Page 1

BISM2 Bluetooth™ Version 2.0 Serial Module

1. General Description

Ezurio’s BISM2 Bluetooth Serial Module is a fully integrated and qualified Class 1 Bluetooth solution

designed for lowest cost of integration and ownership for designers wishing to incorporate Bluetooth

functionality into their products. The module is qualified to Bluetooth Version 2.0.

The BISM2 Module is based on Cambridge Silicon Radio’s BlueCore 04 chipset. The module contain

all of the hardware and firmware for a complete Bluetooth solution, requiring no further components.

The Module has an integrated, high performance antenna which is matched with the Bluetooth RF and

baseband circuitry. The firmware integrated into the BC04 chipset implement the higher layer

Bluetooth protocol stack, up to and including the Generic Access Profile (GAP), Service Discovery

Profile (SDAP), Serial Port Profile (SPP), Dial Up Networking Profile (DUN) and Audio Gateway. A

virtual processor is used within the BC04 to implement an AT command processor. This interfaces to

the host system over a straight forward serial port using an extensive range of AT commands. The AT

command set abstracts the Bluetooth protocol from the host application, saving many months of

programming and integration time. It provides extremely short integration times for data oriented

cable replacement and voice applications. A low cost development system is available for fast

product evaluation and development.

An alternative version of firmware is available that provides programming support for multi-point

applications.

The Module can be configured so that it can be attached to a ‘dumb’ terminal or attached to a PC or

PDA for cable replacement applications.

In addition to the Bluetooth functionality, The BISM2 Module provides access to 8 General I/O lines

and 2 analogue I/O lines. These can be configured to provide connection to simple devices such as

switches or LEDs without requiring any external processing. Both the GPIO and ADC lines can be

accessed either via the wired host UART connection, or remotely over the Bluetooth link.

The BISM2 module is supplied in a small form factor pcb (25mm x 35mm x 10mm), that connects to

a main pcb using a 40 way Hirose connector. The module includes a high sensitivity, high gain

antenna which provides excellent range. Typical open field performance provides ranges of over 250

metres at transmit powers of only 4mW.

Support is provided for low power modes that make the BISM2 particularly applicable to battery

powered installations.

The BISM2 module is Lead-free and is RoHSA compliant and supports an industrial temperature range

of -40°C to +85°C.

1.1 Applications

•

POS Equipment

•

Medical Equipment

•

Telematics

•

Voice Applications

•

Industrial Automation

•

Automotive Applications

Bluetooth is a trademark owned by Bluetooth SIG, Inc., USA, and is licensed to Ezurio Ltd

www.ezurio.com © Ezurio Ltd 2005

1

Page 2

2. Features

Feature Implementation

Bluetooth Transmission Class 1

Fully Bluetooth pre-qualified Bluetooth 2.0

Range 250 metres typical (free space)

Frequency 2.400 – 2.485 GHz

Max Transmit Power +6dBm

Min Transmit Power +0dBm

Receive Sensitivity Better than -90dB

Antenna Gain +2dBi

Data Transfer rate Up to 250Kbps

Serial Interface RS-232 bi-directional for commands and data using AT commands

Serial parameters

Physical size 25 x 35 x 10 mm, 8g

Current consumption

Low power sniff mode 2.5mA typ

Temperature Range Normal operation: -40°C to +85°C

Interface Levels 3.3V

Audio

Profiles

Multipoint 7 slaves

Field upgradeable Over UART

Protocols

GPIO

Lead free Lead-free and RoHS compliant

Default 9600,n,8,1 - Configurable from 9600bps.

Support for DTR, DSR, DCD, RI, RTS, CTS

Less than 36mA during data transfer with a configurable low power

mode

Audio can be transferred over SCO channels through the PCM interface

at 64kbps

Server - SPP (Full), DUN, Audio Gateway, Headset, Handsfree

Client - All RFCOMM based profiles

UART

Single point firmware is controlled and configured using AT

Commands, multipoint firmware uses a simple packet based protocol

and requires a host to enable the module to function effectively.

Single point only allows a point to point connection where as

multipoint allows up to 7 simultaneous connections.

8 x digital

2 x analogue

www.ezurio.com © Ezurio Ltd 2005

2

Page 3

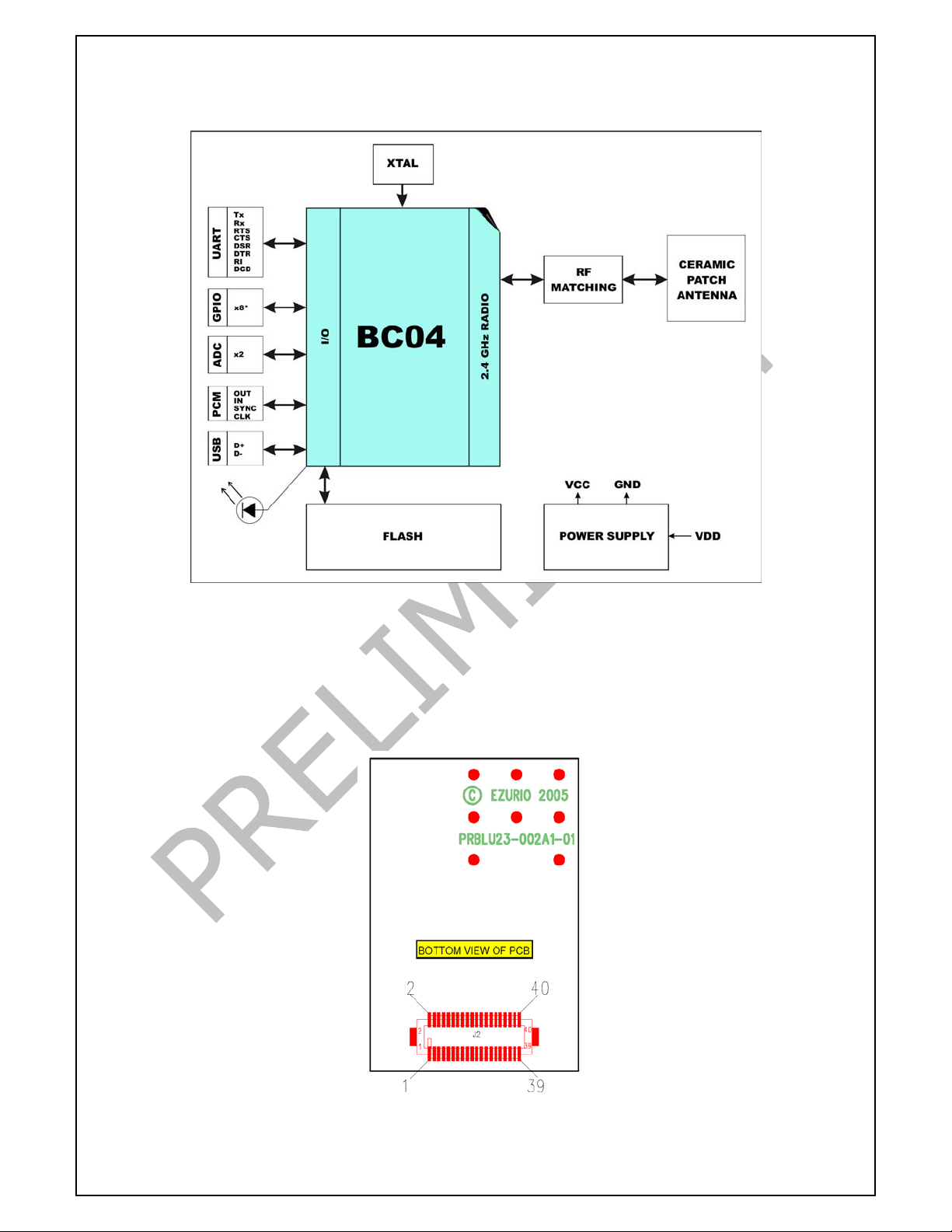

3. Functional Block Diagram

* GPIO lines are utilised for DTR, DCD, RI and LED, but can be re-assigned

3.1

The Module is equipped with a 40-pin 0.5mm pitch board-to-board connector that connects to the

application platform.

