Page 1

T HE 402 OPERATOR AND

November, 2003

402 Operator And

455 D Control Panel

Installation Manual

455 D C

NSTALLATION MANUAL

I

ONTROL PANEL:

CONTENTS

Important Safety Information 2

Technical Data 4

Unpacking the Operator 5

The 402 Compact Operator General Characteristics 6

Installation Instructions 6

Prepare the Gate 6

Manual Release Mechanism 7

Install the Operator 7

Install the 455 D Control Panel 9

Exploded View, 402 CBC 11

402 Parts List 12

Maintenance 26

Safety in Gate Design 26

Troubleshooting 27

Limited Warranty 28

The 455 D Control Panel General Description 14

Installing the 455 D Control Panel 14

Connect the Main Power Supply 14

Connect the Operator to the Control Panel 15

Check the Motor’s Direction of Rotation 15

Connect Other Devices 16

Set Other Operating Controls 18

Programming 20

Learning of Operating Times 22

Learning of Normal Times 22

Learning Times with Gatecoder 22

Automated Systems Test 23

Installation Instructions

The 455 D Control Panel

Logic Tables of 455 D Control Panel 24

FAAC International, Inc.

303 Lexington Avenue

Cheyenne, WY 82007

www.faacusa.com

Page 2

November, 2003

Page 2

455 D Control Panel Installation Manual

402 Operator And

IMPORTANT SAFETY INFORMATION

Both the installer and the owner and/or operator of this

system need to read and understand this installation

manual and the safety instructions supplied with other

components of the gate system. This information

should be retained by the owner and/or operator of the

gate.

WARNING! To reduce the risk of injury or death

1. READ AND FOLLOW ALL

INSTRUCTIONS.

2. Never let children operate or play with gate

controls. Keep the remote control away from

children.

3. Always keep people and objects away from

the gate. NO ONE SHOULD CROSS THE PATH

OF THE MOVING GATE.

4. Test the gate operator monthly. The gate

MUST reverse on contact with a rigid object

or stop when an object activates the noncontact sensors. After adjusting the force or

the limit of travel, retest the gate operator.

Failure to adjust and retest the gate operator

properly can increase the risk of injury or

death.

5. Use the emergency release only when the

gate is not moving.

6. KEEP GATES PROPERLY MAINTAINED. Read

the owner’s manual. Have a qualified service

person make repairs to gate hardware.

7. The entrance is for vehicles only. Pedestrians

must use separate entrance.

8. SAVE THESE INSTRUCTIONS.

When installing the photo-beams supplied with this

unit two things need to be considered.

1. Care should be exercised to reduce the risk of

nuisance tripping, such as when a vehicle, trips

the sensor while the gate is in motion.

2. One or more photobeams shall be located

where the risk of entrapment exists, such as

the perimeter reachable by the moving gate

leaf.

GATE DESIGN

1. A gate is a potential traffic hazard, so it is important that you locate the gate far enough away

from the road to eliminate the potential of traffic

getting backed up. This distance is affected by the

size of the gate, how often it is used, and how fast

the gate operates.

2. The operator you choose to install on your gate

must be designed for the type and size of your gate

and for the frequency with which you use the

operator.

3. Your gate must be properly installed and must work

freely in both directions before the automatic

operator is installed.

4. An automatic operator should be installed on the

inside of the property/fence line. Do not install the

operator on the public side of the property/fence

line.

5. Pedestrians should not use a vehicular gate system.

Prevent such inappropriate use by installing

separate gates for pedestrians.

6. Exposed, reachable pinch points on a gate are

potentially hazardous and must be eliminated or

guarded.

7. Outward swinging gates with automatic operators

should not open into a public area.

8. The operating controls for an automatic gate must

be secured to prevent the unauthorized use of those

controls.

9. The controls for an automatic gate should be

located far enough from the gate so that a user

cannot accidentally touch the gate when operating

the controls.

10. An automatic gate operator should not be installed

on a gate if people can reach or extend their arms

or legs through the gate. Such gates should be

guarded or screened to prevent such access.

INSTALLATION

1. If you have any question about the safety of the

gate operating system, do not install this operator.

Consult the operator manufacturer.

2. The condition of the gate structure itself directly

affects the reliability and safety of the gate

operator.

3. Only qualified personnel should install this

equipment. Failure to meet this requirement could

cause severe injury and/or death, for which the

manufacturer cannot be held responsible.

4. The installer must provide a main power switch that

meets all applicable safety regulations.

5. Clearly indicate on the gate with the 2 warning signs

that are included (visible from either side of the

gate).

Page 3

November, 2003

402 Operator And

455 D Control Panel Installation Manual

Page 3

6. It is extremely unsafe to compensate for a damaged

gate by increasing hydraulic pressure.

7. Devices such as reversing edges and photobeams

must be installed to provide better protection for

personal property and pedestrians. Install reversing

devices that are appropriate to the gate design and

gate application.

8. Before applying electrical power, be sure that the

voltage requirements of the equipment correspond

to your supply voltage. Refer to the label on your

operator system.

USE

1. Use this equipment only in the capacity for which it

was designed. Any use other than that stated should

be considered improper and therefore dangerous.

2. When using any electrical equipment, observe some

fundamental rules:

• Do not touch the equipment with damp or

humid hands or feet.

• Do not install or operate the equipment

with bare feet.

• Do not allow small children or incapable

persons to use the equipment.

3. If a gate system component malfunctions, turn off

the main power before making any attempt to repair

it.

4. Do not attempt to impede the movement of the

gate. You may injure yourself as a result.

5. This equipment may reach high temperatures

during operation; therefore, use caution when

touching the external housing of the operator.

6. Learn to use the manual release mechanism

according to the procedures found in this installation manual.

7. Before carrying out any cleaning or maintenance

operations, disconnect the equipment from the

electrical supply.

8. To guarantee the efficiency of this equipment, the

manufacturer recommends that qualified personnel

periodically check and maintain the equipment.

U.L. CLASS AND FAAC OPERATOR

Model

Class I: Residential Vehicular Gate Operator

402 750

422 760

412 400

620 640

885

Class II: Commercial/General Access Vehicular Gate Operator

400 640

620 885

Class III: Industrial/Limited Access Vehicular Gate Operator

400 640

620 885

Class IV: Restricted Access Vehicular Gate Operator

Duty Cycle Typical Use

• Home use

• Small apartment building, for

Limited duty

• Apartment buildings

Continuous duty

Continuous duty

• Very public access

• No public access

example, up to 4 units in a

building, with limited public

access

620 640

885

Continuous duty

• Prison rated security

Page 4

Page 4

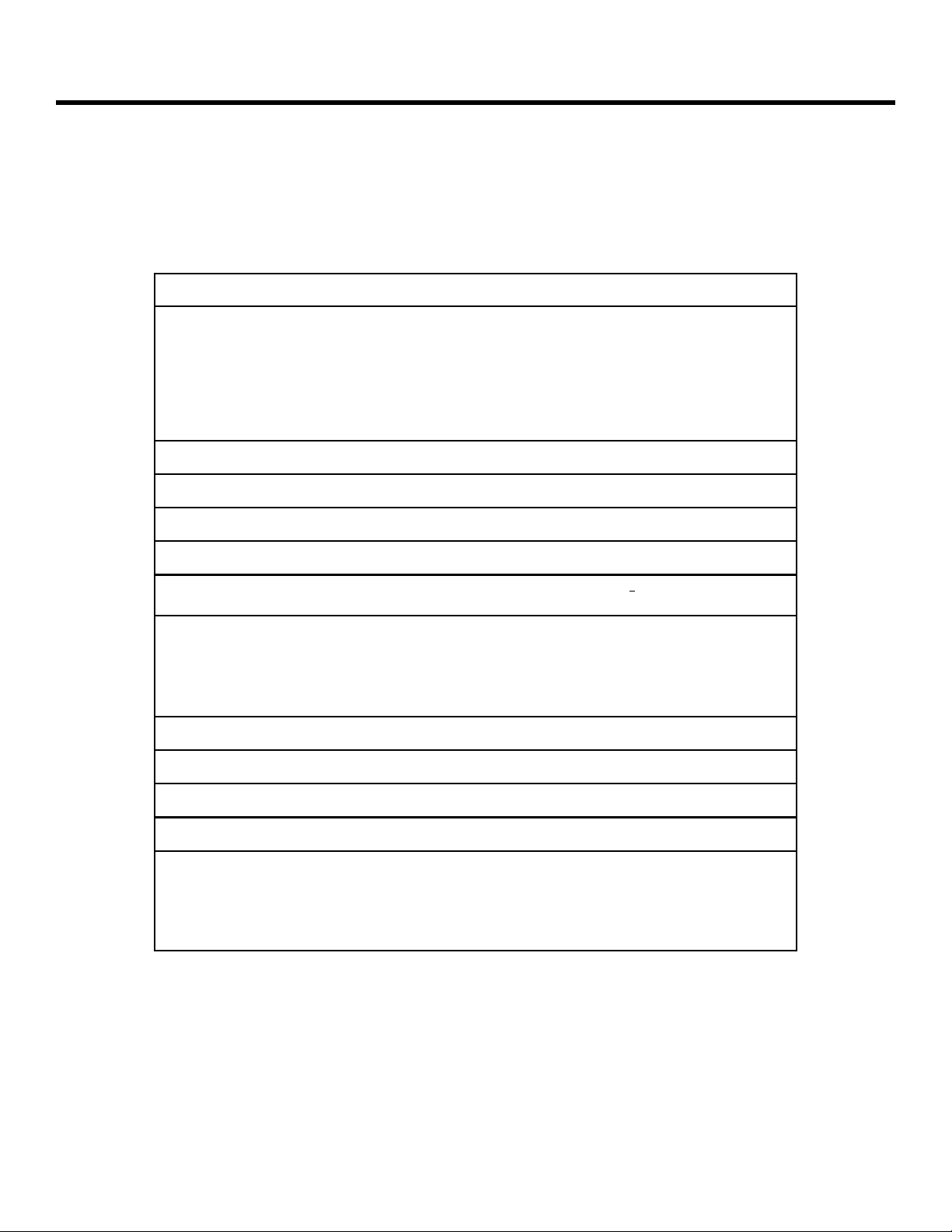

HE 402 COMPACT OPERATOR

T

Parameter 402 Operator

Physical dimensions:

Weight, lb (kg) 14-1/3 (6.5)

Length, in. (mm) 36 (914)

Width ´ height, in. (mm) 3-1/2 ´ 3-1/2 (90 ´ 90)

Motor speed, rpm 1400

90-deg opening time, sec 12

November, 2003

402 Operator And

455 D Control Panel Installation Manual

TECHNICAL DATA

Thrust and traction force, lb (kg) 0–1100

Maximum duty cycle, motor run time 50%

Power voltage required, VAC

(frequency, Hz)

Current draw, amps

115 VAC power source 2.4

220 VAC power source 1.2

Operating temperature range, deg F (deg C)

Thermal cut out, deg F (deg C) 212 (100)

Oil quantity, qt (liter) 1-1/2 (1.4)

Oil type FAAC XD 220 or Shell/Tellus 15

Gate leaf constraints

Maximum weight per leaf, lb (kg) 900 (410)

Maximum length per leaf, ft (m) 10 (3)

1

115 (50–60) + 10% or

230, +6 or -10% (50–60)

-4 to 131 (-20 to 55)

1

1

Your standard 220 VAC power source meets the specification for

the required power supply of 230 VAC, +6 or –10%.

