Page 1

SCIROCCO PLUS

Downdraft Range hood

Internal or Remote Blower

READ AND SAVE THESE INSTRUCTIONS

The Installer must leave these instructions with the

homeowner. The homeowner must keep these

instructions for future reference and for local electrical

inspectors' use.

READ THESE INSTRUCTIONS BEFORE YOU START INSTALLING THIS RANGE HOOD

WARNING: - TO REDUCE THE RISK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers cause smoking and greasy spillovers that may ignite.

Heat oils slowly on low or medium setting.

b) Always turn hood ON when cooking at high heat or when ambeing food

(i.e. Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambé).

c) Clean ventilating fans frequently. Grease should not be allowed to accumulate on fan or lter.

d) Use proper pan size. Always use cookware appropriate for the size of the surface element.

WARNING: - TO REDUCE THE RISK OF INJURY TO PERSONS IN THE EVENT OF A RANGE TOP GREASE FIRE, OBSERVE

THE FOLLOWING (*):

a) SMOTHER FLAMES with a close-tting lid, cookie sheet, or metal tray, then turn off the burner.

BE CAREFUL TO PREVENT BURNS. If the ames do not go out immediately EVACUATE AND CALL THE

FIRE DEPARTMENT.

b) NEVER PICK UP A FLAMING PAN - You may be burned.

c) DO NOT USE WATER, including wet dishcloths or towels - a violent steam explosion will result.

d) Use an extinguisher ONLY if:

1) You know you have a Class ABC extinguisher, and you already know how to operate it.

2) The re is small and contained in the area where it started.

3) The re department is being called.

4) You can ght the re with your back to an exit.(*) Based on “Kitchen Firesafety Tips” published by NFPA.

• Installation Instructions

• Use and Care Information

ALL WALL AND FLOOR OPENINGS WHERE THE Range Hood IS INSTALLED MUST BE SEALED.

CAUTION: TO REDUCE THE RISK OF FIRE AND ELECTRIC SHOCK, Install This Range hood Only With Remote Blower Models Rated Maximum

2.8 A suitable for use with solid state speed controls.

Consult the cooktop or range installation instructions given by the manufacturer before making any cutouts.

LISEZ BIEN CETTE FICHE AVANT D'INSTALLER LA HOTTE

AVERTISSEMENT - POUR MINIMISER LE RISQUE D’UN FEU DE GRAISSE SUR LA TABLE DE CUISSON : a) Ne jamais laisser

un élément de la table de cuisson fonctionner sans surveillance à la puissance de chauffage maximale; un renversement/

débordement de matière graisseuse pourrait provoquer une inammation et le génération de fumée. Utiliser toujours une

puissance de chauffage moyenne ou basse pour le chauffage d’huile. b) Veiller à toujours faire fonctionner le ventilateur

de la hotte lors d’une cuisson avec une puissance de chauffage élevée ou lors de la cuisson d’un mets à amber (i.e.

Crepes Suzette, Cherries Jubilee, Peppercorn Beef Flambé). c) Nettoyer fréquemment les ventilateurs d’extraction. Veiller

à ne pas laisser de la graisse s’accumuler sur les surfaces du ventilateur ou des ltres. d) Utiliser toujours un ustensile

de taille appropriée. Utiliser toujours un ustensile de taille adapté à la taille de l’élément chauffant.

AVERTISSEMENT: - POUR PRÉVENIR LES BLESSURES EN CAS DE FEU SUIVRE LES RECOMMANDATIONS SUIVANTES

(*): a) ÉTOUFFEZ LE FEU avec un couvercle métallique et fermez le brûleur. Si le feu ne s'éteint pas tout de suite, QUIT-

TEZ LES LIEUX ET APPELEZ LES POMPIERS. b) NE TOUCHEZ JAMAIS UNE CASSEROLE EN FLAMMES. c) N'UTILISEZ

JAMAIS DE L'EAU ou un torchon mouillé pour éteindre le feu - ce qui pourrait causer une explosion de vapeur. d) N'utilisez

un extincteur que si: 1. Vous avez un modèle ABC et vous connaissez bien son mode d'emploi. 2. Le feu est petit et peu

répandu. 3. Les pompiers sont déjà prévenus. 4. Vous avez une sortie derrière vous. (*) Basé sur la "cuisine Firesafety

incline" édité par NFPA.

TOUTE OUVERTURE DANS LE MUR OU LE PLANCHER À PROXIMITÉ DE LA HOTTE DOIT ÊTRE SCELLÉ

AVERTISSEMENT: POUR RÉDUIRE LE RISQUE D'INCINDIE ET DE CHIC ÉLEXTRIQUE, prière d’installer cette hotte uniquement avec un

aspirateur détaché maximum 2.8 A apte à l’utilisation avec un dispositif de réglaeg de vitesse à semiconducteurs.

Consultez la che technique avant de découper les armoires.

Version 3/15 - Page 1

Page 2

VENTING REQUIREMENTS

!

!

Determine which venting method is best for your application.

Ductwork can extend either through the wall or the roof.

The length of the ductwork and the number of elbows should

be kept to a minimum to provide efcient performance. The

size of the ductwork should be uniform. Do not install two

elbows together. Use duct tape to seal all joints in the ductwork

system. Use caulking to seal exterior wall or oor opening

around the cap.

Flexible ductwork is not recommended. If it is used, each foot

of exible ductwork used is equivalent to two feet of straight

metal ductwork when calculating the ductrun length. Thus,

a exible elbow equals two standard elbows.

Make sure there is proper clearance within the wall or oor

for exhaust duct before making cutouts. Do not cut a joist or

stud unless absolutely necessary. If a joist or stud must be

cut, then a supporting frame must be constructed. For best

results, internal blowers should use 6" round ducting and

remote blowers should transition to 10" round duct as soon

as possible. If small ducting is used, it should be transitioned

to 9 or 10" round as soon as possible.

WARNING - To Reduce The Risk Of Fire, Use Only Metal Ductwork.

CAUTION: To reduce risk of re and to properly exhaust air, be

sure to duct air outside - do not vent exhuast air into spaces

within walls or ceilings or into attics, crawl spaces or garages.

Cold Weather installations (NOT INCLUDED)

An additional back draft damper should be installed to minimize

backward cold air ow and a nonmetallic thermal break should be

installed to minimize conduction of outside temperatures as part of

the vent system. The damper should be on the cold air side of the

thermal break. The break should be

vent system enters the heated portion of the house.

as close as possible to where the

WARNING

• Venting system MUST terminate outside the

home.

• DO NOT terminate the ductwork in an attic or

other enclosed space.

• DO NOT use 4" laundry-type wall caps.

• Flexible-type ductwork is not recommended.

• DO NOT obstruct the ow of combustion and

ventilation air.

• Failure to follow venting requirements may result

in a re.

ELECTRICAL REQUIREMENTS

A 120 volt, 60 Hz AC-only electrical supply is required on a

dedicated 15 amp fused circuit. A time-delay fuse or circuit

breaker is recommended. The fuse must be sized per local

codes in accordance with the electrical rating of this unit as

specied on the serial/rating plate located inside the unit

near the eld wiring compartment. THIS UNIT MUST BE

CONNECTED WITH COPPER WIRE ONLY. Wire sizes

must conform to the requirements of the National Electrical

Code, ANSI/NFPA 70 - latest edition, and all local codes and

ordinances. Wire size and connections must conform with the

rating of the appliance. Copies of the standard listed above

may be obtained from:

National Fire Protection Association

Batterymarch Park

Quincy, Massachusetts 02269

This appliance should be connected directly to the fused

disconnect (or circuit breaker) through exible, armored or

nonmetallic sheathed copper cable. Allow some slack in the

cable so the appliance can be moved if servicing is ever

necessary. A UL Listed, 1/2" conduit connector must be

provided at each end of the power supply cable (at the

appliance and at the junction box).

When making the electrical connection, cut a 1 1/4" hole in the

wall. A hole cut through wood must be sanded until smooth.

A hole through metal must have a grommet.

SUITABLE FOR USE WITH SOLID STATE SPEED CONTROLS.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRICAL

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

A) Use this unit only in the manner intended by

the manufacturer. If you have any questions, contact the

manufacturer.

B) Before servicing or cleaning unit, switch

power off at service panel and lock the service disconnecting

means to prevent power from being switched

on accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

WARNING - TO REDUCE THE RISK OF FIRE, ELECTRICAL

SHOCK, OR INJURY TO PERSONS, OBSERVE THE

FOLLOWING:

A) Installation Work And Electrical Wiring Must Be Done

By Qualied Person(s) In Accordance With All Applicable

Codes And Standards, Including Fire-Rated Construction.

B) Sufcient air is needed for proper combustion and

exhausting of gases through the ue (chimney) of fuel

burning equipment to prevent backdrafting. Follow the

heating equipment manufacturer's guideline and safety

standards such as those published by the National Fire

Protection Association (NFPA), and the American Society

for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

C) When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

D) Ducted fans must always be vented to the outdoors.

WARNING

• Electrical ground is required on this range hood.

• If cold water pipe is interrupted by plastic,

nonmetallic gaskets or other materials, DO NOT

use for grounding.

• DO NOT ground to a gas pipe.

• DO NOT have a fuse in the neutral or grounding

circuit. A fuse in the neutral or grounding circuit

could result in electrical shock.

• Check with a qualied electrician if you are in

doubt as to whether the range hood is properly

grounded.

• Failure to follow electrical requirements may result

in a re.

For residential use only.

Version 3/15 - Page 2

Page 3

RÈGLEMENTS D'ÉVACUATION

!

!

Conrmer la sortie d'évacuation - soit par le mur, soit par

le toit.

Utilisez une longueur de tuyauterie minimale avec les moindres

de coudes pour la plus grande efcacité. Le diamètre de

tuyauterie doit être uniforme. N'installez jamais 2 coudes

ensemble. Scellez bien tous les joints avec un ruban adhésif

métallique à l'intérieur et scellez bien le clapet extérieur avec

du calfeutrage.

Utilisez un tuyau d'évacuation rigide lorsque possible. Un

tuyau exible égale deux fois plus qu'un tuyau rigide, ce qui

réduit la puissance d'évacuation.

Veillez à ce que l'espace pour le tuyau soit ample - ainsi on

n'aurait pas besoin de découper les supports de mur intérieur.

Si ce découpage est nécessaire, veillez bien à ce qu'un

renforcement soit mis en place.

Pour de meilleurs résultats, utilisez un tuyau de transition de

9 ou 10 pouces dès que possible.

AVERTISSEMENT - Pour Ne Pas Risquer Un Feu, Utilisez Seulement

Les Matériaux Métalliques.

Raccordez cet appareil directement au coupe-circuit avec un

l exiblle couvert en cuivre en laissant un peu de lâchement

dans le l pour permettre le déplacement de l'appareil.

Veillez a ce qu'un contact d'un demi-pouce (1/2 po.) soit

installé à chaque bout de l (soit à l'appareil ainsi qu'à la

boite à fusible).

Faites un trou de 1 1/4 po. dans le mur. S'il s'agit d'un trou en

bois - sablez-le bien, tandis qu'un trou passant par le métal

demande un bouche-trou.

A utiliser avec un dispositif de reglage de vitesse a semiconducteurs.

AVERTISSEMENT – POUR MINIMISER LES RISQUES D’INCENDIE,

CHOC ÉLECTRIQUE OU DOMMAGES CORPORELS, OBSERVER LES

PRESCRIPTIONS SUIVANTES: Suivez les recommandations du fabricant

et entre en communication avec lui pour toute information.

Fermez le courant avant tout entretien et veillez a ce qu'il reste fermé.

Si on ne peut pas verrouiller le panneaux du service électrique,

afchez un avis de danger sur la porte.

AVERTISSEMENT – POUR MINIMISER LE RISQUE DE CHOC ÉLECTRIQUE:

Ce ventilateur doit être installé avec un mur d'isolement iterrupteur

de commande.

Installations pour régions à climat froid

On devrait installer un clapet antireux additionnel pour minimiser le

reux d'air froid, et incorporer un élément non métallique d'isolation

thermique pour minimiser la conduction de chaleur par l'intermédiaire

du conduit d'évacuation, de l'intérieur de la maison à l'extérieur. Le

clapet anti-reux doit être placé du côté air froid par rapport à l'élément

d'isolation thermique. L'isolant thermique doit être aussi proche que

possible de l'endroit où le système d'évacuation s'introduit dans la

partie chauffée de la maison.

AVERTISSEMENT

• Le système d'évacuation DOIT sortir à l'extérieur.

• N'ÉVACUEZ PAS le conduit soit dans une

mansarde soit dans un espace enfermé.

• N'UTILISEZ PAS un clapet de séchoir à 4 pouces.

• N'utilisez pas un conduit exible.

