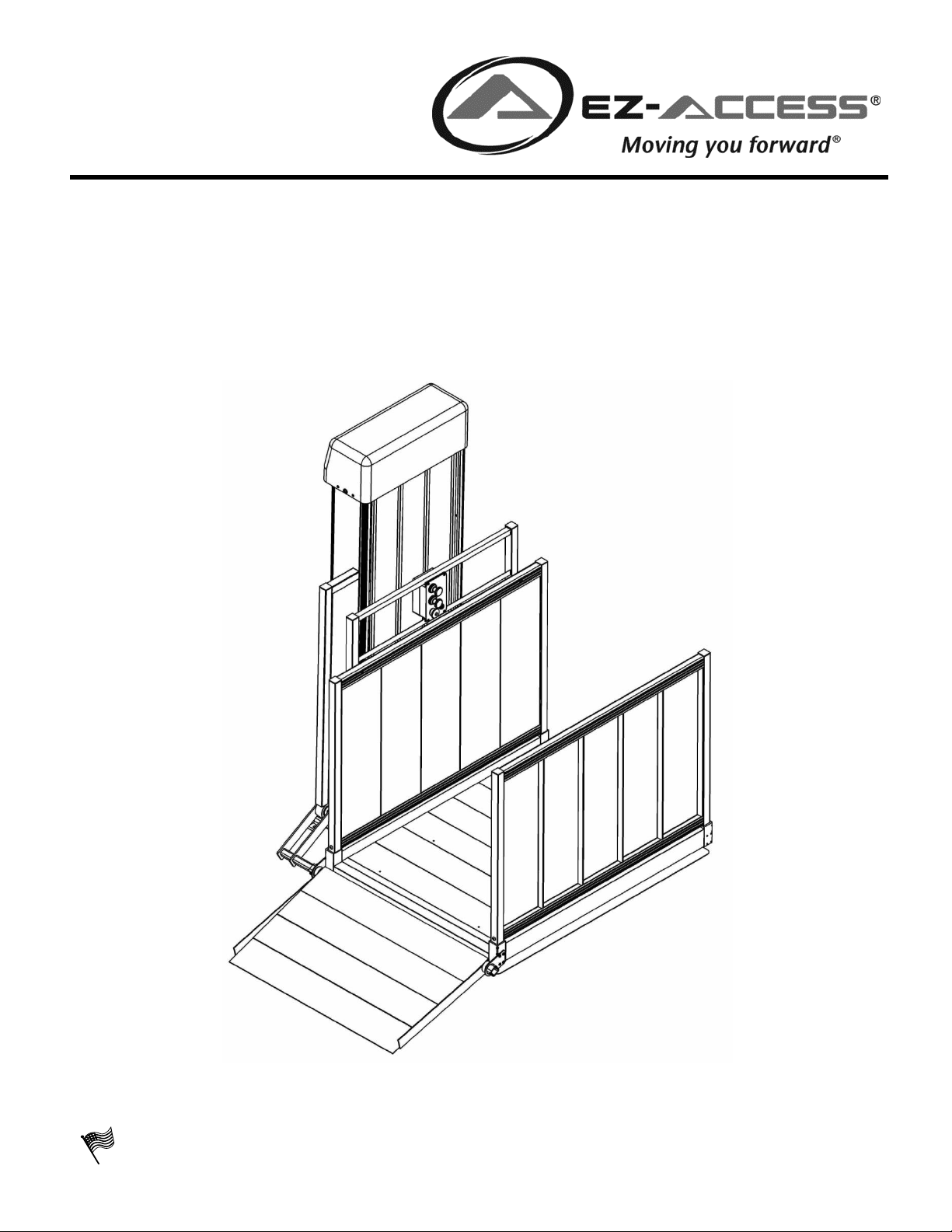

Page 1

PASSPORT® Vertical Platform Lift (VPL)

Installation Manual for Models

PL52SP3651, PL72SP3651, PL52TP3860 and PL72TP3860

Manufactured in the USA

© 2012-2013 EZ-ACCESS®, a division of Homecare Products, Inc. All rights reserved.

All text and images contained in this document are proprietary and may not be shared, modified,

distributed, reproduced, or reused without the express written permission of EZ-ACCESS.

12274 REV 05-20-14

Page 2

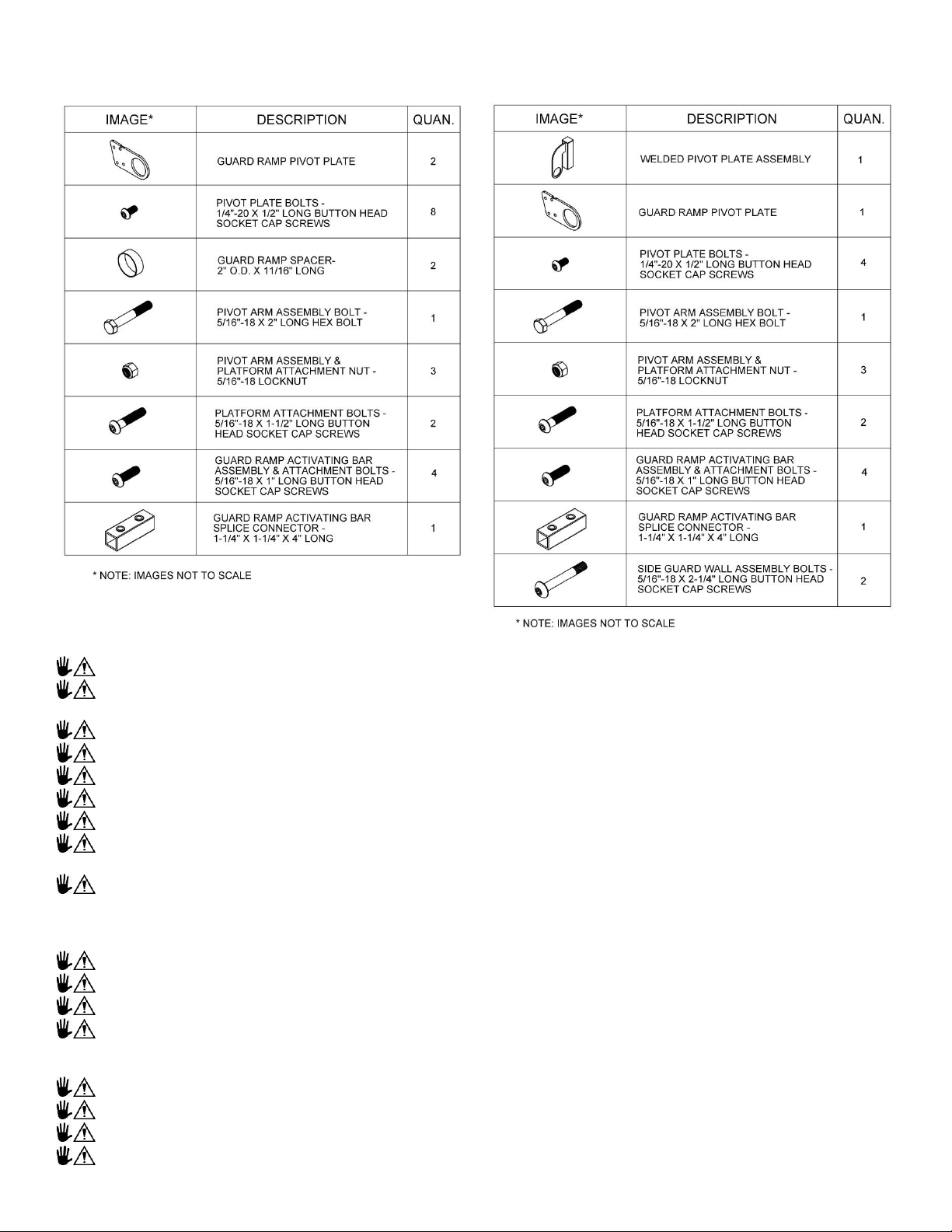

Model PL52SP3651 - 52” Maximum Height

Straight Through Platform

Model PL52TP3860 - 52” Maximum Height

90° Turn Platform

Model PL72SP3651 - 72” Maximum Height

Straight Through Platform

Model PL72TP3860 - 72” Maximum Height

90° Turn Platform

UNLESS NOTED OTHERWISE, THIS MANUAL APPLIES TO MODELS PL52SP3651, PL72SP3651,

PL52TP3860 AND PL72TP3860

Page | 2

Page 3

Hardware Bag Contents for

Straight Through Platform

Hardware Bag Contents for

90° Turn Platform

ATTENTION INSTALLER – VERIFY PRIOR TO INSTALLATION:

Check for shipping damage immediately upon receipt.

Note any freight damage on freight bill while driver is still present. In most cases, freight damage claims will not be

allowed unless noted on the freight bill. Pictures of damage before the unit is unpacked can be very helpful.

Contact shipper right away with any freight damage concerns.

The VPL is shipped with a packing list. Confirm all items are present before starting installation.

Layout installation site taking into consideration VPL entry and exit points, height, and electrical supply location.

The VPL platform must be at least 3/8” but no more than 3/4” from the edge of the upper landing (horizontally).

The VPL platform guard walls must be at least 2” but no more than 3” (horizontally) from walls or other obstructions.

It is the installer’s responsibility to verify local codes and regulations regarding power supply and electrical

connections. The VPL is supplied with a 12’ AC power cord.

The VPL must be anchored to a level, 3,500 PSI concrete pad at least 4” thick. Minimum pad dimensions are 41” x

50” to anchor the legs and support the tower. However, a larger pad will be needed if it is desired that the guard

ramp land on the pad and/or the approach to the ramp be incorporated into the pad. Final pad location, orientation

and dimensions are the installer’s responsibility to determine based on field conditions.

Confirm the structural integrity of any existing fascia.

Verify that the upper landing area is level.

Determine which side the guard ramp will be attached to and verify adequate clearances.

Check for adequate headroom clearance above VPL platform. The PL52SP3651 and PL52TP3860 require

approximately 100” to travel to its maximum platform height not including the occupant. The PL72SP3651 and

PL72TP3860 require approximately 120” to travel to its maximum platform height not including the occupant.

Platform must travel up and down and guard ramp must fold and unfold without interference or obstruction.

Refer to the Top Landing Gate Placement and Installation section if installing a Top Landing Gate.

Read and understand the entire Installation Manual before proceeding with installation.

Please leave User Manual with the VPL user.

Page | 3

Page 4

TABLE OF CONTENTS

Read the User Manual in its entirety. Understand and learn the location and function of all the features, safety

devices, and labels before operating any VPL.

