Page 1

844

Slide Gate Operator

FAAC International Inc.

Headquarter & East Coast Operations

5151 Sunbeam Road

Suites 9-11

Jacksonville, FL 32257

Tel. 866 925 3222

www.faacusa.com

FAAC International Inc.

West Coast Operations

357 South Acacia Avenue

Unit 357

Fullerton, CA 92831

Tel. 800 221 8278

Page 2

CONTENTS

IMPORTANT SAFETY INFORMATION 4

Important Safety Instructions 4

Important Installation Instructions 4

General Safety Precautions 5

UL325 Gate Operator Classications 6

Installing the Warning Signs 6

1. DESCRIPTION & SPECIFICATIONS 7

1.1. MAXIMUM USE CURVE 7

1.2 TECHNICAL SPECIFICATIONS 8

2. DIMENSIONS 8

3. ELECTRIC EQUIPMENT (STANDARD) 8

4. INSTALLING THE SYSTEM 9

4.1. PRELIMINARY CHECKS 9

4.2. FOUNDATION PLATE INSTALLATION 9

4.5. INSTALLATION OF CHAIN PINIONS 11

5. CONTROL BOARD 780D 12

5.1. WARNINGS 12

5.2. 780D TECHNICAL SPECIFICATIONS 12

5.3. LAYOUT AND COMPONENTS 12

5.4. ELECTRIC CONNECTIONS 13

5.5. PROGRAMMING 16

6. START-UP 19

6.1. ELECTRIC CONNECTIONS 19

6.2. DEFINITION OF OPENING DIRECTION AND OPERATION OF LIMIT-SWITCH LEDS 19

6.3. DETERMINING STOP POINTS AT TRAVEL LIMIT 19

6.4. CHECK OF INPUTS 20

6.5. CHECK OF MOTOR CONNECTION 20

6.6. MECHANICAL CLUTCH ADJUSTMENT 20

6.7. CHECK OF STOP POINTS 20

6.8. SAFETY DEVICES AND ACCESSORIES CHECK 20

7. FINAL OPERATIONS 20

8. MANUAL OPERATION 21

9. RESTORING NORMAL OPERATION 21

10. MAINTENANCE 21

11.1. DISASSEMBLING THE TRANSFORMER-BOARD UNIT 21

11.2. OIL TOP-OFFS 21

12. REPAIRS 21

13. 844 SPARES DIAGRAM 24

14. TROUBLESHOOTING 26

FAAC MODEL 844 Slide Gate Operator

2

Page 3

LIMITED WARRANTY 27

Read this instruction manual before you begin installing the product.

= Information regarding personal safety and proper maintanence of the product.

FAAC Model 844 - Rev: 01 - December 2010

3

FAAC MODEL 844 Slide Gate Operator

Page 4

IMPORTANT SAFETY INFORMATION

Important Safety Instructions

WARNING: TO REDUCE THE RISK OF SEVERE

INJURY OR DEATH:

• READ AND FOLLOW ALL INSTRUCTIONS.

• Never let children operate or play with the gate

controls. Keep remote controls away from children.

• Always keep people and objects away from the

gate. NO ONE SHOULD CROSS THE PATH OF A

MOVING GATE.

• Test the gate operator monthly. The gate MUST

reverse on contact with a rigid object or when an

object activates a non-contact sensor. If necessary,

adjust the force or the limit of travel and then retest

the gate operator. Failure to properly adjust and retest

the gate operator can increase the risk of injury or

death.

• Use the manual release mechanism only when the

gate is not moving.

• KEEP GATE PROPERLY MAINTAINED. Have

a qualied service person make repairs to gate

hardware.

• The entrance is for vehicles only. Pedestrians must

use a separate entrance.

• SAVE THESE INSTRUCTIONS.

Important Installation Instructions

1. Install the gate operator only when the following conditions have been met:

• The operator is appropriate for the type and usage

class of the gate.

• All openings of a horizontal slide gate have been

guarded or screened from the bottom of the gate to

a minimum of 4 feet (1.25 m) above the ground to

prevent a 2.25 inch (55 mm) diameter sphere from

passing through openings anywhere in the gate or

through that portion of the adjacent fence that the gate

covers when in the open position.

• All exposed pinch points are eliminated or guarded.

• Guarding is supplied for exposed rollers.

2. The operator is intended for installation on gates used by

vehicles only. Pedestrians must be provided with a separate access opening.

3. To reduce the risk of entrapment when opening and

closing, the gate must be installed in a location that allows

adequate clearance between the gate and adjacent structures. Swinging gates shall not open outward into public

access areas.

4. Before installing the gate operator, ensure that the gate

has been properly installed and that it swings freely in

both directions. Do not over-tighten the operator clutch or

pressure relief valve to compensate for a damaged gate.

5. User controls must be installed at least 6 feet (1.83 m)

away from any moving part of the gate and located where

the user is prevented from reaching over, under, around or

through the gate to operate the controls. Controls located

outdoors or those that are easily accessible shall have

security features to prevent unauthorized use.

6. The Stop and/or Reset buttons must be located within

line-of-sight of the gate. Activation of the reset control

shall not cause the operator to start.

7. All warning signs and placards must be installed and

easily seen within visible proximity of the gate. A minimum

of one warning sign shall be installed on each side of the

gate.

8. For gate operators that utilize a non-contact sensor (photo

beam or the like):

• See instructions on the placement of non-contact

sensors for each type of application.

• Exercise care to reduce the risk of nuisance tripping,

such as when a vehicle trips the sensor while the gate

is still moving.

• Locate one or more non-contact sensors where the

risk of entrapment or obstruction exists, such as at the

reachable perimeter of a moving gate or barrier.

• Use only FAAC “Photobeam” photoelectric eyes to

comply with UL325.

FAAC MODEL 844 Slide Gate Operator

4

Page 5

Important Installation Instructions (continued)

9. For gate operators that utilize a contact sensor (edge

sensor or similar):

• Locate one or more contact sensors where the risk

of entrapment or obstruction exists, such as at the

leading edge, trailing edge, and post mounted both

inside and outside of a vehicular horizontal slide

gate

• Locate one or more contact sensors at the bottom

edge of a vehicular vertical lift gate.

• Locate one or more contact sensors at the bottom

edge of a vertical barrier (arm).

• Locate one or more contact sensors at the pinch

point of a vehicular vertical pivot gate.

• Locate hard-wired contact sensors and wiring so

that communication between sensor and gate

operator is not subjected to mechanical damage.

• Locate wireless contact sensors, such as those

that transmit radio frequency (RF) signals, where

the transmission of signals are not obstructed or

impeded by building structures, natural landscaping

or similar hindrances. Wireless contact sensors shall

function under their intended end-use conditions.

• Use only FAAC MSE MO, CN60 or M60 edge

sensors.

General Safety Precautions

Gate Construction

Vehicular gates should be constructed and installed in

accordance with ASTM F2200: Standard Specication for

Automated Vehicular Gate Construction.

For more information, contact ASTM at: www.astm.org

Installation

• If you have any questions or concerns regarding the

safety of the gate operating system, do not install the

operator and consult the manufacturer.

• The condition of the gate structure itself directly affects

the reliability and safety of the gate operator.

• Only qualied personnel should install this equipment.

Failure to meet this requirement could cause severe

injury and/or death, for which the manufacturer cannot

be held responsible.

• The installer must provide a main power switch that

meets all applicable safety regulations.

• It is extremely unsafe to compensate for a damaged

gate by increasing hydraulic pressure.

• Install devices such as reversing edges and photo

beams to provide better protection for personal property

and pedestrians. Install reversing devices that are

appropriate to the gate design and application.

• Before applying electrical power, ensure that voltage

requirements of the equipment correspond to the supply

voltage. Refer to the label on your gate operator system.

Usage

• Use this equipment only in the capacity for which it was

designed. Any use other than that stated should be

considered improper and therefore dangerous.

• The manufacturer cannot be held responsible

for damage caused by improper, erroneous or

unreasonable use.

• If a gate system component malfunctions, disconnect

the main power before attempting to repair it.

• Do not impede the movement of the gate, you may

injure yourself or damage the gate system as a result.

• This equipment may reach high thermal temperatures

during normal operation, therefore use caution when

touching the external housing of the gate operator.

• Use the manual release mechanism according to the

procedures presented in this manual.

• Before performing any cleaning or maintenance

operations, disconnect power to the equipment.

• All cleaning, maintenance or repair work must performed

by qualied personnel.

5

FAAC MODEL 844 Slide Gate Operator

Page 6

UL325 Gate Operator Classications

RESIDENTIAL VEHICULAR GATE OPERATOR CLASS I

A vehicular gate operator system intended for use in a single family dwelling, garage or associated parking area.

COMMERCIAL / GENERAL ACCESS VEHICULAR GATE OPERATOR CLASS II

A vehicular gate operator system intended for use in commercial locations or buildings such as multi-family housing

units (ve or more single family units), hotels, parking garages, retail stores or other buildings that service the general

public.

INDUSTRIAL / LIMITED ACCESS VEHICULAR GATE OPERATOR CLASS III

A vehicular gate operator system intended for use in industrial locations or buildings such as factories, loading docks

or other locations not intended to service the general public.

RESTRICTED ACCESS VEHICULAR GATE OPERATOR CLASS IV

A vehicular gate operator system intended for use in guarded industrial locations or buildings such as airport security

areas or other restricted access locations that do not service the general public, and in which unauthorized access is

prevented via supervision by security personnel.

Installing the Warning Signs

This FAAC swing gate operator is supplied with two

warning signs to alert people that a possible hazard

exists and that appropriate actions should be taken

to avoid the hazard or to reduce exposure to it.

Permanently install one warning sign on each side

of the gate so they are fully visible to trafc and

pedestrians.

Use appropriate hardware such as metal screws

(not supplied) to permanently install each warning

sign.

