EZ-ACCESS PATHWAY 3G Assembly Manual

Manufactured in the USA

LIFETIME WARRANTY. Please register at www.ezaccess.com/warranty-satisfaction.

16397 REV 6-20-17

PATHWAY® 3G

Modular Access System

Assembly Manual

Click here to view detailed product descriptions and prices. Call 800-397-5899 to or

All text and images contained in this document are proprietary and may not be shared, modified, distributed,

Image shown with multiple ramp and

platform handrail options.

der today!

© EZ-ACCESS®, a division of Homecare Products, Inc. All rights reserved.

reproduced, or reused without the express written permission of EZ-ACCESS.

PATHWAY® 3G

Modular Access System

Assembly Manual

ATTENTION INSTALLER and END USER

• For residential use only!

• 1,000 Lb. weight capacity.

• Read this manual in its entirety, ensuring you understand all instructions and warnings prior to ramp

assembly and use.

• INSTALLER: Please leave this ASSEMBLY MANUAL with the end user.

• Please read and become familiar with the ‘MAINTENANCE AND SAFETY’ section of this manual.

• Fill out online warranty registration.

TOOLS TYPICALLY REQUIRED

1/2″

9/16″

5/16″

LEVEL

FILE

RUBBER

POWER

25’

#2

5/16″

SOCKET OR 1/2″ WRENCH

SOCKET OR 9/16″ WRENCH

SOCKET OR 5/16″ WRENCH

MALLET

DRILL

TAPE MEASURE

PHILLIPS HEAD SCREW DRIVER PLIERS

DRILL BIT (IF BRACE ASSEMBLIES ARE

USED)

5/32″

3/16″

BOX

HAMMER

1/4″

DIGGING

HACKSAW

ALLEN WRENCH (INCLUDED)

ALLEN WRENCH (INCLUDED)

KNIFE

MASONRY DRILL BIT (USED WHEN

INSTALLING TO CONCRETE PORCH, STEP, ETC.)

TOOLS (IF AN OBSTACLE NEEDS TO BE

REMOVED)

(FOR OPTIONAL HANDRAIL KITS)

VIEW PACKING LIST

Each ramp system is shipped with a packing list. Be sure to check that all items and tools are present before starting

installation.

SYMBOL MEANINGS

The WARNING symbol indicates a potentially hazardous condition/situation. The safety warnings

throughout this manual, and on your equipment, if any, are for the protection of people and property.

Failure by any operator to abide by safety warnings will result in a waiver of all liabilities, loss of your

warranty, and could result in equipment damage and or failure, property damage, risk of serious bodily

injury, and or death. The symbol may appear in various colors and in conjunction with other symbols and

with or without the written word “WARNING”.

The NOTE symbol indicates important information. Failure to obey all notes could result in improper

operation, less-than-optimum equipment performance, and at the sole discretion of the equipment

manufacturer, may void your warranty. The symbol may appear in various colors and in conjunction with

other symbols and with or without the written word “NOTE”.

Page 2 of 72

PROPER SET UP AND USE WARNINGS

Read and follow all labels, instructions, and warnings prior to assembly and use. To obtain a copy of

complete instructions and warnings, call customer service at 1-800-451-1903.

Use caution at all times. Proper maintenance and upkeep to the PATHWAY® 3G Modular Access System

and all PATHWAY® system components is vital.

The term “system” refers to the entire PATHWAY 3G Modular Access System, including any gates, stairs,

ramps, platforms, risers, handrails, supports, transition plates, landing pads, and any/all hardware and

components which are intended to be assembled on the PATHWAY 3G Modular Access System.

Regularly check that all parts are in good condition and check the system for damage. Ensure all fasteners

and locking mechanisms are in place and tightened. If any part of the system is damaged, loose, or

missing, DO NOT USE until system repairs can be made by a certified installer or other qualified person.

Do not walk, sit, stand, etc. on the system until the installation is complete.

Consult local building codes regarding securing system for wind loads.

Use system only with a qualified helper.

Keep the system clear of debris and clutter. Do not use if walking surface is unsafe.