Do not exceed the VPL weight capacity of 750 pounds (340 Kg).

Do not use VPL for anything other than its intended purpose of personal residential use for lifting of individuals and

personal mobility devices.

Keep all body parts away from moving components and within the platform guards during VPL operation.

The Platform Safety Rail option must be installed if the VPL is used by a standing occupant.

Never play on or near the VPL.

Turn off power and engage the brake on all mobility devices prior to cycling the VPL.

Remove ice, snow, leaves and other potentially unsafe materials from VPL and landings before each use.

Inspect VPL for damaged, missing, or inoperable parts before each use. Never use a damaged or unstable VPL.

Periodically check all fasteners and verify all nuts, bolts, screws and other fasteners are undamaged and secure. Do

not attempt to repair or modify the VPL. Only qualified technicians may service the VPL. Contact your dealer to

schedule any needed inspections, repairs or service.

Section 1 - - - - Symbols, Safety and Warnings

Section 2 - - - - Labeling and Dealer Contact Information

Section 3 - - - - Optional Equipment Notice

Section 4 - - - - Assembling the VPL

Section 5 - - - - Optional Equipment - Wireless Remote

Section 6 - - - - Optional Equipment - Top Landing Gate

Section 7 - - - - - - - Top Landing Gate Optional Equipment - Pathway Connector Kit

Section 8 - - - - - - - Top Landing Gate Optional Equipment - Deck Connector Kit

Section 9 - - - - Optional Equipment - Platform Safety Rail

Section 10 - - - - Optional Equipment - Platform Safety Pan Weather Guard

Section 11 - - - - Optional Equipment - Interlock

Section 12 - - - - Optional Equipment - Call/Send Control

Section 13 - - - - - - - Call/Send Control Optional Equipment - Call/Send Control Mounting Kit

Section 14 - - - - Maintenance and Service

Section 15 - - - - Electrical Drawings

See User Manual - - - - Features

- - - - Operation

- - - - Emergency Operation

- - - - Specifications

- - - - Troubleshooting

- - - - Main Component Drawings and Overall Dimensions

- - - - Warranty

SECTION 1 - SYMBOLS, SAFETY AND WARNINGS

SYMBOL MEANINGS

This is the WARNING symbol. This symbol may appear in various colors and in conjunction with other symbols.

The WARNING symbol indicates a failure to obey that safety warning could result in property damage, damage to

equipment, serious personal injury or death as well as the serious personal injury or death of others.

This is the NOTE symbol. This symbol may appear in various colors and in conjunction with other symbols. This

indicates a failure to obey all notes could result in improper operation, less than optimum VPL performance, and at the

sole discretion of the VPL manufacturer, may void your warranty.

SAFETY WARNINGS: The safety warnings throughout this manual are for the protection of people and

property. Failure by any operator to obey all VPL safety warnings will result in a waiver of all liabilities, loss of

your warranty and could result in equipment damage and or failure, injury to property, risk of serious bodily

injury, and or death.

Page | 4

Page 5

Observe and avoid all pinch points.

Whenever not actively using the VPL, turn keyed power switch to “OFF” position and remove key.

Always unplug VPL from electrical outlet before cleaning. Only plug VPL back in when area around VPL is dry.

Never operate VPL with damaged electrical wires, cords, or plugs.

The AC electrical plug on this VPL is grounded and intended to be used only with a properly grounded AC outlet. Do

not remove ground pin from AC power cord. If ground pin is broken or missing, immediately contact your dealer to

schedule repairs.

Stop using VPL and immediately and contact your dealer for inspection and service if any defect is suspected.

Do not tamper with or attempt to modify the VPL or any of its systems.

Use VPL only with a qualified helper, if required.

Do not use the VPL to support, attach, or hang planters, baskets, lights, adornments, decorations, clothing, fabrics

or other ornamentals or furnishings.

Components inside the tower must be serviced by a qualified technician. Contact you dealer to schedule

inspections, repairs or service.

Periodic inspections by a qualified technician are recommended to help prevent unsafe conditions.

The VPL’s electrical cord must be routed and situated in a manner that poses no hazards. Do not lay power cords

on or across electrically conductive materials, such as metals and always route power cords in such a manner so no

one can trip over them and that they are not exposed to risk of accidental or incidental damage.

Before and during VPL operation, ensure all hair, jewelry, shirts, ties, shoe laces and all other forms of clothing and

other personal ornamentation are-not and do-not hang up on anything that may create a hazard.

Correct installation, proper use, and following of instructions and obeying safety warnings and of the VPL are

necessary for safe operation.

If service outside the guidelines of this manual is required, please contact your dealer for additional information,

for replacement labels and manuals or to schedule any needed inspections, repairs or service.

VPL must be anchored to a concrete slab before operating the VPL while it is occupied. Using the VPL while

occupied before installation can be hazardous.

Maintaining all labels and manuals in legible condition is required by the VPL owner and is essential for safe

VPL operation. The VPL comes with various product safety labels. Do not remove safety labels or devices. If

any labels are missing, damaged or become illegible they must be replaced. An illegible decal will fail to alert

individuals on or around the machine of a procedure or hazardous operating conditions. Contact your dealer for

additional information, replacement labels and manuals or to schedule inspections, repairs or service.

Illumination: VPL requires a minimum illumination at the landing edge of the floor with the landing door open of

not less than 50 Ix (5 fc).

Illumination of at least 100 lx shall be provided:

(a) at the drive unit in the location where periodic maintenance and inspection are required;

(b) on the carriage at the seat or platform surface and at the operating devices; and

(c) at the floor level of landing/loading points.

For proper warranty coverage, fill out and return the included warranty form.

Keep all panels and protective coverings in place.

The VPL warranty is not transferable.

Attempting to tamper with or modify any portion of the VPL will void your warranty.

Except as described elsewhere in this manual, maintenance must only be performed by qualified technicians.

Contact your dealer to schedule any needed maintenance, inspections, repairs or service.

Caustics, high alkaline detergents and solutions should not be used to clean aluminum.

Using this VPL for anything other than its intended purpose will void the warranty.

Page | 5

Page 6

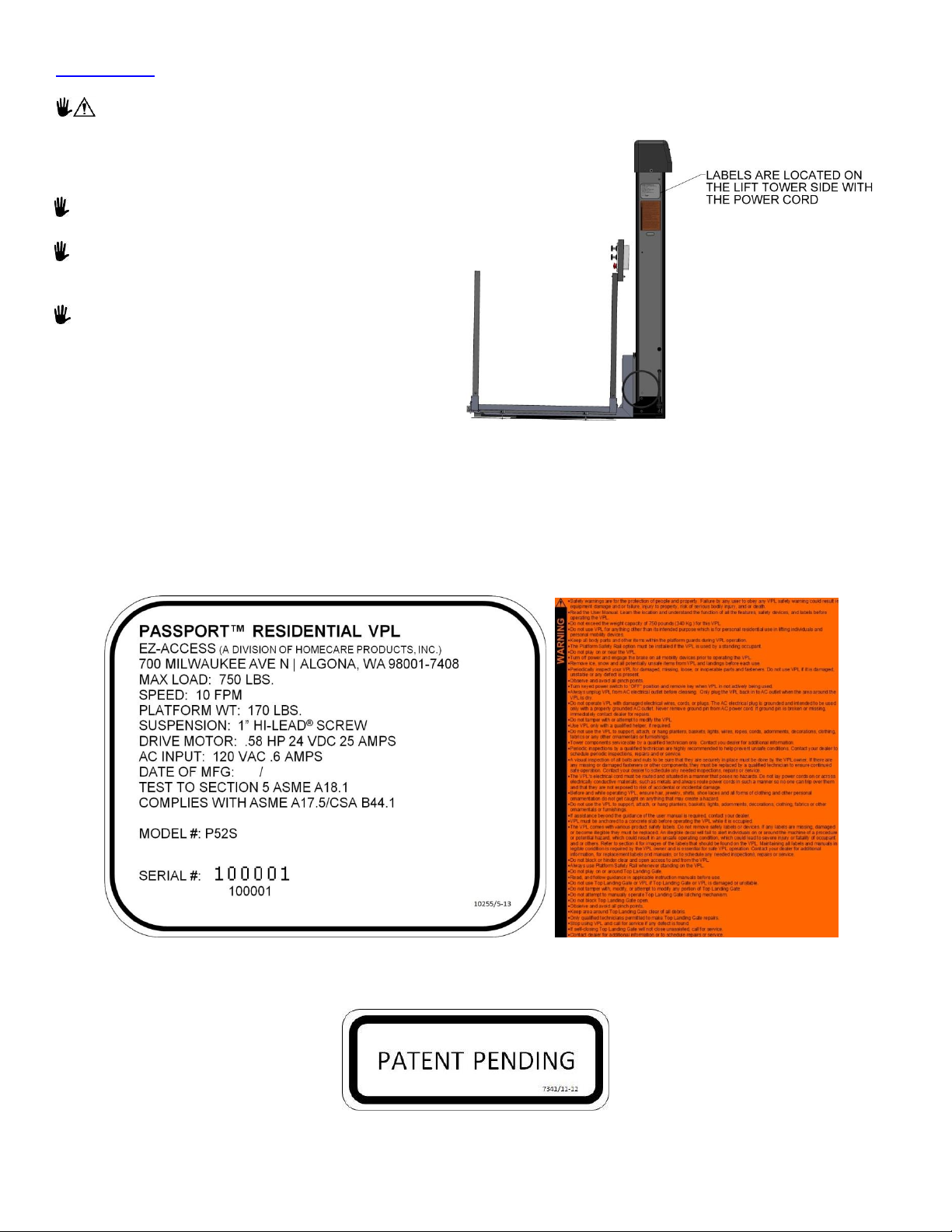

SECTION 2 – LABELING AND DEALER CONTACT INFORMATION

VPL Safety labels come pre-installed.

Each VPL should have labels positioned on the

The labels shown at right are for illustrative

FIG. 2.1

FIG. 2.2

FIG. 2.3

Insert image w/ Pat. Pen.

sticker

Assure all labels are present and legible.

FIG. 2.2 represents a typical VPL Serial Number Label. Assure the VPL Serial Number Label is present and

legible on each VPL. FIG. 2.3 is a condensed version of the VPL Standard Safety Label that comes on each

VPL. The VPL Standard Safety Label includes standard safety information as well as VPL Options safety

information. Your particular lift may, or may not, have these Options.

Page | 6

FIG. 2.4

Page 7

DEALER CONTACT

DEALER NAME:

ADDRESS:

TELEPHONE:

INTERNET:

If you need additional assistance, please or call one of the numbers below.