FAAC MODEL 844 Slide Gate Operator

6

Page 7

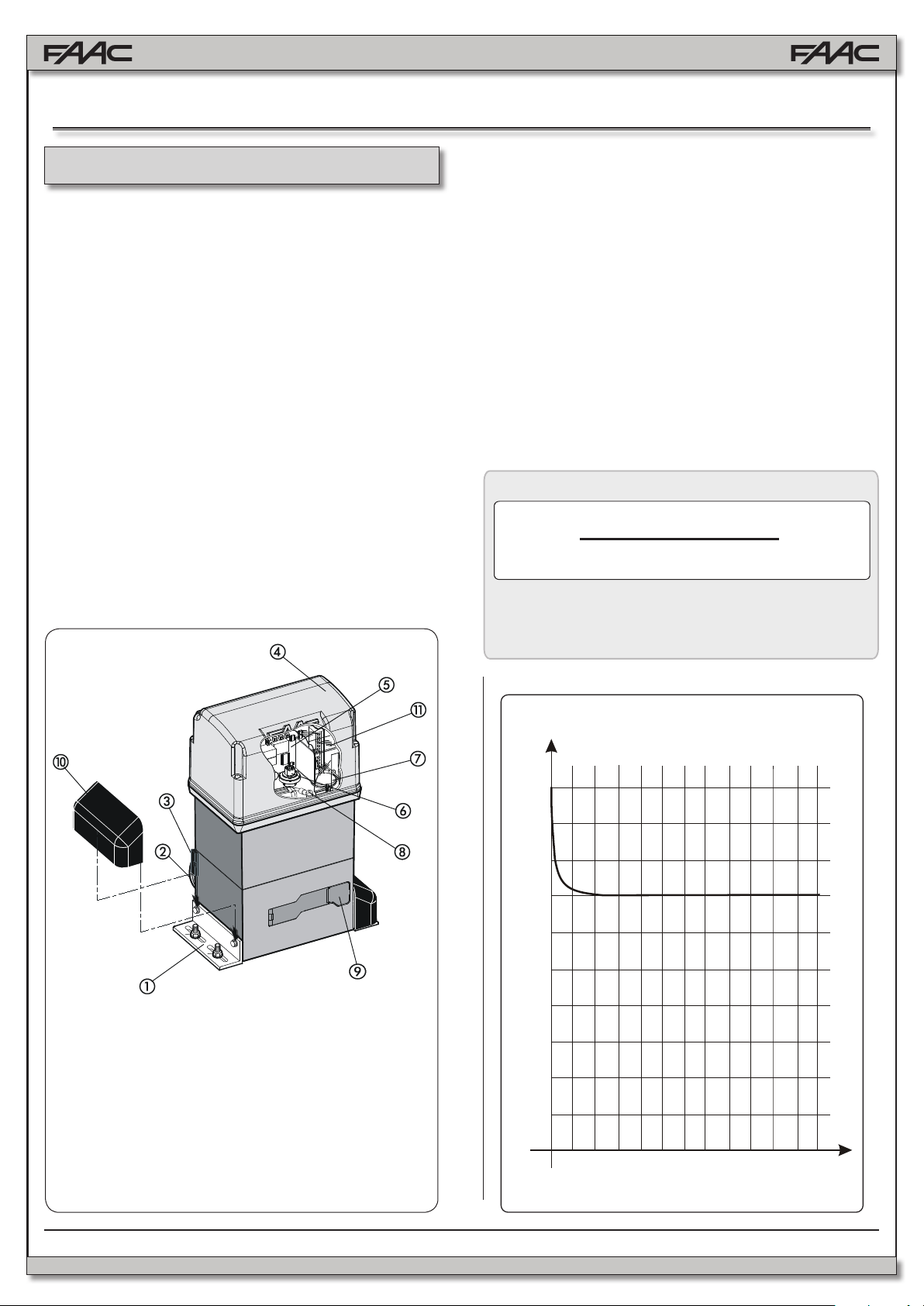

MODEL 844 OPERATOR

1. DESCRIPTION & SPECIFICATIONS

These instructions apply to the following models:

844 ER Z16 CR, 844 R, 844 R CAT, 844 R RF

The FAAC Model 844 automated system for sliding

gates is an electro-mechanical operator transmitting

motion to the sliding leaf via a rack or chain pinion

appropriately coupled to the gate.

The non-reversing system ensures the gate is

mechanically locked when the motor is not operating

and, therefore, no lock needs to be installed.

The gearmotor is equipped with a mechanical

clutch which, combined with an electronic device,

offers the necessary adjustable anti-crushing

safety and guarantees stopping or reversing the

gate movement. A handy manual release makes it

possible to move the gate in the event of a power

cut or malfunction. The control board, if supplied

with the gearmotor, it is placed inside the operator.

The 844 automated system was designed and

manufactured to control access of vehicles. Avoid

any other use whatever.

Fig. 1

1.1. MAXIMUM USE CURVE

The curve makes it possible to establish maximum

work time (T) according to use frequency (F). The

844 gearmotor can operate non-stop at 70% use

frequency.

To ensure efcient operation, operate in the work

range below the curve.

Important: The curve is obtained at a temperature

of 75°F. Exposure to direct sunlight can reduce use

frequency down to 20%.

Calculating Use Frequency

The percentage of effective work time (opening +

closing) compared to total time of cycle (opening +

closing + pause times).

Calculation Formula

%F =

Where: Ta = opening time

Tc = closing time

Tp = pause time

Ti = time of interval (between 2 complete cycles)

Ta + Tc

Ta + Tc + Tp + Ti

X 100

1 Mounting Brackets

2 Pinion

3 Limit Sensor Switch

4 Operator Cover

5 780 D Control Board

6 Adjustment Screw for

Anti-crushing Clutch

7 Oil Filling Plug

8 Operator Grounding

9 Lever Operated Release

System

10 Protective Side Co

11 Cover for 780D Control

Board

100

90

80

70

60

50

40

30

20

10

Use Frequency Graph

% Freq. Used % Duty Cycle

12 3456789101112

0

Time (h)

7

FAAC MODEL 844 Slide Gate Operator

Page 8

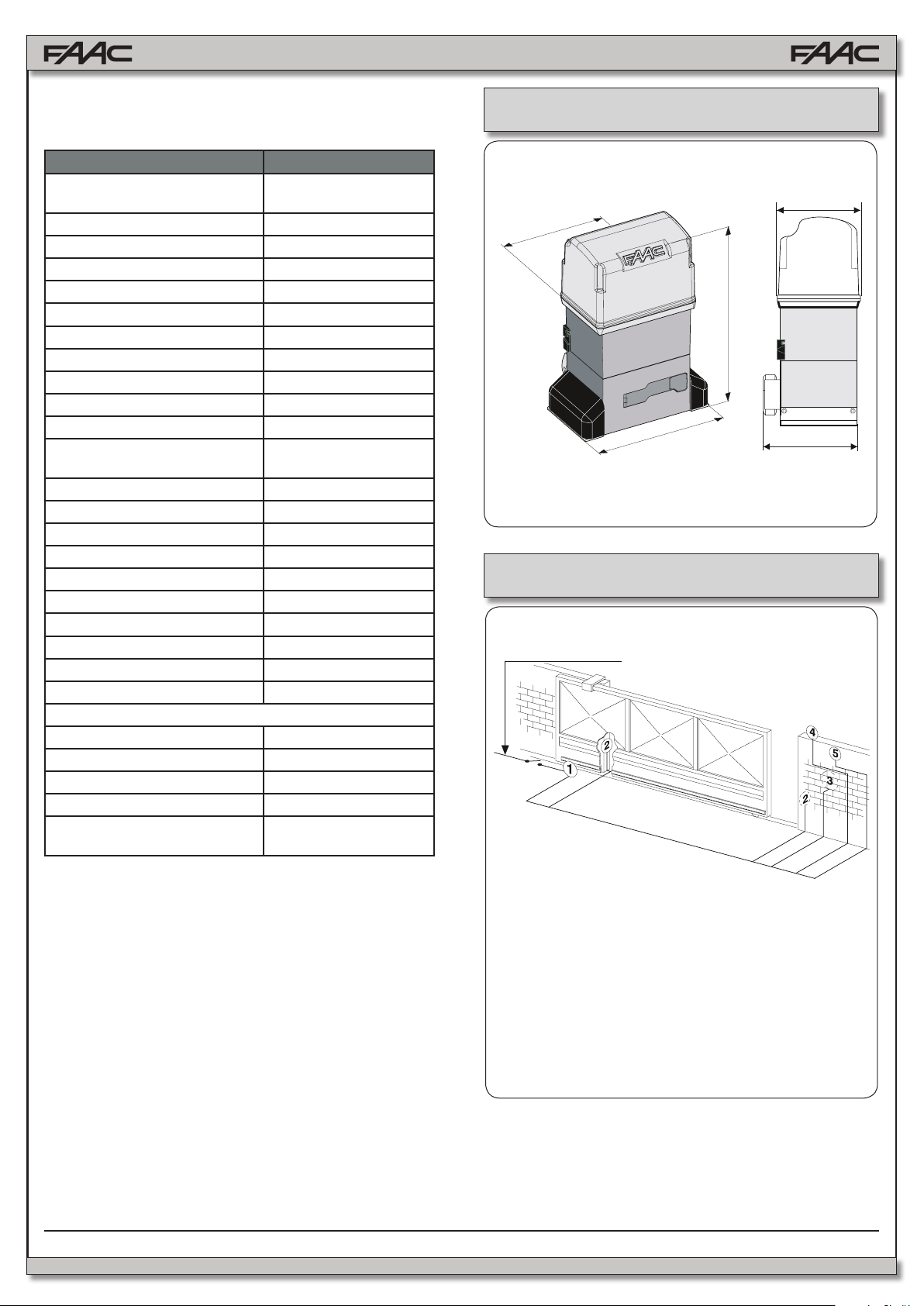

1.2 TECHNICAL SPECIFICATIONS

6

- Measurements in Inches

TABLE 1: SPECIFICATIONS FOR 844 OPERATOR

2. DIMENSIONS

MODEL

Power Supply (VAC +6% -10%

844

115 or 230

60Hz)

Absorbed Power (W)

Reduction Ratio

Type of Pinion

650

1 : 30

Z16 - Z20

Rack Module 4 - step 12.566

Max. Thrust (lbF)

Max. Torque (lbF/ft)

Winding Thermal Protection (°F)

250 (Z16) - 180 (Z20)

26

248

Use Frequency 70% (see graph)

Oil Quantity (Gallons)

Type of Oil

Ambient Operating Temperature

0.5

FAAC XD 220

-4 to +131

(°F)

Weight (lbs)

Protection Class

Gate Max. Weight (lbs)

Gate Speed (feet/min)

Gate Max. Length (feet)

32

IP 44

3950 (Z16) - 2200 (Z20)

32 (Z16) - 40 (Z20)

132 (Z16) - 164 (Z20)

