Need to ask a question?

Contact technicalsupport@fablicator.com 10/24/2017

FABLICATOR

User Manual

Contents

Unpacking the Startup Kit ............................................................................................................................. 3

Unpacking the SX .......................................................................................................................................... 5

Loading Filament ........................................................................................................................................... 8

Removing Filament ..................................................................................................................................... 11

Slicing your first part ................................................................................................................................... 14

Printing Your First Part ................................................................................................................................ 17

Extruder Problems ...................................................................................................................................... 19

Clearing an Extruder Clog ............................................................................................................................ 21

Wedged Filament removal .......................................................................................................................... 23

Cleaning a blocked nozzle tip (simple method) .......................................................................................... 28

Cleaning a blocked nozzle tip (involved method) ....................................................................................... 32

2

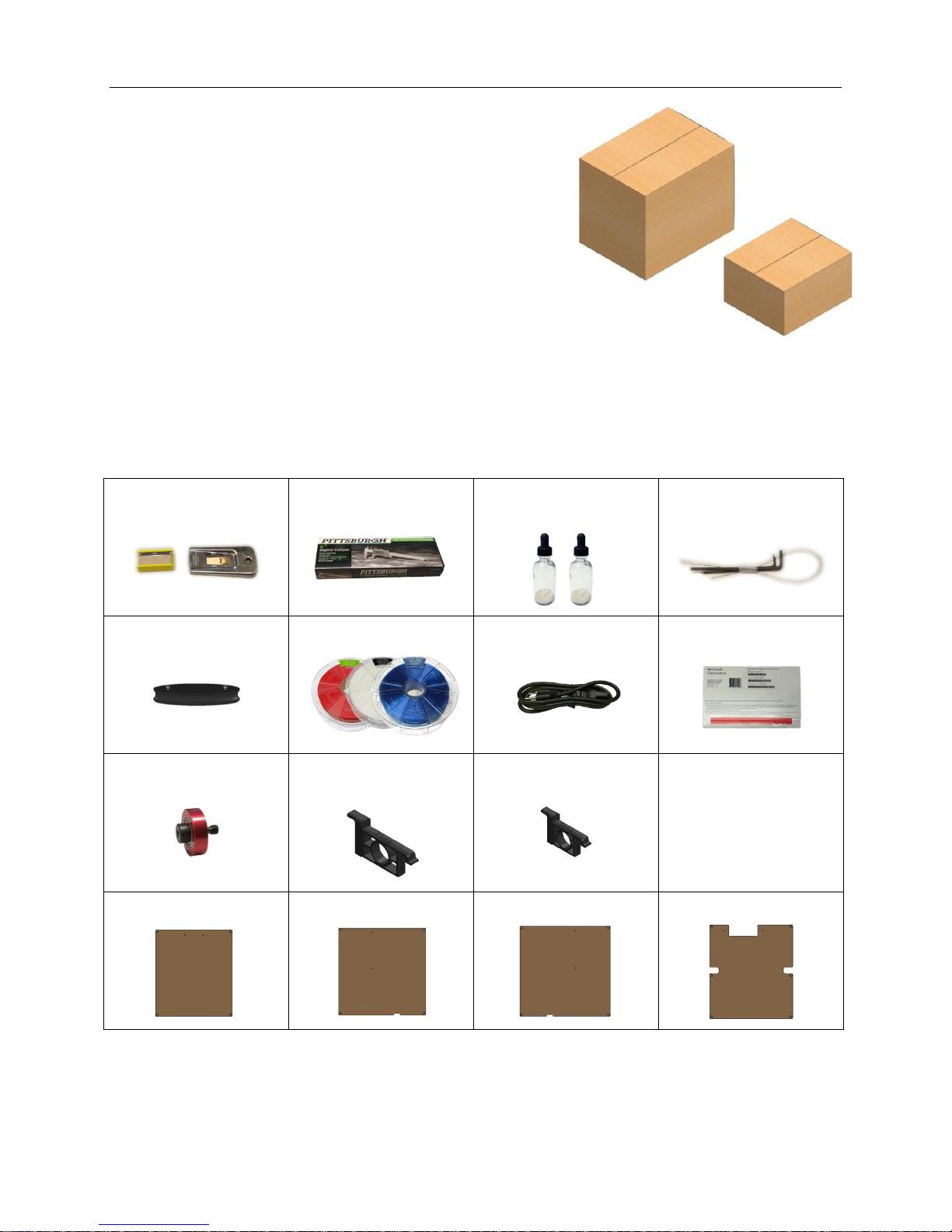

Unpacking the Startup Kit

1.

Verify the following are contained within the small startup

kit box.

