L on the operator keyboard.

The status display shows LINE.

- Start the punching from the NC/Computer.

- Tear off the tape when the punching is ready.

If required, blank tape can be fed by depressing

OFF L and FEED before tearing off the tape.

Note

The data transmission should be made at 600 bit/s.

Reading

Reader Tape Loading

Load the tape according to section 1.5 Reader Tape

Loading.

Reading instruction

- Depress the ON L key on the operator keyboard.

The status display shows LINE.

- Clear the NC/Computer for reading.

- Depress the START key to start the reading.

- Depress the STOP key to stop the reading.

- Depress the START key to restart the reading.

Note

The data transmission should be made at 600 bit/s.

Because reading is faster than transmission, the

reader can stop before the whole tape is read. The

reader will res tart automatically and con tinue

until the whole tape is read.

The tape can be run quickly through the reader

either forwards or reverse, without data being

read, by depressing the FF or FB key respectively.

The equipment must be off line.

When data is sent over the line, by reading or

punchi n g , a sp e c ial s ign ( a t re a ding, at

punching) is shown in the display to indicate

communication. At punching the display returns to

"Line", when data has been sent. At reading, when

the communication stops by any reason, the display

shows "data" if there is data in the buffer. The

buffer can be cleared by pressing the Stop key <*>

and the display goes back to "Line".

If punching is started after reading and there

still i s data in t h e buffer, the buffer i s

automatically cleared. By sending to N4000 for

punching, the display switches from "data", if the

buffer is not cle ared, to the specia l l ine

communication sign.

Ta pe c op y in g

Tap e c o pyin g i nstr u c tion

- Depress the OFF L key on the operator keyboard.

The status display shows OFF.

- Depress the COPY key.

The status display shows COPY.

- Put the tape in the reader.

- Depress the START key.

Copying will start.

- Depress the OFF L and ON L keys when copying is

finished.

If the raeder stops during copying, it is due to

the fact that the reader is faster than the punch.

The copying will restart automatically and

continue until the whole tape is copied.

