Page 1

QUALCOMM

Incorporated

5775 Morehouse Drive,

San Diego, California 92121-1714 US

200 Series and Accessory Installation Guide

Qualcomm Mobile Computing Platform

80-J9968-1 Rev. A

Month 2009

Page 2

QUALCOMM Incorporated

5775 Morehouse Drive

San Diego, CA 92121-1714

U.S.A.

Copyright

All rights reserved.

QUALCOMM, OmniTRACS, OmniExpress, SensorTRACS, QTRACS, GlobalTRACS, and

TrailerTRACS are registered trademarks of QUALCOMM Incorporated in the United States and may be

registered in other countries.

Qualcomm Enterprise Services, QES, T2, MVPc, and TruckMAIL are trademarks of QUALCOMM

Incorporated. QES is a service mark of QUALCOMM Incorporated.

Other product and brand names may be trademarks or registered trademarks of their respective owners.

Qualcomm endeavors to ensure that the information in this document is correct and fairly stated, but

Qualcomm is not liable for any errors or omissions. Published information may not be up to date, and it is

important to confirm current status with Qualcomm.

This technical data may be subject to U.S. and international export, re-export or transfer (expo rt ) laws.

Diversion contrary to U.S. and international law is strictly prohibited.

80-J9968-1 Rev. A

Month 2009

© 2009 QUALCOMM Incorporated.

Page 3

Contents

Important Safety Information

Safety Definitions ................................................................................................xi

Safety Advice ......................................................................................................xi

Chapter 1 How the Qualcomm® Mobile Computing Platform 200 Series Works

MCP200 Overview ............................................................................................1-2

Why MCP200 Makes Companies More Efficient ..............................................1-2

MCP200 Component Description .....................................................................1-3

CDMA Wireless Network and PCS ...................................................................1-4

How MCP200 Uses PCS ............................................................................1-4

Optional Data Satellite ......................................................................................1-5

GPS Network ....................................................................................................1-5

How the MCP200 Uses GPS .....................................................................1-5

Wi-Fi® Network .................................................................................................1-5

How the MCP200 Uses Wi-Fi® ..................................................................1-5

What Is MCP200? .............................................................................................1-6

Chapter 2 Component Overview

Equipment Installation ......................................................................................2-2

Wireless Interface Box 200 (WIB200) ...............................................................2-3

Wireless Interface Box (WIB200) Cable .....................................................2-3

Optional Satellite Data Modem (SDM) ..............................................................2-3

Satellite Data Modem (SDM) Cable ...........................................................2-3

Display Interface Unit 200 (DIU200) .................................................................2-4

Display Cable .............................................................................................2-4

Procedures for Using the DIU200 ..............................................................2-4

Mobile Application Server 200 (MAS200) .........................................................2-5

Backup Battery .................................................................................................2-6

Accessory Cable for the Qualcomm® MCP200 .........................................2-6

Speaker Switch Cable ................................................................................2-6

Power Cable ...............................................................................................2-6

Optional Remote Control Device (RCD) ...........................................................2-7

Optional Accessories for the MCP200 ..............................................................2-7

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION iii

Page 4

Chapter 3 General Wiring and Installation Guidelines

Making Electrical Connections .........................................................................3-2

Approved Qualcomm Electrical Connectors ..............................................3-2

Wire Stripping ............................................................................................3-2

Butt Splicing................................................................................................3-3

Crimping .....................................................................................................3-4

Ring Terminals .........................................................................................3-10

Proper Grounding ...........................................................................................3-10

General Installation Guidelines ......................................................................3-11

Routing and Protecting Cables ......................................................................3-11

Chapter 4 Installation Planning

Installation Guidelines ......................................................................................4-2

Safety, Reliability, and Accessibility ...........................................................4-2

Typical Installation Sequence ..........................................................................4-2

Typical Installation Locations for MCP200 Components ..................................4-3

Conventional Vehicle Types ......................................................................4-4

Straight Truck Vehicle Types (All Makes) ..................................................4-6

Cabover Engine Vehicle Types (All Makes) ..............................................4-6

Special Cable Ordering Instructions for Tilt Cabs ......................................4-7

Installation Planning Worksheets for the MCP200 Components .....................4-8

Tools and Supplies Recommended for Installations ......................................4-11

Qualcomm Approved Sealants ................................................................4-11

Contents

Chapter 5 Mobile Application Server 200 (MAS200) Installation

General Installation Guidelines ........................................................................5-2

Installing the Backup Battery into the MAS200 ................................................5-2

Installing the MAS200 into the Mounting Surface ............................................5-3

Selecting a Mounting Location ...................................................................5-3

Securing the MAS200 ................................................................................5-5

Installing the Power Cable ...............................................................................5-5

Power Cable Run .......................................................................................5-5

Power Cable Routing .................................................................................5-5

Low Voltage Disconnects (LVDs) ..............................................................5-5

Power Cable Wire Connections .................................................................5-6

Grounding Guidelines ......................................................................................5-7

Installing the Accessory Cable .........................................................................5-7

Cable Run ..................................................................................................5-8

Connecting Cables to the MAS200.............................................................5-9

DO NOT COPY

Chapter 6 Wireless Interface Box 200 (WIB200) Antenna Installation

General Installation Guidelines ........................................................................7-2

Option A—Antenna Installation Using VHB Tape ............................................7-2

iv

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 5

Contents

Antenna Surface Preparation .....................................................................7-2

Option B—Mount Method Installation Using Hardware ....................................7-3

Mount Surface Preparation ........................................................................7-3

Routing the WIB200 Cable ...............................................................................7-4

Connecting the Antenna Cable to the MAS200 ................................................7-4

Chapter 7 Optional Satellite Data Modem (SDM) Installation

General Installation Guidelines .........................................................................8-2

Selecting a Mount .......................................................................................8-2

Orienting the SDM on the Mount ......................................................................8-2

Installing Mounting Bolts ...................................................................................8-3

Line-of-Sight Requirements ..............................................................................8-4

Trailer Swing Area ............................................................................................8-5

Installing the SDM Cable ..................................................................................8-5

Connecting the SDM Cable ........................................................................8-5

SDM Cable Run .........................................................................................8-6

SDM Cable Installation ...............................................................................8-6

Connecting the SDM Cable to the MAS200 .....................................................8-7

PY

Chapter 8 Display Interface Unit 200 (DIU200) Installation

General Installation Guidelines .........................................................................9-2

Selecting a Mounting Location ...................................................................9-2

Installing the DIU200 Holster Using Well-nut Fasteners ...................................9-3

Installing the DIU200 Cable ..............................................................................9-4

DIU200 Cable Run .....................................................................................9-4

Connecting the Display Cable to the DIU200 ...................................................9-4

Inserting the DIU200 into the Holster ................................................................9-5

Connecting the Display Cable to the MAS200 ..................................................9-6

N

O

T

O

D

Chapter 9 Optional Text-to-Speech (TTS) Installation

General Installation Guidelines .......................................................................10-2

Selecting a Mounting Location .................................................................10-2

Installing the Remote Control Device (RCD) ..................................................10-2

Connecting the RCD to the Accessory Cable ..........................................10-2

Selecting a Speaker ........................................................................................10-3

Speaker Requirements .............................................................................10-3

Choosing a Speaker .................................................................................10-3

Option A—Connecting to an Existing or Shared Speaker ..............................10-4

Connecting Speaker Switch Cable to Accessory Cable ...........................10-5

Option B—Connecting to a Dedicated 8-ohm Speaker ..................................10-6

CO

Chapter 10 Vehicle Data Bus Connections

Vehicle Data Source Overview .......................................................................11-2

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION v

Page 6

J1939 Data Bus .......................................................................................11-2

J1708/J1587 Data Bus ............................................................................11-2

Traditional Sensors ..................................................................................11-2

Vehicle Data Source Selection .......................................................................11-3

Guidelines for Connecting to the J1939 Data Bus .........................................11-3

J1939 Pre-installation Check Out ...................................................................11-4

Resistance Test (to Verify that J1939 Is Present) ...................................11-4

Checking the MCP200 Accessory Cable for CAN0 and CAN1 ................11-5

Option 1—Connecting J1939 Using CAN 1 (for All After-Market Installations) 11-5

Making the Connection ............................................................................11-6

Option 2—Connecting J1939 Using CAN0 (for Most OEM Prewires) ............11-8

Making the Connection.............................................................................11-9

Connecting J1708 /J1587 ............................................................................11-10

Verifying Data Source Connectivity ..............................................................11-11

Chapter 11 System Verification

What Is Basic Qualcomm® MCP200 System Verification? ...........................12-2

MCP200 Display Unit Screens .......................................................................12-2

MCP200 System Screen .........................................................................12-3

MCP200 OVT/CDMA Screens .................................................................12-4

MCP200 SDM Screens ............................................................................12-5

MCP200 GPS Screen ..............................................................................12-6

MCP200 Config Screen ...........................................................................12-7

MCP200 Engineering Screen ..................................................................12-8

MCP200 CER Screen ..............................................................................12-8

VDS (Status) Screen ...............................................................................12-9

