Page 1

www.ezurio.com

Embedded USB / HCI Bluetooth™ Module

Part Numbers: TRBLU024-00100, TRBLU024-00200, TRBLU024-00300, TRBLU024-00400

1. General Description

Ezurio’s Embedded Intelligent Bluetooth Serial Module is a fully integrated and qualified Class 1 Bluetooth solution

designed for lowest cost of integration and ownership for designers wishing to include Bluetooth functionality in

their products. The module is qualified to Bluetooth Version 2.0.

The Embedded Intelligent Bluetooth Serial Module is designed to give a rugged solution that is ideal for industrial

automation and ruggedised handheld devices. It works over a wide temperature range of -40°C to +85°C. The

physical form of the module allows designers to mount the antenna section of the module outside a screened

enclosure.

The Embedded Intelligent Serial Module is based on Cambridge Silicon Radio’s BlueCore4 chipset. The module

contains all of the hardware and firmware for a complete Bluetooth solution, requiring no further components.

The Module has an integrated, high performance antenna which is matched with the Bluetooth RF and baseband

circuitry. The firmware integrated into the module implements the higher layer Bluetooth protocol stack, up to

and including the Generic Access Profile (GAP), Service Discovery Profile (SDAP), Serial Port Profile (SPP) and

Audio Gateway. A virtual processor is used within the BC04 to implement an AT command processor. This

interfaces to the host system over a straight forward serial port using an extensive range of AT commands. The

AT command set abstracts the Bluetooth protocol from the host application, saving many months of programming

and integration time. It provides extremely short integration times for data oriented cable replacement and voice

applications. A low cost development system and integrated RS232 products with the same firmware are

available for fast product evaluation and development.

An alternative version of firmware is available that provides support for multi-point applications.

The Module can be configured so that it can be attached to a ‘dumb’ terminal or attached to a PC or PDA for cable

replacement applications.

In addition to the Bluetooth functionality, The Embedded Intelligent Serial Module provides access to 6 General

I/O lines and one ADC input. These can be configured to extend the UART control or to provide connection to

simple devices such as switches or LEDs without requiring any external processing. The GPIO lines can be

accessed either via the wired host UART connection, or remotely over the Bluetooth link. Support is also provided

for a PCM connection to an external audio codec.

The Embedded Intelligent Bluetooth Module is supplied in a small form factor PCB (17.7mm x 46.0mm x 5.0mm),

that solders directly. The module includes a high sensitivity, high gain antenna which provides excellent range.

Typical open field performance provides ranges of over 250 metres at transmit powers of 4mW.

Support is provided for low power modes that make the Embedded Intelligent Bluetooth Module particularly

applicable to battery powered installations.

The Embedded Intelligent Bluetooth Module is Lead-free and RoHS compliant and supports an industrial operating

temperature range of -40°C to +85°C.

1.1 Applications

• POS Equipment • Automotive Applications

• Industrial Automation • Telematics

• Vending Equipment • Medical

• Windows CE solutions • Embedded Windows XP Applications

• Audio Applications

Bluetooth is a trademark owned by Bluetooth SIG, Inc., USA, and is licensed to Ezurio Ltd

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 1

Page 2

www.ezurio.com

2. Features

Feature Implementation

Bluetooth Transmission Class 1

Fully Bluetooth pre-qualified Bluetooth 2.0

Range 250 metres typical (free space)

Frequency 2.400 – 2.485 GHz

Max Transmit Power +6dBm

Min Transmit Power -27dBm

Receive Sensitivity Better than -86dB

Data Transfer rate 2.1 Mbps max data rate. 3.0 Mbps symbol,rate

Serial Interface USB 1.2 compliant HCI interface

Physical size 17.7mm x 46.0mm x 5.0mm, 8g

Current consumption Less than 36mA during data transfer in standard power mode. Lower powers

Low power sniff mode 2.5mA typ

Temperature Range Normal operation: -40°C to +85°C

Supply Voltage 3.3V – 7.0V

Audio Audio can be transferred over SCO channels through the PCM interface at

Profiles Server - SPP (Full), DUN, Audio Gateway, Headset, Handsfree

Multipoint Max 7 slaves with multipoint

Field upgradeable Over USB interface

GPIO 6 x digital (DTR can also be allocated as GPIO)

ADC 1 x 8 bit

Indicators Pads for 2 programmable LEDs

Lead free Lead-free and RoHS compliant

are attainable with a configurable low power mode.

64kbps. PCM can be configured as master or slave.

Support for dual slave PCM connections.