Clutch twin-disk in oil bath

Protective Treatment cataphoresis

Control Board

780D

Limit-Switch magnetic or inductive

Overall Dimensions LxHxD (inches)

See Fig. 2

Electric Motor Technical Specications

RPM

Power (W)

Absorbed Current (A)

Starting Capacitor (µF)

Power Supply (VAC +6% -10%;

1700

650

3.5 (230V) ; 7 (115V)

35 (230V) ; 70 (115V)

115 or 230

60Hz)

Fig. 2

8 ¾

15 ¼

10 ¾

7 ½

3. ELECTRIC EQUIPMENT (STANDARD)

Fig. 3

VAC ~ 15 AWG

20 AWG

20 AWG

20 AWG

15 AWG

20 AWG

FAAC MODEL 844 Slide Gate Operator

Operator 844 with 780D equipment

Photocells

Key-operated push-button

Flashing lamp

Radio receiver

8

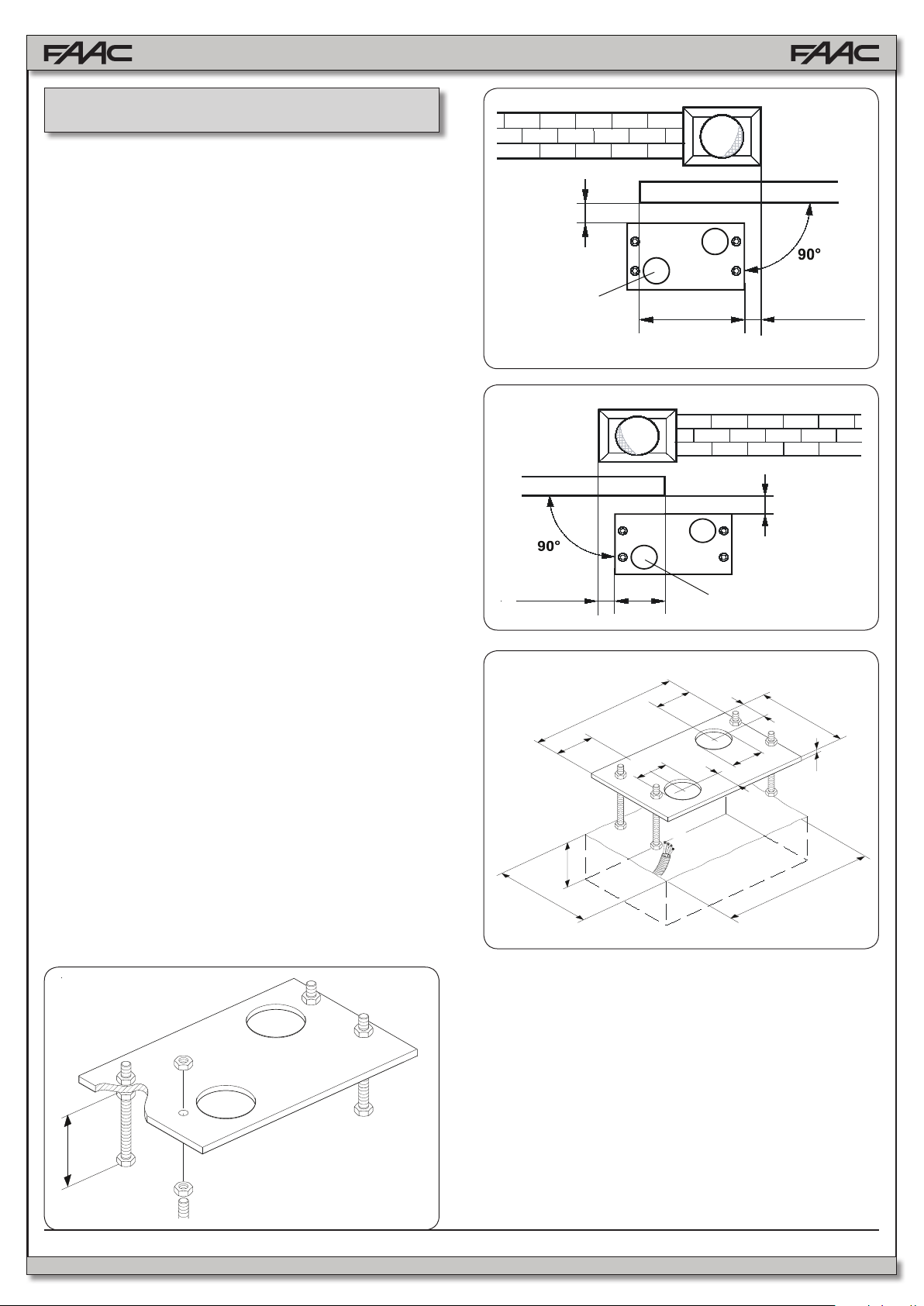

Page 9

¾0

4. INSTALLING THE SYSTEM

4.1. PRELIMINARY CHECKS

To ensure safety and an efciently operating automated

system, make sure the following conditions are observed:

• The gate structure must be suitable for automation. For

example, wheel diameter must be in proportion to the

weight of the gate to be automated, an upper guide must

be provided, mechanical stop limits to prevent the gate

derailing must be installed.

• The soil must permit sufcient stability for the concrete

pad.

• There must be no pipes or electric cables in the pad

excavation area.

• If the operator is exposed to passing vehicles, install, if

possible, adequate means of protection against accidental impact.

• Check if an efcient grounding is available for connection to the gearmotor.

2

- Measurements in Inches

Fig. 5

Fig. 6

8

to 2

4.2. FOUNDATION PLATE INSTALLATION

1. Assemble the foundation plate as shown in Fig 4. The

foundation plate must be located as shown in Fig 5 (right

closing) or Fig 6 (left closing) to ensure that the rack and

pinion mesh correctly.

2. Prepare a concrete pad as shown in Fig.7, following

the suggested dimensions. It’s recommended to have

the pad a minimum of 4” above level grade to avoid any

ooding of the operator. The underground depth of the

concrete pad is determined by the soil condition and

the local building codes. Make sure the concrete pad is

leveled.

3. Provide one or more conduit pathways for all power and

accessory connections. Extend the conduit about of 1/2”

above the level of the concrete pad.

4. After the concrete is poured in the forms and before it

has a chance to set, insert the foundation plate into the

cement and position it ush with the top of the concrete

and aligned with the top of the lower gate frame. Use the

dimensions shown in Figs 5 or 6 to align your foundation plate. Allow the concrete to set for a minimum of two

days before installing the operator.

5. Route the wires in the conduits. To facilitate the connections allow for about 15” of extra length of cables out of

the conduit. Separate the high and low voltage wires in

different conduits.

0 to 2

Fig. 7

7

2

6

3

11.5

3

2⅜

4

- Measurements in Inches

1.75

2⅜

1.75

- Measurements in Inches

6.25

0.25

12.25

9

Fig. 4

2.5

4.3. MECHANICAL INSTALLATION

1. Assemble the mounting brackets and anti-vibration spacers on the operator as shown in Fig. 8.

2. Open the cover, remove the securing screws.

3. Attach the operator to the plate, using the supplied washers and nuts as shown in Fig. 9.

4. During this operation, route cables through the opening inside the lower half-casing of the operator (Fig.10 - Ref. A).

To access the electronic equipment, route the cables through

the appropriate hole, using the supplied rubber cable-clamp.

Make sure to strip the jacket on all cables so that the clamp

holds single cables only (Fig.10 - Ref. B).

FAAC MODEL 844 Slide Gate Operator

Page 10

4 ⅜ (Z16)

5. Secure the operator to the foundation plate, tighten nuts as

shown in Fig. 12.

6. Prepare the operator for manual operating mode as described in

Section 8.

Fig. 8

Fig. 9

15 ¾

Fig. 12

4.4. INSTALLING THE RACK

4.4.1. STEEL RACK TO WELD (Fig. 13)

1. Place the three

threaded dowel nuts

on the rack element,

positioning them at

the top of the slot.

In this way, the slot

play will allow any

adjustments to be

made.

2. Manually move the

leaf to its closed

position.

3. Lay the rst piece of rack level on the pinion and weld the

threaded dowel nut to the gate as shown in Fig. 15.

4. Move the gate manually, checking that the rack is resting on the

pinion, then weld the second and third dowel nut.

5. Place another rack element next to the previous one, use a

third piece of rack (as shown in Fig. 16) to synchronize the

teeth of the rst two elements.

6. Move the gate manually and weld the three threaded dowel

nuts. Proceed as described until the gate is fully covered.

Fig. 13

- Measurements in Inches

4 ¾ (Z20)

2 ½

FAAC MODEL 844 Slide Gate Operator

Fig. 10BFig. 10A

2

- Measurements in Inches

Fig. 11

⅝ to 1 ¼

4.4.2. STEEL RACK TO SCREW (Fig. 14)

1. Manually move the

leaf to its closing

position.

2. Lay the rst piece

of rack level on

the pinion and

place the spacer

between the rack

and the gate,

positioning it at the

top of the slot.

3. Mark the drilling point on the gate. Drill a Ø ¼ inch hole and apply thread with a Ø 5/16 inch male tap. Screw in the bolt.

4. Move the gate manually, checking that the rack is resting on the

pinion. Repeat step 3.

5. Place another rack

element next to the

previous one, use

a third piece of rack

(as shown in Fig. 16)

to synchronize the

teeth of the rst two

elements.

6. Move the gate

manually and

secure the rst

element. Proceed as

previously described

until the gate is fully

covered.

Fig. 14

Fig. 15

10

Page 11

1

Fig. 16

⅛ to ½

Notes on Rack Installation

• Make sure that, during gate travel, no rack elements derail

from the pinion.

• Do not, for any reason, weld the rack elements either to

the spacers or to each other.

• When the rack has been installed, to ensure that it

meshes correctly with the pinion, lower the gearmotor

position by about 1/16

inch (Fig. 17).

• Manually check that

the gate regularly

inch

16

reaches the

mechanical stop limits

and make sure there

is no friction during

gate travel.

Fig. 17

4.5.2. MODEL 844 ER RF (Figs. 20 & 21)

1. Insert the pin g on the shaft, using a hammer.

2. Fit the idle transmissions bracket on the operator ange, using

the four screws a (M5 x 12) and the appropriate washers b, in the

kit as shown in Fig. 20.

3. Fit the chain pinion on the shaft, making the channel coincide

with the pin and tighten the screw d and the appropriate washers

e and f.

