EZ

METER

Watthour Meters

Product Selection Guide

User Manual

Installation Manual

Dual 3-Wire, Single Phase Meter (Model A4231/3)

CAUTIONS

Legends

Serious injury can result from electric shock.

Be sure to turn off the power before installing or

servicing any meter.

Fire can result from loose electrical

connections. Ensure that all connections are

secure.

A loose or improperly connected neutral can

damage equipment and cause fires. Most meters

that count faster than they should are connected

to a bad neutral.

Current transformers (CTs) should not be

placed over wires with current flowing through

them without connecting them to the meter or

twisting the two wires coming from the CTs

together. A very serious shock hazard exists if

the wires are just left loose.

These meters should only be installed by

experienced electricians. If you do not fully

understand these instructions, call Customer

Support at 1-805-688-9696 for clarification.

These symbols appear on meter labels.

1 Caution, risk of Danger

Equipment protected throughout by double

G

insulation

H Alternating Current

Abbreviations & Glossary

Common abbreviations used in this manual

include:

AMR - Automatic Meter Reading System

CT - Current transformer

KWH - Kilowatthour

Element - An input for measuring power,

usually a current transformer (CT)

Contact Information

In most localities, a permit and inspection is

required to install the meters. In some localities,

it is illegal to use an unapproved meter for

revenue billing. Check with your local Weights

EZMeter Technologies

583 N Refugio Road

Santa Ynez CA 93460 USA

1-805-688-9696

& Measures office or other regulatory agency.

www.ezmeter.com

salesinfo@ezmeter.com

Note: This manual applies to meters that have a letter (A-G) as the first character of the model

number. A separate manual is available for meters made prior to 2010 by Davidge Controls.

Rev.6/26/17

Copyright 2017 EZMeter Technologies

i

Contents

CAUTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Legends. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Abbreviations & Glossary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

Safety Certification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

Accuracy Certification.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

A Note for California Users.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 3

Limited Warranty.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 4

Product Selection Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Automatic Meter Reading (AMR).. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 5

Bi-directional Meters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

Voltage.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 6

Maximum Current and Current Transformers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Display and Resolution. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 7

Enclosures... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Model Numbers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 8

Part Number Suffixes for Ordering. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 11

EZMeter Current Transformers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

Operating Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 13

Understanding the Meter Electronics Module Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 14

Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 16

Installing the NEMA4X Enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 16

Installing the flush mount enclosure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 16

A note on different meter types:.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 16

Installing the CTs.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 16

Electrical Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 18

Surge Protection.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 18

Display Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 18

Isolated Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 19

RS-232 and RS-485 Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 19

I2C Port Connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 20

Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 21

Testing the Installed Meter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 25

Page 1

Trouble Shooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 26

Installing a Grid Connect NET485 (Ethernet-RS422/485 Adapter). . . . . . . . . . . . . . . . . . . . . Page 27

Connecting Digi Radio Modems to EZMeters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 29

Connecting Snap Link Radios to EZMeters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 31

RS.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 32

Phantom Neutral Installation Guide.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 36

Obvius AcquiSuite Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 37

Next Century Radio Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 38

Modbus Interface Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 39

Modbus Registers & Summed Accumulator Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 41

EZMeter Power Suite Quick Start Guide.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Page 47

Page 2

Safety Certification

Underwriter’s Laboratories (UL)

Most EZMeters have been tested by UL

to UL916 and carry the UL Recognized

Component mark for the United States

(UL916) and Canada (CAN/C22.2 No

1010.1-04). File number is E362606.

Accuracy Certification

A Note for California Users

All meters used in California for which a

charge is made for power must have been

inspected by a Weights & Measures

inspector and placed in service by a

Licensed Service Agent or a Weights &

Measures official. The meter must be

reinspected by Weights and Measures every

ten years. It is a misdemeanor to fail to do

this. See the ezmeter.com website for more

on these requirements.

All EZ Meters are guaranteed to meet

the latest ANSI C12.1 accuracy standard for

electric meters. This standard allows an

error of up to 1% when new and 2% when

field tested.

In California, Maryland and Canada,

meters are regulated by the government

when used for revenue billing. Contact the

local Weights and Measures office. Only

meters that have been Type Approved by the

California Division of Measurement

Standards may be used for revenue billing

within California (all EZ Meters exceed

California’s accuracy requirements, but all

are not type approved).

The only EZMeters that have been

certified for revenue billing in California are

the 200 amp versions of the 120 volt to

neutral meters when using the Model JD6W

current transformer. Approved California

meters are models

A31x3x/yzxx

where x may be any digit, y may be 0 or 3

and z may be 0 or 1. 0 is assumed if x and y

are not present. The CTEP certificate

number is 5674(a)-14.

Page 3

Limited Warranty

EZMeter Technologies warrants its products, if used in accordance with all applicable instructions,

to be free from original defects in material and workmanship for a period of five years from the date

of manufacture. If the product should prove defective in material or workmanship within that

period, EZMeter Technologies will repair or replace the product, in its sole discretion. Service under

this Warranty can only be obtained by your delivering or shipping the product (with all shipping or

delivery charges prepaid) to: EZMeter Technologies, 583 Refugio Road, Santa Ynez, CA 93460.

EZMeter Technologies will pay return shipping charges. Call EZMeter Technologies at (805)

688-9696 for a Return Material Authorization (RMA) before sending any equipment back for repair.

THIS WARRANTY DOES NOT APPLY TO NORMAL WEAR OR DAMAGE RESULTING

FROM ACT OF GOD, ACCIDENT, MISUSE, ABUSE, OR NEGLECT. SELLER MAKES NO

EXPRESS WARRANTIES OTHER THAN THE WARRANTY EXPRESSLY SET FORTH

HEREIN, EXCEPT TO THE EXTENT PROHIBITED BY APPLICABLE LAW. ALL IMPLIED

WARRANTIES INCLUDING ALL WARRANTIES OF MERCHANTABILITY OR FITNESS

ARE LIMITED IN DURATION TO THE WARRANTY PERIOD SET FORTH ABOVE AND

THIS WARRANTY EXPRESSLY EXCLUDES ALL INCIDENTAL AND CONSEQUENTIAL

DAMAGES. (Some states do not allow limitation on how long an implied warranty lasts, and some

states do not allow the exclusion or limitation of incidental or consequential damages so the above

limitations or exclusions may not apply to you. This Warranty gives you specific legal rights, and

you may have other rights which vary from jurisdiction to jurisdiction).

Damage from lightning strikes, power surges, and improperly connecting the meter to the power

source are not covered by the warranty.

Page 4

Product Selection Guide

This chapter provides information to help you choose the best meter for your requirements.

Automatic Meter Reading (AMR). Every EZMeter is available with one of four Automatic Meter

Reading (AMR) capabilities: None, Pulse, EZ Plus, or ModBus.

No AMR requires someone to visit each meter periodically and manually write down the reading

from the display.

A Pulse meter generates an isolated pulse, usually every kwh, which is detected by some type of

data logger or pulse counting radio. EZ Meters are compatible with most type of pulse counting

systems including Oscar, Inovonics and Hexagram. These systems are usually installed at the site

and connected to a billing service via telephone modem or the internet. The pulse is generated by an

optocoupler and mimics a dry-contact closure, except that it is polarity sensitive. Standard pulse

duration is 50 milliseconds. Other pulse lengths are available. Contact the factory.

EZ Plus and Modbus are two separate software protocols used for addressing meters using a

serial interface. Either one is available with an RS-232 or RS-485 interface.

RS-232 is a very common interface that is intended for a single device within about 30 feet.

Because of the addressing scheme used in the EZ Plus and Modbus protocols, multiple meters can

be addressed, but no tests have been conducted to see how many will work. RS-232 meters are not

currently in production, but may be special ordered.