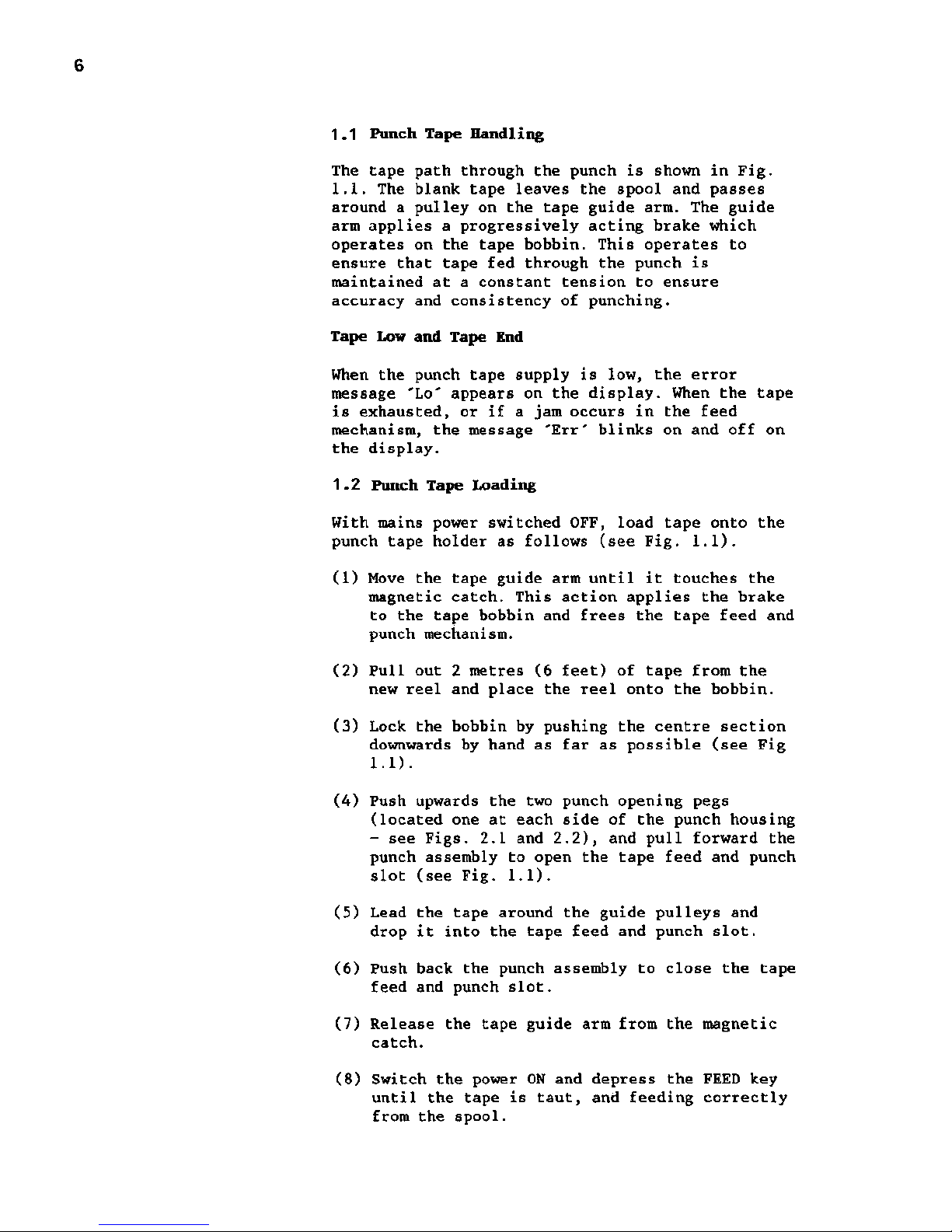

1.1 Punch Tape Handling

The tape path through the punch is shown in Fig.

1.1. The blank tape leaves the spool and passes

around a pulley on the tape guide arm. The guide

arm applies a progressively acting brake which

operates on the tape bobbin. This operates to

ensure that tape fed through the punch is

maintained at a constant tension to ensure

accuracy and consistency of punching.

Tape Low and Tape End

When the punch tape supply is low, the error

message 'Lo' appears on the display. When the tape

is exhausted, or if a jam occurs in the feed

mechanism, the message 'Err' blinks on and off on

the display.

1.2 Punch Tape Loading

With mains power switched OFF, load tape onto the

punch tape holder as follows (see Fig. 1.1).

(1) Move the tape guide arm until it touches the

magnetic catch. This action applies the brake

to the tape bobbin and frees the tape feed and

punch mechanism.

(2) Pull out 2 metres (6 feet) of tape from the

new reel and place the reel onto the bobbin.

(3) Lock the bobbin by pushing the centre section

downwards by hand as far as possible (see Fig

1.1).

(4) Push upwards the two punch opening pegs

(located one at each side of the punch housing

- see Figs. 2.1 and 2.2), and pull forward the

punch assembly to open the tape feed and punch

slot (see Fig. 1.1).

(5) Lead the tape around the guide pulleys and

drop it into the tape feed and punch slot.

(6) Push back the punch assembly to close the tape

feed and punch slot.

(7) Release the tape guide arm from the magnetic

catch.

(8) Switch the power ON and depress the FEED key

unt il the tape is taut , and feeding correct ly

from the spool.

GUIDE

PULLEYS

B O B B I N B L A N K T A P E S P O O L T A P E L O W D E T E C T O R

□ DD

DDD

odd

ODD

TAPE FEED AND

PUNCH SLOT

i

GUIDE

PULLEY

MAGNETIC

CATCH

TAPE GUI DE AR M

LOCK ELEASE

BOBBIN LOCK

Fig. 1.1 Punch Tape Loading

8

1.3 Punching Accuracy

The accuracy of punching can be checked by using

the Facit template part no. 1114 00 50-00/0 as

shown in Fig. 1.2. It is recommended that this

check is carried out approximately every 50th tape

reel used.

(1) Lay the punched tape on the template as shown

in Fig. 1.2, with a feed hole accurately

centered on the leftmost vertical line.

(2) Examine the 50th feed hole on the rightmost

v e rt i ca l lin e . I f t h is l in e is v is i bl e wi t hi n

the hole, (i.e. within +-0.5 %), the punch

accuracy is acceptable.

(3) I f the v e r t ical l i n e is n o t visib l e (i.e.

outside +-0.5 %) the punch mechanism requires

servicing.

c

- 50 Characters = 127mm = 5 inches -

I H'il l.t-H *-+]

I ' t

t1-rt'H-4~f

T*T

—t-l 4 -I- +4- +-h+ 4—n

FACIT

FEED HOLE

CENTRED

ON GRID

e

i

e

©

0 5 O T H F E E DHOL E (ACCURATE)