Page 5

November, 2003

402 Operator And

455 D Control Panel Installation Manual

UNPACKING THE OPERATOR

Page 5

When you receive your 402 Compact Operator, complete

the following steps.

Inspect the shipping box for physical damage such as

leaking oil or a torn carton. Then inspect the operator

after you remove it from the box. Notify the carrier

immediately if you note any damage because the carrier

must witness the damage before you can file a claim.

As you unpack the box, insure that all the parts listed

below are included (see Figure 1). If you have ordered a

kit (a pair of operators), you will have twice the quantity

of parts listed below (except where noted), and you will

also have a radio receiver and two transmitters.

1 Control panel box with control panel inside (only 1

per kit)

1 402 Operator unit

1 Protective cover for the operator

1 End cap or guard cover

1 Rear mounting bracket (for post or wall)

1 Rear mounting plate (use is optional)

1 2 in. (50 mm) operator pin with 1 nut for

attachment to rear mounting bracket

1 Mounting fork support

1 2-3/4 in. (70 mm) operator pin with 1 self-locking

nut for attachment to rear flange of operator

1 1-1/8 in. (29 mm) pin for fixing the front coupling

to the operator’s piston rod

2 E clips for either end of the pin fixing the front

coupling to the operator’s piston rod

1 Front mounting brackets

1 Nameplate (with 2 screws) for covering pressure

adjustment screws

1 Manual Release key

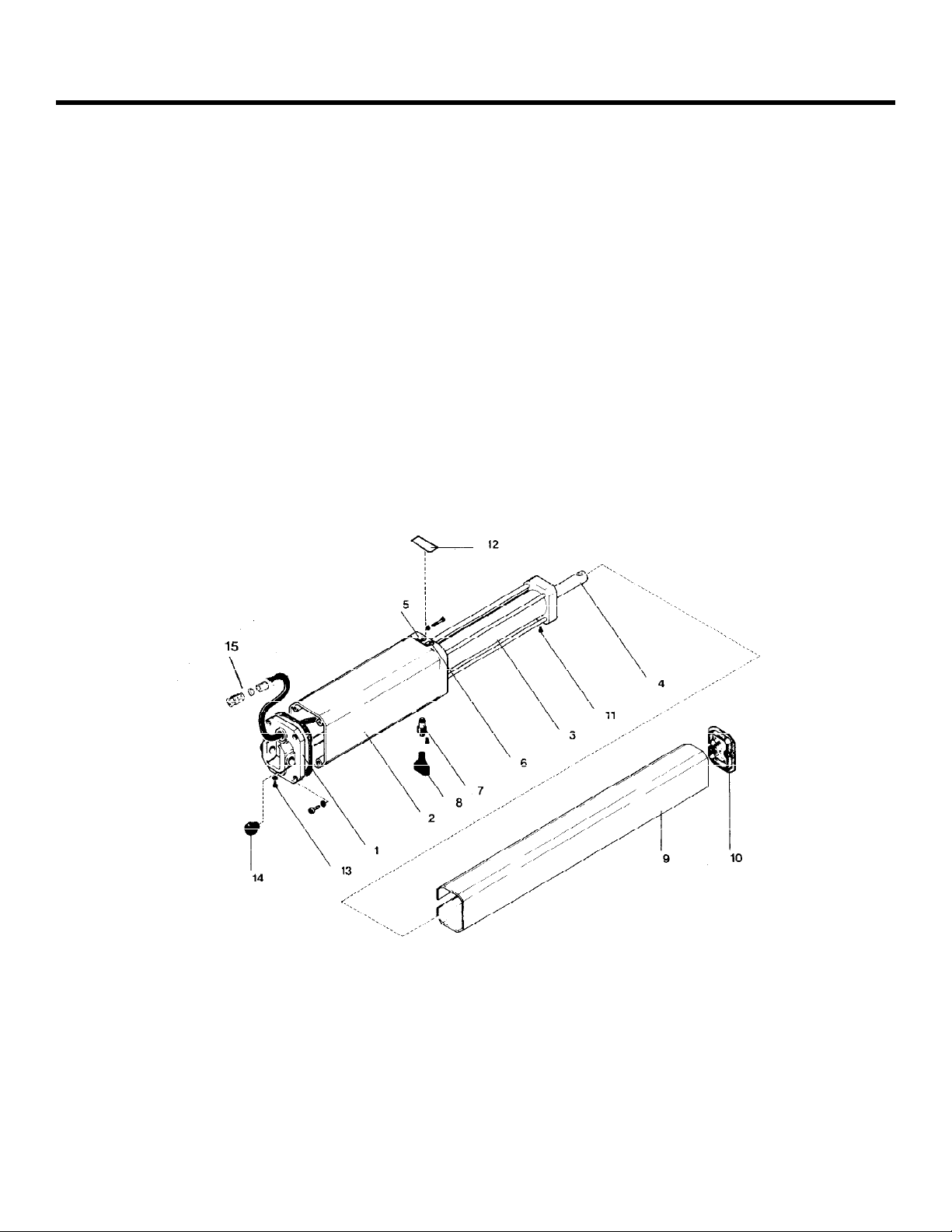

Figure 1. The 402 Compact Operator

1 Rear flange 8 Manual Release key

2 Operator casing containing pump and motor 9 Cover

3 Cylinder body 10 Cover end cap

4 Piston rod with hole for attaching to front mounting bracket 11 Cover fixing screw (1 of 2)

5 Green screw for adjusting pressure 12 Nameplate secured with screws

6 Red screw for adjusting pressure 13 Oil vent screw

7 Manual Release Mechanism 14 Oil loading cap

Page 6

Page 6

November, 2003

402 Operator And

455 D Control Panel Installation Manual

THE 402 COMPACT OPERATOR

GENERAL CHARACTERISTICS

The 402 Compact Operator is an automatic, light-duty

gate operator it can accommodate a gate leaf up to 10 ft

(3m) in length and up to 900 lbs (410 kg) in weight.

Note: The 402 Compact Operators are

recommended for use with solid gates.

The self contained 402 operator is an electro-hydraulic

unit consisting of an electric motor, a pump, a valve

assembly and a hydraulic cylinder, all housed in an

anodized aluminum oil reservoir.

All models of the 402 operator have one hydraulic lock.

The CBC version is designed to lock when the piston is

extended. The CBA version is designed to lock when the

piston is retracted.

The hydraulic lock is a service device rather than a

security device. Additional external locks are

recommended under the following conditions:

• Your gate leaf is 10 ft or longer.

• Your installation site requires tight security.

• Your gate site is subject to vandalism.

• Your gate site is subject to strong or very

gusty wind.

• Your gate system has an open-hold-open

device.

The electronic control panel is a microprocessor-based

controller that accepts a range of product accessories

and reversing devices to allow flexibility in designing

the gate system. The 450 MPS control panel allows you

to set the opening/closing time, a leaf delay for a two-

not

leaf gate system, the operating logic for your gate

system, the pause time, the reversing stroke, and the

behavior of reversing devices.

For its protection, the single phase, bi-directional

electric motor shuts off automatically if its operating

temperature reaches 212 deg F (100 deg C). Also for the

protection and proper operation of the 402 operator,

each gate leaf on which it is installed must have a fixed

positive stop in both the open and closed positions.

The 402 Operator also includes a triangular key

operated Manual Release Mechanism and two bypass

valves which precisely control the force applied to the

gate leave(s). The Manual Release Mechanism is a key

operated device that disengages or engages the

hydraulic system of the 402 Operator. When the

hydraulic system is disengaged, you can open and close

the gate leaf by hand. Such manual operation of the

gate leaf is necessary during installation and useful

during power failures.

The two bypass valves located on the top of the

operator needs to be adjusted to meet the safety

standards of FAAC International, Inc. The standards

state the gate leaf should stop, if it encounters a force

greater than 33 lbs. (15 kg). Once the pressures are

adjusted, the by pass valve screws are covered so that

the pressures are not altered.

Additional reversing devices such as photobeams or

reversing edges should be installed to provide more

complete safety for people and property.

The electronic control panel is a microprocessor-based

controller that accepts a wide range of product

accessories and reversing devices. Thus allowing for

flexible gate system design.

INSTALLATION INSTRUCTIONS

Installing the 402 Compact Operator involves preparing

the gate, installing the operator(s), installing the control

panel, and fine-tuning the pressure adjustments on the

operator(s).

Note: The following installation instructions

assume you are fully capable of installing an

operator. This manual does not instruct you in

designing a gate, installing a gate, or basic

electrical wiring. The installation tasks discussed in

this manual are tasks peculiar to the 402 Operator.

PREPARING THE GATE

Before installing the 402 Operator, you need to prepare

the gate itself for the operator. Be sure to do the

following things:

1. Make sure that the gate is plumb.

2. Make sure that the gate moves smoothly on its

hinges without excessive friction by swinging

it open and closed by hand. Lubricate all the

gates’ moving parts.