Flowchart—Basic MCP200 System Verification ..........................................12-11

Basic MCP System Verification Procedure ..................................................12-13

Qualcomm® MCP System Verification Form ...............................................12-18

DO NOT COPY

Contents

Chapter 12 SensorTRACS® Performance Monitoring Verification

SensorTRACS® System Overview ................................................................13-2

Performing SensorTRACS® System Verification ...........................................13-2

Conducting a Road Test ..........................................................................13-2

SensorTRACS® System Display Screens .....................................................13-3

Accessing the SensorTRACS® Screens .................................................13-3

Summary Screen......................................................................................13-4

Performance Screen.................................................................................13-5

Parameters Screen...................................................................................13-6

Odometer Screen ....................................................................................13-7

PTO Screen..............................................................................................13-8

Installer Screen ........................................................................................13-9

Special Alert Display Messages ...................................................................13-12

Warning Messages ................................................................................13-12

vi

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 7

Contents

Power Take-off (PTO) Overview ...................................................................13-12

PTOP (Power Take-off Pump)/PTOC (Power Take-off Compressor).....13-13

PTO Data Input Verification Procedure ........................................................13-14

Chapter 13 Vehicle Maintenance Installation

Vehicle Maintenance Overview ......................................................................14-2

Feature Requirements ..............................................................................14-2

Connecting the J1939 Wires ...........................................................................14-3

Enabling a Vehicle for Vehicle Maintenance ..................................................14-3

Vehicle Maintenance System Verification .......................................................14-4

Chapter 14 TrailerTRACS® System Installation

TrailerTRACS® System Overview ..................................................................15-2

Hardware Requirements ..........................................................................15-2

TrailerTRACS® System Wiring for the Truck .................................................15-2

Fuse Kit Installation ..................................................................................15-2

TrailerTRACS® System Verification ...............................................................15-3

Enabling the Option for the TrailerTRACS® System ...............................15-3

Trailer Connection/Disconnection ............................................................15-4

TrailerTRACS® Diagnostic Screen ..........................................................15-5

Refrigeration Status Screen .....................................................................15-6

T

CO

PY

Chapter 15 Buzzer Installation

Buzzer Overview .............................................................................................17-1

Mounting Location ..........................................................................................17-2

Installation Guidelines .....................................................................................17-2

Installation Verification ....................................................................................17-2

N

O

O

D

Chapter 16 Remote Message Waiting Light (RMWL) Installation

RMWL Overview .............................................................................................18-1

Installing the Remote Message Waiting Light .................................................18-2

Installation Verification ....................................................................................18-2

Chapter 17 Wired Panic Button Installation

Wired Panic Button Overview .........................................................................19-1

Installing the Panic Button ..............................................................................19-2

Installation Verification ....................................................................................19-4

Automated Panic Button Test System Dial-in Procedure .........................19-4

Chapter 18 In-Cab Printer Installation

Wiring Configuration .......................................................................................20-2

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION vii

Page 8

Installation Guidelines ....................................................................................20-2

Location ...................................................................................................20-2

Cables ......................................................................................................20-2

Mounting Bracket ...........................................................................................20-2

Installing the Printer .......................................................................................20-3

Installation Verification ...................................................................................20-4

Return Material Authorization (RMA) Process ...............................................20-4

O’Neil Printer Parts List ..................................................................................20-4

Chapter 19 In-Cab Scanner Installation

Installation Guidelines ....................................................................................21-2

Location ...................................................................................................21-2

Scanner Cable .........................................................................................21-2

Mounting the Scanner ....................................................................................21-2

Scanner Mounting Option ........................................................................21-2

Holster Mounting Option ..........................................................................21-2

Installing the Scanner .....................................................................................21-3

Calibrating the Scanner ..................................................................................21-3

Sending a Scan ..............................................................................................21-4

Cleaning the Scanner .....................................................................................21-5

Return Material Authorization (RMA) Process ...............................................21-5

BCS Solutions Scanner Parts List ..................................................................21-6

Contents

Appendix A Wiring Diagrams and Charts

Qualcomm® MCP200 Electrical Diagram ........................................................A-2

Qualcomm® MCP200 Wiring Diagram ............................................................A-3

Power Cable Pin Callouts ................................................................................A-4

Optional Satellite Data Modem (SDM) Cable 9-Pin Connector Callouts ..........A-5

Primary Accessory Cable Pin Callouts .............................................................A-6

Secondary Accessory Cable Pin Callouts ........................................................A-7

Display Interface Unit 200 (DIU200) Connector Pin Callouts ...........................A-8

Six-pin Data Link Connector Pin Callouts ........................................................A-9

Nine-pin Data Link Connector Pin Callouts ....................................................A-10

Radio Connector Pin Callouts ........................................................................A-11

CAN Conductor Cable ....................................................................................A-12

DO NOT COPY

Appendix B Environmental and Power Requirements

MCP200 Environmental and Power Requirements ..........................................B-2

Appendix C Standard RMA Procedure

The Return Material Authorization Process .....................................................C-1

How to Obtain an RMA Number .......................................................................C-2

Required Information .................................................................................C-2

viii

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 9

Contents

Creating an RMA On-line...........................................................................C-4

RMA Policies ...................................................................................................C-4

What to Return/Not Return ........................................................................C-4

Where to Return Equipment ......................................................................C-5

“Past Due” Equipment ...............................................................................C-6

Customer-Damaged Equipment ................................................................C-6

Missing, Lost, Stolen, or Destroyed Equipment ........................................C-6

Permanent Fleet Size Reduction Request Form .......................................C-7

Appendix D Upgrading the Qualcomm® MCP Using Secure Digital Cards

Checking the Software Versions Installed .......................................................D-2

SD Card Instructions ........................................................................................D-3

Upgrading Only the MAS Software ..................................................................D-3

Upgrading the MAS Operating System and MAS Software .............................D-4

Upgrading the SDM Software ..........................................................................D-5

Upgrading the MDU Software ..........................................................................D-6

PY

Appendix E Preventive Maintenance Inspection

How Often Should Inspections Be Performed? ...............................................E-2

Inspecting the Mobile Application Server 200 (MAS200) ................................E-2

Inspecting the Display Interface Unit 200 (DIU200) .........................................E-4

Inspecting the Wireless Interface Box 200 (WIB200) and the Optional Satellite Data Modem

(SDM) ..............................................................................................................E-6

Verifying TrailerTRACS® System Connections ...............................................E-9

T

O

CO

N

Appendix F Component and Document Information

DCNs for Documents Referenced in this Guide ..............................................F-2

MCP200 System Component MCNs Referenced in this Guide ....................... F-2

MCNs for Sealants and Lubricants Referenced in this Guide ......................... F-6

MCN for Qualcomm-recommended Torque Wrench Referenced in this Guide F-6

Appendix G Feedback Form

Feedback Form ................................................................................................G-1

Company Information ................................................................................G-1

Documentation Content .............................................................................G-2

Documentation Format ..............................................................................G-2

O

D

Glossary

Index

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION ix

Page 10

Contents

DO NOT COPY

x

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 11

Safety Definitions

The following Caution and Warning definitions are intended to advise the driver when it is

safe to use a display unit.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in

minor or moderate injury. It may also be used to alert against unsafe practices.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

Safety Advice

The following Safety Advice is provided for drivers, installers, and application developers who

use and/or locate all types of display units.

If you are a Driver, do not use a display unit when the vehicle is in motion.

If you are an Installer, do not locate the display unit, including third-party devices, where it

obstructs the driver’s field of vision, distracts the driver from the driving task, o r interferes with

the driver’s operation of controls or displays. The following label is to be posted in clear view

for the driver to see.

Important Safety Information

If you are a Third-party Device Manufacturer or Application Developer, it is your

responsibility to provide appropriate warnings regarding the safe use of your device(s) in

conjunction with Qualcomm

his attention from the road while driving a vehicle.

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION xi

DO NOT COPY

®

equipment. Applications should not require the driver to divert

Page 12

Safety Advice Important Safety Information

FCC notice:

Caution: Any changes or modifications to this device not explicitly approved by

manufacturer could void your authority to operate this equipment.

This equipment complies with FCC radiation exposure limits set forth for an

uncontrolled environment. This equipment should be installed and operated with

minimum 20 cm between the radiator and your body. This transmitter must not be

collocated or operating in conjunction with any other antenna or transmitter unless

authorized to do so by the FCC.

IC Notice:

The device’s user manual does not contain the following or equivalent statement as

per RSS-GEN section 7.1.5: Operation of this device is subject to the following two

conditions: (1) this device may not cause interference, and (2) this device must

accept any interference, including interference that may cause undesired operation

of the device.

DO NOT COPY

xii

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 13

1

How the Qualcomm® Mobile Computing Platform 200 Series Works

Topics in this chapter provide a basic overview of the MCP 200 Series and how its

components interact to deliver effective, two-way communications and other value-added

services.

MCP200 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Why MCP200 Makes Companies More Efficient. . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

MCP200 Component Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

CDMA Wireless Network and PCS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Optional Data Satellite . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

GPS Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Wi-Fi® Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

What Is MCP200? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

For technical questions, contact Qualcomm Enterprise Services (QESSM) Customer Support.