• N'ENCOMBREZ PAS la circulation d'air.

• Faute de suivre cet avertissement pourrait

occasionner un feu.

FICHE TECHNIQUE ÉLECTRIQUE

Le raccordement électrique doit se faire avec un circuit séparé

de 15 ampères fusible à 120V, 60 Hz, courant alternant. On

recommande un coupe-circuit. La taille du fusible doit se

conformer aux codes municipaux suivant la spécication

électrique sur la plaque intérieure. Le diamètre du l

devra aussi se conformer aux règlements du code national

électrique, ANSI/NFPA 70 - ainsi qu'aux règlements locaux

et les spécications de cet appareil. On peut obtenir ces

informations chez:

l'Association Nationale de la Prévention du Feu

Batterymarch Park

Quincy, Massachusetts 02269

Uniquement pour usage menager.

AVIS: Pour L'évacuation Générale - Veillez à Ne Pas Evacuer Des

Matériaux Ou Vapeurs Explosif.

AVERTISSEMENT – POUR MINIMISER LES RISQUES D’INCENDIE,

CHOC ÉLECTRIQUE OU DOMMAGES CORPORELS, OBSERVER LES

PRESCRIPTIONS SUIVANTES: L'installation Et Le Raccordement

Electrique Doivent Se Faire Par Un Technicien Qualié Selon Tous

Les Codes Municipaux.

An d'obtenir un rendement maximal en ce qui a trait à la combustion

ainsi qu'à l'évacuation des gaz par la conduite de cheminée, une

bonne aération est nécessaire pour tous les appareils à combustion.

Suivez les conseils et mesures de sécurité du fournisseur tels que

ceux publiés par l'Association Nationale de la Sauvegarde contre

l'Incendie et l'Association Américaine d'Ingénieurs de Chauffage,

Frigorifaction et Air Climatisé ainsi que les codes municipaux.

En perçant un mur veillez à ne pas perforer un autre l électrique.

Une ventilateur à évacuation extérieure doit être raccordée à

l'extérieur.

AVERTISSEMENT

• Une prise à terre est nécessaire pout cette hotte.

• N'utilisez pas un tuyau à l'eau froide pour la mise

à terre s'il est branché à un joint plastique, nonmétallique ou autre.

• NE JOIGNEZ PAS la mise à terre à conduit de gaz.

• N'INSTALLEZ PAS un fusible dans le circuit de

mise à terre - ce qui peut causer une secousse

électrique.

• Vériez avec un électricien certié à ce que la hotte

soit bien mise à terre.

• Faute de suivre ces recommandations pourrait

occasionner un feu.

Version 3/15 - Page 3

Page 4

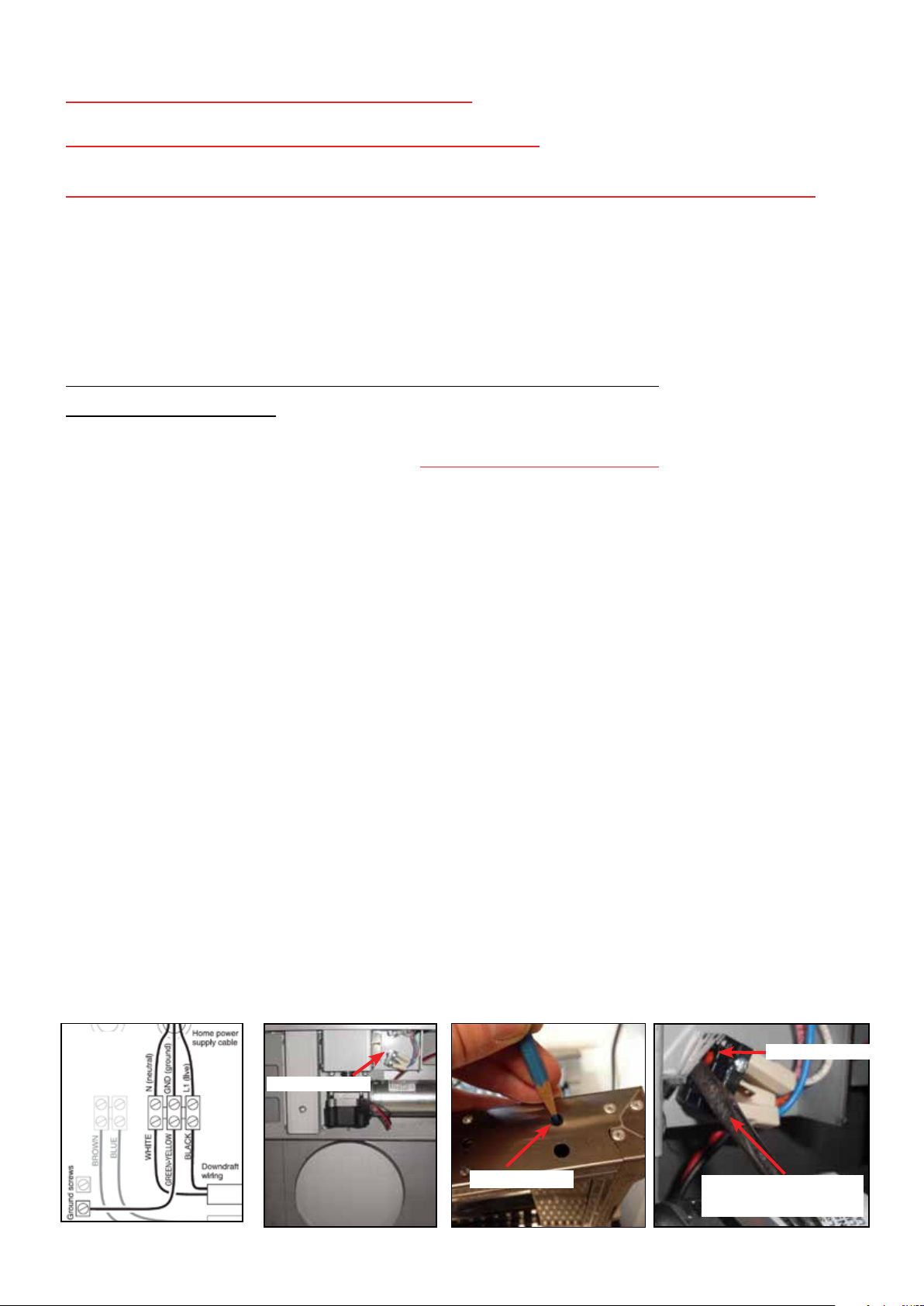

ATTENTION INSTALLERS

INSTALLATEURS ATTENTION

Important Please read before beginning installation

A safety switch, which stops the hood from rising up for safety reasons, will also stop the rise

if it moves into the locked or “activated” position during shipment. These steps will put the

safety switch in the “deactivated” or unlocked position to complete installation.

Please perform these steps before proceeding with

normal installation

Step 1) Remove the product from the box and (with the electrical circuit OFF) connect the house power

to the hood by connecting the green, white and black wires into the hood wiring box, located on the bottom left side of the hood. Once the electrical connections are made and the wiring box is closed, turn the

circuit back on.

Step 2) Remove the entire front access panel from the hood to expose the internal gears and switches by

removing the screws holding the panel in place (see photo)

Step 3) Press and hold the on/off button (with a pointy object) on the top / right of the hood (see photo)

Step 4) While holding the on/off button, place a small flat head screwdriver underneath the safety

switch to disengage the lever from the safety switch button (see photo). This switch is the front switch in

the pair of switches on the bottom of the hood (in front of lower limit switch). By pulling this lever away

from the depressed safety switch button, this will return the hood to normal operation and the hood

will now rise and fall down normally. These steps should only be required once and the safety switch will

operate normally going forward.

Step 5) Test the hood by pressing the on / off button on top of the hood for several up and down cycles

to ensure the hood is operating without holding the switch on the bottom. Disconnect the power

Step 6) Proceed with the rest of the steps to install the product per the installation instructions

Step 1

Step 2 Step 3 and 4 Step 4

wiring box

safety switch

on/off button

safety switch

flat head screwdriver

pushing lever up

Version 3/15 - Page 4

Page 5

TOOLS NEEDED FOR INSTALLATION

!

• Saber Saw or Jig Saw

• Drill

• 1 1/4" Wood Drill Bit

• Pliers

• Phillips Screwdriver

• Flat Blade Screwdriver

• Wire Stripper or Utility Knife

• Metal Snips

• Measuring Tape or Ruler

• Level

• Pencil

• Caulking Gun

• Duct Tape

• 7 MM Nut Driver

PARTS SUPPLIED FOR INSTALLATION

• 6 Mounting Brackets (2 support legs, 2 under counter and

2 over-counter brackets

• 2 End Caps

• 2 Stainless Grease Filters

• Stainless steel top strip

• Nuts to connect top strip

• Installation Screws

• 1 Literature Package

PARTS NEEDED FOR INSTALLATION

• 2 Conduit Connectors

• Power Supply Cable

• Wiring Cable - Optional Remote Blower Only

• 1 Wall or Roof Cap

• All Metal Ductwork

CALCULATE THE DUCTRUN LENGTH

The ductwork length should not exceed 55 equivalent feet for

6" duct, or 75 equivalent feet for 10" round duct. Calculate

the length of the ductwork by adding the equivalent feet listed

in FIGURE 1 for each piece of duct in the complete system.

An example is given in FIGURE 2.

For best results, use no more than three 90° elbows. Make

sure that there is a minimum of 24" of straight duct between

elbows if more than one is used. Do not install two elbows

together. Round duct is recommended instead of rectangular

duct especially if elbows are needed. For internal blower

models, rectangular duct should be transitioned to 6" round

as soon as possible.

45˚ Elbow

90˚ Elbow

90˚ Flat Elbow

Wall Cap

FIGURE 1

5.0 feet

7.0 feet

12.0 feet

0.0 feet

9 Feet Straight Duct

2 - 90˚ Elbows

Wall Cap

Total System

FIGURE 2

9.0 feet

14.0 feet

0.0 feet

23.0 feet

GENERAL INSTALLATION GUIDELINES

(IMPORTANT - READ BEFORE INSTALLATION)

CHOOSE A BLOWER TO PAIR WITH THE SCIROCCO PLUS

• Internal Blower model #IBDD600

• Remote Blower model # RBORIG900 OR RBORIG1200

• Use your existing remote blower rated at max 4.2 Amp suitable for

use with solid state variable speed control

PLAN THE DUCTWORK

The Scirocco Plus downdraft system is designed to offer wide

exibility in ducting. The interior blower can be ducted on the

front or back of the downdraft unit in multiple directions: down,

left, right or backwards (front side only) using a 6" round vent.

The remote blower can be ducted from the front or back of the

downdraft unit, pointing down using a 10" round vent.

The remote blower requires a separate wiring cable that

should be installed at the same time that the ductwork is

installed. For best results, 10" duct is recommended for the

remote blower. A damper plate is included in the box with the

downdraft package and must be attached over the

opening of the front / back of the downdraft blower box.

Remote blower can be mounted on either an outside wall or

the roof of the home.

The Scirocco Plus is meant to be installed with residential

use cook tops, cook tops / oven combinations, free standing

ranges WITHOUT backguards and range tops. This product

is not recommended for use with slide in ranges which may

require additional space behind the range for oven venting OR

with freestanding ranges WITH backguards. Always consult

your cooking manufacturer installation instructions for cooking

product dimensions and specic cfm needs.

In the event of installations where the blower is located

on the back of the unit, it is advised to leave an access

door or opening to reach the bottom of the Scirocco

Plus where the wiring box and motor is located should

service be needed.

NOTE: When using this hood with a range top or free

standing range with the motor box reversed behind

the hood, a 3/4" clearance is required on the front

of the hood to clear a duct plate and front edge of

the down draft body. A ller strip may be needed on

the counter top in this type of installation to cover

this gap between the cooking surface and the hood.

WARNING

When planning the cutout for the downdraft:

• Draw both the cooktop and downdraft cutouts on the

countertop before making any cuts.

• Check that there is enough room in the cabinet for both.

Failure to follow these warnings could result in damage to

the countertop.