Confirm the system is correctly leveled and positioned securely. Periodically check for ground shifts.

Metal conducts electricity. Do not use near exposed wiring or hang lights from system.

Never place anything on, under, or attach anything to system.

Only use components supplied or approved by manufacturer with system.

Do not sit, stand, or climb on guards, gates, or handrails.

Do not use handrails, gates, or any other part of the system, to support planters, decorations, etc.

Do not play on or around system, including, but not limited to, running, jumping, bicycles, scooters,

skateboards, etc.

Properly support and restrain system in transit or storage.

At all times, keep the system clear of dirt, leaves, and other debris that may accumulate on the surface.

Simply sweeping the system or using a garden hose will usually suffice, but, if needed, a damp cloth or

soft brush with soap and water can be used (avoid alkaloid detergents). Rinse well and use extra caution

when system surface is wet.

The system may be slippery when wet or icy.

If system surface is covered with ice and/or snow, DO NOT USE until accumulation is removed and the

tread surface swept clean. Please refer to ‘DEICING SECTION’ of this for more information.

Regularly check that all parts are in good condition and check the system for damage. Ensure all fasteners

and locking mechanisms are in place and tightened. If any part of the system is damaged, loose, missing,

or unstable DO NOT USE until repairs can be made by a certified installer or other qualified person.

For additional care, usage, or general safety information, please call 1-800-451-1903.

Page 3 of 72

TABLE OF CONTENTS

SECTION 1: BASIC SYSTEM COMPONENTS

IDENTIFYING COMPONENTS ......................................................................................................................... 5-11

SECTION 2

SECTION 3

SECTION 4

SECTION 5

SECTION 6

SECTION 7

SECTION 8:

SECTION 9

: PLATFORMS

INSTALL PLATFORMS ......................................................................................................................................... 12

INSTALL SUPPORT TUBES AND FEET AND ADJUST PLATFORM HEIGHT ...................................................... 13-14

CONNECT TWO PLATFORMS TOGETHER .................................................................................................... 14-15

PLATFORM RAMP TO RAMP 45° ANGLE ........................................................................................................... 16

8’ X 5’ TURN BACK PLATFORM .......................................................................................................................... 16

INSTALL UNIVERSAL ANGLE BRACE - PLATFORMS ............................................................................................ 17

INSTALL UNIVERSAL CROSS BRACE ................................................................................................................... 17

: RAMPS

CONNECT RAMP SECTIONS ............................................................................................................................... 18

INSTALL RAMPS ON PLATFORMS ...................................................................................................................... 19

ATTACH RAMP LEGS TO RAMPS: ................................................................................................................. 20-21

INSTALL UNIVERSAL ANGLE BRACE - RAMPS .................................................................................................... 21

INSTALL GROUND TRANSITION RAMP .............................................................................................................. 22

INSTALL A SINGLE RAMP RUN TO AN EXISTING STRUCTURE ............................................................................ 23

ANCHOR RAMP UPPER TRANSITION ................................................................................................................. 24

ANGLE RAMPS WITH RESPECT TO PLATFORMS, PORCHES, OR DECKS ............................................................. 25

: HANDRAILS

RAMP HANDRAILS ....................................................................................................................................... 26-27

FIELD CONVERT TWO-LINE RAMP HANDRAILS TO VERTICAL PICKETS ............................................................. 27

ASSEMBLE HORIZONTAL PICKET RAMP HANDRAILS ........................................................................................ 28

ASSEMBLE STANDARD PLATFORM HANDRAILS .......................................................................................... 29-30

INSTALL STANDARD PLATFORM HANDRAILS .............................................................................................. 31-32

CONVERT TWO-LINE PLATFORM HANDRAILS TO OTHER STYLES ..................................................................... 32

8’ X 5’ TURN BACK PLATFORM HANDRAILS (OPTIONAL EQUIPMENT) ....................................................... 32-34

45° ANGLE PLATFORM HANDRAILS (OPTIONAL EQUIPMENT) .................................................................... 35-41