Customer Support is staffed 24 hours a day, 365 days a year:

In the United States, call 800-541-7490

In Canada, call 800-863-9191

DO NOT COPY

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 1-1

Page 14

MCP200 Overview How the Qualcomm® Mobile Computing Platform 200 Series Works

MCP200 Overview

MCP200 is a high bandwidth mobile computing platform designed to help increase customer

service, reduce operating costs, enhance driver productivity, and ensure vehicle safety.

®

MCP200 offers multi-mode communications (terrestrial and Wi-Fi

optional); and delivers more processing power on the mobile unit, an increased number of

hardware ports, and a Windows

Data transmitted through the MCP200 is backward compatible and interoperable with the

host, so customers can access information across various Qualcomm platforms, such as

MCP 100 Series, OmniTRACS

Communications System, and Untethered Asset Management Service.

®

Embedded Standard operating system.

®

Mobile Communications System, OmniExpress® Mobile

are standard, satellite is

Why MCP200 Makes Companies More Efficient

• Companies can maintain two-way contact with their vehicles and drivers 24 hours a day.

• Dispatchers can send pickup and delivery information directly to drivers, keeping vehicles

on the road.

• Text-to-speech alerts drivers of incoming messages and their importance, so drivers can

choose to immediately listen to messages without pulling off the road.

• Dispatchers know when vehicles are expected to arrive at locations, and can pass that

information on to customers.

• Provides dispatchers with vehicle location and position history information by tracking the

location of each MCP200 using latitude and longitude or distance and direction from

landmarks (usually large towns and cities).

• Drivers can inform the dispatcher of road conditions or problems.

• Optional devices allow monitoring of driver performance, engine diagnostics, trailer

locations, and refrigeration status.

DO NOT COPY

• Decision support software enables customers to optimize assets and inform shippers and

consignees of load status.

• Over-the-air software upgrades allow drivers to remain on the road rather than having to

stop at service centers.

• Display interface unit 200 (DIU200) provides a color graphical display, with a sliding

keyboard that integrates touchscreen functionality, extended temperature range, and

improved clarity for delivering critical information to drivers.

• Hours of service data ensures regulatory compliance.

• On-board navigation application provides truck-specific route mappings.

1-2

• International Fuel Tax Agreement (IFTA) simplifies fuel reporting for inter-state operations.

• Helps with safety and accident prevention.

• Optimizes fuel management.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 15

How the Qualcomm® Mobile Computing Platform 200 Series Works MCP200 Component Description

K

w

PWR

IO 1

IO 2

9

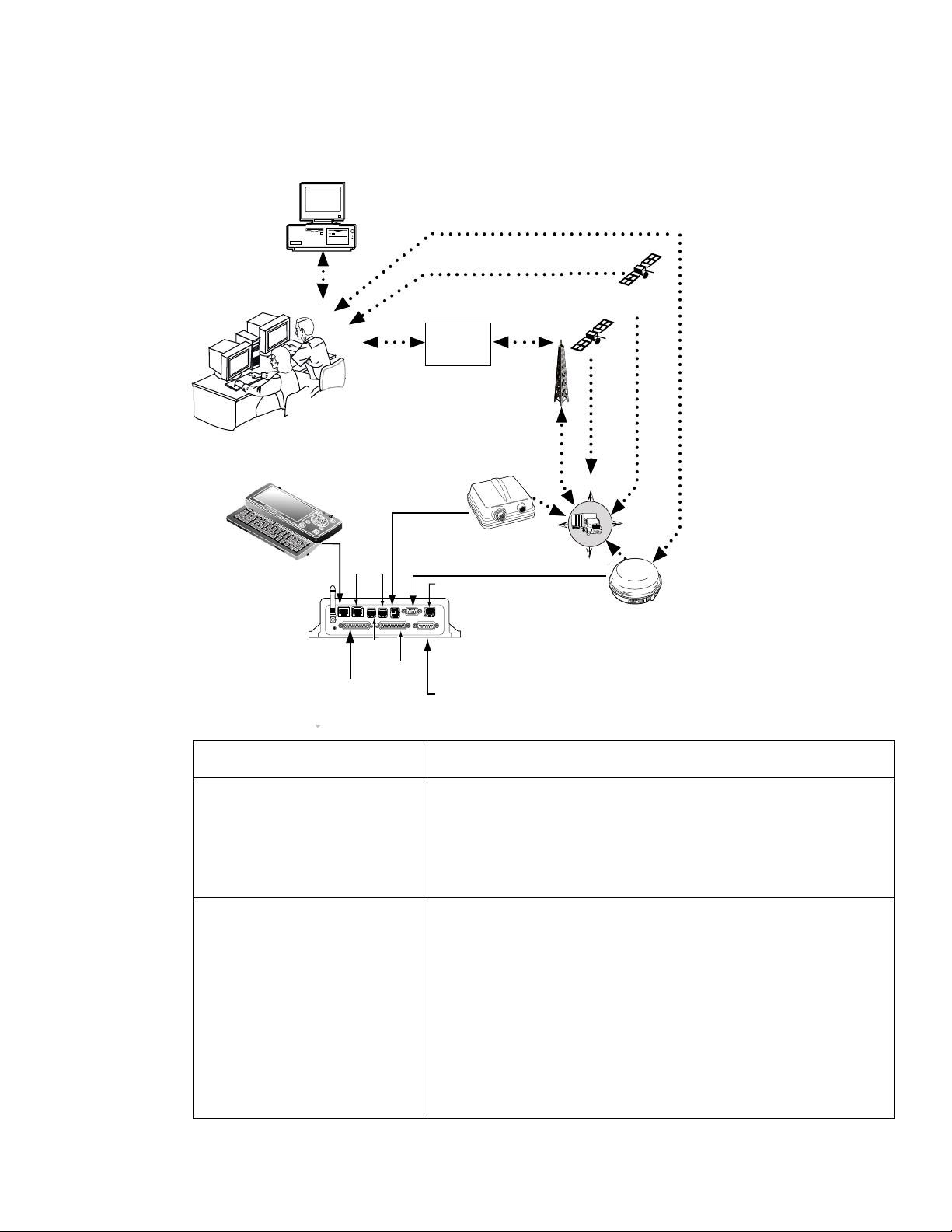

MCP200 Component Description

Customer dispatch

computer

Shift

Ctn

Fn

Esc

Tab

F

1

Alt

F

2

F

3

F

4

F

5

F

6

F

7

F

8

lkXZ

lkXZ

Ctn

Home

DIU200

MAS200

F

9

F

1

0

F

1

0

Shift

End

Up

Pg

F

1

1

F

1

2

Backspac

Insert

e

Delete

S

y

m

A

b

o

A

l

A

Dn

Pg

NOC

IDD

IO 2

Primary

Accessory

cable

USB

1/2

USB

3G

Secondary

IO 1

Accessory

cable

O

Terrestrial

network

LAN

PWR

N

Power/

Ignition

WIB200

O

GPS

Satellite

N

W

CO

S

T

Data

Satellite

PY

E

SDM

09AAA_01

Component Description

Network Operations Center

(NOC)

D

• Responsible for processing and managing message

traffic between dispatch center and fleet.

• Within the NOC is the Network Management Computer

(NMC), which receives and handles message traffic.

• Located at QUALCOMM Incorporated, in San Diego, CA.

Qualcomm Dispatch

Software (QTRACS

software)

®

• Software on the trucking company’s dispatch computer

and dispatcher’s interface with the MCP200.

• Allows dispatcher to send and receive messages, request

MCP200 location information, and perform other dispatch

functions.

• QTRACS/400 and QTRACS/Windows customers

communicate with the NMC via dialup using PPTP or a

frame relay connection.

• QTRACS/Web customers communicate via the NMC

using RI/Web client over a PPTP connection.

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 1-3

Page 16

CDMA Wireless Network and PCS How the Qualcomm® Mobile Computing Platform 200 Series Works

Code Division Multiple

Access (CDMA)

Wireless Network

Optional Data Satellite • Handles all two-way message traffic between the vehicle

GPS Positioning Satellites • Uses 24 satellites to provide vehicle positioning

Mobile Computing Platform

200 (MCP200)

CDMA Wireless Network and PCS

• MCP200 uses CDMA technology to connect dispatchers and vehicles over the wireless

airwaves.

• The Personal Communications Service (PCS) System is a low-powered, higher frequency

competitive technology to cellular, ideal for “in-city” trucking and transport.

• Radio frequency (RF) signals are received from the

antenna by the MCP200 via the wireless interface box

(WIB200) from a wireless communication network, which

varies depending on geographic location.

and the NMC if you are using a satellite data modem

(SDM).

information.

• Driver’s interface with the Qualcomm platform and the

component that resides in the vehicle.

• Allows the driver to send and receive messages.

• Wherever a terrestrial wireless network exists, drivers can send messages to and receive

messages from dispatchers while traveling.

How MCP200 Uses PCS

• The MCP200 includes the MAS200, which consists primarily of a microprocessor, a

wireless modem module, and data storage.