Version 3/15 - Page 5

Page 6

14 " (357 mm)

retractable

vent height

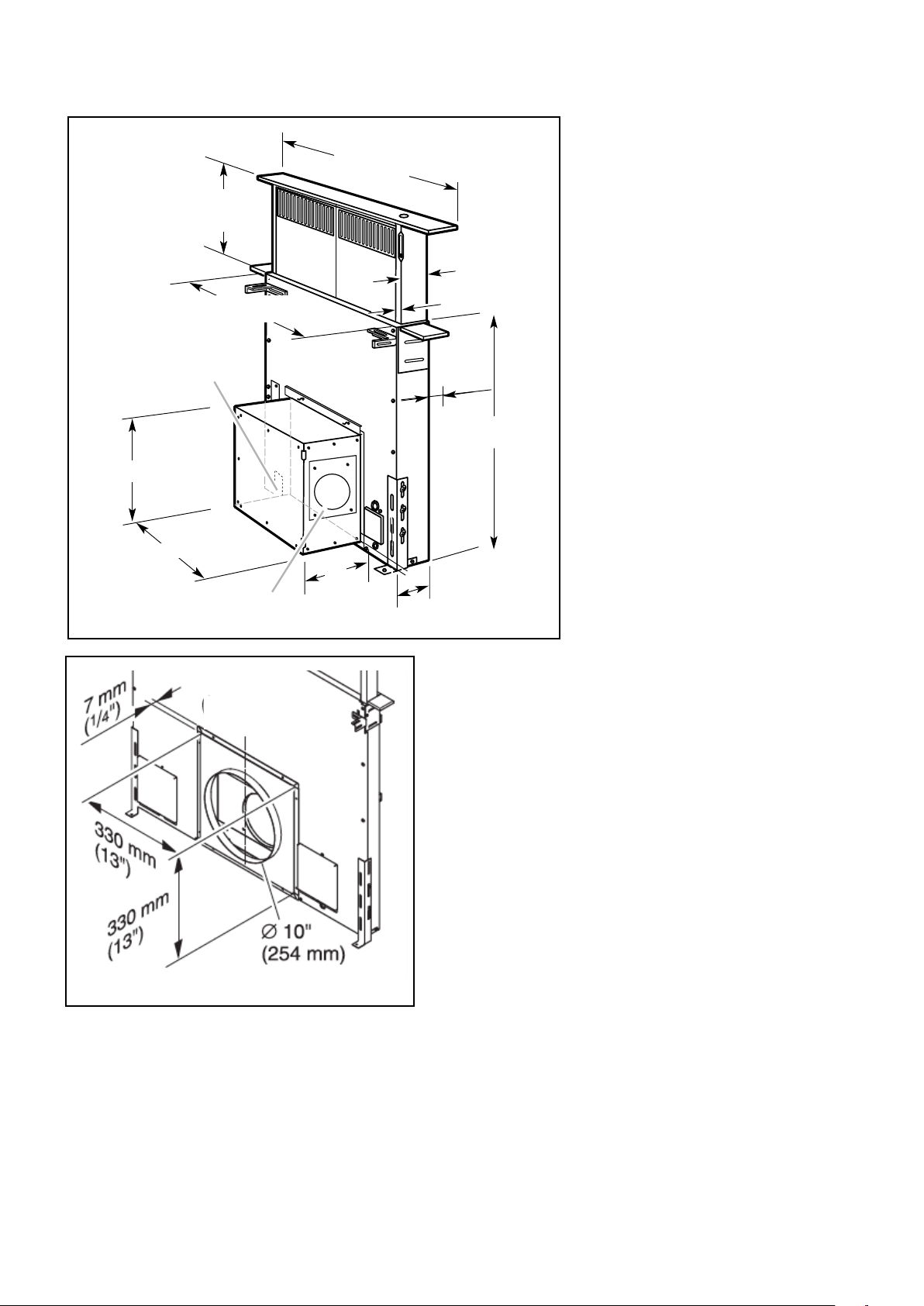

PRODUCT DIMENSIONS

Top trim widths:

30 " (762 mm) vent

36 " (914 mm) vent

11⁄2 " (38 mm)

27" (686 mm) for 30" (762 mm) vent

33" (838 mm) for 36" (914 mm) vent

Terminal box cover

13" (330 mm)

13" (330 mm)

FIGURE 3

6" (152 mm)

diameter

vent collar

3⁄8" (9.5 mm)

x

283⁄4"

(730 mm)

10 "

(254 mm)

21⁄8 " (54 mm)

FIGURE 4

FIGURE 3 - Dimensions with IBDD600 Internal blower

box

The blower box can be mounted in

such a way that the vent collar is

aligned to the left, the right, downwards

or towards the rear, as desired.

FIGURE 4 - Connection plate when using the

#RBORIG900 or #RBORIG1200 remote blower

The blower or the connection plate can

also be mounted in the same position

on the rear of the appliance.

x in FIGURE 3 = Distance to the rear of the cabinet

or wall. Must be a minimum of ½".

Exhaust duct connection diameters

IBDD600:. . . . . . . . . . . . . . . 6"

RBORIG900 / 1200: . .. . 10"

Version 3/15 - Page 6

Page 7

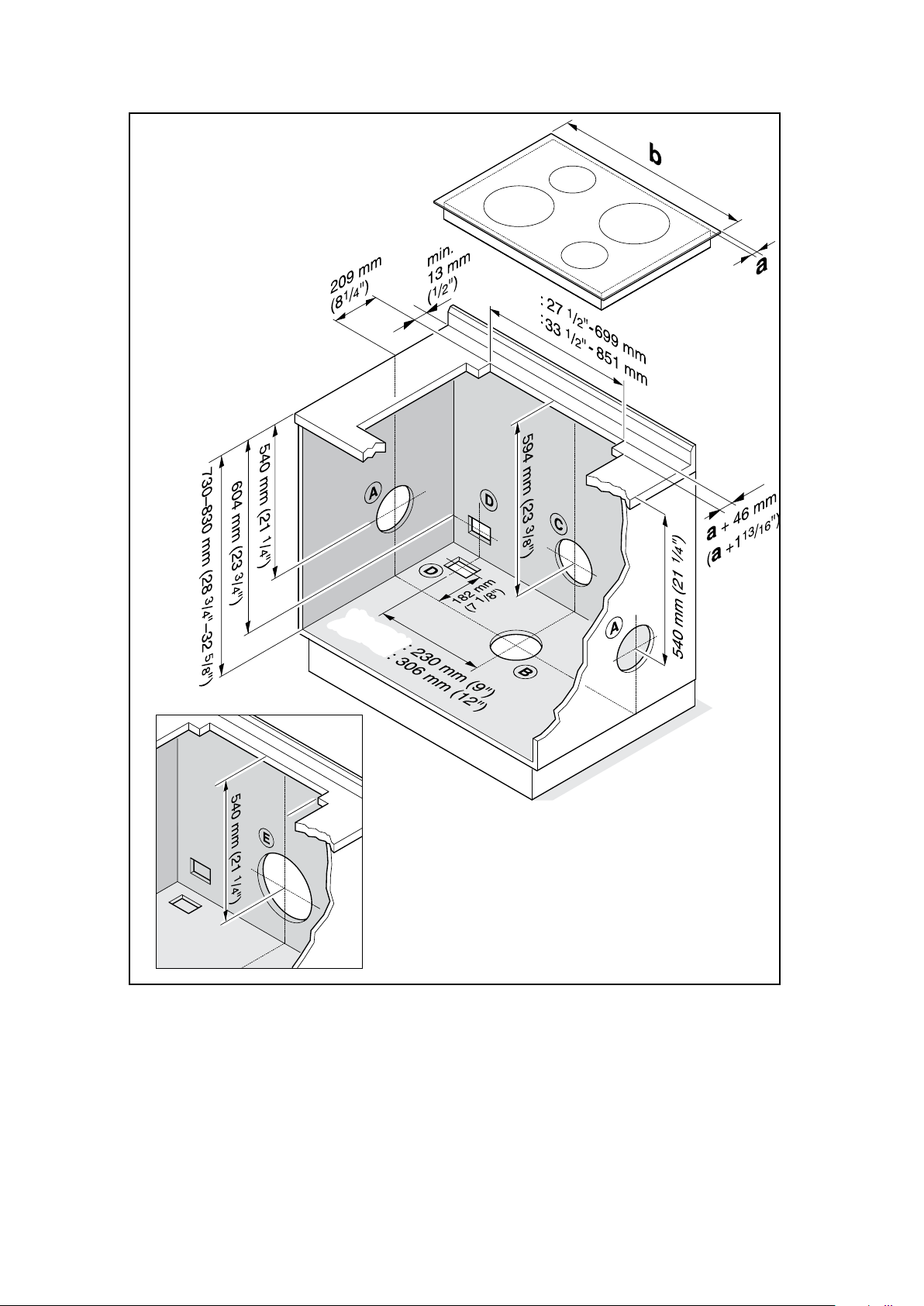

CABINET CUT OUT DIMENSIONS

30”

36”

30

36

NOTE:

A = Left, right IBDD600 ducting

B = Ducting IBDD600 down

C = Ducting IBDD600 to the rear

D = Power cord cut out for Remote Blower

E = 10" Ducting for Remote Blower

a = Cooktop overhang

b = Minimum width of the cooktop:

30" : 28" (711 mm)

36" : 34" (864 mm)

FIGURE 5

Version 3/15 - Page 7

Page 8

PRODUCT DIMENSIONS

FIGURE 6

See the previous page with FIGURE 5, and

FIGURE 6 above for reference. When using

the IBDD600 internal blower installed on the

front of the appliance use 6" Round ducting.

Holes for ducting are shown on FIGURE 5, 6:

(A) to the left or right (B) downwards,

(C) to the rear. If the blower is being installed

to the rear of the appliance, a cut-out must be

made in the rear of the cabinet or wall where it

will be mounted and the appropriate

clearances must be maintained behind the

cabinet.

See FIGURE 5, (D) Feed the power cord

and control cable downwards or to the rear

when using an remote blower.

See FIGURE 5 (E) When using the remote

blower, install 10" ducting to the

rear. If installing the exhaust ducting to the

front, appropriate clearances must be

maintained in the cabinet.

INSTALLATION NOTES

– The specied dimensions minimum

cut-out dimensions must be observed.

– If an oven or stove is installed before

the ventilation system, read the associated

installation instructions. Note all installation

dimensions and guidelines regarding

ventilation systems.

– Be aware of kitchen cabinets, back

splashes and/or racks in the area of the

ventilation system and the cooktop. Ensure

that the area where the vent rises is free of

obstacles.

– Make sure that any required minimum

distance between the front edge of the

countertop and the front edge of the cooktop

is maintained.

– If there is a cabinet drawer in the way, it

must be shortened or removed. The front

panel of the drawer could also be installed to

permanently cover the drawer cut-out.