O - 0 . 5% I AC C EP TA B L E

& L I M I T S

+ 0.5% I

Fig. 1.2 Check Intercharacter Spacing

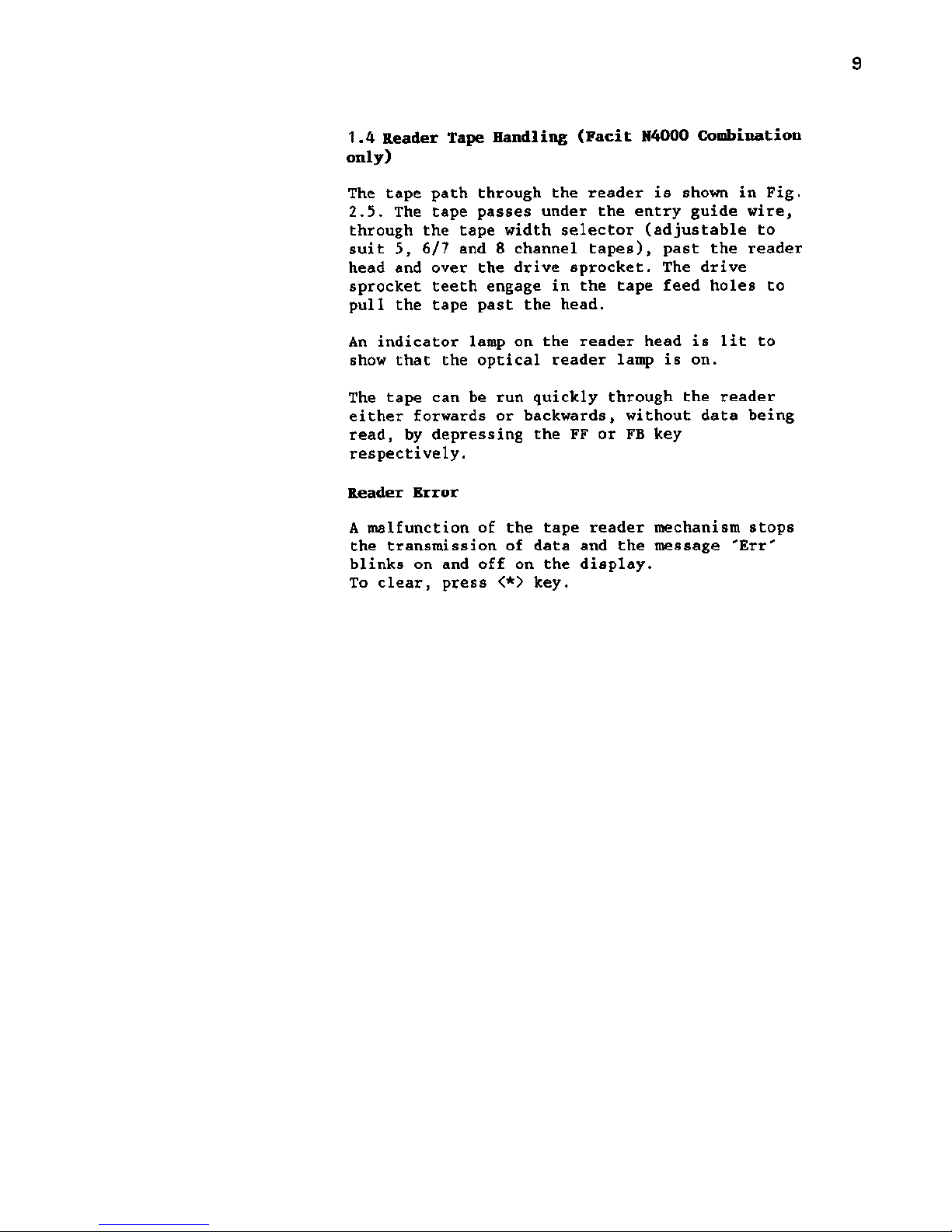

1.4 Reader Tape Handling (Facit N4000 Combination

only)

The tape path through the reader is shown in Fig.

2.5. The tape passes under the entry guide wire,

through the tape width selector (adjustable to

suit 5, 6/7 and 8 channel tapes), past the reader

head and over the drive sprocket. The drive

sprocket teeth engage in the tape feed holes to

pull the tape past the head.

An indicator lamp on the reader head is lit to

show that the optical reader lamp is on.

The tape can be run quickly through the reader

either forwards or backwards, without data being

read, by depressing the FF or FB key

respectively.

Reader Error

A malfunction of the tape reader mechanism stops

the transmission of data and the message 'Err'

blinks on and off on the display.

To clear, press <*> key.