RS-485 is a protocol used commonly in building and industrial control systems. Up to 256

devices can be on one network, even more if repeaters or radio links are used. RS-485 is the most

commonly used serial interface for meter reading. USB to RS-485 adapters are available at low cost

from a number of vendors. TCP/IP to RS-485 adapters are also available allowing a network of

power meters to be connected to the internet. Most telephone modems have an RS-232 port which

requires an RS-232 to RS-485 adapter to connect the meter network to a phone line. Another option

for extending an RS-485 network is to use two radios, something frequently done to avoid trenching

between two buildings. More powerful radios have a range up to seven miles

The modular design of EZMeter communications allows other modules to be developed and

implemented fairly inexpensively. Expect a meter with a built-in radio shortly.

EZ Plus is a relatively easy to implement protocol that will provide all the information available

by Modbus. The free EZMeterReader billing program uses the EZ Plus protocol. The EZMeter

Power Suite package supports both EZ Plus and Modbus. Since it is a binary protocol, there is a

chance it could conflict with an ASCII protocol if sharing the same network. The network must be

1200, 4800, 9600 or 19,200 baud, 8 data bits, 1 stop bit, no parity.

Page 5

Modbus is an old protocol and the de facto standard for building and industrial automation. The

register map is available on page 39. Several third party software vendors offer software already

configured to the EZMeter register map. Meters can be ordered for either big (default) or little

endian and either signed (default) or unsigned integers.

Bi-directional Meters. All one, two and three element meters are available as bi-directional meters

that measure the number of kwh that flow in each direction. These meters are most often used in

conjunction with solar, wind or other alternative energy systems connected to the grid.

Voltage. Each EZMeter must be ordered to match the electric system where it will be installed. The

first character of the model number determines the voltage range the meter can handle.

Note: Each meter model is capable of handling a range of voltages. Select the meter with the

voltage range that includes the voltage you want to measure.

A. 100-130 volts to neutral, 200-260 volts line to line, single output:

Single element: 100-130 volts to neutral, single phase.

Two element: 100-130 volts to neutral, 200-260 volts line to line, single phase or two phases of

a three phase system.

Three element: 100-130 volts to neutral, four wire, three phase wye.

A. 100-130 volts to neutral, 200-260 volts line to line, dual output:

Two element: Two 100-130 volts to neutral, single phase services or

One bidirectional 100-130 volts to neutral, 200-260 volts line to line, single phase or two phases

of a three phase system.

Three element: One 100-130 volts to neutral, single phase plus one 100-130 volts to neutral,

200-260 volts line to line, single phase or two phase of three phase system, or one

bidirectional 100-130 volts to neutral, four wire, three phase wye.

Four Element: Two 100-130 volts to neutral, 200-260 volts line to line, single phase or two

phases of three phase system.

B. Three element only: 100-130 volts to neutral on two legs, 200-260 volts to neutral on the third

leg, 200-260 volts line to line, four wire, three phase delta. Can also be used in place of an A

single output meter with a slight loss of accuracy at the low end on L3.

C. 200-260 volts to neutral, 400-500 volts line to line

Single element: 200-260 volts line to neutral, single phase

Two element: 200-260 volts to neutral, 400-500 volts line to line, or two phases of three phase.

Three element: 200-260 volts to neutral, 400-500 volts line to line, three phase wye

D. 240-300 volts to neutral, 430-500 volts line to line

Single element: 240-300 volts line to neutral, single phase

Two element: 240-300 volts to neutral, 430-500 volts line to line, or two phases of three phase.

Three element: 240-300 volts to neutral, 430-500 volts line to line, three phase wye

When used with the EZMeter Technologies Phantom Neutral module, this meter will monitor

a three-wire, three phase delta service.

Page 6

E. Three element only: 240-300 volts to neutral on two legs, 430-500 volts to neutral on the third

leg, 430-500 volts line to line, four wire, three phase delta.

F. Dual Element only: 200-260 volts line to line, three wire, three phase delta

G. Dual Element only: 440-500 volts line to line, three wire, three phase delta

Maximum Current and Current Transformers. Each EZMeter is calibrated to work with a

specific model current transformer (CT) at any current up to the maximum rating for the meter.

Solid core CTs require that the power be turned off and the wire carrying the load to be measured

must be disconnected, run through the CT, and reconnected. Split core CTs come apart and can be

installed without disconnecting the wires.

Solid core CTs are available for current ranges up to100, 150, 200, 250 or 400 amps. Split core

CT ranges up to 60, 200, 400, 800, 1200 or1600 amps.

CTs can be installed in parallel. If want to measure several circuits in a breaker panel and the

circuits are on the same leg, but opposite sides of the breaker panel, you can use two CTs, one on

each side, so you don’t have to rewire the panel.

The wires on CTs can be extended a reasonable distance as long as the wire resistance does not

exceed one ohm.

Display and Resolution. Each EZMeter can be equipped with either an LCD display or an electromechanical counter that displays accumulated kilowatt hours. Some considerations:

An electro-mechanical counter costs less than an LCD display, but there are a few trade-offs.

The standard counter is rated to work down to 10EC (14EF) and is not suitable for outdoor use in

cold climates. An extended temperature range counter rated down to -30E (-22EF) is available at

added cost. If the temperature drops below the counter’s operating range, the counts will be lost

forever unless you are using an automatic meter reading system. If you have a dual output meter,

the LCD display will actually cost less than two counters. Counters are recommended when a local

display is required, but the meters will be read by an AMR system. They are also recommended for

locations in bright sunlight where an LCD display is difficult to read.

LCD displays have several advantages. Single output meters display accumulated kwh on the

top line of the display while the bottom line cycles through volts, watts, amps, and power factor.

The dual output meters display accumulated kwh for the second channel on the bottom line. If

mounted in a location where the display stops working because of low temperature, the display will

return to normal operation with no loss of kwh when it warms up.

Counters for meters with 0.1 kwh resolution have a red number on the right side to indicate

tenths of kwh. The other numbers are all white. Counters for meters with 1.0 kwh or 0.01 kwh

resolution have all numbers the same color. The LCD displays have a resolution of 0.01 kwh.

Page 7

Enclosures. A variety of enclosures that hold different numbers of meters are available. Most are

NEMA4X rated plastic enclosures with the meters mounted on a plastic panel inside. Use of plastic

enclosures allows AMR radios to be mounted inside. Interior rated enclosures have a clear cover

while exterior rated ones have a solid cover. The LCD displays are available only on the solid door

version.

Available versions are:

5" x 6.9" x 3" enclosure holds one or two meters and one or two displays. An optional fixture

allows the enclosure to be flush mounted in a wall.

6" x 6" x 4" enclosure holds one or two meters and two displays.

12" x 7" x 5" enclosure holds up to four meters and displays. It can hold six meters if two are

mounted on the back of the enclosure with velcro.

13" x 13" x 6" enclosure holds up to eight meters and eight displays.

19" x 15" x 7" enclosure holds up to twelve meters and twelve displays.

Model Numbers. Each digit in a model number specifies a different feature or option. Use the

table below to determine the options in the electronics module of your meter.

First Character - Voltage (see detailed description on page 6)

A = 100-130 volts to neutral, 200-260 line to line

B = 100-130 volts to neutral on two legs, 200-260 volts line to neutral on third leg, 200-260

volts line to line, four wire, three phase delta

C = 200-260 volts to neutral, 400-500 volts line to line

D = 240-300 volts to neutral, 430-500 volts line to line

E = 240-300 volts to neutral on two legs, 400-500 volts to neutral on the third leg, 400-500 volts

line to line, four wire, three phase delta.

F = Dual Element only: 200-260 volts line to line, three wire, three phase delta

G = Dual Element only: 430-500 volts line to line, three wire, three phase delta

Second Character - Number of elements supported

1 = One element

2 = Two element

3 = Three element

4 = Four element (dual two element meter)

Third Character - Display option

0 = No counter driver (AMR only)

1 = One counter (standard meter)

2 = Two counters (dual 2-in-1 meter)

3 = 2 line LCD display (standard meter)

4 = 2 line LCD display (dual 2-in-1 meter)

Page 8

Fourth Character - Maximum rated current (Meter Class)

0 = 60 amps

1 = 100 amps

2 = 150 amps

3 = 200 amps

4 = 250 amps

5 = 400 amps

6 = 800 amps

7 = 1200 amps

8 = 1600 amps

9 = 2000 amps

Fifth Character - Automatic Meter Reading (AMR)

0 = No AMR or AMR through I2C port

1 = Isolated pulse output

2 = RS-485 EZ Plus protocol

3 = RS-485 Modbus protocol

4 = RS-232 EZ Plus protocol

5 = RS-232 Modbus protocol

6 = TinyMesh radio

7 = Next Century radio power/pulse interface

Valid meter model numbers contain at least five characters. The model number may contain up to

five additional characters. If none of the additional characters are present, the “0" value is implied.