Client - All RFCOMM based profiles

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 2

Page 3

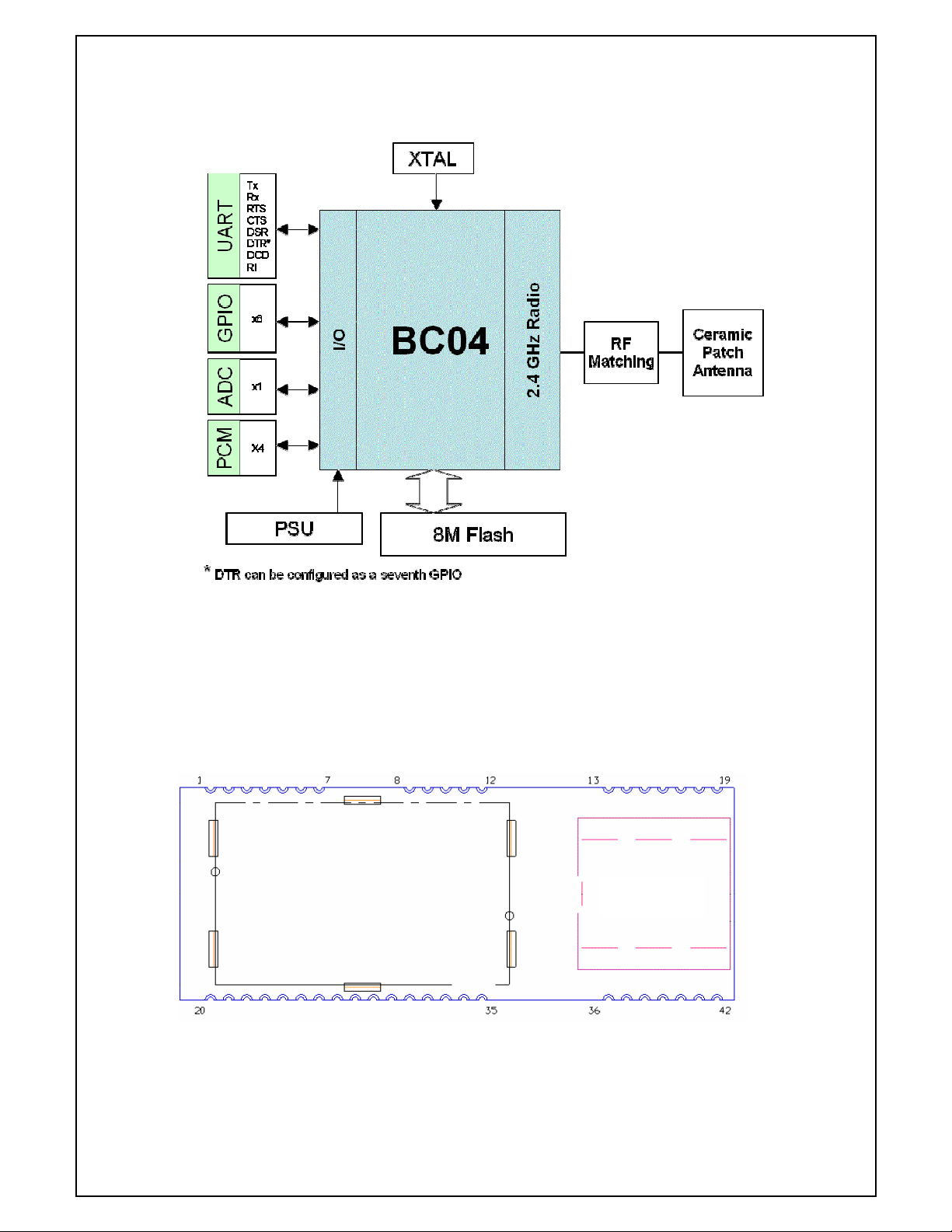

3. Functional Block Diagram

www.ezurio.com

3.1 Connection Diagram

The Module is connected to a “mother” PCB by direct soldering to edge pads. Pads adjacent to the

antenna do not provide an electrical connection, but are used for additional mechanical stability.

