Page 1

615

615

Page 2

Leggere completamente questo manuale di istruzioni prima di iniziare l’installazione del prodotto.

Il simbolo evidenzia le note importanti per la sicurezza delle persone e l’integrità dell’automazione.

Il simbolo richiama l’attenzione sulle note riguardanti le caratteristiche od il funzionamento del prodotto.

Read this instruction manual to the letter before you begin to install the product.

Symbol highlights notes that are important for people’s safety and for the good condition of the automated system.

Symbol draws your attention to the notes about the product’s characteristics or operation.

Lire ce manuel d’instructions dans son entier avant de commencer l’installation du produit.

Le symbole met en évidence les remarques pour la sécurité des personnes et le parfait état de l’automatisme.

Le symbole attire l’attention sur les remarques concernant les caractéristiques ou le fonctionnement du produit.

Vor der Installation des Produkts sind die Anweisungen vollständig zu lesen.

Mit dem Symbol sind wichtige Anmerkungen für die Sicherheit der Personen und den störungsfreien Betrieb der

Automation gekennzeichnet.

Mit dem Symbol wird auf Anmerkungen zu den Eigenschaften oder dem Betrieb des Produkts verwiesen.

Lean completamente este manual de instrucciones antes de empezar la instalación del producto.

El símbolo identifica notas importantes para la seguridad de las personas y para la integridad de la automación.

El símbolo llama la atención sobre las notas relativas a las características o al funcionamiento del producto.

Lees deze instructiehandleiding helemaal door alvorens het product te installeren.

Het symbool is een aanduiding van opmerkingen die belangrijk zijn voor de veiligheid van personen en voor een goede

automatische werking.

Het symbool vestigt de aandacht op opmerkingen over de eigenschappen of de werking van het product.

Page 3

300 mm

250 mm

400 mm

5 mm

=

=

=

=

Inserto Immagini - Pictures Collection

Inserto Immagini - Pictures Collection

Collection de Figure - Cojunto de Imagenes

Photo Kollektion - Fotoverzameling

Collection de Figure - Cojunto de Imagenes

Photo Kollektion - Fotoverzameling

1

1015

2

3x0,5 mm

2x1,5 mm

105

230V~

3X1,5mm

2

2

2

2x1,5 mm

6

2

6

2

2x0,5 mm

1

2

2x0,5 mm

4

2

2x1,5 mm

5

3

2

3x0,5 mm

2

2

A

85

LP=L-105

L

A

mm.

25

90

105,3

Sez. A-A

3

250 mm

5

4

Page 4

6

7b

7a

8

Page 5

+

L

E

BLOCCA / LOCK

BLOQUE / VERRIEGELT

BLOQUEAR / VERGRENDEL

SBLOCCA / UNLOCK

DEBLOQUE / ENTRIEGELT

DESBLOQUEAR / ONTGRENDEL

-

-

+

1

-

10

2

11

12

BLOCCA / LOCK

BLOQUE / VERRIEGE

BLOQUEAR / VERGR

SBLOCCA / UNLOCK

DEBLOQUE / ENTRIEGELT

DESBLOQUEAR / ONTGRENDEL

1

13

9

Page 6

64

P1

P2

14

15

18

139,5

110

mm.

mm.

P1

290

A

85

L

16

P2

A

85

L

16A

17

Page 7

300 mm

250 mm

400 mm

5 mm

=

=

=

=

Inserto Immagini - Pictures Collection

Inserto Immagini - Pictures Collection

Collection de Figure - Cojunto de Imagenes

Photo Kollektion - Fotoverzameling

Collection de Figure - Cojunto de Imagenes

Photo Kollektion - Fotoverzameling

1

1015

2

3x0,5 mm

2x1,5 mm

105

230V~

3X1,5mm

2

2

2

2x1,5 mm

6

2

6

2

2x0,5 mm

1

2

2x0,5 mm

4

2

2x1,5 mm

5

3

2

3x0,5 mm

2

2

A

85

LP=L-105

L

A

mm.

25

90

105,3

Sez. A-A

3

250 mm

5

4

Page 8

6

7b

7a

8

Page 9

+

L

E

BLOCCA / LOCK

BLOQUE / VERRIEGELT

BLOQUEAR / VERGRENDEL

SBLOCCA / UNLOCK

DEBLOQUE / ENTRIEGELT

DESBLOQUEAR / ONTGRENDEL

-

-

+

1

-

10

2

11

12

BLOCCA / LOCK

BLOQUE / VERRIEGE

BLOQUEAR / VERGR

SBLOCCA / UNLOCK

DEBLOQUE / ENTRIEGELT

DESBLOQUEAR / ONTGRENDEL

1

13

9

Page 10

64

P1

P2

14

15

18

139,5

110

mm.

mm.

P1

290

A

85

L

16

P2

A

85

L

16A

17

Page 11

INDEX

INDEX

CE DECLARATION OF CONFORMITY FOR MACHINES ................................................................................................. 2

WARNINGS FOR THE INSTALLER ................................................................................................................................. 2

1 DESCRIPTION AND TECHNICAL SPECIFICATIONS .................................................................................................... 3

1.1 MAXIMUM USE CURVE ............................................................................................................................................. 3

2 ELECTRIC PREPARATIONS (standard system) .......................................................................................................... 3

3 DIMENSIONS ..........................................................................................................................................................3

4 INSTALLING THE AUTOMATED SYSTEM ..................................................................................................................... 4

4.1 PRELIMINARY CHECKS ............................................................................................................................................. 4

4.2 MASONRY FOR FOUNDATION PLATE ........................................................................................................................ 4