• The user interface device (DIU200) is the driver’s display terminal that enables the driver

to read, write, and send messages.

• The antenna (located inside the WIB200) relays messages between dispatch and the

driver.

• The antenna receives and transmits wireless information to and from the MAS200.

• The antenna interfaces with local wireless networks. Communication is collected at the

PCS gateway and obtained by Qualcomm’s NOC where it is distributed to the dispatch

center . Disp atchers respond by send ing a message back to Qualcomm’s NOC, where it is

relayed to the PCS gateway and broadcast out to the wireless network to be picked up by

the vehicle’s antenna.

DO NOT COPY

1-4

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 17

How the Qualcomm® Mobile Computing Platform 200 Series Works Optional Data Satellite

Optional Data Satellite

• Used if you are using an SDM.

• Located approximately 22,300 miles over the equator at 83° west longitude (south of

Georgia).

• Uses Ku-band signals to handle all two-way message traffic between the vehicle and the

NMC.

• Sends the message along the forward message link to the MCP200.

• Receives the message back from the driver along the return message link.

GPS Network

• A worldwide radio-navigation system formed from a constellation of 24 satellites and their

ground stations.

• Uses satellites as reference points to calculate positions accurate to a matter of meters.

• Allows every square meter of the planet to have a unique address.

• Originally created for and used by the military.

PY

• Currently used in a number of industries, including construction, film, farming, computer,

transportation, telecommunication, and wireless.

• A standard feature of the MCP200.

How the MCP200 Uses GPS

• MCP200 receives positioning data from the GPS receiver, which is integrated inside the

antenna to determine location.

• NOC receives position data from the MCP200 whenever a message is sent to a vehicle

and acknowledged, and whenever a driver sends a message to a dispatcher.

• NOC automatically retrieves position data from the NOC at regular intervals and makes it

available to the dispatcher.

• Dispatcher can request a position report from the MCP200 at any time.

Wi-Fi® Network

• A wireless networking technology that uses radio waves to provide wireless high-speed

internet and network connections.

• Provides Wi-Fi enabled devices, such as PCs, game consoles, mobile phones, MP3

players, and PDAs, access to the internet when within range (“hotspot” area) of a wireless

network.

CO

T

O

N

O

D

• Applications and devices that support Wi-Fi are interoperable with one another.

• Based on IEEE 802.11 standards.

How the MCP200 Uses Wi-Fi®

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 1-5

Page 18

What Is MCP200? How the Qualcomm® Mobile Computing Platform 200 Series Works

What Is MCP200?

• Mobile part of the Qualcomm platform installed in a customer’s vehicle.

• Provides the driver with the ability to exchange messages with the dispatch center.

• Sends vehicle location information to the NOC.

• Each MCP200 has its own unique unit address which is the serial number on the MAS200.

This address is used by the NMC to route messages to the correct vehicle. The unit

address for a particular vehicle changes if the MAS200 in the vehicle is replaced.

• MCP200 operator, typically the driver, uses the display screens for creating, sending, and

reading messages; system verification; and troubleshooting.

Wireless Interface Box

(WIB200)

Antenna

Esc

Tab

F1

F2

Shift

F3

Ctn

F4

Fn

F5

Alt

F6

F7

F8

F9

F10

F10

F11

lkXZ

lkXZ

F12

Backspac

Insert

Ctn

e

Home

Delete

Shift

Symbol

End

Up

AAA

Pg

Dn

Pg

OPTIONAL

Satellite Data Modem

(SDM)

Display Interface Unit

(DIU200)

DO NOT COPY

OPTIONAL

Mobile Application

Server (MAS200)

• Standard components:

- Wireless interface box (WIB200)—Contains terrestrial and Wi-Fi

antennae that provide CDMA/GSM/UMTS communication.

- Mobile application server (MAS200)—Communication unit which contains the operating

circuitry and memory for the MCP200. The “black box” of the platform.

- Display interface unit (DIU200)—Standa rd display unit for the MCP200, which the driver

uses to communicate with the dispatcher. Consists of a color graphical display with a

Remote Control

Device (RCD)

®

08AAA_053

modems, and

1-6

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 19

How the Qualcomm® Mobile Computing Platform 200 Series Works What Is MCP200?

sliding keyboard that integrates touchscreen functionality , extended te mperature range,

and improved clarity for drivers.

• Optional components:

- Satellite data modem (SDM)—Contains the antenna that communicates with the

satellite and GPS receiver.

- Remote control device (RCD)—Small keypad that allows the driver to safely listen to

incoming messages without having to sop the vehicle and read the message(s) on the

display.

PY

D

CO

T

O

N

O

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 1-7

Page 20

What Is MCP200? How the Qualcomm® Mobile Computing Platform 200 Series Works

1-8

DO NOT COPY

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 21

2

Component Overview

Topics in this chapter provide a basic component and wiring overview of the Qualcomm®

mobile computing platform 200 (MCP200) installation.

• For planning and installation instructions, see Chapters 4–11.

• For optional accessory installation, refer to Optional Accessories for the MCP200 on

page 2-7.

Equipment Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Wireless Interface Box 200 (WIB200) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Optional Satellite Data Modem (SDM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Display Interface Unit 200 (DIU200) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Mobile Application Server 200 (MAS200) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Backup Battery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Optional Remote Control Device (RCD) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Optional Accessories for the MCP200 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

For technical questions, contact Qualcomm Enterprise Services (QESSM) Customer Support.

Customer Support is staffed 24 hours a day, 365 days a year:

In the United States, call 800-541-7490

In Canada, call 800-863-9191

DO NOT COPY

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 2-1

Page 22

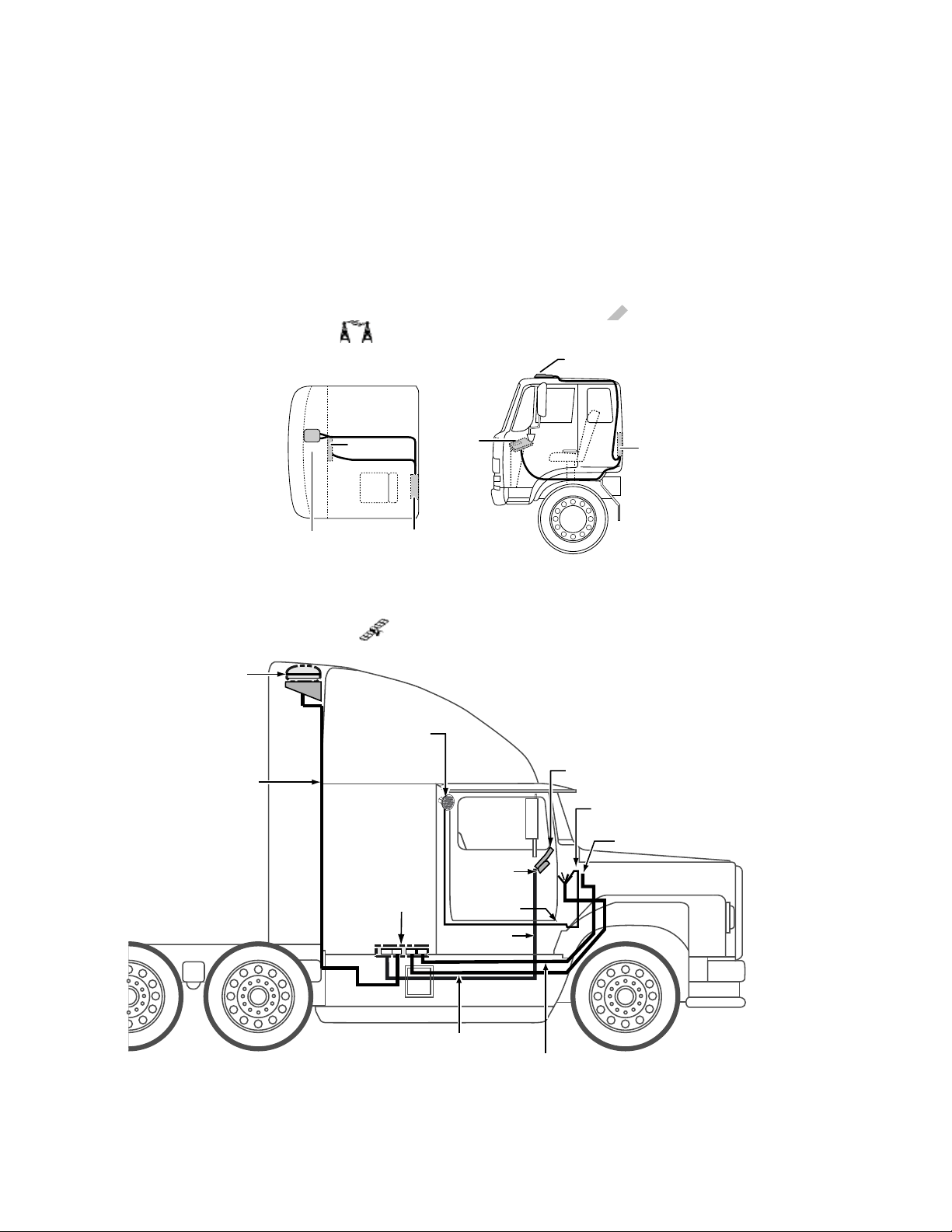

Equipment Installation Component Overview

SDM

SDM Cable

Accessory Connections

(e.g., RMWL, J1708, RCD, TTS)

Power Cable

Accessory Cable

Power Connections

MAS

Display Cable

Remote

Control Device

CB or

Stereo Speaker

Speaker

Cable

Media Display Unit

TMCP_SMCP

Satellite MCP Connection Points

MAS

Display

Typical truck cab - top view

MAS

Antenna

cable

Terrestrial

Antenna

Terrestrial

Antenna

Display

Terrestrial MCP Connection Points

Equipment Installation

Qualcomm MCP200 masterpack:

• Wireless interface box 200 (WIB200) • Cables

• Display interface unit 200 (DIU200) • Backup battery

• Mobile application server 200 (MAS200)

DO NOT COPY

2-2

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 23

Component Overview Wireless Interface Box 200 (WIB200)

Wireless Interface Box 200 (WIB200)

The WIB200 includes terrestrial and Wi-Fi® modems, and antennae that provide CDMA/

GSM/UMTS communication. The hardware provides reliable communication and GPS

positioning.