Connection Diagram

www.ezurio.com © Ezurio Ltd 2005

3

Page 4

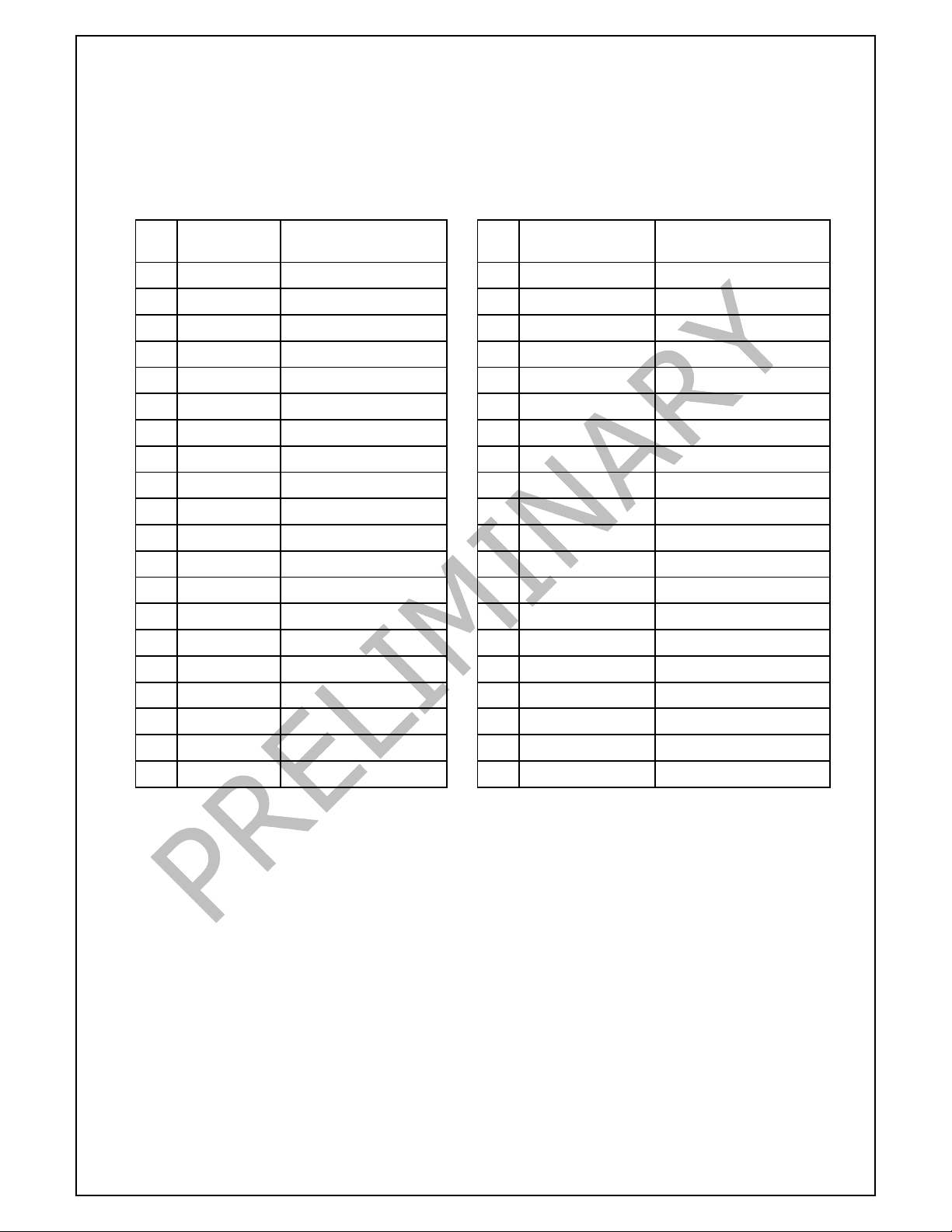

3.2 Pin Descriptions

The Hirose DF12C board-to-board connector on the module is a 40-pin double-row receptacle.

The table below defines the pin functions. Note that this pin-out is as viewed from the underside of

the Module.

Pin

Signal Description Pin

No.

1 Analogue 0 1.8v Max 2 GPIO1 I/O for Host.

3 Analogue 1 1.8v Max 4 GPIO2 I/O for Host

5 SPI_MISO SPI bus serial O/P 6 UART_RI ‘Ring’ Input or Output

7 SPI_CSB SPI bus chip select I/P 8 UART_DCD Input or Output

9 SPI_CLK SPI bus clock I/P 10 UART_DSR Input

11 GND 12 GPIO3/UART_DTR I/O for Host

13 RESET Reset I/P 14 GPIO4 I/O for Host

15 GND 16 GPIO5 I/O for Host

17 SPI_MOSI SPI bus serial I/P 18 GND

19 UART_CTS Clear to Send I/P 20 PCM_CLK PCM Clock I/P

21 UART_TX Transmit Data O/P 22 PCM_IN PCM Data I/P

23 UART_RTS Request to Send O/P 24 PCM_SYNC PCM Sync I/P

25 UART_RX Receive Data I/P 26 PCM_OUT PCM Data O/P

27 VCC_3V3 3.3V Output (Note 3) 28 N/C

29 VCC_5V 3.6V < VIN < 6.0V 30 GND

31 N/C 32 RESERVED Do not connect

33 GPIO6 I/O for Host 34 RESERVED Do not connect

35 GPIO7 I/O for Host 36 GND

37 GPIO8 I/O for Host 38 GND

39 RESERVED DO NOT CONNECT 40 N/C

Signal Description

No.

Notes:

UART_RX, UART_TX, UART_CTS, UART_RTS, UART_RI, UART_DCD and UART_DSR are all 3.3v level

logic. For example, when RX and TX are idle they will be sitting at 3.3V. Conversely for handshaking

pins CTS, RTS, RI, DCD, DSR a 0v is treated as an assertion.

Pin 6 (UART_RI) is active low. It is normally 3.3v. When a remote device initiates a connection, this

pin goes low. This means that when this pin is converted to RS232 voltage levels it will have the

correct voltage level for assertion.

Pin 8 (UART_DCD) is active low. It is normally 3.3v. When a connection is live this pin is low. This

means that when this pin is converted to RS232 voltage levels it will have the correct voltage level for

assertion.

Pin 10 (UART_DSR) is an input, with active low logic. It should be connected to the DTR output of the

host. When the BISM2 Module is in high speed mode (See definition for S Register 512), this pin

should be asserted by the host to ensure that the connection is maintained. A deassertion is taken to

mean that the connection should be dropped, or an online command mode is being requested.

The GPIO pins can be accessed using S Registers 621 to 625. GPIO4 and GPIO5 are also connected

to LEDs on the module. If these I/O pins are set for input, then the LED will be driven by the host and

www.ezurio.com © Ezurio Ltd 2005

4

Page 5

appropriate drive current requirements must be satisfied. By default GPIO4 is used to drive the right

LED which indicates connection status. A Logic 1 switches on the LED.

GPIO3 is used for DTR output (active low).

Analogue 0 and 1 should not exceed 1.8v and S Registers 7xx are used to access them.

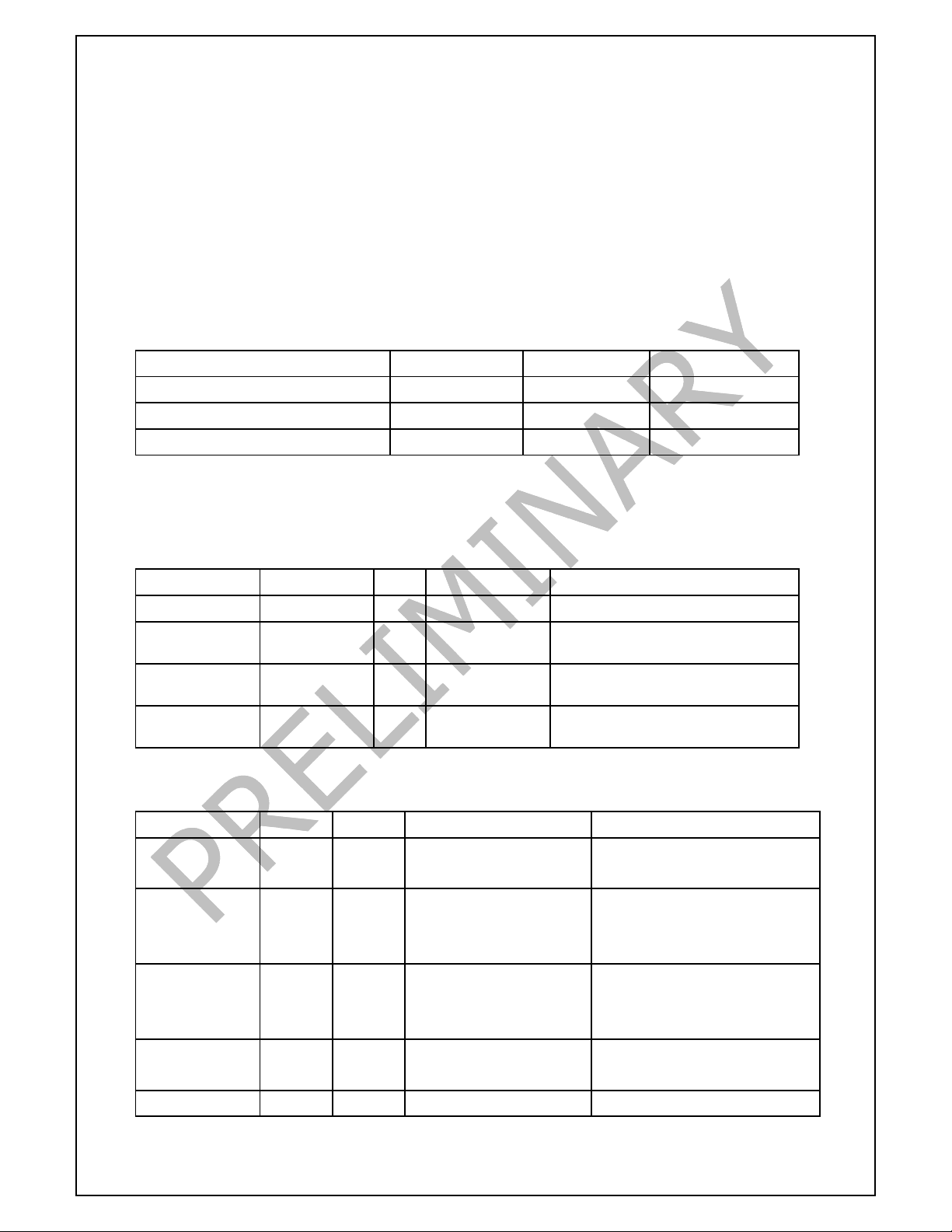

3.3 Electrical Specifications

3.3.1 Absolute Maximum ratings

Absolute maximum ratings for supply voltage and voltages on digital and analog pins of the Module

are listed below; exceeding these values will cause permanent damage.

Parameter Min Max Unit

Peak current of power supply 0 100 mA

Voltage at digital pins -0.3 3.7 V

Voltage at POWER pin 3.3 7 V

3.3.2 Recommended Operating Parameters

3.3.2.1 Power Supply

Signal Name Pin No I/O Signal level Comments

Vcc 29 I 3.6V to 6V I

GND 11, 15, 18,

6 Ground terminals to be attached

30, 36, 38

VCC_1V8 39 O 1.8V typical For monitoring only. No current

VCC_3V3 27 O 3.3V typical For monitoring only. No current

3.3.2.2 RS-232 Interface

Signal Name Pin No I/O Signal level Comments

UART_TX 21 O VOLmax=0.2V

min=2.8V

V

OH

UART_RX 25 I VILmax=0.8V

min=2.10V

V

IH

max=3.7V

V

IH

UART_CTS 19 I VILmax=0.8V

min=2.10V

V

IH

max=3.7V

V

IH

UART_RTS 23 O VOLmax=0.2V

min=2.8V

V

OH

UART_DSR 10 I VILmax=0.8V

= 50mA

typ

in parallel

source

source

www.ezurio.com © Ezurio Ltd 2005

5

Page 6

min=2.10V

V

IH

max=3.7V

V

IH

UART_DTR 12 O VOLmax=0.2V

min=2.8V

V

OH

UART_RI 6 I or O O/P : VOLmax=0.2V

V

I/P : V

V

V

min=2.8V

OH

max=0.8V

IL

min=2.10V

IH

max=3.7V

IH

UART_DCD 8 I or O O/P : VOLmax=0.2V

V

I/P : V

V

V

min=2.8V

OH

max=0.8V

IL

min=2.10V

IH

max=3.7V

IH

Shared with GPIO3

Direction may be programmed.