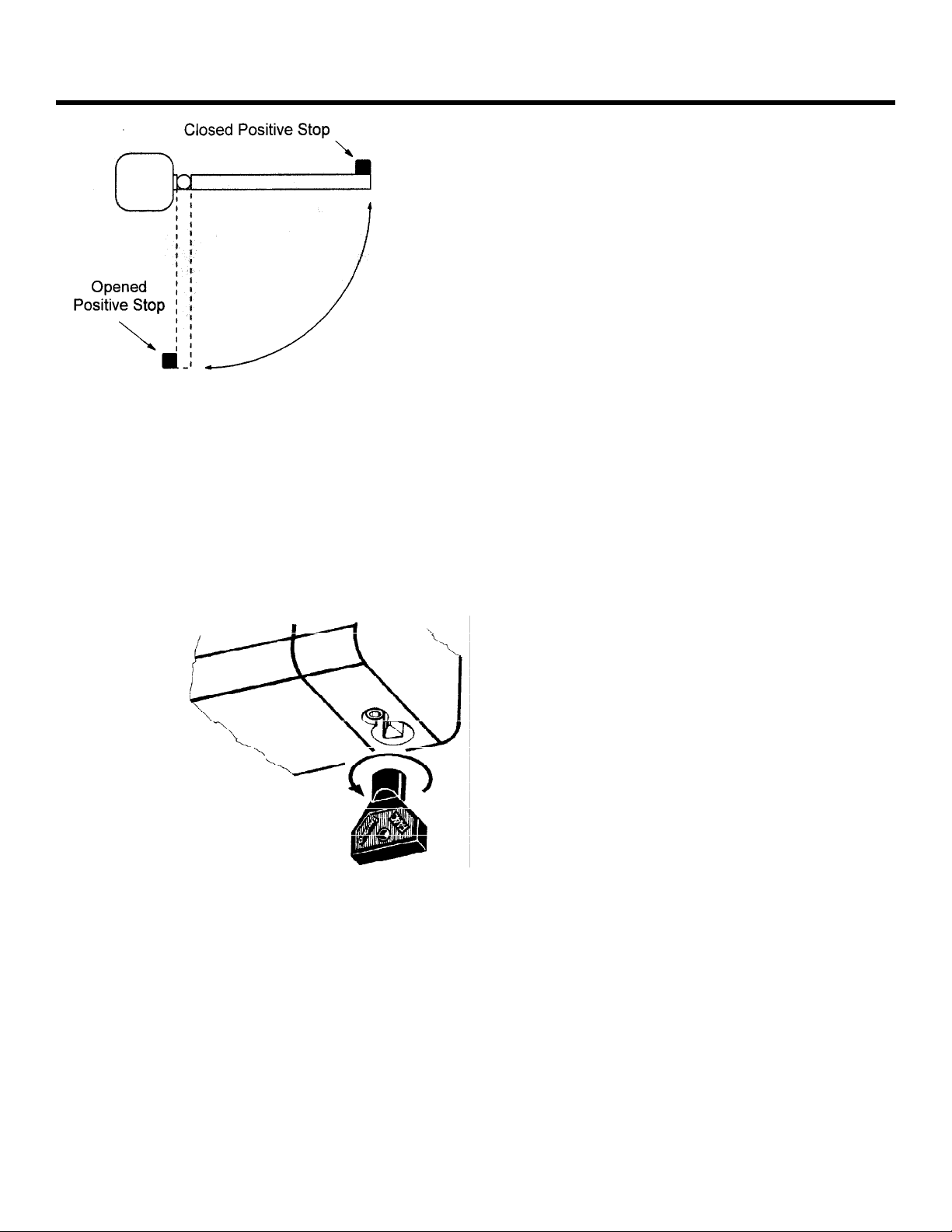

3. Provide positive stops for the gate leaves in

the fully open and fully closed positions (see

Figure 2).

Page 7

November, 2003

402 Operator And

455 D Control Panel Installation Manual

Figure 2.

Positive Stops

MANUAL RELEASE MECHANISM

Insert the key and turn it counterclockwise one full turn

to disengage the operator’s hydraulic system (see Figure

3). You can now move the gate leaf slowly by hand to

open or close the gate.

Operating the gate leaf by hand is necessary during

installation and is useful during power failures.

You re-engage the hydraulic system by turning the key

clockwise one full turn.

Turn the key counterclockwise 1/2 turn to disengage

the hydraulic drive

Figure 3. The Manual

Release key, bottom view

NSTALLING THE OPERATOR

I

Installing the model 402 operator consists of the

following steps:

1. Attaching the rear mounting bracket

2. Attaching the operator to the rear mounting

bracket

3. Attaching the front mounting bracket to the

operator

4. Attaching the operator to the gate leaf

5. Adjusting the hydraulic pressures for the

operator

Page 7

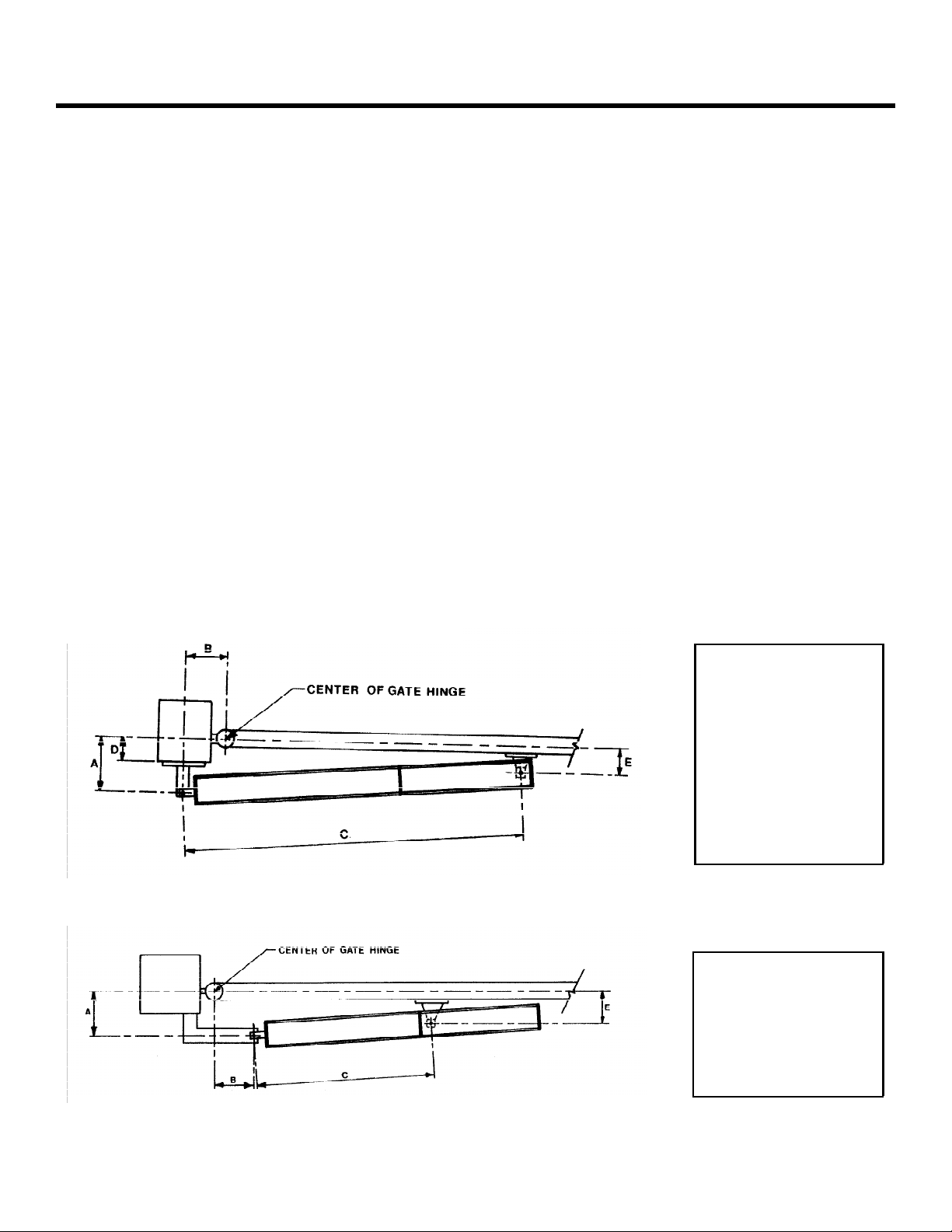

ATTACH THE REAR MOUNTING BRACKET

Attach the rear mounting bracket according to the

dimensions in Figure 4.

WARNING! You must achieve the A and B

dimensions, dimensions as specified in Figure

4. Modification of the rear bracket may be

necessary to achieve these dimensions (I.e.,

cutting or extending the bracket provided)

If you have a steel gate post, weld the rear bracket

directly to it. If the gate post is made of any other

material, attach the optional mounting plate, with

lag bolts or anchors, and weld the bracket to it.

For an outward swing gate refer to Figure 5.

ATTACH THE MOUNTING HARDWARE

Place the operator so that the red and green pressure

adjusting screws face up. Place the mounting fork (hex

cut up if you have a nylon rear fork) in the operator’s

rear flange, secure with the long brass pin and selflocking nut.

Attach the fork assembly to the rear mounting bracket

and secure with the short pint, washer, and nut.

Push the front pin through the front mounting bracket

then the piston red to temporarily attach them

together.

ATTACH THE FRONT MOUNTING BRACKET

TO THE OPERATOR

Insert the triangular key over the Manual Release

mechanism on the underside of the operator and

turn the key counterclockwise one turn.

For inward swing, pull the piston completely out and

push it back inward approximately 1/4 “ (6mm).

For outward swing, push the piston in completely

and pull it back out approximately 1/4“ (6mm).

NOTE: Be sure the operator is level and that

the gate is against the closed positive stop.

Hold the front mounting bracket flush against the

gate, mark the location of the front mounting

bracket, remove the operator from the gate.

Remove the front mounting bracket from the piston

rod.

NOTE: Clamping the front mounting bracket at

the marked location before checking the swing,

Page 8

Page 8

November, 2003

402 Operator And

455 D Control Panel Installation Manual

as instructed below, will ensure proper location

of the front mounting bracket.

Bolt or weld the front mounting bracket to the

marked location on the gate.

WARNING! Do Not Weld the front mounting

bracket with the operator attached. Doing so

will seriously damage the operator.