Part Scraper Tool

Calipers

Primer Bottles

Allen Wrenches and

music wire

Front Panel Handle

3 Spools Filament

Power Cord

Windows Backup CD

Flex Idler

76mm Spool Holder

54mm Spool Holder

User Manual

Front and Back panels

Left Side Panel

Right Side Panel

Top Panel

3

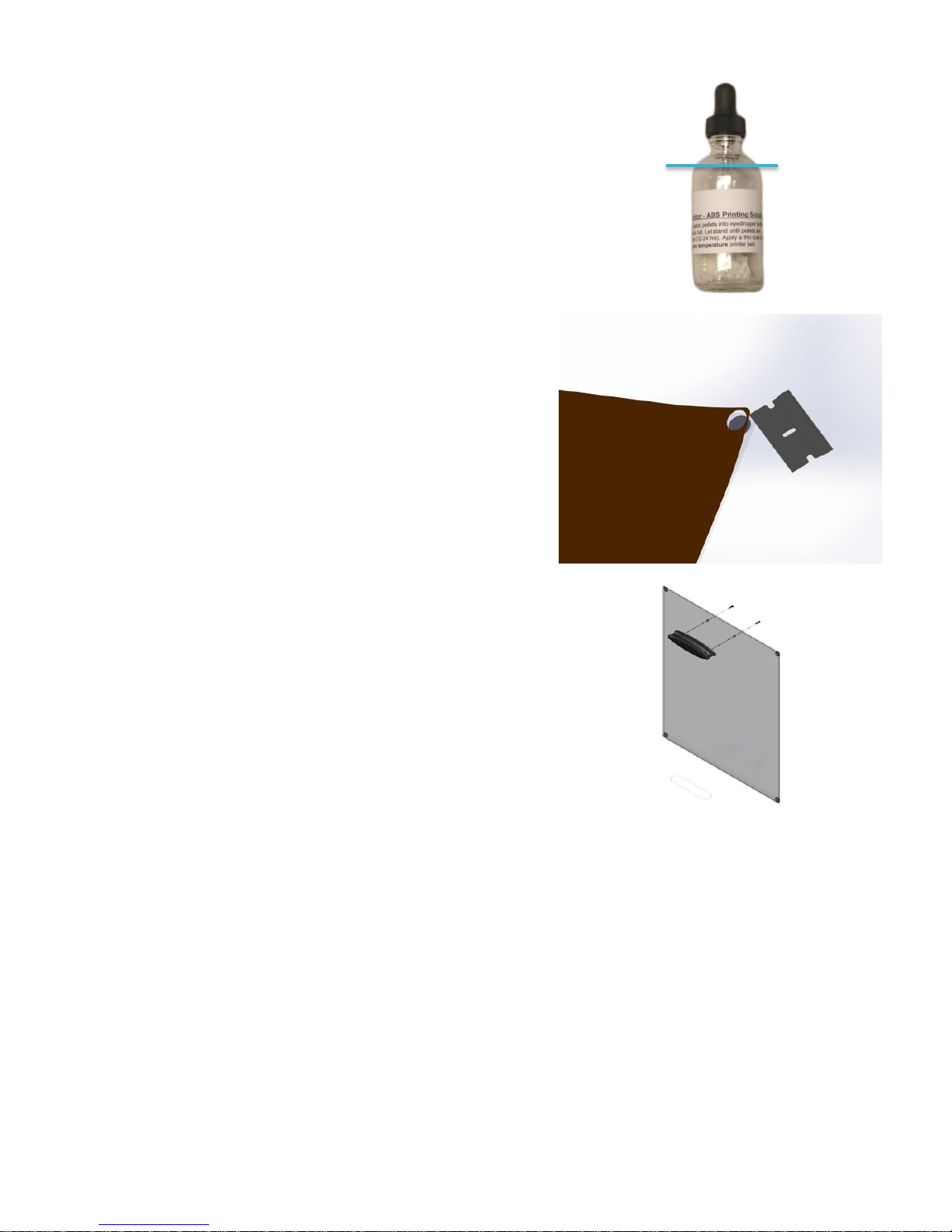

2.

Add acetone to the dropper bottles to begin dissolving the

primer pellets.

The bottles should be filled to the line shown.

3.

Peel the protective covers from the plastic panels. Use your

fingernail or a razor blade to lift up the edge to get them

started.

4.

Assemble the front panel and front panel handle.

4

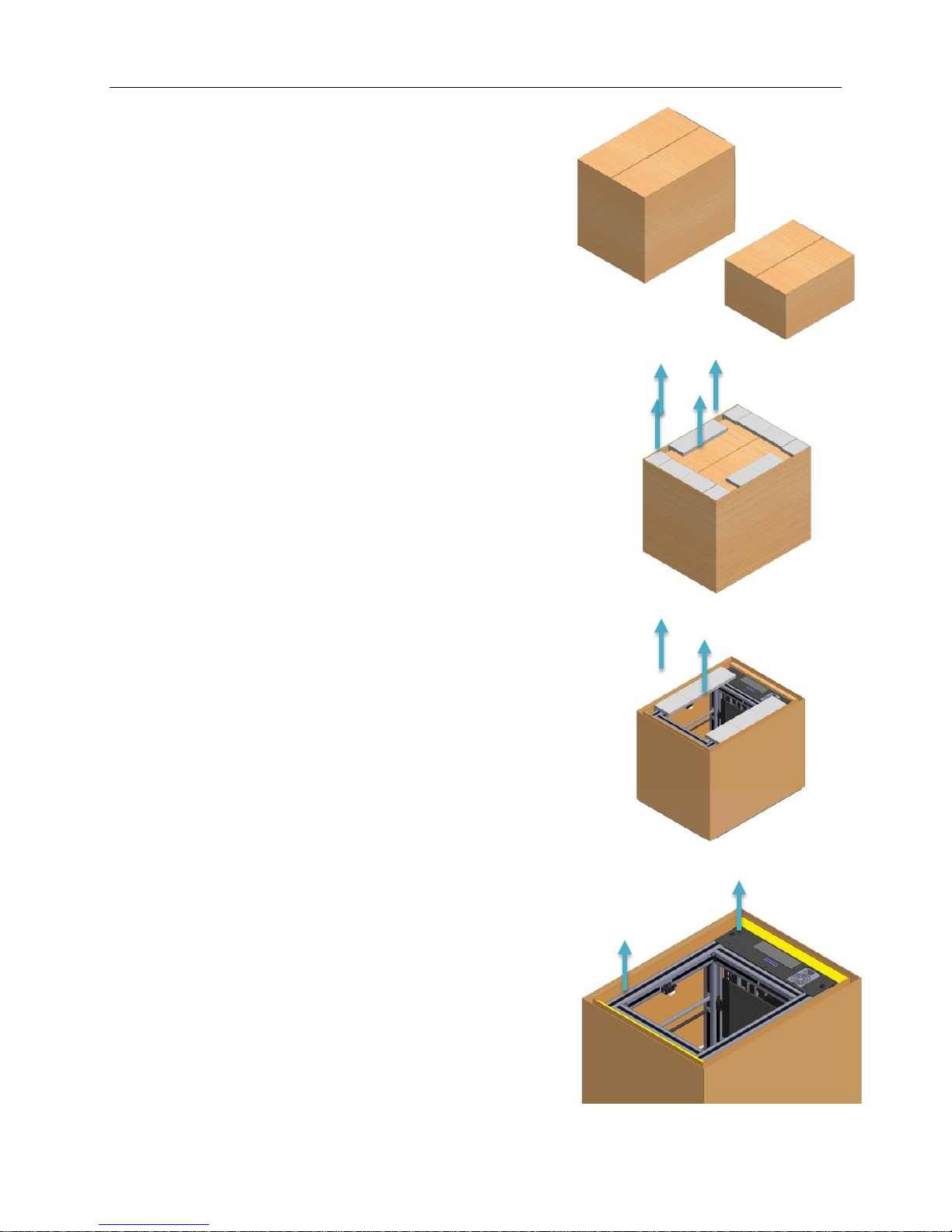

Unpacking the SX

1.

The SX is shipped in two Packages. One large package

containing the printer and one smaller package

containing the required accessories.

Unpacking the unit and accessories in an uncluttered

area is recommended.

2.

Start by opening the large box and removing the

protective foam inserts.

3.

Open the inner box and remove the foam inserts

4.

Remove the protective wood and cardboard panels

above and below the machine. (Highlighted in yellow)