Customer Service: 1-800-451-1903 Technical Support: 1-800-332-1381 Internet: www.ezaccess.com.

Contact dealer with questions and for additional information.

SECTION 3 - OPTIONAL EQUIPMENT NOTICE

VPL OPTIONS ARE SOLD SEPARATELY. Options do not come with a Standard VPL, options must be

ordered separately.

Page | 7

Page 8

SECTION 4 - ASSEMBLING THE VPL

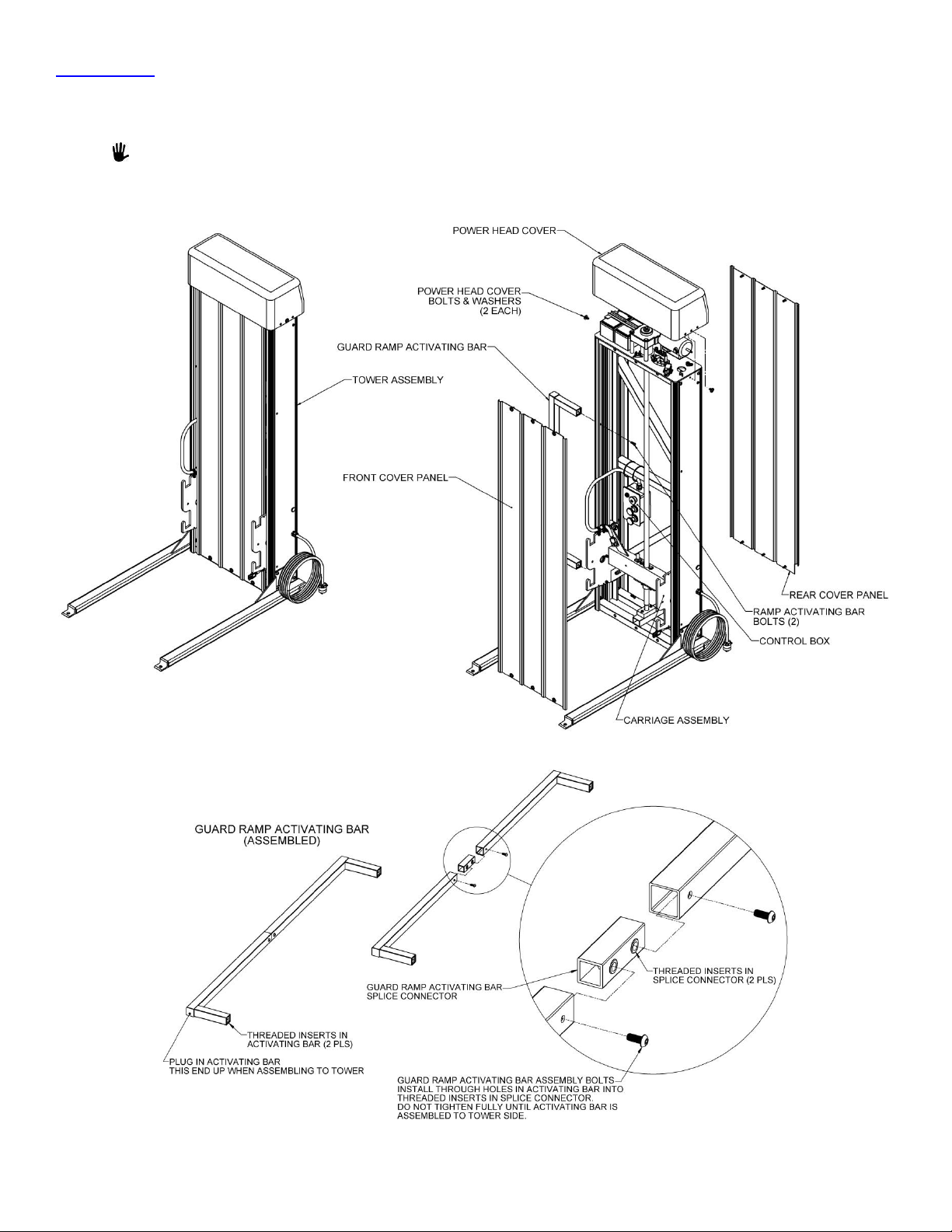

FIG. 4.1

FIG. 4.2

1. Remove the power head cover first by removing the two button head bolts on either end (FIG. 4.1).

2. Remove front and rear tower covers.

The fully assembled VPL net weights are approximately PL52SP3651 - 384 lbs (175 kg),

PL52TP3860 - 376 lbs (171 kg), PL72SP3651 - 415 lbs (189 kg), PL72TP3860 - 407 lbs (185 kg).

For ease, assemble VPL a few inches away from its final position and reposition as required.

Page | 8

Page 9

3. The guard ramp activating bar is shipped with the platform. Locate the guard ramp activating bar splice

FIG. 4.3

connector and the 5/16”-18 x 1” long assembly bolts in the hardware bag then assemble the guard

ramp activating bar as shown in FIG. 4.2. Do not tighten the assembly bolts fully until after the

activating bar is attached to the tower.

4. Determine which side of the platform will have the guard ramp and attach the guard ramp activating bar

in the two open holes on the corresponding side of the tower using two 5/16”-18 x 1” long attachment

bolts. The guard ramp activating bar must always be installed on the same side as the guard ramp

(FIG. 4.1). Tighten all fasteners, including the splice connector bolts, securely.

The 90° Turn Platform guard ramp activating bar extends further from the tower than the Straight

Platform guard ramp activating bar. The extension for the Straight Platform is approximately 7-7/8”

and approximately 12-3/8” for the 90° Turn Platform. The correct guard ramp activating bar must be

used with its intended platform for the guard ramp to operate correctly.

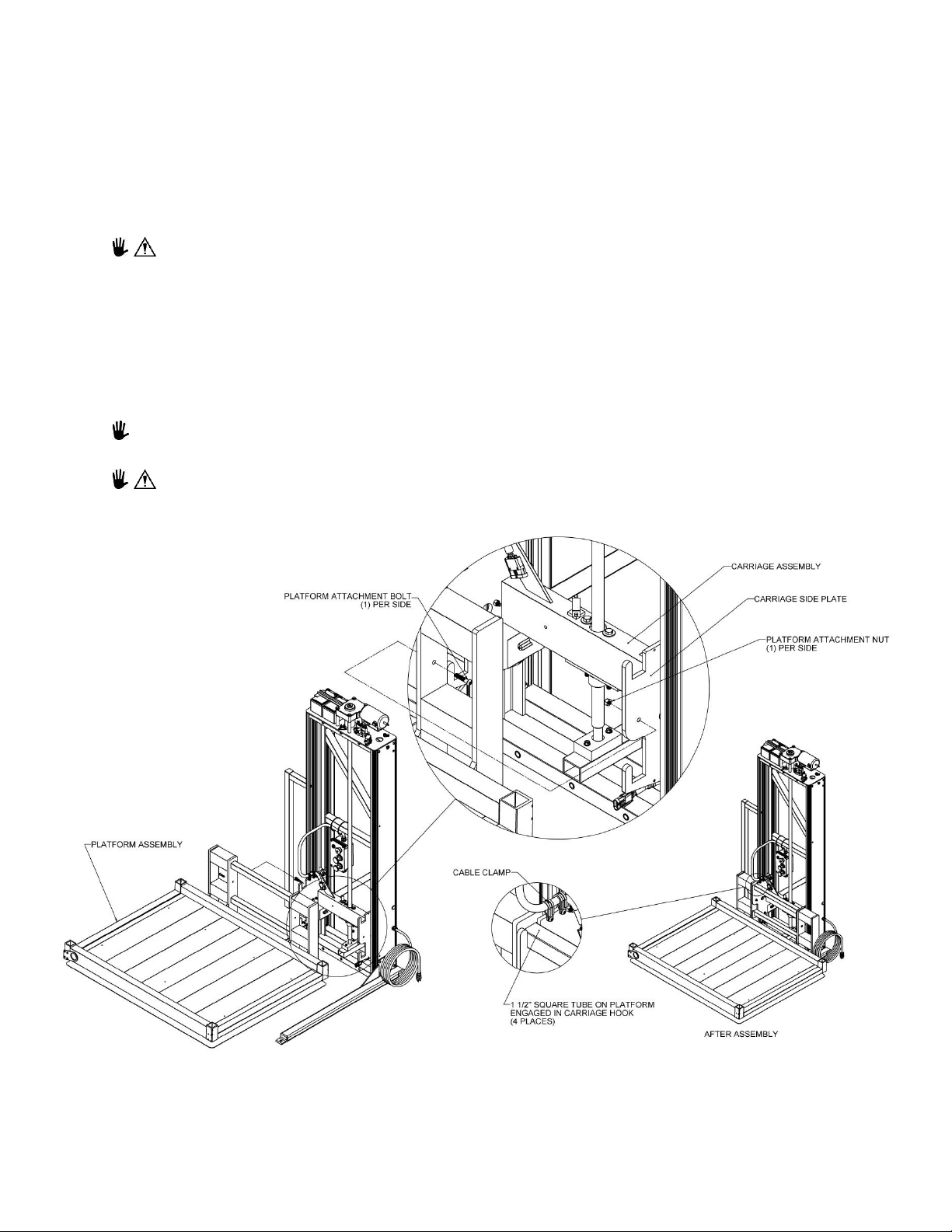

5. Lift the platform assembly onto carriage engaging both 1½” square tubes on the platform to the

corresponding hooks in the carriage. Locate the two 5/16”-18 x 1-1/2” attachment bolts and locknuts in

the hardware bag and install through the mating holes in the platform assembly and the carriage side

plate then tighten securely (FIG. 4.3).

The outer cable clamp holding the control box wire bundle may need to be removed from the

carriage to fully engage the platform tubes.

Never lift or carry the platform using the safety pan. Damage to the safety pan sensors can occur

rendering the lift unsafe or inoperable.