10

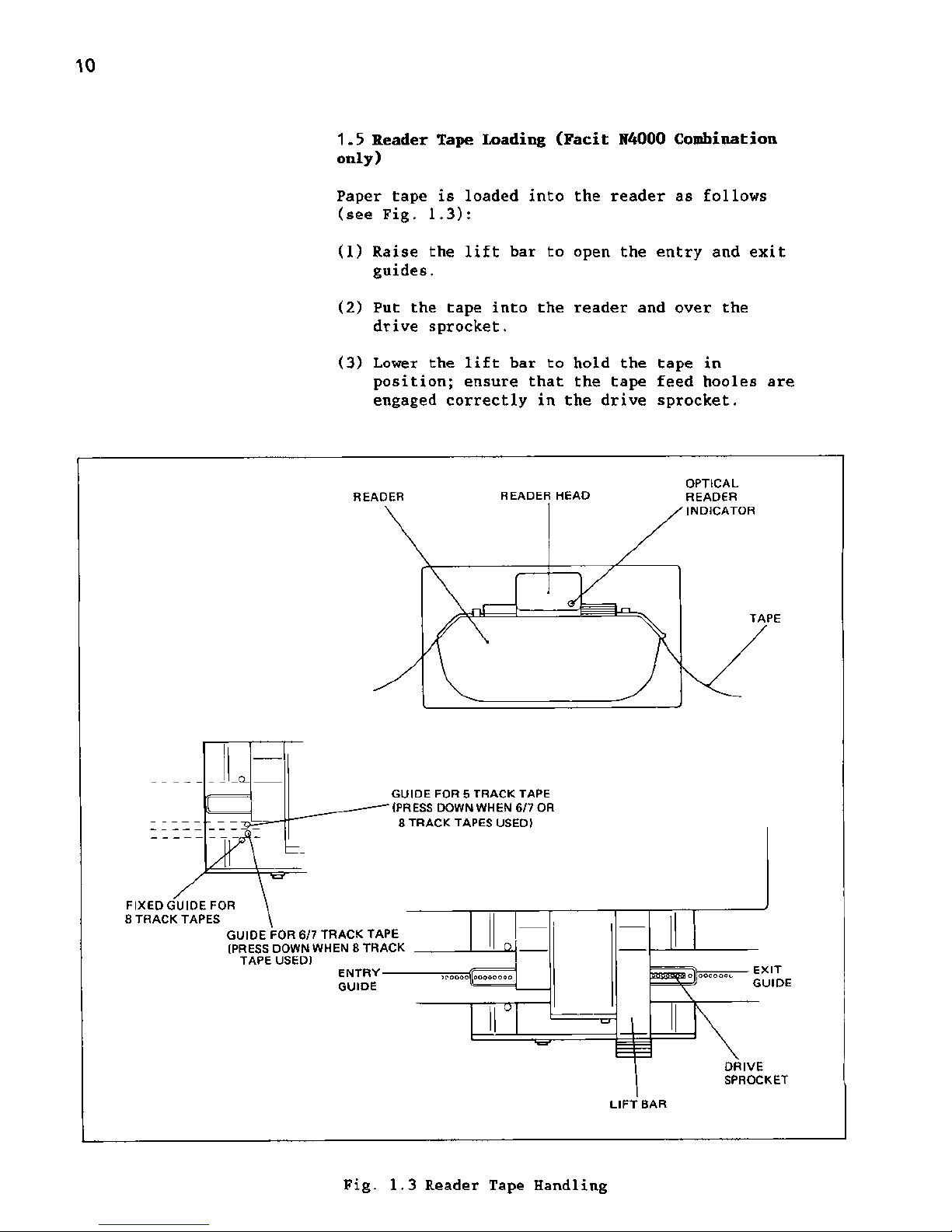

1.5 Reader Tape Loading (Facit N4000 Combination

only)

Paper tape is loaded into the reader as follows

(see Fig. 1.3):

(1) Raise the lift bar to open the entry and exit

guides.

(2) Put the tape into the reader and over the

drive sprocket.

(3) Lower the lift bar to hold the tape in

position; ensure that the tape feed hooles are

engaged correctly in the drive sprocket.

READER READER HEAD

OPTICAL

READER

INDICATOR

TAP E

GUIDE FOR 5 TRACK TAPE

(PRESS DOWN WHEN 6/7 OR

8 TRACK TAPES USED)

FIXED GUID E FOR

8 TRACK TAPES

GUIDE FOR 6/7 TRACK TAPE

(PRESS DOWN WHEN 8 TRACK

TAPE US ED)