Sixth Character - Always a slash / unless there are no additional characters.

Seventh Character - The CT Model.

Additional CT models may be added at any time. Presently the models are:

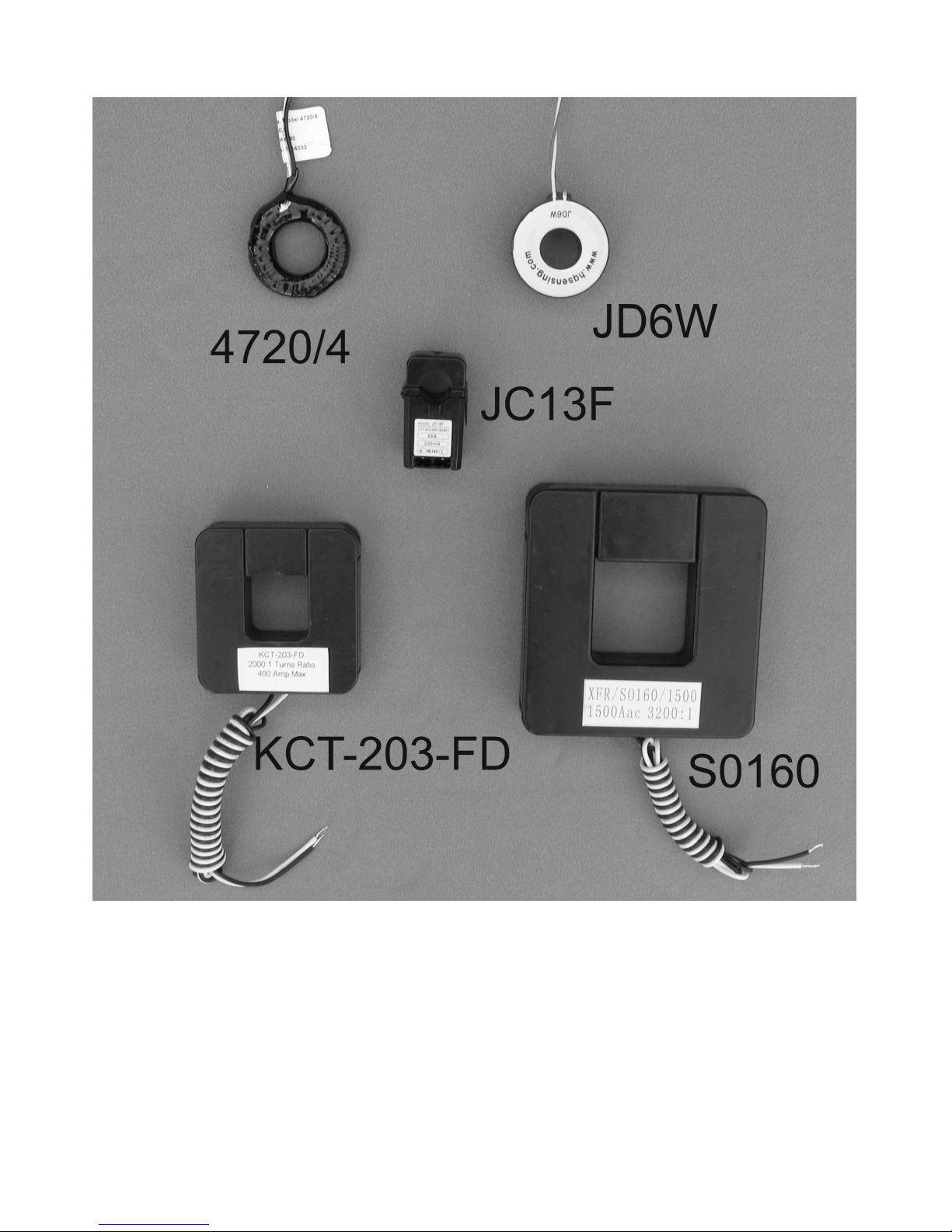

0 = 4720/4 - 400:1, 250 max amps, solid core, 1" ID (discontinued)

1 = JC16F - 400:1, 100 max amps, split core, 0.6" ID

2 = S0140 - 3000:1, 1600 max amps, split core, 1.25" ID (discontinued)

3 = JD6W - 2500:1, 400 max amps, solid core, 0.7" ID

4 = S0160 - 3300:1, 1600 max amps, split core, 2.0" ID

5 = KFC-203-FD - 2000:1, 400 max amps, split core, 1.2" ID

6 = JC36S3 - 3000:1, 800 max amps, split core, 1.4" ID (special order)

7 = WC3-200 - 400:1, 400 max amps, split core, .94" x .75" inside

8 = WC4-800 - 800:1, 800 max amps, split core, 1.7" x 1.3" inside (special order)

9 = WC5-1600 - 1600:1, 1600 max amps. Split core, 3.5" x 2.0" inside (special order)

A = XH-BCT-1000 - 1000:1, 250 max amps, solid core, 1.0" ID (special order)

B = XH-SCT-T24/200 - 2500:1, 260 max amps, split core, 0.93" x 0.99" inside

C = WC6-2000 - 2000:1, 2000 max amps, split core, 8.4" x 4.7" inside

D = JD7W - 417:1, 250 max amps, solid core, 0.7" ID

E = Eaton Model 417, equivalent to JD7W

Page 9

Eighth Character - Resolution

0 = Display: 1.0 kwh

Isolated: 1.0 kwh

1 = Display: 0.1 kwh

Isolated: 0.1 kwh

2 = Display: 0.01 kwh

Isolated: 0.01 kwh

3 = Display: 0.01 kwh

Isolated: 1.0 kwh

Ninth Character - Parity and Bidirectional

0 = No parity, standard meter

1 = No parity, bidirectional meter

2 = Even parity, standard meter

3 = Even parity, bidirectional meter

4 = Odd parity, standard meter

5 = Odd parity, bidirectional meter

Tenth Character - Baud Rate (Modbus Configuration) or Isolated Pulse Timing.

For Serial Port meters (modbus configuration, EZPlus where noted)

0 = 9600 Baud (little endian, unsigned integers and EZPlus)

1 = 19,200 Baud (little endian, unsigned integers and EZPlus)

2 = 9600 Baud (little endian, signed integers)

3 = 19,200 Baud (little endian, signed integers)

4 = 9600 Baud (big endian, unsigned integers)

5 = 19,200 Baud (big endian, unsigned integer)s

6 = 9600 Baud (big endian, signed integers)

7 = 19,200 Baud (big endian, signed integers)

8 = 4800 Baud (EZPlus only)

9 = 1200 Baud (EZPlus only)

For Isolated Pulse Meters

0 = 50 ms pulse, 150 ms recovery

A-Y = Pulse length is position of letter in alphabet time 129 ms, recovery time is 129 ms longer

than pulse length

Z = Custom pulse length

Page 10

Part Number Suffixes for Ordering. The part numbers above are printed on the meter cases and

enclosures. For ordering and invoicing, a part number suffix consisting of a hyphen (-) and two

digits may be appended to the part number. The first digit is the number of CTs that go with the

meter. The second digit represents the type of mechanical counter that goes with the meter. The

codes are

5 = Counter for 0.1 kwh resolution, one red wheel, standard temperature range (4921/1)

6 = Counter for 1.0 or 0.01 kwh resolution, all white wheels, standard temperature (4921/0)

7 = Only one type 5 counter for dual meter with 4 CTs.

8 = Only one type 6 counter for dual meter with 4 CTs

9 = LCD Counter and ribbon cable

In addition, California approved meters require special marking on the current transformers.