Antenna

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 3

Page 4

www.ezurio.com

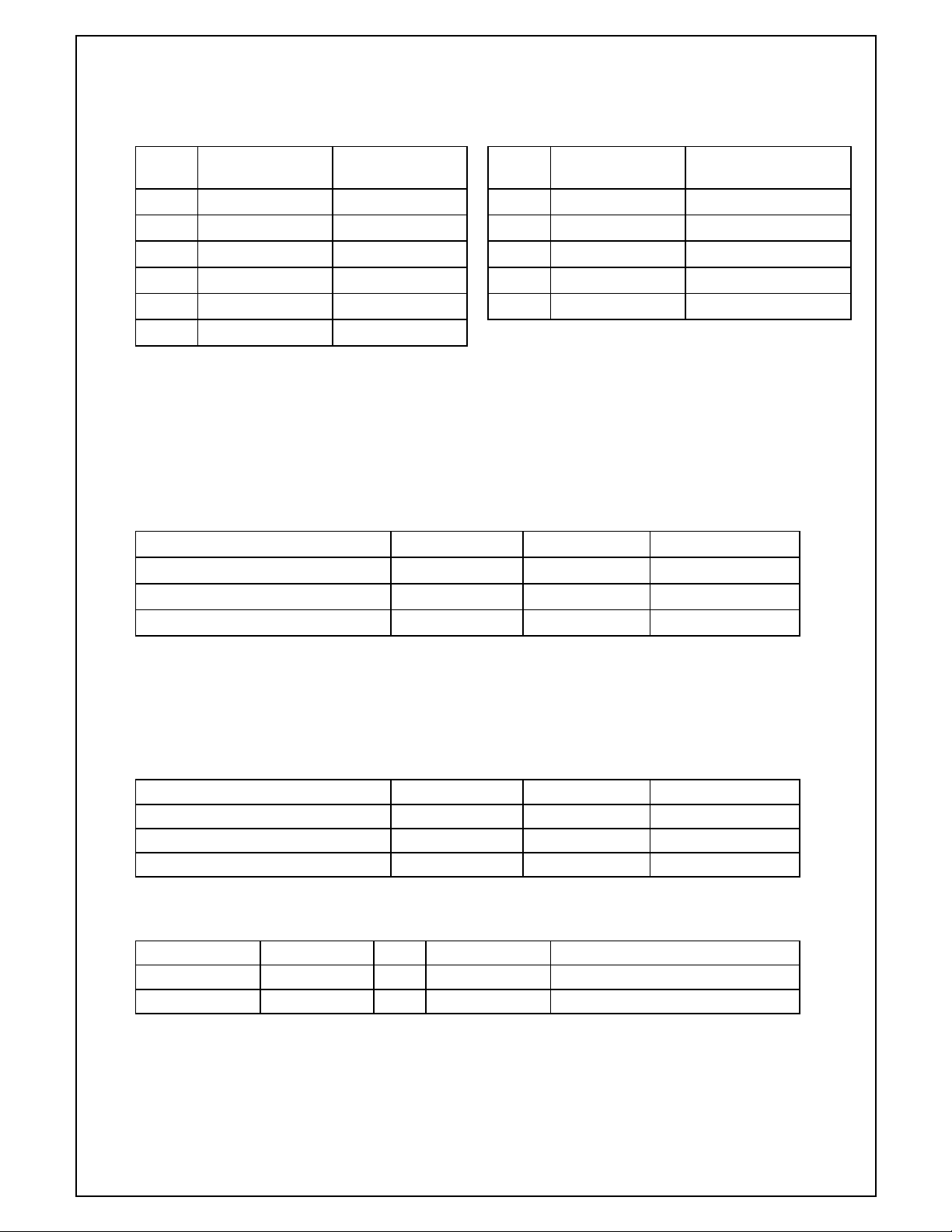

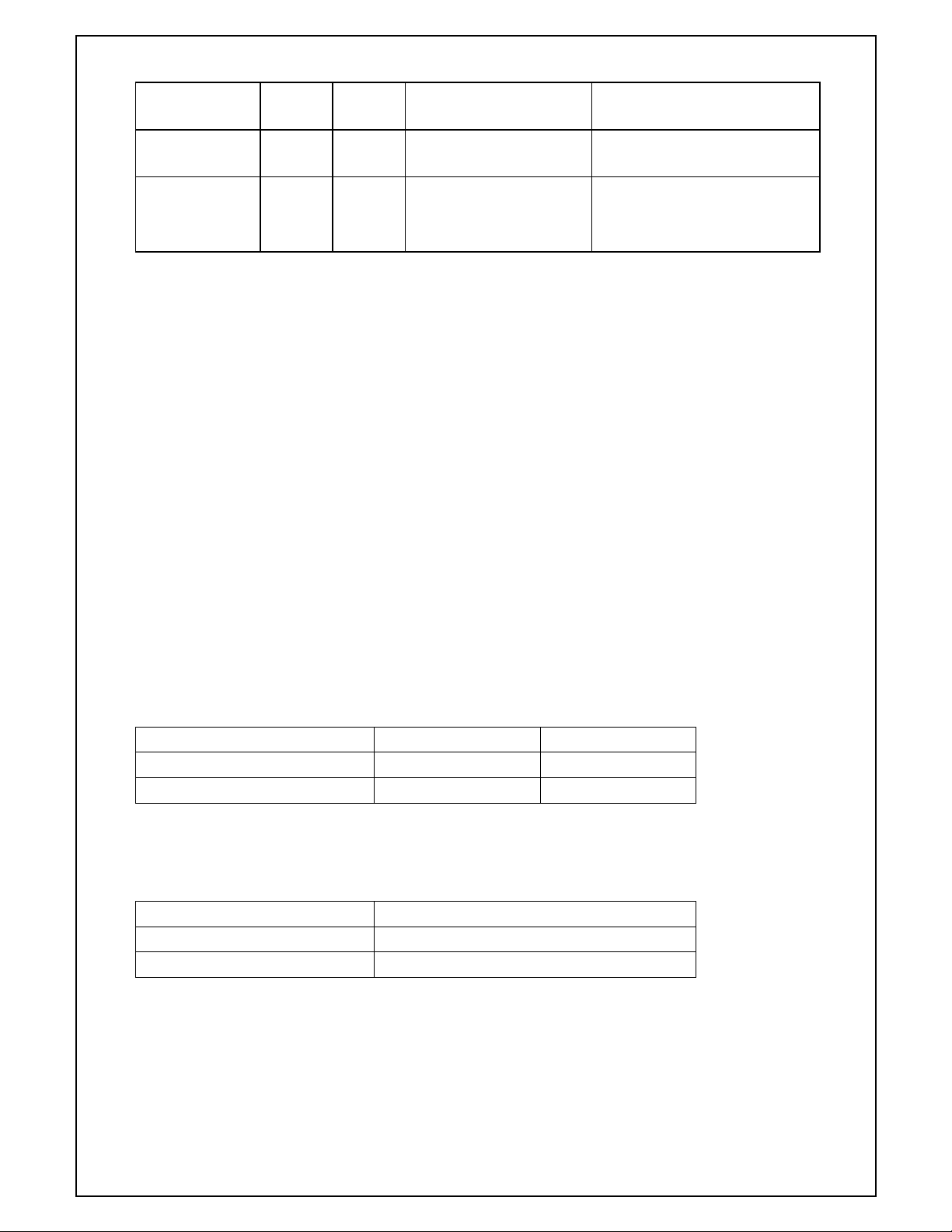

3.2 Pin Descriptions

The table below defines the pin functions. Refer to the previous section for the pin location.

Pin

No.

Signal Description Pin

No.

Signal Description

1 Vcc 2 USB D+

3 USB D- 4 GND

5 RESET Reset I/P * 6-19 N/C Do not Connect

20 GND 21-33 N/C Do not Connect

34 MPIO_10 (LED1) I/O for Host 35 MPIO_11 (LED2) I/O for Host

36-42 N/C Do not Connect

* The reset line has a fixed 10kOhm pull up resistor to ground.

3.3 Electrical Specifications

3.3.1 Absolute Maximum ratings

Absolute maximum ratings for supply voltage and voltages on digital and analogue pins of the Module

are listed below; exceeding these values will cause permanent damage.

Parameter Min Max Unit

Peak current of power supply 0 100 mA

Voltage at digital pins -0.3 3.7 V

Voltage at POWER pin 3.6 7 V

3.3.2 Recommended Operating Parameters

3.3.2.1 Power Supply

Absolute maximum ratings for supply voltage and voltages on digital and analogue pins of the Module are listed

below; exceeding these values will cause permanent damage.

Parameter Min Max Unit

Peak current of power supply 0 100 mA

Voltage at digital pins -0.3 3.3 V

Voltage at POWER pin 3.3 7 V

3.3.2.2 Power Supply

Signal Name Pin No I/O Voltage level Comments

Vcc 1 I 3.3V to 7.0V I

GND 4, 20, 29

The module contains a power on reset circuit that ensures the module is reset at power on. The internal reset

circuit is triggered when the input voltage to the module drops below ~1.7V and is hence only suitable for

providing a power on reset signal. If the supply voltage to the module can drop below the minimum voltage level

in normal operation, then it is recommended that an external brownout circuit is provided to assert the module

reset and to ensure that the module is reset when the module supply voltage drops below 3.1V.

= 30mA

typ

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 4

Page 5

www.ezurio.com

This will ensure that the module will return to an operational state when the supply voltage comes back within

specification. For example, if the module supply can drop to 2.7V and then be restored to 3.3V there is no

guarantee that the module will still be operational unless the reset signal has been asserted.

3.3.2.3 UART Specific Recommendations

Function Signal Name Pin No I/O Signal level Comments

USB D- 3 I VILmax =0.3vdd_usb

VIHmin =0.7vdd_usb

USB D+ 2 I VILmax =0.3vdd_usb

VIHmin =0.7vdd_usb

Normally inactive.

Pull to GND

through 10K

Normally inactive.

Pull to GND

through 10K

Reset RESET 5 I Threshold 2.6V Active LOW

Terminology: USB Signal Levels. vdd_usb refers to the internal voltage generated by the LDO

regulator on the module, which is typically 3.3V. Hence 0.3vdd_usb and 0.7vdd_usb correspond to

1.0V to 2.3V. If Vcc falls below the recommended minimum of 3.6V, these values will be reduced.