ATTACH THE OPERATOR TO THE GATE

Re-attach the operator to the mounting brackets. Once

the operator is mounted and level, remove the vent

screw from the bottom of the valve body. Use a 3mm

hex wrench.

WARNING! Failure to remove the vent screw may

result in erratic operation of the operator or blown

seals.

Slowly move the gate open and close.

WARNING! The piston should not bottom out in

either direction. Doing so will seriously damage

the operator.

Be sure that the gate reaches the positive stop

before the piston bottoms out.

After checking the swing of the gate, secure all nuts and

bolts.

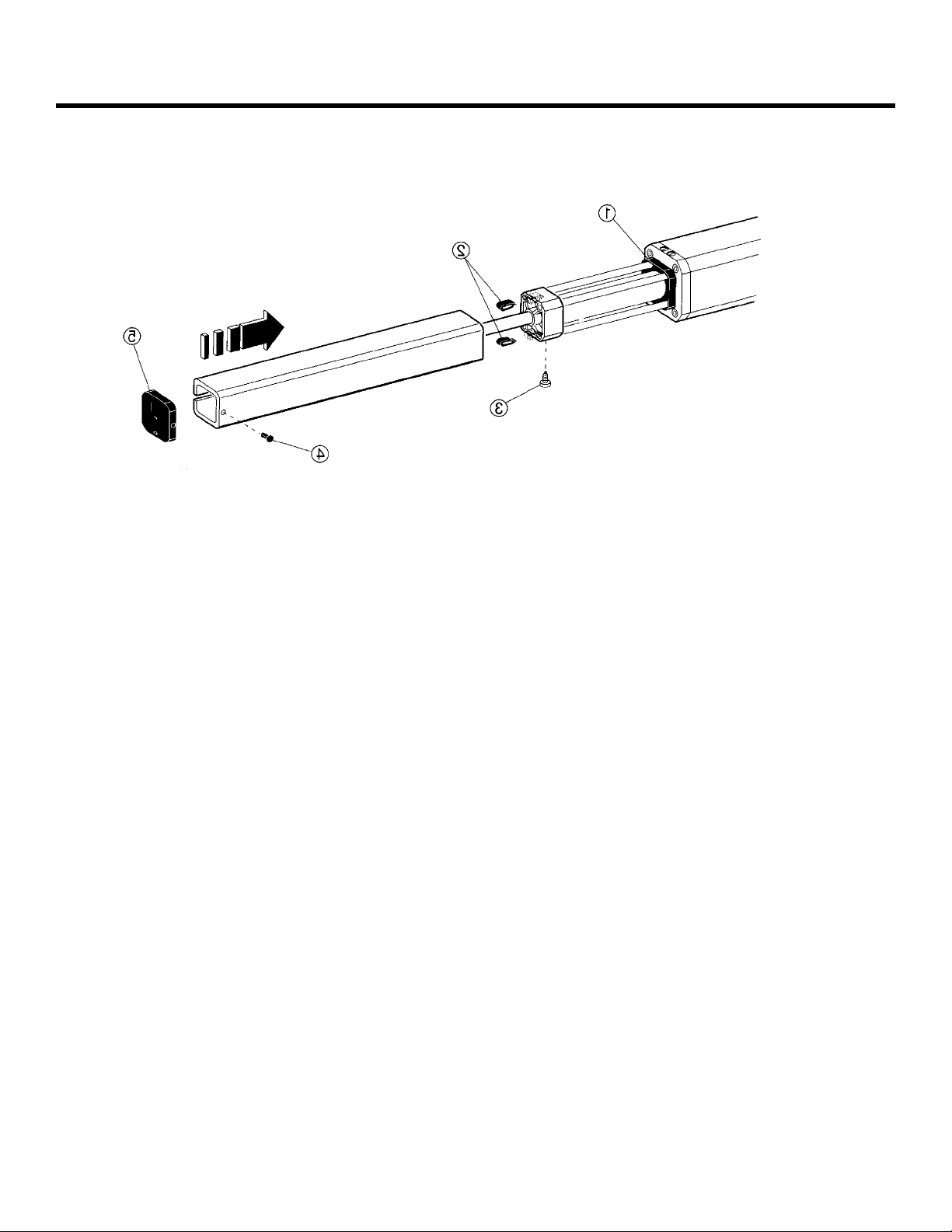

Once the operator is secure, install the protective cover

over the piston of the operator, first insert the two

spacers (items labeled 2 in Figure 6) in the front flange

of the operator as shown. The spacers dampen any

vibrations to the operator.

Next, slip the cover over the operator. The slit in the

cover should face the gate, and the cover should be

placed firmly over the rear of the operator cover (item 1

in the figure).

Finally, use the black plastic screws (items 3 and 4) to

fix the cover to the operator and the end cap (item 5).

Figure 4. An inward swinging gate, top view: important mounting dimensions

402 Standard

A 4-1/2 in. (114 mm)

B 4-1/2 in. (114 mm)

C 35-1/2 in. (902 mm)

D If greater than 2 in.

(50 mm), construct

a recess liner.

E Must be less than A

402 Standard

A 4-1/2 in. (114 mm)

B 4-1/2 in. (114 mm)

C 26-1/2 in. (673 mm)

E Must be less than A

Figure 5. An outward swinging gate, top view: important mounting dimensions

Page 9

November, 2003

402 Operator And

455 D Control Panel Installation Manual

Page 9

Figure 6. Install the cover for the 402

Operator

INSTALLING THE 455 D CONTROL PANEL

Locate the control panel in the most convenient position

possible, considering the movement of the gate. Figure

6 shows a basic layout for a two-leaf gate with the 402

Compact Operator.

Installing the control panel consists of the following

general steps:

• Connecting the main power to the control

panel

• Connecting the activating device

• Connecting the operator to the control panel

• Checking the direction of the motor's rotation

• Connecting other devices to the control panel

• Set operating modes

The installer is responsible for grounding the gate and

operator systems, for providing the main power breaker

switch, and for making sure that the entire gate system

meets all applicable electrical codes.

For the complete 455 D Control Panel Installation

Instructions, see pages 14—25 of this manual.

Page 10

Page 10

November, 2003

402 Operator And

455 D Control Panel Installation Manual

Figure 7. The layout of a sample gate system

6

1

5

3

A

A

Locate switches at least

10 ft from the gate

2

8

1

A

4

5

C

B

3

7

B

A

C

D

9

1 Operator

2 Control Panel

3 Photocell A 2 × 18 AWG A 2 × 18 AWG

4 Switch B 4 × 14 AWG B 4 × 14 AWG

5 Junction box (see text) C 5 × 18 AWG C 5 × 18 AWG

6 Reversing edges D 4 × 14 AWG up to 414 ft D 3 × 14 AWG up to 130 ft

7 Gate stops

8 Switch

9 Wiring to main circuit breaker

220 VAC 115 VAC

Wire Gauges for Given Voltage

3 × 10 AWG up to 340 ft

Page 11

November, 2003

402 Operator And

455 D Control Panel Installation Manual

EXPLODED VIEW, 402 CBC

Page 11

Page 12

Page 12

November, 2003

402 Operator And

455 D Control Panel Installation Manual

402 PARTS LIST

POS PART NO. DESCRIPTION QTY

1 2036 Galvanized Nut (8mm) 1

2 7220015 Rear Bracket 1

3 7284005 Rear Bracket Plate 1

4 7182075 Short Pin 1

5 7221115 Rear Fork 1

6 2037 Self-Locking Nut (8mm) 1

7* 7109145 Strain Relief 1

8* 7109155 Strain Relief Nut 1

9* 7039305 Strain Relief Brass Washer 1

10* 2581 Fiber Washer 1

11 7514055 Electric Power Cord 1

12 7170435 Rear Flange 1

13 7099101 Gasket (D80) 2

14 7450005 Operator Body 1

15 N/A Self-Threading Screw 1

16 7119475 Silent Block 2

17 2365 Motor Bolt (4mmX50) 4

18 2366 Lock Washer 4

19 2367 Hex Nut (4mm) 4

20** 77000425 115V 1400 RPM Motor 1

21 7119485 Vibration Dampener 2

22 N/A Vent Screw Label 1

23 7182175 Long Pin 1

24 N/A Socket Head Screw

(5X20mm)

25 7110015 Plug (Oil) 1

26 2274 Vent Screw (4x6mm) 1

27 7094065 Gasket (Copper) 1

28 3204395 1 Lt Lobe Pump 1

29 N/A Pump Pin 2

30 7203275 By-Pass Protection Cover 1

31 760285 Spacers (Protective Cover) 2

32 7271545 Protective Cover End Cap 1

33 7114025 Protective Cover Plug 1

34 7272085 Protective Cover 1

35 4304015 Front Mounting Bracket 1

36 7182355 Pin Front Bracket 1

37 N/A Black Plastic Screw 1

38 7090010015 O-Ring (3) 3

39 N/A Stainless Steel Screw

(2.9mm x 6.5mm)

8

2

POS PART NO. DESCRIPTION QTY

101 4404065 Inlet Valve 2

102 N/A O-Ring 5

103 7049135 Valve Retainer 2

104 4180205 Blank Lock Valve 1

105*** 4180135 Green By-Pass Valve 1

106*** 4181045 Red By-Pass Valve 1

107 7090150 O-Ring (By-Pass Valve) 2

108 7210025 By-Pass Spring 2

109 7119335 By-Pass Seat 2

110 7090350 O-Ring (Front Flange) 2

111 7090665 O-Ring (Alum Retract Tube) 2

112 7361315 Retract Tube (Alum) 1

113 7230225 Tie-Rod (Cylinder) 4

114 N/A O-Ring (Front Flange Internal) 1

115 N/A Star Washer 4

116 4994165 Front Flange 1

117 4350065 Piston Assembly 1

118 7095035 Piston Rod Packing 1

119 7366065 Cylinder 1

120 7271555 Protective Cover Guide 1

121 7090300 O-Ring (Shuttle Piston) 1

122 4180285 Shuttle Piston 1

123 4404085 Lock Valve 1

124 4180355 Manual Release 1

125 713002 Triangular Release Key 1

126 N/A Galvanized Screw 1

127 709069 O-Ring (Manual Release) 1

128 4994365 Valve Body (CBC) 1

129 7049005 Brass Retainer 1

130 3905235 Skin Pack 1

131 2168* Seal Kit 1

132 6105 1 Qt. Monolec Oil 1

∗ Included in Kit #2167A*

∗ * 220V 1400RPM Motor Part #77000415

∗ ** Items include item #107, 108, and 109 in a kit

Page 13

November, 2003

402 Operator And

455 D Control Panel Installation Manual

T HE 455 D

ONTROL PANEL:

C

I

NSTALLATION MANUAL

Page 13

P

AGES 14— 25

Page 14

Page 14

November, 2003

402 Operator And

455 D Control Panel Installation Manual

THE 455 D CONTROL PANEL

GENERAL DESCRIPTION

The FAAC 455 D control panel is used to operate the

following models.