4.3 INSTALLING THE UPRIGHT. ........................................................................................................................................ 4

4.4 INSTALLING THE BEAM ............................................................................................................................................. 4

4.5 INSTALLING AND ADJUSTING THE BALANCING SPRING ............................................................................................ 4

5 BALANCING SPRINGS ............................................................................................................................................. 4

5.1 SPRINGS FOR RECTANGULAR BEAMS WITH SKIR ...................................................................................................... 4

5.2 SPRINGS FOR RECTANGULAR BEAMS WITH FOOT AND WITH SKIRT AND FOOT ......................................................... 4

5.3 SPRINGS FOR 615BPR RAPIDA (RAPIDE)................................................................................................................... 4

5.4 SPRINGS FOR ROUND BARS ..................................................................................................................................... 4

5.5 TRANSFORMATION FROM RIGHT TO LEFT VERSION .................................................................................................. 5

ENGLISH

6 START-UP ................................................................................................................................................................. 5

6.1 ADJUSTING THE TRANSMITTED TORQUE .................................................................................................................... 5

6.2 ADJUSTING THE MECHANICAL TRAVEL LIMITS .......................................................................................................... 5

6.3 ADJUSTING THE MAGNETIC TRAVEL LIMITS............................................................................................................... 5

6.4 AUTOMATED SYSTEM TEST........................................................................................................................................ 5

7 MANUAL MODE OPERATION................................................................................................................................... 5

8 RESTORING NORMAL OPERATION MODE................................................................................................................ 5

9 AVAILABLE ACCESSORIES .......................................................................................................................................

10 MAINTENANCE ...................................................................................................................................................6

11 REPAIRS ................................................................................................................................................................ 6

5

The symbol

The symbol

Notes on reading the instruction

Read this installation manual to the full before you begin installing the product.

indicates notes that are important for the safety of persons and for the good condition of the automated system

draws your attention to the notes on the characteristics and operation of the product.

.

1

Page 12

CE DECLARATION OF CONFORMITY FOR MACHINES

(DIRECTIVE 2006/42/EC)

Manufacturer: FAAC S.p.A.

Address: Via Calari, 10 - 40069 Zola Predosa BOLOGNA - ITALY

Declares that: Barrier mod. 615BPR,

• is built to be integrated into a machine or to be assembled with other machinery to create a machine under

the provisions of Directive 2006/42/EC;

• conforms to the essential safety requirements of the other following EEC directives:

2006/95/EC Low Voltage Directive

2004/108/EEC Electromagnetic Compatibility Directive

Furthermore, the manufacturer declares that the machinery must not be put into service until the machine into

which it will be integrated or of which it will become a component has been identified and its conformity to the

conditions of Directive 2006/42/EEC and subsequent modifications assimilated in Italian National legislation under

DLgs No. 17 of 27-01-2010 has been declared.

.

ENGLISH

Bologna, 01-02-2010

The Managing Director

A. Marcellan

WARNINGS FOR THE INSTALLER

GENERAL SAFETY OBLIGATIONS

1) ATTENTION! To ensure the safety of people, it is important that you read

all the following instructions. Incorrect installation or incorrect use of

the product could cause serious harm to people.

2) Carefully read the instructions before beginning to install the product.

3) Do not leave packing materials (plastic, polystyrene, etc.) within reach

of children as such materials are potential sources of danger.

4) Store these instructions for future reference.

5) This product was designed and built strictly for the use indicated in this

documentation. Any other use, not expressly indicated here, could

compromise the good condition/operation of the product and/or be

a source of danger.

6) FAAC declines all liability caused by improper use or use other than that

for which the automated system was intended.

7) Do not install the equipment in an explosive atmosphere: the presence

of inflammable gas or fumes is a serious danger to safety.

8) The mechanical parts must conform to the provisions of Standards EN

12604 and EN 12605.

For non-EU countries, to obtain an adequate level of safety, the Stand-

ards mentioned above must be observed, in addition to national legal

regulations.

9) FAAC is not responsible for failure to observe Good Technique in the

construction of the closing elements to be motorised, or for any deformation that may occur during use.

10) The installation must conform to Standards EN 12453 and EN 12445.

For non-EU countries, to obtain an adequate level of safety, the Stand-

ards mentioned above must be observed, in addition to national legal

regulations.

11) Before attempting any job on the system, cut out electrical power.

12) The mains power supply of the automated system must be fitted with an

all-pole switch with contact opening distance of 3 mm or greater. Use

of a 6A thermal breaker with all-pole circuit break is recommended.

13) Make sure that a differential switch with threshold of 0.03 A is fitted

upstream of the system.

14) Make sure that the earthing system is perfectly constructed and connect metal parts of the closure to it.

15) The automated system is supplied with an intrinsic anti-crushing safety

device consisting of a torque control. Nevertheless, its tripping threshold must be checked as specified in the Standards indicated at point

10.

16) The safety devices (EN 12978 standard) protect any danger areas

against mechanical movement Risks, such as crushing, dragging, and

shearing.

17) Use of at least one indicator-light (e.g. FAACLIGHT ) is recommended

for every system, as well as a warning sign adequately secured to the

frame structure, in addition to the devices mentioned at point “16”.

18) FAAC declines all liability as concerns safety and efficient operation of

the automated system, if system components not produced by FAAC

are used.

19) For maintenance, strictly use original parts by FAAC.

20) Do not in any way modify the components of the automated system.

21) The installer shall supply all information concerning manual operation

of the system in case of an emergency and shall hand over to the user

the warnings handbook supplied with the product.

22) Do not allow children or adults to stay near the product while it is

operating.