Page | 9

Page 10

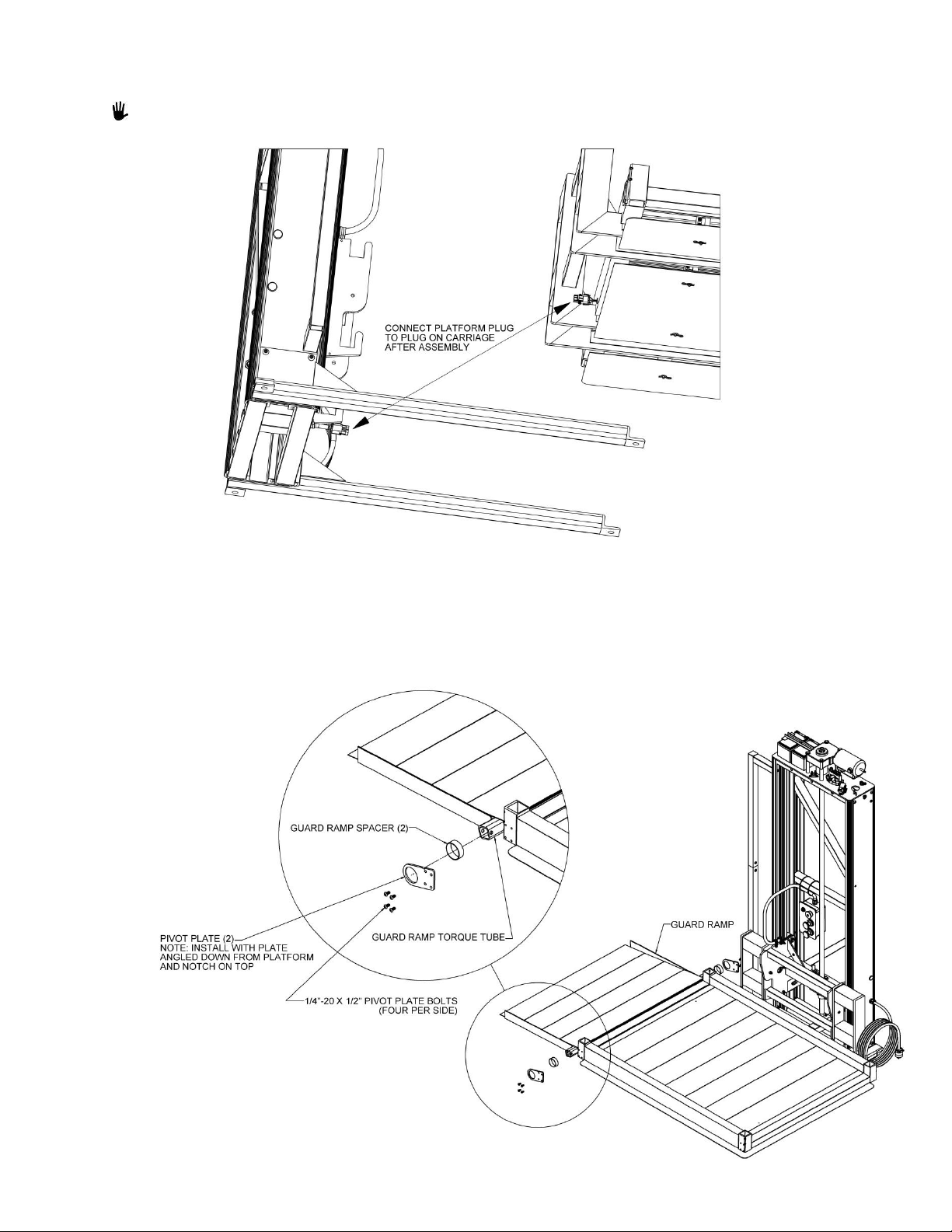

6. Locate the wiring connector protruding from the back of the platform and attach to the corresponding

FIG. 4.4

FIG. 4.5

connector on carriage (FIG. 4.4).

If installing a 90° Turn Platform, skip to Step 13 after connecting platform plug.

7. Locate the guard ramp (included in the box with the platform), the guard ramp pivot plates, the 1/4”-20 x

1/2” pivot plate attachment bolts and guard ramp spacers (included in the hardware bag) then slide the

pivot plates and spacers over the ramp torque tubes as shown (FIG. 4.5).

Page | 10

Page 11

8. Position the guard ramp with pivot plates on the entry side of the platform and secure both pivot plates

FIG. 4.6

to the platform with the 1/4”-20 x 1/2” pivot plate attachment bolts (FIG. 4.5).

9. Install the pivot arm assembly (included in the box with the platform) by first locating the 5/16”-18 x 2”

hex bolt and locknut included in the hardware bag (FIG. 4.6).

a. Slide the pivot arm into the torque tube on the guard ramp until the bolt hole in the torque tube

aligns with the hole in the pivot arm which centers the roller under the guard ramp activating bar.

There are two bolt holes in the pivot arm. One should center the roller under the guard ramp

activating bar for the Straight Platform and the other for the 90° Turn Platform.

b. Secure with the 5/16”-18 x 2” hex bolt and locknut installed in the orientation shown.

c. Verify that the roller is positioned beneath the guard ramp activating bar.

The roller will contact activating bar when operated. Avoid pinch points!

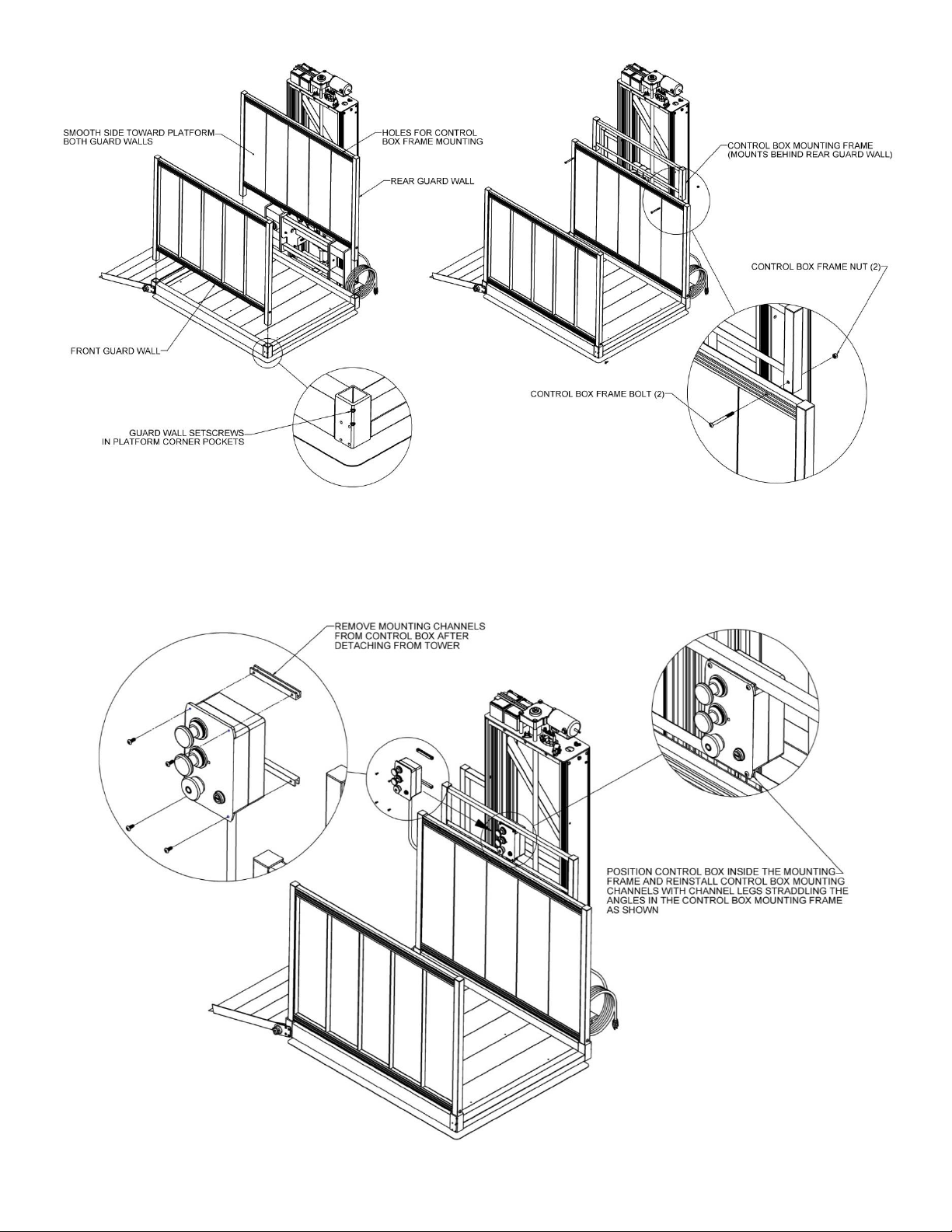

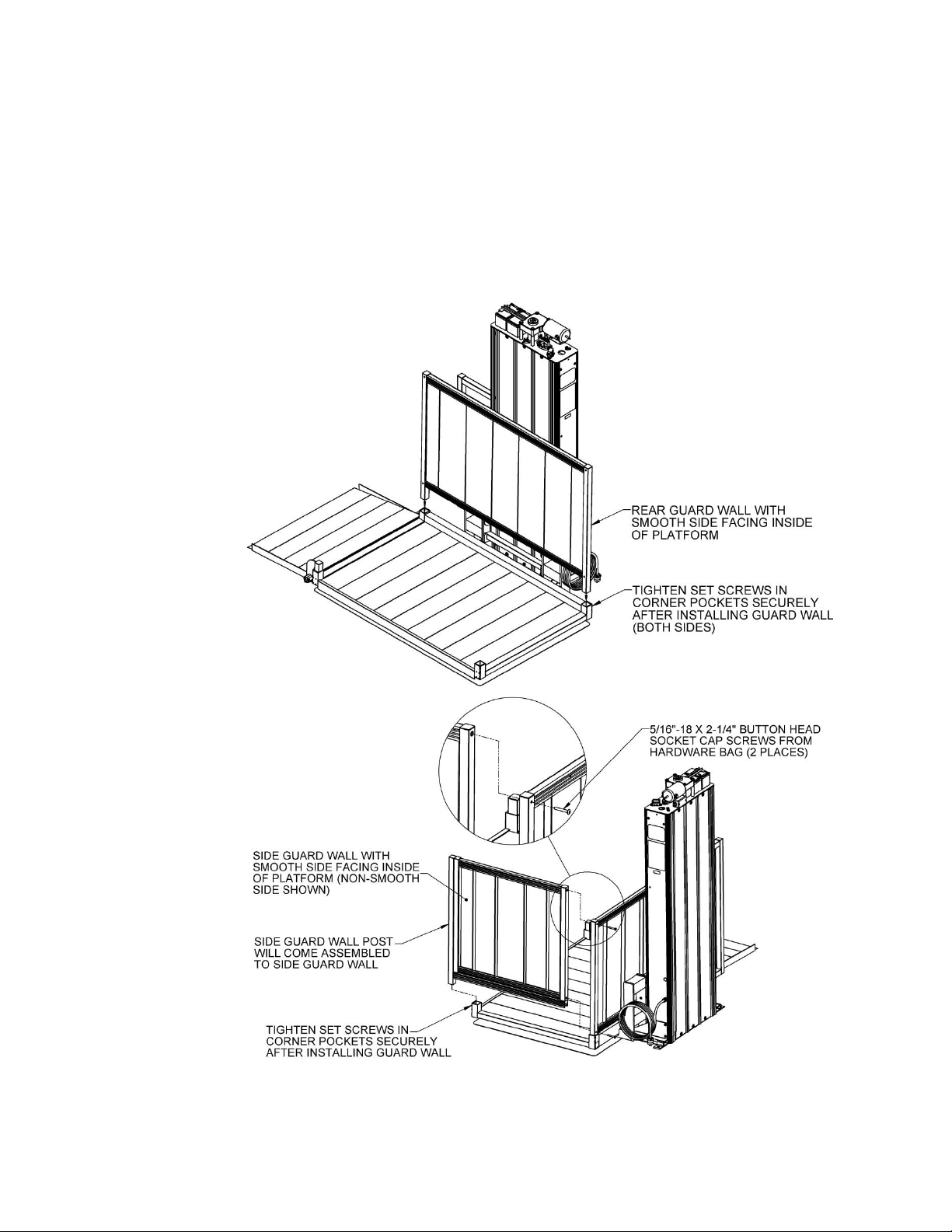

10. Install the guard walls with the smooth side toward inside of the platform as shown (FIG. 4.7).

a. Loosen the two set screws in each platform corner pocket as needed to fully engage the guard wall

posts and tighten all set screws securely after the guard walls are installed.