4. Pass the chain as shown in Fig. 21A and install the cover with

screw a and washer c as in Fig. 20.

4.5.3. LIMIT SWITCHES

In case of operators with magnetic limit switches, you have to

provide a bracket to mount them on the gate, following the proper

distances showed in Fig. 21B.

Fig. 20

g

b

a

c

a

f

e

d

• Do not use grease or other lubricants between rack and

pinion.

4.5. INSTALLATION OF CHAIN PINIONS

The operators for chain and idle transmissions require the

installation of a Z16 or Z20 chain pinion.

4.5.1. MODEL 844 ER CAT (Figs. 18 & 19)

1. Insert the pin on the shaft, using a hammer.

2. Fit the chain pinion on the shaft, making the channel

coincide with the pin. Tighten the screw and the appropriate washers.

Fig. 18

Fig. 19

Fig. 21A

Fig. 21B

0 to ⅜

- Measurements in Inches

11

FAAC MODEL 844 Slide Gate Operator

Page 12

5. CONTROL BOARD 780D

5.1. WARNINGS

Important: Before attempting any work on the control board

(connections, maintenance), always turn off power.

• Check local wiring codes in all cases and follow all local building

codes. Wiring and hookup should be performed by qualied

electricians/installers only.

• AC power should be supplied from a circuit breaker panel and

must have its own dedicated circuit breaker. This supply must

include a green ground conductor.

• Properly ground the gate operator to minimize or prevent damage

from power surges and/or lightning. Use a grounding rod if necessary. Connect the ground cable to the PE terminal on J7 (Fig. 22),

and to the ground lug on the operator (Fig. 40). A surge suppressor is recommended for additional protection.

• Always separate power cables from control and safety cables

(push-button, receiver, photocells, etc.).

5.2. 780D TECHNICAL SPECIFICATIONS

Power Supply V~

(+6% -10%)

Absorbed Power (W) 10

Motor Max. Load (W) 1000

Accessories Max.

Load (A)

Operating Ambient

Temperature

Protection Fuses 2 (see Fig. 22 and Section 5.3)

Function Logics Automatic / “Stepped” automatic /

Work Time Programmable (from 0 to 4.1 min.)

Pause Time Programmable (from 0 to 4.1 min.)

Thrust Force Adjustable over 50 levels

Terminal Board

Inputs

On-Connector Inputs Opening and closing limit-switch -

115 or 230

0.5

-4°F to +131°F

Semi-automatic / Safety devices /

Semi-automatic B / Dead-man C /

“Stepped” semi-automatic / Mixed B/C

logic

Open - Partial Open - Opening safety

devices - Closing safety devices - Stop

- Edge - Power supply+ground

Motor capacitor

780D Technical Specications (continued)

Terminal Board

Outputs

Rapid Connector 5-pin card connection for RP receivers

Programming 3 keys (+, -, F) and display, "basic" or

Flashing lamp - Motor - 24 VDC

accessories power supply- 24 VDC

indicator-light / Timed output / Electric

lock command - 'trafc lights' - Failsafe

"advanced" mode

5.3. LAYOUT AND COMPONENTS

DL SIGNALLING AND PROGRAMMING DISPLAY

Led INPUTS STATUS CONTROL LED

J1 LOW VOLTAGE TERMINAL BLOCK

J2 CONNECTOR FOR RP RECEIVER

J5 CONNECTOR FOR MOTOR STARTING CAPACITOR

J6 MOTOR AND FLASHING LAMP CONNECTION TERMINAL BLOCK

J7 VAC POWER SUPPLY TERMINAL BLOCK

J8 DOUBLE CONNECTOR - RAPID CONNECTION TO LIMIT-SWITCH

F1 MOTOR AND TRANSFORMER PRIMARY WINDING FUSE (F 5A - 230V;

F 10A - 115V)

F2 LOW VOLTAGE AND ACCESSORIES FUSE (T 800mA)

F "F" PROGRAMMING PUSH-BUTTON

– "–" PROGRAMMING PUSH-BUTTON

+ "+" PROGRAMMING PUSH-BUTTON

J1 CONNECTOR

1 OPEN A (total opening)

2 OPEN B (partial opening)

3 FSW-OP (opening safety devices)

4 FSW-CL (closing safety devices)

5 STOP

6 SAFE (“edge” safety devices)

7 - (negative for power supply to accessories)

8 - (negative for power supply to accessories)

9 +24V (supply to accessories)

10 +24V (supply to accessories)

11 FSW-TX (negative for emitting photocells - FAILSAFE)

12 AA (negative for Audio Alarm)

J7

J6

F1

FAAC MODEL 844 Slide Gate Operator

J5

F2

J8

Led

+

–

F

J1

DL

Led

J2

Fig. 22

12

Page 13

5.4. ELECTRIC CONNECTIONS

S

AF

E

+

+

O

P

EN

B

A

O

P

EN

O

P

CL

S

AF

E

+

+

O

P

EN

B

A

O

P

EN

O

P

CL

S

AF

E

+

+

O

P

EN

B

A

O

P

EN

O

P

CL

BLUE

J

5

J1

S

A

F

C

E

L

For connection of the

photocells and safety

devices, see Section

5.4.1.

STOP

A

A

+

+

Audio Alarm 24 Vcc

max. 125mA

PARTIAL

OPEN

TOTAL

OPEN

O

OP

P

E

E

N B

N

O

A

P

~ VAC

VAC (Max. 60W)

Capacitor

LIMIT-SWITCH

Opening Safety Devices:

Tripped when an obstacle is detected only during gate

opening movement. They cause immediate reversing

and resumption of the opening motion on release (see

programming in Section 5.5.2.)

Closing Safety Devices:

Tripped when an obstacle is detected only during gate

closing movement. They cause reversing, either immediate

or on release (see programming in Section 5.5.2.)

Opening/Closing Safety Devices:

Tripped during the gate opening and closing movements.

They cause stopping and restart motion on release.

"Edge" Safety Devices:

Tripped during the gate opening and closing movements.

They cause immediate reversal of motion and stopping

after two seconds.

Encoder:

Monitors for an obstacle during gate opening and closing

movements. It causes immediate reversal of motion and

stopping after two seconds.

N.B: If two or more safety devices have the same function (opening, closing, opening and closing, edge), the contacts must

be connected to each other in series (Fig. 25).

N.C. contacts must be used.

N.B: If safety devices are not used, jumper the terminals as

shown in Fig. 26.

The most common photocell and safety device lay-outs are shown

below (from Fig. 27 to Fig. 34).

Connection of two N.C. contacts in series

(e.g. Photocells, Stop, Edge, etc.)

Fig. 25

Connection of no safety device

A

Fig. 23

Fig. 26

5.4.1. Connection of Photocells and Safety Devices

Before connecting safety devices and photocells, it is advisable

to select the type of operation according to the area they have to

protect (see Fig. 24 for example).

Opening or opening/

Closing

closing photocells

photocells

"Edge" safety devices

Closing photocells

Fig. 24

Connection of a closing safety device and an opening safety

device

Fig. 27

Connection of an "edge" safety device

Fig. 28

13

FAAC MODEL 844 Slide Gate Operator

Page 14

SA

FE

+

+

O

PE

N

B

A

O

P

EN

O

P

CL

Connection of a pair of opening photocells

P

O

CL

N

EN

B

A

PE

P

O

O

FE

SA

+

+

Connection of a pair of closing photocells

Fig. 29

Connection of two pairs of closing photocells and two edge

safety devices

P

L

O

C

N

N

E

E

B

A

P

P

O

O

E

F

A

S

+

+

Fig. 32

Fig. 30

Connection of a pair of opening photocells, a pair of closing

photocell and an edge safety device

P

L

O

C

N

N

E

E

B

A

P

O

OP

TX OP

E

F

A

S

RX OP

+

+

Connection of a pair of closing photocells, a pair of opening

photocells and a pair of opening/closing photocells

P

L

O

C

N

N

E

E

B

A

P

P

O

O

TX OP/CL

RX OP TX OP

E

F

A

S

RX OP/CL

+

+

FAAC MODEL 844 Slide Gate Operator

Fig. 31

Fig. 33

14

Page 15

Connection of a pair of closing photocells and a pair of

opening/closing photocells

P

O

CL

N

N

E

E

B

A

P

P

O

O

TX OP/ CL

Connection of two N.O. contacts in parallel

(e.g. Open A, Open B)

E

F

A

S

RX OP/CL

+

+

Fig. 34

Fig. 35

5.4.2. J7 Terminal Block - Power Supply (Fig. 23)

POWER SUPPLY (Terminals PE-N-L):

PE : Ground connection

N : AC Power ( Neutral )

L : AC Power ( Line )

5.4.3. J6 Terminal Block - Motors / Flashing Lamp (Fig. 23)

MOTOR - (Terminals MOT-C, MOT-1, MOT-2): Motor con-

nection (see Section 6.5).

LAMP - (Terminals LAMP L, LAMP N): Flashing lamp

output same VAC as input; max 60W.

5.4.4. J1 Terminal Block - Accessories (Fig. 23)

Consult the relevant tables for a detailed description of

operation in the different logics

OPEN A - “Total Opening” Command (Terminal 1): any

pulse generator (push-button, detector, etc.) which, by closing a contact, commands total opening and/or closing of the

gate leaf.

To install several total opening pulse generators, connect the

N.O. contacts in parallel (Fig. 35).

OPEN B - “Partial Opening” or “Closing” Command

(Terminal 2): any pulse generator (push-button, detector,

etc.) which, by closing a contact, commands partial opening

and/or closing of the gate leaf. In the B, C and B/C logics, it

always commands gate closure.

To install several partial opening pulse generators, connect

the N.O. contacts in parallel (Fig. 35).

FSW OP - Opening Safety Devices Contact (Terminal 3):

The purpose of the opening safety devices is to protect the

leaf movement area during opening. During opening, in the

A-AP-S-E-EP logics the safety devices reverse the movement of the gate, or stop and restart the movement when it

is released (see advanced programming in Section 5.5.2).

During the opening cycle in logicsthe B, C and B/C, they

interrupt movement. They never operate during the closing

cycle.

If the Opening safety devices are engaged when the gate

is closed, they prevent the opening movement.

To install several safety devices, connect the N.C. contacts in

series (Fig.25).

NB: If no opening safety devices are connected, jumper

inputs FSW OP and -TX FSW (Fig. 26).

