Faber PURE BF80S, SENSE, WHISPER, SILENCE, SPECTRA NOVA Installation Manual And User's Manual

...

PURE (BF80S)

SILENCE

FEELING

SENSE

WHISPER

SPECTRA NOVA

CADRA NOVA

MISTY

Room-sealed built-in gas-fireplace with “Log Burner Technology”

Installation guide and user manual

40010556

39-04

UK/IRL

2 < < < <

UK/IRL

> > > > 3

1 Index:

1 Index: ...................................................................................... 3

2 Introduction .............................................................................. 5

3 Safety and general information ...................................................... 6

3.1 General safety...................................................................6

4 Installation requirements.............................................................. 8

4.1 Builders opening and surround................................................8

4.2 Flue requi r e me n t s............................................................ 10

4.3 Tables for determining the right flue restrictor.......................... 12

4.3.3 Terminal position............................................................................ 15

4.3.4 Using an existing chimney as air inlet.................................................... 17

5 Instructions for installation .......................................................... 18

5.1 Gas Conne c t ion ............................................................... 18

5.2 Preparing the app l i a nces ................................................... 18

5.2.3 Preparing the Sense ......................................................................... 19

5.2.4 Preparing the Widescreen and Whisper .................................................. 19

5.2.5 Preparing the Pure (BF80S)................................................................. 21

5.2.6 Preparing the Misty.......................................................................... 22

5.2.7 Preparing the Spectra Nova and Cadra Nova ............................................ 24

5.3 Placing th e applia n c e ....................................................... 25

5.4 Placing th e log set ........................................................... 27

6 Installation of the flue ................................................................ 29

6.1 Connection with use of concentric duct material........................ 29

6.2 Connection onto an existing chimney...................................... 29

6.3 Remote control................................................................ 31

6.3.1 Installation remote control................................................................. 32

6.3.2 Setting the right transmission code....................................................... 32

7 Commisioning (functional checks) ..................................................33

7.1 Check pilot ignition........................................................... 33

7.2 Functional burner check ..................................................... 33

7.3 Functional balanced flue check............................................. 34

7.4 Check reference pressure and burner pressure .......................... 34

8 Final check and handing over........................................................ 36

9 Servicing ......................................... Fout! Bladwijzer niet gedefinieerd.

8.1 Routine servicing.............................................................. 37

8.1.1 Cleaning the glass ........................................................................... 37

8.1.2 Cleaning the combustion chamber and burner.......................................... 38

8.1.3 Burner tray (dis)assembly .................................................................. 38

8.1.4 Gas control block ............................................................................ 39

8.2 Propane conversion........................................................... 39

8.3 Combustion tests.............................................................. 39

8.4 List of spare parts............................................................. 40

User guide.................................................................... 45

9 Safety instructions for the user .....................................................47

9.1 General safety instructions.................................................. 47

10 Controlling the appliance.............................................................49

10.1 General ......................................................................... 49

10.2 To light ......................................................................... 50

10.3 To extinguish .................................................................. 50

10.3.1 When the pilot extinguishes................................................................ 50

10.4 Remote control versions ..................................................... 51

10.4.1 Using the remote control................................................................... 51

UK/IRL

4 < < < <

10.4.2 Setting the right transmission code....................................................... 51

10.4.3 Changing the batteries...................................................................... 52

11 Cleaning and service instructions................................................... 53

12 Disposal of packaging and appliance ............................................... 54

UK/IRL

> > > > 5

2 Introduction

Note: these instructions should be read carefully and retained for

future reference. Please leave these instructions with the user.

This guide is concerning the following types of appliances:

• Widescreen interior: Types Silence and Feeling

• Roundscreen interior: Type Misty

• MV100/MV200 interior: Type Spectra Nova and Whisper

• MV150 interior: Types and Cadra Nova

Special features:

• Realistic flame and glow effect because of the "Log burner"

technology.

• Room sealed appliance, inlet and outlet are led to the outside using a

natural draught concentric pipe system (100 mm/150 mm) (no power

fan required). No additional ventilation required.

• Air supply and flue-gases go to outside atmosphere through wall or

roof. A maximum horizontal extension of 6 meters is possible.

• Remote Control option on all appliances.

• Meets the essential requirements of the European Gas Appliance

Directive (GAD) and carries the CE mark.

UK/IRL

6 < < < <

3 Safety and general information

• Before installation, ensure that the local distribution conditions

(identification of the type of gas and pressure) and the adjustment of

the appliance are compatible.

• This gas appliance is factory set and shall not be adjusted by the

installer.

• This appliance does not contain any component manufactured from

asbestos or any asbestos related products.