• Height: 3.4 inches

• Width: 6.5 inches

• Length: 6.5 inches

• Extended operating temperature range:

-30C to +70 C / -22F to +158F

• 802.11 compatible

• Lightweight housing for easy installation.

• Rugged design

PY

Wireless Interface Box (WIB200) Cable

• Connects the WIB200 to the MAS200.

• Standard length is two feet.

Optional Satellite Data Modem (SDM)

The SDM communicates bi-directionally via an antenna to a geostationary satellite. The SDM

is lightweight and rugged in design with strengthened antenna housing for protection against

weather and external elements.

• Height: 6.8 inches

• Diameter: 12 inches

• Weight: 7.0 pounds

• Operating temperature range:

-40C to +70C / -40F to +158F

• Connects with one Ku-band satellite for two-way data transmission. A secondary

frequency exists as a backup satellite.

• Robust sealing mechanism for use in all outdoor environments.

• Housing has the same bolt pattern as the OmniTRACS

(ACU) for ease of installation.

O

D

N

O

CO

T

®

antenna communication unit

Satellite Data Modem (SDM) Cable

• Connects the SDM to the MAS200.

• Standard length is 20 feet.

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 2-3

Page 24

Display Interface Unit 200 (DIU200) Component Overview

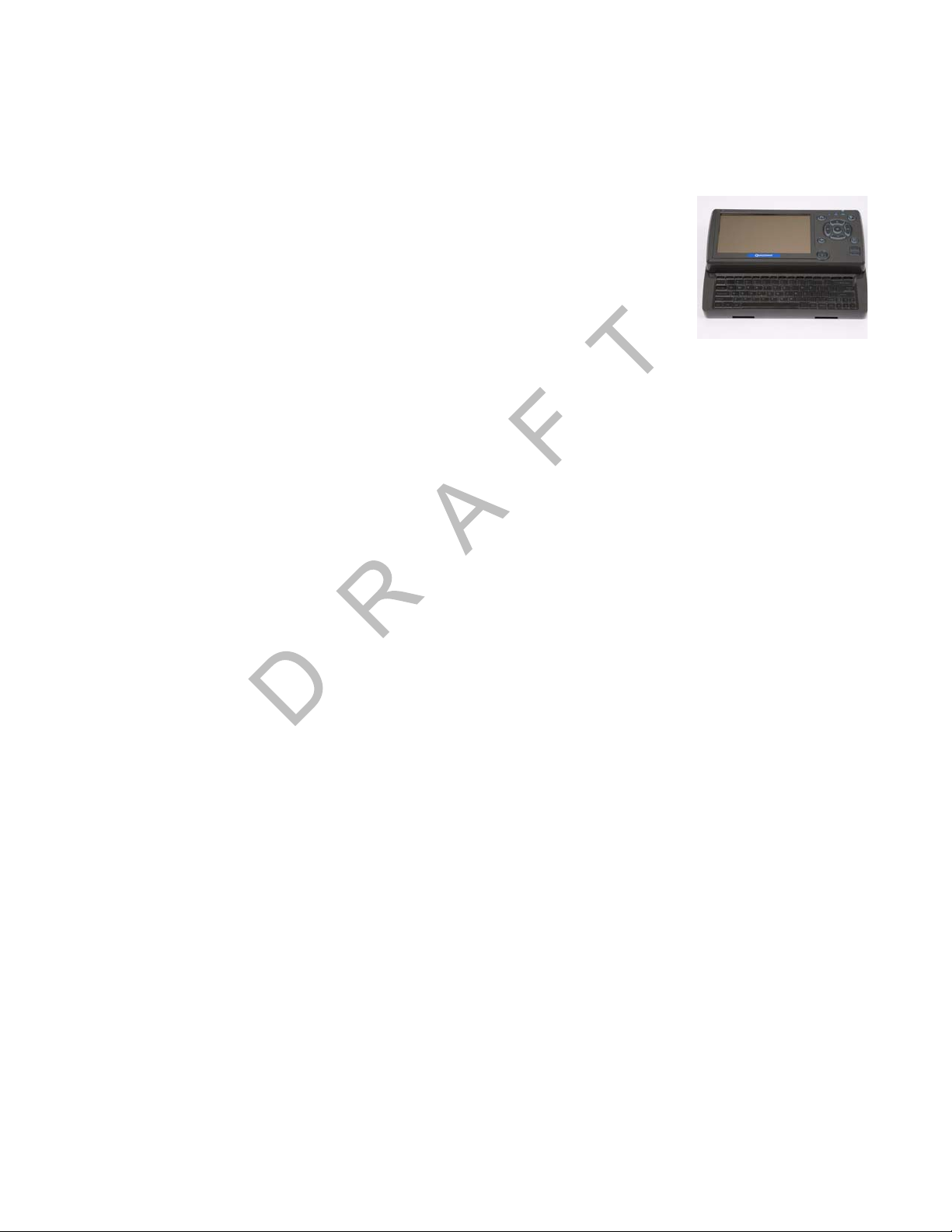

Display Interface Unit 200 (DIU200)

A color graphical display with sliding keyboard that integrates touchscreen functionality,

extended temperature range, and improved clarity for delivering

critical information to drivers.

• Dimensions—Open: 10.4 x 8.5 x 2.0 inches

Dimensions—Closed: 10.4 x 5.3 x 2.0 inches

• Weight: 3.2 pounds

• Screen size: 7-inch diagonal

• Resolution: 800 x 480

• Extended operating temperature range: -30C to +70C / -22F to +158F. Display brightness

is reduced at temperatures above +60C / +140F to reduce internal heat generation.

• Standard QWERTY keyboard with 4 arrow/navigation keys.

• Three indicator LEDs alert drivers of incoming messages, connectivity, and other

information.

• 16:9 aspect ratio color TFT LCD touchscreen includes stylus. Icon- and task- driven to

maximize driver efficiency.

• Holstered dash mount and tethered display allows for use anywhere in the cab.

• Display and keyboard are backlit, allowing the driver to distinguish keys in the dark. An

ambient light sensor adjusts backlight when it gets dark.

• Integrated speaker can be used for audio throughout the cab.

• One standard USB port for peripherals.

• Utilizes in-motion user interface to reduce driver distraction and increase safe driving.

• Touchscreen provides valid Cartesian touch coordinates for the entire active display

surface.

DO NOT COPY

Display Cable

• Connects the DIU200 to the MAS200.

• Standard length is 20 feet: 17 feet of straight cable; 3 feet of coiled cable.

Procedures for Using the DIU200

What to use for navigating the DIU200 touchscreen—PDA stylus (provided) or your

fingers.

What NOT to use for navigating the DIU200 touchscreen—pencils, pens, metal objects, or

any other devices which could possibly scratch the touchscreen.

2-4

What to use when cleaning the DIU200—a soft cloth and either plain water, glass cleaner,

or mild soap. Do not spray any liquid directly onto the DIU200.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 25

Component Overview Mobile Application Server 200 (MAS200)

Mobile Application Server 200 (MAS200)

The hardware component that leverages the Windows® Embedded Standard operating

system to deliver computing intelligence, processing power, and

expansion capability.

• Dimensions: 9.7 x 6.5 x 2.4 inches

• Weight: 4.3 pounds

• Extended operating temperature range:

-40C to +70C / -40F to +158F

• Storage temperature range: -40C to +85C / -40F to +185F

• On-board memory: 8 GB of compact flash solid state memory and 1 GB RAM. Optional

16GB flash memory upgrade available.

• Rugged hardware is compliant to SAE xJ1455 vibration profiles.

• .NET framework version 3.5.

• Intel

• Backup battery for cold crank condition.

• Supports a wide range of port interfaces that allow connections to on-board equipment:

• Supports these other interfaces:

®

Extended Temperature Atom 1.3 GHz.