Make sure guard wall with two holes in top rail is installed closest to the tower as shown (FIG. 4.8).

Page | 11

Page 12

FIG. 4.7

FIG. 4.8

11. Install control box mounting frame to rear guard wall by first removing nuts and bolts from control box

FIG. 4.9

mounting frame posts (FIG. 4.9).

a. Install the mounting frame between the guard wall and tower with the nuts and bolts oriented as

shown and tightened securely.

Page | 12

Page 13

12. The control box is secured to inside of tower with zip ties. Locate and cut the zip ties to free the

FIG. 4.10

FIG. 4.11

control box (FIG. 4.9).

a. Remove fasteners securing mounting channels to control box.

b. Position control box into the mounting frame as shown and reinstall the mounting channels

using the fasteners removed in the previous step.

c. Check to make sure that the control box is free to slide entire length of mounting frame.

13. When assembling a 90° Turn Platform, one pivot plate is installed on the side closest to the lift tower

and a welded pivot plate assembly is installed in the opposite corner. After completing Steps 1

through 6 of this section, proceed with the following steps.

14. Determine the end of the platform where the Guard Ramp will be installed then locate the welded

pivot plate assembly (found in the hardware bag) and insert it in the corner pocket furthest from the lift

tower on that side until fully engaged and tighten the set screws in the corner pocket securely

(FIG. 4.10).

Page | 13

Page 14

15. Install the Guard Ramp by first inserting the outer torque tube into the hole in the welded pivot plate

FIG. 4.12

FIG. 4.13

assembly. Then install the pivot plate (found in the hardware bag) over the torque tube on the

opposite side and attach to the platform in the orientation shown using the four 1/4”-20 x 1/2” pivot

plate attachment bolts (FIG. 4.11).

16. Complete Step 9 of this section, installing the pivot arm assembly, before proceeding with guard wall

installation.

17. Install the rear guard wall with the smooth side toward the inside of the platform as shown (FIG. 4.12).

a. Loosen the two set screws in each platform corner pockets closest to the lift tower as needed to

fully engage the guard wall posts and tighten all set screws securely after the guard wall is

installed.

Page | 14

Page 15

18. The side guard wall will come with its post installed on one side. If the post is not on the side needed

for the smooth side to be installed toward the inside of the platform, disassemble the post from the

guard wall and reinstall on the opposite side before proceeding. Install the side guard wall with the

smooth side toward the inside of the platform as shown in FIG. 4.13.

a. Loosen the two set screws in the remaining open platform corner pocket as needed to fully

engage the guard wall post.

b. Align the threaded inserts in the side guard wall with the holes in the rear guard wall post and

install the two 5/16”-18 button head socket cap screws (included in the hardware bag) through the

rear guard wall post into the threaded inserts then tighten securely.

c. Tighten the platform corner pocket set screws securely after the side guard wall is installed.

19. The installation of the control box mounting frame and the control box is the same for the 90° Turn

Platform and the Straight Platform. Complete Steps 11 and 12 of this section before proceeding with

the next section, Confirm Basic VPL Operation.

Page | 15

Page 16

CONFIRM BASIC VPL OPERATION

20. The batteries are fully charged when VPL is shipped.

The batteries will maintain their charge for approximately two months under normal conditions.

21. The VPL can now be operated to confirm basic function.

Do not operate the VPL while occupied until it is anchored in place.

Since the cover panels have not been reinstalled, the lift mechanism will still be exposed at this

point. Be sure to keep all body parts and loose clothing, as well as other people and pets, clear of

the VPL to avoid potential injury.

22. Slide control box to one side so the VPL can be operated while standing on the ground.

23. Verify that the keyed switch on the control box is in the Power “OFF” position.

Do not plug VPL into 120 volt outlet at this time.

24. The VPL is shipped with the white wire which connects to the negative battery terminal disconnected.

Without standing on the platform, locate and reconnect the wire (there should only be one open

terminal on the batteries, see FIG. 4.14. The VPL should not operate when the wire is connected to

the battery as long as the keyed switch is the Power “OFF” position. However, in case of unexpected

operation, be sure you are positioned to prevent injury in case the VPL operates accidentally when

the wire is connected.

A small amount of sparking is normal when connecting the wire.

25. While standing on the ground, not on the platform, turn the keyed power switch to the Power “ON”

position. The power indicator on the control box should illuminate.

26. Press the UP button. The VPL should immediately operate in the upward direction. The UP indicator

should illuminate continuously. The Obstruction indicator will illuminate briefly until the platform has

traveled upward one or two inches then should go out.

27. Run the VPL up approximately 12” and release the UP button to stop upward travel. Press the Down

button. The platform should travel downward and the DOWN indicator light should illuminate

continuously. Continue to run the platform down until the VPL stops.

28. The VPL should stop at the bottom of its travel automatically. The Obstruction and the Enter/Exit

indicators should be illuminated when the platform reaches the bottom of its travel and stops.

29. Run the VPL up to about 12” again. Actuate the safety pan under the platform and press the DOWN

button simultaneously. The VPL should stop its downward travel and the Obstruction indicator should

illuminate. Release the safety pan and press the DOWN button again. The Obstruction indicator

should not be illuminated and the VPL should be able to continue downward operation.

30. If supplied with a Call/Send Control (optional equipment), operate VPL up and down about 12” a few

times using the Call/Send Control to verify proper operation.

31. Plug VPL into AC power, verify charger LED is illuminated. (FIG. 4.15 and FIG. 4.15A.)

Page | 16

Page 17

FIG. 4.14

FIG. 4.15

32. Turn the keyed master switch to the Power “OFF” position, remove key and disconnect VPL from AC

power.

33. Reinstall the back cover panel at this time.

FIG. 4.15A

THE VPL IS NOW READY TO SET IN PLACE - VPL PLACEMENT AND INSTALLATION:

IF USING THE VPL WITH A TOP LANDING GATE, PROCEED TO THE TOP

LANDING GATE INSTALLATION SECTION PRIOR TO PLACING AND

INSTALLING THE VPL.

34. Position the VPL in its approximate final position. The gap between the fascia and the edge of the

VPL platform is required by code to be between 3/8” and 3/4”.

35. Plug VPL into AC power, reinsert key into the keyed power switch and turn to the Power “ON”

position.

36. Run the VPL Platform up to the upper landing height. If supplied the optional Call/Send Control, use

the Call/Send Control to operate the VPL. If a Call/Send Control is not included, use a ladder or other

means to operate the control.

Do not operate the VPL occupied until it is anchored in place. Anchoring the VPL must be

completed before running occupied.

Page | 17

Page 18

37. Check for adequate running clearances. The platform must be able to travel up and down and the

FIG. 4.16

guard ramp must be able to fold and unfold without interference or obstruction.

38. Shim VPL legs as needed to fine tune level.

There is a one degree (1°) preload angle built into the VPL platform. Level the VPL using the tower

as plumb reference not the platform surface.

39. Anchor the VPL using four 1/2” Red Head® Trubolt® Wedge or Trubolt®+ Seismic Wedge concrete

anchors or equivalent (not supplied). Always follow the manufacturer’s instructions for proper

installation of concrete anchors.

Any portion of the anchor extending over 1/4” above the top of the leg must be cut off after

installation to avoid interference with the platform.

If using with a Top Landing Gate, it is recommended that the VPL not be shimmed or anchored

until the Top Landing Gate has been completely installed.

40. Once anchoring the VPL is complete, it can be operated safely while occupied for the remainder of

the installation.

41. The lower travel limit of the VPL is set at the factory and should not require adjustment.

42. Upper travel limit adjustment is factory set at the maximum height. Run the VPL upwards until the

platform stops and the ENTER/EXIT indicator illuminates.

43. Measure the vertical distance from the platform deck to the upper landing and record this dimension.

44. Lower the VPL past the upper landing.

Page | 18

Page 19

45. Locate the limit switch trigger on the upper right inside of the tower side. Place a mark on the tower

side aligned with one of the flat head adjustment screws on the limit trigger (FIG. 4.16).

46. Measures down from the mark on the tower side by the same dimension recorded in the previous

step and mark the tower at this point.

47. Loosen the two flat head adjustment screws in the limit switch trigger until the trigger moves but do

not remove them completely. Slide the limit switch trigger assembly down until the same flat head

screw where the upper mark was made is now aligned with the lower mark on the tower side.

Tighten the two screws.

48. Run the VPL Platform up until it stops and the ENTER/EXIT indicator is illuminated.

49. Check the height alignment between the upper landing and the platform deck and fine tune by

adjusting limit switch trigger up or down as needed. Final height should be set so the platform height

is approximately 1/4” above the landing height when the VPL is unoccupied.

50. Verify proper operation of guard ramp.

51. Double check to ensure the flat head screws on the limit switch trigger are securely tightened.

52. Replace the front tower panel followed by the power head cover.

Page | 19

Page 20

SECTION 5 - OPTIONAL EQUIPMENT - WIRELESS REMOTE

The Wireless Remote transmitter FOB allows remote operation of the VPL, from a suitable location.