• The pilot and flame sensing device fitted to this fire is also a safet y

device. If for any reason any part of the pilot assembly is to be

replaced the entire assembly including the pilot burner,

thermocouple, electrode and injector must be exchanged complete

for a pilot assembly from the original manufacturer only.

Ventilation

This appliance is room-sealed and doesn't require purpose provided

ventilation.

3.1 General safety

It is the law in the UK that all gas appliances, are installed by a

competent person in accordance with the Gas Safety (Installation and

Use) Regulations (as amended), the relevant British Standards for

Installation work, Building Regulations, Codes of Practice and the

manufacturers instructions.

The installation should also be carried out in accordance with the

following where relevant:

• BS5871 Part1 BS5440 Parts 1 & 2 BS1251.

• Building Regulations Document J (as applicable).

Building Regulations and Standards issued as relevant by the Department

of the Environment or the Scottish Development Department.

UK/IRL

> > > > 7

In the Republic of Ireland installation should be carried out in accordance

with IS813, ICP3, IS327, Building Regulations, Codes of Practice, the

manufacturers instructions and any other rules in force.

Failure to comply with the above could leave the installer liable to

prosecution and invalidate the appliance warranty.

Safety instructions for the user: see chapter 9.

UK/IRL

8 < < < <

4 Installation requirements

Note:

Since the appliance is a source of heat, circulation of air occurs.

Therefore it is of importance that you do not use the appliance shortly

after a renovation of the home. Because of the natural circulation of air,

moist and volatile components from paint, building materials, carpet etc.

will be attracted. These components can settle themselves down onto

cold surfaces in the form of soot.

As on all heat producing appliances, soft furnishings such as blown vinyl

wallpaper placed too near to the appliance may become scorched or

discoloured. This should be born in mind when installing the appliance.