Swing gate operators:

400 412

402 750

422 760

Barrier gate operators:

610/615

The 455 D programming controls the following:

Operating logic: A, S, E, EP, B, and C logics

available.

Reversing device behavior: Choose whether a

triggered reversing device during closing

immediately reverses gate movement or stops

the gate and reverses gate movement when no

longer triggered.

Torque or Pressure: Force adjustment for the 412

operator. Adjustable from 0 to 50.

Caution: For all hydraulic operators, the torque

must be programmed to the maximum (50)

setting.

Pause time between opening and closing:

adjustable from 0 to 240 seconds.

Opening/Closing time: adjustable

from 0 to 120 seconds.

Leaf delay on closing: adjustable from 0 to 28

seconds.

The 455 D control panel should be installed in an

enclosure that is conveniently located as close as

possible to the gate operator. All electrical

connections from the control panel to the operator

must be made in a weatherproof junction box.

The 455 D control panel requires a single-phase

power supply voltage (115 VAC [±10%] or 230 VAC

[+6 or -10%], 50–60 Hz). The power supply should be

protected by a 15 amp dedicated circuit breaker (not

provided).

The installer is responsible for grounding the operator

system, for providing the main power breaker switch,

and for making sure that the entire gate system meets

all applicable electrical codes. The installer should refer

to the installation manual for a given operator for more

information.

N

OTE: An installation is U.L. compliant only

when you install the FAAC operators according

to the UL325 standards.

INSTALLING THE 455 D CONTROL PANEL

Locate the control panel in the most convenient position

possible, considering the movement of the gate.

Installing the control panel consists of the following

general steps:

• Connecting the main power to the control

panel

• Connecting the activating device

• Connecting the operator to the control panel

• Checking the direction of the motor's rotation

• Connecting other devices to the control panel

• Set operating modes

CONNECT THE MAIN POWER SUPPLY

WARNING! Turn the main power off before you

make any electrical connections or before

programming.

Wire the main power supply to control panel terminals

in block J3 (see Figures 9 and 11). The installer is

responsible for insuring that a separate, grounded

circuit protected by a circuit breaker is between the

control panel and the main power supply. All wiring

should conform to applicable electrical codes, and all

wiring and fittings should be weatherproof and/or

suitable for burial.

Connect the ground to the grounding terminal in block

J3 and connect the power wires to the terminals labeled

N (neutral) and L (line).

N

OTE: For a 230V system, a neutral is not

needed. Connect one 115V line to the L (Line)

and a second 115V line to the N (Neutral).

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

Page 15

November, 2003

402 Operator And

455 D Control Panel Installation Manual

Page 15

CONNECT THE OPERATOR(S) TO THE

ONTROL PANEL

C

WARNING!

you make any electrical connections or before

programming.

CAUTION: The operators are grounded only by

the grounded circuit the installer provides.

USING A JUNCTION BOX

If an operator is more than 2 ft away from the control

panel, you must use a junction box for connection.

Use a U. L. Listed cord grip where the operator cord

enters the junction box.

Note: If you have a one-leaf gate design, the

operator must be connected to Motor 1

(terminals 1,2, & 3)

To wire up motor 1, connect the white wire to

terminal 1(on the J4 terminal strip), the black wire to

2, and the red wire to 3. Wire each leg of the capacitor

(supplied) to terminals 2 & 3.

Note: If you want to delay the closing of one gate

leaf in a two-leaf gate design, be sure to connect

its operator to Motor 1.

In order to wire motor 2 in a bi-parting system,

Turn the main power off before

connect the white wire to terminal 4 (on the J4

terminal strip), the black wire to 5, the red wire to 6.

Wire each leg of the capacitor (supplied) to terminals

5 & 6.

CHECK THE MOTOR’S DIRECTION OF

OTATION

R

WARNING! The pressure valves are not preset at

the factory and may operate a gate leaf with

enough force to endanger people and seriously

damage the gate leaf itself.

After you have connected the main power supply, and

the operator(s) to the control panel, you need to

check the direction of rotation for each operator

motor in your gate design.

Note: To check a motor’s direction of rotation,

you must have three closed circuits on terminal

block J1. Install one circuit between terminals 11

and 16, another circuit between terminals 12

and 19, and another circuit between terminals

13 and 19.

J3 terminal block for

main power supply

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

J3

K

1-455D115 = 115V

1-455D = 230V

M

N L

MAIN

Figure 8. The 455 D Control Panel

MOTOR 2

M

LAMPCOMOP CL

CLCOMOP

F1

1 2 3 4 5 6 7 8

MOTOR 1

F2

J4J5J1

9 10 11 12 13 14 15 16 17 18 19

NC -B -

A + TX

STOP

V1- 4

61C455D

J4 terminal block for connecting the operator(s)

J1 terminal block for low-

J2

F-+

voltage accessories

RADIO

J2 quick connector port

F Function Push Button

— Programming Push

Button

+ Programming Push

Button

FUSES

J6

22 23 24 25

20 21

FCA 1

FCA 2

+OP -CL

+24 VFSW

FS W

W. L.

LOCK

FCC1

F1

Main Power

FCC2

F2

Accessories

220

VAC

5 A 10 A

800

mA

115

VAC

800

mA

Page 16

Page 16

November, 2003

402 Operator And

455 D Control Panel Installation Manual

N L

115 VAC +/- 10%

or

230 VAC +6/ -10%

50-60 Hz

1 2 3 4 5 6 7 8

MOTOR 1

BLUE

M1

OPCOM CL

C1

OPCOM CL

MOTOR 2

BLUE

M2

C2

Figure 9.

The terminal strip wiring of the

455 D with photobeams

NOTE: In o rder to compl y with UL 325, two sets

of FAA C photobeams m ust be installed. One set

shoul d be 6 i n. outsi d e the clos ed gate(s) and act

as a c losing reversing device. Another set should

be 6 in. bey ond the swing of the gate(s) and ac t

as an opening reversi ng dev i ce. The installer is

responsible for determining the appropriate

mounting hei ght.

You cannot check the motor’s direction of rotation

without these circuits (jumpers) or the accessories.

When properly prepared for testing, the LEDS FSWOP,

STOP, and FSWCL should be illuminated (see figure 11

on page 17).

WARNING! Running the operator—even for

testing purposes—without a connected reversing

device is potentially dangerous. Do not place

yourself within the path of the moving gate

during your test.

Disengage the operator(s) with the Manual Release

key (see operator installation manual), and open the

gate by hand about halfway.

Next, engage the operator(s) with the Manual Release

key so that you can check the rotation of the motor

(s).

To activate the operator(s) momentarily short across

terminals 9 and 14.

Turn on the main power and send an activating signal

to the operator. The gate leaf (or leaves) should open.

If a gate leaf closes, then you need to turn off the

main power and reverse the connection of the red

and black wires on terminal block J4 for the operator

controlling that leaf. Then you need to recheck the

rotation direction again.

After having completed your test of the motor’s

direction of rotation, replace any test circuits you

installed (between terminals 11 and 16, between 12

and 19, and between 13 and 19) with the proper

reversing and stop devices. The instructions for

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

installing such accessories follow.

9 10 11 12 13 14 15 16 17 18 19

LAMP

STOPOPE N OP EN

(1 of 2 )

-

OPCL -

FS W

CONNECT OTHER DEVICES

WARNING! Turn the main power off before you

make any electrical connections.

P

OWER SUPPLY FOR ACCESSORIES: You can access a 24

VDC output for supplying power to accessories

through terminals 17 or 18, (+) and 14 or 15 or 16, () on terminal block J1. In most cases, this source can

be used to power 24 VDC accessories.

NOTE: The 455 D control panel allows a

maximum accessory load of 800 mA.

R

EVERSING DEVICES: Reversing devices include

photocells, inductive loops, and so forth. All of the

reversing devices should have contacts of the

normally closed (N.C.) type. Where you connect a

device depends on whether you want the device to

operate during opening or during closing.

N

OTE: UL does not recognize the FAAC system

with loop detectors or safety edges. FAAC

photobeams must be used to comply with UL

325.

To wire photobeams, refer to page 19 (see FSWOP for

opening photobeams, and FSWCL for closing

photobeams). Photobeams must be connected as

shown. See also page 19 for the wiring of inductive

loops. If using more than one reversing device, they

must be wired in series.

- - +

Other safeties

1

2

3

4

5

1

2

+

24V

FS W OP

FS W CL

FS W

20 21

W.LIGHT

24 vdc

3 W

1

2

1

2

3

4

5

22 23 24 25

LOCK

ELECTRIC LOCK

Page 17

November, 2003

402 Operator And

455 D Control Panel Installation Manual

(a)

To the U. L. Listed gate operator

U.L. Listed Control Panel Enclosure

(b)

Page 17

U.L. Listed

cord grip

Junction box

Legend

Figure 10.

Wiring detail (a) inside

the junction box and (b)

from the junction box or

operator to the high-

voltage terminal strip on

White

Red

Black

Yellow/

Green

the 455 D control panel

Conduit to U.L. Listed

To the U.L. Listed

control panel

control panel enclosure

according to N.E.C.

ACTIVATING DEVICES AND RADIO RECEIVER: The activating

devices and radio receiver for your gate must have

normally open (N.O.) contacts. Connect such devices to

terminals 9 and 14.

N

OTE: The FAAC radio receiver plugs into the 5

prongs labeled J2 (Quick connect port).

Page 19 shows how to connect a three or four wire

receiver.