ENTRYGUIDE

^cooooloooooooo

olooooooo

EXIT

GUIDE

DRIVE

SPROCKET

LIFT BAR

Fig. 1.3 Reader Tape Handling

11

2 Design and Construction

2.1 Brief Description

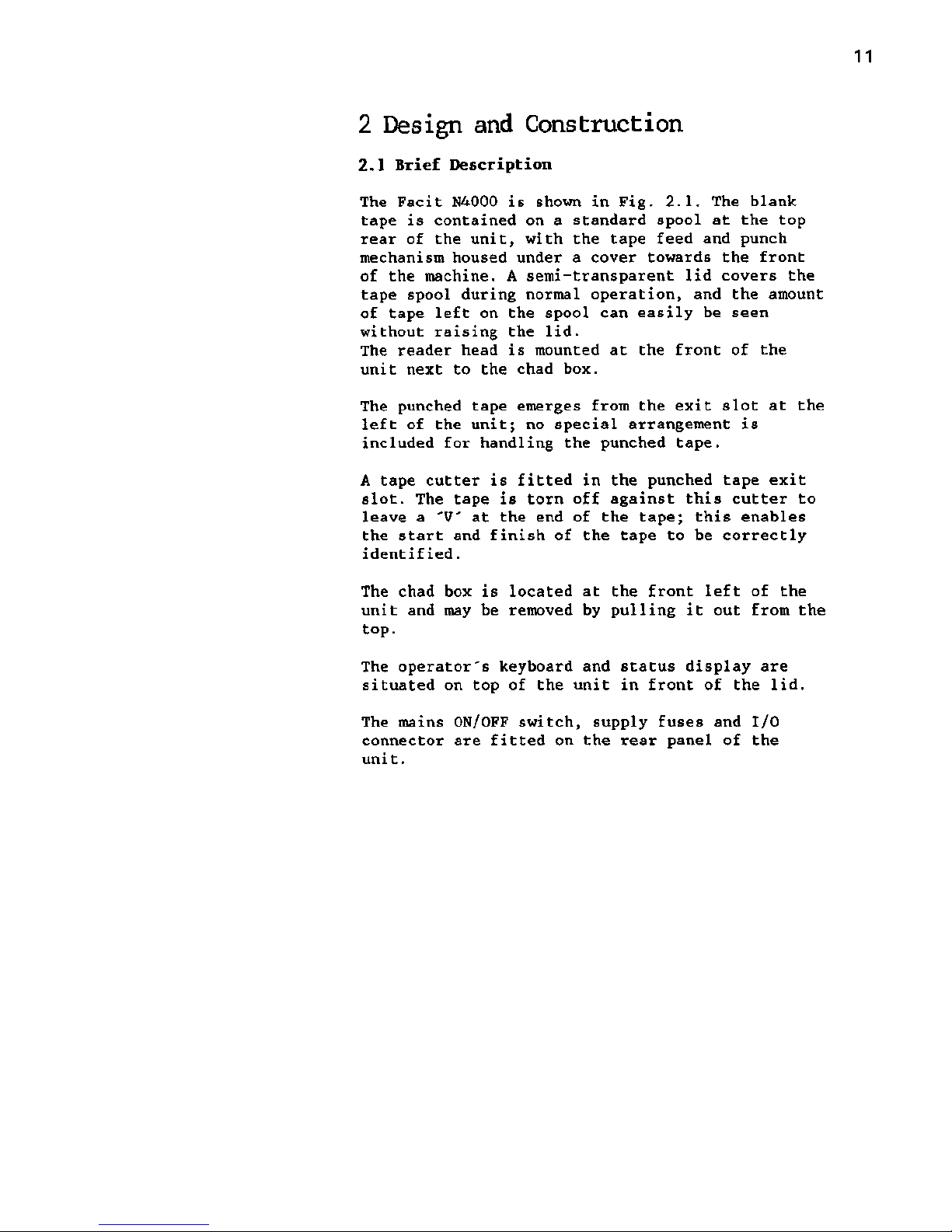

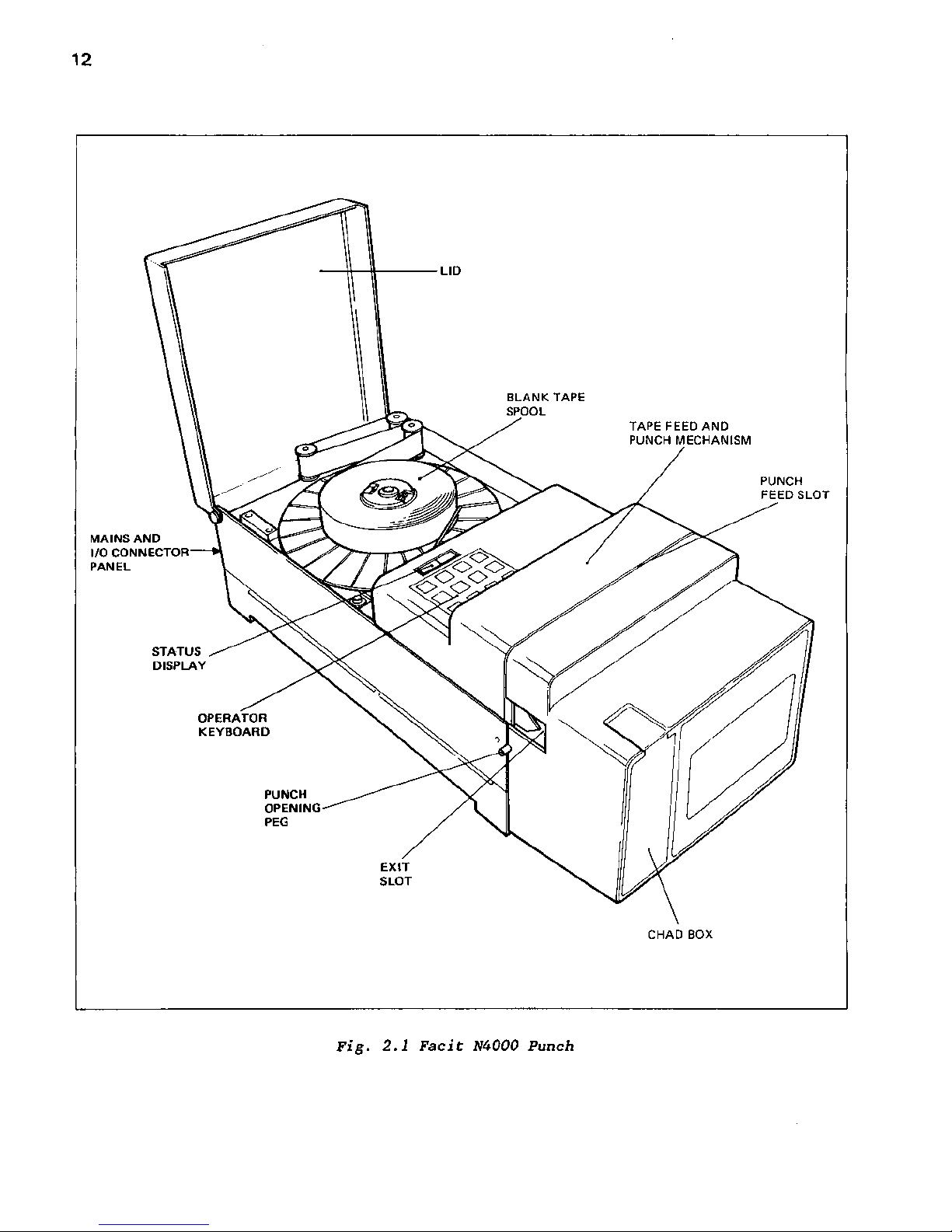

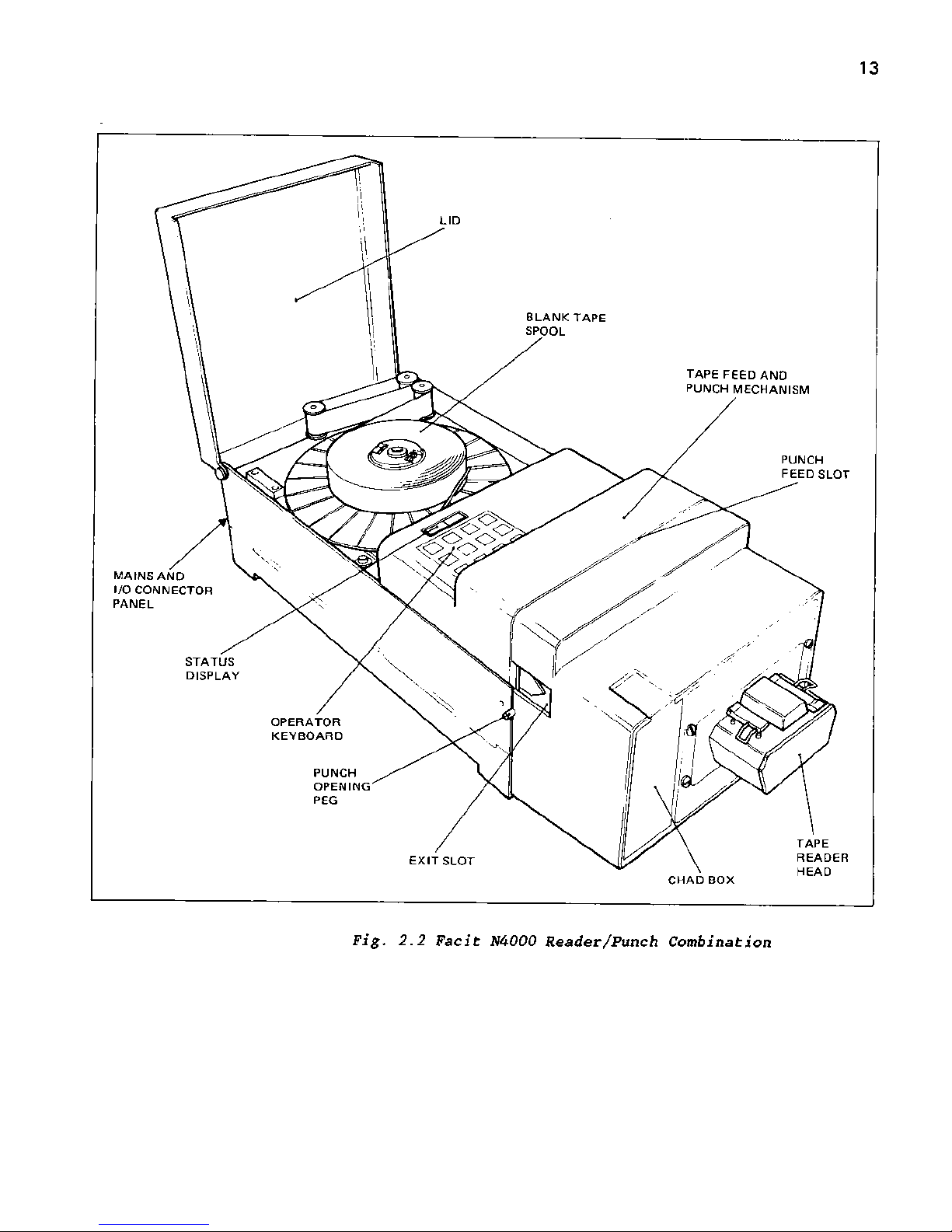

The Facit N4000 is shown in Fig. 2.1. The blank

tape is contained on a standard spool at the top

rear of the unit, with the tape feed and punch

mechanism housed under a cover towards the front

of the machine. A semi-transparent lid covers the

tape spool during normal operation, and the amount

of tape left on the spool can easily be seen

without raising the lid.