Direction may be programmed.

3.3.2.3 SPI Bus

Signal Name Pin No I/O Signal level Comments

SPI_MOSI 17 I VILmax=0.8V

min=2.10V

V

IH

max=3.7V

V

IH

SPI_MISO 5 O VOLmax=0.2V

min=2.8V

V

OH

SPI_CSB 7 I VILmax=0.8V

min=2.10V

V

IH

max=3.7V

V

IH

SPI_CLK 9 I VILmax=0.8V

min=2.10V

V

IH

max=3.7V

V

IH

Used to reprogram Flash

3.3.2.4 PCM Interface

Signal Name Pin No I/O Signal level Comments

PCM_CLK 20 I or O O/P : VOLmax=0.2V

V

I/P : V

V

V

min=2.8V

OH

max=0.8V

IL

min=2.10V

IH

max=3.7V

IH

PCM_IN 22 I VILmax=0.8V

min=2.10V

V

IH

max=3.7V

V

IH

PCM_SYNC 24 I or O O/P : VOLmax=0.2V

www.ezurio.com © Ezurio Ltd 2005

6

If unused keep pins open

Page 7

V

I/P : V

V

V

PCM_OUT 26 O VOLmax=0.2V

V

OH

min=2.8V

OH

max=0.8V

IL

min=2.10V

IH

max=3.7V

IH

min=2.8V

3.3.2.5 General Purpose I/O and ADC

Signal Name Pin No I/O Signal level Comments

GPIO 1 - 5 2,4,12,

14,16

I or O O/P : VOLmax=0.2V

V

I/P : V

V

V

min=2.8V

OH

max=0.8V

IL

min=2.10V

IH

max=3.7V

IH

AIO_0, AIO_1 1, 3 I/O Vout max=VDD_PIO-.3

Vout min=VDD_PIO

3.3.2.6 Miscellaneous

Function Signal Name Pin No I/O Signal level Comments

Reserved USB D- 32 I VILmax =0.3vdd_pads

VIHmin =0.7Vdd_pads

Reserved USB D+ 34 I VILmax =0.3vdd_pads

VIHmin =0.7Vdd_pads

Reset RESET 13 I VDD falling

Normally inactive.

Pull to GND

through 10K

Normally inactive.

Pull to GND

through 10K

threshold=1.5V typ

VDD rising

threshold=1.6V typ

www.ezurio.com © Ezurio Ltd 2005

7

Page 8

4. I/O Characteristics

4.1 Power Consumption

The current drain from the Vcc power input line is dependent on various factors. The three most

significant factors are the voltage level at Vcc, UART Baudrate and the operating mode.

The hardware specification for the Module allows for a voltage range of 3.6 to 6.0 at Vcc. Tests have

shown that there is no significant difference in current draw when Vcc is 5 or 6V. Therefore the data

presented below, pertains to Vcc levels of 3.6 and 5v only. Tests have shown that where power drain

is an issue, it is best to keep Vcc at the lower end of the range.

The UART baudrate has a bearing on power drain because as is normal for digital electronics, the

power requirements increase linearly with increasing clocking frequencies. Hence higher baudrates

result in a higher current drain.

Finally with regards to operating mode the significant modes are; idle, waiting for a connection,

inquiring, initiating a connection, sniff and connected. With connected mode, it is also relevant to

differentiate between no data being transferred and when data is being transferred at the maximum

rate possible. The AT command Set document describes how to configure the Module for optimal

power performance.

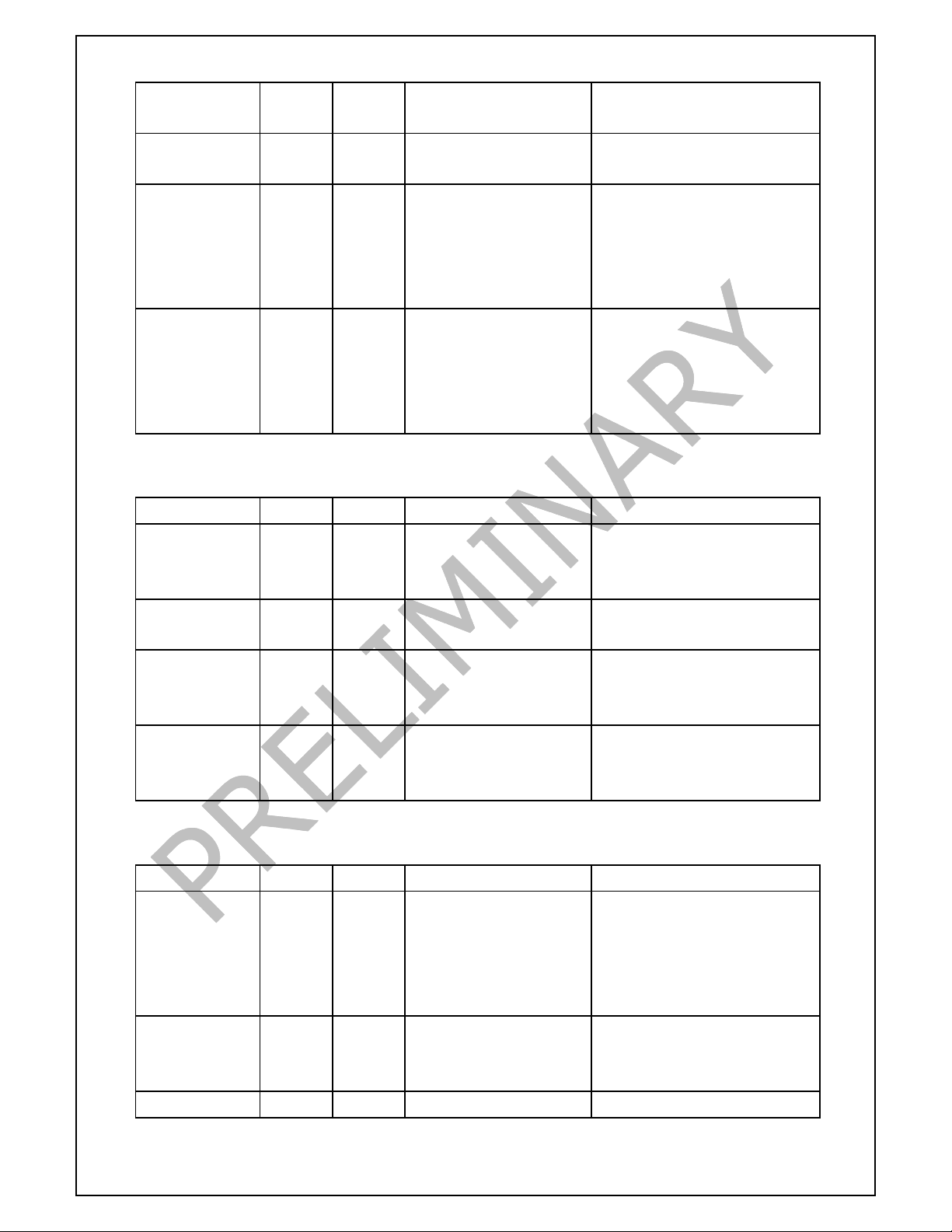

4.1.1 Typical Current Consumption in mA

Baudrate

9600 38400 115200 460800

3.6v 1.60 1.80 1.96 3.00 Idle Mode, S512=1

5.0v 2.00 2.10 2.30 3.40

3.6v 59.00 59.00 59.00 59.00 Wait for Connection Or Discoverable Mode,

AT+BTP

S508=S510=640, S509=S511=320

AT+BTP

S508=S510=1000, S509=S511=11*

5.0v 65.00 65.00 65.00 65.00

3.6v 2.75 2.94 3.10 4.12 Wait for Connection Or Discoverable Mode,

5.0v 3.26 3.36 3.55 4.63

3.6v 50.00 50.00 50.00 50.00 Inquiring Mode, AT+BTI

5.0v 54.00 54.00 54.00 54.00

3.6v 50.00 50.00 50.00 50.00 Connecting Mode (ATDxxx)

5.0v 54.00 54.00 54.00 54.00

3.6v 6.00 6.10 6.40 7.20 Connected Mode (No Data Transfer)

5.0v 7.20 7.20 7.40 8.20

3.6v 21.50 22.50 24.50 32.50 Connected Mode (Max Data Transfer)

5.0v 24.50 26.00 28.00 36.00

* Note: calculated figures

4.2 Interface Pins

To be supplied

www.ezurio.com © Ezurio Ltd 2005

8

Page 9

5. DC Characteristics

5.1 RF Performance

5.1.1 Transmit Power

Conducted Transmit Power min: 1.0mW (0dBm) max: 4mW (6dBm)

Antenna Gain +2dBi typ.