DECODER CARD: If you are installing the Digicard

magnetic card reader, or the Digikey keyboard, use the

quick-fit connector J2 for the DS decoder card (see

Figure 8).

N

OTE: If your using both a receiver and decoder,

hard wire the decoder and plug in the receiver.

OPEN/HOLD OPEN DEVICE: To open and hold open the

gate, simply maintain a contact across terminals 9 and

14. (“A” Mode only)

STOP BUTTON: The stop button you install must have

normally closed (N.C.) contacts. Multiple stop buttons

must be wired in series. Connect your stop device

between terminals 11 and 16.

N

OTE: The 455 D will not operate the motors

without a closed circuit between 11 & 16.

The LED Indicators: The nine light emitting diodes

(LEDs) on the control panel can be used to check for the

proper function of the devices attached to the panel.

The LED lights are on whenever the contacts are closed

across each of the respective terminals.

OP_A and OP_B (Partial Opening) should illuminate only

when an activating signal is sent for 2 and 1 gate leaves,

respectively. STOP should be illuminated except when

the stop button is pressed. FSWOP and FSWCL should be

illuminated except when the reversing devices, for

Cord grip or

conduit from

U.L. Listed gate

operator(s)

LED On Off

OP_A Command Given No Command

OP_B Command Given No Command

Stop No Command Command Given

FSW

Open

FSW

Close

FCA1

Opening reversing

devices clear

Closing reversing

devices clear

Flashes when gate coder is in use.

FCC1

FCA

2

Flashes when gate coder is in use.

FCC

2

FSWOP

OP_A

STO P

OP_B

FSWCL

FCA1

FCA2

This display shows the

meaning of each LED.

Figure 11. The 455 D display.

455 D Control Panel

High-voltage

terminal strip

J3 J4

COM OP CL COM OP CL

Op.1 Op.2

J1

Ground

Reversing device

triggered

Reversing device

triggered

Operator 1

Operator 2

FCA1

FCC1

FSWOP

OP_A

STOP

FCC2

OP_B

FSWCL

FCA2

This display shows the normal

status of the control panel.

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

FCC1

FCC2

Page 18

Page 18

November, 2003

402 Operator And

455 D Control Panel Installation Manual

opening and closing, respectively, are triggered. Use

the LEDs and the next table to determine if the

accessory devices you have installed are operating

properly.

Electric Locks: An electric lock can be wired to the

455 D in

If a reversing stroke is needed to allow the electric lock

to release, this must be done in advanced

programming.

See page 19 for the connections for a magnetic locking

device.

terminals 18 and 21 (12Vac pulsed provided).

WARNING LIGHT: Connect a warning light to

terminals 18 and 20 in the group labeled

in terminal block J1 and J5. The terminals provide

an output voltage of 24 VDC, maximum power 3

Watts. This output voltage will power most 24 VDC

warning lights.

N

OTE: The behavior of the warning light varies

according to the logic you have set.

W.LIGHT

LOGICS A, S, E, EP, AND B: The warning light is on

steadily during opening and the pause phase. During

closing, the light flashes.

LOGIC C: The warning light is on steadily during

opening and flashes during closing.

SET OTHER OPERATING CONTROLS

WARNING

make any electrical connections.

You need to program the control panel for your gate's

operation. The 455 D Control Panel has on board

programming that controls a wide range of functions.

OPERATING LOGICS

NOTE: The 455 D Control Panel provides inputs

for opening reversing devices and closing

reversing devices. FAAC strongly recommends

the use of reversing devices, such as photocells

or other non-contact sensors.

•

A (automatic): The gate opens on command

and automatically closes after a pause phase. A

second command while opening is ignored; a

second command during the pause phase

interrupts the pause time; a second command

during closing reopens the gate. A maintained

open command will hold the gate open.

•

S (security): The security mode is like A logic

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

except that a second command during opening

immediately closes the gate. A maintained

open command will not hold the gate open.

! Turn the main power off before you

• E (semi-automatic): This mode requires a

command to open and a command to close.

A second command during opening stops the

gate. A second command during closing

reopens the gate.

•

EP (semi-automatic, step by step): This

mode requires a command to open and a

command to close. A second command

during opening or closing causes the gate to

stop. A third command then reverses the

previous motion of the gate.

•

B (manned, pulsed): This mode is designed

for guard station use and requires a three-

The three programming push buttons allow the

programming of the torque (or pressure), the pause

time between opening and closing, and the leaf delay

on closing.

button switch (pulsed) to open, close, and

stop the gate.

•

C (manned and constant): This mode

requires constant pressure switches. One to

open and one to close. No pressure on a

switch stops the gate.

WARNING! Turn the main power off before you

make any electrical connections.

For all FAAC hydraulic operators using the 455 D

control panel, the force must be set at its maximum

setting of 50 in order to supply the correct voltage to

the operator.

PAUSE TIME: The pause time between opening and

closing can be adjusted from 0 seconds to 4 minutes.

Time is adjusted in one-second increments from 0—

59 seconds. When 60 seconds is reached, time is

adjusted in 10 second increments up to 4 minutes.

i.e. if display shows 2.5, it means 2 minutes and 50

seconds.

LEAF DELAY: You may choose to delay one leaf on

closing for overlapping gate leaves. Be sure the

operator on the leaf for delayed closing is connected

to Motor 1. On opening, the leaf connected to Motor 2

is delayed 2.5 sec.

N

OTE: If an opening leaf delay is desired, it must

be enabled in the Advance Programming.

However, if enabled, you cannot

opening delay of the operator connected to

Motor 2.

The closing leaf-delay time is adjustable from 0 to 4

minutes.

adjust

NOTE: If the opening/closing time is set at less

than the leaf delay time, the delayed leaf closes

at the end of the closing time.

this

Page 19

November, 2003

402 Operator And

455 D Control Panel Installation Manual

Page 19

Free Ex it Loop/ Phone/ F ireb ox

(Hold Open D ev ices )

9

14

FAAC

Rev ersing Phot oc ells

(for opening)

Additional

Reversing Devices

19

17

13

14

17

Magnetic Loc k

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

-

Lock

+

17

NO

C

14

18

21

Shadow Loop

1

TX

2

1

2

3

RX

4

5

19

12

Additional

Reversing Devices

7

8

12 vac

Relay

N.C.

N.O.

COM

Coil Volt age =

Mot or V olt age

N.C.

N.O.

COM

C

NC

Additional

Reversing Devices

19

17

12

19

17

Reversing Devices

19

12

15

17

FAAC

Rev ersing Phot oc ells

(for c los ing)

FAAC

Safet y Loop

Additional

Detector

(for c los ing)

3 & 4 Wire R adio R ec eiv ers

1

TX

2

14

1

2

3

RX

9 NO

14

17

If 4 Wire Receiver

C

-

+

4

5

Safet y Series

Wiring

1

TX

2

PHOTO-BEAMS

RX

DETECTOR

(FAAC)

FAAC

LOOP

1

1

2

7

8

19

17

12

14

17

2

3

4

5

1

2

7

8

NO = Normally Open, NC = Normally Closed, C = Common, TX = Transmitter, RX = Receiver

Figure 12. Common Accessories wired to 455 D Control Panel

Page 20

Page 20

November, 2003

402 Operator And

455 D Control Panel Installation Manual

PROGRAMMING

To program the automated system, the

“Programming Mode” must be accessed.

Programming is split into two parts: BASIC and

ADVANCED.

BASIC PROGRAMMING

To access BASIC PROGRAMMING, press the “F” key.

• If you press it (and hold it down), the display

shows the name of the first function.

• If you release the key, the display shows the

value of the function that can be modified with

keys + and — .

• If you press and hold down the “F” key again

(and hold it down), the display shows the name

of the next function, etc.

• When you reach the last function, press “F” to

exit the program, and the display resumes

showing the status of the inputs.

The table on the right shows the sequence of

functions accessible in BASIC PROGRAMMING.

ADVANCED PROGRAMMING

To access ADVANCED PROGRAMMING, press the “F”

key and, as you hold it down, press the “+” key:

• If you release the “+”, the display indicates the

name of the first function.

• If you release the “F” key, too, the display

shows the value of the function that can be

modified with keys “+” and “—”.

• If you press the “F” key (and hold it down), the

display shows the name of the next function,

and if you release it, the value that can be

modified with keys “+” and “—”.

• When you reach the last function, press the “F”

key to exit the program, and the display

resumes showing the status of the inputs.

The table on page 9 shows the sequence of

functions accessible in ADVANCED

BASIC PROGRAMMING

F

Display Function Default

O

PERATING LOGICS

A = Automatic (Timer to Close)

E = Semi Automatic

S = Security

EP = (Semi-Automatic) Step by Step

B = Manned, Pulsed

C = Manned, constant

AUSE TIME

P

This is the time between open and

closing and is adjustable from 0 to

4 min. This is only true in “A”

Mode. (see pause time description)

F

ORCE/TORQUE MOTOR 1

This adjusts the force / torque that

motor 1 is applying to the gate

leaf. Setting is 0 to 50.*

F

ORCE/TORQUE MOTOR 2

This adjusts the force / torque that

motor 2 is applying to the gate

leaf. Setting is 0 to 50.*

C

LOSING LEAF DELAY

Delays the closing of operator

wired into motor one outputs. Adjustable from 0 to 4 minutes

(Same as pause time)

M

OTOR RUN TIME

This enables where you choose

from “simple” learning or

“complete” learning of the motor

run time. See page 10 & 11 for

complete details.

Simple Learning

+

~ 1 s.

Complete Learning

+

> 3 s.

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

PROGRAM BUTTONS

+ -

LEFT MIDDLE RIGHT

F

* With Hydraulic operators the Force/Torque must be set to

the maximum setting of 50.

XIT PROGRAMMING

E

Exit from programming and return

to display of inputs status.

Page 21

November, 2003

402 Operator And

455 D Control Panel Installation Manual

Page 21

ADVANCED PROGRAMMING

+

F

+

Display Function De-

fault

M

AXIMUM TORQUE AT INITIAL THRUST:

The motors operate at maximum

torque (ignoring the torque setting)

at start of movement. Useful for

heavy leaves.

4 = Enable

No = Disabled

L

AST STROKE AT CLOSING:

The motors are activated at full

speed for 1s to facilitate locking of

the electric lock.