: CLOSURES

SINGLE-LINE CLOSURE AND TOP RAIL ......................................................................................................... 42-45

TWO-LINE CLOSURE LOWER RAIL ..................................................................................................................... 46

VERTICAL PICKET CLOSURE ......................................................................................................................... 47-48

HORIZONTAL PICKET CLOSURE ................................................................................................................... 49-50

TURN BACK CLOSURES ................................................................................................................................ 51-53

: FINAL PLATFORM/RAMP STEPS AND CHECKS

SECURE RAMPS TO PLATFORMS ....................................................................................................................... 54

INSTALL RAMP HANDRAIL END LOOPS ....................................................................................................... 55-56

INSTALL RAMP HANDRAIL END CAPS ................................................................................................................ 57

INSTALL RAMP CORNER PROTECTORS .............................................................................................................. 57

TOUCH-UP ARCHITECTURALLY FINISHED HANDRAILS ...................................................................................... 57

FINAL CHECKS .................................................................................................................................................... 57

: OPTIONAL EQUIPMENT

RAMP SUPPORT – TOP ...................................................................................................................................... 58

RAMP LOWER TRANSITION ............................................................................................................................... 59

SINGLE BRIDGE PLATE ....................................................................................................................................... 59

LANDING PAD .............................................................................................................................................. 60-61

PLATFORM TIE STRAPS ...................................................................................................................................... 62

LIGHTNING GROUND ROD ................................................................................................................................ 63

TIE DOWN ................................................................................................................................................... 64-66

GATE ............................................................................................................................................................ 67-68

MAINTENANCE & SAFETY

PERIODIC MAINTENANCE & SAFETY ................................................................................................................. 69

: DE-ICING NOTES ............................................................................................................................. 69-70

Page 4 of 72

1. BASIC SYSTEM COMPONENTS

Because each ramp configuration will differ from one another, your system may or may not contain all these

basic system components. Identify your system components before you begin. Check which surface option and

handrail options are included.