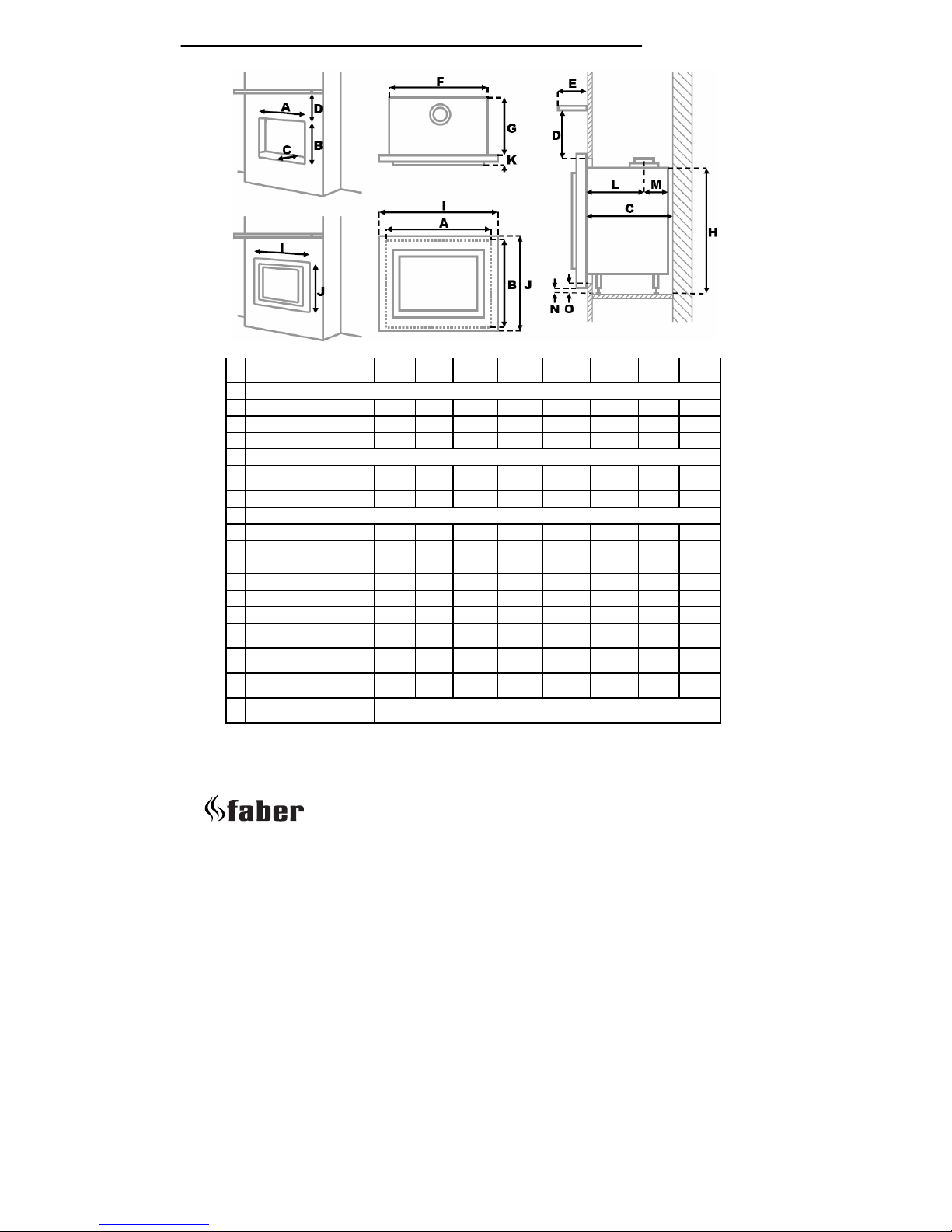

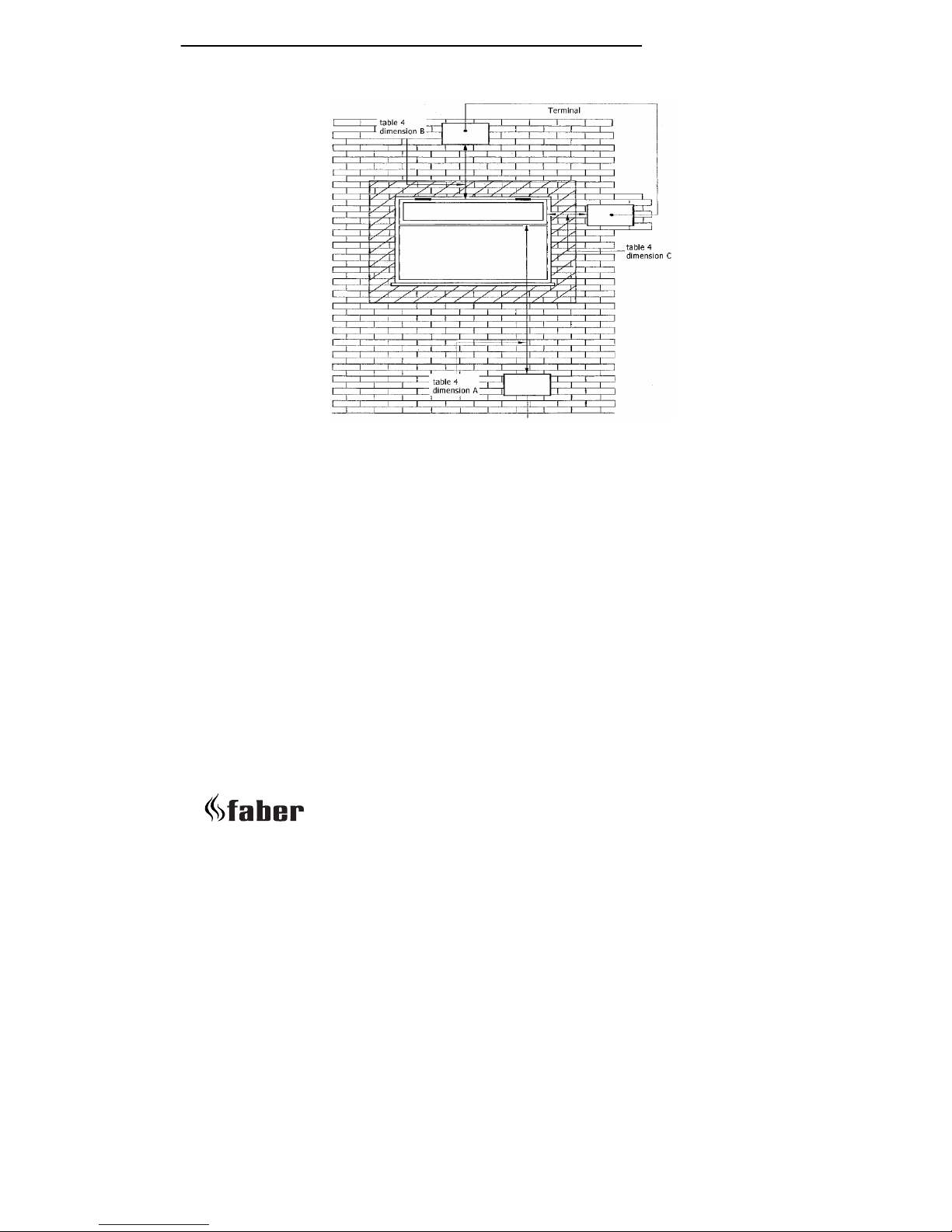

4.1 Builders opening and surround

The appliance can be installed in the following situations:

In a non-combustible fireplace or builders opening. This could be either

an existing builders opening or a new made prefab builders opening. For

the measurements, see figure 1 and index.