23) Keep remote controls or other pulse generators away from children,

to prevent the automated system from being activated involuntarily.

24) Transit is permitted only when the automated system is idle.

25) The user must not attempt any kind of repair or direct action whatever

and contact qualified personnel only.

26) Check at least every 6 months the efficiency of the system, particularly

the efficiency of the safety devices (including, where foreseen, the

operator thrust force) and of the release devices.

27) Anything not expressly specified in these instructions is not permitted.

2

Page 13

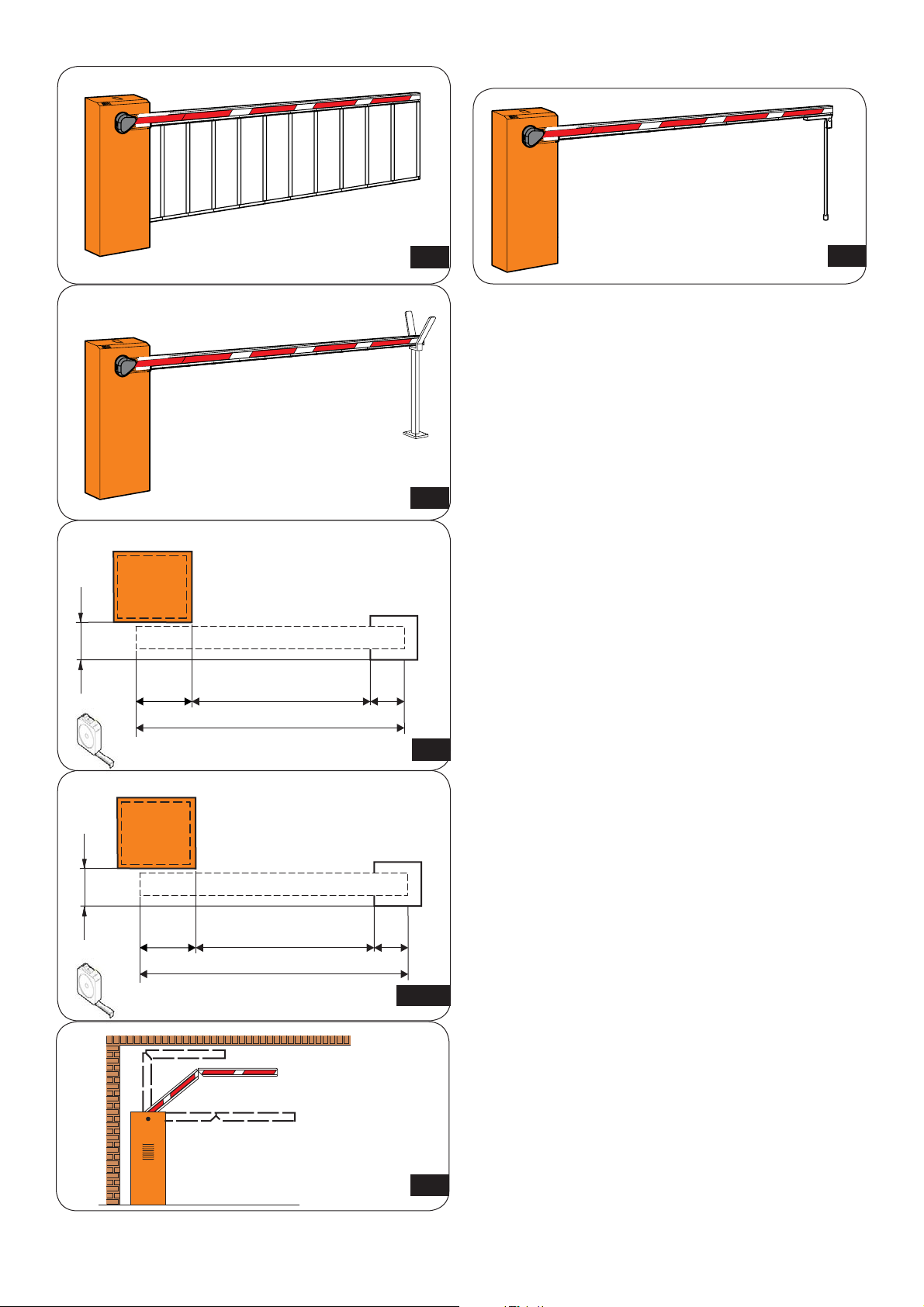

AUTOMATED SYSTEM 615BPR

The 615BPR automated system consists of an aluminium

beam with reflex reflectors, and a steel upright subjected

to cataphoresis treatment and painted with polyester paint.

The upright houses the hydraulic operator and the electronic

control unit.

The operator, which moves the beam, consists of a hydraulic

power pack and a double-acting cylinder.

The system is supplied with an adjustable torque limitation

system. It also includes a device stopping the beam in any

position, and a handy manual release command for use in

case of power cuts or faults.

The beam and the relevant balancing spring must be ordered

by referring to the sales price list.

The 615BPR automated system was designed and built

for controlling vehicle access. Do not use for any other

purpose.