Effective Transmit Power min: 0dBm max Max: +6dBm

5.1.2 Receive Sensitivity

Receive Sensitivity -86dBm (at 25°C)

Antenna Gain +2dBi typ

Effective Receive Sensitivity -88dBm (at 25°C)

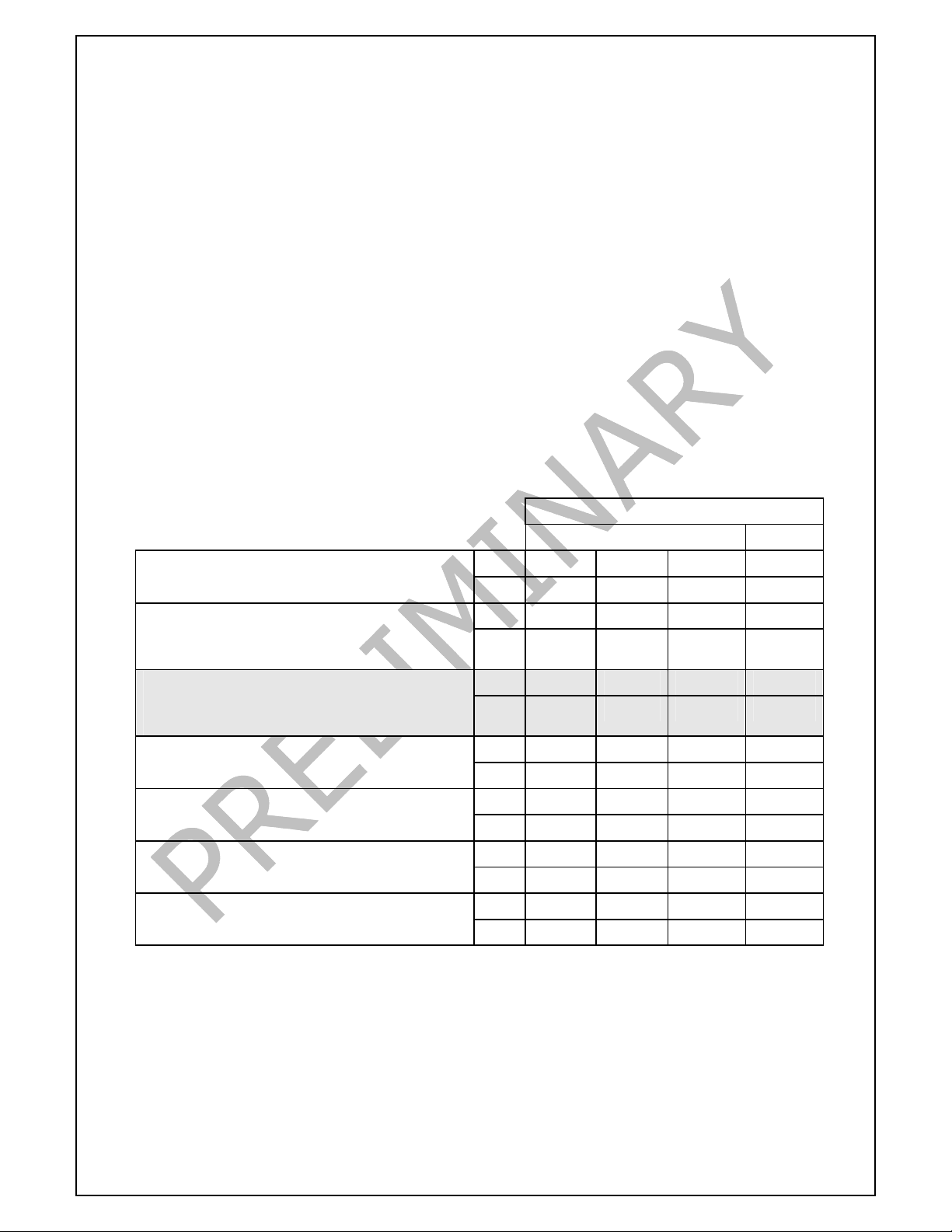

5.1.3 RF Performance Data

Attenuation Setting dBm

-100

0

-40 deg

-10

-20

-30

-40

-50

-60

-70

-80

-90

Receive Sensitivity

-20 deg 0 deg 20 deg 40 deg 60 deg 80 deg 100 deg

NOTE: Measured as attenuation required

to achieve better than 0.1% BER

Temperature Deg. C.

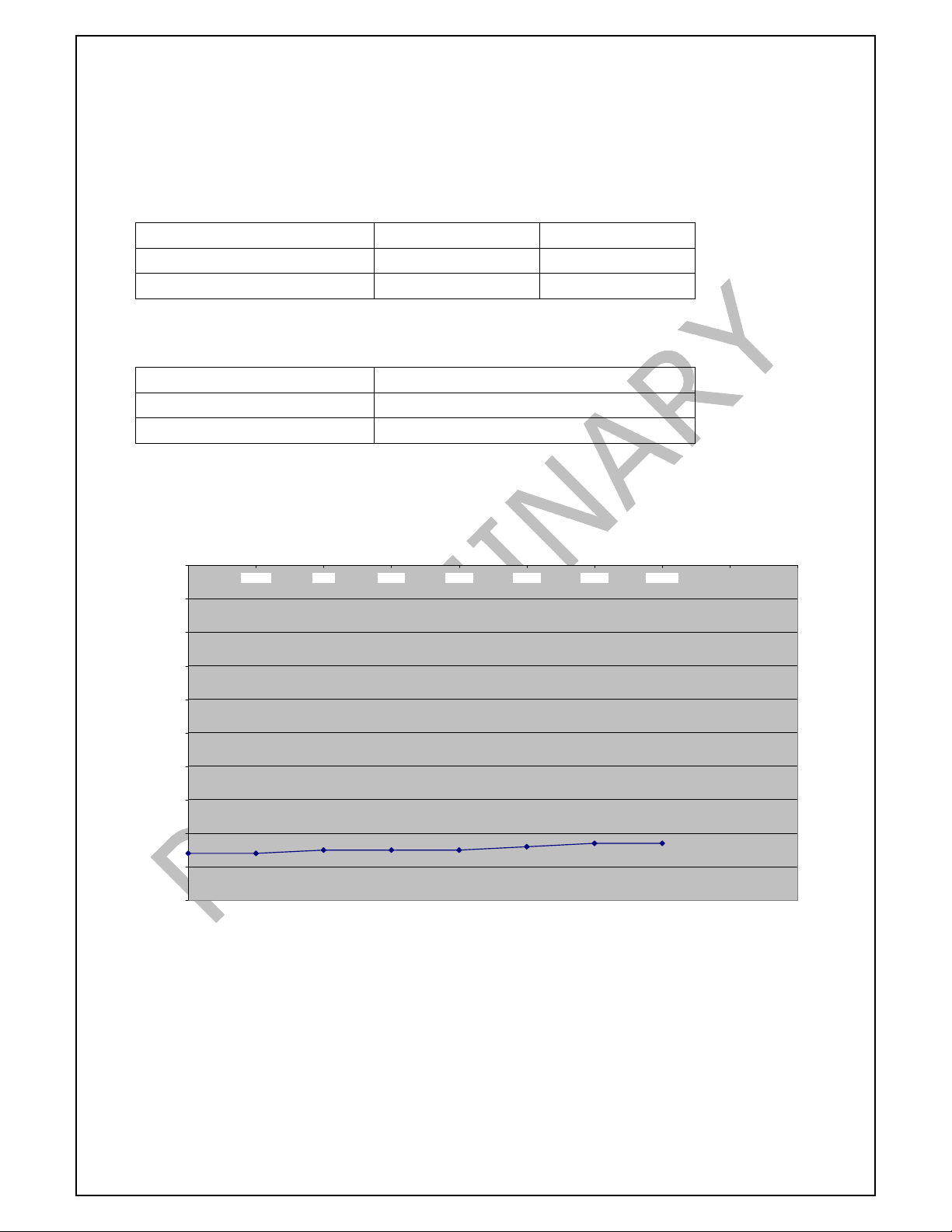

5.2 Range

See the Data Transfer Rate vs distance graph below. The data throughput of the Module is limited to

280Kbps by the parsing of the data being transferred through the AT command processor. The graph

below shows the typical data thoughput with and without the AT command processing. Distances are

measured in free space between 2 Modules.

www.ezurio.com © Ezurio Ltd 2005

9

Page 10

Data Transfer Rate / Distance

800

700

600

500

400

300

Data Transfer Rate (kbps)

200

100

0

10m 50m 100m 150m 200m 250m 300m

Distance (meters)

5.3 Temperature Performance

Data Transmit Rate with Temperature and Attenuation

800

700

600

500

400

300

Data Transmission Rate kbs

200

RF data rate

Serial port data rate

-40 deg

-20 deg

0 deg

20 deg

40 deg

60 deg

80 deg

100 deg

100

0

-60dBm -65dBm -70dBm -75dBm -80dBm -85dBm -90dBm

dBm attenuation

www.ezurio.com © Ezurio Ltd 2005

10

Page 11

/

/

/

/

/

6. Functional Description

The BISM2 Bluetooth module is a self-contained Bluetooth product and requires only power to

implement full Bluetooth communication. The integrated, high performance antenna together with the

RF and Base-band circuitry provides the Bluetooth wireless link and the UART interface provides a

connection to the host system.

The variety of interfaces and the AT command set allow the BISM2 module to be used for a wide

number of short range wireless applications, from simple cable replacement to complex multipoint

applications, where multiple radio links are active at the same time.

The complexity and flexibility of configuration are made simple for the design engineer by the

integration of a extremely comprehensive set of AT commands, supplemented with a range of “S”

registers which are used for non=volatile storage of system parameters. These are fully documented

in the “Blu2i AT Command Reference Manual”.

To provide the widest scope for integration a range of different physical host interfaces are provided:

6.1 Interfaces

6.1.1 UART interface

UART_TX, UART_RX, UART_RTS and UART_CTS form a conventional asynchronous serial data port.

The interface is designed to operate correctly when connected to other UART devices such as the

16550A. The signalling levels are nominal 0V and 3.3V and are inverted with respect to the signalling

on an RS232 cable. The interface is programmable over a variety of bit rates; no, even or odd parity;

stop bit and hardware flow control. The default condition on power-up is pre-assigned in the external

Flash. Two-way hardware flow control is implemented by UART_RTS and UART_CTS. UART_RTS is an

output and is active low. UART_CTS is an input and is active low. These signals operate according to

normal industry convention.

By writing different values to the S register the UART_RI can be continuously polled to detect

incoming communication. The UART_RI signal serves to indicate incoming calls.