FSW CL - Closing Safety Devices Contact (Terminal 4):

The purpose of the closing safety devices is to protect the

gate movement area during closing. During closing, in the

A-AP-S-E-EP logics, the safety devices reverse the movement of the gate, or stop and reverse the movement when it

is released (see advanced programming in Section 5.5.2).

During the closing cycle in logics B, C and B/C, they interrupt

movement. They never operate during the opening cycle. If

the Closing safety devices are engaged when the gate is

open, they prevent the closing movement.

To install several safety devices, connect the N.C. contacts in

series (Fig.25).

NB: If no closing safety devices are connected, jumper

terminals FSW CL and -TX FSW (Fig. 26).

STOP - STOP Contact (Terminal 5):

Any device (e.g. a push-button) which, by opening a contact,

stops gate movement.

To install several STOP devices, connect the N.C. contacts in

series (Fig. 25).

NB: If STOP devices are not connected, jumper the STOP

and - terminals.

SAFE - EDGE Safety Device Contact (Terminal 6):

The purpose of the "edge" safety device is to protect the

leaf movement area during opening/closing. In all logics,

during opening and closing, the safety device reverses gate

movement for 2 seconds. If the safety devices operate again

during the 2-seconds reversing time, it stops movement

(STOP) without any reversing.

If the Edge safety device is engaged while the gate is closed or open, it prevents movement.

To install several safety devices, connect the N.C. contacts in

series (Fig.25).

NB: If edge safety devices are not connected, jumper the

SAFE and - inputs (Fig. 26).

– Negative for power supply to accessories

(Terminals 7 and 8)

+ 24 VDC - Positive for power supply to accessories

(Terminals 9 and 10)

Important: Accessories max. load is 500 mA. To calculate the

load, refer to the instructions for the individual accessories.

15

FAAC MODEL 844 Slide Gate Operator

Page 16

TX -FSW - Negative for Power Supply to Photocell

Transmitters (Terminal 11)

If you use this terminal to connect the negative transmitters

of the photocell power, you may, if necessary, also use the

FAIL SAFE function (see advanced programming in Section

5.5.2).

If this function is enabled, the equipment checks operation of

the photocells before every opening or closing cycle.

A.A. - Power Supply to Audio Alarm (Terminal 12)

Connect a 24 VDC - 125mA max audio alarm compliant with

UL325. 31.1.4. The alarm will sound upon two sequential activations of an entrapment protection device, continuosly until

the activation of a STOP command. To comply with UL325

the STOP input must be connected to a wired control located

in the line-of-sight of the gate.

5.4.5. J2 Connector - Rapid Connection to RP

This is used for rapid connection of RP receivers (see Fig.

38). Fit the accessory with the components side toward

connector J1. Insert and remove after cutting power.

5.4.6. J5 Connector - Rapid Connection to Capacitor

Quick-t connector for connecting the motor starting

capacitor.

5.4.7. Double Connector J8 - Limit-Switch Quick Fit

Quick-t connector for connecting the limit-switch. For

connecting both the MLS magnetic limit-switch and the

inductive limit-switch (Fig. 23 Ref. ) to the operator.

5.5. PROGRAMMING

To program operation of the automated system, access the

"PROGRAMMING" mode with keys F,+ and - on the cover.

Attention: before attempting to power up the system,

re-position the board's cover to avoid contact with high

voltage parts and to access the push-button keys on the

cover (Fig. 39).

-

+

Programming is divided in two parts: BASIC and ADVANCED.

5.5.1. BASIC PROGRAMMING

To access BASIC PROGRAMMING, press key F:

• If you press it (and hold it down), the display shows the name of

the rst function.

• If you release the key, the display shows the value of the function

that can be modied with keys + and -.

• If you press F again (and hold it down), the display shows the

name of the next function, etc.

• When you reach the last function, press F to exit the program,

and the display resumes showing the gate status.

The following table shows the sequence of functions

accessible in BASIC PROGRAMMING:

F

Fig. 39

RP

Fig. 38

BASIC PROGRAMMING

F

Display Function Default

FUNCTION LOGICS (see table of logics):

= Automatic

= "Stepped" automatic

= "Safety" Automatic

= Semi-automatic

= "Stepped" Semi-automatic

= Dead-man

= "B" Semi-automatic

= Mixed Log. (B opening / C closing)

PAUSE TIME:

This has effect only if automatic logic

was selected.

Adjustable from to sec. in onesecond steps.

Subsequently, display changes to minutes and tens of seconds (separated by a

point) and time is adjusted in 10-second

steps, up to the maximum value of

minutes.

E.g. if the display shows , pause

time is 2 min. and 50 sec.

FAAC MODEL 844 Slide Gate Operator

16

Page 17

Display Function Default

FORCE:

Adjusts Motor thrust.

= minimum force

= maximum force

OPENING DIRECTION:

Indicates the gate opening movement

and makes it possible not to change the

motor connections on the terminal board.

= Rightward opening movement

= Leftward opening movement

STATUS OF AUTOMATED SYSTEM:

Exit from programming, save data, and

return to gate status viewing.

= Closed

= Now opening

= At "STOP"

= Open

= Pause

= "FAIL SAFE" tripped

= Now closing

= Now reversing

= Photocells tripped

Display Function Default

FAIL SAFE:

If this function is activated, it enables a function

test of the photocells before any gate movement. If the test fails (photocells not working are

indicated by the value on the display), the

gate does not start moving.

= Active

= Disabled

PRE-FLASHING (5 s):

Activates the ashing lamp for 5 seconds before

start of movement.

= Disabled

= Only before opening

= Only before closing

= Before every movement

RESERVED:

Fixed to

5.5.2. ADVANCED PROGRAMMING

To access ADVANCED PROGRAMMING, press key F and,

as you hold it down, press key +:

• If you release key + , the display indicates the name of the rst

function.

• If you release key F too, the display shows the value of the

function that can be modied with keys + and -.

• If you press key F (and hold it down), the display shows the

name of the next function, and if you release it, the value that

can be modied with keys + and - is shown.

• When you reach the last function, press F to exit the program,

and the display resumes showing the gate status.

The following table shows the sequence of functions

accessible in ADVANCED PROGRAMMING:

ADVANCED PROGRAMMING

F

+

+

Display Function Default

MAXIMUM TORQUE AT INITIAL THRUST:

The motor operate at maximum torque (ignoring the torque setting) at start of movement.

Useful for heavy leaves.

= Active

= Disabled

FINAL BRAKING:

When the gate reaches the opening or

closing limit-switch, a braking stroke can be

selected to ensure the leaf is stopped immediately. If decelerations are selected, braking

starts when they nish.

At value, braking is disabled.

Time can be adjusted from to in

0.01-second steps.

= Braking disabled

from to = Timed braking

CLOSING PHOTOCELLS LOGIC:

Select the tripping mode of the closing photocells.

They operate for the closing movement only:

they stop movement and reverse it when they

are released, or they reverse it immediately.

= Reverse on release

= Reverse immediately to opening

17

FAAC MODEL 844 Slide Gate Operator

Page 18

Display Function Default Display Function Default

OPENING PHOTOCELLS LOGIC:

Select the tripping mode of the opening photocells.

They operate for the opening movement only:

they stop the movement and restart it when they

are released, or they reverse it immediately.

= Reverse immediately to closing

= Restart movement on release

ENCODER:

If the encoder is present, you may enable its

use.

If the encoder is present and enabled, "decelerations" and "partial opening" are controlled by

it (see relevant paragraphs).

The encoder operates as an anti-crushing device. If the gate hits an obstacle during opening

or closing, the encoder immediately reverses

the gate leaf movement for 2 seconds. If the

encoder operates again during the 2-seconds

reversing time, the movement stops (STOP)

without commanding any reversing.

If no encoder is supplied, the parameter must

be set to . If there is the encoder, adjust

the sensitivity of the anti-crushing system,

by varying the parameter between

(maximum sensitivity) and (minimum

sensitivity).

From to = Encoder active and sensitivity adjustment

= Encoder disabled

Pre-limit switch DECELERATION:

You can select gate deceleration before the

opening and closing limit-switches have been

tripped.

Time can be adjusted from to in

0.1-second steps.

If an encoder is used, the adjustment is not

determined by time but by motor revs, thus

obtaining greater deceleration precision.

= Deceleration disabled

From to = Deceleration enabled

PARTIAL OPENING:

You can adjust the width of partial leaf opening.

Time can be adjusted from to in

1-second steps.

If an encoder is used, the adjustment is not

determined by time but by motor revs, thus

obtaining greater partial-opening precision. For

example, with pinion Z20, partial opening can

vary from 2' to 13'.

WORK TIME (time-out):

It is advisable to set a value of 5 to 10 seconds

over the time taken by the gate to travel from

the closing limit-switch to the opening limitswitch and vice versa.

Adjustable from to sec. in one-second

steps.

Subsequently, display changes to minutes and

tens of seconds (separated by a point) and

time is adjusted in 10 second steps, up to a

maximum value of minutes.

Attention: the set value will not exactly

match the motor's maximum operating time

if decelerations are used.

ASSISTANCE REQUEST (combined

with next function):

If activated, at the end of countdown (see the

next function: "Cycle Programming") it effects

2 sec. (in addition to the value already set with

the PF function) of pre-ashing at every Open

pulse (job request). It can be useful to set

scheduled maintenance jobs.

= Active

= Disabled

CYCLE PROGRAMMING:

To set countdown of system operation cycles.

Settable (in thousands) from to

thousand cycles.

The displayed value is updated as cycles

proceed.

Post-limit switch DECELERATION:

You can select gate deceleration after the

opening and closing limit-switches have been

tripped.

Time can be adjusted from to in

0.1-second steps.

If an encoder is used, the adjustment is not

determined by time but by motor revs, thus

obtaining greater deceleration precision.

= Deceleration disabled

from to = Deceleration enabled

FAAC MODEL 844 Slide Gate Operator

GATE STATUS:

Exit from programming, save data and return

to viewing gate status (see Section 5.5.1.).

Note 1: To reset the programming default settings, check

that the edge input is closed (SAFE LED ON), and

simultaneously press keys +, - and F, holding them

down for 5 seconds.

Note 2: Modications of programming parameters take

effect immediately, whereas changes are saved to

memory only after you exit programming and return

to normal gate status viewing. If the equipment is

powered down before returning to status viewing,

any modications will be lost.