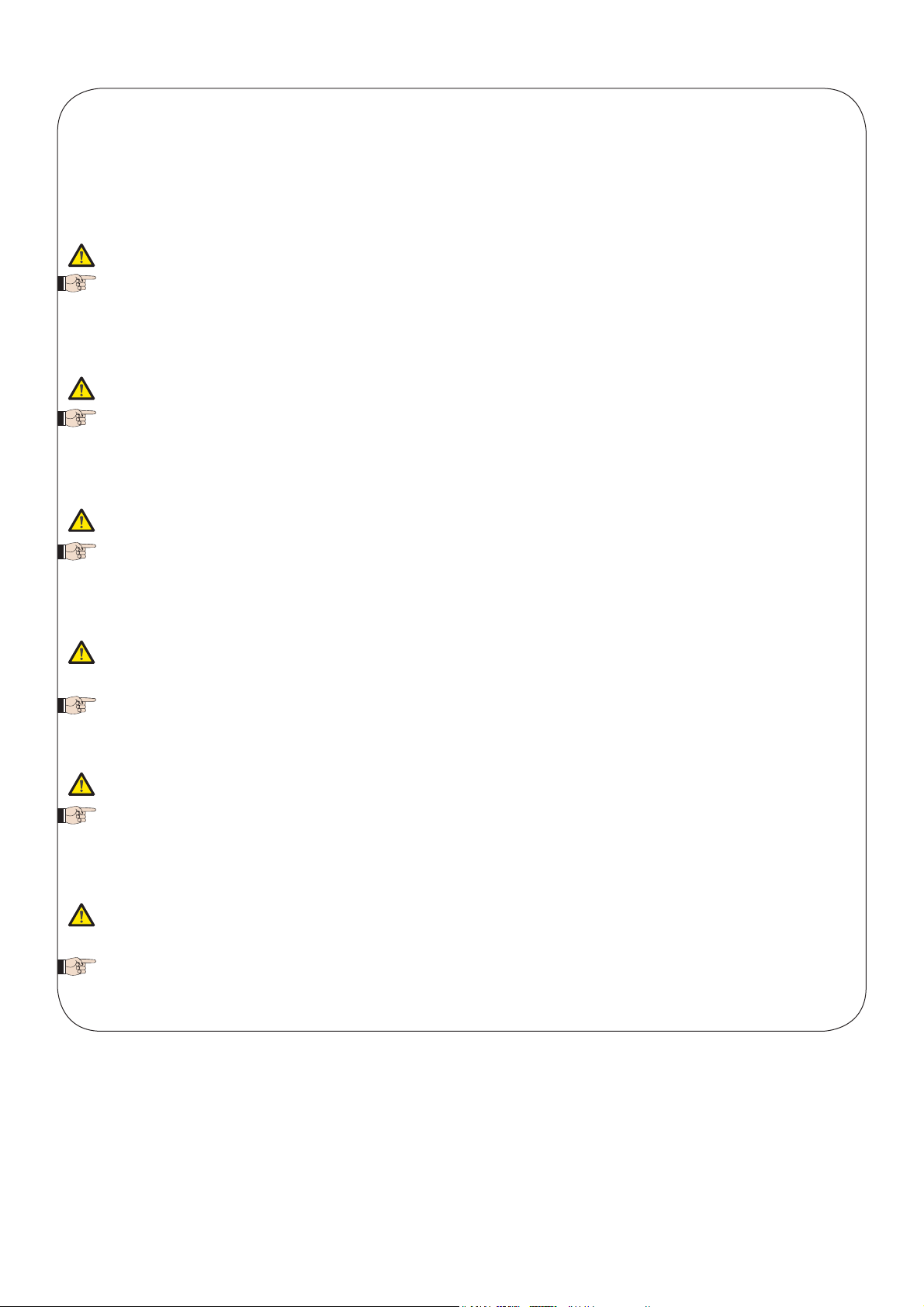

1 DESCRIPTION AND TECHNICAL SPECIFICATIONS

Fig. 1

foundation plate

barrier upright

control board

emergency release

torque adjustment screws

double acting piston

travel limit screw

M12 nut blocking the tie rod

rocker

1.1 MAXIMUM USE CURVE

The curve makes it possible to establish maximum work time (T)

according to use frequency (F).

E.g. The 615 BPR automated system can operate non-stop at a use

frequency of 50%.

To ensure efficient operation, operate in the work range under the

curve.

Important: The curve is obtained at a temperature of 20 °C. Exposure

to the direct sun rays can reduce use frequency down to 20%.

Calculation of use frequency

The percentage of effective work time (opening + closing) compared

to total time of cycle (opening + closing + pause times).

Calculation formula:

oil filling plug

breather screw

balancing spring

spring adjustment tie-rod

hydraulic power pack

travel limit sensors

travel limit magnets

Tab. 1 - Technical specifications “Barrier 615BPR"

BARRIER MODEL

Beam max. length (m)

Max. opening time (sec) 5,7 2,9

Angular speed (rad/sec)

Pump flow-rate (l/min)

Max. torque (Nm) 400 300

Types of beam

Use frequency (at 20°C)

Max. consecutive cycles (at 20°C)

Power supply 230V~ (+6 -10 %) 50Hz

Absorbed power (W) 220

Type of oil FAAC HP OIL

Oil quantity (Kg) 0,9

Thermal protection for winding

Torque adjustment system standard by-pass valves

Operating ambient temperature -40 ÷ +55 °C

Hood protective treatment cataphoresis

Hood paint Polyester RAL 2004

Protection class IP 44

Weight (Kg) 34

Upright dimensions LxHxP(mm) 270 x 1015 x 140

Electric motor technical specifications

RPM

Power (W) 220

Absorbed current (A) 1

Power supply 230V~ (+6 -10 %) 50Hz

615BPR STD

5 2,5

0.28 0,54

1.5 3

Rectangular / Rectangular

skirt articulated / Round

50% 40%

220 340

1400 2800

615BPR RAP

120° C

2. ELECTRIC PREPARATIONS (standard system)

Fig. 2

ENGLISH

Ta + Tc

%F = X 100

Ta + Tc + Tp + Ti

where:

Ta = opening time

Tc = closing time

Tp = pause time

Ti = interval time between

one complete cycle and

another.