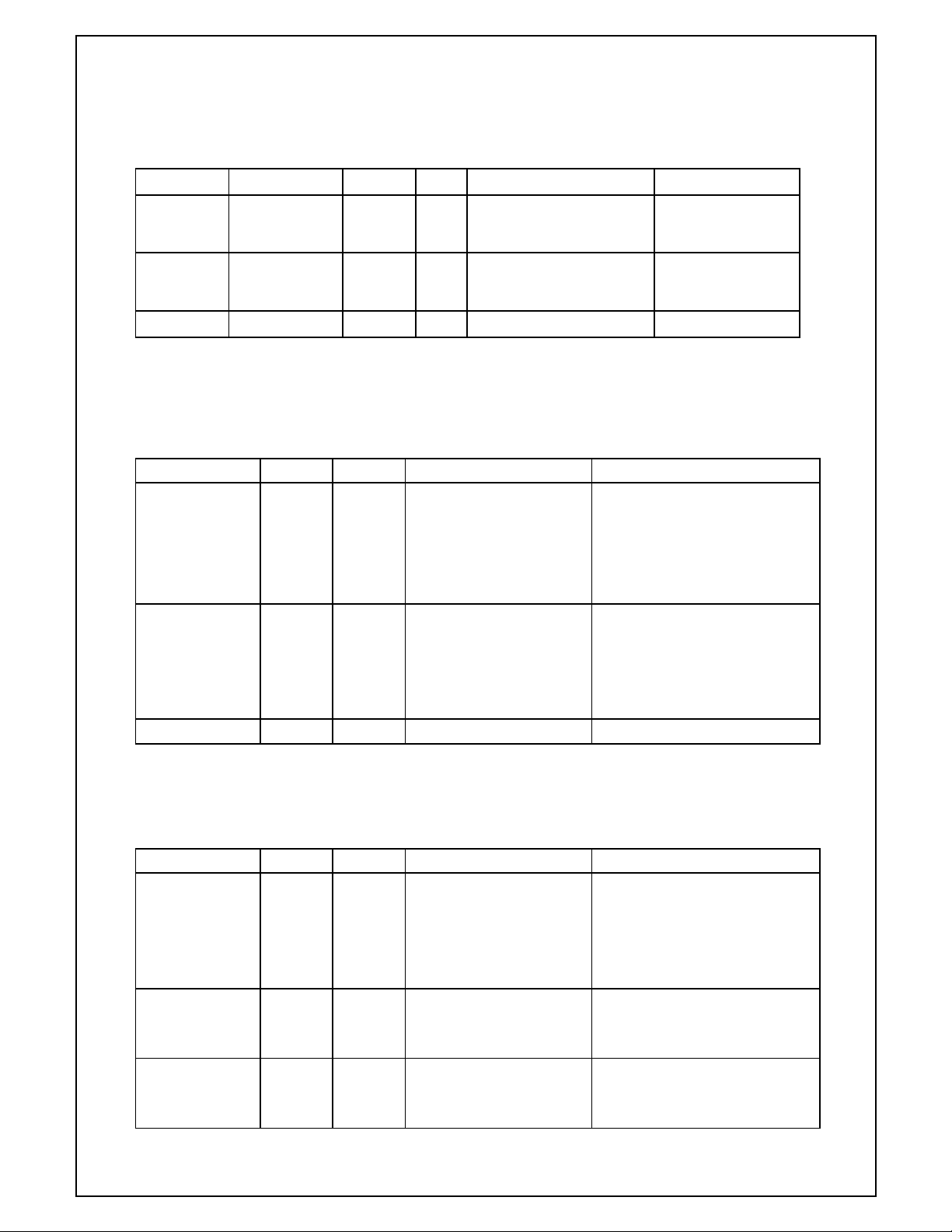

3.3.2.4 General Purpose I/O and ADC

Signal Name Pin No I/O Signal level Comments

GPIO 4, 5, 6, 7,

8, 9

GPIO 3 27 I or O O/P : VOLmax=0.2V

ADC 0 37 I Range 0 – 1.8V ADC

36, 35,

6, 7, 38,

34

I or O O/P : VOLmax=0.2V

VOHmin=2.8V

I/P : VILmax=0.8V

VIHmin=2.1V

VIHmax=3.4V

VOHmin=2.8V

I/P : VILmax=0.8V

VIHmin=2.1V

VIHmax=3.4V

GPIO_4 and 5 are shared with the

onboard LED pads.

GPIO_9 is also used for

PCM_SLVCLK.

Shared with DTR

PIO lines can be configured through software to be either inputs or outputs with weak or strong pull-ups or pulldowns. At reset, all PIO lines are configured as inputs with weak pull-downs.

3.3.2.5 PCM Interface

Signal Name Pin No I/O Signal level Comments

PCM_CLK 32 I or O O/P : VOLmax=0.2V

VOHmin=2.8V

I/P : VILmax=0.8V

VIHmin=2.1V

VIHmax=3.4V

PCM_IN 31 I VILmax=0.8V

VIHmin=2.1V

VIHmax=3.4V

PCM_SYNC 30 I or O O/P : VOLmax=0.2V

VOHmin=2.8V

I/P : VILmax=0.8V

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 5

If unused keep pins open

Page 6

www.ezurio.com

VIHmin=2.1V

VIHmax=3.4V

PCM_OUT 33 O VOLmax=0.2V

VOHmin=2.8V

PCM_SLV_CLK

(GPIO9)

O O/P : VOLmax=0.2V

VOHmin=2.8V

Available as a clock when two

connected devices are both in PCM

slave mode.

Shared with GPIO_9

4. I/O Characteristics

4.1 Power Consumption

The hardware specification for the Module allows for a voltage range of 3.3 to 7.0 at Vcc. Tests have

shown that there is no significant difference in current draw when Vcc is 5 or 6V. Tests have shown

that where power drain is an issue, it is best to keep Vcc at the lower end of the range.

With regards to operating mode the significant modes are; idle, waiting for a connection, inquiring,

initiating a connection, sniff and connected. With connected mode, it is also relevant to differentiate

between no data being transferred and when data is being transferred at the maximum rate possible.

The firmware within the USB/HCI module will always attempt to place the module into the lowest

possible power configuration.

5. DC Characteristics

5.1 RF Performance

5.1.1 Transmit Power

Conducted Transmit Power min: 1.0mW (0dBm) max: 4mW (6dBm)

Antenna Gain +2dBi typ.

Effective Transmit Power min:0dBm Max: +6dBm

Output power can be reduced by program control via the HCI interface

5.1.2 Receive Sensitivity

Receive Sensitivity (Typ) -86dBm (at 25°C)

Antenna Gain +2dBi typ

Effective Receive Sensitivity -88dBm (at 25°C)

6. Functional Description

The Embedded USB / HCI Bluetooth module is a fully featured HCI Bluetooth product and requires

only power and an external higher layer Bluetooth stack to implement full Bluetooth communication.