Version 3/15 - Page 8

Page 9

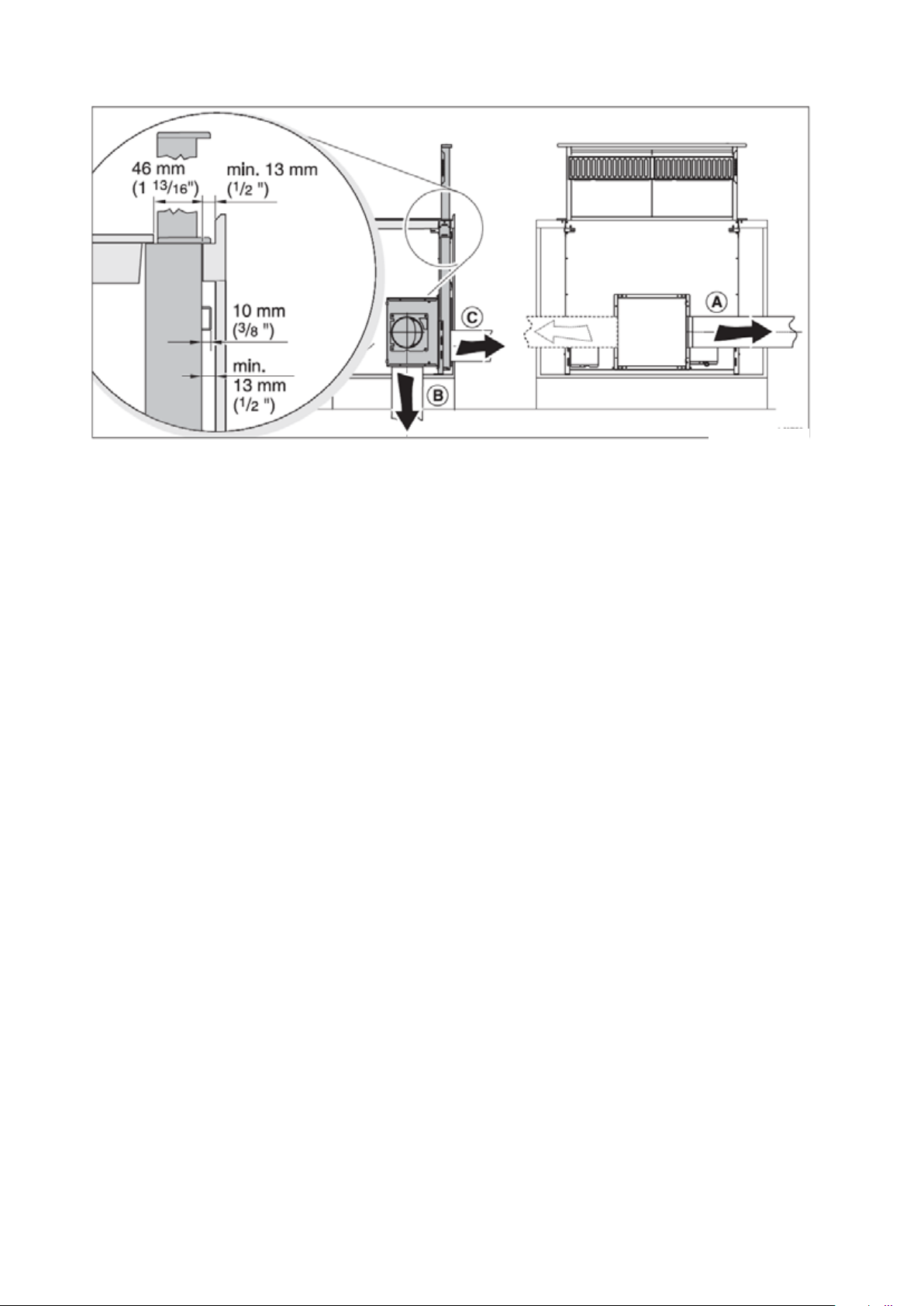

PRODUCT DIMENSIONS

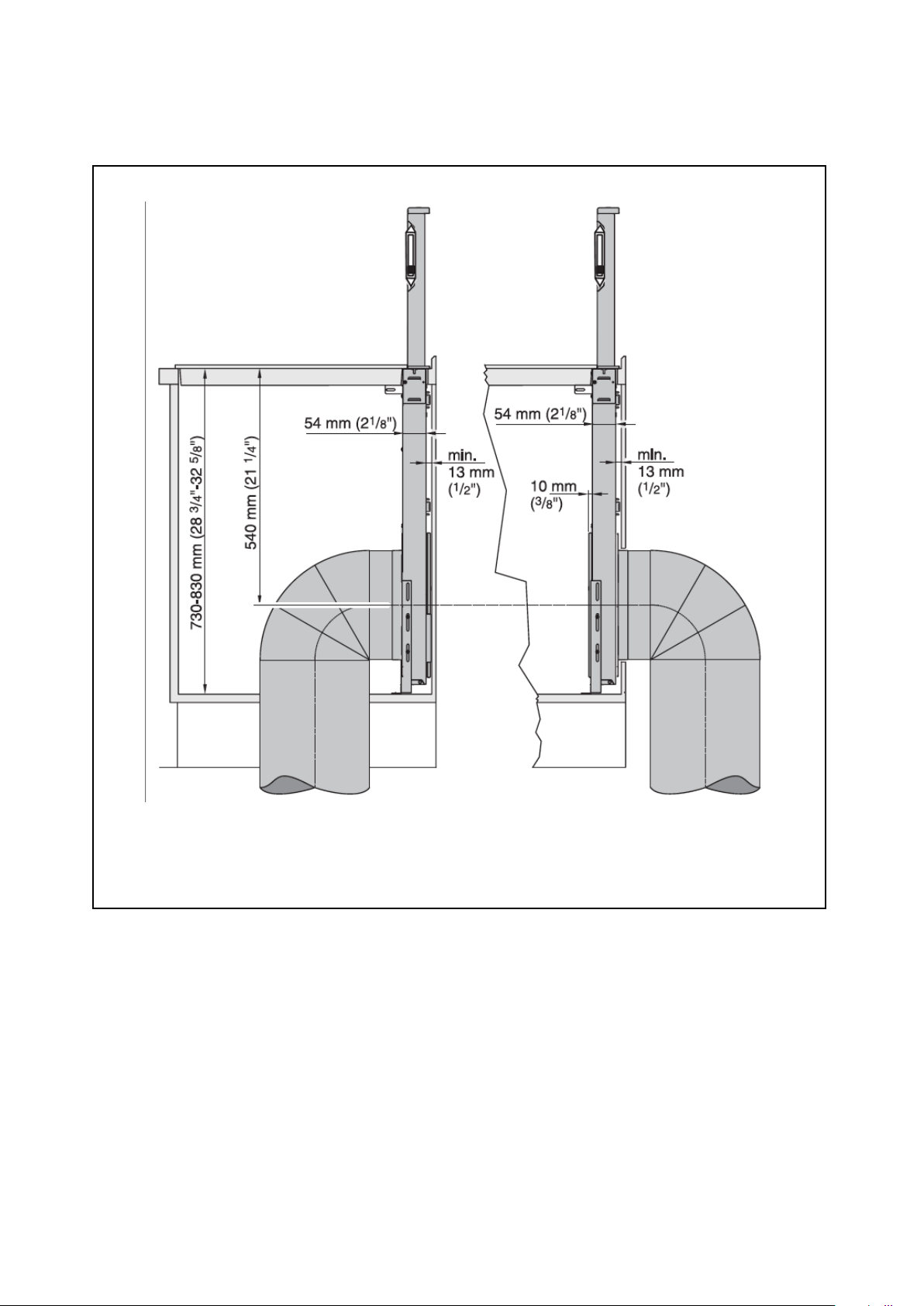

Installation using the IBDD600 internal blower

NOTE:

Left side of diagram shows the IBDD600 mounted in front of

the Scirocco Plus

Right Side of the diagram shows the IBDD600 mounted behind

the Scirocco Plus. The blower must be accessible to install the

ductwork

Note: When using with cooking applainces other than

cook tops which require reversing the motor box to the

back, a 3/4" clearance on front of the Scirocco is needed

to clear a duct plate and front edge of the down draft body.

FIGURE 7

Version 3/15 - Page 9

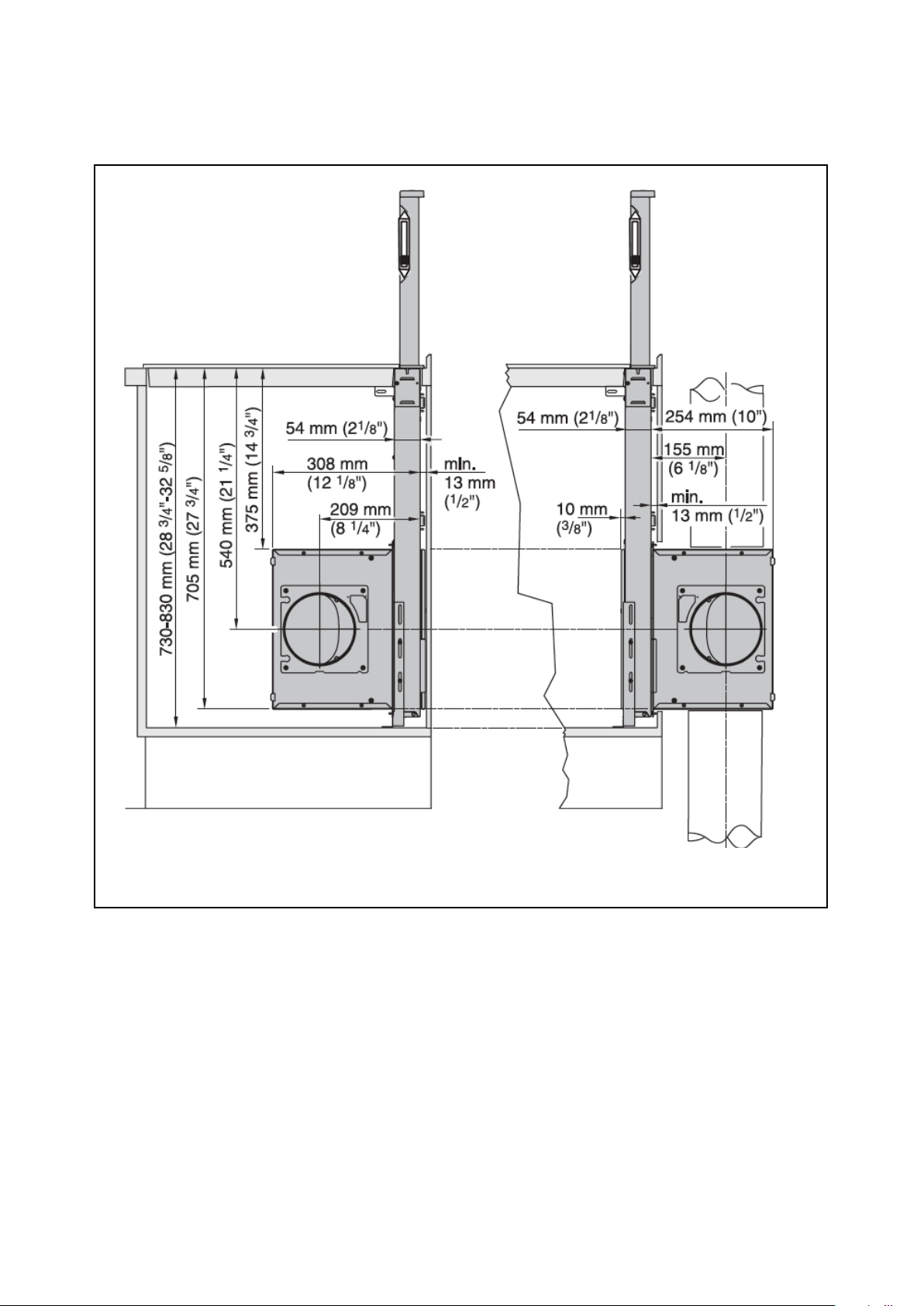

Page 10

PRODUCT DIMENSIONS

Installation using the remote blower

NOTE:

Left side of diagram shows the remote blower ducting

to the outside in front of the Scirocco Plus

Right side of the diagram shows the remote blower

ducting to the rear of the Scirocco Plus. Note that

the back must be accessible to install ductwork.

Note: When using with cooking applainces other

than cook tops which require reversing the

motor box to the back, a 3/4" clearance on front

of the Scirocco is needed to clear a duct plate

and front edge of the down draft body.

FIGURE 8

Version 3/15 - Page 10

Page 11

PRODUCT INSTALLATION

PLEASE READ SAFETY AND PRODUCT DIMENSIONS PAGES

BEFORE PROCEEDING WITH INSTALLATION

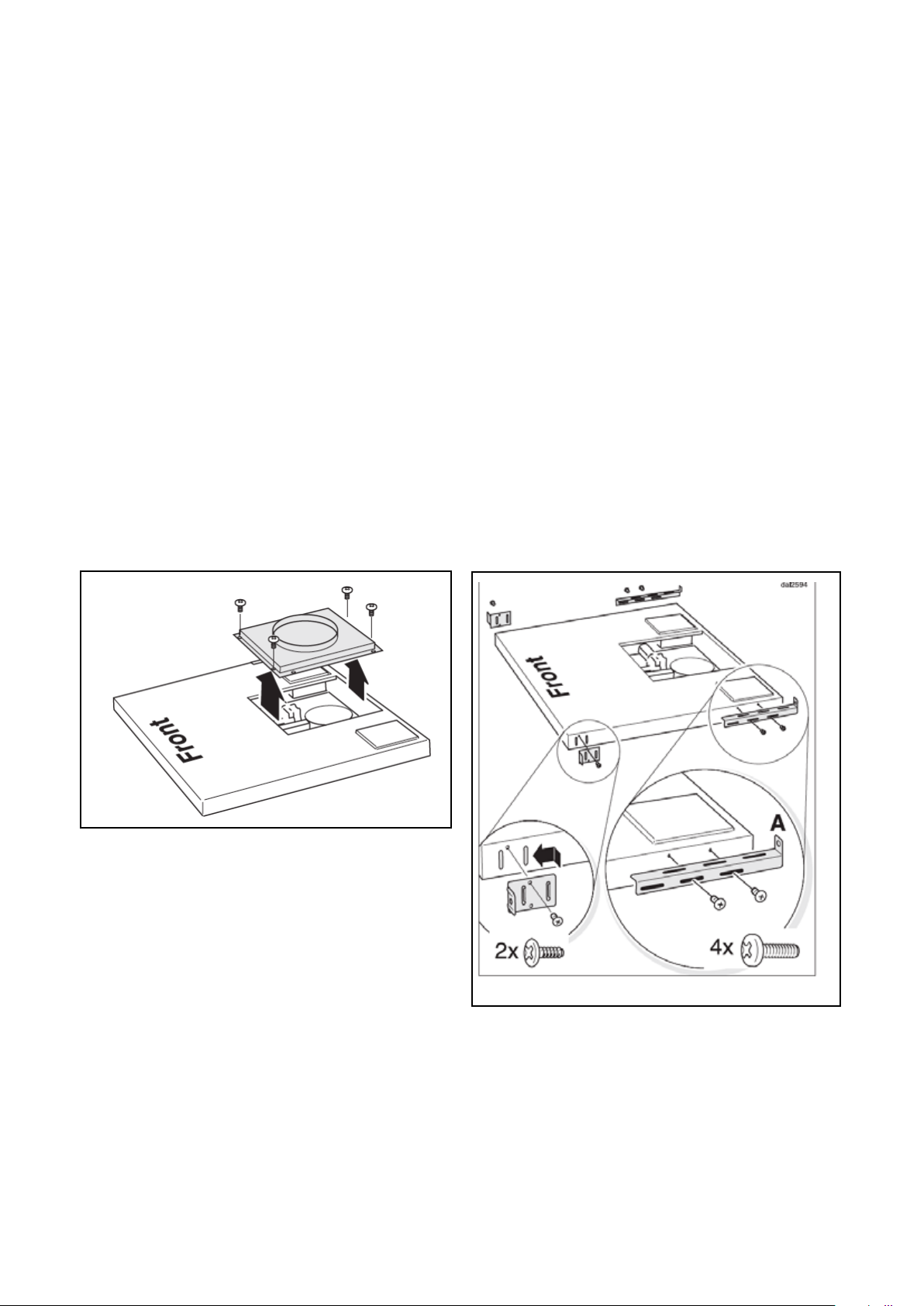

1) The downdraft system is installed directly behind the cooktop. For

easiest installation, install the ventilation system rst, then the

cooktop.The ventilation system must not be installed in an area where

there are strong drafts, for instance near windows, doors, etc.