18

Page 19

6. START-UP

2

1

6.1. ELECTRIC CONNECTIONS

Make all electrical connections to the board as described in Section

5, including grounding the operator (Fig. 39).

Fig. 40

6.2. DEFINITION OF OPENING DIRECTION

AND OPERATION OF LIMIT-SWITCH LEDS

Power up the system and set the opening direction on the

board (see Section 5.5.1).

If opening direction is to the RIGHT ( ):

OPENING limit-switch LED = FC1

CLOSING limit-switch LED = FC2

If opening direction is to the LEFT ( ):

OPENING limit-switch LED = FC2

CLOSING limit-switch LED = FC1

Attention: Due to the powerful magnetic elds

produced by the supplied magnets, do not place magnetic

storage devices (credit cards, magnetic tapes, oppy

disks, etc) or sensitive electronic equipment (watches,

CRT monitors, LCD screens, etc.) near the magnets.

Notes on Magnet Positioning

• To ensure correct operation, allow at least 3/4 inch from the mechanical stop limit in the gate stop position. Carry out this check

after determining the values of the pre- and post-limit switch

decelerations (see Section 5.5.2.) and after running at least one

complete cycle of the automated system.

• The distance between the limit-switch and magnets must be

from 1/4 to 1/2 inch.

• Magnets should be tted on the rack and not on the screws.

If necessary, position the magnet at the side of the screw and

adjust decelerations (see Section 5.5.2) in order to obtain the

correct stop point.

FC1

FC2

6.3. DETERMINING STOP POINTS AT

TRAVEL LIMIT

Operator 844 has a limit sensor switch which, by detecting the transit

of a reference applied to the rack, commands the motor to stop. The

device can be magnetic (Fig. 41) or inductive (Fig. 42).

6.3.1. Magnetic Limit-Switch (MLS)

The MLS limit-switch detects the transit of two magnets tted on the

side of the rack facing the operator.

Procedure for correct positioning of the two supplied magnets:

1. Check that the operator is in manual mode (see Section 8).

2. Manually open the gate to within 3/4 to 2 inches of the travel limit

mechanical stop.

3. Fit the magnet (without removing the protective lm from the

adhesive side) on the side of the rack facing the operator, aligning the upper edges. Slide the magnet on the rack in opening

direction until the relevant LED goes off (Fig. 22 and 41), then

move the magnet forward an additional 1 3/4 inches.

4. Manually close the gate to within 3/4 to 2 inches of the travel limit

mechanical stop.

5. Fit the magnet (without removing the protective lm from the

adhesive side) on the side of the rack facing the operator, aligning the upper edges. Slide the magnet on the rack in closing

direction until the relevant LED goes off (Fig. 22 and 41), then

move the magnet forward an additional 1 3/4 inches.

6. Move the gate to its halfway travel point and relock the system

(see Section 9).

7. Find out the desired pre- and post-limit-switch deceleration

values (see Section 5.5.2) and run the automated system for at

least one complete cycle.

8. Check that the gate stops approximately 3/4 to 2 inches from its

mechanical stop point. If necessary, correct the position of the

magnets and check that the stop point is correct.

9. Mark the position of the magnets on the rack, and remove them.

10. Clean the rack on its tting points, remove the lm on the

adhesive parts of the magnets (Fig. 41 Ref. 1) and re-position the

magnets with the adhesive strip in contact with the rack (Fig. 41

Ref. 2).

Fig. 41

6.3.2. Inductive Limit-Switch

Operator 844 has an inductive limit-switch which detects the travel of

the two steel plates tted on the top of the rack.

Procedure for correct positioning of the two supplied steel plates:

1. Assemble the limit-switch by centering the plate with respect to

the threaded pins of the support (Fig. 42).

2. Check that the operator is in manual operating mode (see Section 8).

3. Manually open the gate to within 3/4 to 2 inches of the mechanical stop limit.

4. Allow the plate to move on the rack in opening direction until the

relevant LED goes off (Figs. 22 and 42); next, move the plate

forward an additional 1 3/4 inches and secure it to the rack by

tightening the screws.

5. Manually close the gate to within 3/4 to 2 inches of the mechanical stop limit.

6. Allow the plate to move on the rack in closing direction until the

relevant LED goes off (Figs. 22 and 42); next, move the plate

forward by an additional 1 3/4 inches and secure it to the rack by

tightening the screws.

FC1

FC2

Fig. 42

19

FAAC MODEL 844 Slide Gate Operator

Page 20

Notes on Plate Positioning

• To ensure correct operation, allow at least 3/4 inch from the mechanical stop limit in the gate stop position. Carry out this check

after determining the values of the pre- and post-limit switch

decelerations (see Section 5.5.2.) and after running at least one

complete cycle of the automated system.

• The distance between the limit-switch and the plates must be <

3/16 inch.

6.4. CHECK OF INPUTS

The table below shows the status of the LEDs in relation to to

the status of the inputs.

Note the following: Led ON = closed contact

Led OFF = open contact

Check the status of the LEDs as per the following table.

Table 2: Operation of the Signalling Status LEDs

LEDS ON OFF

OP-A Command activated Command inactive

OP-B Command activated Command inactive

FC1 Limit-switch free Limit-switch engaged

FC2 Limit-switch free Limit-switch engaged

FSW OP Safety devices disengaged Safety devices engaged

FSW CL Safety devices disengaged Safety devices engaged

STOP Command inactive Command activated

SAFE Safety devices disengaged Safety devices engaged

ENC

NB: The status of the LEDs while the gate is closed are shown in bold. If

opening direction is to the left, the status of LEDS FC1 and FC2 is reversed.

Flashes while the motor rotates

6.5. CHECK OF MOTOR CONNECTION

Check that the

motor wiring

is as shown in

Fig. 43 (standard

connection).

MOT 2

MOT 1

MOT

COM

BROWN

BLACK

BLUE

M

J6

Fig. 43

6.6. MECHANICAL CLUTCH ADJUSTMENT

In addition to its electronic safety devices (encoder and force

adjustment), the 844 operator is also equipped with a mechanical

clutch.

For gate force and the encoder, please consult Sections 5.5.1 and

5.5.2.

Adjusting the Operating Threshold of the Mechanical Clutch:

1. Cut electrical power to the automated system.

2. Keep the motor shaft locked with a wrench and turn the clutch

adjustment screw with an Allen wrench or screwdriver as shown in

Fig. 44 Ref. A.

- To increase torque, turn the screw clockwise.

- To reduce torque, turn the screw counter-clockwise.

The operator is supplied with the clutch set to maximum level.

Therefore, you must initially turn the screw counter-clockwise

to reach the best setting.

3. Power up the automated system and check that the torque you

have just set is correct.

The operator is supplied as standard with a clutch adjustment

spring for gates up to 2200 lbs. For heavier gates, use the supplied alternative spring. For spring replacement instructions,

see Fig. 44 Ref. B.

A B

Fig. 44

6.7. CHECK OF STOP POINTS

Be careful when setting the post-limit-switch deceleration

and braking. If the deceleration is too long and braking is

insufcient, the magnet or steel plate tted on the gate's rack

can overshoot the sensor until it is disengaged. When the gate

stops, check that only the light limit-switch is engaged. The

relevant LED must be OFF. If it went OFF and then ON again,

or if both limit-switch LEDS are OFF, you must reduce the

post-limit-switch deceleration value and/or increase the braking

value (see Section 5.5.2).

6.8. SAFETY DEVICES AND ACCESSORIES

CHECK

Check for the correct operation of all safety equipment, anticrushing devices (ENCODER sensor), and accessories used in

the system.

7. FINAL OPERATIONS

• After installation, apply the danger sticker to the top of the

cover (Fig. 45).

Fig. 45

• Snap-t the side panels, put the equipment's cover on

and secure it with the supplied screws (Fig. 46).

• Remove the vent stop screw (Fig. 47).

• Explain to the customer the correct operation and use of

the operator, and indicate the potentially dangerous areas

of the automated system.

Fig. 46

FAAC MODEL 844 Slide Gate Operator

20

Page 21

Fig. 47

8. MANUAL OPERATION

If the gate has to be operated manually due to a power blackout or

malfunction of the automated system, use the release device as follows:

1. Open the protection door and insert the supplied key in the lock

(Fig. 48).

10. MAINTENANCE

Check the operational efciency of the system at least once every 6 months, especially the efciency of the safety and release

devices (including operator thrust force).

11.1. DISASSEMBLING THE TRANSFORMERBOARD UNIT

If you have to disassemble the transformer-board unit,

proceed as follows:

Remove all terminal boards and connectors from the board.

Unscrew the 3 screws from the board and the 2 from the

transformer. Lift the unit up and gently remove the transformer

from the couplings on the board as shown in Fig. 53.

Fig. 48

2. Turn the key clockwise and pull the release lever as shown in Fig.

49.

3. Open and close the gate manually.

Fig. 49

9. RESTORING NORMAL OPERATION

To prevent an involuntary pulse from activating the gate, cut

power to the system before re-locking the operator.

1. Re-close the release lever.

2. Turn the key counter-clockwise

3. Remove the key and close the lock protection door.

4. Move the gate until the release engages.

Fig. 53

11.2. OIL TOP-OFFS

Periodically check the oil level inside the operator.

A once-a-year check is enough for medium or low usage. For

heavy duty usage, a check every 6 months is recommended.

To access the tank, temporarily remove the plastic oil ller cap

(Fig. 54).

Oil level is visually checked and must cover the copper coil of

the electric motor.

If more oil is needed, add it through the oil ller hole.

Use FAAC XD 220 oil only.

Fig. 54

21

12. REPAIRS

For any repairs, contact an FAAC authorized repair center.