Although the appliance is tested for installation without a hearth, the

appliance must not stand on combustible materials or carpets. If the

appliance is placed on a combustible floor then a fibrelux or similar

heatproof board of 12 mm thickness should be placed under it. Any under

floor vents or openings within the builders opening should be sealed off.

Do not place the lintel, surround or marble stone directly onto the

appliance. If possible, apply a lintel made of cement or something similar.

Insulate the appliance with a ceramic blanket (25 mm). See also chapter

4: Installation instructions. Preferred choice for insulation is unbound

insulation wool (at 1000 °C gives no smell).

UK/IRL

> > > > 9

Builders opening (mm) Feeling Sense Silence Pure

(BF80S)

Whisper Spectra

Nova

Cadra

Nova

Misty

Builders opening (mm)

A Opening width

960 960 960 760 780 780 680 710

B Opening height

649 649 649 670 705 698 798 890

C Opening depth (min.)

385 385 385 397 430 430 430 370

Shelf dimensions

D Minimum height shelf

from top frame

350 350 350 350 350 350 350 350

E Depth shelf

150 150 150 150 150 150 150 150

Dimensions of the appliance (mm)

F Box width

880 880 880 750 750 750 650 698

G Box depth

369 366 369 397 397 375 375 338

H Box height

636 636 636 714 714 715 815 879

I Frame width

1064 1136 1064 795 815 794 694 740

J Frame height

678 750 678 795 720 703 803 905

K Frame thickness

47 57 20 35 16 30 30 144

L Position flue collar

measured from frame

255 255 255 255 257 235 235 196

M Position flue collar

measured from back

111 111 111 142 140 140 140 142

N Height underside foot to

underside frame

17 -20 17 -7 8 0 0 ?

O Height underside foot to

builders opening

≥ N (=dimensions in the row above)

tabel 1

*point A to C have a tolerance of -0 mm and +5 mm.

UK/IRL

10 < < < <

If the builders' opening is constructed out of non-combustible composition

board (Fibrelux) and you install the appliance without a mantel then:

• Ventilate the space above the appliance (min. 1000 mm2 ).

• Always fit the DC convection set.

• The plaster of the outside has to be resistant to a high temperature.

Use therefore the plaster materials especially made for this, to

prevent discoloring (min. 100 °C temperature resistant).

• Make sure the plaster dries well: 1 day for every millimetre plaster

applied, e.g. 4 mm plaster should dry for at least 4 days before the

appliance is used.

If the appliance is to be fitted against a wall with combustible cladding,

the cladding must be removed from the area covered by the surround.

The minimum height from the top surface of the fire to the underside of

any shelf made from wood or other combustible materials is as follows:

• For a shelf up to 150 mm deep – Minimum height = 350 mm (fig. 1).

• If the shelf depth is greater than 150 mm add 50 mm to the

upperclearance height for every 25 mm increase in shelf depth.

• Side clearance = Minimum distance from the side of the fire frame to

combustible material = 150 mm.

4.2 Flue requirements

• The appliance is of the type C11/C31. The appliance will need to be

supplied with the approved flue pipes and terminal, it is not possible

to supply your own.

• The minimum effective height of the flue system must be 0.5 or 1

meter, depending on the appliance.