4 = Enable

No = Disabled

R

EVERSING STROKE:

Before opening, while the gate is

closed, the motors thrust to close

for 2 s thus facilitating release of the

electric lock.

4 = Enable

No = Disabled

L

EAF 2 OPENING DELAY (2S):

Enables delayed start (at opening) of

leaf 2, avoiding interference between

leaves.

4 = Enable

No = Disabled

F

AIL SAFE:

If this function is activated, it enables a function test of the photocells before any gate movement. If

the test fails (photocells not serviceable), the gate does not start the

movement.

4 = Enable

No = Disabled

P

RE FLASHING (5S):

Activates the flashing lamp for 5s

before start of movement.

4 = Enable

No = Disabled

E

LECTRIC LOCK ON LEAF 2:

For using the electric lock on leaf 2

instead of on leaf 1.

4 = Enable

No = Disabled

Display

Function De-

fault

I

NDICATOR-LICHT:

If 0 is selected, the output functions

as a standard indicator-light (lighted

at opening and pause, flashing at

closing, and off when gate closed).

Different figures correspond to timed

activation of the output, which can be

used (via a relay) to power a courtesy

lamp. Time can be adjusted from 0

to 59s in 1s increments, and from 1.0

to 4.1 min. in 10s steps.

0 = Standard Indicator-Light

From 1 to 4.1 = Timed Output

C

LOSING PHOTOCELLS REVERSE AT RE-

LEASE

: Enable this function if you

want the closing photocells to stop

the gate movement and reverse it

after the beam is cleared. Default setting is immediate reverse.

4 = Enable

No = Disabled

A.D.M.A.P. F

If this function is enabled, the safety

devices operate in compliance with

French standard NFP 25/362.

A

SSISTANCE REQUEST (COMBINED WITH

NEXT FUNCTION): If activated, at the

end of countdown (settable with the

next function, i.e. “Cycle programming”) it effects 8s of pre-flashing at

every Open pulse (job request). Can

be useful for setting scheduled maintenance jobs.

C

YCLE PROGRAMMING:

For setting count down of system

operation cycles. Settable (in thousands) from 0 to 99 thousand cycles.

The displayed value is updated as

cycles proceed. This function can be

used to check use of the board or to

exploit the “Assistance Request” function

.

XIT PROGRAMMING:

E

Exit from programming and return to

display of inputs status.

UNCTION:

4 = Enable

No = Disabled

4 = Enable

No = Disabled

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

Page 22

Page 22

November, 2003

402 Operator And

455 D Control Panel Installation Manual

LEARNING OF OPERATING TIMES

WARNING:

safety devices are disabled

all traffic must be avoided in the path of the gate

leaf(s).

During the learning procedure, the

! Therefore, any and

NOTE: Programming must start with the gate(s)

in the closed position.

Opening/closing time is established by the learning

procedure which varies slightly according to whether

you are or are not using Gatecoders.

LEARNING OF NORMAL TIMES

Normal learning (i.e. without Gatecoders) can be done

in two different ways:

SIMPLE LEARNING (WITHOUT SLOW DOWN)

“B

Close the gates, enter

TIME LEARNING function and press the + push-button

for 1 second the display begins flashing and the

leaves begin the opening movement.

Wait for the leaves to reach the opening positive stop

and then supply an OPEN A command after the

desired motor run time has been reached (by pushbutton or radio control) to stop the movement: the

leaves stop and the display stops flashing. One more

command given will close the gate.

The procedure has ended and the gate is ready to

operate.

ASIC PROGRAMMING

COMPLETE LEARNING (WITH SLOW DOWN)

NOTES:

•

If you do not wish to slow the gate operator

(s) down, wait for the gate to reach its

positive stop and supply two (2) consecutive

open commands (within 1 second).

• If only one gate operator (1) is used, you

must go through the entire programming

procedure, as if you were programming for

two gate operators (2). When the operator

has finished opening, supply 5 open

commands until the gate operator begins to

close, and then resume normal operations.

Close the gates, enter

TIME LEARNING function and press the + push-button

for more than 3 seconds: the display begins flashing

and leaf 1 begins opening. The following functions

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

can be commanded by the OPEN A (by push-button

wired to terminals 9 and 14, or radio control):

“B

ASIC PROGRAMMING

”,

select the

”,

select the

• When gate operator (1) reaches the position

that you want it to slow down, an open

command must be given to start the slow

down phase.

• When gate operator (1) reaches the positive

stop and the desired motor run time has

been reached, an open command must be

given to shut the motor off. At this point

gate operator (2) will automatically start to

open.

• When gate operator (2) reaches the position

that you want it to slow down, an open

command must be given to start the slow

down phase.

• When gate operator (2) reaches the positive

stop and the desired motor run time has

been reached, an open command must be

given to shut the motor off. At this point

gate operator (2) will automatically start to

close.

• When gate operator (2) reaches the position

that you want it to slow down, an open

command must be given to start the slow

down phase.

• When gate operator (2) reaches the positive

stop and the desired motor run time has

been reached, an open command must be

given to shut the motor off. At this point

gate operator (1) will automatically start to

close.

• When gate operator (1) reaches the position

that you want it to slow down, an open

command must be given to start the slow

down phase.

• When gate operator (1) reaches the positive

stop and the desired motor run time has

been reached, an open command must be

given to shut the motor off.

The display stops flashing and the gate is ready for

normal operation.

LEARNING TIMES WITH GATECODER

Learning with the Gatecoder can be done in two

different ways:

SIMPLE LEARNING

Close the gates, enter

TIME LEARNING function and press the + push-button

for 1 second: the display begins flashing and the

leaves begin the opening movement.

The movement stops automatically when the opening

positive stop is reached and the display stops

flashing.

“Basic Programming”,

select the

Page 23

November, 2003

402 Operator And

455 D Control Panel Installation Manual

Page 23

The procedure has ended and the gate is ready to

operate, using default slow down automatically set

by the control panel.

COMPLETE LEARNING

NOTES:

• If only one gate operator (1) is used, you

must go through the entire programming

procedure, as if you were programming a

gate operator (2). When the gate operator

(1) has finished opening, supply 5 open

commands until the gate operator begins

to close, and then resume normal

operations.

Close the gates, enter

the TIME LEARNING function and press the + pushbutton for more than 3 seconds: the display begins

flashing and leaf 1 begins opening movement. The

following functions can be commanded by the OPEN

A command (by radio control or key push-button):

• When gate operator (1) reaches the

position that you want it to slow down, an

open command must be given to start the

slow down phase. When the gate operator

reaches its positive stop, the operator will

automatically shut off.

• An open command must be given to start

opening gate operator (2).

• When gate operator (2) reaches the

position that you want it to slow down, an

open command must be given to start the

slow down phase. When the gate operator

reaches its positive stop, the operator will

automatically shut off.

• An open command must be given to start

closing gate operator (2).

“B

ASIC PROGRAMMING

”

, select

• When gate operator (2) reaches the position

that you want it to slow down, an open

command must be given to start the slow

down phase. When the gate operator reaches

its positive stop, the operator will

automatically shut off.

• An open command must be given to start

closing gate operator (1).

• When gate operator (1) reaches the position

that you want it to slow down, an open

command must be given to start the slow

down phase. When the gate operator reaches

its positive stop, the operator will

automatically shut off.

The display stops flashing and the gate is ready for

normal operation.

NOTES:

• The open command to slow down the gate

should be given before the gate reaches the

positive stop to prevent the gate from hitting

the stop at full speed. The positive stop could

be mistaken for an obstacle and then upon

hitting it, the gate(s) would automatically

reverse on contact.

AUTOMATED SYSTEM TEST

When you have finished programming, check if the

system is operating correctly.

Most important of all, check that the force is adequately

adjusted and that the safety devices are operating

correctly.

If pressure adjustments on hydraulic operators are not

set before programming. It may need to be

reprogrammed for desired results.

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

Page 24

Page 24

November, 2003

402 Operator And

455 D Control Panel Installation Manual

A (Automatic) Logic (455 D)

Gate Status Open A Open B Stop Opening

Opens both leaves

Closed

Opening No effect No effect Stops

Opened

Closing Opens both leaves Opens leaf Stops No effect

Stopped Closes the leaves Closes the leaf

and closes them

after pause time

Interrupts the

pause time

Opens single leaf

connected to Motor

1 and closes it after

pause time

Interrupts the

pause time

No effect No effect No effect Off

Stops No effect

No effect

(opening is

inhibited)

Reversing

Device(s)

Stops; gate closes

when reversing device no longer trig-

gered

No effect

S (Security) Logic (455 D)

Gate Status Open A Open B Stop Opening

Opens both leaves

Closed

Opening Closes both leaves Closes leaf Stops

and closes them after

pause time

Opens single leaf

connected to Motor

1 and closes it after

pause time

No effect No effect No effect Off

Reversing

Device(s)

Stops; gate closes

when reversing device no longer trig-

gered

Closing

Reversing

Device(s)

No effect On

Gate remains open

until reversing devices

no longer triggered

Depends on DIP

switch 4

No effect

(opening is inhibited)

Closing

Reversing

Device(s)

No effect On

Warning Light

On

Flashes

On

Warning Light

Gate remains open

Opened Closes both leaves Closes leaf Stops No effect

Closing

Stopped Closes the leaves Closes the leaf

Opens both leave

Opens leaf Stops No effect

No effect

(opening is

inhibited)

No effect

until reversing devices

no longer triggered

Depends on DIP

switch 4

No effect (opening is

inhibited)

B (Manned, Pulsed) Logic (455 D)

Gate Status Open A Open B Stop Opening

Closed

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

Opening No effect No effect Stops No effect Stops On

Opened No effect

Closing No effect No effect Stops Stops No effect Flashes

Stopped

Opens 1 or both

leaves

Opens 1 or both

leaves

No effect No effect No effect No effect Off

Closes 1 or both

leaves

Closes 1 or both

leaves

No effect No effect No effect On

No effect No effect No effect On

Reversing

Device(s)

Closing

Reversing

Device(s)

On

Flashes

On

Warning

Light

Page 25

November, 2003

402 Operator And

455 D Control Panel Installation Manual

E (Semi-automatic) Logic (455 D)