Append a letter “C” to the model number to be sure your meter will pass the state testing procedure.

Page 11

EZMeter Current Transformers. Each meter is manufactured to work with one model of current

transformer (CT). While it is true that a CT with the same turns ratio can be substituted for another

without causing a significant error, for best accuracy, use the CT specified on the meter label. The

meter has been calibrated to account for variations in how the CT responds to different phase

angles, a function of the core material rather than the turns ratio.

The seventh character of the meter model number specifies the CT that should be used. If there is

no character in the seventh position the 4720/4 CT should be used. See the table on page 10.

Page 12

Operating Instructions

After installation, the EZ Meter is simple to operate. You read the meter the same way you read

the odometer in a car. The label on the front of the meter indicates the resolution of the display,

either full kilowatt hours (kwh), tenths of kwh or hundredths of kwh The label on the outside of the

enclosure also states the resolution. The mechanical counters are available with all white digits or

all white except the right hand digit being red which indicates tenths of kwh. Normally, the display

reads in full kwh, except if the right most digit is a different color, it is reading in tenths. And except

if someone did not use the correct display with the meter module. Look at the label to be sure.

To charge a tenant for power used, subtract the meter reading at the beginning of the billing

cycle from the meter reading at the end of the cycle and multiply the difference by the rate per

kilowatt hour.

Whenever power is applied to the L1 terminal, the red LED on the electronics module should

light. The light will flash off then back on every time one of the legs measures 1/100 of a kwh (or

whatever quantity is indicated by the Kt value on the meter label (see below).

For meters made in 2015 and earlier: (see the date code on the label. 4Q15 = Oct-Dec 2015)

If the red LED flashes on and off every second, the meter is detecting a high

phase angle power factor is below .7) on one or more of the legs. This could

indicate a piece of equipment is not operating properly or it could mean that

the CTs and voltage references were not paired properly when using three

phase power. See the installation instructions for curing this condition. To

disable the high phase angle alarm (if you want to test the accuracy of the

meter at a high phase angle), install a jumper between the two pins on the

I2C connector closest to the display connector on the front row.

For meters made after 2015:

Beginning in January 2106, the low power factor warning is only active when reverse current is

detected. This means that if the CTs were installed correctly, the continuous flashing of the red LED

usually indicates that the voltage and current inputs to the meter were not properly matched during

installation and the meter is only recording half (or 2/3) the power being consumed. This only

occurs when the power is supplied from a three phase transformer.

Meters with electro-mechanical displays have a green LED that will flash briefly every time the

display counter advances.

Meters with an RS-485 interface have a bi-color LED that flashes red briefly every time the

meter senses traffic from the serial port. It flashes green when it responds to a request over the serial

port. Meters with an RS-232 interface, and the original RS-485 meters, have a yellow LED that

flashes when the meter responds. If the bi-color LED comes on bright red and stays on, it indicates

the serial connection was not properly installed or the isolated power has failed.

You can clean the outside of the meter enclosure with a general purpose cleanser such as 409 or

Fantastic if necessary. Do not use harsh bathroom cleaners or alcohol.

Page 13

If the meter appears to operate erratically, it is probably because it measures each phase

separately and flashes the red LED when each phase accumulates 1/100 kwh (or other resolution).

The resolution may be different for the red LED, the display and the isolated output. Check the

meter label where the resolution of each will be noted.

If you believe the meter is not measuring correctly, perform the test on page 25 and see the

troubleshooting suggestions on page 26.

Understanding the Meter Electronics Module Label

The center section on the meter label reveals a lot of data about the meter, but some of it is in

the language used by the metering standards.

Display Units - The resolution of the meter display. Either 1.0, 0.1 or 0.01 KWH. Multiply by the

value show on the display to get the total KWH the meter has recorded. Meters with 1.0 resolution

have all digits the same color and the display shows KWH with no conversion needed. Meters with

0.1 resolution are usually sold with the right hand digit being a different color and is read as if there

were a decimal point before the odd colored digit. Some older meters had the notation Kt: 1000

along with the display resolution. That confusing statement is no longer required by California

Measurement Standards.

Red LED (Kt) - The Red LED serves two functions. If it is flashing about once a second, it

indicates a low power factor on one or more legs. A slower flash indicates the meter has recorded

the amount of energy shown on the label, usually .01 KWH (10 WH) for most meters. It may be as

high as .5 KWH for high voltage, high current meters.

Depending on the type of meter, the next line will provide the isolated output resolution or the type

of serial communication and the default baud rate.

Oper. Temp: - The operating temperature range applies to the electronics module only. The low

temperature is usually lower than the low temperature for the electro-mechanical display.

Voltage - The range of voltages in which the meter will operate measured between line and neutral

(L/N). If there is no neutral, it is the voltage line to line (L/L). For four wire delta meters, the

voltage for the high leg is shown on the left for L3.

Max Amps (CL) - The maximum load (in amps) on each leg that the meter can handle. This is also

referred to as the meter class.

Test Amps (TA) - This is another term from the standards and is set by the manufacturer, usually at

15% of the class rating (maximum amperage).

Max current draw: All EZ Meters use 2 watts or less for operation of the meter.

Page 14

CT Ratio: The turns ratio of the current transformer that is intended for use with this meter.

Vertically printed next to the labeling of the CT terminals is the model number of the current

transformer the meter was calibrated against. Each model of CT has a slightly different phase angle

adjustment which is programmed into the meter during calibration. Using a current transformer

with a different model number, but the same turns ratio may cause an error of a few tenths of one

percent. Using a current transformer with a different turns ratio, or a current transformer with an

internal burden resistor, will cause a significant error.

Page 15

Installation Instructions

These instructions are for meters whose model number begins with a letter, not a number.

The EZ Meter consists of an electronics module, one or more current transformers (CTs), a

display of one or two electro-mechanical or LCD display counters, and an enclosure that holds from

one to 12 meters. If the meter will be mounted outside in direct sunlight, be sure to order a UV

resistant enclosure or paint the standard enclosure. The CTs and display may be mounted in the

same enclosure or mounted in a remote location. A common practice is to mount the CTs in a

breaker panel and mount everything else in a separate adjacent enclosure. A circuit breaker rated at

20 amps or less should be installed before the meter. Be sure no one will be able to turn off the

breaker and defeat the meter. If a fuse is used to protect the meter, it should be a delayed-action fuse

and the meter’s power supply will short hot to neutral for half a cycle (1/120 second) on power up.

Installing the NEMA4X Enclosure: Use the metal brackets provided to mount the enclosure in a

suitable location. Drill a hole anywhere in the side or back of the enclosure for a conduit to connect

to a breaker panel or disconnect box in compliance with local electrical codes. After the meter has

been installed and tested, secure the cover using the screw or small padlock provided. You should

also label each display counter with the unit name or number.

Installing the flush mount enclosure: This enclosure was designed to be recessed into a sheet

rock wall. Cut a 6” square opening in the sheet rock adjacent to a stud. Drill a hole in the back or

side of the enclosure for a conduit. Install the CTs and make the electrical connections as described

below before installing the enclosure in the wall. Fillister head screws with holes are provided so

that the cover may be secured with a seal if required.

A note on different meter types: All EZmeters come with a 12 pin connector for voltage and CT

inputs. There are three voltage inputs and three CT inputs (3&3) or two voltage inputs and four CT

inputs (2&4). The 3&3 configuration must be used whenever a three phase wye or delta load is

being measured. Either configuration can be used for measuring single phase loads, even if the load

uses one or two legs of a three phase service. The 2&4 configuration is most commonly used in

marinas and apartment buildings where two 3-wire 120/240V (or 120/208V) services are close

enough to each other to be monitored by one meter.

Installing the CTs: (See the appropriate Figure on pages 22 and 23.) If you are using solid core

CTs, you must turn off the power to begin your installation. Disconnect one end of the wire (or

wires) with the load to be measured and pass it through the center of the CT and reconnect the

wire(s) where it was attached before. Connect the two wires coming out of the CT to the appropriate

terminals on the electronics module. Begin connecting CTs to CT #1 and continue until all the CTs

for that meter are installed. The CT should be installed with the arrow facing the direction of current

flow or the label facing the source.