UART_DSR is an active low input. It should be connected to DTR output of the host. When the module

is running in high speed mode (See definition for S Reg 512), this pin should be asserted by the host

to ensure connection is maintained. A de-assertion is taken to mean that the connection should be

dropped, or an online command mode is being requested.

The module communicates with the customer application using the following signals:

RS-232

Port /TXD @ application sends data to the module’s UART_RX signal line

Port /RXD @ application receives data from the module’s UART_TX signal line

Serial Module

UART Interface

UART_TX

UART_RX

UART_CTS

UART_RTS

UART_DTS

Application

RXD

TXD

RTS

CTS

DTR

RS232 Interface

Figure 6.1 : UART interfaces

www.ezurio.com © Ezurio Ltd 2005

11

Page 12

6.1.2 SPI bus

The Module is a slave device that uses terminals SPI_MOSI, SPI_MISO, SPI_CLK and SPI_CSB. This

interface is used for program firmware update.

Note: The designer should be aware that no security protection is built into the hardware or firmware

associated with this port, so the terminals should not be permanently connected in a PC application.

6.1.3 GPIO Port

Eight lines of programmable bi-directional input/outputs (I/O) are provided that can be accessed

either via the UART port, or Over The Air from a second Bluetooth unit. These can be used as data

inputs or to control external equipment. By using these in OTA mode, a BISM21 module can be used

for control and data acquisition without the need for any additional host processor.

Each of the GPIO[1:8] ports can be independently configured to be either an Input or Output. A

selection of ports can be accessed synchronously.

GPIO 1 and 2 can be configured as event counters.

The ports are powered from V

accessed via S Registers 621 to 625.

Low latency I/O can be accessed by using Ezurio’s I/O via enquiry process.

. The mode of these lines can be configured and the lines are

CC

6.1.4 PCM CODEC Interface

PCM_OUT, PCM_IN, PCM_CLK and PCM_SYNC carry up to three bi-directional channels of voice data,

each at 8ksamples/s. The format of the PCM samples can be 8-bit A-law, 8-bit µ-law, 13-bit linear or

16-bit linear. The PCM_CLK and PCM_SYNC terminals can be configured as inputs or outputs,

depending on whether the module is the Master or Slave of the PCM interface.

The Module is compatible with the Motorola SSI TM interface and interfaces directly to PCM audio

devices including the following:

6.1.4.1 Compatible Codec Chips

•

Qualcomm MSM 3000 series and MSM 5000 series CDMA baseband devices

•

OKI MSM7705 four channel A-law and µ-law CODEC

•

Motorola MC145481 8-bit A-law and µ-law CODEC

•

Motorola MC145483 13-bit linear CODEC

6.1.5 ADC

The BISM2 provides access to two 8-bit ADCs are available. These provide a range o 0mV to

1,800mV, which can be read using the S registers 701 and 702.

Suitable external scaling and over-voltage protection should be incorporated in your design.

6.1.6 Pass Through Serial

To be supplied

www.ezurio.com © Ezurio Ltd 2005

12

Page 13

7. Integrated Firmware

7.1 General

The BISM2 has been designed to provide the fastest route to market for designers who wish to use

Bluetooth to wirelessly enable their products. To achieve this Ezurio has implemented a wide ranging

set of AT commands that control all of the standard Bluetooth tasks. These remove the complexity of

Bluetooth from the design engineer and allow the wireless link to be controlled by means of a simple

set of commands.

For applications where multiple concurrent live connections need to be maintained a variant of

firmware is available which is specifically targeted at multipoint operation.

For both applications a comprehensive range of windows based software and is available to speed up

the design process. A low cost development kit is also available that can be used for prototyping both

cable replacement and multipoint applications.

7.2 Profiles

Bluetooth has been designed to accommodate a very wide range of wireless applications. To enable

these different applications the Bluetooth SIG (Special Interest Group) has defined a series of

different profiles that define the way in which Bluetooth devices communicate with each other and

perform basic functions. These provide a base line of interoperability for specific application

scenarios, upon which more complex user applications can be developed.

There are over 30 different profiles, many of which have been developed for specific applications.

The BISM2 firmware is provided with support for the profiles that are most commonly required for

cable replacement applications.

The current profiles support includes:

•

GAP Generic Access Profile. The base connection profile upon which others are based.

•

SDP Service Discovery Profile. The profile to find other Bluetooth devices and the services

they support.

•

SPP Serial Port Profile. Emulation of a serial cable for cable replacement applications.

•

DUN Dial Up Networking. Profile support for connection to an external PSTN, GSM, GPRS

or VPN connection.

•

Audio Gateway. The base element for Headset and Handsfree profile. A portion of these

profiles must be implemented within the host system.

For other profile support, please contact Ezurio Ltd at blu2i@ezurio.com

7.3 AT Overview

The AT command set is well known by engineers and was developed to aid the integration of PSTN

modems. It provides simple high level commands for complex functions that can easily be

incorporated into programs or used within programming scripts.

Ezurio has used this familiar concept and extended it to Bluetooth to simplify the integration of

Bluetooth for product designers. Rather than having to understand the many stages of setting up a

Bluetooth connection or function, a single AT command is all that is required.

For example to connect to a Bluetooth device with an address 00809844EA13, all that is needed is to

send the string

ATD00809844EA13

to the UART of the BISM2 module. The module will attempt to make a connection and return OK or

ERROR, depending o whether the connection was successful.

www.ezurio.com © Ezurio Ltd 2005

13

Page 14

The complexity of the AT command set developed by Ezurio is such that most Bluetooth functionality

can be covered, greatly reducing development time.

To provide additional functionality a range of “S” registers has been implemented. These allow

program settings to be stored to control the BISM2 function and also give access to configuring and

reading ports and status registers within the BISM2.

Full details of the AT command set are provided in the Blu2i AT Command Reference Manual.

7.3.1 AT features at a glance

7.3.1.1 General

•

Configure two modules to automatically connect and transfer data, audio or a combination of

data and audio when both devices are powered.

•

Automatically re-connect devices when a connection is dropped.

•

Remotely access the AT parser of the remote unit from a master device to perform Over The

Air (OTA) configuration.

•

Configure the module to enter a state on power up and after a period of time change to

another state automatically

•

Read and write to GPIO lines

•

Read the ADC channels

•

Get fast GPIO status through an inquiry response (patent pending)

7.3.1.2 Audio

•

Set up audio connections

•

Enable / disable Auto Answer for incoming connections

7.3.1.3 UART

•

Change the baud rate from 1200 to 961,200 baud.

•

Use the DSR line to drop connections

•

Configure as DTE or DCE

•

Change escape sequence character

•

Change the number of Stop bits and Parity

•

Enable or disable echoes

7.3.1.4 Security

•

Enable Authentication by requiring a PIN code for incoming AND / OR outgoing connections

•

Enable data to be encrypted over the air for incoming AND / OR outgoing connections. The

module can be configured to be:

non-connectable and non-discoverable,

non-connectable but discoverable,

connectable but non-discoverable,

connectable and discoverable.

•

Automatically store Paired devices in a trusted device database in the flash memory

7.3.1.5 Bluetooth

•

Set the module to be a master or slave

•

Make a Bluetooth connection to a specified device

•

Perform a full inquiry for other Bluetooth devices

•

Query a remote device to check if a service is offered

•

Fetch the friendly name of a remote device

www.ezurio.com © Ezurio Ltd 2005

14

Page 15

•

Increase or decrease the delay before the master abandons a connection attempt

•

Change the device class code

•

Set the device’s friendly name

•

Change the Inquiry scan time

•

Change number of returned devices from an inquiry scan

•

Obtain the RSSI value for a connection

7.3.1.6 Power Management

•

Decrease or increase the output power to suit your connection range

•

Configure the modules to work in Sniff and other low power modes.

7.4 Multipoint Firmware

The Module consists of the same hardware as that used for the single point ‘AT’ blu2i module

described elsewhere. Whereas the latter only allows one-to-one connection, the module described

here allows simultaneous connections to a minimum of 3 slaves, and depending on hardware build,

up to 7 slaves. It also allows connections to multiple profiles to one or more slaves. Hence this

document adopts a concept of channels instead of slave connections.

The term ‘host’ in this document is taken to mean any entity which is a source of command

messages, sink for response/event messages and both source and sink for multiplexed data packets.

7.5 OTA (Over the Air) Configuration

When the BISM2 is placed in slave mode it’s settings can be remotely controlled by a master unit.

This places the slave unit’s AT parser in remote mode providing over the air configuration. This mode

is of use for remote sensor applications, where no host processor is required to control the slave

Bluetooth unit.

7.6 Bootmodes

The module has the capability of booting into 1 of 8 modes. These will be supported in future

releases of firmware and selected via an S Register.

Boot Mode 1 is default and gives functionality equivalent to the BISM1 module.

These modes will specify different PSKEY settings to allow for different basic operation. Please

contact Ezurio for further information.

8. Low Power Modes

The current drain from the Vcc power input line is dependent on various factors. The three most

significant factors are the voltage level at Vcc, UART baud rate and the operating mode.

The hardware specification for the blu2i module allows for a voltage range of 3.6 to 6.0v at Vcc. Tests

have shown that there is no significant difference in current draw when Vcc is 5 or 6V. Therefore the

data presented below, pertains to Vcc levels of 3.6 and 5v only. Tests have shown that where power

drain is an issue, it is best to keep Vcc at the lower end of the range.

The UART baud rate has a bearing on power drain because as is normal for digital electronics, the

power requirements increase linearly with increasing clocking frequencies. Hence higher baud rates

result in a higher current drain.

www.ezurio.com © Ezurio Ltd 2005

15

Page 16

Finally with regards to operating mode the significant modes are; idle, waiting for a connection,

inquiring, initiating a connection and connected. With connected mode, it is also relevant to

differentiate between no data being transferred and when data is being transferred at the maximum

rate possible.

The operating mode can best be described by stating the AT commands required to enter that mode.

In addition, there are certain S Registers which have a direct impact on power consumption, which

are described next.