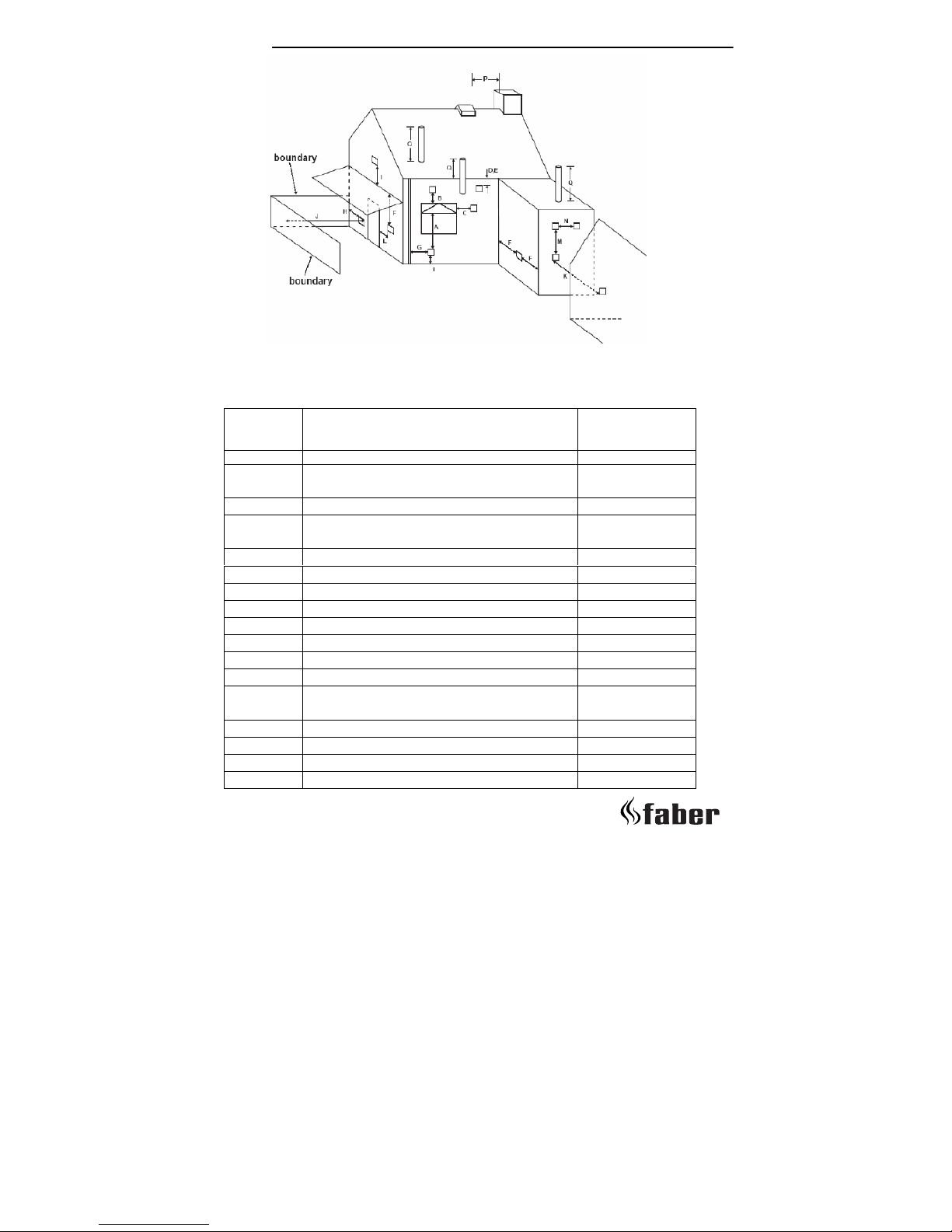

• Terminal locations, through the wall and roof. See fig. 3.

Flue routing;

• a horizontal extension with elbows is allowed for a maximum of 6

meters (depending on the type and situation).

• vertical max. 12 meters.

UK/IRL

> > > > 11

Determine on the base of the table 2 and 3, depending on the type and

terminal position, if the desired situation is possible. To establish this you

will need to calculate:

• The effective height (this is the real difference in height between the

upper side of the appliance and the terminal).

• The total horizontal flue length, where:

à each elbow, which is in the horizontal area, counts for 2 meters.

à each 45°-bend, which is in the horizontal area, counts for 1 m

à elbows and bends at the transition of horizontal to vertically are

not to be counted.

à the wall mounted terminal counts for 1 meter.

Flue restrictor

If applicable, in the table is also stated the size of a flue restrictor. This

restrictor needs to be fitted in the combustion chamber when placing the

appliance (see chapter 4.2). Normally the smallest flue restrictor is fitted.