Page 16

CTs Are Directional (or Not)

If the meter is otherwise installed correctly, it will accurately record all the power that flows

through the CTs. If you are working with three phase power, even if only one or two legs of it,

you should be sure the arrows or labels are facing in the right direction. The meter has a phase

angle warning that flashes the red LED every second if power factor is below 0.7 and polarity is

reversed. This will happen if the CTs are facing the proper direction, but the voltage and current

sources are not properly matched. (L1 voltage and L1 CT should be on the same phase, etc).

If you want the phase angle warning (red LED flashes) to work all the time, simply install the

CTs backwards. Doing so will cause Modbus and Plus meters to report watts as a negative

number. Rather than physically turning the Cts around if needed, just reverse the black and white

wires where they connect to the meter.

You can install more than one CT on each leg if you need to. You might need to if you were

measuring several circuits in one breaker panel and the wires were not long enough for all to go

through one CT or if you wanted to measure power being used in two separate breaker panels. Just

be sure all the wires on each leg go through CTs that are connected to the same terminal on the

meter and that the direction marks on the CTs are aligned the same. Multiple CTs should be

connected in parallel.

If you run more than one wire through a CT, be sure that the current flow is the same direction

for all wires and that all the wires are the same leg (phase). That means there should be no voltage

variation between the wires (if you touched them together, they would not spark). Failure to do so

will cause the power flowing in one wire to be subtracted from the power flowing in the other wire

instead of being added to it.

The CT wires can be extended if needed. We have tested them at 500 feet and they can probably

be extended even further. If the line resistance is much over one ohm, accuracy of the meter will be

affected, especially at high phase angles. Be sure to install the CT wires in conduit. Connections

should either be soldered or made with gel filled wire nuts. Any resistance in the connection will

cause the meter to read lower than it should. The wire used should meet local codes for insulation.

Any size wire from 22 AWG to 12 AWG may be used. #18 is suggested.

You can install split core CTs without disconnecting the wire. If you have to install them

without turning off power, connect the wires to the meter before securing the two parts of the CT

over the wire carrying the load. Be sure to secure the two parts of the CT so it cannot come apart.

Note: Working in an electric panel that has power connected to it is an OSHA violation.

Do not mix CTs with different turns ratios on the same meter.

Page 17

WARNING

Hazardous voltages exist in CT wires when they are not connected to a meter and current is

flowing through wire passing through the CT. Wire nut the CT wires together if you must

remove the meter and leave the CTs in place. Failure to do so may damage the CT or shock

someone.

Electrical Connections: You need to provide a voltage reference for each phase of the power you

are metering plus connect the neutral to the meter as well. The voltage ranges printed on the

electronics module label (before L1, etc) refer to the voltage between neutral and that terminal and

indicate what meter works with what electrical system. The voltage associated with the meter name

is the most commonly used voltage in the range. See the diagrams on pages 19 and 20 for specific

models. For meters that do not have a Neutral reference, the voltage ranges printed on the label are

line to line voltages.

You can use any size wire from 28 AWG to 12 AWG. Be sure insulation meets local codes.

Each phase should be protected by a circuit breaker or fuse of 20 amps or less. For safety, a switch

or circuit breaker must be installed between the meter and the mains power source. It shall be in

close proximity to the meter and within easy reach of the operator and shall be marked as the

disconnecting device for the equipment. If a fuse is used, it should be a slow-blow type. Connecting

the meter on the protected side of a GFCI may cause the GFCI to trip when power is applied to the

meter.

IMPORTANT

You must ensure that the leg connected to the AC L1 terminal is the same leg which passes

through CT L1, and the same for (AC L2 & CT L2) and (AC L3 & CT L3). This is especially

important when connected to three phase power because the meter will only record 50% of the

power used on legs that are not properly paired. After the installation is complete, turn on a 60

watt or greater load for each leg and observe the red LED. If it is flashing, you most likely did not

wire the meter properly (The flashing LED indicates a power factor of 0.7 or less - optimum

power factor is1.0).

Surge Protection: Like computers, TVs and other electronic devices, EZMeters are subject to

damage from electrical surges. In fact they are particularly likely to be damaged because they are

typically installed as the first piece of electronics that the surge hits when it enters the submetered

electrical distribution system. Consider a whole-house surge protection device or other sacrificial

protection device.

Display Connections: (See Fig 1 and Fig 7) The electro-mechanical counter comes already

connected to the meter. If you purchased an OEM version of the product, connect as shown in the

Page 18

diagrams. If you have a three element, dual output meter, DISP1 is matched with CT #1 and L1

while DISP2 is matched to L2, L3 and the remaining CT(s). If you have a four element, dual output

meter, the power flowing through the CTs marked ‘A’ is displayed on DISPA while the CTs marked

‘B’ display on DISPB.

If you have the LCD displays, they connect to the I2C/LCD header. The diagram below shows the

connections. The wire numbers start with the red wire being #1 and continuing sequentially.

Isolated Outputs: (See Fig. 7) If you have a pulse output meter, connect the two wires from the

pulse counting equipment to ISO- and ISO+ respecting polarities. The grounded terminal of the

pulse counting device needs to be connected to the ISO- terminal on the meter. If you have a three

element, dual output meter, connect one set to ISO- and ISO1 and the other set to ISO- and ISO2.

They correspond with DISP1 and DISP2. On four element, dual meters, the terminals are labeled

ISOA, DISPA, and ISOB and DISPB.

RS-232 and RS-485 Connections: (See Fig. 1 and Fig. 10) The serial connections are optically

isolated from the electronics of the meter and require an external power source. Any power supply

capable of delivering 5-18 volts DC and 50 mA per meter will work. Connect the power supply

ground to the IGND terminal and the power supply hot wire to IPWR.

For RS-232, connect the RX- terminal to pin 2 of your DB9 RS-232 Connector, TX+ terminal to

pin 3 and IGND to pin 5.

For RS-485, there does not appear to be a lot of consistency in pin labeling. Some are labeled

Rx+ or Rx- and Tx- or Tx+. Others are labeled A and B. We have seen four-wire RS-422/485

adapters that work when Rx+ and Rx- were connected together and others where Rx+ and B- were

connected together. We have also seen adapters that work when TX+ is connected to Tx on the

adapter and others where TX+ is connected to Rx on the adapter. We suggest you find the proper

configuration on your workbench before installing all the meters in the field.

Connecting a meter to an RS-232 or RS-485 connector can be a lot of hassle. To make the

process easier EZMeter Technologies resells USB to RS-232 and USB to RS-485 adapters made by

FTDI Chip. These adapters have a 1.8 meter wire bundle that can be connected directly to the meter.

Instructions for connecting FTDI Chip

Model USB-RS485-WE-1800-BT

Model USB-RS232-WE-1800-BT

Page 19

For the RS-485 model, connect the orange and brown wires to the A (RX-) terminal, the yellow

and green wires to the B (TX+) terminal, the black wire to the IGND terminal and the red wire to

IPWR (Be sure to check that there is at least 4.8 VDC between IGND and IPWR if there are

multiple meters installed). The brown and green wires install a termination a 120 ohm termination

resistor. For the RS-232 model, the orange and yellow wires are reversed. If a separate DC power

supply is required, connect it to the IGND and IPWR terminals. Instructions and drivers for

Windows, Linux and OS-X are at www.ftdichip.com.

The meters should be connected in daisy chain fashion (the wire should loop from one meter to

the next) with a twisted pair of wires. CAT5 or CAT6 stranded cable is suggested, and telephone

wire will work fine as long as the pairs are twisted.

It is important that twisted pairs be used for connecting the meter. That means use one twisted pair

for both A and B. If you want redundancy, use two twisted pairs in parallel. Do not twist the solid

and striped wires of one pair together for A and another pair for B. That defeats the purpose of using

twisted pairs and will most likely not work unless you have a very short wire run to the meters.