The blu2i Module has 2 LEDs which can be configured to display connection status. One led is used to

display connection status, while the other is used to either display ‘Ring Indicate’ status or follow the

state of the incoming DSR line on the UART interface. Tests have shown that these LEDs can consume

up to 5.3mA which is more than double the current draw when in Idle mode. Therefore S Registers

533 and 534 can be used to completely disable these indications.

Finally S Registers 508 to 511, which specify the page and inquiry scan intervals and windows, can be

used to adjust the average current drain when in discoverable and or connectable modes. Registers

508 and 509 specify the interval and window for page scans and registers 510 and 511 specify the

interval and window for inquiry scans. Register pairs 508/509 and 510/511 describe duty cycles when

the blu2i module goes into scan modes. It is while scanning that the highest current draw occurs. The

average current draw is determined by simple arithmetic using the values stored in the 508/509 and

510/511 register pairs.

The operating modes described above are entered using AT commands as follows

Idle On power up, with S Register 512 = 1

Wait for Connection AT+BTG (100% page scan duty cycle)

Discoverable Only AT+BTQ (100% inquiry scan duty cycle)

Connecting ATD

Connected No Data

Connected Max data transfer

All current consumption values in the table below assume that the connection status indication

functionality of the LED has been disabled by setting S Registers 533 and 534 to 0.

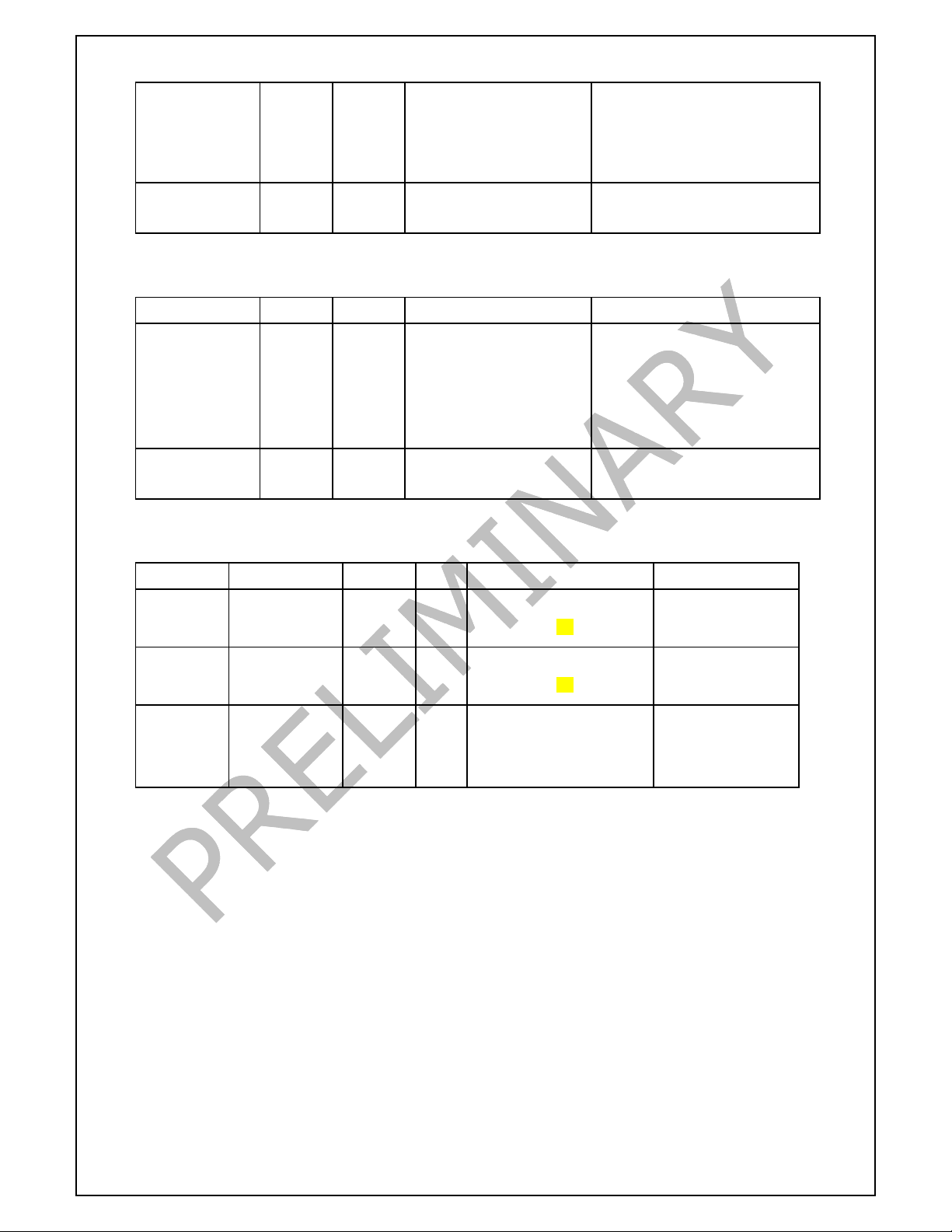

Baud rate

9,600 38,400 115,200 460,800

3.6V 1.60 1.80 1.96 3.00 Idle Mode, S512=1

5.0V 2.00 2.10 2.30 3.40

3.6V 59.00 59.00 59.00 59.00 Wait for Connection Or Discoverable

Mode, AT+BTP

5.0V 65.00 65.00 65.00 65.00

S508=S510=640, S509=S511=320

3.6V 2.75 2.94 3.10 4.12 Wait for Connection Or Discoverable

Mode, AT+BTP S508=S510=1000,

S509=S511=11

5.0V 3.26 3.36 3.55 4.63

3.6V 50.00 50.00 50.00 50.00 Inquiring Mode, AT+BTI

5.0V 54.00 54.00 54.00 54.00

3.6V 50.00 50.00 50.00 50.00 Connecting Mode (ATDxxx)

5.0V 54.00 54.00 54.00 54.00

3.6V 6.00 6.10 6.40 7.20 Connected as Master Mode (No Data

Transfer)

5.0V 7.20 7.20 7.40 8.20

Sniff NOT activated

www.ezurio.com © Ezurio Ltd 2005

16

Page 17

Connected as Master Mode (Max Data

Transfer)

Sniff NOT activated

Connected as Slave Mode (No Data

Transfer)

Connected as Slave Mode (No Data

Transfer)

Sniff Enabled (AT&F1 setting)

All current values are in milliamps (mA).

As can be seen, the current drain while waiting for a connection or discoverable mode is about 30

times higher than in idle mode. This is when the page/inquiry scan duty cycle is 100%. These modes

give the quickest response to a page or inquiry request from a remote peer.

It is possible to reduce the duty cycle down to as low as 0.5% at the expense of response time. The

response time can be specified via S Registers 508 and 510 for page and inquiry respectively, where

the worst case response time can be as high as 2.5 seconds. Then the duty cycle can be varied by

changing the value of S Registers 509 and 511 appropriately.

For example, if S Register 508 and 510 are both set to 1000ms and S Register 509 and 511 are both

set to 11ms then the duty cycle is reduced to 1%, this means that average current drain at 5.0v will

be 2% of 65mA plus the normal idle mode current, that is, it is as low as 2.75mA. However, in this

case, it can take up to 1 second to establish a connection.

The connected state current consumption while a master or slave can be considerably reduced by

enabling Sniff mode, described in detail in the next section.

3.6V 21.50 22.50 24.50 32.50

5.0V 24.50 26.00 28.00 36.00

5.0V 32.00 33.00 33.50 34.00

5.0V 4.90

mA

3.6V 3.20 Current per LED (when fitted)

5.0V 5.30

8.1 Low Power Modes using Sniff

Bluetooth connections are master/slave in nature. A master sends packets and a slave has to

acknowledge that packet in the next timeslot. Timeslots in Bluetooth are 625 microseconds wide. This

implies that a master will always know when packets will be sent and received, which further means

it is able to optimise power usage by switching on power hungry circuitry only when needed.

A slave on the other hand does NOT have prior knowledge of when a packet will be received and has

to assume that a packet will be received from a master on every receive slot. This means that it has

to leave its receiving circuitry on for most of the receive slot duration. The result of this is high power

consumption as illustrated in the power table above, where a slave with no data transmission still

consumes around 31mA whereas a master consumes only 6mA.

This problem was identified very early in the evolution of Bluetooth (especially since headsets spend

all their time as a slave in a Bluetooth connection) and it was solved by having a mode called Sniff,

with appropriate lower layer negotiating protocol.

Sniff mode during connection is basically an agreement between the slave and its master that data

packets will only be exchanged for N timeslots every M slots. The slave can then assume that it will

never be contacted during N-M slots, and so can switch its power hungry circuitry off. The

specification goes further by also specifying a third parameter called ‘timeout’ (T) which specifies

‘extra’ timeslots that the slave will agree to listen for after receiving a valid data packet. Put another

way, if a data packet is received by the slave, then it knows that it MUST carry on listening for at

least T more slots. If within that T slot time period another data packet is received, then the timer is

restarted. This mechanism ensures low power consumption when there is no data transfer – at the

www.ezurio.com © Ezurio Ltd 2005

17

Page 18

expense of latency. When there is a lot of data to be transferred, it acts as if sniff mode were not

enabled.

It is stated above that during sniff mode, a slave listens for N slots every M slots. The Bluetooth

specification states that a master can have up to 7 slaves attached to it with all slaves having

requested varying sniff parameters. It may therefore be impossible to guarantee that each slave gets

the M parameter it requested. In light of this, the protocol for enabling sniff mode specifies that a

requesting peer specify the M parameter as a minimum and maximum value. This will allow the

master to interleave the sniff modes for all slaves attached.

For this reason, the sniff parameters are specified in the BISM2 module via four S registers. S

Register 561 is used to specify ‘N’, S Register 562 is used to specify ‘T’ and S Registers 563/564 are

used to specify minimum ‘M’ and maximum ‘M’ respectively. Although the specification defines these

parameters in terms of timeslots, the S register values have to be specified in units of milliseconds

and the firmware does the necessary translation to timeslots.