The reader head is mounted at the front of the

unit next to the chad box.

The punched tape emerges from the exit slot at the

left of the unit; no special arrangement is

included for handling the punched tape.

A tape cutter is fitted in the punched tape exit

slot. The tape i s t orn off against this cutte r to

leave a 'V at the end of the tape; this enables

the start and finish of the tape to be correctly

identified.

The chad box is located at the front left of the

unit and may be removed by pulling it out from the

top.

The operator's keyboard and status display are

situated on top of the unit in front of the lid.

The mains ON/OFF switch, supply fuses and I/O

connector are fitted on the rear panel of the

unit.

12

MAINS AND

I/O CONNECTOR

PAN EL

STATUS

DISPLAY

OPERATOR

KEYBOARD

PUNCH

OPENING

PEG

EXIT

SLOT

TAPE FEED AND

PUNCH MECHANISM

PUNCH

FEED SLOT

CHAD BOX

Fig. 2.1 Facit M000 Punch

13

MAINS AND

I/O CONNECTOR

PAN EL

STATUS

DISPLAY

TAPE FEED AND

PUNCH MECHANISM

PUNCH

FEED SLOT

OPERATOR

KEYBOARD

PUNCH

OPENING

PEG

EXIT SLOT

CHAD BOX

TAP E

READER

HEAD

Fig. 2.2 Facit N4000 Reader/Punch Combination

15

3 Operation

The unit is intelligent and all programming

functions are performed by entries made on the

built-in keyboard.

All program parameters are held in RAM, and a

battery is incorporated on the interface board to

preserve the memory contents when the unit is

switc h ed o ff. The batte r y c a pacity is suffici e nt

to retain the memory contents for several years.

3.1 Punch buffer

The overall operation of the punch, and the

control of incoming data, is performed by the

buffer. The buffer's to tal capac ity is*v9 K. This

capacity is shared between Channels 1 and 2

according to the buffer stop address selected for

channel 1, in the Program step 12. Each buffer

accepts data from its source until full; a n

instruction is then sent to the source to stop the

transmission. The minimum size for either buffer

is 256 characters.

The required code conversion of the incoming data

is performed prior to reading into the buffer;

data in the buffer is therefore always in the

correc t version for direct punching out .

3.2 Punching out data

Whichever channel has assumed priority for

incoming data keeps this priority when punching

data.

Data transfer from buffer to punch is controlled

and selected in the Program mode (see section 5).

3.3 Buffer Status Sign alling

The acceptance of incoming data is controlled by

the Full or Empty status of its associated part of

the buffer.

The buffer Full or Empty condition is indicated

either by X-ON/X-OFF protocol or Ready/Busy status

signall ing, selectable s eparately f or each c hannel

in the Program mode.

3.4 Punch Speed

The punching speed is 30, 62 or 75 characters per

second, operator selectable.

16

3.5 Time Out

If data is sent to both channels simultaneously,

the channel receiving data first assumes priority

and starts punching. An End of Message character

or a Time Out selected in Program mode 10 can

change priority to the other channel. The Time Out

function is explained fully in Appendix 6.

3.6 Tape Reader (Facit N4000 reader/punch

combination only)

Where a reader is included on the unit, data read

from a punched tape is transmitted via channel 1

or channel 2.

Reading takes place at a speed of 200/500

characters per second, operator selectable.

When the reader is started from the keyboard

(start key) data is always transmitted via channel

1. When the reader is started remote, using the

start reader code, data can be transmitted via

channel 1 or 2 depending on the channel used to

send the start reader code. The channel not

affected by reading can accept data for punching.

If reading is attempted while data for punching

remains in any of the buffers for channel 1 or 2,

reading is inhibited and BUSY is displayed,

reading can start when the existing contents are

punched and the channel buffer is empty.

The reader stops when the Stop key is depressed, a

stop reader code is received (either sent over the

line or read on the tape), or when the tape end is

reached.

The transmission continues until the buffer is

empty even if the reader stops due to any of the

conditions above.

The transmission can be controlled using the

X-0N/X-0FF protocol. Sending the code DC3 will

stop transmission and the code DCl will start

transmission.