If you have at least a two pair cable, you can run the power from the DC power supply on one of

the pairs. Depending on the length of the cable and the impedance of the RS-485 adapter a 120

ohm resistor may need to be installed across the A and B pins on the last meter in the daisy chain.

These resistors are built into the FTDI USB to RS-485 and Grid Connect NET485 adapters. Install a

120 ohm resistor on the first meter in the daisy chain. Some systems may require two 470 ohm

resistors, one between +5 VDC and the B (TX+) terminals and the other between Ground and the A

(RX-) terminals. See Fig. 10. All the resistors can be connected directly to the meter terminals.

Experiment with different resistor combinations until communication is established. See the RS-485

troubleshooting section for more information.

Maxim Integrated Devices, manufacturer of the RS-485 drivers used in the meters, has a very

helpful document titled Guidelines for Proper Wiring of an RS-485 (TIA/EIA-485-A) Network at

http://www.maximintegrated.com/an763.

Be sure to write down the serial number and Modbus address of each meter and its location. The

EZ Power Suite requires a unique serial number for every meter location.

Application Notes at the end of this document deal with troubleshooting an RS-485 installation,

connecting Digi radios and the NET485 ethernet to RS-485 module.

I2C Port Connection: (Not yet available) The I2C port (Eye Squared See) is used to connect an

LCD display to the meter. The meter should be powered down before connecting the display. The

display will not function until the meter has been powered up again after the display has been

installed. An exception to this applies to Modbus versions of the meter that have previously been

connected to an LCD display. The display can be disconnected while the meter is running, then the

optional configuration dongle can be connected, then the display can be reconnected.

Page 20

Notes on Wiring Diagrams on following pages:

The voltages shown on most of the diagrams are for the allowable voltage range for meters made for

110-120 volt electric systems found in the USA. The voltage shown is for line-to-neutral or line-toline for meters that do not use a neutral. Meters for higher voltages are configured the same way

except a higher voltage range is specified. For instance, Figure 1 specifies Type A, C and D meters.

Type A (the first letter of the model number) is for 110-120 volt to neutral systems, Type C for 220

or 240 volt systems and Type D for 277 volt systems.

Fig. 2 shows a 4 wire delta (hot leg, high leg, stinger leg). Be sure your L3 leg is the high voltage

leg.

Fig 3 and Fig 6 show the same meter as in Fig 1, but with only two or one CTs connected. Be sure

you have power on L1 or the meter won’t work.

Fig 4 shows a 3 wire, 3 phase delta system. This meter only uses two CTs.

Fig 5 shows the same meter as in Fig 4, but with only 1 CT connected.

Fig 7 shows how to connect to the isolated pulse outputs. If you have a single output meter, ISO2

will be labeled ISO+ and ISO1 will be N/C (No Connect).

Fig 8 shows the special purpose dual two element meter with isolated pulse outputs. The

RS232/RS485 versions connect as shown in Fig 1.

Fig 9 shows a three element, bidirectional meter. The power that flows in one direction is displayed

on one counter and power that flows in the opposite direction is displayed on the other counter. This

is the only installation where the direction of the CTs makes a difference.

Fig 10 shows the typical connections needed for an RS-485 network.

Page 21

Page 22

Page 23

Fi

g.

10. RS-485 Network Layout

Page 24

Testing the Installed Meter

After the meter has been installed, it is

a good idea to turn power on the system and

check to see that the meter was connected to

the power line properly. This can be

determined easily by looking at the red LED

in the top, center portion of the label on the

electronics module. This LED should glow a

bright red whenever power is on. If it is

flashing continuously, about one flash per

second, it is indicating a high phase angle.

This could be caused by the load on the

system, but frequently indicates that the

voltage and current inputs are not matched

properly when using three phase power. This

warning requires a current flow of

approximately 60 watts on each leg.

If the meter is receiving power, the next

step is to verify that the meter is operating

properly. You will need a hair drier or other

small appliance that uses approximately 1500

watts or more to be able to do the test in a

reasonably short time. Since the meter

measures each phase separately, you will need

to test each phase individually.

You can get a rough idea of the accuracy

of the meter with the following test. If you

have a high voltage or high current meter, the

red LED may flash at 0.5 kwh or 0.1 kwh

instead of 0.01 kwh. Check the meter label.

You will have to adjust the times for other

resolutions.

WATTS is the wattage shown on the

nameplate of the appliance providing the load.

For example, a 1500 watt heat gun on 120

volts will use 0.01 kwh in 4,320,000 / 120 /

1500 or 24 seconds. If you don’t get this

exact value, it does not mean the meter is

defective. Many name plates are only

approximate. The label on the EZMeter itself

states power consumption of 2 watts, but that

only happens when the serial port is read or

the mechanical counter advances. Another

factor that influences the accuracy of this test

is the power factor of the electricity being

measured. If a big power factor exists, the

test may take several more seconds than what

is calculated, perhaps half again as much.

To check a 120 volt service, turn on your

heater and begin timing when the red LED

flashes the first time. The red LED should

flash again about 24 seconds later (or

whatever time you figured using the formula

above for the load you are testing with).

If you have several meters but don’t have

a voltage meter, you can test several meters

and if they all use the same number of

seconds, you can assume the meters are

working okay even if the time observed is

different than the calculated time. This test

will also correct for variation in the actual

number of watts used by the appliance versus

the number shown on the name plate.

Without getting into phase angle,

resistance and impedance measurements, the

following formula will tell you how many

seconds it should take to count 0.01 kwh:

SECONDS=4,320,000/VOLTS / WATTS

where VOLTS is the AC voltage measured at

the meter (it is important to measure this as

variations up to 10% are common) and where

Page 25

Trouble Shooting

Try the following steps if the meter does not

work. A simple AC voltmeter

will make trouble shooting much easier.

No Red LED

Be sure that line and neutral wires are

connected properly and that power is turned

on. Check this with your voltmeter by

measuring the voltage between the Neutral

and L1 terminals. The voltage should fall in

the range specified for the meter. If it does

not, you have not connected it properly, the

power is not turned on, or you have the wrong

meter for your electrical system. Check the

voltage between the neutral (usually white

wire) and ground. This voltage should be

close to zero.

the meter, at the panel, or where it connects to

ground. Check your neutral. If a CT wire is

shorted to neutral or ground, it will also cause

a very high reading.

The time is wrong when doing the accuracy

check.

Be sure all the terminals are wired

correctly and screwed down tightly.

Be sure the hair dryer or other electrical

load is plugged into the proper circuit and that

it is the only thing drawing current through

the meter.

Be sure the wire to the hair dryer only

passes through the current transformer one

time and that the neutral wire does not pass

through it.

No Green LED

The green LEDs are normally off. They

flash briefly when the mechanical counter

advances..

Green LED flashes but Counter does not

change

The meter is correctly detecting the usage

of power but the mechanical counter is not

moving. Be sure the counter is connected

properly with one wire going to COMN and

one wire going to DISPL When the green

LED flashes, the mechanical counter should

advance. With 2-in1 meters, when the top

green LED flashes, the counter connected to

DISP1 should advance indicating current

measured with the transformer connected to

the CT #1 terminals. When the bottom green

LED flashes, the counter connected to DISP2

should advance.

If the counter is properly connected and

does not advance when it should, replace the

counter with a different one.

I have several meters and one appears to be

reading lower than the others.

If you think one of the meters is reading

low, swap the meter with one that appears to

be reading right.

Communication problems

See the RS485 Troubleshooting Ap Note.

Still doesn’t work

Check at www.ezmeter.com for more

trouble shooting suggestions or call Customer

Support at 1-805-688-9696 between 9:00AM

and 5:00PM Pacific Time, Monday through

Friday. Each meter is covered by a five year

limited warranty (see page 4). There is a

charge for meters that are returned for repair

that are not defective.

Green LED Flashes too often

The most common cause of inaccurate

meters is a poor neutral connection, either at

Page 26

EZMeter Technologies Application Note

Installing a Grid Connect NET485 (Ethernet-RS422/485 Adapter)

Several companies make Ethernet to RS485 adapters that are suitable for connecting EZ Meters

to the internet or a local area network (LAN). Most come with a fixed IP address and setting one up

is both time consuming and difficult. EZMeter Technologies recommends the Grid Connect

NET485 for its ease of setup.