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 6

Page 7

www.ezurio.com

The integrated, high performance antenna together with the RF and Base-band circuitry provides the

Bluetooth wireless link and the USB interface provides a connection to the host system.

6.1 GPIO Port

Eight lines of programmable bi-directional input/outputs (I/O) are provided that can be accessed

either via the UART port, or Over The Air (OTA) from a second Bluetooth unit. These can be used as

data inputs or to control external equipment. By using these in OTA mode, an embedded Bluetooth

Serial module can be used for control and data acquisition without the need for any additional host

processor. A further line can be used as an input.

Each of the GPIO ports can be independently configured to be either an Input or Output. A selection

of ports can be accessed synchronously.

The ports are powered from VCC. The mode of these lines can be configured and the lines are

accessed via S Registers in the range 623 to 629.

Low latency I/O can be accessed by using Ezurio’s I/O via an enhanced inquiry process.

6.2 PCM CODEC Interface

PCM_OUT, PCM_IN, PCM_CLK and PCM_SYNC carry up to three bi-directional channels of voice data,

each at 8ksamples/s. The format of the PCM samples can be 8-bit A-law, 8-bit µ-law, 13-bit linear or

16-bit linear. The PCM_CLK and PCM_SYNC terminals can be configured as inputs or outputs,

depending on whether the module is the Master or Slave of the PCM interface.

In applications where the PCM master cannot supply a clock signal, the module can be configured to

generate a clock signal on this GPIO: PCM_SLVCLK. Please contact an Ezurio FAE for further details.

The Module is compatible with the Motorola SSI TM interface and interfaces directly to PCM audio

devices including the following:

6.2.1 Compatible Codec Chips

PCM_OUT, PCM_IN, PCM_CLK and PCM_SYNC carry up to three bi-directional channels of voice data, each at

8ksamples/s. The format of the PCM samples can be 8-bit A-law, 8-bit µ-law, 13-bit linear or 16-bit linear. The

PCM_CLK and PCM_SYNC terminals can be configured as inputs or outputs, depending on whether the module is

the Master or Slave of the PCM interface. Please contact an Ezurio FAE for further details.

The Module is compatible with the Motorola SSI TM interface and interfaces directly to PCM audio devices

including the following:

• Winbond W61360 13-bit linear CODEC (Motorola MC145483 compatible)

• OKI MSM7702 single channel A-law and µ-law CODEC

• OKI MSM7705 four channel A-law and µ-law CODEC

The default codec support is for the Winbond W61360

• Codec development boards that mate with the EZURiO Wireless Developers Kit are available for each of

the three codecs listed above.

6.3 ADC

The module provides access to one 8-bit ADC. This provides an input range of 0mV to 1,800mV,

which can be read using S register 701.

Suitable external scaling and over-voltage protection should be incorporated in your design. The

module provides 5 samples per second at the UART with a baud rate of 115,200 or above.

Low latency access of the upper 6 bits of the ADCs can be obtained by using Ezurio’s I/O via an

enhanced inquiry process.

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 7

Page 8

www.ezurio.com

6.4 LEDs

Pads are provided to allow two LEDs to be added for diagnostic purposes. They are controlled by an

S registers 624 and 625 to display the status of various parameters and are useful for debug and

test.

7. Integrated Firmware

7.1 Bluetooth Stacks

Most users will use the Embedded USB / HCI Bluetooth module with a pre-qualified Bluetooth stack.

The USB interface has been configured to present the device as a generic Bluetooth module. This

allows it to be plugged directly into most upper layer Bluetooth stacks, where it will enumerate and

start operating.

The module has been tested with the following stacks and requires no further drivers for these.

• Windows XP SP1 (we recommend the use of SP2)

• Windows XP SP2

• Windows XP embedded

• Windows CE

• Windows Vista (beta)

Ezurio can supply a Widcomm Windows stack that runs on Windows 98, 2000, ME and XP and which

provides a wider range of profiles than the Microsoft stacks. There is an additional per machine

license for the Widcomm stack.

7.1.1 Features of the HCI Stack

7.1.1.1 Standard Bluetooth v2.0 + EDR mandatory functionality:

• Adaptive frequency hopping (AFH), including classifier

• Faster connection - enhanced inquiry scan (immediate FHS response)

• LMP improvements

• Parameter ranges

7.1.1.2 Optional Bluetooth v2.0 + EDR functionality supported:

• Adaptive Frequency Hopping (AFH) as Master and Automatic Channel Classification

• Fast Connect - Interlaced Inquiry and Page Scan plus RSSI during Inquiry

• Extended SCO (eSCO), eV3 +CRC, eV4, eV5

• SCO handle

• Synchronisation

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 8

Page 9

7.1.1.3 Standard Bluetooth components:

• Baseband (including LC)

• LM

• HCI

• Standard USB v1.1 HCI Transport Layer

• All standard radio packet types

(2)

(1)

• Full Bluetooth data rate, enhanced data rates of 2 and 3Mbps

•

Operation with up to seven active slaves

(1)

• Scatternet v2.5 operation

• Maximum number of simultaneous active ACL connections: 7

• Maximum number of simultaneous active SCO or eSCO connections: 3

• Operation with up to three SCO / eSCO links, routed to one or more slaves

• All standard SCO voice coding, plus transparent SCO

• Standard operating modes: Page, Inquiry, Page-Scan and Inquiry-Scan

• All standard pairing, authentication, link key and encryption operations

(2)

www.ezurio.com

• Standard Bluetooth power saving mechanisms: Hold, Sniff and Park modes, including Forced

Hold

• Dynamic control of peers' transmit power via LMP

• Master/Slave switch

• Broadcast

• Channel quality driven data rate

• All standard Bluetooth test modes

(1) This is the maximum all owed by Bluetooth v2.0 + EDR specification.

(2) Supports all combinati ons of active ACL and SCO channels f or both master and slave operation, as specified by the Bl uetooth v2.0 + EDR

specification.

7.2 Additional Stack Functionality

The firmware extends the standard Bluetooth functionality with the following features:

Hardware low power modes: Shallow Sleep and Deep Sleep. The chip drops into modes that

significantly reduce power consumption when the software goes idle.