17

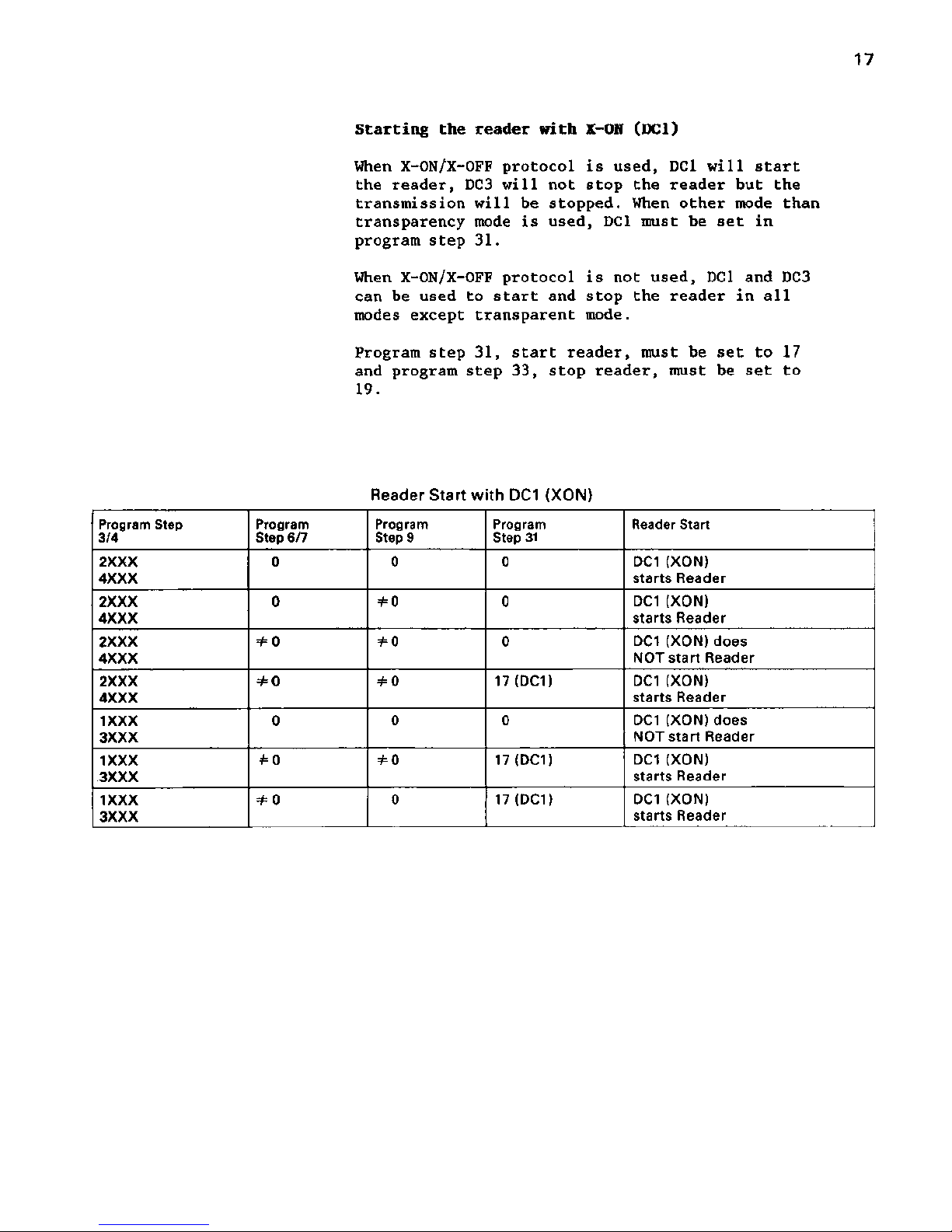

Starting the reader with X-ON (DCl)

When X-ON/X-OFF protocol is used, DCl will start

the reader, DC3 will not stop the reader but the

transmission will be stopped. When other mode than

transparency mode is used, DCl must be set in

program step 31.

When X-ON/X-OFF protocol is not used, DCl and DC3

can be used to start and stop the reader in all

modes except transparent mode.

Program step 31, start reader, must be set to 17

and program step 33, stop reader, must be set to

19.

Reader Start with DC1 (XON)

Program Step

3/4

Program

Step 6/7

Program

Step 9

Program

Step 31

Reader Start

2XXX

4XXX

0 0 0

DC1 (XON)

starts Reader

2XXX

4XXX

0 =£0 0 DC1 (XON)

starts Reader

2XXX

4XXX

=£0 *0 0 DC1 (XON) does

NOT start Reader

2XXX

4XXX

=#0 *0

17(DC1)

DC1 (XON)

starts Reader

1XXX

3XXX

0 0 0 DC1 (XON) does

NOT start Reader

1XXX

3XXX

#0 *0

17(DC1)

DC1 (XON)

starts Reader

1XXX

3XXX

=/=o 0 17(DC1)

DC1 (XON)

starts Reader

Loading...

Loading...