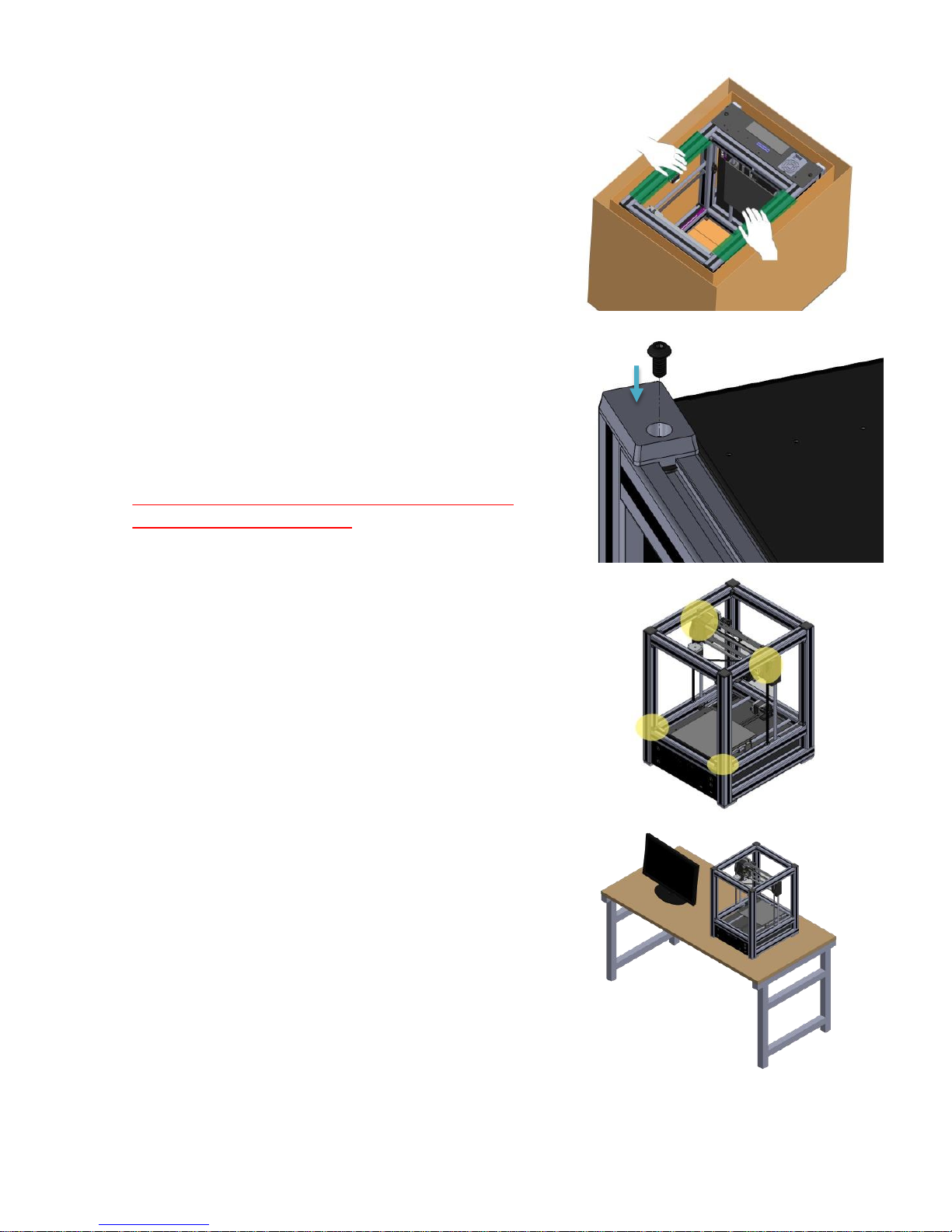

5

5.

A second person is very helpful for this step.

Lift the printer by the green highlighted areas, and set

upside-down onto a flat, clean, non-abrasive surface.

6.

Cut the feet free of the zip ties on the side of the

printer.

Screw the feet to the bottom four corners of the

machine as shown using the existing hardware.

Failure to attach the feet will cause the printer to

badly scratch most surfaces!

7.

Place the Fablicator on a sturdy table or desk

Remove the yellow Z axis spacers and all remaining

yellow zip ties.

8.

Connect your monitor, keyboard, mouse, and power

cord to the printer. The connections are on the back of

the machine and are the same as a standard PC.

6

9.

Insert the spool holder into the frame on either side of

the machine.

10.

Attach the clear magnetic panels to the machine.

The Fablicator SX is now completely assembled and

ready to start printing.

7

Loading Filament

1.

Turn on the printer using the blue power button

2.

Turn off the XYZ and EXT disable switches on the front

of the machine. These switches disable the motors

controlling the extruder and XYZ axis when

illuminated.

The built in yellow LEDs should be OFF

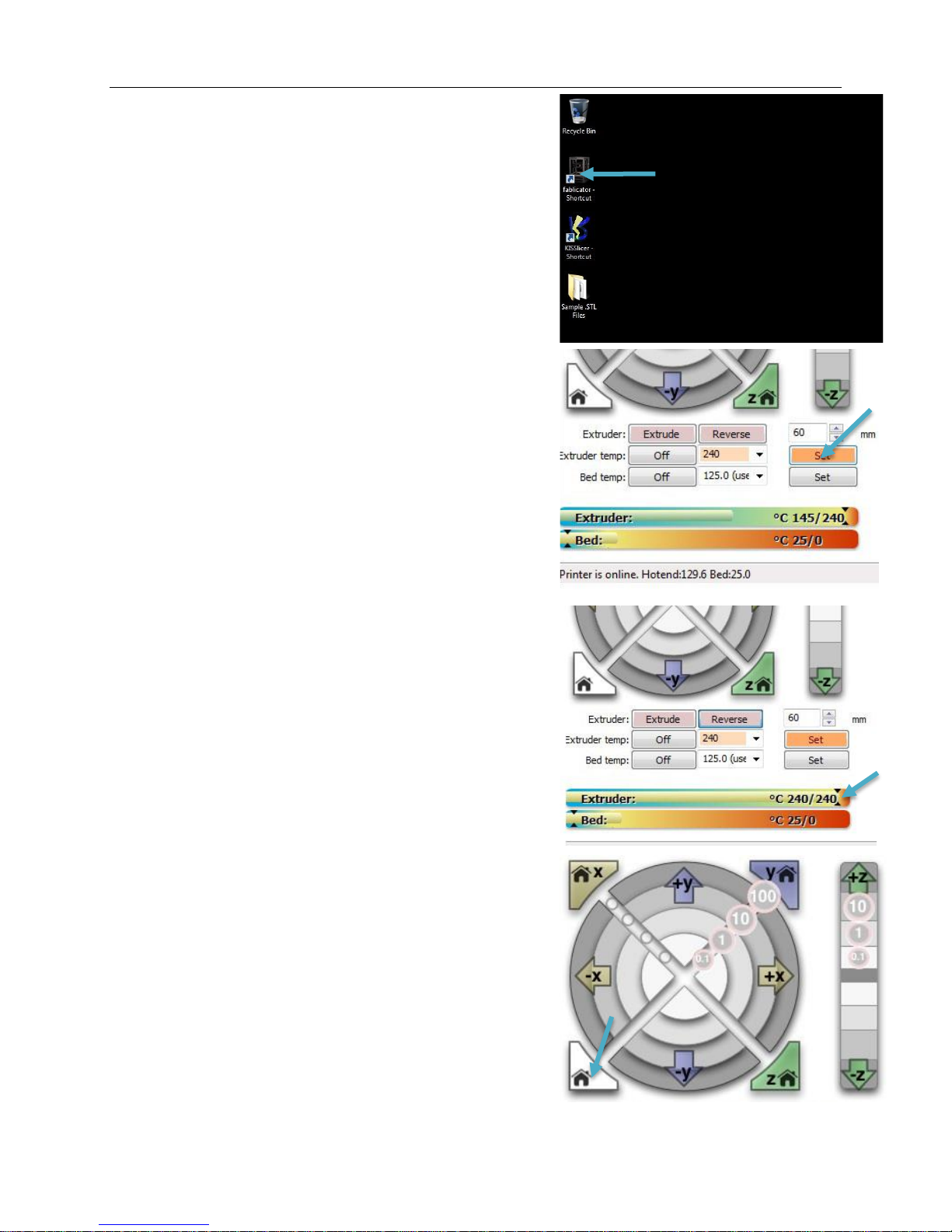

3.

Open the Fablicator shortcut on the desktop

This will open the interface to control the Fablicator

SX.

4.

First, the filament needs to be loaded into the

machine.

Press the Set button to the right of the Extruder Temp

text to set the extruder to 240C. . This will heat up the

extruder so filament can be loaded and unloaded.

Caution: After this step, the tip of the extruder will be

extremely hot. Do not touch it.

8

5.

Wait for the Extruder temp to exceed 200 C

The extruder temp bar shows the current extrude

temperature vs. the set temperature

6.