8. Interfaces

8.1 USB Interface

The embedded USB / HCI module contains a full speed (12Mbits/s) USB interface that is capable of

driving a USB cable directly. No external USB transceiver is required. The device operates as a USB

peripheral, responding to requests from a master host controller such as a PC. Both the OHCI and the

UHCI standards are supported. The set of USB endpoints implemented can behave as specified in the

USB section of the Bluetooth specification v2.0+EDR. The module only operates as a USB slave.

The module contains inline resistors to provide a match for the characteristic impedance of a USB

cable as defined by the USB standard.

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 9

Page 10

www.ezurio.com

The module contains a USB pull-up resistor. This pulls the USB+ pin weakly high when the USB

interface is ready to enumerate. It signals to the USB host that it is a full speed (12Mbit/s) USB

device. This pull-up is implemented as a current source, and is compliant with section 7.1.5 of the

USB specification v1.2. It pulls USB+ high to at least 2.8V when loaded with a 15kΩ 5% pull-down

resistor (in the hub/host) when VCC is 3.6V or higher. This presents a Thevenin resistance to the host

of at least 900Ω.

8.1.1 USB Enumeration

The embedded USB / HCI module enumerates with the following information:

Device Descriptor:

bcdUSB: 0x0200

bDeviceClass: 0xE0

bDeviceSubClass: 0x01

bDeviceProtocol: 0x01

bMaxPacketSize0: 0x40 (64)

idVendor: 0x04BF

idProduct: 0x0320

bcdDevice: 0x2652

iManufacturer: 0x01

iProduct: 0x02

iSerialNumber: 0x00

bNumConfigurations: 0x01

Current Config Value: 0x01

Device Bus Speed: Full

Device Address: 0x03

Open Pipes: 5

Endpoint Descriptor:

bEndpointAddress: 0x81

Transfer Type: Interrupt

wMaxPacketSize: 0x0010 (16)

bInterval: 0x01

Endpoint Descriptor:

bEndpointAddress: 0x02

Transfer Type: Bulk

wMaxPacketSize: 0x0040 (64)

bInterval: 0x01

Endpoint Descriptor:

bEndpointAddress: 0x82

Transfer Type: Bulk

wMaxPacketSize: 0x0040 (64)

bInterval: 0x01

Endpoint Descriptor:

bEndpointAddress: 0x03

Transfer Type: Isochronous

wMaxPacketSize: 0x0000 (0)

bInterval: 0x01

Endpoint Descriptor:

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 10

Page 11

www.ezurio.com

bEndpointAddress: 0x83

Transfer Type: Isochronous

wMaxPacketSize: 0x0000 (0)

bInterval: 0x01

9. Low Power Modes

The embedded USB / HCI module supports all of the standard low power modes as specified by the

Bluetooth 2.0 + EDR standard.

In addition the firmware contains power management which will automatically place the device in

sleep modes whenever there is a period of inactivity.

9.1 Low Power Modes using Sniff

Bluetooth connections are master/slave in nature. A master sends packets and a slave has to

acknowledge that packet in the next timeslot. Timeslots in Bluetooth are 625 microseconds wide. This

implies that a master will always know when packets will be sent and received, which further means it

is able to optimise power usage by switching on power hungry circuitry only when needed.

A slave on the other hand does NOT have prior knowledge of when a packet will be received and has

to assume that a packet will be received from a master on every receive slot. This means that it has

to leave its receiving circuitry on for most of the receive slot duration. The result of this is high power

consumption, where a slave with no data transmission still consumes around 31mA whereas a master

consumes only 6mA.

This problem was identified very early in the evolution of Bluetooth (especially since headsets spend

all their time as a slave in a Bluetooth connection) and it was solved by having a mode called Sniff,

with appropriate lower layer negotiating protocol.

Sniff mode during connection is basically an agreement between the slave and its master that data

packets will only be exchanged for N timeslots every M slots. The slave can then assume that it will

never be contacted during N-M slots, and so can switch its power hungry circuitry off. The

specification goes further by also specifying a third parameter called ‘timeout’ (T) which specifies

‘extra’ timeslots that the slave will agree to listen for after receiving a valid data packet. Put another

way, if a data packet is received by the slave, then it knows that it MUST carry on listening for at

least T more slots. If within that T slot time period another data packet is received, then the timer is

restarted. This mechanism ensures low power consumption when there is no data transfer – at the

expense of latency. When there is a lot of data to be transferred, it acts as if sniff mode were not

enabled.

It is stated above that during sniff mode, a slave listens for N slots every M slots. The Bluetooth

specification states that a master can have up to 7 slaves attached to it with all slaves having

requested varying sniff parameters. It may therefore be impossible to guarantee that each slave gets

the M parameter it requested. In light of this, the protocol for enabling sniff mode specifies that a

requesting peer specify the M parameter as a minimum and maximum value. This will allow the

master to interleave the sniff modes for all slaves attached. This is illustrated in the diagram below.

For this reason, the sniff parameters are specified in the Embedded Intelligent Bluetooth Module via

four S registers. S Register 561 is used to specify ‘N’, S Register 562 is used to specify ‘T’ and S

Registers 563/564 are used to specify minimum ‘M’ and maximum ‘M’ respectively. Although the

specification defines these parameters in terms of timeslots, the S register values have to be

specified in units of milliseconds and the firmware does the necessary translation to timeslots.

High Power Consumption

Low Power Consumption

Data Exchange

T

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 11

N

Slots

Slots

Data Exchange

Data Exhange

Data Exchange

Data Exchange

T

T

Slots

Slots

T

Slots

N

Data Exchange

Slots

T

Slots

N

Slots

Page 12

10. Enhanced Data Rate

www.ezurio.com

EDR has been introduced with Version 2.0 of the Bluetooth standard to provide 2x and 3x

rates with minimal disruption to higher layers of the Bluetooth stack. Ezurio’s embedded USB/HCI

module provides support for both of these new data rates and is compliant with the Bluetooth

v2.0+EDR specification.

At the baseband level EDR utilises both the same 1.6kHz slot rate and the 1MHz symbol rate as

defined for the basic data rate. Where EDR differs is that each symbol in the payload portion of a

packet represents 2 or 3-bits. This is achieved using two new distinct modulation schemes. These are

summarised below. Link Establishment and management are unchanged and still use GFSK for both

the header and payload portions of these packets.

(1) The inclusion of 3x data rates is optional.