CO

- J1708 Bus connects to J1708 bus of older trucks.

- (2) J1939/CAN Bus connect to J1939 bus of newer trucks. Can be used to drive some

serial tachographs.

- (4) USB 2.0 Host Ports allow USB peripherals, such as handheld scanners,

keyboards, and storage devices.

- RS-232 Interface allows connectivity to devices, such as printers, barcode readers,

and scanners.

- Configurable Interface (RS-232 or RS-485) connects to modular truck interface

systems.

- Ethernet Port RJ45 Connector

- (2) Display Ports allow for in-dash infotainment system and one other display.

- (7) Power Drivers act as switches to control lights, buzzers, door locks, etc.

D

N

O

T

O

PY

- (6) Digital Inputs allow the MAS200 to sense door openings, button pushes, alarm

status, power takeoff (PTO) clutch position, etc.

- (2) Analog Inputs allow the MCP200 to read and react to analog values, such as

temperature, light levels, and humidity levels.

- Panic Button Input allows connection of a panic button for emergency driver

signaling.

- Engine and Vehicle Speed Inputs sense the speed of the engine and the vehicle.

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 2-5

Page 26

Backup Battery Component Overview

Pull Tab

Battery Pack

- (2) Tamper Detect Lines detect tampering with the SDM and WIB200.

- Decoy Tamper Detect Line detects tampering with decoy vehicle wiring.

- Indicator Box Output drives a warning lamp to alert drivers of overspeed or overrev.

- Tethered Asset Management Rec eiver allows the MAS200 to determine what trailer

is attached to the tractor.

- Audio Output drives a truck’s speakers which allow for voice navigation and

messaging prompts, i.e., text-to-speech.

Backup Battery

• Qualcomm MCP200 requires a rechargeable lead-acid

battery installed into the MAS200.

• For more specific information about the backup battery,

see Chapter 5.

• When vehicle power is lost to the MCP200, the backup battery allows the MAS200 to shut

down gracefully and properly store data. Without a healthy battery installed, there is a high

probability of experiencing data loss or corruption.

Accessory Cable for the Qualcomm® MCP200

• Connects accessories and options, such as the SensorTRACS system®, the

TrailerTRACS system, and the RCD and speaker to the MAS200 for text-to-spee ch (TTS)

play.

• Standard length is 20 feet.

• Does not support wiring for the CDU, Axle, RPM, PTOP, or PTOC.

Speaker Switch Cable

• Connects a vehicle into a speaker to play text-to-speech.

• Cable length is 8 feet.

• Do not need if a dedicated speaker is added to the vehicle for text-to-speech (TTS).

DO NOT COPY

Power Cable

• Connects the +12/24 VDC unswitched power source (battery), the +12/24 VDC switched

power (ignition), and the system ground to the MAS200.

• Standard length is 20 feet.

2-6

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 27

Component Overview Optional Remote Control Device (RCD)

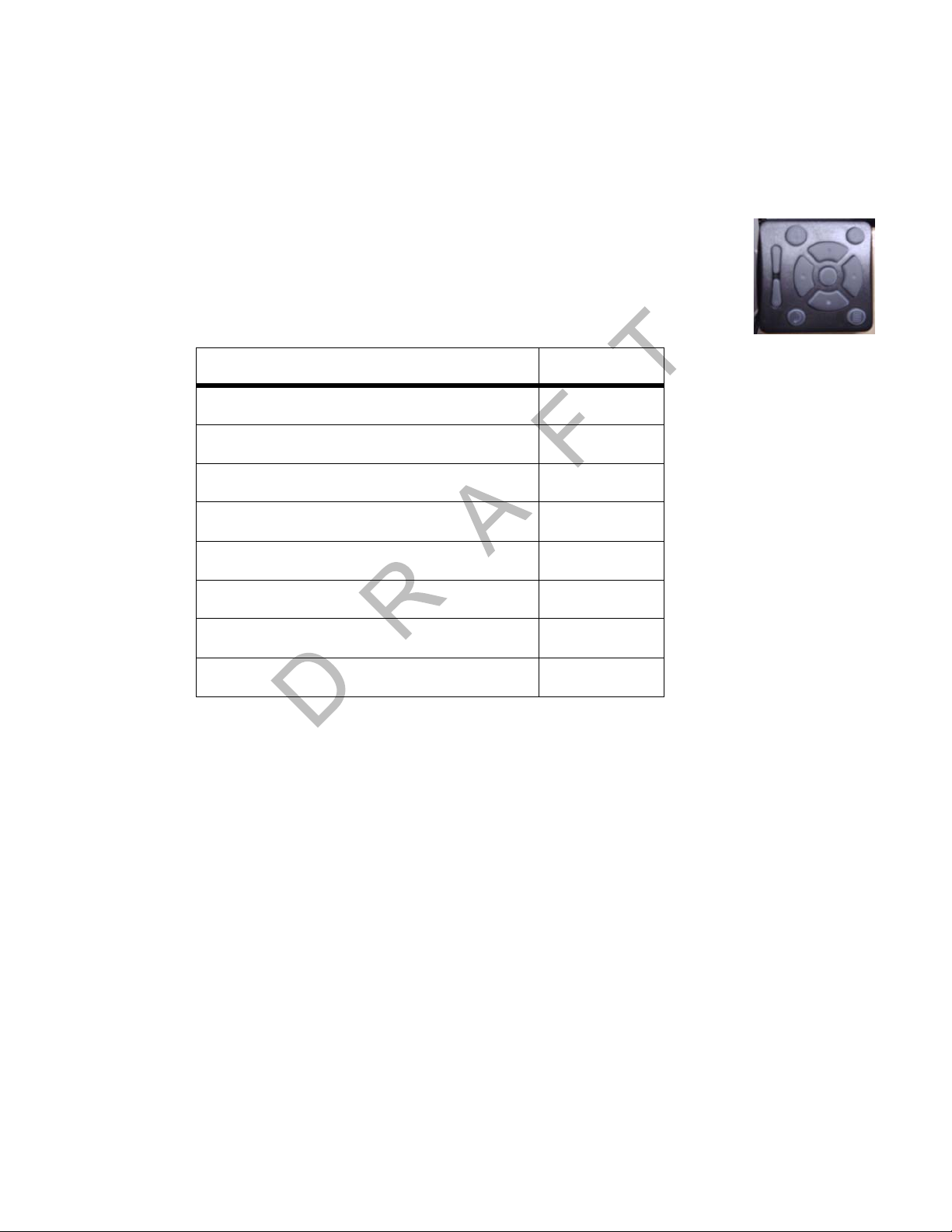

Optional Remote Control Device (RCD)

An easily accessible in-cab device allowing drivers to easily manage message playback and

the text-to-speech (TTS) feature.

• Extended operating temperature range: -30C to +70C.

• Storage temperature range: -40C to +85C.

• Small and easy to mount to the vehicle dash.

Optional Accessories for the MCP200

Accessory Chapter

SensorTRACS system 13

Vehicle Maintenance 14

PY

TrailerTRACS system 15

Buzzer 17

CO

Remote message waiting light 18

Panic button 19

Printer 20

Scanner 21

N

T

O

O

D

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 2-7

Page 28

Optional Accessories for the MCP200 Component Overview

2-8

DO NOT COPY

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 29

General Wiring and Installation Guidelines

Topics in this chapter provide the Qualcomm-approved general methods for making

connections to cables and wires and the proper connectors to use to avoid potential

problems.

Making Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Proper Grounding. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

General Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Routing and Protecting Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

If you have technical questions while reviewing this chapter, please contact Qualcomm

SM

Enterprise Services (QES

365 days a year:

) Customer Support. Customer Support is staffed 24 hours a day,

In the United States, call 800-541-7490

In Canada, call 800-863-9191

3

DO NOT COPY

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 3-1

Page 30

Making Electrical Connections General Wiring and Installation Guidelines

Making Electrical Connections

Approved Qualcomm Electrical Connectors

The only Qualcomm-approved electrical connectors are crimp butt splices and crimp ring

terminals. Qualcomm recommends Nylon insulated, seamless butt connectors with

inspection windows. Heat-shrinkable butt connectors are preferred. When butt splicing

multiple wires on one end of a butt splice and a different number of wires on the other end,

step-down butt splices are recommended.

WAR NI NG

Not following proper wiring guidelines and using improper crimps and butt splices

may cause intermittent connections and may result in unexpected truck down time or

system failure.