Home all axis to make sure the print head is in a

convenient position.

7.

Attach a spool to the spool holder.

There are different sized spools and holders, so you

may need to change the spool holder if it does not fit

the spool you want to use.

8.

Loop the filament over the extrusion, and into the

entrance of the extruder (marked with a yellow arrow)

5.

The extruder temp bar shows the current extrude

temperature vs the set temperature

Wait for the Extruder temp to exceed 200 C

9

9.

The filament should be inserted so it just touches the

drive wheel and idler.

10.

Hold the filament against the drive wheel and idler

while pressing the Extrude button in the Fablicator

interface.

The extruder motor will start to turn and grip the

filament. One press moves the filament 60mm and

stops automatically.

Once the filament starts to move you can let go of the

material.

11.

Press the Extrude button again if filament has not

been extruded at the nozzle tip by the time the

extruder stops.

Once melted filament has come out the tip of the

extruder, the filament is fully loaded.

Remove the excess material from the nozzle tip.

12.

Turn off the extruder by pressing the Off button next

to the Extruder temp text. This is only necessary if you

do not plan to print an object in the next few

minutes.

10

Removing Filament

1.

Open the Fablicator shortcut on the desktop

This will open the interface to control the Fablicator

SX.

2.

The nozzle needs to be heated up to remove the

filament.

Press the Set button to the right of the Extruder

Temp text to set the extruder to 240C. . This will heat

up the extruder so filament can be loaded and

unloaded.

Caution: After this step, the tip of the extruder

will be extremely hot. Do not touch it.

3.

Wait for the Extruder temp to exceed 200 C

The extruder temp bar shows the current extrude

temperature vs. the set temperature

4.

Home all axis to make sure the print head is in a

convenient position.

11

5.

Press the Reverse button which will back out 60mm of

filament from the extruder.

6.

After the extruder motor stops, lightly pull on the

filament and it should come out of the extruder

assembly.

7.

Trim the last 4 inches off of the filament so only

unmarred plastic is visible.

8.

Wrap the loose filament back onto the spool and lock

the strand through the holes on the side of the spool

If the end of the filament is loose, it will get tangled

on the spool and eventually cause knots.

12

9.

If you wish to add another spool of filament, now is a

good time.

Otherwise, turn off the extruder by pressing the Off

button next to the Extruder temp text.

13

Slicing your first part

1.

Open the Fablicator shortcut on the desktop

This will open the interface to control the Fablicator SX.

2.

Click the Load file button in the top left corner

This will allow you to select a .STL file to prepare it for

printing.

3.

Select a .stl file (The example we are using is located in

Desktop > Sample .STL Files >Engineering Samples>

Ruler 6in .STL) and click the “Open” button

This will open the file with KISSlicer.

4.

Once KISSlicer has loaded, a 3D representation of the

part will be visible in the main window. The sample

part is a short ruler in this case.

A Small thumbnail of the part will also be visible in the

“part box” on the top right of the screen (highlighted in

yellow)

14

5.

A right click on the part box allows a part to be scaled,

multiplied, or transformed (rotated, flipped) if desired.

Additional parts can be added to the print using the

Open button.

6.

Select the Style tab, and set this part to 01 Coarse,

Solid using the drop down menu.

The Style primarily changes the layer thickness and

infill density of the part.

Thinner layers and more solid parts take longer to

print.

7.

Select the Support tab, and set this part to 00. No

Support

8.

Select the Ext Map tab, and select the printing material

from the drop down box. We will be printing the

sample part in PLA-PHA

The material set in this window must match the

material loaded into the printer. Incorrect material

setting will lead to failed prints and potential damage

to the printer.

15

9.

Once all the settings are selected, Click the Slice button

in the top right corner.

Choose a filename and save the file to the desktop to

create G-Code for the part. It is good practice to

include the type of material used in the file name for

future reference.

10.

After the file is sliced, you can preview the layers using

the paths radio button.

You can use the vertical slider on the right side of the

preview window to scroll through the layers and see

exactly what the printer will do line by line.

It is recommended to always preview these paths.

11.

There is also a Time, Material Volume, and Cost

estimate visible on the right side of the screen

Lastly, the settings used to slice your part are visible on

the bottom right of the screen.

12.

When done previewing your print, close KISSlicer.

You MUST close KISSlicer before loading the g-code file

into the Fablicator interface

16

Printing Your First Part

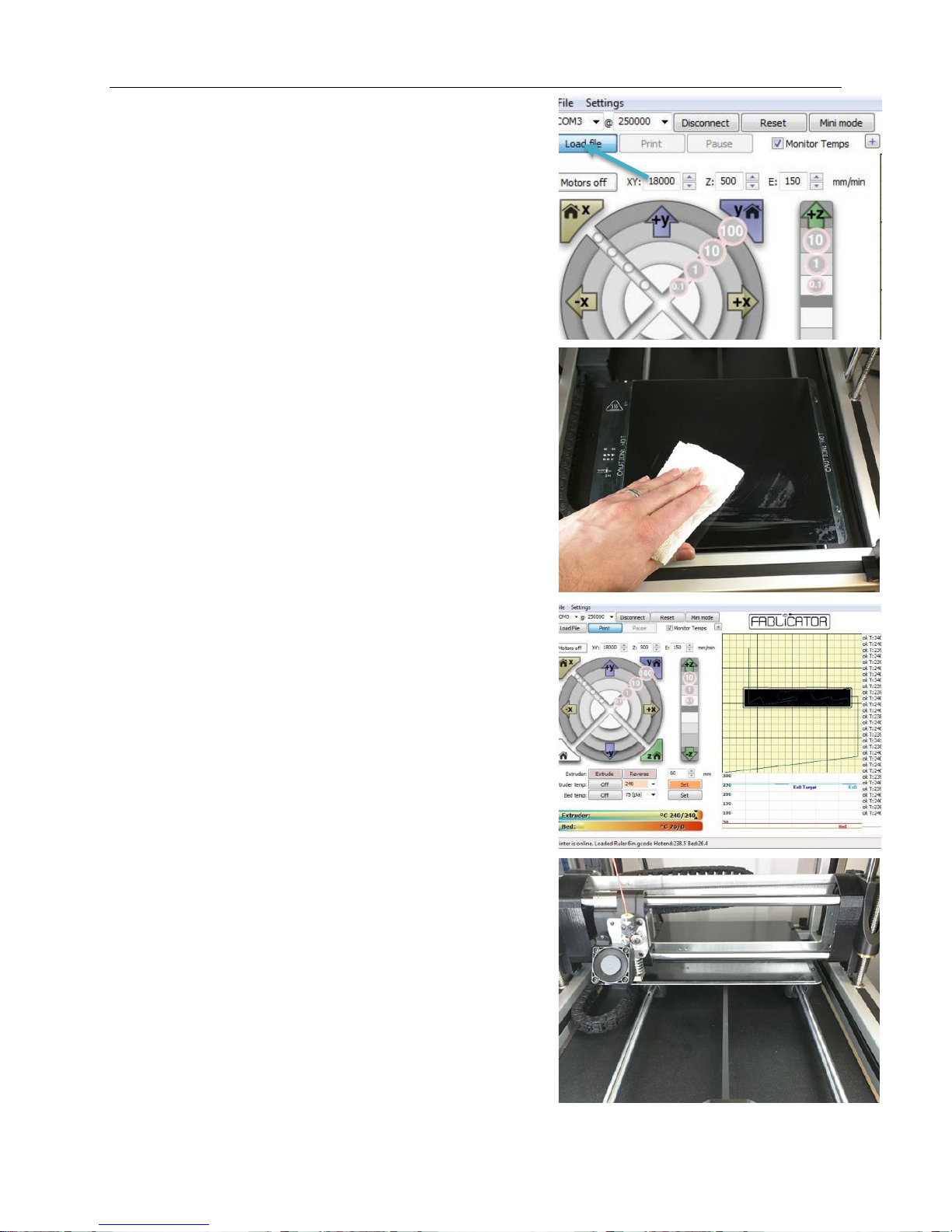

1.