The Wireless Remote option can be used in conjunction with the Call/Send Control option.

Additional FOB transmitters are available. Multiple FOB transmitters allow VPL operation from

various locations, for instance from a dry warm vehicle or from the comfort of your home.

Do not allow unauthorized persons to use the VPL or the VPL Wireless Remote transmitter FOB.

WIRELESS REMOTE COMPONENT LIST:

FIG. 5.1

FIG. 5.2

To prevent unwanted electrical discharge, always turn off VPL power, unplug VPL AC power cord, and

unplug White ground wire from battery before installing antenna.

FIG. 5.2 shows the Gama Receiver mounting location. Place the receiver on VPL lower rail as shown. Hold

receiver steadily and insert a marker into the holes where the two #8-32 Thread Cutting Screws will go and

mark the VPL frame.

Page | 20

Page 21

FIG. 5.3

FIG. 5.4

FIG. 5.5

FIG. 5.6

FIG. 5.7

FIG. 5.8

With the receiver properly grounded and secured, the VPL power (both AC and DC) disconnected you will now

install the antenna. First, drop the antenna cable down through the cable access port on the VPL FIG. 5.6.

FIG. 5.5 Location of Dual Lock, on the underside of the antenna.

Next, locate the Splitter FIG. 5.9

Page | 21

Page 22

FIG. 5.9

FIG. 5.10

Peel protective adhesive cover off of dual lock on antenna. FIG. 5.5. Press to stick the dual lock, with antenna,

in the location shown in FIG. 5.6.

Assure any excess antenna cable is neatly and securely stowed away from all VPL moving parts!

Always assure area around VPL is clear before activating the VPL by wireless remote, remote, or push

button.

Page | 22

Page 23

SECTION 6 - OPTIONAL EQUIPMENT – TOP LANDING GATE

Never use the Top Landing Gate for uses other than its intended function.

Do not modify the Top Landing Gate and latching mechanism.

Do not operate the Top Landing Gate latch manually while the VPL is in operation.

Never block the Top Landing Gate open or closed.

Keep the area around the Top Landing Gate free of debris.

Do not play on or around the Top Landing Gate or attach foreign objects to the Top Landing Gate.

Keep hands and other body parts clear of pinch points at all times.

Use only recommended fasteners and attachment points for anchoring the Top Landing Gate.

Call your dealer for service if the Top Landing Gate does not fully close unassisted and do not use Top

Landing Gate until repairs have been completed by a qualified technician.

PRIOR TO INSTALLATION:

Always plan for and layout the installation site before beginning an installation. Consider the direction of

the Top Landing Gate swing and the Top Landing Gate’s position on the porch or deck with respect to

where the VPL will be installed.

A smooth fascia panel is required to fill the area underneath the Top Landing Gate (between the porch

or deck and the ground). It is the installer’s responsibility to construct this fascia or confirm an existing

fascia meets building codes and reinforce structurally if needed.

Verify and follow all local codes and regulations regarding use of a Top Landing Gate with a VPL.

Confirm the structural integrity of the existing fascia and landing surface and reinforce as required to

support the Top Landing Gate.

Verify adequate clearances for the VPL user to maneuver between the Top Landing Gate and the door.

TOP LANDING GATE WITH 90° TURN PLATFORM:

When using a Top Landing Gate with a 90° Turn Platform, the gate latch must be on the same side as

the side guard wall. Determine which side the lift platform will be accessed from and which side will

have the side guard wall before ordering (FIG. 6.1B).

The Top Landing Gate will not span the entire length of a 90° Turn Platform at the upper landing. It is

the contractor’s responsibility to fill this area completely, making sure the side facing the lift is smooth,

and reinforce all existing handrails and guardrails structurally if needed (FIG. 6.1B).

ASSEMBLING THE TOP LANDING GATE

1. The Top Landing Gate is designed to work in conjunction with a VPL and will come factory assembled

with the hinges either on the right or the left (looking at the Top Landing Gate from the VPL side). Aside

from minor adjustments in the Top Landing Gate and latch height with respect to the sill, no assembly is

required.

2. Prior to installing the VPL and Top Landing Gate determine where the Top Landing Gate will be

mounted. If the porch or deck has a railing, remove a section at least 50” wide for the Top Landing Gate

installation. Pour a concrete slab for mounting the VPL below the removed section (Refer to Page 2 for

slab requirements).

Page | 23

Page 24

INSTALLATION:

FIG. 6.1A

FIG. 6.1B

Page | 24

Page 25

3. The area between the ground and the porch or deck where the VPL Platform will travel must be closed.

FIG. 6.2

Consult local building codes and close this area as required.

4. Install the VPL as described elsewhere in the manual. The side of the VPL platform adjacent to the

fascia must be between 3/8” and 3/4” of the porch or deck and the front or rear guard wall of the

straight platform or the side guard wall of the 90° Turn Platform must align with the latch roller on the

Top Landing Gate depending on which way the Top Landing Gate opens (FIG. 6.1A, 6.1B & 6.2).

5. Complete the remaining steps in Section 4, Assembling the VPL, Steps 33 through 51.

6. After completing the VPL installation, place the Top Landing Gate on the porch or deck and adjust its

position side to side until the front or rear guard wall of the platform aligns with the latch roller on the

Top Landing Gate without hitting the latch (FIG. 6.2). It is recommended that this be done with weight

on the VPL Platform approximately equal to the VPL user’s weight since the platform has a built in 1°

angle which may affect the alignment.

7. Once the Top Landing Gate is positioned correctly it can be attached to the porch or deck. The Top

Landing Gate will come with four 1/4” self-drilling screws for attaching the Top Landing Gate sill to the

deck surface and two 5/16”-18 x 4-1/2” long hex bolts for attaching the Top Landing Gate sill to the

deck fascia (FIG. 6.3). If the Top Landing Gate is being attached to a concrete porch or deck these

screws and bolts will need to be replaced with concrete anchors and alternate fasteners of the same

size (not included).

Follow the concrete anchor manufactures’ installation instructions when using concrete anchors.

Page | 25

Page 26

Page | 26

FIG. 6.3

FIG. 6.4

Page 27

8. Before connecting the Top Landing Gate cord, the VPL Platform must be set at the upper landing level.

Proceed with Steps 33 through 51 in Section 4 if not already complete. Connect the Top Landing Gate

cord to VPL by first removing rear cover. There will be a cord with a 4-pin connector inside the tower

located in the area where the power cord exits the tower. Bring this cord out of the tower and remove

the Top Landing Gate jumper plug from the connector. Connect the Top Landing Gate cord and tuck

the connected plug back inside the tower (FIG. 6.4).

There will also be a cord with a 3-pin connector in this area for connecting the Call/Send Control.

Leave this cord inside the tower unless installing a Call/Send Control.

9. Reinstall the rear cover with the notch in the lower right corner (looking at the back of the VPL).

10. Secure the Top Landing Gate cord to the porch or deck in such a manner that it will not interfere with

the VPL or Top Landing Gate operation or pose a tripping hazard.

11. Run the VPL Platform down below the landing by approximately 12”. Manually hold the Top Landing

Gate latch in the open position and depress the UP button on the control box simultaneously. The VPL

Platform should not operate and the Top Landing Gate indicator should be illuminated. Release the Top

Landing Gate latch. The Top Landing Gate indicator light should go off and upward travel should now

be possible.

12. Run the VPL several times through its entire travel limits. Make sure that the Top Landing Gate is

unlatched when the platform reaches the upper landing and stops. If the VPL Platform does not stop

level with the upper landing refer to the VPL Placement and Installation section and adjust the upper

limit accordingly. Also confirm the Top Landing Gate is latched when the platform travels in the

downward direction a maximum of 2” below the landing.

13. The Top Landing Gate will come preassembled with approximately a 1/2” gap between the bottom of

the Top Landing Gate frame and the sill. If needed, the Top Landing Gate can be adjusted up or down

to accommodate field conditions.

a. Loosen the two 5/16”-18 x 1/2” set screws in each hinge connector bar enough that the Top

Landing Gate will move but do not remove completely (FIG. 6.5).

b. Move the Top Landing Gate up or down to the desired location and retighten set screws securely.

It may be necessary to manually unlatch the latch and rotate it out of the way to move the Top

Landing Gate.

c. Loosen the two 5/16”-18 x 3/4” long button head socket clamp screws holding the latch mounting

clamp plate enough that the latch assembly will move but do not remove completely. It may be

necessary to manually rotate the latch out of the way to access the clamp screws.

d. Move the latch assembly up or down the same distance the Top Landing Gate was moved and

retighten the clamp screws securely. The ring magnet attached to the Top Landing Gate frame

should be just below the bottom of the latch mounting clamp plate after moving the latch

assembly.

e. Repeat Steps 10 and 11 to make sure the VPL Platform stops at the correct level and the latch

latches and unlatches in the specified travel distance. It may be necessary to fine tune the height

of the latch assembly to assure the magnets are activating the magnetic reed switches located on

the latch mounting clamp plate “inside” the latch post.

Page | 27

Page 28

FIG. 6.5

Page | 28

Page 29

SECTION 7 - TOP LANDING GATE OPTIONAL EQUIPMENT - PATHWAY CONNECTOR KIT

The Pathway Connector Kit,

pictured on the right, is an option designed to

quickly and easily connect a Top Landing

Gate to a Pathway platform handrail.

FIG. 7.1

FIG. 7.2

INSTALLATION:

1. The Pathway Connector Kit connects a gate post to a platform handrail post. It includes two 1-1/2”

diameter handrail tubes, two connector plates, two clamp plates, and the needed hardware (FIG. 7.1). If

connecting both gate posts to platform handrail posts, use two connector assemblies.

The 1-1/2” diameter handrail tubes are sized for the largest platform and must be cut to fit.

2. Install the Pathway Modular Platform in the desired location per the instruction manual included with the

system. Do not install a handrail on the side of the platform where the gate will be installed.

3. A smooth fascia panel is required to fill the area underneath the gate between the platform and the

ground. It is the installer’s responsibility to construct this fascia and confirm it meets building codes.

4. Place the gate on the platform and use the upper mounting holes in the gate sill as a template to drill

5/16” or 11/32” holes through the platform side rail (FIG. 7.2).

Page | 29

Page 30

5. Install the two 5/16”-18 x 4-1/2” long hex bolts through the sill and the platform side rail then secure with

FIG. 7.3

the lock nuts and washers provided.

6. Install the four 1/4” self-drilling screws through the sill and into platform walking surface.

7. Remove the post cap from the gate post where the connector will be installed.

8. Assemble one of the handrail tubes to a connector plate using two #10 x 1” long self-tapping hex

washer head screws.