2) Remove the 10" round connection plate from the front of the

downdraft (FIGURE 9)

3) Put the top mounting brackets in place with screws.

(FIGURE 10)

4) Screw the bottom mounting brackets (A in FIGURE 10) to the side of

the housing using 2 screws each. Do not tighten the screws. The

brackets are different for the right and the left side. Attach them with

mounting clip "A" pointing up.

FIGURE 9

FIGURE 10

Version 3/15 - Page 11

Page 12

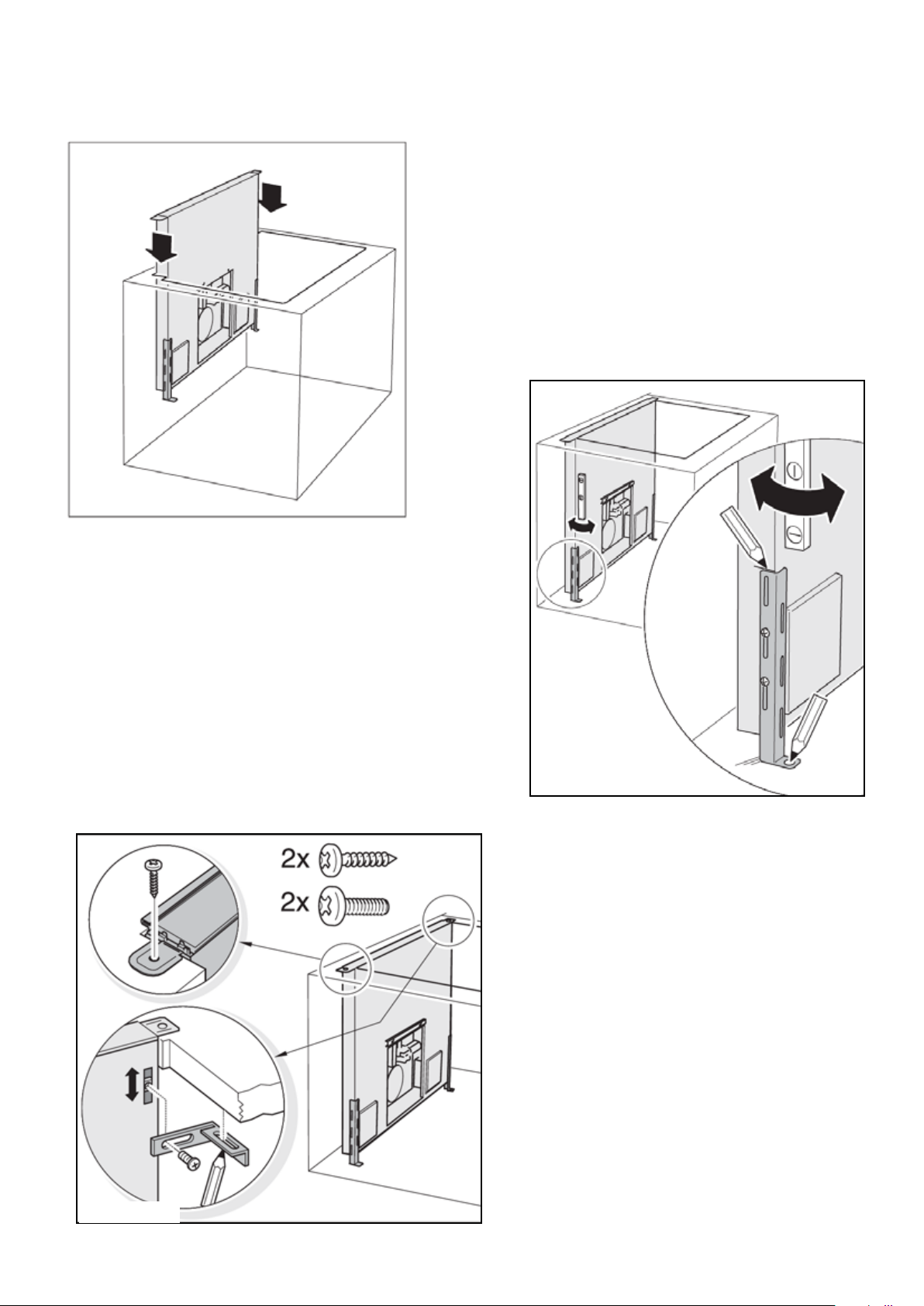

FIGURE 11

PRODUCT INSTALLATION

7) (See FIGURE 13) Level and align the

hood in the cabinet. Push the bottom

mounting bracket on each side down

against the cabinet oor. Mark the top

edge of the mounting bracket on the

housing and the mounting holes on the

cabinet oor.

5) With the assistance of another person, lift the hood

into the prepared cut out in the cabinet. The top

mounting brackets should rest on the countertop.

(FIGURE 11)

6) Secure the hood to the countertop with two screws.

If possible, install the angle brackets underneath the

countertop for additional support. First, loosely screw

the brackets into the sliding nuts in the housing and

push them up under the countertop.

Pre-drill the mounting holes into the countertop from

underneath. Use screws of the proper length.

(FIGURE 12)

FIGURE 13

FIGURE 12

Version 3/15 - Page 12

Page 13

PRODUCT INSTALLATION CONTINUED

INSTALLING IBDD600 IN FRONT OF THE HOOD

8) Remove the screws from the countertop

and lift the hood back out of the cabinet.

Pre-drill the marked mounting holes in the

cabinet oor.

9) Tighten the mounting brackets on the

hood at the pre-marked positions

10) Lay the hood on the oor on a

protected surface to prevent damage in

order to install the motor. At this point

the ductwork venting direction should be

decided (thru the oor, right, left or thru the

rear of the cabinet).

IF USING A REMOTE BLOWER, TURN

TO "REMOTE BLOWER INSTALLATION

ON PAGE 15

- See FIGURE 14 for venting left, right or down.

Disconnect the cable from inside the hood. Plug

in that same cable from the hood into the motor

kit.

- Turn the venting collar on the blower box to the

desired direction - left, right or down.

- Mount the blower box to the housing using 4

screws (FIGURE 15)

Continue to Page 14 for Electrical

Connections

FIGURE 14

FIGURE 15

Version 3/15 - Page 13

Page 14

PRODUCT INSTALLATION

INSTALLING IBDD600 IN FRONT OF THE HOOD,

WHEN VENTING TO THE BACK

- Disconnect the cable from inside the hood. Plug

in that same cable from the hood into the motor

kit. (FIGURE 19)

- When venting to the rear with the IBDD600

blower mounted on the front of the unit, some

modication to the blower box is required

(FIGURE 16)

- Remove the vent collar from the blower box and

close the opening in the blower with the cover

removed from the back of the hood housing

removed from FIGURE 17. Attach it with 4

- Loosen the two screws holding the blower in

screws. (FIGURE 20).

the box. Take the blower out of the box

- Mount the vent collar on the back of the hood

(FIGURE 21)

- Mount the blower box to the housing with 4

screws (FIGURE 22)

Continue to Page 14 for Electrical

Connections

FIGURE 16

- Remove the small cover on the back of the

hood (FIGURE 17)

FIGURE 19

FIGURE 17

- Mount the blower on the front of the hood using

two screws while positioning the vent collar in

the opening of the cover (FIGURE 18)

FIGURE 18

FIGURE 20

FIGURE 21

FIGURE 22

Version 3/15 - Page 14

Page 15

PRODUCT INSTALLATION

INSTALLING IBDD600 IN BACK OF THE HOOD

The blower box can also be installed on the

back of the hood to accommodate the

installation of a cooking range, range top or

wall oven / cook top in front of the hood.

- Remove the large cover on the back of the

hood. (FIGURE 23)

- Turn the venting collar on the blower box to

the desired direction - left, right, down. Plug in

the wiring cable from the motor kit to the hood

and Mount the blower box to the housing

using 4 screws . (FIGURE 24)

- When nished, mount the previously

removed cover onto the front of the unit

(FIGURE 25)

FIGURE 23

PREPARE ELECTRICAL CONNECTION

- Remove the cover of the terminal box

(FIGURE 26)

- Decide whether the power source should

enter the hood from below or from the back.

Remove the respective knock out

- If the hood is being installed with a remote

blower, remove the knock out for the control

cable

- Install a UL listed clamp or conduit tting in

the knock out (not included) (FIGURE 27)

- With assistance for another person lift the

hood into the cabinet cut out. The top

mounting angles should rest on the counter

- Secure the hood to the oor and countertop

(FIGURE 28) with screws into the previously

drilled holes

FIGURE 25

FIGURE 26

FIGURE 24

FIGURE 27

FIGURE 28

Version 3/15 - Page 15

Page 16

PRODUCT INSTALLATION

- Push the side covers into place on the

mounting brackets on top of the counter and

lock them in place (FIGURE 29)

- Connect the appliance to the electric power

supply (see the next page)

- Press the stainless top strip onto the hood.

Push the On / Off push button on top of the

hood, the hood vent will rise.

- Remove the labels, screw and brackets as

shown in FIGURE 30. This bracket is used for

support during transportation

- Connect the top strip to the hood with nuts

underneath the top strip to the screws on the

right and left end to secure the top strip to the

hood. See FIGURE 31, use a size 7 mm nut

driver tool.

- Install grease lters (PAGE 18, FIGURE 36)

- Connect 6" round ducting to the unit.

FIGURE 29

REMOTE BLOWER INSTALLATION

- When using the remote blower, a connection

plate must be installed on the hood instead of

a blower box. It can be mounted to the front

or back of the unit.

- If the connection plate is on the front of the

unit, then the ducting can only come out of the

front

- If the connection plate is on the back of the

unit, then the ducting can only come out of the

back

- The connection plate is installed using 4

screws as shown in FIGURE 32

- The cover plate is installed onto the housing

on the opposite side of the connection plate

(FIGURE 33)

- The remote blower is connected to the

downdraft unit with an additional control cable.

See the installation instructions for the remote

blower. The control cable will be connected in

the wiring box of range hood.

FIGURE 31

- Use 10" round ducting to connect the remote

blower.

FIGURE 32

FIGURE 30

FIGURE 33

Version 3/15 - Page 16

Page 17

ELECTRICAL CONNECTION

WARNING:TO REDUCE THE RISK OF FIRE,

ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

All electrical work should be performed by a

qualied electrician in strict accordance with

national regulations and local safety

regulations. Installation, repairs and other work

by unqualied persons could be

dangerous. Ensure that power to the appliance

is off while installation or repair work

is performed.

This unit may only be used in connection with

Faber internal or remote blowers

WARNING THIS APPLIANCE MUST BE

GROUNDED

- If you have not yet done so, remove

the cover of the terminal box.

- Install a suitable UL listed cable clamp or

conduit tting at the cable knock-out.

- Pass the power supply cable through

the knock-out of the housing into the

terminal box.

Important

The ventilation system must be hard

wired as follows:

- Connect black (L1 / live) cable from the

home power into the right terminal spot

- Connect the green ground wire from the

home power into the middle spot

- Connect the white (neutral) wire from the

home power into the left terminal spot

- Ensure that the terminal screws are tightly

holding all wires into place

Check Operation

1. Push and hold the button on the top of the

downdraft vent for a few seconds. The

retractable section of the downdraft vent

will rise. The blower will start immediately if

the blower control knob is set to an “on”

position.