FAAC MODEL 844 Slide Gate Operator

Page 22

)2("2rofnepootsesreveR

)1(emitesuapsdaoleR

)2("2rofesolcotsesreveR

)delbasidNEPO(

)2("2rofnepootsesreveR

)2("2rofesolcotsesreveR

emitesuapsdaoleR

)delbasidNEPO(

)2("2rofnepootsesreveR

)1(emitesuapsdaoleR

)2("2rofesolcotsesreveR

)delbasidNEPO(

)2("2rofnepootsesreveR

)2("2rofesolcotsesreveR

)delbasidNEPO(

tceffeoN

otsesrever,esaelerno,dnaskcoL

)1(emitesuapsdaoleR

)delb

asidNEPO(

)3()1(emitesuapsdaoleR

.2.5.5hpargarapees

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

nepo

tceffeoN

)NEPOsevas(

)delbasidNEPO(

tceffeoN

otsesrever,esaelerno,dnaskcoL

emitesuapsdaoleR

)delbas

nepo

idNEPO(

)3(emitesuapsdaoleR

.2.5.5hpargarapees

)delbasidNEPO(

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

)NEPOsevas(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

tceffeoN

)delbasidNEPO(

tceffeoN

otsesrever,esaelerno,dnaskcoL

"5re

tfasesolc,esaelernO

)delbasidNEPO(

NEPO("5retfasesolc,esaelernO

.2.5.5hpargarapees

)3()delbasid

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

tceffeoN

tceffeoN

)delbasidNEPO

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

nepo

)NEPOsevas(

tceffeoN

tceffeoN

)NEPOsevas(

)delbasidNEPO(

)delbasidNEPO(

tceffeoN

tceffeoN

otsesrever,esaelerno,dnaskcoL

.2.5.5hpargarapees

)delbasidNEPO(

)3(tceffeoN

tceffeoN

)delbasidANEPO.gnpo.trapnofi(

tceffeoN

tceffeoN

)delbasidNEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

gninepo

nepo

tceffeoN

)NEPOsevas(

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

retfasesolcdnaemitgninepo

laitrapehtroffaelsnepO

)1(emitesuap

)1(yletaidemmifaelehtsnepo-eR

)3()1(emitesuapsdaoleR

)3(faelehtsesolC

)3()1(tceffeoN .2.5.5hpargarapee ts ceffeoN

sesolcdnafaelehtsnepO

)1(emitesuapretfati

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

retfasesolcdnaemitgninepo

laitrapehtroffaelsnepO

emitesuap

)3(noitarepospotS

sesolcdnafaelehtsnepO

emitesuapretfati

,degagnesecivedytefaSgnisolChtiw(faelehtsesolC

yletaidemmifaelehtsnepo-eR

)3()eslupdn2ehttasnepo

)3(noitarepospotS .2.5.5hpargarapee ts ceffeoN

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

retfasesolcdnaemitgninepo

laitrapehtroffaelsnepO

emitesuap

sesolcdnafaelehtsnepO

emitesuapretfati

)3(yletaidemmifaelehtsesolc-eR .2.5.5hpargarapees

)3(yletaidemmifaelehtsesolc-eR

yletaidemmifaelehtsnepo-eR

)3(faelehtsesolC

)delbasidNEPO(

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

laitrapehtroffaelsnepO

emitgninepo

)3(yletaidemmifaelehtsesolc-eR

faelehtsnepO

,degagnesecivedytefaSgnisolChtiw(faelehtsesolC

yletaidemmifaelehtsnepo-eR

)3()eslupdn2ehttasnepo

)3(noitarepospotS .2.5.5hpargarapee ts ceffeoN

22

SUTATSETA AG -NEP BO -NEP PO OT SS ECIVEDYTEFASGNINEP SO ECIVEDYTEFASGNISOL EC CIVEDYTEFASLC/P EO CIVEDYTEFASEGDE

"A"cigoL SESLUP

ESUAPnoNEPO

GNINEPO

GNISOLC

DESOLC

DEKCOL

Tab. 3/a

SUTATSETA AG -NEP BO -NEP PO OT SS ECIVEDYTEFASGNINEP SO ECIVEDYTEFASGNISOL EC CIVEDYTEFASLC/P EO CIVEDYTEFASEGDE

"PA"cigoL SESLUP

Tab. 3/b

ESUAPnoNEPO

GNINEPO

DESOLC

GNISOLC

DEKCOL

SUTATSETA AG -NEP BO -NEP PO OT SS ECIVEDYTEFASGNINEP SO ECIVEDYTEFASGNISOL EC CIVEDYTEFASLC/P EO CIVEDYTEFASEGDE

"S"cigoL SESLUP

Tab. 3/c

ESUAPnoNEPO

GNINEPO

DESOLC

GNISOLC

DEKCOL

SUTATSETA AG -NEP BO -NEP PO OT SS ECIVEDYTEFASGNINEP SO ECIVEDYTEFASGNISOL EC CIVEDYTEFASLC/P EO CIVEDYTEFASEGDE

"E"cigoL SESLUP

DESOLC

NEPO

GNINEPO

GNISOLC

DEKCOL

Tab. 3/d

FAAC MODEL 844 Slide Gate Operator

Page 23

)2("2rofnepootsesreveR

)2("2rofesolcotsesreveR

)2("2rofnepootsesreveR

)delbas

tceffeoN

idB/A-NEPO(

)2("2rofnepootsesreveR

)delbasidB/A-NEPO(

tceffeoN

)2("2rofnepootsesreveR

)delbasidB/A-NEPO(

tceffeoN

)delbasidNEPO(tceffeoN

)delbasidANEPO(

tceffeoN

seunitnoc,esaelerno,dnaskcoL

otsesrever,esaelerno,dnaskcoL

)delbasidB/A-NEPO(

)delbasidBNEPO(

noitarepospotS

gninepo

nepo

)3()delbasidNEPO(tceffeoN )delbasidNEPO(tceffeoN

tceffeoN )delbasidNEPO(tceffeoN

arapees

ANEPO.gnpo.trapnofi(tceffeoN

)delbasid

)delbasidNEPO(

tceffeoN

)NEPOselbasidti,esolctsumtifi(

tceffeoN

)NEPOselbasidti,nepotsumtifi(

tceffeoN

tceffeoN

)delbasidBNEPO(

)delbasidB-NEPO(

noitarepospotS

tceffeoN

tceffeoN

tceffeoN

)delbasidANEPO(

tceffeoN

tceffeoN )2("2rofesolcotsesreveR

)delbasidA-NEPO(

)delbasidANEPO(

noitarepospotS

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidBNEPO(

tceffeoN

)delbasidBNEPO(

noitarepospotS

tceffeoN

tceffeoN

tceffeoN

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidB/ANEPO(

tceffeoN

)delbasidB/A-NEPO(

noitarepospotS

)delbasidB-NEPO(

)delbasidBNEPO(

tceffeoN )2("2rofesolcotsesreveR

tceffeoN

)delbasidA-NEPO(

)delbasidA-NEPO(

)ANEPOseva

noitarepospotS

tceffeoN

s(

)delbasidANEPO(

tceffeoN

)delbasidBNEPO(

tceffeoN

)delbasidBNEPO(

noitarepospotS

tceffeoN

tceffeoN

tceffeoN

tceffeoN

)delbasidANEPO(

tceffeoN

)delbasidB/ANEPO(

tceffeoN

)delbasidB/A-NEPO(

noitarepospotS

)delbasidB-NEPO(

)delbasidBNEPO(

tceffeoN )2("2rofesolcotsesreveR

tceffeoN

)delbasidA-NEPO(

)delbasidA-NEPO(

)ANEPOsevas(

noitarepospotS

tceffeoN

)delbasidNEPO(

tceffeoN

noitarepo

spotS

laitrapehtroffaelsnepO

emitgninepo

)3(yletaidemmifaelehtsesolc-eR

faelehtsnepO

SUTATSETA AG -NEP BO -NEP PO OT SS ECIVEDYTEFASGNINEP SO ECIVEDYTEFASGNISOL EC CIVEDYTEFASLC/P EO CIVEDYTEFASEGDE

"PE"cigoL SESLUP

DESOLC

NEPO

)3(noitceridesrevernitnemevomstratseR

)potSaretfasesolcsyawla(

)3(noitarepospotS .2.5.5hpargarapee ts ceffeoN

noitarepospotS )NEPOsevas(tceffeo .N 2.5.5hparg

SUTATSETA )G gninepo(A-NEP )O gnisolc(B-NEP PO OT SS ECIVEDYTEFASGNINEP SO ECIVEDYTEFASGNISOL EC CIVEDYTEFASLC/P EO CIVEDYTEFASEGDE

GNINEPO

GNISOLC

DEKCOL

"C"cigo NL WODDLEHSYAWLASLORTNOC SESLUP

)delbasidB/A-NEPO(

noitarepospotS

tceffeoN

)delbasidA-NEPO(

faelehtsesolC

tceffeoN

faelehtsnepO

tceffeoN

DESOLC

n/ oitarepospotS

)delbasidB-NEPO(

noitarepospot /S

GNINEPO

GNISOLC

NEPO

"B"cigoL SESLUP

NEPO(tceffeoN

)delbasidB

faelehtsnep tO ceffeoN

SUTATSETA )G gninepo(A-NEP )O gnisolc(B-NEP PO OT SS ECIVEDYTEFASGNINEP SO ECIVEDYTEFASGNISOL EC CIVEDYTEFASLC/P EO CIVEDYTEFASEGDE

DESOLC

nepootsesreve tR ceffeoN

tceffeo fN aelehtsesolC

GNISOLC

NEPO

)delbasidB/ANEPO(

tceffeoN

noitarepo

spotS

faelehtsnep fO aelehtsesolC

tceffeo tN ceffeoN

"C/B"cigo SL LORTNOCNUROTDLOHGNISOLC/ESLUPGNINEPO SESLUP

GNINEPO

DEKCOL

SUTATSETA )G gninepo(A-NEP )O gnisolc(B-NEP PO OT SS ECIVEDYTEFASGNINEP SO ECIVEDYTEFASGNISOL EC CIVEDYTEFASLC/P EO CIVEDYTEFASEGDE

)delbasidBNEPO(

tceffeoN

faelehtsnep tO ceffeoN

tceffeo fN aelehtsesolC

DESOLC

NEPO

NEPO(tceffeoN

)delbasidB/A

noitarepo

spotS

ceffeoN

nepootsesreve tR

faelehtsnep fO aelehtsesolC

tceffeo tN ceffeoN

GNINEPO

GNISOLC

DEKCOL

Tab. 3/e

Tab. 3/f

FAAC MODEL 844 Slide Gate Operator

Tab. 3/g

Tab. 3/h

(2) If a new pulse occurs within 2 seconds after reversing, it immediately stops operation. NB.: Effects on other active pulse inputs in brackets.

(1) If maintained, it prolongs the pause until disabled by the command (timer function) (3) During the partial opening cycle, an OPEN A pulse causes total opening.