9. Hold the connector plate with handrail tube against the outside of the gate post where it will be attached

and mark the handrail tube at the location flush with the platform handrail post.

10. Cut both handrail tubes to the length determined in the previous step.

11. If they were disassembled for cutting, reassemble the connector plate to the handrail tube and

assemble the clamp plate to the connector plate using two 5/16”-18 x 3/4” long button head socket

clamp screws through the larger holes in the connector plate and into the tapped holes in the clamp

plate. Do not tighten fully at this time. Orient the connector plate as shown in FIG. 7.3 with the clamp

plate below the handrail tube and toward the platform side of the gate post.

12. Slide the assembly into the back channel in the gate post closest to the platform post where it will

connect with the clamp plate inside the channel and the connector plate on the outside the post. Slide

down until the screw splines in the handrail tube align with the lower handrail holes in the platform post.

If the screw splines do not align vertically when appearing to align horizontally, the connector plate is

most likely assembled in the wrong orientation. Disassemble the connector plate and clamp plate and

flip the connector plate keeping the holes for the clamp plate below the handrail tube and reassemble.

13. Once the screw splines are aligned correctly use two #10 x 1” long self-tapping hex washer head

screws through the platform post to attach the open end of the handrail tube to the platform post and

tighten the 5/16”-18 x 3/4” long button head socket clamp screws securely.

14. Repeat the procedure for the upper handrail tube.

15. Reinstall the post cap and insert the 3/8” push in plugs in the open holes between the hex washer head

screws in the platform post (FIG. 7.3).

Page | 30

Page 31

SECTION 8 - TOP LANDING GATE OPTIONAL EQUIPMENT - DECK CONNECTOR KIT

FIG. 8.1

INSTALLATION:

1. The Deck Connector Kit can be used to tie the Top Landing Gate post to handrails or posts on an

existing porch or deck. Each Deck Connector Kit includes two clamp plates, two angle connectors and

attachment hardware (FIG. 8.2).

The figure only shows one of many possible orientations of the angle connector. The slots in the

angle connector allow great versatility in how the connector is used but it may still not be

appropriate in every situation.

Page | 31

Page 32

FIG. 8.2

2. Assemble the two 5/16”-18 x 3/4” long button head socket clamp screws through the slots in one leg of

the angle connector and into the tapped holes in the clamp plate.

The angle connector is symmetric, but do not tighten fully at this time.

3. Remove the post cap and slide the clamp plate into the one of the three channels in the “back” side of

the Top Landing Gate post closest to the rail or post where the connection will be made. The angle

connector should be on the outside of the post.

4. Slide the assembly down until the slots in the other leg of the angle connector are positioned where

they will be attached to the existing rail or post and use the slots as a guide to mark where the holes in

the existing rail or post will be drilled. Slide the assembly out of the way and drill 5/16” or 11/32” holes

through the existing rail or post in the marked locations.

5. Reposition the connector assembly to align the slots in the angle connector with the holes drilled in the

previous step then tighten the clamp screws securely. This should clamp the post wall between the

clamp plate and the angle connector holding the connector assembly in place.

6. Install the two 5/16”-18 x 2-1/2” long fully threaded button head socket cap screws through the slots in

the angle connector and the drilled holes and secure with lock nut and washer as shown in FIG. 8.2. If

desired, the cap screws can be replaced with lag screws (not included) when attaching to wood.

7. Repeat previous steps as needed with additional connectors.

Page | 32

Page 33

SECTION 9 - OPTIONAL EQUIPMENT - PLATFORM SAFETY RAIL

The Platform Safety Rail, pictured

at left, is required to be used by

anyone standing on the VPL.

FIG. 9.1

FIG. 9.2

The Platform Safety Rail is a required to be installed and used if anyone will be standing on the VPL.

When properly installed and used, the Platform Safety Rail option is designed exclusively for the

purpose of providing additional personal stability while standing on the VPL.

BEFORE YOU START:

1. The Platform Safety Rail can be installed on either the front or rear platform guard wall when used with

a Straight Platform (FIG. 9.2). Before installing the Platform Safety Rail determine which side will be

more convenient for the intended occupant’s particular situation. When used with a 90° Turn Platform,

the Platform Safety Rail can only be installed on the rear guard wall.

Do not install the Platform Safety Rail on the outside the platform guard walls. Install on the inside

(lift platform side) only.

Page | 33

Page 34

INSTALLATION:

FIG. 9.3A

FIG. 9.3B

DRAWING IN THIS SECTION TO REFLECT

REWRITE INSTRUCTIONS

DRAWING IN THIS SECTION TO REFLECT

REWRITE INSTRUCTIONS

For a Straight Platform, measure 3/4” in from the end of one guard wall post and make a mark. Now measure

2-1/2” down from the top of the guard wall post (excluding the plug) and mark. Find the location where the two

marks cross. Mark a location on the other guard wall post 2-1/2” down from the top of the guard wall post

(excluding the plug) and 48-5/8” away from where the two marks cross on the opposite post. Drill 3/8” diameter

holes through both posts at the marked locations (FIG. 9.3A).

For a 90°Turn Platform, measure 5-3/16” in from the end of one rear guard wall post and make a mark on the

rear guard top rail. Now measure 1” down from the top of the rear guard wall top rail and mark. Find the

location where the two marks cross. Mark a location on the other end of the rear guard wall top rail 1” down

from the top and 48-5/8” away from where the two marks cross on the opposite side. Drill 3/8” diameter holes

through the rear guard wall top rail at the marked locations (FIG. 9.3B).

Page | 34

Page 35

FIG. 9.4

FIG. 9.5

T-Handle Allen wrench or

similar tool

2. Install a round threaded insert into one end of each 1-1/2” diameter x 1-1/4” long tube. Use a rubber

mallet to make sure the threaded inserts seat fully into the tubes.

3. Hold one 1-1/2” diameter x 1-1/4” long tube with the threaded insert to the inside of the guard wall (the

tube will be oriented toward the guard wall post or top rail and the insert will be oriented toward the

other side of the platform). Install a 5/16”-18 x 3” long hex cap screw through the hole you previously

drilled and into the threaded insert and tighten securely. Refer to FIG. 9.4 for the correct orientation.

Repeat for the other guard wall post or top rail.

4. Locate the closure elbows and disassemble them by removing the elbow assembly screws and nuts.

Install the elbow halves without the threaded holes into both ends of the 1-1/2” diameter x 46” long

Platform Safety Rail tube. Make sure rounded side of the elbow halves are facing the same direction in

both ends then tighten internal set screws with a T-Handle Allen wrench or similar tool.

Page | 35

Page 36

5. Install the elbow halves with the threaded holes onto the portion of the 5/16”-18 x 3” long hex cap screw

FIG. 9.6

FIG. 9.7

“GRAB BAR”

which extends past the threaded inserts (shown in FIG. 9.4) and tighten securely. After tightening, the

rounded side of the elbow halves should be on the bottom facing the platform. It may be necessary to

loosen the hex cap screws holding the round tubes with the threaded inserts and rotate in one direction

or the other then re-tighten to get the elbows to end up in the correct orientation when fully secured

(FIG. 9.6).

6. Assemble the 1-1/2” diameter x 46” long Platform Safety Rail tube to the guard wall by reassembling

the elbows. Align the holes in the elbow halves and replace the center insert then insert the elbow

assembly screw through all the components on one side. Repeat on the opposite side. Place the elbow

assembly nuts on the screws and tighten securely (FIG. 9.7).

7. Check to ensure the Platform Safety Rail is properly attached and secured. If needed, tighten internal

set screws, elbow assembly screws and 5/16”-18 x 3” long hex cap screws.

Page | 36

Page 37

SECTION 10 - OPTIONAL EQUIPMENT - PLATFORM SAFETY PAN WEATHER GUARD

The Platform Safety Pan Weather Guard

option, pictured to the right, is made of durable

EPDM materials and installs quickly by simply

clipping onto the Safety Pan.

FIG. 10.1

FIG. 10.2

INSTALLATION:

1. Begin at the rear (closest to the lift) and adjacent to one of the outer carriage arms (FIG. 10.2).

2. Orient the Platform Safety Pan Weather Guard with the flap pointing up toward the platform and firmly

Page | 37

press onto the outer edge of the safety pan until fully engaged.

The Platform Safety Pan Weather Guard may not hold on the safety pan unless fully engaged.

3. Continue pressing and forming the Platform Safety Pan Weather Guard around the edge of the safety

pan until it reaches the carriage arm on the opposite side and trim off the excess.

4. Use the extra piece to fill the area between the two inner carriage arms and trim as needed.

5. Run the lift up and down a few times to confirm that the Platform Safety Pan Weather Guard is not

interfering with the operation of the safety pan or contacting the legs.

Page 38

SECTION 11 - OPTIONAL EQUIPMENT - INTERLOCK

FIG. 11.1A

FIG. 11.1B

Item

Qty.

Description

1

1 ea.

Porta Electric EMDL 06 door

interlock.

2

1 ea.

14 ft. of 18/4 SOOW cord with a

Metripack-150 4-pin female

connector and a ¼” male spade

connector on the red wire.

3

1 ea.

65” of red 16 gauge wire with a

16-14 gauge ¼” female spade

connector on one end. The

opposite end has a 14-16 gauge

butt-splice joining it to a 12 gauge

inline fuse holder with five-amp

automotive-style blade fuse. The

opposite end of the fuse holder

terminates with a 12-10 gauge x

5/16” ring terminal.

4

5 ea.

4” zip tie.

5

1 ea.

16” piece of black 16 gauge wire

with a 16-14 gauge ¼” ring

terminal on one end and a 16-14

gauge ¼” male spade connector

on the opposite end.

FIG. 11.2

Refer to the Porta Electric Door Lock (6-position) Installation instructions that came with your Porta Electric

Door Lock for Interlock

A VPL altered to operate with an Interlock, will not operate correctly if electrically connected to a Top

Landing Gate.

When using an Interlock, the door must swing away from the lift regardless of where the hinges are

located.

Direction of door swing must be specified at the time you place your order for the optional Interlock.

Determine whether the door handle is on the left or right when looking at the door from the VPL platform

before ordering. FIG. 11.1 A & B illustrate the Right Hand and Left Hand Interlock.