2. Slide the control slider on the side of the

vent to check the speed of the blower. If the

blower does not operate:

- Check that the lters are pressed in as far as

they will go.

- Check that circuit breaker has not tripped or

a household fuse has blown.

- Check the downdraft vent fuse located under

the power board.

4. Connect the vent system to 6" (IBDD600

blower) or 10" (remote blowers) round vent

collar plate. Position the vent to avoid wall

studs and oor joists. Complete all vent work.

Use clamps to seal all joints. Vertical vent for

wall-mounted installations should pitch down

slightly toward the vent to allow moisture to

run outside.

5. Install the cooktop according to

manufacturer’s instructions. Check that rear of

cooktop overlaps the edge of the retractable

downdraft vent by ³⁄₈" (9.5 mm). See

Countertop Cutout Dimensions.

NOTE: To get the most efcient use from your

new retractable downdraft vent, read the “Vent

System Use” section.

Version 3/15 - Page 17

Page 18

ELECTRICAL CONNECTION WITH REMOTE BLOWER

- If using a remote blower, install a connection cable between the range hood and the remote

blower.

- See the Remote Blower instructions for more guidelines

- Additional knock outs should be used for the remote blower wiring

- Install a suitable UL listed cable clamp or conduit tting into the knock out

- Connect the home power into the box as described on the previous page

- Using FIGURE 34 as a guide, connect the remote blower wiring as follows into the downdraft

box: Blue on the right side, brown on the left side and the ground / green wire goes under one

of the green ground screws.

- Ensure that the terminal screws are tightly holding all wires into place

- The remote blower will be connected to the additional control cable

- Close the terminal box and attach with a screw (FIGURE 35)

- Turn the power back on

FIGURE 34

FIGURE 35

Version 3/15 - Page 18

Page 19

DOWNDRAFT SYSTEM USE

The retractable downdraft vent system is designed

to remove smoke, cooking vapors and odors from

the cooktop area.

- For best results, the vent should be operating

before cooking is started.

- If you use large or tall utensils, place them on the

large rear element or burner surface.

- A higher heat setting than normally used may be

needed when the downdraft vent is operating.

Operating Downdraft Vent

To Use:

- Push and hold the button on top of downdraft vent

for a few seconds. (This slight delay helps avoid inadvertent raising of the vent during cleaning of the

cooktop area.) The retractable section of the

downdraft vent will rise. The blower will begin to

vent immediately if the blower control knob slider is

set to an “On" position.

To Replace Filters:

1. Place lters into the retractable section of

the downdraft vent. (E in FIGURE 36)

2. Place ngertips into the embossment at

the top of the lters and push down and

back to allow the top tabs to snap in place.

NOTE: Downdraft vent will not operate if the

lters are not in their proper position. If the

lters top tabs are not locked behind the top

ange, the vent may retract but not raise

back up. If retractable downdraft vent does

not operate after clean lters have been

installed:

- Push the lter in as far as it will go. When

the lter is removed, the microswitch behind

the lter is inactivated. This feature will not

allow the vent system to operate until the

lter is properly installed.

- Slide the control slider on the right-hand side

of the downdraft vent to adjust the blower motor

speed.

- For Trouble shooting, see PAGE 16

When cooking is complete:

- Push the button on top of the retractable

downdraft vent. The blower will turn off, and the

retractable section of the vent will return to the

closed position.

If a spill occurs on the cooktop that allows liquids

to seep inside the downdraft vent, you must turn

the downdraft vent off immediately. It is possible to

cause damage to the downdraft vent if water is

allowed inside the downdraft vent while it is

operating. Please follow these steps:

- Immediately turn off the downdraft vent at the

speed control located on the right-hand side of the

downdraft vent.

- Turn off the power supply to the downdraft vent at

the circuit breaker box or fuse box.

- Allow plenty of time for the downdraft vent to dry

naturally. Do not open the downdraft vent to

remove the water.

A- Top trim

B - On / Off button

C - Blower control slider

D - End cap

E - Grease lters

FIGURE 36

Version 3/15 - Page 19

Page 20

DOWNDRAFT SYSTEM CARE

Schema Elettrico Schema Electrisch

Electric Diagram Esquema Eléctrico

Schéma Electrique Esquema Eléctrico

Schema Elektrisch

Schema Elettrico Schema Electrisch

Electric Diagram Esquema Eléctrico

Schéma Electrique Esquema Eléctrico

Schema Elektrisch

Surface of Downdraft Vent

To avoid damaging the nish, clean

downdraft vent with soap and water or

Stainless steel cleaner.

Do not use scouring powder or abrasive

solutions.

Vent System Use

For gas cooking surfaces, the vent system may

affect ame stability and cooking performace.

To improve the burner performance, decrease

the blower speed or increase the burner

setting.

Grease Filter Care

Frequently remove and clean the lters in the

retractable section of the downdraft vent. This

will improve the operating efciency of the

downdraft vent system.

To Remove Filters:

1. Place ngertips in the embossment at the

top for the lters.

2. Press down on the lters far enough for the

tab at the top of the lters to clear.

3. Pull forward to release the lter from its

groove.

To Clean:

1. Remove the lters and clean / soak them in

hot dish detergent and water. Because the

stainless steel on the lters could be

scratched, it is not recommended that

the lters be placed in a dishwasher. The

downdraft vent will not operate when the

lters are not in place.

2. Dry the clean lters and reinstall, making

sure that they lock into place.

To Replace Filters:

1. Place lters into the retractable section of

the downdraft vent.

2. Place ngertips into the embossment at the

top of the lters and push down and back to

allow the top tabs to snap in place.

The ame sensing ignitions on some gas

cooking surfaces may be affected by the

downdraft by dispersing the ame away from

the spark igniter. This may cause the spark to

keep running while trying to reignite the burner

that is already lit. The resolve this issue,

decrease the vent speed or increase the

burner setting.

A- Grease lter removal tab

B - Left grease lter

C - Right grease lter

NOTE: Downdraft vent will not operate if the

lters are not in their proper position. If the

lters top tabs are not locked behind the top

ange, the vent may retract but not raise back

up.

If retractable downdraft vent does not

operate after clean lters have been

installed: Push the lter in as far as it will go.

When the lter is removed, the microswitch

behind the lter is inactivated. This feature will

not allow the vent system to operate until the

lter is properly installed.

WIRING DIAGRAM

Version 3/15 - Page 20

Page 21

FABER WARRANTY & SERVICE (SAVE FOR YOUR RECORDS)

All Faber products are warranteed against any defect in materials or workmanship for the

original purchaser for a period of 1 year from the date of original purchase. This warranty

covers labor and replacement parts. To obtain warranty service, contact the dealer from

whom you purchased the range hood, or the local Faber distributor. If you cannot identify

a local Faber distributor, contact us at (508) 358-5353 for the name of a distributor in your

area.

The Following is not covered by Faber's warranty:

1. Service calls to correct the installation of your range hood, to instruct you how to use your

range hood, to replace or repair house fuses or to correct house wiring or plumbing.

2. Service calls to repair or replace range hood light bulbs, fuses or lters. Those

consumable parts are excluded from warranty coverage.

3. Repairs when your range hood is used for other than normal, single-family

household use.

4. Damage resulting from accident, alteration, misuse, abuse, re, ood, acts of God,

improper installation, installation not in accordance with electrical or plumbing codes, or

use of products not approved by Faber.

5. Replacement parts or repair labor costs for units operated outside the United States or

Canada, including any non-UL or C-UL approved Faber range hoods.

6. Repairs to the hood resulting from unauthorized modications made to the

range hood.

7. Expenses for travel and transportation for product service in remote locations and pickup

and delivery charges. Faber range hoods should be serviced in the home.

Record Your Information Below:

Serial #: __________________________

Date of Purchase: ______________

Version 3/15 - Page 21

Page 22

INSTALLATEURS ATTENTION

Important Se il vous plaît lire avant de commencer l’installation

Un interrupteur de sécurité, qui se arrête le capot de la hausse pour des raisons de sécurité, se arrêtera également la hausse si elle se déplace dans la position verrouillée ou “activé” pendant l’expédition. Ces mesures

permettront de mettre l’interrupteur de sécurité dans le “désactivé” ou position déverrouillée pour terminer

l’installation.

Se il vous plaît effectuer ces étapes avant de procéder à l’installation normale

Étape 1) Retirer le produit de la boîte et (avec le circuit électrique hors) connecter l’alimentation de

la maison à la hotte en reliant les fils vert, blanc et noir dans la boîte de câblage de la hotte, situé sur le

côté inférieur gauche du capot. Une fois les connexions électriques sont faits et la boîte de câblage est

fermé, mettez le circuit de retour sur.

Étape 2) Retirez le panneau d’accès avant toute de la hotte pour exposer les engrenages internes et

des commutateurs en enlevant les vis qui maintiennent le panneau en place (voir photo)

Étape 3) Appuyez et maintenez le bouton marche / arrêt (avec un objet pointu) sur le haut / droite de la

hotte (voir photo)

Étape 4) Tout en maintenant le bouton marche / arrêt, placez un petit tournevis à tête plate sous la

sécurité

passer à désengager le levier à partir du bouton interrupteur de sécurité (voir photo). Ce commutateur

est le commutateur avant de la paire de commutateurs sur le fond de la hotte (devant le commutateur

de fin de course basse). En tirant ce levier loin du bouton interrupteur de sécurité est enfoncé, ce sera

de retour le capot à un fonctionnement normal et le capot va maintenant monter et descendre normalement. Ces étapes ne devraient être tenus une fois l’interrupteur de sécurité fonctionnent normalement

aller de l’avant.

Étape 5) Testez le capot en appuyant sur le bouton marche / arrêt sur le dessus de la hotte pendant

plusieurs cycles haussiers et baissiers pour assurer la hotte fonctionne sans tenir le interrupteur sur le

fond. Débranchez l’alimentation

Étape 6) Procéder avec le reste des étapes pour installer le produit selon les instructions d’installation.

Étape 1

Boîte de

câblage

Étape 2 Étape 3 , 4 Étape 4

Interrupteur

de sécurité

Bouton

marche / arrêt

tournevis à tête plate levier

interrupteur

de sécurité

poussant vers le haut

Version 3/15 - Page 22

Page 23

!

OUTILS REQUIS POUR L'INSTALLATION

Saber • scie sauteuse

• Perceuse

• 1 1/4 "Foret à bois

• Pinces

• Tournevis Phillips

• tournevis à lame plate

Pince à dénuder • ou un couteau

• Métal Cisailles

• Ruban à mesurer ou une règle

• Niveau

• Crayon

• Pistolet à calfeutrer

• Duct Tape

Les pièces fournies pour INSTALLATION

• 6 supports de montage (2 pieds de support, 2 en vertu de comptoir et

2 sur vente libre entre parenthèses

• 2 Embouts

• bande supérieure en acier inoxydable

• Noix de se connecter bande supérieure

• 2 ltres à graisse inox

• Vis installation

• 1 sachet de documentation

• 1 clapet antirefoulement

PIÈCES NÉCESSAIRES POUR L'INSTALLATION

• 2 connecteurs de conduit

• Câble d'alimentation

Câble de raccordement • - En option souferie à distance seulement

• 1 mur ou de toit Cap

• Tous les Matériaux Métalliques

Accessoires optionnels disponibles (choisir 1 VENTILATEUR)

• Ventilateur interne modèle # IBDD600

• Le modèle de souferie à télécommande # RBORIG900 / RBORIG1200

CALCUL DE LA LONGUEUR DU CONDUIT

La longueur des conduits ne doit pas dépasser 55 pieds

équivalent de 6 "conduit, ou 75 pieds équivalent de 10"

conduit rond. Calculer la longueur du conduit en ajoutant les

pieds équivalents répertoriés dans la gure 1 pour chaque

pièce du conduit dans le système complet. Un exemple est

donné sur la gure 2.

Pour de meilleurs résultats, ne pas utiliser plus de trois

coudes à 90 °. Assurez-vous qu'il ya un minimum de 24 "de

conduit droit entre les coudes si plus d'un est utilisé. Ne pas

installer deux coudes ensemble. Conduit ronde est plutôt

recommandé de conduit rectangulaire en particulier si les

coudes sont nécessaires. Pour les modèles ventilateur interne,

conduit rectangulaire devrait être la transition à 6 "rond dès

que possible.

Coude 45˚

Coude 90˚

Coude plat 90˚

Capuchon de mu

FIGURE 1

5.0 pi

7.0 pi

12.0 pi

0.0 pi

9 pi de conduit droit

2 Coudes 90˚

Capuchon de mur

Système total

FIGURE 2

9.0 pi

14.0 pi

0.0 pi

23.0 pi

PLAN DU CONDUIT

Le système Scirocco courant descendant Plus est conçu

pour offrir une grande souplesse dans gaines. Le ventilateur

intérieur peut être canalisé à l'avant ou à l'arrière de l'appareil

courant descendant dans plusieurs directions: vers le bas,

gauche, droite ou vers l'arrière (recto uniquement) à l'aide

d'un 6 rondes "conduit rond Le ventilateur à distance peut

être canalisé vers le bas à l'aide d'un 10." évacuer.