Date Rate Scheme Bits Per Symbol Modulation

Basic Data Rate 1 GFSK

EDR 2 ∏/4 DQPSK

EDR 3 8DPSK (Optional)

(1)

data

Basic Rate and Enhanced Data Rate Packet Structure

11. Application Information

11.1 Antenna Position

The antenna used on the Embedded USB/HCI Bluetooth module is designed to be largely immune

from the effects of proximity detuning. Normally, antennas operating at 2.4GHz are affected by their

surroundings, so that great care is needed in their placement and orientation.

The Embedded USB/HCI Module can be used in most locations and orientations and is only marginally

affected by the presence of a significant ground plane in close proximity.

The antenna distribution is close to isotropic, which means that the orientation of mounting has only a

limited effect on the overall range. However the optimum range is achieved when the two antennae

are directly facing each other

The module should not be located in a sealed metal enclosure, as this will act as a Faraday cage and

severely attenuate the radio signal. A distance of 6mm has been allowed between the metal shield

and the antenna to allow the antenna to protrude through a slow in a metal enclosure.

The antenna finish may tarnish as a result of environmental effects and handling. This is a cosmetic

effect and does not affect the RF performance.

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 12

Page 13

www.ezurio.com

11.2 External Antenna Module

The dimensions for this module are identical to the Surface Mount Module, but the antenna is

replaced with a U.FL connector.

The module is certified for use with the EZURiO external antenna ACC-008. If an alternative antenna

is connected, it will invalidate the RF and Bluetooth approvals for the module.

The antenna connector is a U.FL connector, supplied by Hirose. Mating connectors with cables are

available from Hirose and their distributors, and also from other cable suppliers. The data sheet for

the connector series is available at http://www.hirose.co.jp/cataloge_hp/e32119372.pdf

11.3 Power Supply Considerations

The power supply for the Module has to be a single voltage source of Vcc within the range of 3.3V to

70 V. It must be able to provide sufficient current in a transmit burst. This can rise to 65mA.

11.4 Power-On-Reset (Power Cycling and Brown Out

considerations).

The Module is provided with an active low reset pin. Upon the application of power, the Power On

Reset circuit built into the Module will ensure that the unit starts correctly. The internal reset circuit

is triggered when the input voltage to the module drops below ~1.7V and is hence only suitable for

providing a power on reset signal. If the supply voltage to the module can drop below the minimum

voltage level in normal operation, then it is recommended that an external brownout circuit is

provided to assert the module reset and to ensure that the module is reset when the module supply

voltage drops below 3.1V.

This will ensure that the module will return to an operational state when the supply voltage comes

back within specification. For example, if the module supply can drop to 2.7V and then be restored to

3.3V there is no guarantee that the module will still be operational unless the reset signal has been

asserted.

11.5 RF Shield

To meet FCC requirements and to facilitate IR soldering, all modules are supplied with a soldered RF

shield. This meets the requirement that users may not be able to access RF circuitry without special

tools. Removal of the shield may negate RF approvals.

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 13

Page 14

www.ezurio.com

11.6 Mounting the Module onto the application platform

The antenna (Brown square component on top side of PCB) is designed to minimise detuning effects

from nearby components and metalwork. However, it is good design practise to ensure that other

active circuitry is kept away from the antenna.

The proximity of the antenna to large metallic objects can affect the range and performance of the

system. Designers should carefully consider the location of the Module and the type of enclosure

material that is used.

No tracks should be present on the top layer of the board on which the module is soldered, as these

may cause inadvertent connections to test pads. The recommended land pattern for the mother PCB

is detailed below

12. Qualification

12.1 Bluetooth Qualification Process

The following safety precautions must be observed during all phases of the operation, usage, service

or repair of any application incorporating this Module. Manufacturers of the RF equipment are advised

to convey the following safety information to users and operating personnel and to incorporate these

guidelines into all manuals supplied with the product. Failure to comply with these precautions

violates safety standards of design, manufacture and intended use of the product. Ezurio assumes no

liability for customer failure to comply with these precautions.

12.2 Safety Information:

Switch off the Bluetooth device before boarding an aircraft. Make sure it cannot be switched on

inadvertently. The operation of wireless appliances in an aircraft is forbidden by many airlines to

prevent interference with communications systems. Applications that could result in use on aircraft

should carry appropriate warnings.

Some airlines may permit use of Bluetooth. Check before use.

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 14

Page 15

www.ezurio.com

12.3 Qualifications

12.3.1 RF approvals

The Embedded USB/HCI Bluetooth Module is qualified as a Bluetooth Subsystem. This means that if

it is combined with a higher level Bluetooth stack that is also qualified as a Subsystem, then no

further qualification is required. Final products incorporating Bluetooth technology should be listed

with the Bluetooth qualification body according to the guidelines available on www.bluetooth.org.

The manufacturer must state the Ezurio part number and product reference in his literature in order

to meet the requirements of the Bluetooth and regulatory approvals.

A list of the countries where the Module is approved will be provided by Ezurio as required. As a

minimum the product is listed in Europe, Scandinavia and USA. Ezurio assumes no liability for

customer failure to comply with national RF approvals.

12.3.1.1 Radio.

R&TTE EN 300 328-2 V1.1.1 (2000-07)

EN 301 489-1 V1.3.1 (2001-09)

12.3.1.2 EMC Emissions.

FCC15B Class B

EN55022 Class B

12.3.1.3 EMC Immunity.

EN55024 Class

12.3.1.4 Environmental.

EN300 019-2-4 v2.2.2 (2003-2004)

12.3.1.5 Medical

EN60601-1-2

12.3.1.6 Automotive

SAE1455:REVAug94 Paragraph 4.10.4 (shock)

SAE1455:REVAug94 Paragraph 4.9.4.2 (random)

Emission test to 95/54/EC

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 15

Page 16

12.4 Safety and Regulatory Statements

complies with the appropriate essential requirements of the Article 3 of

the R&TTE and the other relevant provisions, when used for its intended

950: 1992 Safety of information technology equipment +

Amendment A1:1993, Amendment A2:1993, Amendment A3:1995,

s with the basic restrictions

300 GHz)

Protection requirements with respect to electromagnetic compatibility

tibility and

Magnetic Compatibility (EMC)

tions

2001), Radio Equipment and Systems (RES);

Wideband transmission systems; Technical characteristics and test

conditions for data transmission equipment operating in the 2,4 GHz ISM

ques. Part 2:

Harmonized EN covering essential requirements under article 3(2) of the

12.4.1 Europe – EU Declaration of Conformity

www.ezurio.com

DECLARATION OF CONFORMITY

In accordance with Annex IV of the EU directive 1999/5/EC

Ezurio declare under our responsibility that the Bluetooth Module

purpose.