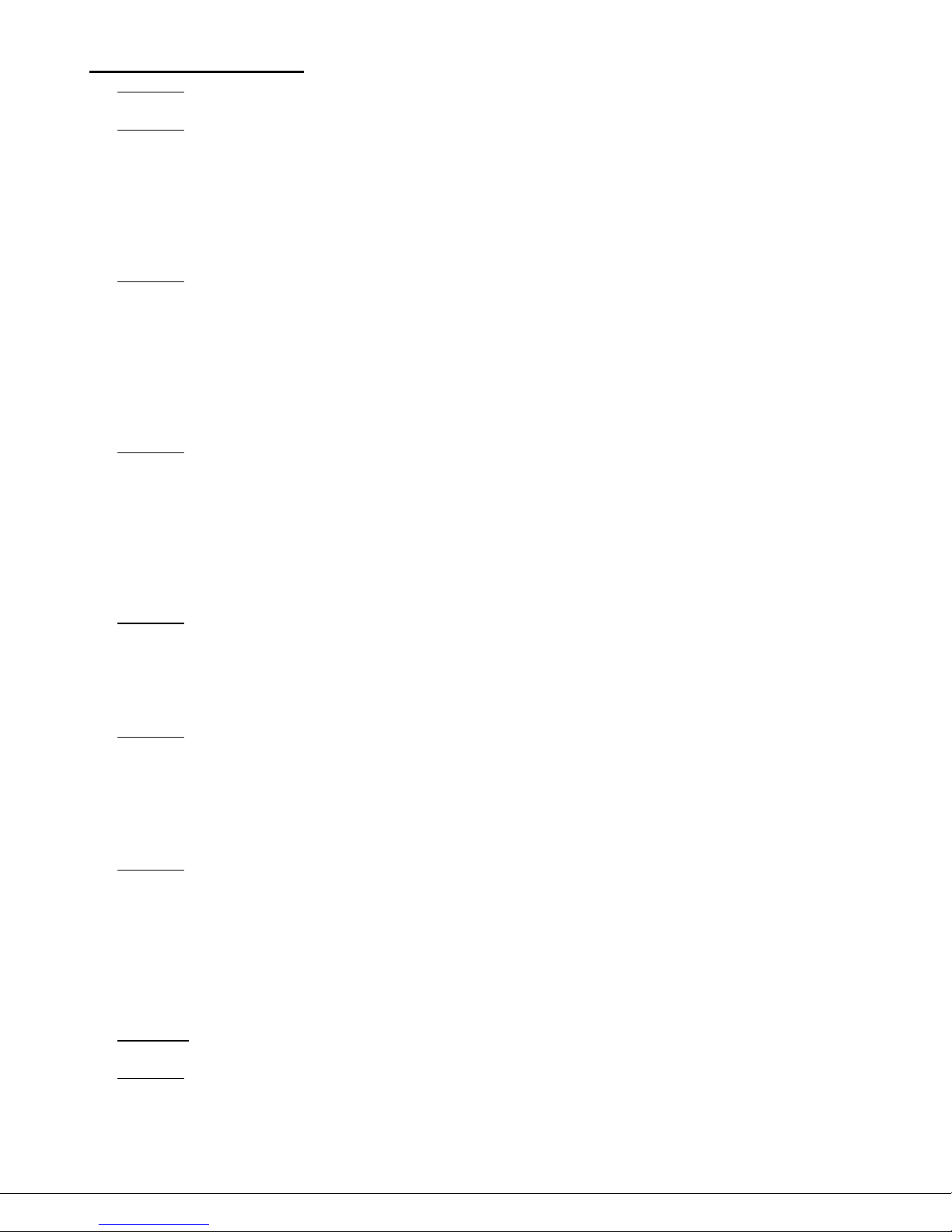

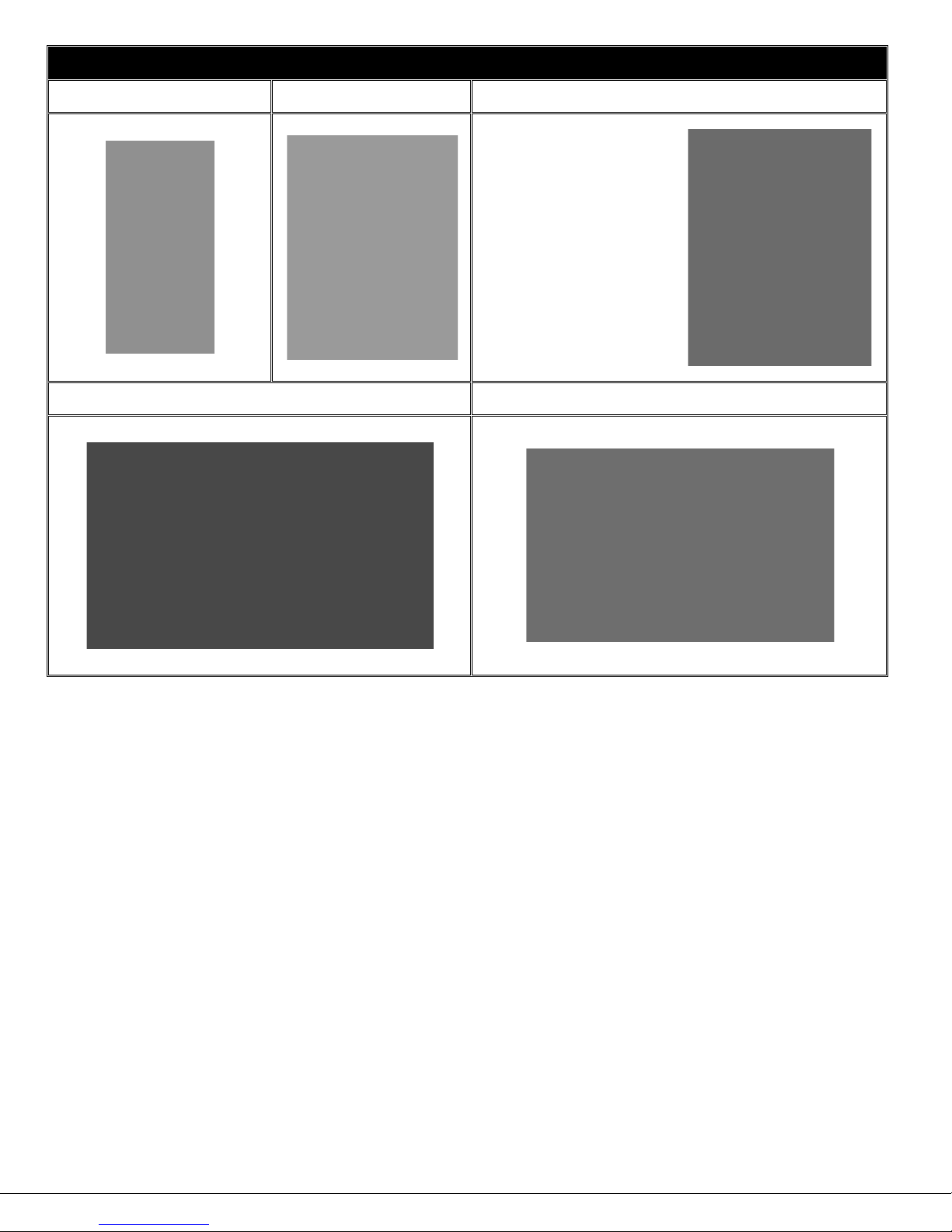

SURFACE OPTIONS

SOLID SURFACE EXPANDED METAL SURFACE PERFORATED SURFACE

RAMPS AND RAMP HANDRAIL OPTIONS

RAMP WITHOUT HANDRAILS RAMP* WITH SINGLE-LINE HANDRAIL

RAMP WITH TWO-LINE HANDRAIL RAMP* WITH VERTICAL PICKETS RAMP* WITH HORIZONTAL PICKETS

*RAMP OR PLATFORM NOT INCLUDED

Page 5 of 72

KEY RAMP COMPONENTS

XX DENOTES USABLE

INCLUDES

COMPONENTS TO

CONNECT RAMPS

AND RAMP

HANDRAILS

SHOWN ASSEMBLED

USED WHEN LEGS

SUPPORT UPPER OR

LOWER END OF

ONLY

PRLXXPR – RAMP LEG PAIRS

LENGTH (LENGTHS

AVAILABLE 10”

THROUGH 100" IN 6”

INCREMENTS)

RAMP GROUND TRANSITION 18” X 36”and 18” X 48”

PRGT & PRGT48

PRHBPR – RAMP HANDRAIL END BRACKET (PAIR) PRRC – CONNECTOR – RAMP TO RAMP

PRST - RAMP SUPPORT TOP PRHP - RAMP HANGER PAIR

RAMP

Page 6 of 72

KEY RAMP COMPONENTS, CONT’D.