Open the Fablicator interface, and Click the “Load File”

button.

Select the G-Code file that was just created, and click Open.

In this example it is Ruler 6in.gcode unless you renamed the

file something else.

2.

Before starting the print, always apply a thin coat of the

primer solution to the print surface. Using a paper towel,

apply 1-3 squirts and wipe the bed in a circular motion to

achieve an even coat.

The bed should still be damp when you finish wiping, and it

will air dry within a few seconds. Video of this process can

be found at LINK

3.

Once the bed is primed and G-Code file loaded, press the

Print button

The Fablicator will automatically home all axis, and move

the extruder to a corner of the bed. The printer will also

automatically heat up the bed and extruder to the material

settings from KISSlicer.

4.

When the bed reaches the target temperature, the print will

begin.

Once the print has finished, the extruder and bed will turn

off automatically.

17

5.

When the print is complete, wait for the bed to cool down

before removing the part with the safety razor, generally the

bed should be below 40C. Cooler is better.

If you do not wait for the part to cool down, it may deform

when you try and remove it, or be extremely difficult to

remove.

18

Extruder Problems

1.

If filament is not exiting the extruder while printing or

manually extruding, you likely have a problem with the

extruder.

If the filament extrudes fine in air, but makes a clicking

sound when printing the first layer of a part, it is most likely

a bed leveling issue instead. See the section on bed leveling

and calibration

2.

First, check that the nozzle is heating up. Set the

temperature within the Fablicator interface to 240

and see if it rises from room temperature.

If no change is seen on-screen, physically check to

see if the heater block is getting hot. Pressing a

piece of filament onto the side of the block is a good

way to tell.

3.

If the heater block is hot, but the software says it’s

cold, the PT100 temperature sensor is likely to

blame.

Check the PT100 connections at the extruder and

computer case. If the connections seem OK, replace

the PT100 sensor.

4.

If the heater block is still cold, the problem is likely

the heater cartridge or controller board.

Check the heater cartridge connections in the

extruder and at the case. If the connections look OK,

test the resistance of the heater cartridge and wires

leading to it.

A functioning cartridge should have a resistance of

~3.5 ohms.

19

5.

If the heater cartridge is very high or low resistance,

replace it.

If the heater cartridge resistance is OK, replace the

controller board.

6.

The second thing to check is that the cooling fan is

spinning and not obstructed by dirt or other debris.

Clean excessive debris and/or check the fan’s

connection. A stopped fan will likely need to be

replaced.

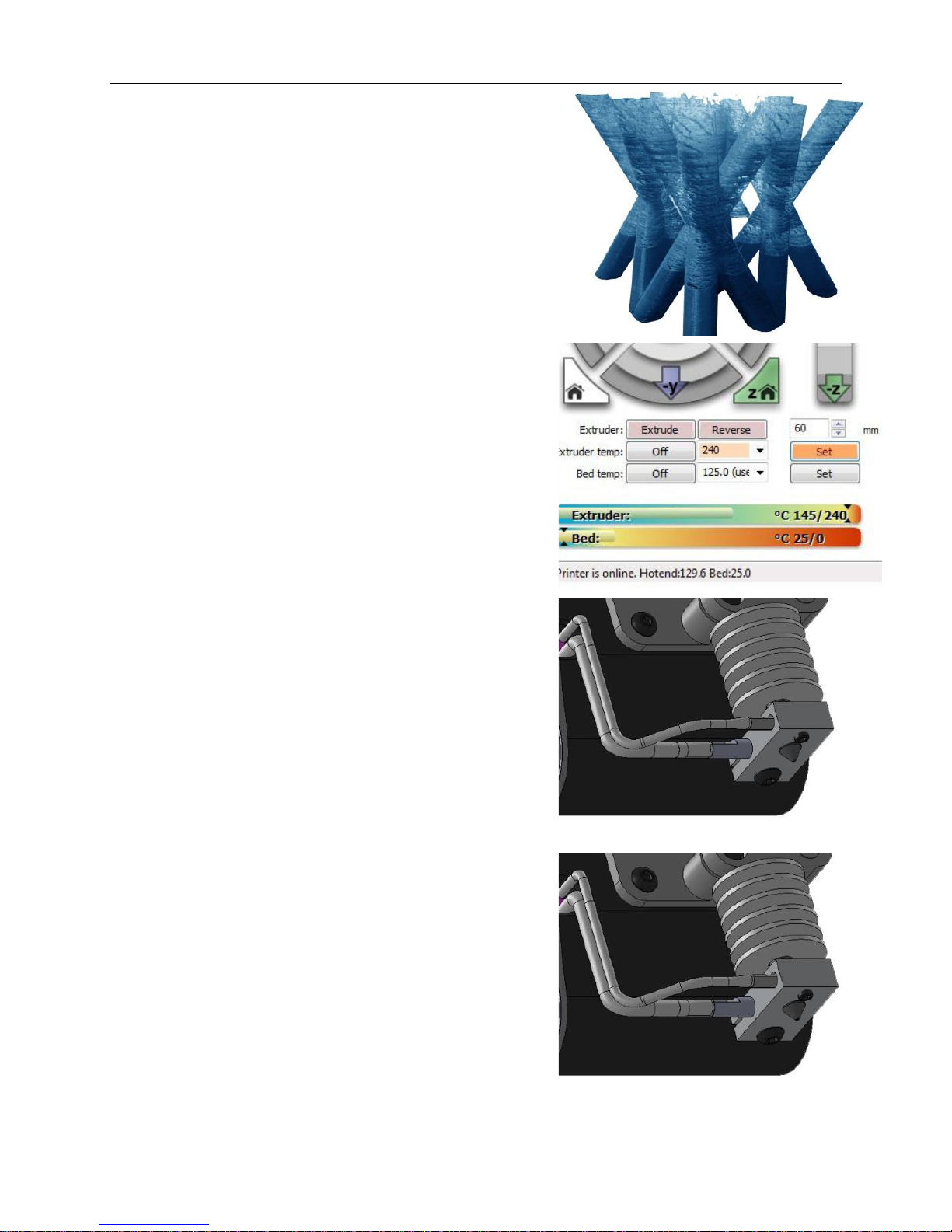

7.

Third, check the entrance to the nozzle between the

idler and drive wheel. If a small piece of filament or

other foreign object is bent over the nozzle entrance

new material will not be able to get past it.

Remove the obstruction as necessary. The idler, fan

shroud and drive wheel may need to be removed for

easy access to this area.

8.

If all of the above are OK, you most likely have an

extruder clog.

20

Clearing an Extruder Clog

1.