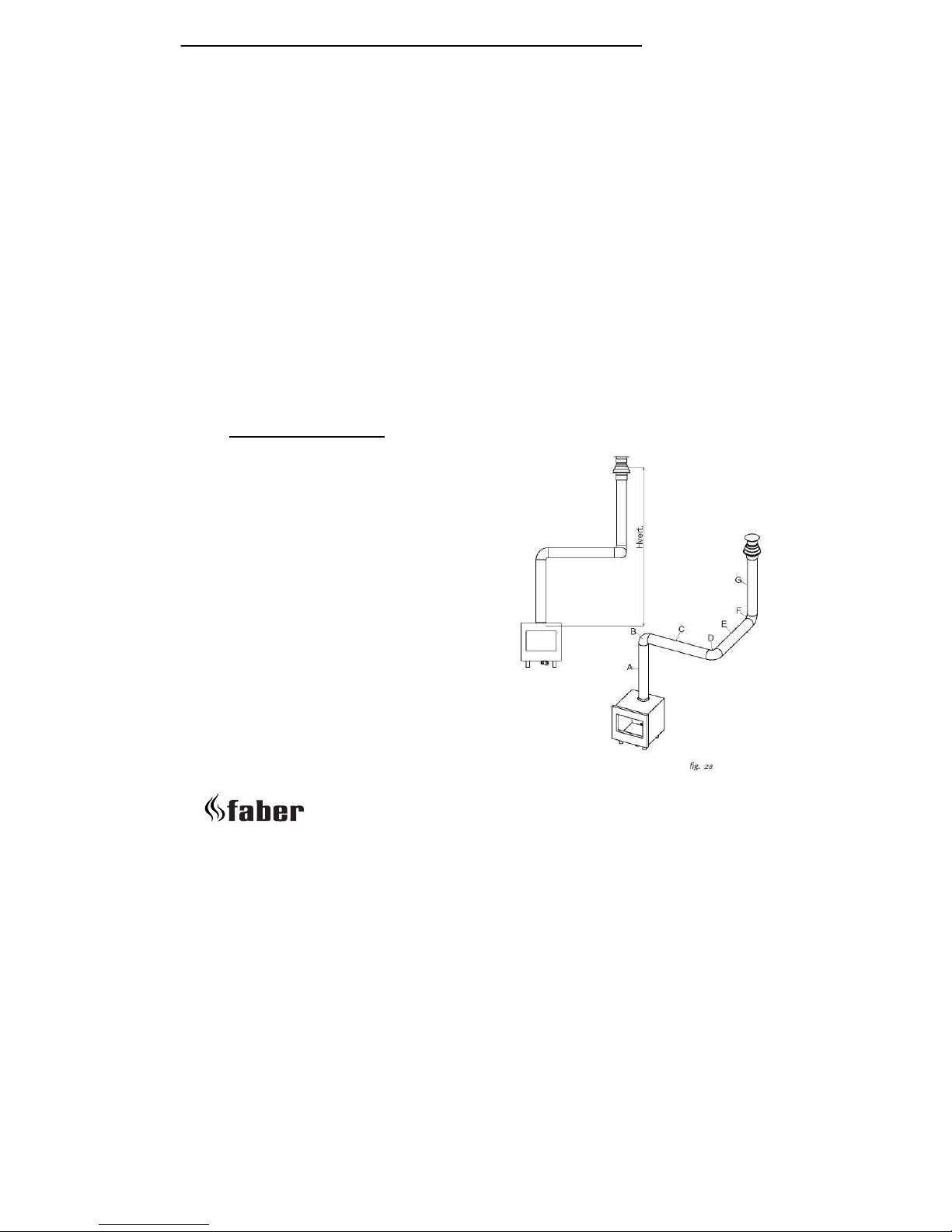

Example calculation 1:

Calculating horizontal extension fig. 2a:

Flue lenght C + E = 1m + 1m 2 m

Elbows D = 2m 2 m

Total horizontal extension 4 m

Measure or calculate effective height

(Hvert)

Flue lenght A 1 m

Roof mounted terinal 1 m

Total effective height 2 m

When calculating on basis of the

Widescreen table nr. 2: It is allowed.

Remove the flue restrictor!

When calculating on basis of the MV100

table nr. 3: Allowed but without flue

UK/IRL

12 < < < <

restrictor. Remove the flue restrictor!

When calculating on basis of theMV150 table nr. 4: Allowed but without

flue restrictor. Remove the flue restrictor!

When calculating on basis of the Roundscreen table nr. 5: Allowed but

without flue restrictor. Remove the flue restrictor!