Health and Safety requirements contained in Article 3 (1) a)

EN 60

Amendment A4:1997, Amendment A11:1997

EN 50371: Generic standard to demonstrate the compliance of lowpower electronic and electrical apparatu

related to human exposure to electromagnetic fields (10 MHz – General public

Art.3 (1) b)

EN 301489-17 V1.1.1 (09-2000), Electromagnetic Compa

radio spectrum Matters (ERM); Electro

standard for radio equipment and services; Part 17: Specific condi

for wideband data HiperLAN equipment

Means of the efficient use of the radio frequency spectrum

EN 300328-2 V1.2.1 (11-

band and using spread spectrum modulation techni

R&TTE directive.

Registered in England

www.ezurio.com No. 5178293

12.4.2 FCC and Industry Canada Statements

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 16

Page 17

www.ezurio.com

Changes or modifications not expressly approved by the party responsible for compliance could void

the user's authority to operate the equipment.

12.4.2.1 FCC Labelling requirement

If the FCC ID is not visible when the module is installed inside another device, then the outside of the

device into which the module is installed must also display a label referring to the enclosed module.

This exterior label can use wording such as the following: “Contains Transmitter Module FCC ID:

PI401B” or “Contains FCC ID: PI401B.” Any similar wording that expresses the same meaning may be

used.

13. Environmental

13.1 Operating temperatures

Parameter Min Typ Max Unit

Operating temp (standard product) -40 25 +85 °C

13.2 Storage temperature

Parameter Min Max Unit

Storage temp -40 +125 °C

13.3 Reliability

Parameter Test Comment

Thermal Shock 200 cycles -40ºC /+85ºC 30 min 1 cycle/hour

Vibration Continuous operation at 60 Hz,

2mm stroke

Shock 50G 11ms Half Sine Wave 6 axis x 3 cycles each axis

Moisture Resistance

High Temp Storage 125ºC, 360 hours

Low Temp Storage -40ºC, 240 hours

High Temp/Humidity

Operation

Thermal shock -40 to 60ºC in 30min 200 cycles with continuous

Electro Static Discharge EN55024:1998 & IEC61000-4-3

Drop Test 75cm to concrete, 3 axis x 2

60ºC, 90%RH, 360 hours

cycles per corner

15g max sine wave, 12 hours

operation

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 17

Page 18

14. Physical Dimensions (all dimensions in mm)

14.1 Top View

www.ezurio.com

14.2 Bottom View

14.3 Side View

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 18

Page 19

www.ezurio.com

14.4 Labelling

The module has a label indicating the part number and the unique Bluetooth address of the module.

14.5 Ordering Information

Part Number Description

TRBLU024-00100

TRBLU024-00200

TRBLU024-00300

TRBLU024-00400

TRBLU024-001NA Embedded Module with no antenna and HCI

TRBLU024-002NA

TRBLU024-003NA

TRBLU024-004NA

Embedded Module with integrated ceramic

antenna and HCI firmware

Embedded Module with integrated ceramic

antenna and H4 firmware

Embedded Module with integrated ceramic

antenna and H5 firmware

Embedded Module with integrated ceramic

antenna and BCSP firmware

firmware

Embedded Module with no antenna and H4

firmware

Embedded Module with no antenna and H5

firmware

Embedded Module with no antenna and BCSP

firmware

15. Related Documents

The firmware incorporated into the Embedded HCI/USB Bluetooth Module is more fully described in

Firmware release notes available from Cambridge Silicon Radio. Details of the HCI interface are

provided in the Bluetooth specification.

• Bluetooth Core 2.0 Specification – www.bluetooth.org

• Bluecore4-External Datasheet for BC417143B-IQN-E4 July 2005 - CSR

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 19

Page 20

www.ezurio.com

16. Disclaimers

EZURIO’S BLUETOOTH PRODUCTS ARE NOT AUTHORISED FOR USE AS CRITICAL COMPONENTS IN

LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE

MANAGING DIRECTOR OF EZURIO LTD.

The definitions used herein are:

a) Life support devices or systems are devices which (1) are intended for surgical implant into the

body, or (2) support or sustain life and whose failure to perform when properly used in accordance

with the instructions for use provided in the labelling can reasonably be expected to result in a

significant injury to the user.

b) A critical component is any component of a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system, or to affect its

safety or effectiveness.

Ezurio does not assume responsibility for use of any of the circuitry described, no circuit patent

licenses are implied and Ezurio reserves the right at any time to change without notice said circuitry

and specifications.

16.1 Data Sheet Status

This data sheet contains data from the Preliminary specification. Supplementary data will be

published at a later date. Ezurio Ltd reserves the right to change the specification without notice in

order to improve the design and supply the best possible product.

Where reference is made to related products from other suppliers, Ezurio takes no responsibility for

the information, availability or performance of such products.

Please check with Ezurio Ltd for the most recent data before initiating or completing a design.

16.2 Warranty

Ezurio warrants that its products shall conform to Ezurio’s published specifications and remain free

from defects in materials and workmanship under normal, proper and intended use for a period of

two (2) years from date of purchase, provided that proof of purchase be furnished with any returned

equipment.

If during the warranty period any component part of the equipment becomes defective by reason of

material or workmanship, and Ezurio is immediately notified of such defect, Ezurio shall at its option

supply a replacement part or request return of equipment, freight prepaid, to its designated facility

for repair. In the event no trouble is found on products returned for repair, Ezurio reserves the right

to charge the customer its standard published repair charge.

This warranty shall not apply to any products that have been subject to misuse, bending, twisting,

neglect, alteration, improper installation, testing or unauthorized repair performed by anyone other

than an Ezurio designated repair facility. Any non-warranty repairs or maintenance shall be at Ezurio’s

standard rates in effect at the time.

This warranty is in lieu of all other warranties, whether expressed, implied, or statutory, including but

not limited to, implied warranties or merchantability and fitness for a particular purpose. In no event

shall Ezurio be liable, whether in contract, in part, or on any other basis, for any damage sustained by

its customers or any other person arising from or related to loss of use, failure or interruption in the

operation of any products, or delay in maintenance, or for incidental, consequential, in direct, or

special damages or liabilities, or for loss of revenue, loss of business, or other financial loss arising

out of or in connection with the sale, lease, maintenance, use, performance, failure, or interruption of

these products.

© 2007 Ezurio Ltd DSH_BT024-00100_1v6 20

Loading...

Loading...