Le ventilateur à distance nécessite un câblage séparé qui

doit être installé en même temps que le conduit est installé.

Pour de meilleurs résultats, 10 "tuyau est recommandé pour

la souferie à distance. Un voile est inclus dans la boîte avec

le package courant descendant et doit être associé au cours

de la l'ouverture de l'avant / arrière de la boîte de soufante

aspirante. Souferie à distance peut être monté soit sur un

mur extérieur ou le toit de la maison.

AVERTISSEMENT

Lors de la planication de la découpe de la hotte:

• Dessinez à la fois la table de cuisson et des découpes hotte

sur le comptoir avant de faire des coupures.

• Vérier qu'il ya assez de place dans l'armoire pour les deux.

Le non-respect de ces consignes pourrait entraîner des

dommages sur le comptoir.

Consignes générales d'installation

(IMPORTANT - À LIRE AVANT L'INSTALLATION)

Le plus Scirocco est destiné à être installé avec plaques de

cuisson résidentiels utilisation, plaques de cuisson / four combinaisons, autoportant gammes SANS Revêtements muraux et

des hauts de gamme. Ce produit n'est pas recommandé pour

une utilisation avec toboggan dans des gammes qui peuvent

nécessiter un espace supplémentaire derrière la plage de

ventilation du four avec OU AVEC Revêtements muraux autonomes gammes. Toujours consulter vos instructions de cuisson

du fabricant d'installation pour les dimensions des produits de

cuisson et les besoins spéciques cfm.

Dans le cas d'installations où le ventilateur est situé à l'arrière

de l'appareil, il est conseillé de laisser une porte d'accès ou

d'ouverture pour atteindre le fond de la Plus Scirocco où la

boîte de câblage et le moteur est situé services devrait être

nécessaire.

REMARQUE: Lorsque vous utilisez ce capot avec une

cuisinière ou de la gamme de sol avec la boîte de moteur

inversé derrière le capot, un «jeu 3/4 est requise sur le

devant de la hotte pour effacer une plaque de conduit et

le bord avant du projet vers le bas corps . Une bande de

remplissage peut être nécessaire sur le comptoir dans ce

type d'installation pour couvrir cet écart entre la surface

de cuisson et le capot.

Version 3/15 - Page 23

Page 24

14 " (357 mm)

retractable

vent height

DIMENSIONS DU PRODUIT

Top trim widths:

30 " (762 mm) vent

36 " (914 mm) vent

11⁄2 " (38 mm)

27" (686 mm) for 30" (762 mm) vent

33" (838 mm) for 36" (914 mm) vent

Terminal box cover

13" (330 mm)

13" (330 mm)

FIGURE 3

6" (152 mm)

diameter

vent collar

3⁄8" (9.5 mm)

x

283⁄4"

(730 mm)

10 "

(254 mm)

21⁄8 " (54 mm)

FIGURE 4

FIGURE 3 - Dimensions avec IBDD600 interne la boîte du

ventilateur

La boîte de ventilateur peut être monté dans

de telle sorte que la collerette d'évacuation est

alignés sur la gauche, la droite, vers le bas

ou vers l'arrière, comme vous le souhaitez.

FIGURE 4 - La plaque de raccordement lors de l'utilisation de

la #RBORIG900 Ou #RBORIG1200 la souferie à distance

Le ventilateur ou la plaque de raccordement peut

également être monté dans la même position

à l'arrière de l'appareil.

x à la FIGURE 3 = Distance à l'arrière de l'armoire

ou un mur. Doit avoir un minimum de ½ ".

Échappement diamètres de raccordement de conduits

IBDD600:. . . . . . . . . . . . . . . 6 "

RBORIG900 / 1200:. .. . 10 "

Version 3/15 - Page 24

Page 25

CABINET CUT OUT DIMENSIONS

30”

36”

30

36

NOTE:

A = gauche, droite IBDD600 conduits

B = Canalisation IBDD600 bas

C = Canalisation IBDD600 à l'arrière

D Cordon d'alimentation = taillé pour la souferie à

télécommande

E = 10 "Conduits pour souferie à distance

un surplomb = Table de cuisson

b = largeur minimale de la table de cuisson:

30 ": 28" (711 mm)

36 ": 34" (864 mm)

FIGURE 5

Version 3/15 - Page 25

Page 26

DIMENSIONS DU PRODUIT

FIGURE 6

Voir la page précédente à la gure 5, et la gure 6 ci-dessus

à titre de référence. Lorsque vous utilisez le ventilateur

interne IBDD600 installé sur le devant de la utilisation de

l'appareil 6 "Trous ronds conduits pour conduits sont indiqués sur la gure 5, 6 :

(A) vers la gauche ou vers la droite (B) Vers le bas, (C) à

l'arrière. Si le ventilateur est installé à l'arrière de l'appareil,

une découpe doit être faite par l'arrière de l'armoire ou le

mur où il sera monté et le cas échéant

dégagements doivent être maintenus derrière l'armoire.

Voir la gure 5, (D) Faites passer le cordon d'alimentation

et vers le bas des câbles de commande ou à l'arrière quand

l'aide d'une souferie à distance.

Voir gure 5 (e) Lors de l'utilisation de la

télécommande souferie, l'installation de 10 "conduits à

l' arrière. Si vous installez le conduits d'échappement à

l' avant, les autorisations appropriées doivent être

maintenu dans l'armoire.

REMARQUES SUR L'INSTALLATION

- Le minimum spécié les dimensions

découpées dimensions doivent être respectées.

- Si un four ou un poêle est installé avant

le système de ventilation, lire la associé

les instructions d'installation. Notez toutes les

installations les dimensions et les lignes

directrices concernant systèmes de ventilation.

- Soyez conscient d'armoires de cuisine, de retour

éclaboussures et / ou supports dans la zone de la

système de ventilation et de la table de cuisson.

Assurez-vous que la zone où l'évent se lève est libre de

tout obstacle.

- Assurez-vous que tout minimum requis

distance entre le bord avant de la comptoir et le bord

avant de la table de cuisson est maintenue.

- Si il ya un tiroir du meuble sur le chemin, il doit être

raccourci ou supprimé. Le panneau avant du tiroir pourrait

également être installé de façon permanente de couvrir

le tiroir découpe.

Version 3/15 - Page 26

Page 27

DIMENSIONS DU PRODUIT

Installation à l'aide du ventilateur interne IBDD600

NOTE:

Le côté gauche du diagramme montre la montée

IBDD600 en face de la plus Scirocco

Côté droit du diagramme montre la IBDD600 monté

derrière le plus Scirocco. Le ventilateur doit être

accessible à installer le réseau de conduits

Remarque: Lors de l'utilisation avec applainces de

cuisson autres que tables de cuisson qui nécessitent

inverser la Boîte de moteur à l'arrière, un 3/4 "de

dégagement à l'avant de la Scirocco est nécessaire

pour effacer une plaque de canal et le bord avant du

corps de tirage vers le bas.

FIGURE 7

Version 3/15 - Page 27

Page 28

DIMENSIONS DU PRODUIT

Installation à l'aide de la souferie à distance

NOTE:

Le côté gauche du diagramme montre la

souferie à distance conduits à l'extérieur en face

de la plus Scirocco

Le côté droit du diagramme montre la souferie à

distance conduits à l'arrière de la plus Scirocco.

Notez que l'arrière doit être accessible à installer

les conduits.

Remarque: Lors de l'utilisation avec applainces de

cuisson autres que tables de cuisson qui nécessitent

inverser la Boîte de moteur à l'arrière, un 3/4 "de

dégagement à l'avant de la Scirocco est nécessaire

pour effacer une plaque de canal et le bord avant du

corps de tirage vers le bas.

FIGURE 8

Version 3/15 - Page 28

Page 29

INSTALLATION DU PRODUIT

S'IL VOUS PLAÎT LIRE LA SÉCURITÉ ET DIMENSIONS DU

PRODUIT PAGES

Avant d'installer

1) Le système de hotte est installée directement derrière la table de

cuisson. Pour faciliter l'installation, installer le premier système de

ventilation, puis le système de ventilation cooktop.The doit pas être

installé dans une zone où il ya des courants forts, par exemple près des

fenêtres, portes, etc

2) Retirez le 10 "plaque de raccordement ronde à l'avant de l'

courant descendant (FIGURE 9)

3) Mettre les tranches supérieures de montage en place avec des vis.

(FIGURE 10)

4) Vissez les supports de montage inférieure (A de la FIGURE 10) sur le

côté du boîtier à l'aide de 2 vis chacun. Ne pas serrer les vis. la

crochets sont différentes pour la droite et la gauche. Joignez-les avec

clip de montage "A" vers le haut.

FIGURE 9

FIGURE 10

Version 3/15 - Page 29

Page 30

FIGURE 11

INSTALLATION DU PRODUIT

7) (Voir Niveau FIGURE 13) et aligner la

hotte dans le meuble. Poussez le support

de xation au bas de chaque côté vers le

bas contre le plancher du placard.

Marquer le bord supérieur du support

de montage sur le boîtier et les trous de

montage sur la plancher de l'armoire.

5) Avec l'aide d'une autre personne, soulevez le capot

dans la découpe préparée dans l'armoire. Le haut

supports de montage doivent reposer sur le comptoir.

(FIGURE 11)

6) Fixer la hotte sur le comptoir avec deux vis. Si

possible, installer les équerres sous le comptoir pour

un soutien supplémentaire. Tout d'abord, visser sans

serrer les supports dans les écrous coulissants dans le

logement et les pousser sous le comptoir.

Pré-percer les trous de montage dans le comptoir de

en dessous. Utilisez des vis de la bonne longueur.

(FIGURE 12)

FIGURE 13

FIGURE 12

Version 3/15 - Page 30

Page 31

INSTALLATION DU PRODUIT SUITE

8) Retirez les vis du comptoir et soulevez

le capot arrière de l'armoire. Pré-percer

les trous marqués de montage dans le

plancher de l'armoire.

INSTALLATION EN IBDD600 avant de la hotte

- Voir Figure 14 pour l'aération gauche, la droite

ou vers le bas. Débranchez le câble de l'intérieur

du capot. Branchez ce même câble de la hotte

dans le kit moteur.

9) Serrer les supports de montage sur le

capot au niveau des positions

pré-marqués

10) Placez le capot sur le sol sur un

surface protégée pour éviter les

dommages an de pouvoir installer le

moteur. A ce point, la direction de

ventilation conduits devrait être décidé

(par l'entremise du sol, à droite, à gauche

ou à travers l'arrière de l'armoire).

SI VOUS UTILISEZ UN souferie à

distance, se tourner vers

"VENTILATEUR Installation à distance

sur PAGE 15

- Tourner le collier de ventilation sur la boîte du

ventilateur dans la direction souhaitée - gauche,

droite ou vers le bas.

- Monter la boîte du ventilateur sur le boîtier à

l'aide de 4 vis (FIGURE 15)

Continuer à la page 14 pour électrique liens

FIGURE 14

FIGURE 15

Version 3/15 - Page 31

Page 32

INSTALLATION DU PRODUIT

INSTALLATION EN IBDD600 avant du capot,

QUAND L'évacuation vers le RETOUR

- Lorsque évacuation vers l'arrière avec la

souferie IBDD600 monté à l'avant de l'unité, une

modication de la boîte de soufage est

nécessaire (FIGURE 16)

- Desserrez les deux vis qui maintiennent le

ventilateur dans la boîte. Prenez le ventilateur de

la boîte

FIGURE 16

- Retirez le petit couvercle au dos de la hotte

(FIGURE 17)

- Branchez le câble électrique de la hotte dans la

souferie (gure 19)

- Retirer le collier de ventilation de la boîte du

ventilateur et fermer l'ouverture dans la

souferie avec le couvercle enlevé à l'arrière du

boîtier hotte retiré de la FIGURE 17. Attachez

avec 4 vis. (FIGURE 20).

- Monter la bague de ventilation à l'arrière de la

hotte (FIGURE 21)

- Monter la boîte du ventilateur sur le boîtier avec

4 vis (gure 22)

Continuer à la page 31 pour électrique

liens

FIGURE 19

FIGURE 17

- Monter le ventilateur à l'avant de la hotte à

l'aide de deux vis tout en positionnant la bague

de ventilation dans l'ouverture du couvercle

(FIGURE 18)

FIGURE 18

FIGURE 20

FIGURE 21

FIGURE 22

Version 3/15 - Page 32

Page 33

INSTALLATION DU PRODUIT

INSTALLATION EN IBDD600 arrière de la hotte

La boîte soufante peut également être

installé à l'arrière de la hotte pour recevoir le

installation d'un plan de cuisson plage ou la

plage en face de la hotte.