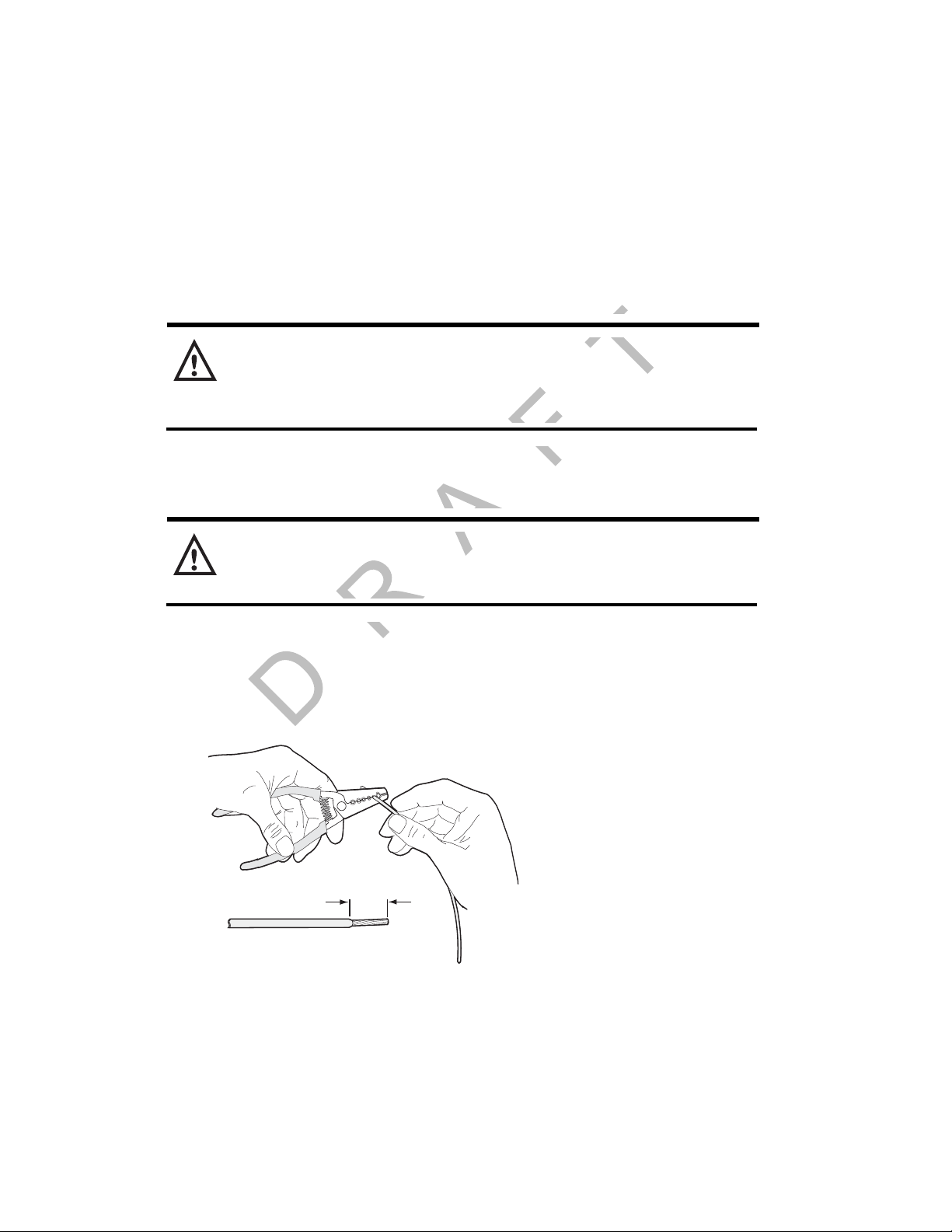

Wire Stripping

Caution

Use care in stripping wires. Vibration can cause nicked wires to fail. Using wire

cutters, knives, or other tools can damage the conductor wire and/or insulation.

Knowing and following proper wire stripping techniques is essential for performing successful

and safe electrical connections of all system components.

1. Using a wire stripper, strip approximately 1/4" off the end of an insulated wire.

DO NOT COPY

Strip

approx.

1/4"

03AAA_270a

3-2

2. After stripping the wire, verify that the wire is not severed, nicked, or damaged by the

stripping tool. If the wire has been properly stripped, it is ready to be butt spliced. If the

wire has been damaged, restrip the wire (see step 1.).

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 31

General Wiring and Installation Guidelines Butt Splicing

Butt Splicing

• Qualcomm recommends Nylon insulated, seamless butt connectors with inspection

windows.

• Heat-shrinkable butt connectors are preferred.

Butt splicing can be done inside and outside the cab or enclosure. See Butt Splicing

Connections Done Inside the Vehicle (Out of the Weather) on page 3-3 and Moisture

Protection for Connections Done Outside the Vehicle on page 3-7.

Make sure the size of the butt splice is appropriate for the job. A good butt splice has these

characteristics:

• The ends of the bare wires are visible through an inspection window.

• The ends of the wires “butt” up against the stop.

• The wires are not exposed beyond splice shielding.

• Crimping does not sever or damage the wires or insulation.

Butt Splicing Connections Done Inside the Vehicle (Out of the Weather)

1. Insert the stripped wires approximately half way into a butt splice, preferably one with

an inspection window for verifying the wire is in the correct position.

T

Push the stripped

wires to the inspection window

O

of the butt splice

CO

PY

N

O

D

Butt splice

03AAA_272

Inspection window

2. Repeat this process for the wire on the opposite end of the butt splice. Once a proper

butt splice is confirmed, it is important to properly crimp the butt splice to hold the

connection.

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 3-3

Page 32

Crimping General Wiring and Installation Guidelines

03AAA_90b

Crimp tooth

INSUL

Do NOT crimp wire here

Crimp here

INSUL

UNINSUL

UNINSUL

Crimping

• When crimping a butt-spliced wire or cable, be sure the insulated butt splice is crimped

using the insulated position on the crimp tool and not the crimping “tooth” of the tool.

• Crimping butt splices incorrectly can result in a severed wire and a failed wire connection.

Caution

DO NOT crimp on the crimp “tooth.”

1. Using a crimping tool, crimp the butt splice one end at a time. First, crimp the inside

crimp area where the wire has been stripped. Apply necessary pressure to this inside

area.

DO NOT COPY

3-4

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 33

General Wiring and Installation Guidelines Crimping

p

Note

The objective is to apply only the necessary pressure to crimp the butt splice closed and hold

the wire connections together. Do not apply so much pressure as to crush the butt splice and

sever the wire or the insulation on the wire.

Butt splice is visibly crushed,

WRONG

possibly damaging the wire

and the wire connection.

Some wires are exposed.

2. After crimping the inside of both ends of the butt splice on the “insulated” area of the

crimping tool, next crimp the outside of both ends of the butt splice.

CORRECT

Crimping is done properly,

protecting the wire and

the wire connection.

No exposed wires.

CO

PY

03AAA_277A

T

O

Wire crim

N

O

D

Crimping Tool

UNINSUL

INSUL

Crimp here

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 3-5

03AAA_271

Page 34

Crimping General Wiring and Installation Guidelines

Crimping locations

Outside crimp (insulated wire)

Inside crimp (stripped wire)

Outside crimp (insulated wire)

Inside crimp (stripped wire)

03AAA_273

3. Verify that the crimps are good and the wires have not been damaged.

4. Do a pull test. Pull on both ends of the wires to ensure a solid butt-spliced connection

exists. The crimped butt splice securely grips the insulated wires.

03AAA_282

WAR NI NG

If using heat shrinkable crimps, DO NOT use a heat gun or open flame near

combustible materials. Use a heat gun only when it is safe and appropriate to do so.

Protect surrounding wiring and other components when using a heat gun.

DO NOT COPY

3-6

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 35

General Wiring and Installation Guidelines Crimping

04AAA_22a

Wrap two

layers minimum

Peel Paper

Backing Off

Moisture Protection for Connections Done Outside the Vehicle

1. For crimps done outside the vehicle, when the crimps are verified to be good, use

plastic seal tape to wrap the entire connection. Use a minimum of two layers of seal

tape to completely wrap the connection.

• 3M industrial tape (tape sealant, vinyl/rubber mastic) is available in a 10’ roll from

Qualcomm (MCN# 800-01788-0168). To find a local or nationwide supplier, visit

http://www.3m.com (Mastic, Scotch

®

Vinyl).

PY

CO

T

O

N

O

D

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 3-7

Page 36

Crimping General Wiring and Installation Guidelines

Strain Relief With or Without Weather Protection Tape

If there is sufficient wire available for the Four-Finger Wrap Method:

1. Wrap a wire around four fingers of a hand, one full loop, so that the wire loop is longer

than the wrapped butt splice.

2. Pinch the loop tightly and center it against the wrapped butt splice.

04AAA_24a

3. Secure the wires together and place 4" tie wraps at the outside ends of the butt splice.

Place tie wraps

at outside ends of

butt splice.

DO NOT COPY

04AAA_23a

4. Cinch the tie wraps tight and cut them flush to the lock head.

3-8

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 37

General Wiring and Installation Guidelines Crimping

a

Caution

Failure to cut the tie wraps flush to the lock head can result in minor injury.

Cut tie wrap

flush with lock head.

PY

CO

T

04AAA_25a

5. Firmly tug on the butt-spliced wire connection to make sure the tie wraps do not pull

loose.

O

N

O

D

04AAA_26

If there is NOT sufficient wire available for the Four-Finger Wrap Method:

1. Securely tie wrap the butt spliced wires to existing wires or harnesses in the nearby

vicinity.

Note

It is good practice to tie wrap the newly installed wires to existing wires approximately

every 15"–18".