Error! Objects cannot be created from editing field codes.

9. Application Examples

9.1 RS232 Modem Signals

Just as a telephony modem has control and status lines, the blu2i Module also provides for 6 control

and status lines as per the table below. The direction column is as seen from the module’s viewpoint.

Direction Function

IN or OUT CI also known as RI (Ring Indicate)

IN or OUT DCD (Data Carrier Detect)

IN DSR (Data Set ready)

OUT DTR (Data Terminal Ready)

IN CTS (Clear to Send)

OUT RTS (Request to Send)

The first four lines are under program control. These use four of the GPIO pins and are mapped to

I/O as per the table below. The last two are under control of the UART driver and their functionality is

always enabled.

PIO Pin Direction Connector Pin Label Function

0 IN/OUT GPIO1 General Purpose I/O

1 IN/OUT GPIO2 General Purpose I/O

2 IN/OUT UART_RI Input/Output from module

3 IN/OUT UART_DCD Input/Output from module

4 IN UART_DSR Input to Module

5 IN/OUT GPIO3/UART_DTR General Purpose I/O (or DTR functionality)

6 IN/OUT GPIO4 General Purpose I/O (Right LED)

7 IN/OUT GPIO5 General Purpose I/O (Left LED)

www.ezurio.com © Ezurio Ltd 2005

18

Page 19

Notes:

1. PIO4 (DSR) is used by the blu2i module to sense that the host is connected, and is intricately

linked with connections. For outgoing calls, if this line is not asserted then an error is indicated.

Similarly for AT+BTP and AT+BTG.

While in a call, for appropriate modes, a de-assertion means fall into command state. If the deassertion exists for longer than the period specified in S Register 519 then the connection is dropped

as if an ATH command was received.

2. PIO2 (RI), is normally de-asserted. When an incoming connection is detected it will be

asserted, until the connection is either answered or rejected using ATA and ATH respectively. See S

Registers 552 & 553 for more details

3. PIO3 (DCD) will be de-asserted when the device is in the unconnected state. Asserted when a

connection is active. See S Registers 552 and 553 for more details.

4. PIO5 is either used as GPIO or driven as UART_DTR. When the unit is configured in pure host

mode, this pin is forced into UART_DTR and is asserted when there is a Bluetooth connection.

GPIO Pins 1,2,3,4 and 5 are available for general purpose use.

9.2 Modem signalling over Bluetooth

The RFCOMM protocol used in Bluetooth for implementing the serial port profile allows for the

exchange of four modem signals. This information is contained in a special transparent message

which contains bits identified as RTR, RTC, DV and IC which depending on the type of serial device

being emulated maps to DTR or DSR, RTS, DCD and RI respectively. In addition, this message also

includes the ability to convey a BREAK input from one end to the other.

To allow for the greatest flexibility and variability in how the modem control signals are used out in

the real world, S Registers 551, 552 and 553 have been provided which allow for any of RTR,RTC,DV

and IC to be mapped to any modem control/status line.

BREAK signal on RX line

If the host sends a break signal of duration greater than 100ms, then the blu2i module is

configured to treat that as a signal to perform a hardware reset.

This being the case it is not possible to convey a BREAK over Bluetooth to the peer device.

Reset

The module can be reset by the host without the need of any I/O using a BREAK signal. The

module has been configured to reset when the RX line detects a break condition for durations

greater than 100 milliseconds.

9.3 Pure Cable Replacement Mode

The module has the capability of being preset into a pure 5-wire data cable replacement mode. The 5

wires being RX, TX, CTS, RTS and GND. This mode requires no changes to a host application since

the Bluetooth connection is automatically set up on power up. If the connection is lost the BISM2

module will constantly retry until the connection is reinstated.

By implication, two devices are needed to replace a cable. One device is pre-configured to always be

a master and the other, a slave.

Assuming the Bluetooth address of the master to be <bdaddr_m> and that of the slave to be

<bdaddr_s>, the master module is configured by sending it the following AT commands:

www.ezurio.com © Ezurio Ltd 2005

19

Page 20

AT&F

ATS512=1

ATS504=1

ATS507=2

ATS530=2000

AT&W

AT+BTR<bdaddr_s>

The ATS507=2 setting puts the device in DSR drop mode only. This means that when the device

needs to be reconfigured, deasserting the DSR line will ensure that the module responds quickly to AT

commands. This further means that in stand alone mode, the DSR input line MUST be asserted e.g.

0V in TTL signal mode.

The slave is configured by:

AT&F

ATS512=4

ATS0=-1

AT&W

AT+BTR<bdaddr_m>

Where <bdaddr_m> is optional. If it is not specified, then the slave unit will accept connections from

any device. If specified then only connections from the device specified will be accepted.

If it is desired that the slave unit should not be discoverable (the master is by default not

discoverable), then the configuration commands are:

AT&F

ATS512=3

ATS0=-1

AT&W

AT+BTR<bdaddr_m>

Where <bdaddr_m> is optional. If it is not specified, then the slave unit will accept connections from

any device. If specified then only connections from the device specified will be accepted.

When the units are next power cycled, the slave unit will wait for the master to connect to it and the

master will continually look for the slave. If a connection attempt fails, the master will wait for 2

seconds before reattempting a connection. This 2 second delay can be varied by issuing it an ATS530

command with an appropriate value in the range 100ms to 15000ms.

IMPORTANT NOTE: When S Register 507 = 0, the DSR input to the module MUST be asserted for the

auto connection to succeed. When operating at TTL levels a 0V is seen as an assert state. When

operating at RS232 levels and voltage greater than 3V is seen as assert. It is usual to connect the

DTR line of the host to the DSR line of this device.

9.4 Audio Cable (voice)

With a pair of these modules it is possible to replace a mono audio cable with two way traffic. That is,

a setup where a microphone is connected to a speaker at the remote end and vice versa. So this

mode effectively replaces two audio cables.

Assuming the Bluetooth address of the master to be <bdaddr_m> and that of the slave to be

<bdaddr_s>, the master module is configured by sending it the following AT commands:

AT&F

ATS512=1

ATS504=1

www.ezurio.com © Ezurio Ltd 2005

20

Page 21

ATS530=2000

ATS532=1

AT&W

AT+BTR<bdaddr_s>

And the slave is configured by:

AT&F

ATS512=4

ATS0=-1

AT&W

AT+BTR<bdaddr_m>

9.5 Modem Control and Status Signals

A serial port has DTR, DSR, RTS, CTS, DCD and RI control lines. RTS and CTS are locally controlled to

prevent local buffer overflow.

However the status of DTR, DRS, DCD and RI can be exchanged with the remote peer device. If for

example, the DTR/DSR lines are to be exchanged between the two peers to simulate the performance

of a physical cable, then it is possible to do so. Refer to the description for S Registers 551, 552 and

553 for more details.

www.ezurio.com © Ezurio Ltd 2005

21

Page 22

10. Application Information

10.1 Antenna Position

The antenna used on the BISM2 Bluetooth module is designed to be largely immune from the effects

of proximity detuning. Normally, antennas operating at 2.4GHz are affected by their surroundings, so

that great care is needed in their placement and orientation.

The BISM2 can be used in most locations and orientations and is only marginally affected by the

presence of a significant ground plane in close proximity.

The antenna distribution is close to isotropic, which means that the orientation of mounting has only

a limited effect on the overall range. However the optimum range is achieved when the two

antennae are directly facing each other

The module should not be located in a sealed metal enclosure, as this will act as a Faraday cage and

prevent the radio signal from penetrating.

10.2 Power Supply Considerations

The power supply for the Module has to be a single voltage source of Vcc within the range of 3.3 V to

6.0 V. It must be able to provide sufficient current in a transmit burst. This can rise to 65mA.

The Module includes regulators to provide local 3.3V. This rail is accessible on connector J2 for

monitoring purposes only. Under no circumstances should this pin be used to source current.

Power (Vcc) can be provided via the board-to-board connector Pin 29 on J2.

10.3 Power-On-Reset (Power Cycling and Brown Out

considerations).

The Module is provided with an active low reset pin (Hirose 40way DF12C connector pin 13). Upon

the application of power, the Power On Reset circuit built into the Module will ensure that the unit

starts correctly. There is no need for an external power reset monitor.

10.4 Mounting the Module onto the application platform

There are many ways to properly install the Module in the host device. An efficient approach is to

mount the PCB to a frame, plate, rack or chassis. Fasteners can be M1.8 or M2 screws plus suitable

washers, circuit board spacers, or customized screws, clamps, or brackets in 2.2mm diameter holes.

Note that care should be taken to ensure the head of the fixing does not interfere with the circuit.

Nylon fixings are recommended. In addition, the board-to-board connection can also be utilized to

achieve better support.

The antenna (Brown square component on top side of PCB) must not be influenced by any other

PCBs, components or by the housing of the host device. The proximity of the antenna to large

metallic objects can affect the range and performance of the system. Designers should carefully

consider the location of the Module and the type of enclosure material that is used.

To prevent mechanical damage, be careful not to force, bend or twist the Module. Be sure it is

positioned flat against the host device.

www.ezurio.com © Ezurio Ltd 2005

22

Page 23

11. Board to Board Connector

This chapter provides specifications for the 40-pin board-to-board connector which serves as physical

interface to the host application. The receptacle assembled on the Module is Hirose type DF12C.

Details are available at: http://www.hirose.co.jp/cat2002e/500/e53700036.pdf

11.1 Stacking Height

Mating headers from Hirose are available in different stacking heights, allowing the spacing between

the BISM2 and carrier pcb to be changed from 3.5mm to 5.0mm.

Item Part number Stacking height HRS number

Receptacle on

Module

Headers DF12 series DF12(3.5)-40DP-0.5V(81) 3.5 mm CL537-0032-4-**

DF12(4.0)-40DP-0.5V(81)

DF12(5.0)-40DP-0.5V(81)

Notes: The headers listed above are without boss and metal fitting.