There are two main types of extruder clogs

1. Debris or charred filament can be blocking the tip

of the nozzle (most common)

2. A piece of filament has gotten wedged in along

the feed path

2.

First, remove the filament from the extruder by

heating the nozzle up and pressing reverse within

the Fablicator interface.

If the filament breaks off rather than pulls out

normally you likely have a piece of wedged filament.

3.

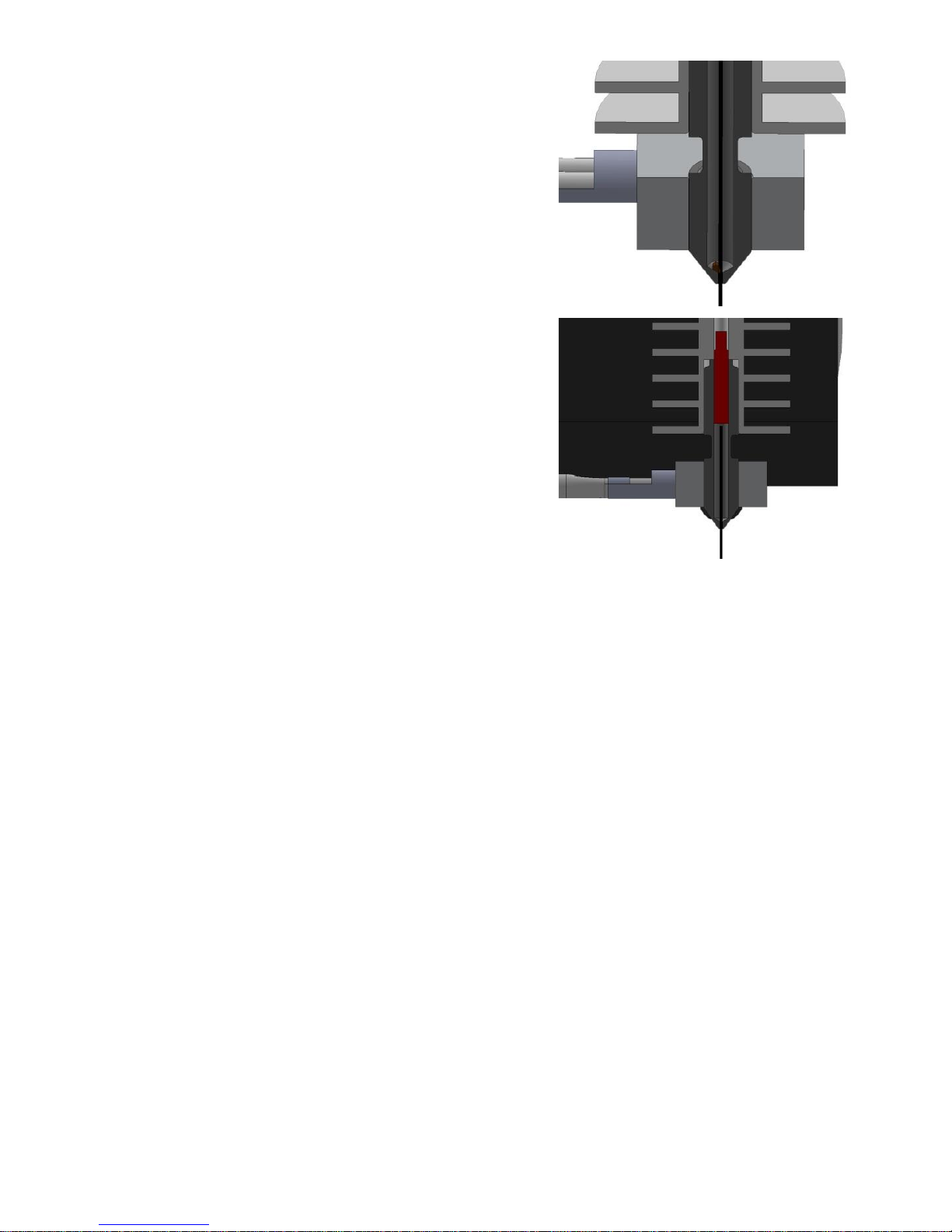

Try feeding a piece of the .012” music wire from the

tip of the nozzle to the top of the extruder.

4.

Use small pliers to hold the wire a short distance

from its end.

A small bit of force may be needed to get the wire

past the first 1/16” of the nozzle

Be very careful to prevent the wire from bending.

21

5.

If the wire easily passes through the entire metal

body of the nozzle assembly, there is probably a

small piece of debris blocking the nozzle.

6.

If the wire stops partway up the metal extruder

body, there is probably a piece of wedged filament

blocking its path.

7.

If you can’t get the wire into the nozzle tip at all, let

someone else have a try. It can be a little tricky, but

is a critical step.

If the wire cannot be fed into the nozzle, the tip of the

nozzle may be damaged and need replacement.

22

Wedged Filament removal

1.

Once determined you are dealing with a piece of

wedged filament, there are two methods to get it unstuck.

2.