INCLUDES RAMP

CORNER PROTECTORS

WITH THE

UPPER

LOOP, THE TUBE

WITH

ATTACHMENT

PLATE IS LONGER

THA

LOWER END

LOOP

WITH THE

LOWER

LOOP, THE TUBE

WITH

ATTACHMENT

PLATE IS

SHORTER

ON THE UPPER

END LOOP

PRHRLU- UPPER HANDRAIL END LOOP PRHRLL - LOWER HANDRAIL END LOOP

END

N ON THE

END

THAN

PRUT – RAMP UPPER TRANSITION PRLT – RAMP LOWER TRANSITION

PHREC - HANDRAIL END CAP

Page 7 of 72

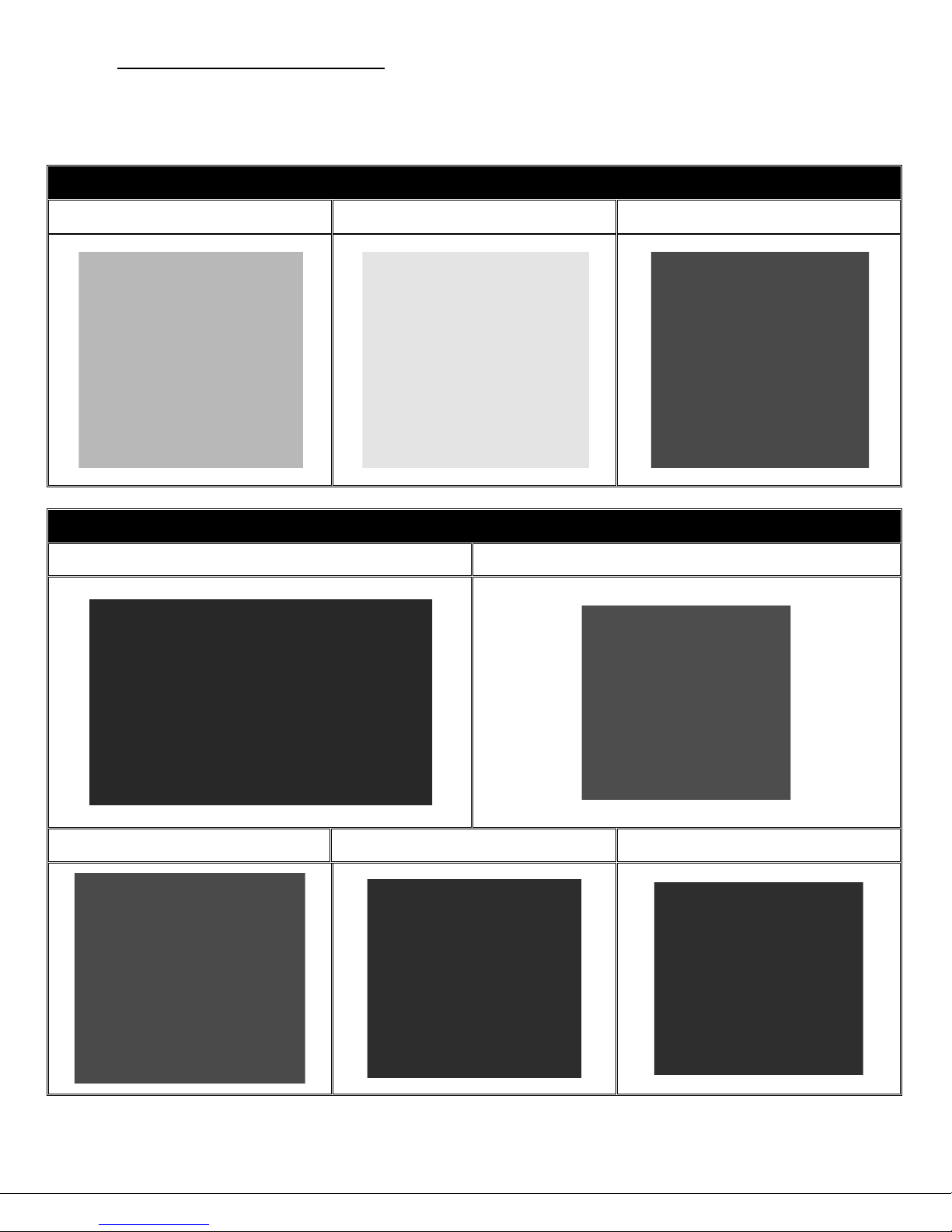

PLATFORMS AND PLATFORM HANDRAIL OPTIONS

PLATFORM (STRAIGHT CONFIGURATION) PLATFORM (TURN CONFIGURATION)

PLATFORM (8’ X 5’ TURN BACK) PLATFORM* WITH SINGLE-LINE HANDRAIL

PLATFORM* WITH VERTICAL PICKET HANDRAIL PLATFORM* WITH HORIZONTAL PICKET HANDRAIL

*RAMP OR PLATFORM NOT INCLUDED

Page 8 of 72

PLATFORMS AND PLATFORM HANDRAIL OPTIONS, CONT’D.