23

Page 24

13. 844 SPARES DIAGRAM

POS. P/N DESCRIPTION

01 7273425 844 OPERATOR PLASTIC COVER

02 7111245 746/844 COVER HOLES CAPS (NR 4)

03 701520 THREAD FORMING SCREW 4x20 UNI

10227 INOX

04 7324745 2003 FAAC LOGO

05 7273435 COVER FOR CONTROL BOARD

746/844

06 701422 AUT.2,9X6,5 6954 B N

07 7501365 TRANSFORMER 203V - 18V/15VA

RES.-FLANG.

08 711969 KAPSTO PLUG GPN-300-F242

09 76010915 CAPACITOR. PP 35MF 250VAC WITH

CONNECTOR

10 722084 CAPACITOR SUPPORT

11 701814 TCIC M4X20 TRILOB.DIN 7500-C Z

12 709062002 O RING GASKET 6,75X1,78

13 7029055 STATOR FIXING NUT

14 7110015 CAP

24

POS. P/N DESCRIPTION

15 7099145 GEAR MOTOR STATOR SCREW NUT

GASKET

16 7580375 CAP SCR.SOCK.HEA.6X25 5931 8GZ

17 7161825 MLS LIMIT SWITCH 746/844

18 390516 BREATHER PLUG PACKAGE

19 701002 CAP SCR.SOCK.HEA.4X10 5931 8GZ

20 7099645 GASKET 844

21 7320065 BREATHER SCREW LABEL

22 7160605 UPPER HALF BODY 746/844

23 7029175 STATOR NUT / EARTH

24 7099245 STRAIN RELIEF GASKET

25 7043355 STRAIN RELIEF RING

26 7109095 CABLE DAMP

27 709000002 O RING GASKET 7,59X2,62

28 7909212 780 D CONTROL UNIT WITH

TERMINALS

29 7273405 BASE FOR 746/844 R COVER

30 7109255 STRAIN RELIEF 746/844 R

FAAC MODEL 844 Slide Gate Operator

Page 25

POS. P/N DESCRIPTION

31 702705 NUT WITH LOCKING WASHER M4

32 701000 TCEI 4X 25 5931 12 K

33 752207 LUG CEMBRE BF-M5

34 703007 WASHER 5 6592 R40 Z

35 701367 TCIC 5 X 10 7687/DIN7985 4,8 Z

36 707010 BEARING 6204-Z 20-47-14

37 7269185 SL.G.O. BEARING SPACER

38 445842 ROTOR WITH CLUTCH

39 7310275 FRICTION DISK

40 7093105 SMIM 10X30X4.5 GASKET

41 7226605 MAGNETIC DISK 746/844

42 7210125 CLUTCH ADJUSTM. SPRING

43 7090030015 GASKET OR 6.75X1.78 ( 106)

44 7181935 PIN FOR CLUTCH ADJUST. 746/844 R

45 704008 CIR CLIP E15 7435

46 7049125 GASKET ADJUSTMENT RING NUT

47 7090410025 GASKET OR 42.52X2.62 (3168)

48 704005 CIR CLIP E24 7435

49 7061185 PIN 5 X 40 M6 UNI 100 C6

50 7310125 744-746-842-844 FRICTION DISK

51 7181995 MOTOR SHAFT 844 ER

52 63000355 746/844 STROKE END UNIT

53 701119 TE 10X16 UNI 5739 10.9 Z

54 7030185 WASHER 10,5X35X4 CAT.A Z

55 701007 CAP SCR.SOCK.HEAD 5X16 8G Z

56 71707615 SIDE FLANGE 820-860

57 7094085 GASKET LATERAL FLANGE 820-860

58 7093005 GASKET FOR MOTOR SHAFT A 25407

59 7070111 BEARING 6205 25-52-15 ECON.

60 7061115 PIN 8X45 RIC.UNI EN22338

61 7180785 SLOW SHAFT 746-844

POS. P/N DESCRIPTION

62 7192075 GEAR 820-860 '92

63 704339 RING

64 7070121 BALL BEARING 6004

65 7182765 UNLOCK PIN 746-844

66 7211015 RELEASE SPRING 746-844-820-860

67 7051085 TAB 820-860

68 704009 CIR CLIP E20 7435

69 704200 RING LMKAS 42 D

70 7093055 GASKET RP 10X30X7

71 7160615 SL.G.O. 746/844 LOWER SEMI-BODY

72 7061035 PIN

73 7230145 STATOR MOUNTING ROD

74 703205 LOCK WASHER 8842 Z

75 455944 844 STATOR W/O CONNECTOR

76 7291115 LEVER FOR LOCK

77 7120885 LOCK ART.3889.3

78 7131005 KEY MOD. 3889.0913

79 409867 746-844 RELEASE LEVER UNIT

80 7019415 RELEASE LEVER SCREW

81 727197 PROTECTIVE SIDE COVER 746/844

82 701107002 HEX.HEAD 5739 8G Z 8X20

83 703002 WASHER 8 6592 R40 Z

84 722351 MOUNTING BRACKET 746/844

85 7269525 SPACER

86 3905745 SKIN PACK 746ER/844ER

87 390829 SKINPACK 746 '98 MOTOR

88 714017 HYDRAULIC OIL FAAC HP OIL LT. 1

FAAC MODEL 844 Slide Gate Operator

25

Page 26

14. TROUBLESHOOTING

If you have a problem installing the operator, check the problems and solutions listed below for suggestions.

PROBLEM SOLUTIONS

A The operator does not respond to the

activating signal.

B The gate is closed and does not open. • Make sure the clutch adjustment is not too weak.

C The gate opens, but will not close. • If there are no optional reversing devices connected to the control

D The gate opens, but the operator con-

tinues to run.

• Make sure the main power switch is on.

• Check the control panel terminal strip for possible broken or discon-

nected wires.

• If a radio signal is being used to activate the operator, be sure the code

sets on both the transmitter and receiver are the same.

• Momentarily short across terminals 1 and 7 on the control panel. If

this activates the operator, a problem probably exists in the activating

device itself.

• Increase the torque if the motor is running and the gate is not moving.

This may be necessary for especially heavy gates.

• Check that the closed limit switch is working. The FC status light should

be off. Make sure that the limit switch plate is not too far away from the

limit switch. The distance between a plate and the switch should be

3/16 in.

• Check fuse F1 and replace it if necessary.

panel, make sure a jumper is installed between terminals 4 and 11 on

the control panel.

• If optional reversing devices have been installed, check them to see if

they are working properly (an activated reversing device will prevent

the gate from closing). Temporarily short across the relevant terminals

to bypass the reversing devices to see if the gate closes. If the gate

closes, then the problem exists within the reversing device(s).

• Check the FC light on the control panel. It should be OFF. If it is ON,

check the alignment of the limit switch plate.

• If the FCC light is ON and the limit switch plate is correctly adjusted,

replace the limit switch.

Note: If the limit switch plates are not detected by the limit switch on the

operator, the motor will run for 120 seconds and then the control panel will

be in alarm status.

26

FAAC MODEL 844 Slide Gate Operator

Page 27

LIMITED WARRANTY

To the original purchaser only:

FAAC International, Inc., warrants, for twenty-four

(24) months from the date of invoice, the gate

operator systems and other related systems and

equipment manufactured by FAAC S.p.A. and

distributed by FAAC International, Inc., to be free

from defects in material and workmanship under

normal use and service for which it was intended

provided it has been properly installed and operated.

FAAC International, Inc.’s obligations under this

warranty shall be limited to the repair or exchange

of any part of parts manufactured by FAAC

S.p.A. and distributed by FAAC International, Inc.

Defective products must be returned to FAAC

International, Inc., freight prepaid by purchaser,

within the warranty period. Items returned will

be repaired or replaced, at FAAC International,

Inc.’s option, upon an examination of the product

by FAAC International, Inc., which discloses, to

the satisfaction of FAAC International, Inc., that

the item is defective. FAAC International, Inc. will

return the warranted item freight prepaid. The

products manufactured by FAAC S.p.A. and distributed by FAAC International, Inc., are not war-

ranted to meet the specic requirements, if any, of

safety codes of any particular state, municipality,

or other jurisdiction, and neither FAAC S.p.A.

or FAAC International, Inc., assume any risk or

liability whatsoever resulting from the use thereof,

whether used singly or in combination with other

machines or apparatus.

Any products and parts not manufactured by

FAAC S.p.A. and distributed by FAAC International, Inc., will carry only the warranty, if any, of

the manufacturer. This warranty shall not apply

to any products or parts thereof which have been

repaired or altered, without FAAC International,

Inc.’s written consent, outside of FAAC International, Inc.’s workshop, or altered in any way so

as, in the judgment of FAAC International, Inc.,

to affect adversely the stability or reliability of the

product(s) or has been subject to misuse, negligence, or accident, or has not been operated

in accordance with FAAC International, Inc.’s or

FAAC S.p.A.’s instructions or has been operated

under conditions more severe than, or otherwise

exceeding, those set forth in the specications for

such product(s). Neither FAAC S.p.A. nor FAAC

International, Inc., shall be liable for any loss or

damage whatsoever resulting, directly or indirectly, from the use or loss of use of the product(s).

Without limiting the foregoing, this exclusion from

liability embraces a purchaser’s expenses for

downtime or for making up downtime, damages

for which the purchaser may be liable to other

persons, damages to property, and injury to or

death of any persons.

FAAC S.p.A. or FAAC International, Inc., neither

assumes nor authorizes any person to assume

for them any other liability in connection with

the sale or use of the products of FAAC S.p.A.

or FAAC International, Inc. The warranty herein

above set forth shall not be deemed to cover

maintenance parts, including, but not limited to,

hydraulic oil, lters, or the like. No agreement to

replace or repair shall constitute an admission by

FAAC S.p.A. or FAAC International, Inc., of any

legal responsibility to effect such replacement, to

make such repair, or otherwise. This limited warranty extends only to wholesale customers who

buy directly through FAAC International, Inc.’s

normal distribution channels. FAAC International,

Inc., does not warrant its products to end consumers.

Consumers must inquire from their selling dealer

as to the nature and extent of that dealer’s warranty, if any. This warranty is expressly in lieu of

all other warranties expressed or implied includ-

ing the warranties of merchantability and tness

for use. This warranty shall not apply to products

or any part thereof which have been subject to

accident, negligence, alteration, abuse, or misuse

or if damage was due to improper installation or

use of improper power source, or if damage was

caused by re, ood, lightning, electrical power

surge, explosion, wind storm, hail, aircraft or vehicles, vandalism, riot or civil commotion, or acts

of God.

FAAC MODEL 844 Slide Gate Operator

27

Loading...

Loading...