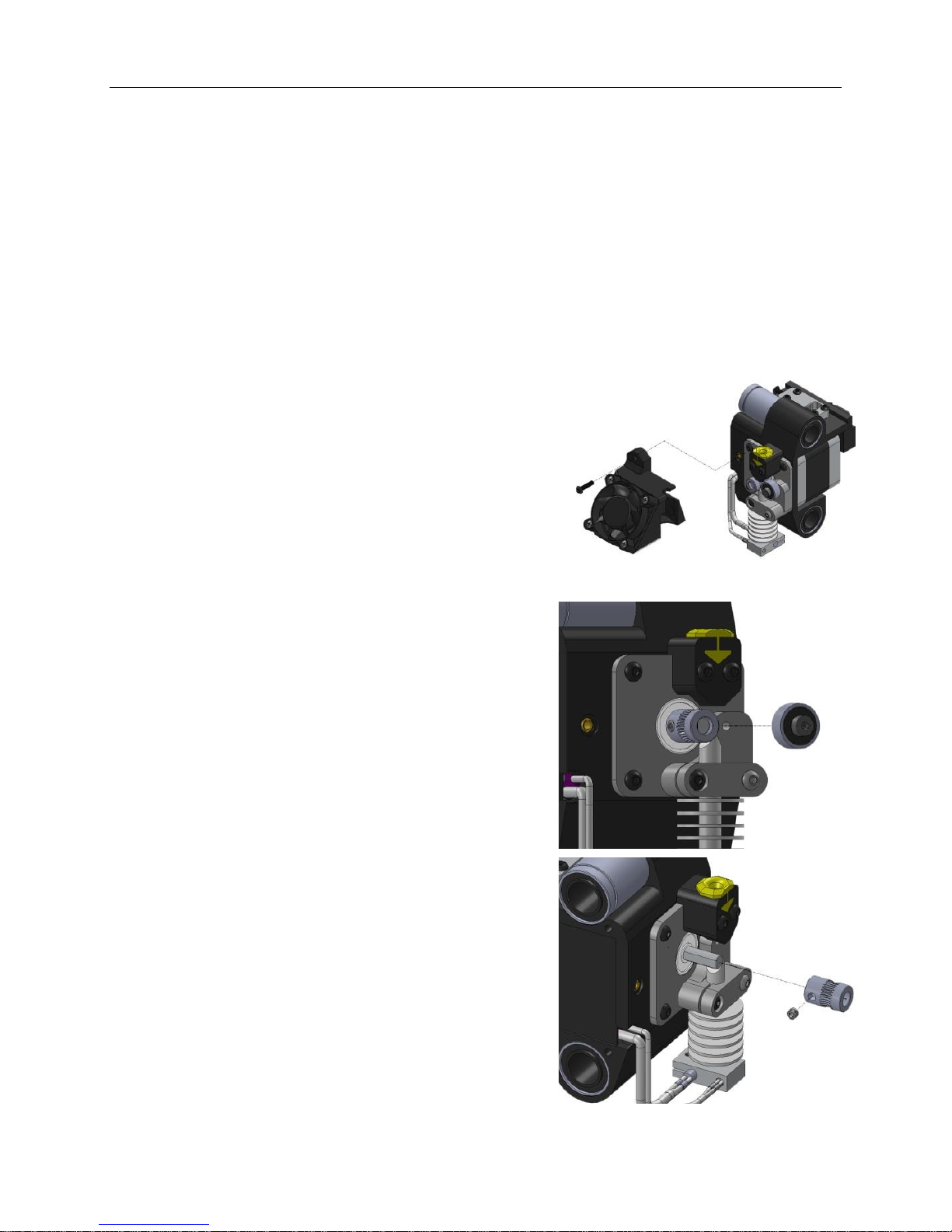

First, remove the fan shroud

Remove the screw, and tilt the shroud out of the

way.

Be careful, as the fan wire will remain attached.

3.

Second, remove the idler wheel using the 2mm hex

key

4.

Third, Remove the filament driver (attached with a

grub screw using a 1/16” allen key included in the

startup kit)

You may need to use the front EXT disable switch to

allow manually moving the drive wheel, and then

rotate the driver so the set screw is at an easy to

access position

23

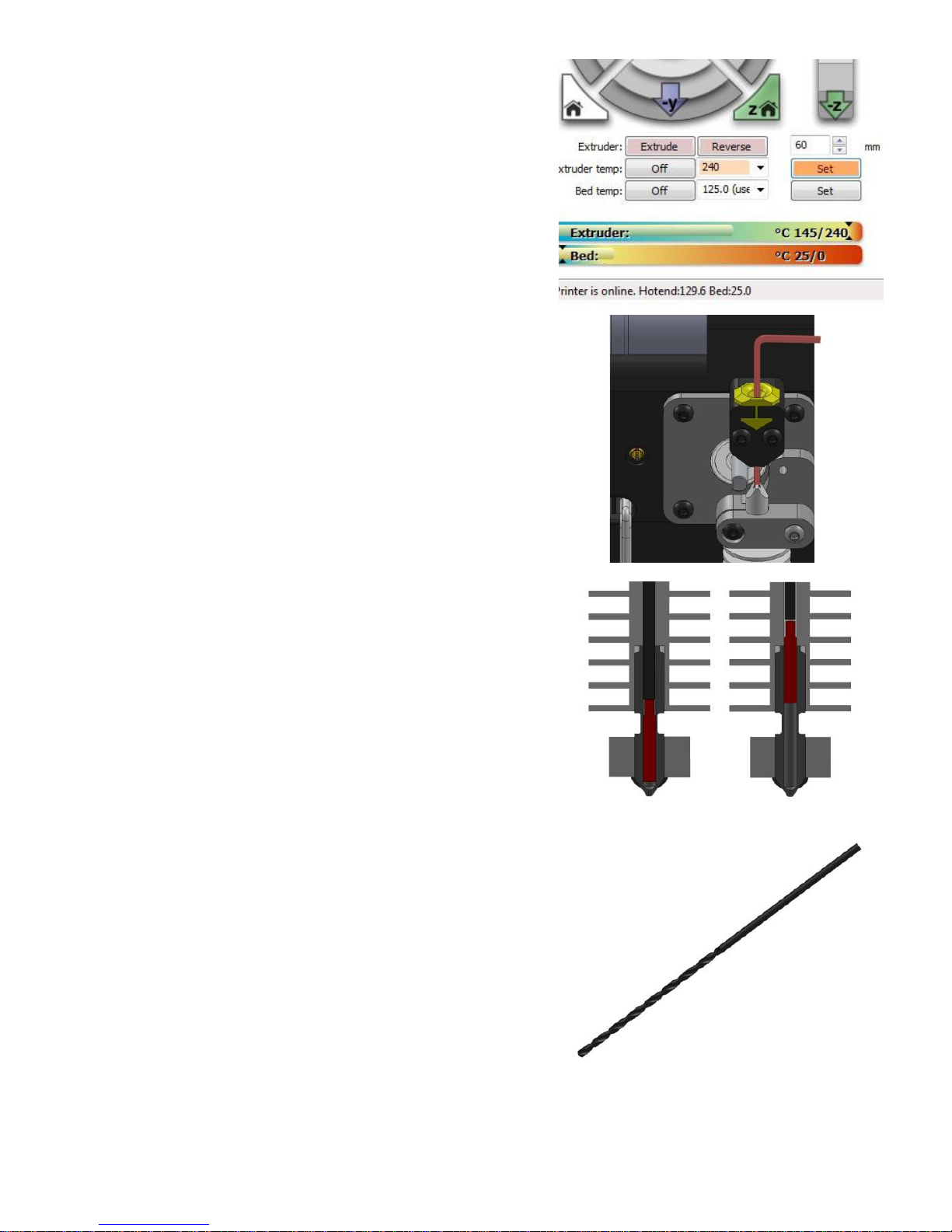

5.

Make sure the fan shroud is not in contact with the

nozzle heater block. A piece of tape is suggested to

hold it out of the way.

Then heat up the extruder in the Fablicator interface

6.

Using the long arm of the 1/16” Allen key, push

down hard on the key to attempt to dislodge the

filament. The Allen key is highlighted in red for

clarity

Lightly tapping the Allen key with a hammer may be

of assistance.

7.

If the filament starts to push down into the nozzle

continue until the clog has passed and is re-melted

in the nozzle tip.

Some plastic should exit the tip.

8.

If the clog will not budge, using an extra-long 5/64”

drill bit may be necessary.

24

9.

Mark the drill bit with tape to below its maximum

insertion depth as shown.

Going too far risks cutting into the tip of the nozzle.

10.

Carefully drill down into the filament, removing 1/8

to 1/16 inch of plastic before removing and cleaning

the bit.

Pulling the bit out of the nozzle and cleaning off the

built up plastic is crucial.