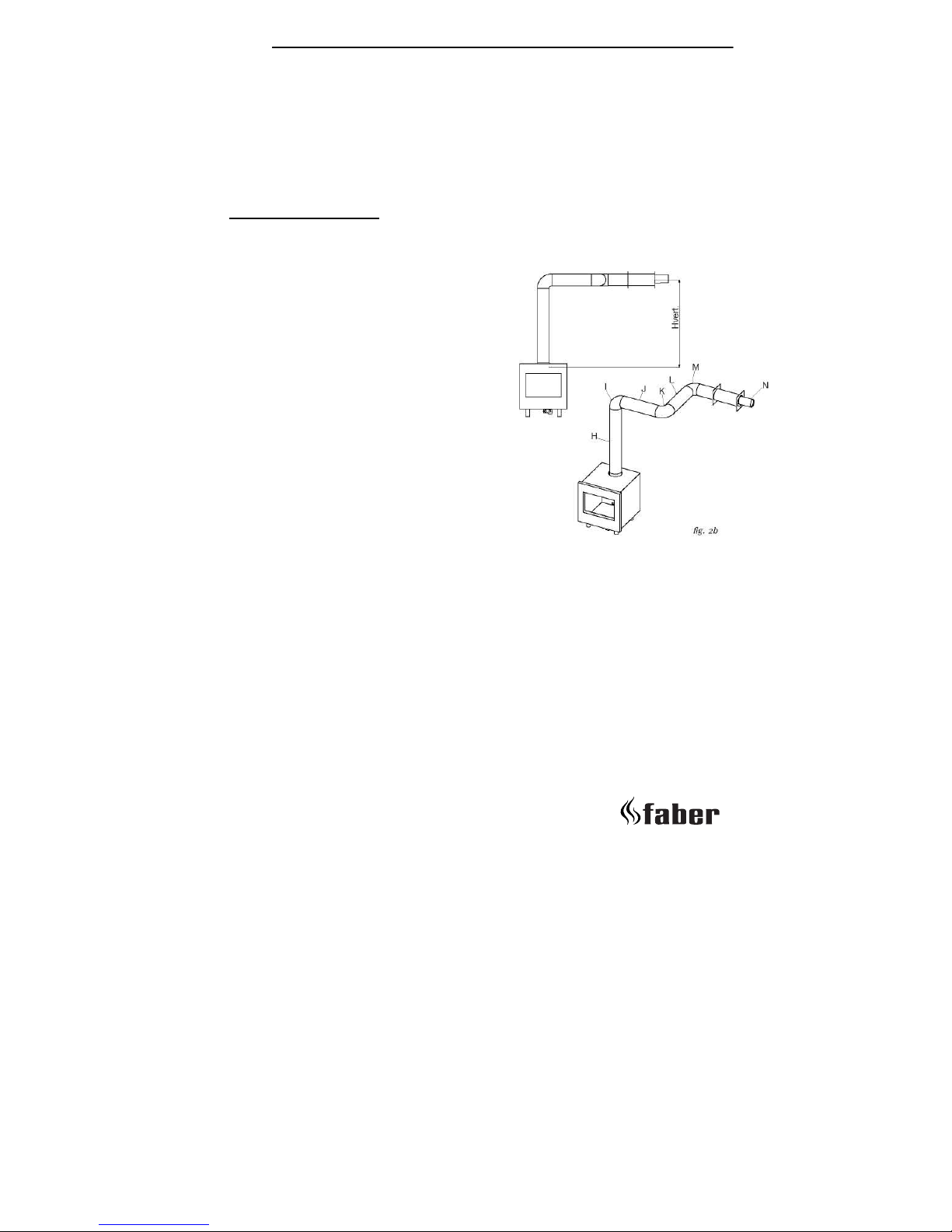

Example calculation 2

Calculation horizontal extension fig. 2b:

Flue lenght J + L = 0,5 + 0,5 1 m

Elbows K + M = 2m + 2m 4 m

Terminal 1 m

Total horizontal extension 6 m

Calculation effective height (Hvert)

Flue lenght H 1 m

When calculating on basis of the

Widescreen table nr. 2: Combination not

allowed.

When calculating on basis of the MV100

table nr. 3: Allowed but without flue

restrictor. Remove the flue restrictor!

When calculating on basis of the MV150

table nr. 4: Combination not allowed.

When calculating on basis of the Roundscreen table nr. 5: Combination

not allowed.

4.3 Tables for determining the right flue restrictor

Calculate the total horizontal- and vertical length of the flue, according

to the calculations displayed above. Determine according to tables 2, 3, 4

and 5 on the following pages the right flue restrictor size. When meeting

an X, and when the values are outside the table, the combination is not

allowed. Normally the 30 mm flue restrictor is preinstalled.