Operator 615BPR

Photocells

Key-operated push-button

Flashing lamp

Receiver

Loop Detector

1) To lay cables, use adequate rigid and/or flexible

tubes

2) Always separate connection cables of low voltage

accessories from those operating at 230v~. To prevent

any interference whatever, use separate sheaths.

3 DIMENSIONS

Fig. 3

10

Dimensions are in mm.

3

Page 14

4 INSTALLING THE AUTOMATED SYSTEM

4.1 PRELIMINARY CHECKS

To ensure safety and an efficiently operating automated

system, make sure the following conditions are observed:

• When moving, the beam must not, on any account,

meet any obstacles or overhead power cables.

• The soil must permit sufficient stability for the foundation

plinth.

• There must be no pipes or electrical cables in the plinth

excavation area.

• If the barrier body is exposed to passing vehicles, install,

if possible, adequate means of protection against

accidental impact.

4.2 MASONRY FOR FOUNDATION PLATE

Fig. 4

ENGLISH

1) Make a foundation plate as shown in fig.4 (referred to

clayey soil)

Wall the foundation plate as shown in fig.4, supplying

2)

one or more sheaths for routing electrical cables. Using a

spirit level, check if the plate is perfectly level. Wait for the

cement to set.

4.3 INSTALLING THE UPRIGHT

Fig. 5

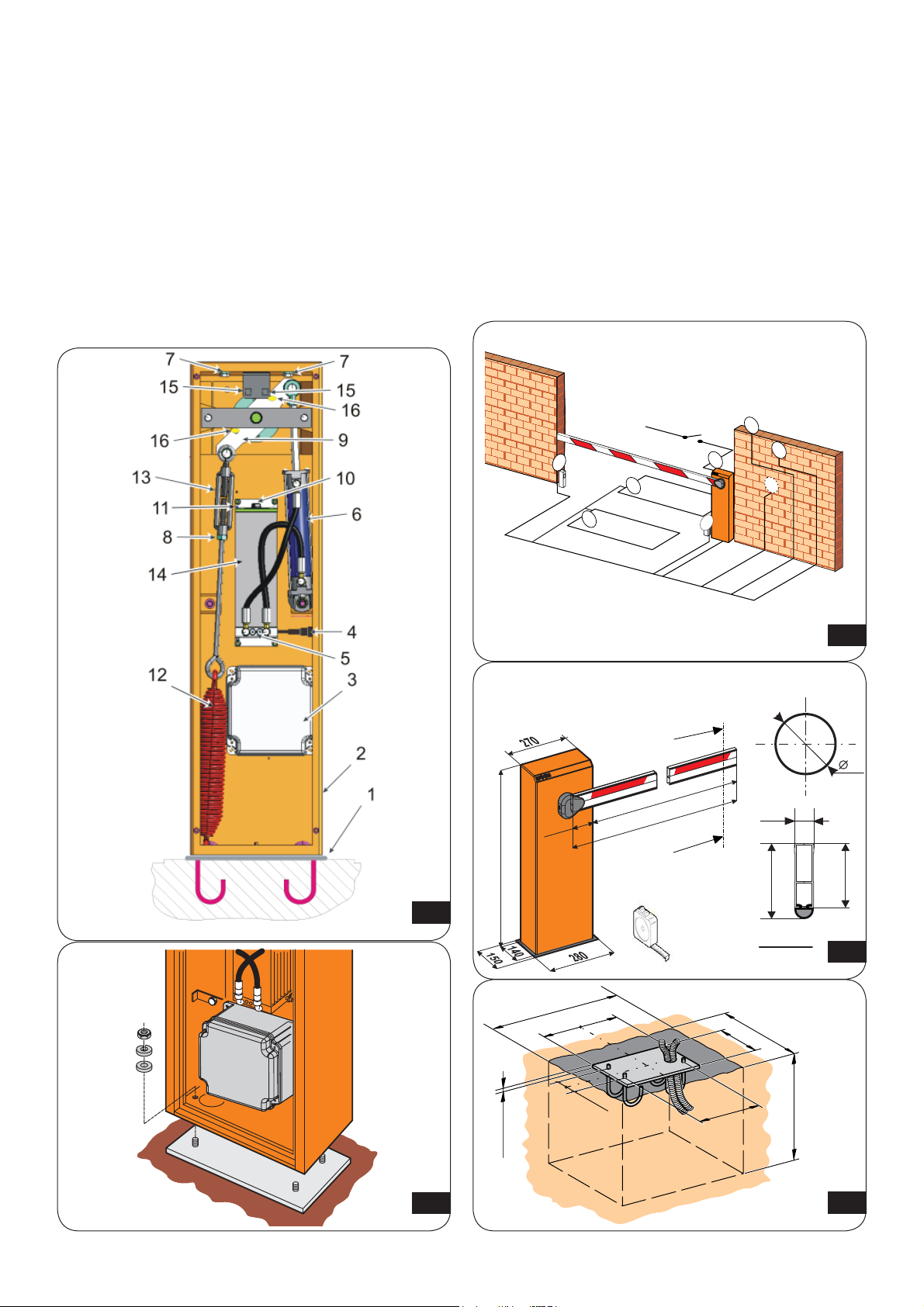

4.5 INSTALLING AND ADJUSTING THE BALANCING

SPRING

Fig. 8

1) Check if the balancing spring matches the type of beam

installed: see chapter 5.

2) While keeping the beam in vertical position, assemble

the tie rod and spring as shown in fig.8

3) Release the operator (see chapter 7) and position the

beam at 45°, then adjust the tie-rod and set the spring until

the weight of the beam is balanced in that position.