DO NOT EXCEDED THE DEPTH MARKED WITH

TAPE

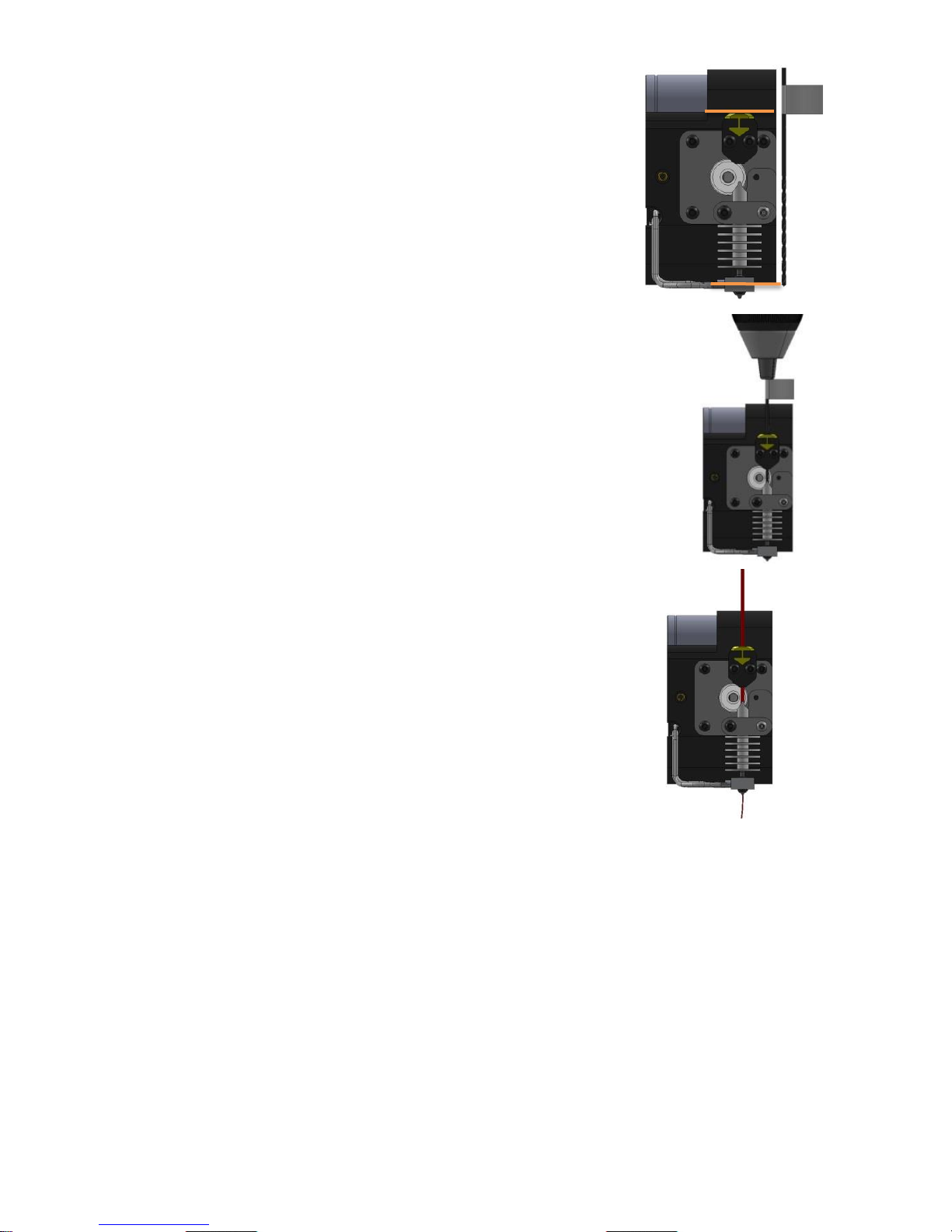

11.

Once the filament path is all clear, heat up the nozzle

in the Fablicator interface and manually push

filament down into the nozzle before doing any

reassembly.

The filament should flow easily.

12.

If not, you may have additional debris blocking the

nozzle tip.

Continue with cleaning a blocked nozzle tip.

If everything appears to be flowing nicely,

reassemble the extruder.

25

13.

To reassemble the extruder, pull the filament out of

the nozzle while the extruder is hot.

14.

Reattach the filament driver. (the side with the set

screw should be closest to the motor)

Align the flat on the extruder motor with the set

screw on the filament driver. You may need to use

the front EXT disable switch to allow manually

moving the drive wheel, and then rotate the driver so

the set screw is at an easy to access position

15.

Now reattach the idler wheel.

16.

Reattach the cooling fan and shroud.

The fan tilts in around the extruder heat sink.

Do not allow the wires to be pinched on the side of

the shroud when reassembling.

26

17.

After double checking the Driver set screw, idler

screw, and fan shroud screws are all snug, the

extruder is ready to be used again.

27

Cleaning a blocked nozzle tip (simple method)

1.

With some luck, there is a quick way to remove the

debris from the Fablicator nozzle tip.

2.

First, heat the nozzle to 240C and pass the music

wire completely through the nozzle from the tip

through the inlet.

3.

Next, load PLA or PLA/PHA filament into the

extruder as normal.

Extrude the material until it exits the tip and/or you

hear a clicking sound from the extruder typical of a

clog.

Even if the extruder seems to be working fine at this

point, please continue.

4.

Turn the extruder heater off.

28

5.

Press the disable motor switch on the front of the

machine marked EXT.

The yellow LED should be illuminated.

6.

Wait for the extruder temperature to reach 90C.

AS SOON AS the temperature reaches 90C, pull up

on the filament and manually remove it from the

extruder in a firm, but not violent, manner.

7.

Ideally, the filament should have a bit of a cone

shaped tip to it, and may have a black or discolored

tip which indicates you have removed some of the

material blocking the nozzle.

8.

If the nozzle does not have a cone shaped tip, reheat

the extruder, turn off the extruder disable switch,

and re-load fresh filament.

29

9.

Repeat steps 3-8, slightly varying the temperature

when you pull the filament out (maybe 80c or 85c)

10.

Once an approximately cone shaped tip is visible, reheat the extruder

If you are unable to get the cone shaped tip after a

few tries, skip to step 12.

If a clog persists, try the involved method in the next

section

11.

Feed the music wire from tip to entrance one last

time.

12.

Make sure the disable switch is no longer activated

(no yellow LEDs) and load fresh filament as usual

30

13.

Press the extrude button a few times to ensure

filament is extruding freely.

You may need to repeat this method a few times to

completely remove a tough clog.

If a clog persists, you can continue to the involved

method in the next section

31

Cleaning a blocked nozzle tip (involved method)

1.

First, remove the fan shroud

2.

Second, remove the idler wheel

3.

Third, Remove the filament driver (attached with a

grub screw using a 1/16” allen key included in the

startup kit)

4.

Make sure the fan shroud is not in contact with the

nozzle heater block. A piece of tape is suggested to

hold it out of the way.

Then heat up the extruder in the Fablicator interface

32

1.

Try and feed a piece of the .012” music wire from

the tip of the nozzle to the top of the extruder.

2.

If you encounter resistance, use small pliers to hold

the wire a short distance from its end.

A small bit of force may be needed to get the wire

past the first 1/16” of the nozzle

Be very careful to prevent the wire from bending.

3.

If you can’t get the wire into the nozzle tip at all, let

someone else have a try. It can be a little tricky, but

is a critical step.

If the wire cannot be fed into the nozzle, the tip of the

nozzle may be damaged and need replacement.

4.

Once the wire has been fed through the extruder,

guide the long 5/64” drill bit into the extruder

nozzle and gently spin it between your fingers. Until

you meet resistance.

Do not apply a large amount of force to the bit. We

only want to remove the excess filament and

contaminants, not drill into the metal of the

extruder.

33

5.

Remove the drill from the extruder, and clean off the

removed filament.

Be careful, the drill tip and filament will be hot.

6.

Insert the music wire again, and repeat steps 4-6 a

few times until it appears all the molten filament has

been removed from the nozzle tip.

7.

Manually add new filament into the nozzle and try

pushing it through with your fingers. If it still feels

blocked, remove the filament and repeat steps 1-6

again.

If both the simple and involved methods fail to fix a

clog, please contact Fablicator technical support.

34

Loading...

Loading...