XX DENOTES

PLATFORM (45° ANGLE W/ TWO-LINE HANDRAILS) PLATFORM (45° ANGLE W/VERTICAL PICKETS)

45° Angle Platform not available with SINGLE-LINE or HORIZONTAL PICKET handrails

KEY PLATFORM COMPONENTS

PSTSXXPR – PLATFORM FEET & SUPPORT TUBE PAIRS PPPC – CONNECTOR – PLATFORM TO PLATFORM

USABLE LENGTH

(LENGTHS

AVAILABLE 10”

THROUGH 100")

PBP36, PBP48, PBP60 – BRIDGE PLATE PPTS – PLATFORM TIE STRAP

Page 9 of 72

CLOSURE OPTIONS

PPCSL – SINGLE-LINE CLOSURE HANDRAIL PPCTL – TWO-LINE CLOSURE HANDRAIL

PPCVP4, PPCVP5, PPCVP5

VERTICAL PICKET CLOSURE HANDRAIL

PPCHP – HORIZONTAL PICKET CLOSURE HANDRAIL

Page 10 of 72

ADDITIONAL OPTIONS

• PUCB4 USED

PTDK – TIE DOWN KIT PUAB – ANGLE BRACE PUCB4, PUCB5 & PUCB8 – UNIVERSAL CROSS BRACE

ON 4’

PLATFORM

SIDE

• PUCB5 USED

ON 5’ & 6’

PLATFORM

SIDES

• PUCB8 USED

ON 8’

PLATFORM

SIDE

PLP – LANDING PAD PUG36 – PATHWAY 3G GATE 36”