UK/IRL

> > > > 13

0123456

0XXXXXXX

100XXXXX

1,50000XXX

2303000000

3 45453030 0 0 0

4 4545303030 0 0

5 505045303030 0

6 505045303030 0

7 606050454530 X

8 6060605050 X X

9 65656060 X X X

10656565XXXX

116565XXXXX

1265XXXXXX

0123456

0XXXXXXX

130000000/X*

2303000000

3 454530 0 0 0 0

4 454530 0 0 0 0

5 5050454530 0 0

6 5050454530 0 0

7 606060505045 X

8 6060606050 X X

9 65656060 X X X

10656565XXXX

116565XXXXX

1265XXXXXX

Table 2: Widescreen (Feeling, Silence, Sense)

Vertical length in m

Table 3: MV200 (Pure (BF80S), Spectra Nova, Whisper)

Horizontal length in m

Vertical length in m

The numbers in the table

represent the width in mm of the

flue restrictor

X Combination NOT allowed

0 remove flue restrictor

The numbers in the table

represent the width in mm of the

flue restrictor

X Combination NOT allowed

0 remove flue restrictor

Horizontal length in m

UK/IRL

14 < < < <

0123456

0XXXXXXX

0,5X0XXXXX

1X3000000

2403000000

3 404030 0 0 0 0

4 50404030 0 0 0

5 505040403030 0

6 505050404030 0

7 605050404040 X

8 6060505050 X X

9 60606050 X X X

10656060XXXX

116565XXXXX

1265XXXXXX

0123456

0XXXXXXX

0,5X0XXXXX

1X3000000

0,5403000000

2403000000

3404000000

4 50404030 0 0 0

5 505040403030 0

6 505050404030 0

7 605050404040 X

8 6060505050 X X

9 60606050 X X X

10656060XXXX

116565XXXXX

1265XXXXXX

Tabel 4: binnenwerk MV150 (Cadra Nova)

Vertical length in m

Tabel 5: binnenwerk Roundscreen (Misty)

Vertical length in m

Horizontal length in m

Horizontal length in m

The numbers in the table

represent the width in mm of the

flue restrictor

X Combination NOT allowed

0 remove flue restrictor

The numbers in the table

represent the width in mm of the

flue restrictor

X Combination NOT allowed

0 remove flue restrictor

UK/IRL

> > > > 15

4.3.1 Terminal position

Verify if the required terminal position meets the local installation

regulations regarding disturbance, good functioning and ventilation. (Also

see: safety requirements).

Note:

The terminal must be located so that the outlet is not obstructed. If the

flue terminal is located within 2 meters of a footway, path or where

people could come into contact with it then a suitable terminal guard

must be fitted.

Terminals located close to shared walkways, footpaths etc. could be

subject to legal constraints and this should be pointed out to the

customer before installation. If in any doubt about flue location advice

should be sought from local building control, or if appliancerelated, from

the manufacturer including wherever possible a dimensioned sketch.

Avoid locating the terminal in close proximity to plastic materials such as

gutters or other combustibles. If this is unavoidable then a suitable

deflector should be made.

Some important requirements for a good functioning are:

The wall-mounted terminal has to be at least 0,5 m off:

à Corners of the building.

à Below eaves.

à Balcony's etc. unless the duct is dragged to the front side of the

overhanging part.

The roof mounted terminal has to be at a distance of at least 0.5 meters

of the sides of the roof, excluded the ridge.

UK/IRL

16 < < < <

Dimension Terminal position

(kW input 7.5 kW expressed in net)

Balanced flue

room sealed

Natural Draught

A Direct below an opening, airbrick, opening

windows, etc.

300 mm

B Above an opening, airbrick, opening window, etc. 300 mm

C Horizontally to an opening, airbrick, opening

window, etc.

300 mm

D Below gutters, soil pipes or drain pipes 500 mm

E Below eaves 500 mm

F Below balconies or cat port roof 600 mm

G From a vertical drain pipe or soil pipe 300 mm

H Dfrom an internal or external corner 600 mm

I Above ground roof or balcony level 300 mm

J From a surface facing the terminal 600 mm

K From a terminal facing a terminal 600 mm

L From an opening in the carport (e.g. window) into

the dwelling

1200 mm

M Vertically from a terminal on the same wall 1500 mm

N Horizontally from a terminal on the same wall 300 mm

P From a vertical structure on the roof 600 mm

Q Above intersection with roof 500 mm

Flue terminal

Fig. 3

Tabel 6

UK/IRL

> > > > 17

4.3.2 Using an existing chimney as air inlet

You can connect the appliance onto an existing chimney. The existing

chimney then functions as air supply, where a flexible stainless steelliner

(to BS715) of 100 mm performs the flue function.

Requirements:

• Any existing chimney used as an air supply must only service this

appliance.

• A chimney that has previously been used for solid fuel must be swept

before use.

• The existing chimney needs to be airtight.

• The existing chimney needs to have an opening of min. 150 x 150 mm.

• The chimney needs to be intact and well looked after.

• Use the adjustable roof-mounted-terminal especially made for this,

and the chimney connection set.

• The minimum distance between two terminals should be at least 450

mm.

Example of how terminal position is measured

Fig. 4

Loading...

Loading...