- Retirez le couvercle du grand sur le dos de la

hotte. (FIGURE 23)

- Tourner le collier de ventilation sur la boîte du

ventilateur dans la direction

souhaitée - gauche, droite, bas. Branchez le

câble électrique à partir du kit moteur de la

hotte et monter la boîte du ventilateur sur le

boîtier aide de 4 vis. (FIGURE 24)

- Lorsque vous avez terminé, montez le

préalable capot retiré sur l'avant de l'unité

(FIGURE 25)

FIGURE 23

PRÉPARER BRANCHEMENT ELECTRIQUE

- Retirer le couvercle de la boîte à bornes

(FIGURE 26)

- Décider si la source d'alimentation doit

entrer dans la hotte du ci-dessous ou à

l'arrière. Retirez le knock out respective

- Si la hotte est installée avec un ventilateur à

distance, retirez le knock out pour le câble de

commande

- Installer un collier de UL ou des raccords de

conduit dans le coup sur (non inclus) (gure

27)

- Avec l'aide d'une autre personne soulever le

capot dans le cabinet découper. Le haut

les angles de montage doit reposer sur le

comptoir

FIGURE 24

- Fixer la hotte à l'étage et le comptoir (gure

28) avec des vis dans les trous préalablement

percés

FIGURE 26

FIGURE 27

FIGURE 25

FIGURE 28

Version 3/15 - Page 33

Page 34

INSTALLATION DU PRODUIT

- Poussez sur le côté couvre en place sur les

supports de montage sur le dessus du

comptoir et de les verrouiller en place

(Figure 29)

- Connecter l'appareil à l'alimentation

électrique (voir la page suivante)

- Appuyer sur la bande inoxydable haut sur le

capot. Appuyez sur le bouton Marche / Arrêt

poussoir sur le dessus du capot, le capot de

ventilation va augmenter.

- Retirer les étiquettes et les supports, vis

comme illustré à la FIGURE 30. Ce support

est utilisé pour le support pendant le transport

- Raccorder la bande supérieure de la hotte

avec des écrous en dessous de la bande

supérieure aux vis sur le côté droit et gauche

pour xer la bande supérieure de la hotte. Voir

la FIGURE 31, utiliser une taille de l'outil 7 mm

tournevis à douille.

- Installez des ltres à graisse (Page 35, gure

36)

- Raccorder 6 "Conduit rond à l'unité.

FIGURE 29

DISTANCE INSTALLATION DE LA

SOUFFLERIE

- Lorsque vous utilisez la souferie à distance,

une plaque de connexion doit être installé sur

le capot au lieu d'un caisson de soufage. Il

peut être monté à l'avant ou l'arrière de l'unité.

- Si la plaque de connexion est à l'avant de

l'unité, alors le conduit ne peut sortir de l'avant

- Si la plaque de connexion est sur le dos de

l'appareil, puis le conduit ne peut venir que de

l'arrière

- La plaque de raccordement est installé à

l'aide de 4 vis comme le montre la gure 32

- La plaque de recouvrement est installée sur

le boîtier sur le côté opposé de la plaque de

raccordement (gure 33)

- La souferie à distance est connecté à l'

unité aspirante avec un câble de commande supplémentaire. Voir les instructions

d'installation pour la souferie à distance. Le

câble de commande sera connecté dans la

boîte de câblage de la hotte.

FIGURE 31

- Utilisez 10 "gaines rondes pour connecter le

ventilateur à distance.

FIGURE 30

FIGURE 32

FIGURE 33

Version 3/15 - Page 34

Page 35

RACCORDEMENT ELECTRIQUE

AVERTISSEMENT: POUR RÉDUIRE LE RISQUE D'INCENDIE,CHOC ÉLECTRIQUE OU

DE BLESSURES PERSONNES,

RESPECTER CE QUI SUIT:

Tous les travaux électriques doivent être

effectués par un électricien qualié en stricte

conformité avec les réglementations nationales

et de la sécurité locale réglementation.

Installation, les réparations et autres travaux

par des personnes non qualiées pourrait être

dangereuse. Assurez-vous que la puissance

de l'appareil est éteint lors de l'installation ou

de réparation est effectuée.

Cette unité ne peut être utilisé dans le cadre de

Faber interne ou soufantes à distance

AVERTISSEMENT CET APPAREIL DOIT

ÊTRE MIS À LA TERRE

- Si vous n'avez pas encore fait, retirez

le couvercle de la boîte à bornes.

- Installez un câble approprié pince UL cotées

ou raccord de conduit sur le câble knock-out.

- Faire passer le câble d'alimentation à travers

l'entraînement du boîtier dans le la boîte à

bornes.

Important

Le système de ventilation doit être dur

câblés comme suit:

- Connectez le l noir (L1 / live) câble de

l'alimentation à domicile dans la tache borne

de droite

- Raccorder le l de terre vert de la puissance

à domicile dans le point du milieu

- Raccorder le blanc (neutre) de la puissance

à domicile dans la tache terminal de gauche

- Veiller à ce que les vis des bornes sont

étroitement tenant tous les ls en place

Vérier le fonctionnement

1. Appuyez et maintenez le bouton sur le

dessus de l'évent hotte pendant quelques

secondes. la section rétractable du système

d 'extraction va augmenter. Le ventilateur

démarre immédiatement si le bouton de

commande du ventilateur est réglé à une "marche"

la position.

2. Faire glisser le coulisseau de commande sur le

côté de l'évent pour contrôler la vitesse de la

soufante. Si le ventilateur ne fonctionne pas:

- Vérier que les ltres sont pressés dans la

mesure où ils iront.

- Vérier que le disjoncteur ne s'est pas déclenché

ou un fusible est grillé.

- Vériez le fusible de ventilation aspirante située

sous la carte de puissance.

4. Branchez le système de ventilation à 6 "(IBDD600 ventilateur) ou 10" (souferie à télécommande) conduit rond collerette. Positionner l'évent

pour éviter les montants du mur et les solives de

plancher. Remplissez tous les travaux de

ventilation. Utilisez des brides pour sceller tous

les joints. Évent vertical pour un montage mural

devrait piquer du nez légèrement vers la

cheminée pour permettre à l'humidité an de

fonctionner à l'extérieur.

5. Installez la plaque de cuisson en fonction de

les instructions du fabricant. Vériez que la table

de cuisson arrière de chevauchements au bord de

la escamotable I'appareil par ³ / ₈ "(9,5 mm). Voir

Dimensions ouverture du comptoir.

REMARQUE: Pour obtenir l'utilisation la plus

efcace de votre système d 'extraction nouvelle

rétractable, lire le "Système utilisation Vent"

section.

Version 3/15 - Page 35

Page 36

RACCORDEMENT ELECTRIQUE AVEC TELECOMMANDE VENTILATEUR

- Si vous utilisez un ventilateur à distance, d'installer un câble de connexion entre la hotte et la

souferie à distance.

- Voir les instructions pour la souferie à distance des lignes directrices plus

- Knock outs supplémentaires devraient être utilisés pour le câblage souferie à distance

- Installer un collier de câble UL approprié cotées ou des raccords de conduit dans le knock out

- Branchez l'alimentation à domicile dans la zone telle que décrite à la page précédente

- En utilisant la gure 34, comme un guide, connecter le câblage du ventilateur à distance

comme suit dans la boîte de hotte: bleu sur le côté droit, brun sur le côté gauche et le sol / le l

vert passe sous l'une des vis de terre verte.

- Veiller à ce que les vis des bornes sont étroitement tenant tous les ls en place

- Le ventilateur à distance sera connecté au câble de commande supplémentaire

- Fermez la boîte à bornes et le xer avec une vis (gure 35)

- Tournez le dos à la puissance

FIGURE 34

FIGURE 35

Version 3/15 - Page 36

Page 37

UTILISATION DU SYSTÈME DE HOTTE

Le système de ventilation aspirante escamotable

est conçu pour éliminer les vapeurs de fumée de

cuisson et les odeurs de la cuisine.

- Pour de meilleurs résultats, l'évent doit être

opérationnel avant la cuisson est commencé.

- Si vous utilisez des ustensiles grands ou grand,

les placer sur l'élément arrière grand ou la surface

du brûleur.

- Une plus grande chaleur que normalement utilisé

la mise peut être nécessaire lorsque le système d

'extraction est en marche.

I'appareil de fonctionnement

Pour utiliser:

- Appuyez et maintenez le bouton sur le dessus de

I'appareil pendant quelques secondes. (Ce léger

retard permet d'éviter les rassemblements par

inadvertance de l'évent pendant le nettoyage de la

zone de cuisson.) La section rétractable de la

I'appareil va augmenter. Le ventilateur va

commencer à évacuer immédiatement si le curseur

bouton de commande du ventilateur est réglé à

une position «On».

Pour remplacer les ltres:

1. Placer les ltres dans la section rétractable du système d 'extraction. (E de la

FIGURE 36)

2. Placer le bout des doigts dans le bossage

au sommet des ltres et pousser vers le

bas et le dos pour permettre aux languettes

supérieures à enclencher en place.

REMARQUE: I'appareil ne fonctionne pas si

les ltres ne sont pas dans la bonne

position. Si les onglets de ltres haut ne

sont pas verrouillés derrière le rebord

supérieur, l'évent peut se rétracter, mais

soulève pas remonter. Si I'appareil

rétractable ne fonctionne pas après

nettoyage des ltres ont été installés:

- Pousser le ltre dans la mesure où il ira.

Lorsque le ltre est enlevé, le micro-derrière

le ltre est inactivé. Cette fonctionnalité ne

permet pas le système de ventilation de

fonctionner jusqu'à ce que le ltre est

correctement installé.

- Faites glisser le curseur de contrôle sur le côté

droit de l'I'appareil pour régler la vitesse du moteur

du ventilateur.

- Pour le dépannage, voir page 16

Lorsque la cuisson est terminée:

- Appuyez sur le bouton sur le dessus de

l'enrouleur I'appareil. Le ventilateur s'éteint, et le

section rétractable de l'évent retourne à la position

fermée.

Si un déversement se produit sur la table de

cuisson qui permet de liquides de s'inltrer à

l'intérieur du système d 'extraction, vous devez activer le système d' extraction immédiatement. Il est

possible de causer des dommages à l'I'appareil si

l'eau est autorisés à l'intérieur du système d

'extraction alors qu'il est exploitation. S'il vous plaît

suivez ces étapes:

- Éteignez immédiatement l'I'appareil au contrôle

de la vitesse situé sur le côté droit de l'I'appareil.

- Coupez l'alimentation électrique à l'I'appareil à la

boîte de disjoncteur ou la boîte à fusibles.

- Prévoyez sufsamment de temps pour le système

d 'extraction à sécher naturellement. Ne pas ouvrir

le système d 'extraction de

éliminer l'eau.

A- Haut garniture

B - Le bouton On / Off

C - curseur de contrôle du

ventilateur

D - Embout

E - ltres à graisse

FIGURE 36

Version 3/15 - Page 37

Page 38

CARE SYSTEM HOTTE

Schema Elettrico Schema Electrisch

Electric Diagram Esquema Eléctrico

Schéma Electrique Esquema Eléctrico

Schema Elektrisch

Schema Elettrico Schema Electrisch

Electric Diagram Esquema Eléctrico

Schéma Electrique Esquema Eléctrico

Schema Elektrisch

Surface de I'appareil

Pour éviter d'endommager la nition,

nettoyer I'appareil avec du savon et de l'eau ou

Nettoyant pour acier inoxydable.

Ne pas utiliser de poudre à récurer ou de solutions abrasives.

Filtre à graisse soins

Foire enlever et nettoyer les ltres dans la section

rétractable du système d 'extraction. Cela permettra d'améliorer l'efcacité

opérationnelle du système de ventilation

aspirante.

Pour enlever les ltres:

1. Placer le bout des doigts dans le bossage en

haut pour les ltres.

2. Appuyez sur les ltres assez loin pour l'onglet

en haut des ltres à défricher.

3. Tirer vers l'avant pour libérer le ltre de sa

rainure.

Vent d'utilisation du système

Pour les surfaces de cuisson au gaz, le système

de ventilation peut affecter la stabilité de la amme

et le performace de cuisson. Pour améliorer les

performances du brûleur, de diminuer la vitesse du

ventilateur ou augmenter le brûleur

réglage.

La détection de amme allumages sur une partie

du gaz surfaces de cuisson peuvent être affectés

par la courant descendant en dispersant la amme

loin de l'allumeur. Cela peut provoquer l'étincelle