Physical Connections to meter. The NET485 module must be mounted in a location where a

hard-wired LAN connection meets the end of the RS485 network. The A pins must be wired

together and the B pins must also be wired together. The two termination resistor jumpers next to

the green connector should be removed unless you have very long wires for your RS485 network.

NET485 EZMETER DC POWER SUPPLY

TXD A & RXD A A or RXTXD B & RXD B B or TX+

SGND & GND IGND GND

8-24VDC IPWR 8-16VDC

Firmware Setup. An active ethernet cord must be plugged into the NET485 and DC power must

be supplied to the GND and 8-24VDC pins on the green connector before setting up the firmware.

Step 1. Determine and set the IP address. Install the Lantronix DeviceInstaller software on your

computer from the CD that came with the NET485 or download it from the Grad Connect website.

Run the program. It will search your network for your adapter and may take several seconds to find

it. Your device should show up in the main part of the screen with an icon labeled Xport. Double

click on the icon and a list of the devices properties will be displayed. You are looking for the IP

address which is about a third of the way down the page. For subsequent steps, you can use either an

internet browser (Internet Explorer, Firefox, Safari, etc) or you can click on the Web Configuration

tab in the program.

Step 2. If you clicked on the Web Configuration tab, the IP address and port (80) will be

showing in the address box. Click the white arrow with the green background to the right of the

address. If you are using a browser, continue to the next step.

Step 3. Enter ‘admin’ as the user name and leave the password box empty, then click ‘OK’.

Step 4. Set up the Serial Port. Click ‘Serial Settings’ under Channel 1 in the menu on the left

side of the screen. Change the Protocol to ‘RS485 - 2 wire’. Set the baud rate to match whatever is

printed on the label of the EZMeter (They all have to be the same or you won’t be able to

communicate with some of them.) Flow Control should be ‘None’, Data Bits ‘8’, Parity ‘None’, and

Stop Bits ‘1’ for EZPlus meters. Refer to the label for Modbus meters as they may require different

settings. Under Pack Control, the ‘Enable Packing’ box should be unchecked. There should be a

green dot in No for everything under ‘Flush Mode’. Click the ‘OK’ button at the bottom of the page

when you are done.

Page 27

Step 5. Set up the connection data. Click ‘Connection’ on the menu on the left side of the

screen.

Under Connect Mode: Protocol = ‘Yes’, Accept Incoming = ‘Yes’, Password Required = ‘No’,

Active Connect = ‘No’

Under Endpoint Configuration. Local Port is one of the values you will enter into the

EZMeterReader software package to connect to this device. The default is 10001 which is fine unless

you have multiple devices that use this port and you want to be able to access the device over the

internet. Then it will need its own port. Be sure to note the number you assign. Remote Port = ‘0’,

Remote Host = ‘0.0.0.0’ and Auto increment for active content is unchecked.

Do not make any changes to Common Options or Disconnect Mode.

Click ‘OK’ to save any changes you made.

Step 6. Select ‘Network’ on the main menu. Set a DHCP Host Name or Fixed IP Address. A

fixed IP is suggested if your network does not support DHCP host names. Click “Network’ on the

menu. Under IP Configuration, either:

(a) Select ‘Obtain IP address automatically’ and all the ‘Enable’s below it. Enter a name in the

‘DHCP Host Name’ box. This is the name that you will enter in the IP Address field in the EZMeter

Reader program. Or

(b) Select ‘Use the following IP configuration’ and enter the desired IP address. Change the other

values only if your network requires.

Under ‘Ethernet Configuration’ be sure the ‘Auto Negotiate’ box is checked.

Click ‘OK’ to save any changes you made.

Step 7. Setting passwords. This step is optional, but highly recommended if the NET485 device

will be exposed to incoming messages from the internet.

Select ‘Server’ from the menu. Under ‘Server Configuration’ enter a password in the ‘Telnet

Password’ box and again in the box below it.

Click ‘OK’ to save any changes you made.

Note: If you ever come back and change any of the settings in the ‘Advanced’ section, be sure to

re-enter the password before you click the ‘OK’ button. Otherwise the password will be reset to a

blank (empty) password.

Step 8. Apply Settings (Very Important). Click ‘Apply Settings’ on the menu. If you fail to do

this, everything you have done up to this point will not be loaded into the NET 485 device and you

will have wasted your time.

The Grid Connect NET485 can be ordered online from www.gridconnect.com/net485.html or

pre-configured from EZMeter Technologies. When ordered from EZMeter Technologies, a 12 vdc

power supply is included.

Page 28

EZMeter Technologies Application Note

Connecting Digi Radio Modems to EZMeters

The MaxStream division of Digi Corporation makes several radio modems that work as

wireless RS-485 network extenders. The three series, XCite, XStream and XTend all have the

same function with XCite having the shortest, and Xtend being the most powerful. Maximum

range for the different models (from the Digi specifications) are:

Model Indoor/Urban Range Line of Sight Range

Xcite 300 feet 1000 feet

XStream 1500 feet up to 20 miles

XTend 3000 feet up to 40 miles

Choosing the right radio. Adequate range is the most important consideration in choosing a

radio. The range figures above should be considered ballpark figures and not relied on

completely. Interference from other radios and physical objects can severely affect the actual

range of the radios. To get the maximum ranges shown, expensive, directional antennas are

required. Each radio comes with software for configuring the radio and testing communication

between two radios. Before a radio is permanently installed, be sure to use the provided test

program to be sure the radios will communicate with each other.

The other important consideration is the operating temperature rating. For indoor use,

Commercial (0EC to 70EC) is adequate. Outdoor installations generally require the Industrial

(-40EC to 85EC) rating.

Testing the Range. Follow the instructions in the Quick Start Guide to establish

communication. If your computer has an RS-232 port, use it and the included cable for this test.

If your computer does not have an RS-232 port, you will need to configure the radio connected to

the computer for RS-485 and connect it as described below. The radio with the loopback

connector must remain configured for RS-232 during the test.

Connecting a Radio to Your Computer. If the radio will be installed near the computer, it is

usually simpler and cheaper to connect to the radio using RS-232 rather than RS-485. Simply

use the RS-232 cable provided with the radio or purchase a USB to RS-232 adapter. Plug it into

the connector on the radio, set the DIP switch for RS-232 (switch 1 on, the others off) and plug in

the power supply.

If the cable from the computer to the radio will be more than thirty feet long, use RS-485.

We suggest the FTDIChip USB to RS-485 Adapter (Model USB-RS485-WE-1800). Connect

the yellow wire to Pin 2 on the L-COM DB9MT1 adapter, the orange wire to Pin 8, and the black

wire to Pin 5. Set the DIP switch for 2-wire RS-485 by turning all the wires off.

If some meters will be connected directly to a USB to RS-485 adapter (or an ethernet to RS485 adapter) and other meters need the radio link, both radios may be connected as described in

the next section.

Page 29

Connecting a Radio to the Meters. Before connecting a radio to the meter network, it is a good

idea to connect a portable computer to the network to determine that everything is working

properly. It is easier to troubleshoot if you know the problem is in the wiring rather than with the

radios.

These instructions assume the RS-485 network has already been installed and is working.

Connect the B- wire from the meters to Pin 2 on the L-COM BD9MT1 adapter, the A+ wire to

Pin 8, the IGND wire to Pin 5 and the IPWR wire to Pin 9. Be sure to set all the switches on the

DIP switch off for 2-wire RS-485.

Troubleshooting. Troubleshooting is best accomplished by separating the RS-485 network from

the radios and checking each system separately. To test the radios, remove the DB9 adapter from

the radio connected to the meters and install the loopback connector furnished with the radio.

Move switch 1 on the DIP switch to on and be sure there is power to the radio. You will need to

provide power to the radio if it was powered from the same source as the isolated power

connected to the RS-485 connector on the meter. The radio comes with a plug in power supply

as well as a short cord that will connect to a 9 volt battery. Use the software provided with the

radio to test the communication.