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 3-9

Page 38

Ring Terminals General Wiring and Installation Guidelines

Wire gripping impression

is well formed

Bare wire

protrudes 0.03 to

0.125 inch

OM/E-0093-97

Flat Washer

Flat Washer

Flat Washer

Star Washer

Lock Washer

Nut

Terminal Connector

Terminal Connector

Terminal

Screw

Ring Terminals

When making electrical connections, crimp ring terminals onto the ends of the wire s to ensure

good contacts. A properly crimped ring terminal has these characteristics:

• The barrel crimping indent is well-formed and properly positioned.

• The insulated wire’s grip impression is well-formed and provides proper support without

crushing the insulation.

• The wire does not move independently of the lug. Firmly tug on the ring termin al to ensure

it does not pull loose.

• The end of the bare wire protrudes through the crimp barrel approximately 0.03 to 0.125"

depending on the lug size and crimp tool.

Proper Grounding

3-10

Install the ring terminal on the ground connection using one of the following options:

DO NOT COPY

When establishing a good chassis ground, avoid areas that may be potentially isolated from

ground by a hinge or bad welds. It is extremely import an t th at you cre ate clean, secure, tight,

metal-to-metal grounds. If grounding terminals are not available, remove the paint from the

surface of the metal connected to the chassis to make the ground. Make sure the wires are

not strained or vulnerable to damage.

WAR NI NG

Not following proper grounding guidelines may cause intermittent connections and

may result in unexpected truck downtime or system failure.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 39

General Wiring and Installation Guidelines General Installation Guidelines

Bend Diameter

General Installation Guidelines

• Determine the most direct and protected route when routing cables to connect the

components to each other and to the vehicle. Refer to Chapter 4.

• The standard cable length for the power, display, and accessory cables is 20 feet.

- If you are working with a tilt cab, a longer cable may be necessary.

• Do not trim cable lengths to fit a specific vehicle.

• Keep protective caps in place or wrap connector with plastic/electrical tape until you’re

ready to connect the cable to the component.

• Use only wire strippers for stripping wires.

• Use only the appropriate insulated crimping tool for crimping insulated connectors.

• Use existing holes for cable routing whenever possible.

Routing and Protecting Cables

PROTECT THE ENTIRE LENGTH of cabling with convoluted tubing when routing the cable:

• Limit the minimum bend diameter:

- accessory cable to 5.0 inches

- display cable to 1.5 inches

- power cable to 2.5 inches

- antenna cable to 2.5 inches

- SDM cable (optional) to 2.5 inches

• Provide strain relief for all cables

• Use supplied grommets

• Use tie wraps

• Debur any drilled holes

DO NOT route cables:

• Near audio system amplifiers

• Near exhaust pipes and other sources of heat

PY

CO

T

O

N

O

D

• Near the brake, clutch, or accelerator pedals, and linkage

• Near foot traffic areas

• Near the windshield wiper mechanism

• Near CB radio wires

• Over sharp edges

• Over moving parts

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 3-11

Page 40

Routing and Protecting Cables General Wiring and Installation Guidelines

Rear View

Cable tied to existing

boomerang brackets

Convoluted tubing

05AAA_223E

Drip loop

Terrestrial Antenna

A

Special Exterior Routing Guidelines

• Always use convoluted tubing to protect the cables. Secure the cables to the vehicle with

tie wraps at approximately 18" intervals.

• Route away from exhaust pipes and moving parts. If an exhaust pipe or moving part must

be crossed, use extra tie wraps and route the cable in such a manner that if the tie wrap

fails, the cable will be caught or rest on a safe part (not hot or moving).

• Seal all external holes for cables with refrigeration/tar tape or silicone sealant to keep

moisture out.

• Route cables with any existing vehicle cables.

Special Interior Routing Guidelines

• Route cables under kick plates or carpets.

• Avoid high foot traffic areas.

• When reinstalling kick plates or carpets, be careful that screws do not penetrate cables.

• Route cables with any existing vehicle cables.

• Use convoluted tubing and refrigeration/tar tape when cables are routed through interior

holes with sharp edges.

Storing Excess Cabling

• Secure excess cabling with tie wraps.

• Stow out of sight.

Service Loops (Drip Loops)

• Provide for all cables.

• Ensure that service loops do not cause any obstruction.

DO NOT COPY

Satellite Data Modem

Drip loop

Convoluted tubing

Cable tied to existing

boomerang brackets

3-12

Rear View

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

05AAA_223

Page 41

General Wiring and Installation Guidelines Routing and Protecting Cables

Access Holes

• Use existing holes for cable routing.

• If you drill, drill the smallest hole for the purpose:

- 1-1/2" hole is recommended for cables with a 9-pin DSUB connector, e.g., SDM cable.

- 1" hole is needed for the connectors on the antenna cable.

• Finish holes prior to routing cables:

- Debur holes.

- Use supplied grommet/convoluted tubing with internal holes.

- Extend convoluted tubing beyond the hole.

Access hole

sealed with

grommet

Tie-wraps

Fire Wall

of Vehicle

Convoluted

Tubing

PY

CO

T

06AAA_89

O

N

O

D

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 3-13

Page 42

Routing and Protecting Cables General Wiring and Installation Guidelines

3-14

DO NOT COPY

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 43

4

Installation Planning

Topics in this chapter provide guidelines for planning a basic Qualcomm® MCP200

installation.

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Typical Installation Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Typical Installation Locations for MCP200 Components . . . . . . . . . . . . . . . . . . . . . 4-3

Installation Planning Worksheets fo r the MCP200 Components . . . . . . . . . . . . . . . 4-8

Tools and Supplies Recommended for Installations . . . . . . . . . . . . . . . . . . . . . . . 4-11

For technical questions, contact Qualcomm Enterprise Services (QESSM) Customer Support.

Customer Support is staffed 24 hours a day, 365 days a year:

In the United States, call 800-541-7490

In Canada, call 800-863-9191

DO NOT COPY

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 4-1

Page 44

Installation Guidelines Installation Planning

Installation Guidelines

Safety, Reliability, and Accessibility

• Use eye protection when using a drill/performing work that may be hazardous to the eyes.

• Use ear protection in noisy work areas.

• Wear appropriate clothing/uniforms and safety shoes.

• Make sure you know what is behind the area before you drill.

• Use hood safety lanyards when the vehicle hood is open.

• Make sure ladders are in good working order.

• Place ladders in safe positions.

• Install equipment so it will not cause damage to the vehicle or work loose over time.

• Make sure there are no loose components/cables and no unsecured components.

• Use solid mounting surfaces.

• Do not modify or design your own mounts without first obtaining Qualcomm approval

(applies domestically only).

• Mount WIB200 in locations where the unit will receive uninterrupted and undegraded GPS

satellite signals. Refer to Routing the WIB200 Cable on page 7-4.

• Mount optional SDMs in locations where the unit will receive uninterrupted and

undegraded GPS satellite signals. Refer to Line-of-Sight Requirements on page 8-4.

• Install all components in locations where they will not be abused.

• Do not mount antennas on headache racks or exhaust stacks.

• Route all cables away from hot or abrasive areas.

• Ensure that electrical connections are solid and the system ground is a clean, secure,

metal-to-metal chassis ground.

• Choose installation locations where future maintenance can be easily serviced.

• Choose installation locations where components are safe from tampering and damage.

Typical Installation Sequence

1. Determine component installation locations best-suited for your vehicle.

2. Install and route cables.

3. Antenna, see Chapter 7: Wireless Interface Box 200 (WIB200) Antenna Installation or

Chapter 8: Optional Satellite Data Modem (SDM) Installation.

DO NOT COPY

4-2

4. Display unit holster and display unit, see Chapter 9.

5. Remote control device (RCD), see Chapter 10.

MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 80-J9968-1 Rev. A

Page 45

Installation Planning Typical Installation Locations for MCP200 Components

6. Accessories.

7. MAS200, see Chapter 5.

8. After you install the MCP200 components, see Chapter 12.

Typical Installation Locations for MCP200 Components

SDM

CB or

Stereo Speaker

SDM Cable

MAS

Remote

Control Device

Speaker

Cable

CO

Display Cable

Media Display Unit

Accessory Connections

(e.g., RMWL, J1708, RCD, TTS)

PY

Power Connections

T

O

Accessory Cable

N

• Securely mount the wireless interface box 200 (WIB200) with a clear “line-of-sight” to the

GPS satellite (see Chapter 7).

O

Power Cable

Scene2A_revised

D

• Securely mount the optional satellite data modem (SDM), if being used, to the mounting

assembly with a clear “line-of-sight” to the satellite (see Chapter 8).

• Install the display unit in the cab where it can be easily accessed by the driver.

WAR NI NG

The driver should not use the display unit while the vehicle is in motion.

• Install the MAS200 in a dry, protected space, such as the side box or bunk area.

• Install the optional RCD, if being used, within reach of the driver but where it will not

interfere with the operation of the vehicle.

80-J9968-1 Rev. A MAY CONTAIN U.S. AND INTERNATIONAL EXPORT CONTROLLED INFORMATION 4-3

Page 46