INTERLOCK KIT CONTENTS:

Page | 38

Page 39

INTERLOCK ELECTRICAL CONNECTIONS:

Terminal

Terminal

Terminal

Terminal

Terminal

Terminal

1

2

3

4

5

6

Unused

Unused

White

Black

Green

Red

A = White

B = Green

C = Black

D = Red

FIG. 11.3

FIG. 11.4

FIG. 11.5

FIG. 11.6

INSTALLATION PREPARATION:

Strip the 18/4 SOOW cord to expose ½” of copper conductor (see FIG. 11.2 and 11.5). Remove the cover from

the Porta Electric EMDL 06 door interlock and connect the wires from the SOOW cord as shown in FIG. 11.3.

INSTALLATION:

1. Turn VPL Keyed Power Switch to the “OFF” position, remove key, and unplug VPL from AC power.

Failure to turn the VPL Keyed Power Switch to the “OFF” position and remove key and unplug AC

power cord could create a dangerous situation and result in equipment damage or failure, injury

to property, risk of electrical shock, risk of fire, risk of crushing injuries, risk of serious personal

injury, or death.

2. Remove the power head plastic cover. (FIG. 4.1).

3. Disconnect white 10 gauge ground wire from negative battery terminal (FIG. 4.9).

4. Leaving control box connected, remove rear platform guard wall and set it on surface that will not

scratch the guard wall (FIG. 4.6).

5. Remove front and rear cover panels from lift tower. (FIG. 4.1).

6. Remove ½” nut from center stud on reversing relay. (FIG. 11.5).

7. Install 5/16” ring terminal on yellow wire with inline fuse holder over center stud. Replace nut, tighten

securely. (FIG. 11.6).

Page | 39

Page 40

8. Route the red wire (attached to yellow fuse wire in FIG. 11.6) down through the cable access port (FIG.

FIG. 11.7

(Only use jumper without gate)

FIG. 11.8

FIG. 11.8a

FIG. 11.9

FIG. 11.10

5.6) and run parallel to the AC power cord down right side of lift tower behind wire hold-downs. (FIG.

5.7, 11.6). String red wire down to match the length of the other two plugs (FIG. 11.7).

9. Locate the 4-pin female connector on end of the rainbow ribbon cable near base of tower and remove

the gate bypass jumper (FIG. 11.7). Connect the 4-pin male connector end of 14’ SOOW cord to this

plug and join the single red wires with the attached 1/4” male and female spade connectors (FIG. 11.8).

Route cord out through notch in rear tower cover panel. (FIG. 11.8a).

10. From front side of tower, locate the blue wire from gate bypass switch (wire No. 4 on right side of

carriage) where it joins the black wire J3H from female 8-pin connector on left side of carriage and

disconnect the spade connector where the wires join. (FIG. 11.9).

11. Connect the male spade connector on the end of the 16” black wire with the 1/4” ring terminal on the

opposite end to the female spade connector on the blue wire disconnected in the previous step. (FIG.

11.10).

Page | 40

Page 41

FIG. 11.11

FIG. 11.12

12. Remove 1/4” nut & bolt attaching purple ground wire to upper left gusset on carriage. Slide 1/4” ring

terminal on other end of 16” black wire over bolt and reassemble so both purple and black wires are

grounded to carriage. (FIG. 11.11).

13. Secure the added wires to existing wires with the zip ties provided. Cut excess material from zip ties as

needed. (FIG. 11.12)

14. Reinstall the front and rear cover panels on lift tower.

15. Reinstall the rear platform guard wall.

16. Follow the Porta Electric EMDL 06 Door Interlock manufacturer’s instructions for the mounting and use

of the Interlock on an existing door.

17. Reattach the white 10 gauge ground wire to negative battery terminal.

18. Reinstall the plastic cover on power head.

19. Plug in AC power cord and turn the VPL Keyed Power Switch to the “ON” position.

TEST EXTERIOR DOOR INTERLOCK:

20. With door closed, operate lift through entire range of travel up and down. The door interlock mechanism

should only unlatch and allow door to open when lift platform is within 3” of threshold. The door must

also be closed and interlock latched for platform to descend more than 3” from the threshold.

Once modified to operate with an Interlock, the VPL will not operate correctly while

electrically connected to the Top Landing Gate.

Page | 41

Page 42

SECTION 12 - OPTIONAL EQUIPMENT - CALL/SEND CONTROL

Multiple Call/Send Controls

can be used with the VPL.

This allows you to “call” the

platform from multiple

locations. (FIG. 12.1)

From the bottom of the

stairs, or landing; simply

press the DOWN button and

the platform descends.

From the top landing, deck,

or porch; simply press the

UP button and the platform

ascends.

FIG. 12.1

FIG. 12.2

INSTALLATION:

1. Connect the Call/Send Control cord to VPL by first removing rear cover. There will be a cord with a

3-pin connector inside the tower located in the area where the power cord exits the tower. Bring this

cord out of the tower, connect the Call/Send Control plug and tuck the connected plug back inside the

tower (FIG. 12.2).

2. Reinstall the rear cover with the notch in the lower right corner (looking at the back of the VPL).

3. Mount the Call/Send Control securely using #10 bolts or screws (not included) in a suitable location

where it can be accessed easily by the VPL user.

4. Secure the Call/Send Control cord in such a manner that it will not interfere with the VPL operation or

pose a tripping hazard.

Page | 42

Page 43

SECTION 13 - OPTIONAL EQUIPMENT - CALL/SEND CONTROL MOUNTING KIT

FIG. 13.1

FIG. 13.2

The Call/Send Control Mounting Kit (FIG. 13.1) option contains the necessary hardware to quickly attach your

Call/Send Control of your Top Landing Gate post. Multiple Call/Send Controls can be used with your VPL.

Please contact your dealer if you are interested in this, or any other option. Or call 1-800-451-190

3, or visit us online at www.ezaccess.com.

INSTALLATION: OPTIONAL EQUIPMENT – Top Landing Gate Call/Send Control Mounting Assembly

1. The Top Landing Gate Call/Send Control Mounting Assembly mounts the Call/Send Control to the Top

Landing Gate post. It includes two mounting bars, one attachment bar and the needed hardware

(FIG.13.1). The Call/Send Control is ordered separately.

The Gate Call/Send Control Mounting Assembly must be installed on the latch mounting post in the

orientation shown (extending away from the gate on the same side as the gate latch bars). It cannot

be installed on the hinge side.

Page | 43

Page 44

2. Assemble the two mounting bars to the Call/Send Control using four #10-24 x 3/4” long button head

Do not operate VPL if the safety pan is malfunctioning.

socket cap screws and nylon locking nuts as shown in FIG. 13.2. Assemble the bars in such a

manner that the larger hole is on the gate side when mounted to the same post which contains the

latching mechanism.

3. Install two 5/16”-18 x 3/4” long button head socket clamp screws through the larger holes in the

mounting bars and into the tapped holes in the attachment bar but do not tighten fully at this time.

4. Remove the post cap.

5. Attach the Call/Send Control and mounting assembly by sliding the attachment bar into the channel at

the back of the latch mounting post while the mounting bars remain on the outside the post.

6. Slide the assembly below the upper gate latch bar and tighten the clamp screws securely. This

should clamp the post wall between the attachment bar and the mounting bars holding the Call/Send

Control in place.

7. Reinstall the post cap.

8. If not done so previously, bring the 3-pin connector out of the VPL tower in the same manner

described in the Call/Send Control section and connect it to the cord in the VPL tower.

9. Secure the Call/Send Control cord to the porch or deck in such a manner that it will not interfere with

the VPL or gate operation or pose a tripping hazard.

SECTION 14 - MAINTENANCE AND SERVICE

The Maintenance and Service information below is provided to give the installer a more complete

understanding of our VPL product.

1. Except as described elsewhere in this manual, maintenance must be performed only by qualified

technicians. Contact your dealer with questions or to schedule any needed inspections, repairs or service.

2. Annual inspections by a qualified technician are highly recommended to help prevent unsafe conditions

and operation. Contact your dealer with questions or for additional information, to request replacement

labels or manuals or to schedule any needed inspections, repairs or service. Contact your dealer with

questions, for additional information, to request replacement labels or manuals, or to schedule any needed

inspections, repairs or service, or call 1-800-451-1903, or visit us online at www.ezaccess.com.

There are two holes in the tower used for mounting the guard ramp activating bar which do not have

fasteners in them. This is normal since the guard ramp activating bar can be mounted on either side.

3. Keep the VPL platform free of debris. Sweeping to clear these areas regularly enough to prevent debris

accumulation is required. Wiping with a damp cloth should be sufficient for additional surface cleaning. If

needed, a soft brush with mild soap and water can be used on the platform and guard ramp surfaces.

Alkaline based detergents are harsh and should therefore not be used to clean your VPL.

4. If the platform and guard ramp surface are covered with frost, ice and or snow, remove frost, ice and or

snow before using the VPL.

Calcium chloride is often used to deice and prevent ice from forming on roads. Used properly, this may

be useful to help rid or keep your VPL platform free of frost, ice and snow.

If using a deicing or ice preventing agent, such as Calcium chloride, always check that the platform is

free of ice before using it. Calcium chloride may not always be effective in removing frost, ice and or

snow.

If the VPL was cleaned with soap, rinse all soap from VPL and let VPL dry before using.

Use extra caution while on the VPL platform and guard ramp surfaces are icy or wet.

If cleaning with water, turn “OFF” VPL and unplug the AC power before cleaning.

5. Periodically check and ensure that the safety pan under the platform moves freely up and down and is not

damaged. This is the built in safety device designed to detect obstructions under the platform and stop

platform downward motion.

Page | 44

Page 45

FIG. 14.1

GREASING THE HI-LEAD SCREW:

1. The Hi-Lead® Screw which drives the lift platform up and down must be lubricated at minimum once per

year or more frequently if the VPL is used in extremely hot or cold locations. Use Chevron Ulti-plex

®

Synthetic Grease EP, NLGI Grade 1.5, or equivalent. (FIG. 14.1)

Failure to use the correct grease and or keep the Hi-Lead® Screw properly lubricated can cause

equipment failure and will void the warranty.

2. Remove the power head plastic cover and either the front or rear cover panel of the lift tower. (FIG. 4.1)

The Hi-Lead® Screw is more easily accessed by removing the rear cover panel.

3. Use a brush or similar tool to work the grease into the screw threads and grease the entire Hi-Lead®

Screw (even the sections above and below where the carriage travels).

4. Move the lift platform up or down approximately 1 foot and grease the previously inaccessible area

where the carriage was located.

5. Cycle the VPL up and down a couple times to help spread the grease and apply additional grease to

any areas which appear ungreased.

6. Reinstall the protective cover panels and power head plastic cover and tighten all screws securely.

Page | 45

Page 46

SECTION 15 – ELECTRICAL DRAWINGS

Page | 46

Page 47

Loading...

Loading...