Page 30

EZMeter Technologies Application Note

Connecting Snap Link Radios to EZMeters

Snap Link radios produced by Synapse are another cable replacement option for creating an

RS485 network. Product information is available on their website at:

http://www.synapse-wireless.com/iot-development/hardware-products/snaplink

One downside to using Snap Link is that a separate USB to RS485 adapter is required. The USB

port built into each radio is only for providing power, not communications.

The default communication setup for the radios is two-wire RS485, 9600 baud, no parity, one

stop bit. Ordering EZMeters in this configuration makes setting up the system easy right out of

the box. Synapse has configuration programs available on their website for changing any of the

parameters if needed.

A lot of the material in the previous app note regarding Digi radios applies to Snap Link as well.

If you are not familiar with setting up radio networks, read that section.

Connecting to a USB Adapter: Use of the FTDIChip USB-RS485-WE-1800-BT adapter

described earlier is suggested. Connect the orange and brown wires to the left-most pin (TX+)

on the connector on the SnapLink radio. The yellow and green wires go to the next pin (TX-).

The black wire connects to the right-most pin (GND). Install the antenna and connect the

provided USB cable to power and this module is ready to go.

Connecting to a NET485 Ethernet Adapter: See the app note above about installing a NET485

device. The two A pins are jumpered together and connected to the left most pin (TX+) while

the two B pins are connected to the adjacent pin (TX-). GND and SGND on the NET485 should

be connected to the right hand pin on the radio (GND) and the ground of the power supply. Put a

jumper on the TX TERM pin of the NET485.

Connecting to one or more EZMeters. Connect the left-most pin (TX+) on the radio connector

to A or RX- on the meter. Connect the adjacent pin (TX-) to B or TX+ on the meter. Connect the

meter IGND to the right-most pin (GND) of the radio’s connector. Be sure to also connect the

isolated power supply to IPWR and IGND. Test the polarity before making the connection.

The default connection will work in most situations. If there are a lot of radios or long distances

involved, programs available on the Synapse website will configure the radios into a mesh

network with some acting as repeaters and others as simple end points. Consult Synapse’s

technical support for assistance configuring a network.

Page 31

EZMeter Technologies Application Note

RS-485 Trouble Shooting

Ideally, you will hook up your system and it will work the first time. If that doesn’t happen, you

have a few options.

1. Use the EZMeter Access program to communicate with the meters through the EZServer

meter reading and logging utility that is part of the EZMeter Power Suite. This is a little

cumbersome as the program was not designed for troubleshooting.

2. Use the EZServerTester program that was installed in the EZMeter folder on your main drive.

Start the program by double clicking on it. Be sure the EZServer is running (Comm Server in

the main menu of EZMeter Access). You will probably connect to t he server using Localhost

(on the same computer) and pushing the Connect button. The program reads the unit

information from the Access database. Click the buttons to get various data stored in the

meter.

3. Use the EZMeter Configuration Tool program. If it was not installed with the Power Suite

(versions 0.3.0 and earlier), download it from http://www.ezmeter.us/downloads/Setup-

EZMeterConfigTool.exe. This program communicates directly with the meters so make sure

the EZServer program will not interfere by trying to read a meter at the same time. The online

help system will get you started and walk you through it.

4. Read Guidelines for Proper Wiring of an RS-485 (TIA/EIA-485-A) Network , an app note

(763) published by Maxim Integrated Devices, manufacturer of the RS-485 drivers used in

the meters. It is at http://www.maximintegrated.com/an763.

On all systems:

Problem: No communication

1. Verify that the meter is powered up and the red LED is on steady. If it is flashing, it could

indicate that the meter does not have a steady source of power. It can also mean that there is a

high phase angle on one or more of the legs.

2. Verify that there is DC power between the IPWR and IGND terminals on the meter. You

should have between 6 and 18 volts.

3. Verify that there is a DC voltage difference of more than 0.1 volts (100 millivolts) between the

B- and A+ terminals. The voltage between IGND and B- should be over 1 volt and between

IGND and A+ should be higher by at least 0.1 volts.

4. If you are using the FTDI Chip USB to RS-485 dongle, be sure the orange wire is connected to

the A+ terminal, the yellow wire is connected to B- and the black wire is connected to

IGRND. If you are using a different RS-485 device, the Tx and Rx wires may need to be

reversed. Be sure the signal ground from the device is connected to IGRND.

5. If you have no communication with any meter on your system, isolate one meter from the

others and work through this guide until you can communicate with that one meter before

connecting to the others.

6. Be sure the label on the meter specifies that it is for RS-485.

7. Be sure your computer program (EZMeter Reader or EZMeter Access) is configured properly.

a. Be sure that at least one connection has been set up and that all the parameters match what

is printed on the meter label.

Page 32

b. Be sure you have added the meter you are trying to communicate with to the system and

that the serial number (EZ Plus) or Modbus address (Modbus) is entered in the appropriate

space without any hyphens or commas.

c. If you have set up more than one connection for your system, make sure that the meter

under test is part of the meters served by the active connection.

d. Make sure the baud rate for your connection is the same as the baud rate printed on the

front of the meter label. For Modbus meters, also check parity and stop bit settings.

e. EZMeter Reader - Click on the meter you want to read in the list of meters, then click then

Read This Meter button. If you get a reply, the right part of the screen will be refreshed

with new numbers. If you do not get a good reply a window will pop up and tell you what

the problem is.

f. EZMeter Plus - Be sure the server is running (Comm Server in the menu bar). Go to the

Units tab in the Setup window, select a unit and click the Read Now button at the bottom of

the window. The Last Reading data will be updated with the current reading, date and time

if the reading is successful.

8. Be sure you do not have too many devices on the network. Up to 255 meters can be installed

on one network as long as there is nothing else. Each device you add to the network adds

impedance to the line. The original RS485 specification allowed up to 32 devices. Mixing

old, high impedance devices with EZMeters will reduce the maximum number of meters that

can be on one network. Repeaters and radio links can be used to increase the number of

meters.

9. Line termination is important and best discovered by trial and error. It sometimes is not

needed at all and other times is required on very short runs. The first step is to install a 120

ohm resistor across the Tx and Rx terminals on the last meter in the chain. If this does not

solve the problem, add a second 120 ohm resistor across Tx and Rx at the adapter. The

NET485 Ethernet adapters have jumper selectable terminating resistors built in.

Using the FTDI Chip USB to RS485 Dongle:

Note: 120 ohm termination is usually required at the last meter, even if there is only one.

Problem: Lights in Dongle do not flash.

1. Be sure you have installed the latest driver for the device from the FTDI Chip website.

2. Verify the COM port to which the USB device is mapped and that the COM port in the

program are set to same value.

3. Try a different Dongle

Problem: The red light in the Dongle flashes but the green one does not.

1. Verify that the meter is powered up and the red LED is on steady. If it is flashing, it could

indicate that the meter does not have a steady source of power. It can also mean that there is

a high phase angle on one or more of the legs.

2. Verify that the orange wire from the Dongle is connected to the TX- terminal on the meter,

the yellow wire is connected to the RX+ terminal and the black wire is connected to the

IGND terminal.

3. Be sure the serial number (EZ Plus) or Modbus address is correct.

4. Watch the white, bicolor LED on the meter (the one above the two green LEDs). It will flash

red when it receives a signal from the Dongle. If it does not flash, there is a problem with the

wiring somewhere. If it flashes red, it did not recognize its address so it did not respond. The

Page 33

address may have been for another meter or the message received may have been corrupted.

Corrupted messages are usually caused by improper termination.

Problem: Both lights in Dongle flash, but there is no reply.

1. Watch the white, bicolor LED. If it flashes red it is not replying. If the meter replies, the LED

will flash red then green so fast that it looks sort of orange. If the meter has replied, but the

program is not recognizing the response, it is most likely a termination problem.

2. If you have multiple meters, try a different one. Something may have happened to the first

one.

3. Try to isolate the meter from electronic noise. If the yellow LED on the meter never flashes,