4) Restore normal operation as described in chapter 7.

5 BALANCING SPRINGS

The 615 BPR automated system requires a balancing spring

for the beam, which must be ordered separately. The spring

varies according to length and type of beam (rigid, skirt or

articulated).

Consult the tables below to see if the spring matches.

5.1 SPRINGS FOR RECTANGULAR BEAMS WITH SKIRT

BALANCING SPRING

Ø

5,5

6,0

7,0

7,5

8,0

rectangular

beam

1315 – 2315 1315 - 2315 721008

2316 – 2815 2316 – 2815 721005

2816 – 3815 721006

3816 – 4815 721018

beam

with skirt

2816 – 3815 721007

code

1) Remove the cover, unscrewing the screws securing it to

the upright.

2) Using the four nuts and washers supplied, secure the

upright on the foundation plate as shown in fig.5

Remember that the hatch of the upright should normally

face the building.

4.4 INSTALLING THE BEAM

Fig. 6

Fig. 7a Fig. 7b

The 615BPR automated system is always supplied

in the right-hand version – for left-hand installation,

see chapter 5.5.

1) Make sure that the rod of the piston secured to the rocker

is completely extended (corresponding to the beam’s

vertical position).

2)

Remove and store the breather screw as shown in fig.6

5.2

SPRINGS FOR RECTANGULAR BEAMS WITH FOOT

AND WITH SKIRT AND FOOT

BALANCING SPRING

Ø

5,5

6,0

7,0

7,5

8,0

beam

with foot

1315 – 1815 1315 - 1815 721008

1816 – 2315 1816 – 2315 721005

2316 – 2815 721006

2816 – 3815 721018

5.3 FOR 615BPR RAPID

BALANCING SPRING

Ø

5,5

rectangular

beam

1315 – 2315 1315 - 2315 721008

5.4 SPRINGS FOR ROUND BARS

BALANCING SPRING

Ø

5,5

6

7,5

round beam code

1500 –3000 721008

3001 – 4000 721005

4001 – 5000 721006

beam with skirt

and foot

2316 – 3315 721007

round

beam

code

code

IMPORTANT: moderately tighten the pocket securing screw

(max 30Nm)