Page 25

Gate Status Open A Open B Stop Opening

Opens single leaf

Closed Opens both leaves

Opening Stops Stops Stops

Opened Closes both leaves Closes leaf Stops No effect

Closing Closes both leaves Closes leaf Stops

Stopped Closes the leaves Closes the leaf

connected to

Motor 1

No effect No effect No effect Off

No effect

(opening is

inhibited)

Reversing

Device(s)

Stops; gate closes

when reversing

device no longer

triggered

No effect

(opening is inhibited)

No effect

EP (Semi-automatic, Step by Step) Logic (455 D)

Gate Status Open A Open B Stop Opening

Closed Opens both leaves Opens single leaf

connected to

Motor 1

No effect

(opening is in-

hibited)

Reversing

Device(s)

No effect

(opening is inhibited)

Closing

Reversing

Device(s)

No effect On

No effect

(opening is inhib-

ited)

Depends on DIP

switch 4

No effect

opening is inhib-

ited)

Closing

Reversing

Device(s)

No effect (opening

is inhibited)

Warning

Light

THE 455 D CONTROL PANEL INSTALLATION INSTRUCTIONS

On

Flashes

On

Warning

Light

Off

Opening Stops Stops Stops Stops; gate closes

Opened Closes both leaves Closes leaf Stops No effect No effect (opening

Closing Stops Stops Stops No effect

Stopped Gate leaves reverse

direction

Gate leaf reverses

direction

No effect

(opening is in-

hibited)

when reversing

device no longer trig-

gered

(opening is inhibited)

No effect

(opening is inhibited)

No effect On

is inhibited)

Depends on DIP

switch 4

No effect

(opening is inhib-

ited)

On

Flashes

On

C (Manned and Constant) Logic (455 D)

Gate Status Open A Open B Stop Opening

Closed Opens 1 or

both leaves

Opening No effect No effect Stops No effect Stops On

Opened No effect Closes 1 or

Closing No effect No effect Stops Stops No effect Flashes

Stopped Opens 1 or

both leaves

No effect No effect No effect No effect Off

both leaves

Closes 1 or

both leaves

No effect No effect No effect On

No effect No effect No effect On

Reversing

Device(s)

Closing

Reversing

Devices(s)

Warning

Light

Page 26

Page 26

MAINTENANCE

THE 402 OPERATOR

The FAAC recommended maintenance schedule varies

according to the frequency of use of the operators,

whether lightly used operators (once or twice an hour)

or heavily used operators (many cycles per hour),

operators used in a humid, salt air climate should follow

the heavy duty use schedule.

CHECK THE OIL.

To check the oil level correctly, remove the operator

from the gate leaf. With the piston rod completely

retracted and pointing to the ground, remove the rear

flange and look at the oil level in the casing of the

operator. The oil level should be about 3/4 in. (20 mm)

from the top edge of the operator casing. If the

operator is too full, it will bleed oil out the vent hole.

November, 2003

402 Operator And

455 D Control Panel Installation Manual

Light duty use: every 12 mo

Heavy duty use: every 6 mo

CHANGE THE OIL.

Light duty use: every 48 mo or 4 yrs

Heavy duty use: every 24 mo or 2 yrs

CHECK THE PRESSURE SETTINGS.

Light duty use: every 12 mo

Heavy duty use: every 6 mo

THE 455 D CONTROL PANEL

Keep the Control Panel free from spider webs, insects,

etc. Otherwise the Control Panel requires no

maintenance.

SAFETY IN GATE DESIGN

• A gate is a potential traffic hazard, so it is

important that you locate the gate far enough

away from the road to eliminate the potential

of traffic getting backed up. This distance is

affected by the size of the gate, how often it is

used, and how fast the gate operates.

• The operator you choose to install on your

gate must be designed for the type and size of

your gate and for the frequency with which you

use the operator.

• Your gate must be properly installed and must

work freely in both directions

automatic operator is installed.

• An automatic operator should be installed on

the inside of the property/fence line. Do not

install the operator on the public side of the

property/fence line.

• Outward swinging gates with automatic

operators should not open into a public area.

before

the

• Pedestrians should not use a vehicular gate

system. Prevent such inappropriate use by

installing separate gates for pedestrians.

• The operating controls for an automatic gate

must be secured to prevent the unauthorized

use of those controls.

• The controls for an automatic gate should be

located far enough from the gate so that a

user cannot accidentally touch the gate when

operating the controls.

• Exposed, reachable pinch points on a gate are

potentially hazardous and must be eliminated

or guarded.

• It is extremely unsafe to compensate for a

damaged gate by over tightening a clutch or

increasing hydraulic pressure.

• An automatic gate operator should not be

installed on a gate if people can reach or

extend their arms or legs through the gate.

Such gates should be guarded or screened to

Page 27

November, 2003

402 Operator And

455 D Control Panel Installation Manual

TROUBLESHOOTING

WARNING! Before you do any work on the control panel,

be sure to turn off the main power.

Page 27

PROBLEM: THE GATE DOES NOT OPEN

COMPLETELY.

SOLUTION:

Check the gate for mechanical obstacles that might

prevent the gate from opening.

If the motor stops running before the gate is completely

open (or closed), you need to adjust the opening/

closing time for the operator or check the bypass valve

adjustment. On the one hand, you can increase the

opening/closing time of the operator so that it runs

long enough to close the gate. You can, on the other

hand, increase the pressure. If the pressure is too weak

the leaf movement may slip, preventing full closure

before the motor stops running.

Check your dimensions for mounting the rear bracket.

Incorrect dimensions can make a full 90-deg swing

impossible.

PROBLEM: THE GATE OPENS BUT DOES NOT

CLOSE.

SOLUTION:

Verify that you have correctly wired the operator to the

control panel.

Verify that the reversing devices are working properly.

If you have installed no reversing devices, make sure

that you have installed a jumper wire across the

reversing device terminals on the control panel.

If the motors are running, insure that the bypass valve

pressure adjustment is correct.

PROBLEM: THE RADIO CONTROLLED

OPENER DOES NOT OPEN THE GATE.

SOLUTION:

Check the light on the front of the remote transmitter. It

should illuminate when you signal the gate. If it doesn't

illuminate and if the batteries are okay, repair or replace

the transmitter.

Verify that the codes on the receiver and transmitter are

the same.

Verify that the wiring for the radio controlled devices is

correct.

Check the fuses on the control panel.

Check the wiring for the antenna and correct it if

necessary.

Determine if the fault is in the receiver by temporarily

connecting a push button device across the control

panel activating terminals. If such a push button device

opens the gate, repair or replace the receiver

Page 28

November, 2003

402 Operator And

455 D Control Panel Installation Manual

LIMITED WARRANTY

Page 28

To the original purchaser only:

Inc., warrants, for twenty-four (24) months from the

date of invoice, the gate operator systems and other

related systems and equipment manufactured by FAAC

S.p.A. and distributed by FAAC International, Inc., to be

free from defects in material and workmanship under

normal use and service for which it was intended

provided

FAAC International, Inc.'s obligations under this

warranty shall be limited to the repair or exchange of

any part of parts manufactured by FAAC S.p.A. and

distributed by FAAC International, Inc. Defective

products must be returned to FAAC International, Inc.,

freight prepaid by purchaser, within the warranty

period. Items returned will be repaired or replaced, at

FAAC International, Inc.'s option, upon an examination

of the product by FAAC International, Inc., which

discloses, to the satisfaction of FAAC International, Inc.,

that the item is defective. FAAC International, Inc. will

return the warranted item freight prepaid. The products

manufactured by FAAC S.p.A. and distributed by FAAC

International, Inc., are not warranted to meet the

specific requirements, if any, of safety codes of any

particular state, municipality, or other jurisdiction, and

neither FAAC S.p.A. or FAAC International, Inc., assume

any risk or liability whatsoever resulting from the use

thereof, whether used singly or in combination with

other machines or apparatus.

S.p.A. and distributed by FAAC International, Inc., will

carry only the warranty, if any, of the manufacturer. This

warranty shall not apply to any products or parts thereof

which have been repaired or altered, without FAAC

International, Inc.'s written consent, outside of FAAC

International, Inc.'s workshop, or altered in any way so

as, in the judgment of FAAC International, Inc., to affect

adversely the stability or reliability of the product(s) or

has been subject to misuse, negligence, or accident, or

has not been operated in accordance with FAAC

it has been properly installed and operated.

Any products and parts not manufactured by FAAC

FAAC International,

International, Inc.'s or FAAC S.p.A.'s instructions or has

been operated under conditions more severe than, or

otherwise exceeding, those set forth in the

specifications for such product(s). Neither FAAC S.p.A.

or FAAC International, Inc., shall be liable for any loss or

damage whatsoever resulting, directly or indirectly,

from the use or loss of use of the product(s). Without

limiting the foregoing, this exclusion from liability

embraces a purchaser's expenses for downtime or for

making up downtime, damages for which the purchaser

may be liable to other persons, damages to property,

and injury to or death of any persons. Neither FAAC

S.p.A. or FAAC International, Inc., assumes nor

authorizes any person to assume for them any other

liability in connection with the sale or use of the

products of FAAC S.p.A. or FAAC International, Inc. The

warranty hereinabove set forth shall not be deemed to

cover maintenance parts, including, but not limited to,

hydraulic oil, filters, or the like. No agreement to replace

or repair shall constitute an admission by FAAC S.p.A. or

FAAC International, Inc., of any legal responsibility to

effect such replacement, to make such repair, or

otherwise. This limited warranty extends only to

wholesale customers who buy directly through FAAC

International, Inc.'s normal distribution channels. FAAC

International, Inc., does not warrant its products to end

consumers. Consumers must inquire from their selling

dealer as to the nature and extent of that dealer's

warranty, if any.

This warranty is expressly in lieu of all other warran-

ties expressed or implied including the warranties of

merchantability and fitness for use. This warranty shall

not apply to products or any part thereof which have

been subject to accident, negligence, alteration, abuse,

or misuse or if damage was due to improper installation

or use of improper power source, or if damage was

caused by fire, flood, lightning, electrical power surge,

explosion, wind storm, hail, aircraft or vehicles, vandalism, riot or civil commotion, or acts of God.

FAAC International, Inc.

303 Lexington Avenue

Cheyenne, WY 82007

www.faacusa.com

Loading...

Loading...