DF12C-40DS-0.5V(81) 3.5 mm – 5 mm CL537-0007-7-

4.0 mm CL537-0057-5-**

5.0 mm

CL537-0157-0-**

11.2 Hirose Connector general specification

Parameter Specification (40 pin Board to Board connector)

Number of Contacts 40

Quantity delivered 2000 Connectors per Tape & Reel

Voltage 50V

Current Rating 0.5A max per contact

Resistance 0.05 Ohm per contact

Dielectric Withstanding Voltage 500V RMS min

Operating Temperature -45°C...+125°C

Contact Material phosphor bronze (surface: gold plated)

Insulator Material PA , beige natural

Stacking height 3.0 mm ; 3.5 mm ; 4.0 mm ; 5.0 mm

Insertion force 21.8N

Withdrawal force 1st 10N

Withdrawal force 50th 10N

Maximum connection cycles 50

www.ezurio.com © Ezurio Ltd 2005

23

Page 24

12. Qualification

12.1 Bluetooth Qualification Process

The following safety precautions must be observed during all phases of the operation, usage, service

or repair of any application incorporating this Module. Manufacturers of the RF equipment are advised

to convey the following safety information to users and operating personnel and to incorporate these

guidelines into all manuals supplied with the product. Failure to comply with these precautions

violates safety standards of design, manufacture and intended use of the product. Ezurio assumes no

liability for customer failure to comply with these precautions.

12.2 Safety Information:

Switch off the Bluetooth device before boarding an aircraft. Make sure it cannot be switched on

inadvertently. The operation of wireless appliances in an aircraft is forbidden by many airlines to

prevent interference with communications systems. Applications that could result in use on aircraft

should carry appropriate warnings.

12.3 Qualifications

12.3.1 RF approvals

The Module is listed as a Bluetooth Product in terms of the Bluetooth SIG Program Reference

Document (PRD). This means that it can be integrated into end products without further testing or

approval listing. The manufacturer must state the Ezurio part number and product reference in his

literature in order to meet the requirements of the Bluetooth and regulatory approvals.

A list of the countries where the Module is approved will be provided by Ezurio as required. As a

minimum the product is listed in Europe and USA. Ezurio assumes no liability for customer failure to

comply with national RF approvals.

12.3.1.1 Radio.

R&TTE EN 300 328-2 V1.1.1 (2000-07)

EN 301 489-1 V1.3.1 (2001-09)

12.3.1.2 EMC Emissions.

FCC15B Class B

EN55022 Class B

12.3.1.3 EMC Immunity.

EN55024 Class

12.3.1.4 Environmental.

EN301 489-1 V1.3.1 (2001-09)

12.3.1.5 Medical

EN60601-1-2

12.3.1.6 Automotive

Emission test to 95/54/EC

www.ezurio.com © Ezurio Ltd 2005

24

Page 25

12.4 Safety and Regulatory Statements

12.4.1 Europe – EU Declaration of Conformity

DECLARATION OF CONFORMITY

In accordance with Annex IV of the EU directive 1999/5/EC

Notified Body consulted: Phoenix Test-Lab

ID-Number of Notified Body: 0700

declare under our responsibility that the blu2i Module

complies with the appropriate essential requirements of the Article 3 of

the R&TTE and the other relevant provisions, when used for its intended

purpose.

Health and Safety requirements contained in Article 3 (1) a)

EN 60 950: 1992 Safety of information technology equipment +

Amendment A1:1993, Amendment A2:1993, Amendment A3:1995,

Amendment A4:1997, Amendment A11:1997

EN 50371: Generic standard to demonstrate the compliance of lowpower electronic and electrical apparatus with the basic restrictions

related to human exposure to electromagnetic fields (10 MHz - 300 GHz)

– General public

Protection requirements with respect to electromagnetic compatibility

Art.3 (1) b)

EN 301489-17 V1.1.1 (09-2000), Electromagnetic Compatibility and

radio spectrum Matters (ERM); Electro Magnetic Compatibility (EMC)

standard for radio equipment and services; Part 17: Specific conditions

for wideband data HiperLAN equipment

Means of the efficient use of the radio frequency spectrum

EN 300328-2 V1.2.1 (11-2001), Radio Equipment and Systems (RES);

Wideband transmission systems; Technical characteristics and test

conditions for data transmission equipment operating in the 2,4 GHz

ISM band and using spread spectrum modulation techniques. Part 2:

Harmonized EN covering essential requirements under article 3(2) of the

R&TTE directive.

Ezurio Ltd tel: +44 (0)20 8938 1000

Unit 2, 126 Colindale Avenue, Colindale fax: +44 (0)20 8905 8608 Registered in England

London NW9 5HD, United Kingdom www.ezurio.com No. 5178293

www.ezurio.com © Ezurio Ltd 2005

25

Page 26

12.4.2 FCC and Industry Canada Statements

This device complies with part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) This device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could void

the user's authority to operate the equipment.

13. Environmental

13.1 Operating temperatures

Parameter Min Typ Max Unit

Operating temp (standard product) -40 25 +85 °C

13.2 Storage temperature

Parameter Min Max Unit

Storage temp -40 +125 °C

13.3 Reliability

Parameter Test Comment

Thermal Shock 200 cycles -40ºC /+85ºC 30 min 1 cycle/hour

Vibration Continuous operation at 60 Hz,

2mm stroke

Shock 50G 11ms Half Sine Wave 6 axis x 3 cycles each axis

Moisture Resistance

High Temp Storage 85ºC, 360 hours

Low Temp Storage -40ºC, 240 hours

High Temp/Humidity

Operation

Thermal shock -40 to 60ºC in 30min 200 cycles with continuous

Electro Static Discharge EN55024:1998 & IEC61000-4-3

Drop Test 75cm to concrete, 3 axis x 2

60ºC, 90%RH, 360 hours

cycles per corner

15g max sine wave, 12 hours

operation

www.ezurio.com © Ezurio Ltd 2005

26

Page 27

14. Physical Dimensions

14.1 Mechanical Dimensions

All dimensions in mm.

14.2 Labelling

The label contains the Part number and the unique Bluetooth address of the module.

www.ezurio.com © Ezurio Ltd 2005

27

Page 28

14.3 Ordering Information

The BISM2 is available with different variants of production firmware. Ordering information is

provided below:

Part Number Description Firmware Version

TRBLU23-00200

TRBLU23-002MP

TRBLU23-002HC

TRBLU23-00300

TRBLU23-003MP

TRBLU23-003HC

BISM2 with integrated ceramic antenna and

standard AT firmware

BISM2 with integrated ceramic antenna and

standard Multipoint firmware

BISM2 with integrated ceramic antenna and

standard HCI firmware

BISM2 with SMA jack and standard AT

firmware

BISM2 with SMA jack and standard Multipoint

firmware

BISM2 with SMA jack and standard HCI

firmware

Version 4.9.0

Version 1.4.5.0

Version 4.9.0

Version 4.9.0

Version 1.4.5.0

Version 4.9.0

15. Related Documents

•

Blu2i AT Reference Manual

•

Blu2i Multipoint Firmware Reference Manual

•

BISM Bluetooth Serial Module Quick Start Guide

•

BISM Bluetooth Module Application Guide

•

BISM Developer’s Kit User Guide

•

Bluetooth Core 2.0 Specification – www.bluetooth.org

16. Datasheet Revision History

Version Date Changes

0.91 10th March 2005 Initial Draft for customer release.

www.ezurio.com © Ezurio Ltd 2005

28

Page 29

17. Disclaimers

EZURIO’S BLUETOOTH PRODUCTS ARE NOT AUTHORISED FOR USE AS CRITICAL COMPONENTS IN

LIFE SUPPORT DEVICES OR SYSTEMS WITHOUT THE EXPRESS WRITTEN APPROVAL OF THE

MANAGING DIRECTOR OF EZURIO LTD.

The definitions used herein are:

a) Life support devices or systems are devices which (1) are intended for surgical implant into the

body, or (2) support or sustain life and whose failure to perform when properly used in accordance

with the instructions for use provided in the labelling can reasonably be expected to result in a

significant injury to the user.

b) A critical component is any component of a life support device or system whose failure to perform

can be reasonably expected to cause the failure of the life support device or system, or to affect its

safety or effectiveness.

Ezurio does not assume responsibility for use of any of the circuitry described, no circuit patent

licenses are implied and Ezurio reserves the right at any time to change without notice said circuitry

and specifications.

17.1 Data Sheet Status

This data sheet contains data from the Preliminary specification. Supplementary data will be

published at a later date. Ezurio Ltd reserve the right to change the specification without notice in

order to improve the design and supply the best possible product.

Please check with Ezurio Ltd for the most recent data before initiating or completing a design.

17.2 Warranty

Ezurio warrants that its products shall conform to Ezurio’s published specifications and remain free

from defects in materials and workmanship under normal, proper and intended use for a period of

two (2) years from date of purchase, provided that proof of purchase be furnished with any returned

equipment.

If during the warranty period any component part of the equipment becomes defective by reason of

material or workmanship, and Ezurio is immediately notified of such defect, Ezurio shall at its option

supply a replacement part or request return of equipment, freight prepaid, to its designated facility

for repair. In the event no trouble is found on products returned for repair, Ezurio reserves the right

to charge the customer its standard published repair charge.

This warranty shall not apply to any products that have been subject to misuse, bending, twisting,

neglect, alteration, improper installation, testing or unauthorized repair performed by anyone other

than a Ezurio designated repair facility. Any non-warranty repairs or maintenance shall be at Ezurio’s

standard rates in effect at the time.

This warranty is in lieu of all other warranties, whether expressed, implied, or statutory, including but

not limited to, implied warranties or merchantability and fitness for a particular purpose. In no event

shall Ezurio be liable, whether in contract, in part, or on any other basis, for any damage sustained

by its customers or any other person arising from or related to loss of use, failure or interruption in

the operation of any products, or delay in maintenance, or for incidental, consequential, in direct, or

special damages or liabilities, or for loss of revenue, loss of business, or other financial loss arising

out of or in connection with the sale, lease, maintenance, use, performance, failure, or interruption of

these products.

www.ezurio.com © Ezurio Ltd 2005

29

Loading...

Loading...