4

Page 15

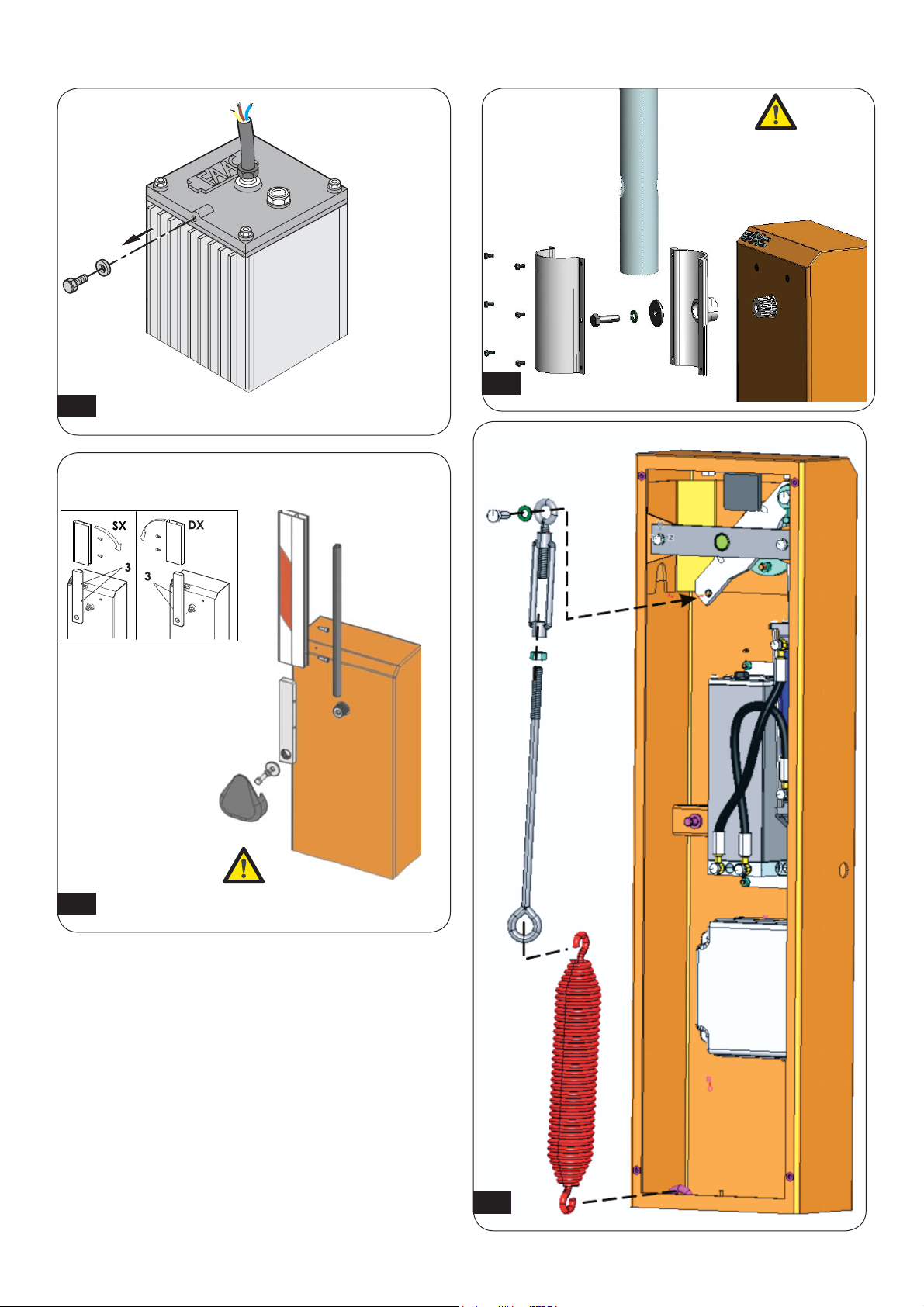

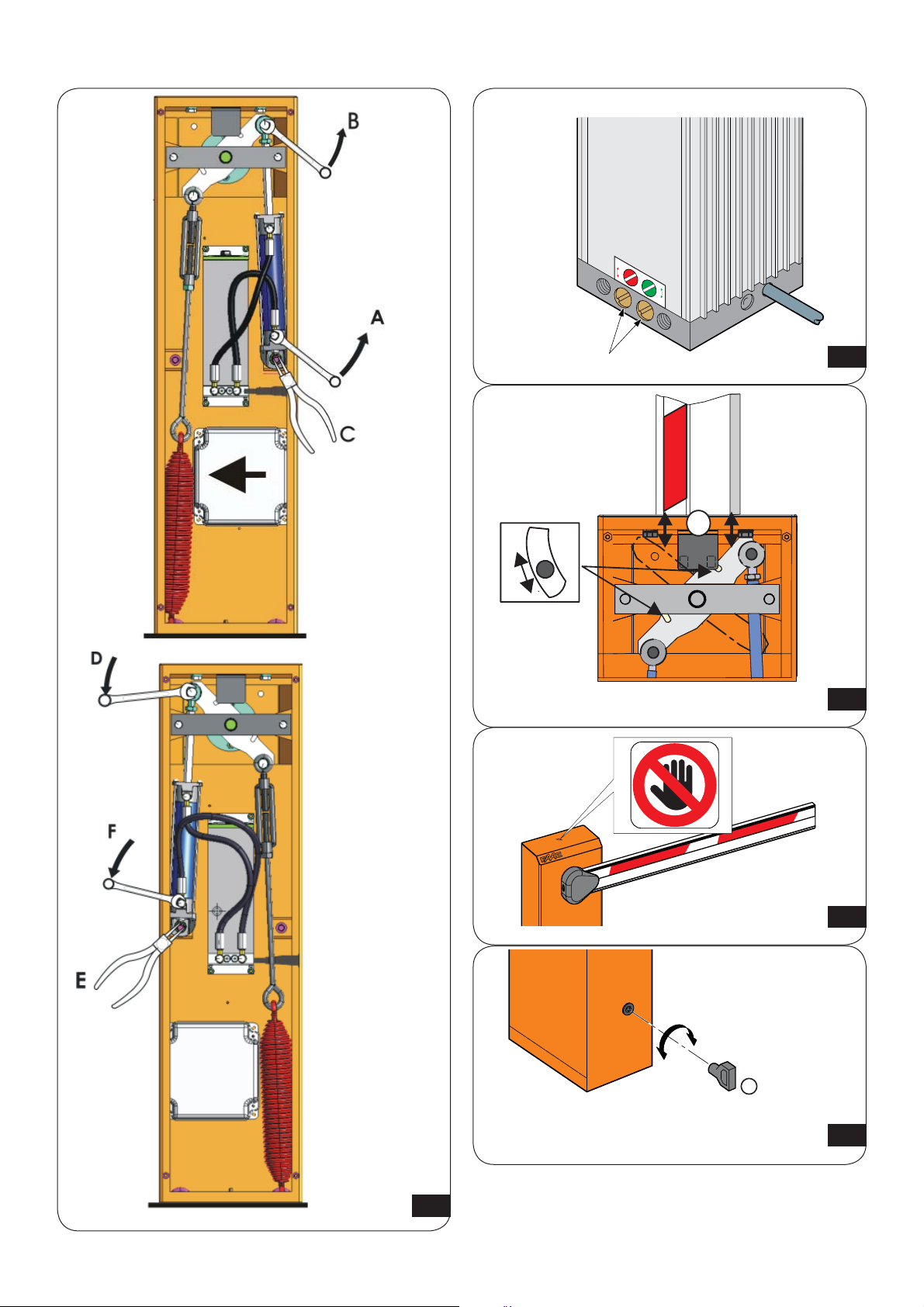

5.5 TRANSFORMATION FROM RIGHT TO LEFT VERSION

Fig. 9

Procedure for converting a right-hand version to

left-hand:

Release the operator.

Loosen the connection (fig.9 ref.A).

Provisionally remove the piston securing screw (fig.9 ref.B)

and the seeger ring (fig.9 ref.C).

Rotate the rocker.

Position the piston from the left side and secure it with the screw

(fig.9 ref.D) and the seeger (fig.9 rif.E) you had removed.

Tighten the connection (fig.9 ref.F).

Re-lock the operator.

Dismantle the container of the control unit and re-install it

on the left of the hood, using the existing holes.

Change over the connectors of the travel-limit sensors (J6

and J9 on the 596/615BPR board).

6 START-UP

6.1 ADJUSTING THE TRANSMITTED TORQUE

Fig. 10

To set the hydraulic system controlling transmitted power,

turn the two by-pass screws (fig.10).

The red screw controls closing movement torque.

The green screw controls opening movement torque.

To increase torque, turn the screws clockwise.

To reduce torque, turn the screws anti-clockwise.

6.2 ADJUSTING THE MECHANICAL TRAVEL LIMITS

Fig. 11

Adjust the position of the beam to maximum closing and

opening positions, using the travel limit mechanical stops

as shown in fig.11.ref.1.

6.3 ADJUSTING THE MAGNETIC TRAVEL LIMITS

7 MANUAL MODE OPERATION

Fig. 13

If the barrier has to be moved manually due to a power cut

or fault of the automated system, use the release device

as follows.

- Fit the standard triangular key (Fig.13) in the lock and turn

it anti-clockwise through 1 turn.

- Open and close the barrier manually.

8 RESTORING NORMAL OPERATION MODE

To prevent an involuntary impulse from activating the barrier

during the manoeuvre, before restoring normal operation,

switch off power to the system, and turn the triangular key

clockwise until it stops, and then remove it.

9 AVAILABLE ACCESSORIES

SKIRT KIT

The skirt kit increases visibility of the beam.

It is available in lengths from 2 m to 3 m.

If a skirt kit is installed, the balancing spring must be

adapted.

FORK SUPPORT

The fork has two functions:

- it prevents the beam, when closed, from bending or splitting

if its end is stressed by extraneous forces.

- it allows the beam to rest when closed and thus prevents

the profile bending downward.

Fig. 14

Fig. 15

POSITIONING THE FORK SUPPORT FOUNDATION PLATE WITH

RECTANGULAR BEAM

Fig. 16

To position the foundation plate of the fork support, refer to

fig.16 where:

P1 = barrier foundation plate

P2 = fork support foundation plate

L = beam length (in mm)

A = L - 195 (in mm)

Dimensions are in mm.

ENGLISH

The point where the automated system begins to make

the slow-down movement can be modified, by moving the

magnetic cylinder inside the seat located on the two arms

of the rocker in the motion unit (fig.11 - ref.2).

6.4 AUTOMATED SYSTEM TEST

Fig. 12

After installation, apply the danger warning sticker on the top

of the upright (Fig. 12).

Check operating efficiency of the automated system and all

accessories connected to it.

Hand the “User’s Manual” to the Client, explain correct

operation and use of the barrier, and indicate the potentially

dangerous areas of the automated system

.

POSITIONING THE FORK SUPPORT FOUNDATION PLATE WITH

ROUND BEAM

Fig. 16A

To position the foundation plate of the fork support, refer to

fig.16A where:

P1 = barrier foundation plate

P2 = fork support foundation plate

L = beam length (in mm)

A = L - 375 (in mm)

ARTICULATION KIT

The articulation kit makes it possible to articulate a rigid

beam to a maximum ceiling height of 3 m. (see specific

instructions).

If the articulated kit is installed, the balancing spring

must be adapted.

Dimensions are in mm.

Fig. 17

5

Page 16

END FOOT

The end foot allows the beam to rest when closed and thus

prevents the profile bending downward.

If a foot is installed, the balancing spring must be

readjusted.

Fig. 18

10 MAINTENANCE

Whenever doing maintenance, always check correct

settings of the by-pass screws, system balancing, and

efficiency of safety devices. The automated system does

not require any type of oil topping-up.

11 REPAIRS

For any repairs, contact FAAC’s authorised Repair Centres.

ENGLISH

6

Page 17

Le descrizioni e le illustrazioni del presente manuale non sono impegnative. La FAAC si riserva il diritto, lasciando inalterate le caratteristiche essenziali dell’apparecchiatura, di apportare in qualunque momento e senza impegnarsi

ad aggiornare la presente pubblicazione, le modifiche che essa ritiene convenienti per miglioramenti tecnici o per

qualsiasi altra esigenza di carattere costruttivo o commerciale.

The descriptions and illustrations contained in the present manual are not binding. FAAC reserves the right, whilst

leaving the main features of the equipments unaltered, to undertake any modifications it holds necessary for either

technical or commercial reasons, at any time and without revising the present publication.

Les descriptions et les illustrations du présent manuel sont fournies à titre indicatif. FAAC se réserve le droit d’apporter à

tout moment les modifications qu’elle jugera utiles sur ce produit tout en conservant les caractéristiques essentielles,

sans devoir pour autant mettre à jour cette publication.

Die Beschreibungen und Abbildungen in vorliegendem Handbuch sind unverbindlich. FAAC behält sich das Recht

vor, ohne die wesentlichen Eigenschaften dieses Gerätes zu verändern und ohne Verbindlichkeiten in Bezug auf die

Neufassung der vorliegenden Anleitungen, technisch bzw. konstruktiv/kommerziell bedingte Verbesserungen vorzunehmen.

Las descripciones y las ilustraciones de este manual no comportan compromiso alguno. FAAC se reserva el derecho,

dejando inmutadas las características esenciales de los aparatos, de aportar, en cualquier momento y sin comprometerse a poner al día la presente publicación, todas las modificaciones que considere oportunas para el perfeccionamiento técnico o para cualquier otro tipo de exigencia de carácter constructivo o comercial.

De beschrijvingen in deze handleiding zijn niet bindend. FAAC behoudt zich het recht voor op elk willekeurig moment de

veranderingen aan te brengen die het bedrijf nuttig acht met het oog op technische verbeteringen of alle mogelijke

andere productie- of commerciële eisen, waarbij de fundamentele eigenschappen van de apparaat gehandhaafd

blijven, zonder zich daardoor te verplichten deze publicatie bij te werken.

FAAC S.p.A.

Via Calari, 10

40069 Zola Predosa (BO) - ITALIA

Tel. 0039.051.61724 - Fax. 0039.051.758518

www.faac.it

www.faacgroup.com

732387 - Rev. F

Loading...

Loading...