Page 11 of 72

2. PLATFORMS

FIG. 2.1

FIG. 2.2

FIG. 2.3

FIG. 2.4

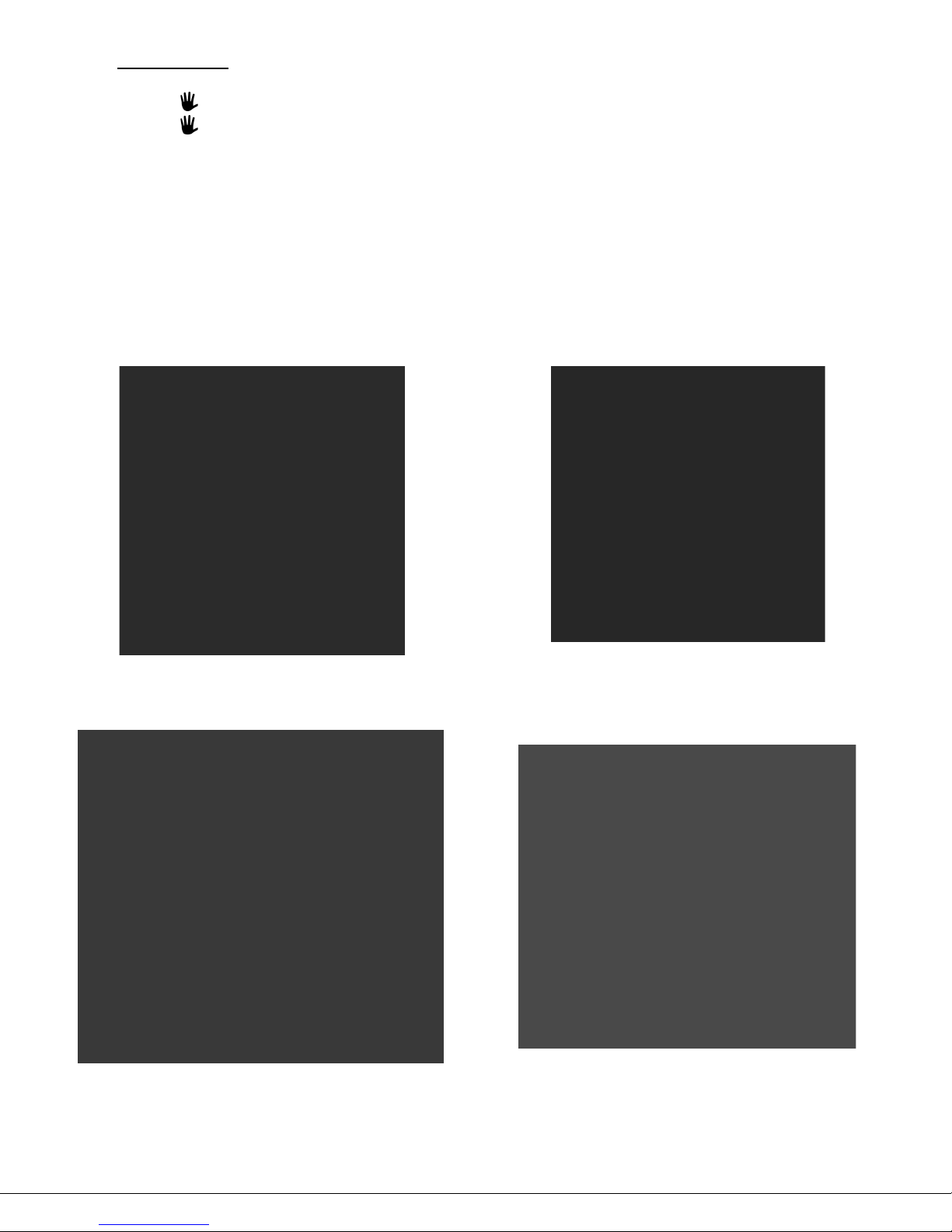

2.1. INSTALL PLATFORMS

If your system does not include a platform, skip to ‘CONNECT RAMP SECTIONS’.

Platform handrails are shown for clarity of how to orient platforms in various configurations. It

2.1.1. There are four basic platform arrangements (one or more of these platform arrangements

is strongly suggested that all platforms and ramps be installed before installing handrails (see

‘HANDRAILS’ section).

may be used in an installation). All four require the same procedure for assembly except for

FIG.2.3 which requires an additional PPPC (PLATFORM TO PLATFORM CONNECTOR).

FIG. 2.1 Platform in straight configuration.

FIG. 2.2 Platform in turn configuration.

FIG. 2.3 Platforms in turn back configuration (two 5' x 4' platforms shown

combined to make 5' x 8’ turn back).

FIG. 2.4 8’ x 5’ turn back platform.

Page 12 of 72

2.2. INSTALL SUPPORT TUBES AND FEET, THEN ADJUST PLATFORM HEIGHT

2.2.1. Support tubes, plugs, and feet come in pairs. Support tubes will come in lengths sufficient

for the heights at specific locations.

2.2.2. Loosen all set screws in the platform corner pockets.

2.2.2.1 The set screws on the outside of the platform are for the platform support tubes.

2.2.2.2. The set screws on the inside of the platform (one above the deck and one below

the deck) are for the handrail posts.

2.2.3. Tip the platform on its side, then slide the support tubes into the four platform corner

pockets. Adjust the support tubes to the approximate platform height needed (FIG.2.5).

FIG. 2.5

2.2.4. Use supplied 3/16″ Allen wrench to tighten the upper of the two set screws in the corner

pocket, just enough to hold the support tube in place but do not over tighten (the second

set screw will be tightened after final height adjustments are complete).

Platforms configured as a turn back platform (FIG. 2.3) will have six tubes to adjust.

Do not attempt to walk on the platform until all support tube set screws have been

tightened securely.

2.2.5. Place the platform (with support tubes attached) into the upright position.

Do not let the weight of the platform bear on the support tubes while tipping the

platform upright.

2.2.6. Lift each corner of the platform and install a base foot on each support tube oriented so

that the foot extends under the platform (FIG. 2.5).

The feet can be oriented in other directions if necessary due to site conditions but

may present a tripping hazard if not oriented under the platform.

Page 13 of 72

It is the installer’s responsibility to install the system in a manner which is safe for

the persons on and around the system and clearly mark any hazards created by the

installation.

2.2.7. Make sure the feet are fully engaged on the tubes and tighten the thumb screw on each

foot securely.

If installing on soft soil it may be necessary to set the base foot on a concrete pad.

2.2.8. Adjust the final height of the platform by adjusting legs, one at a time, by loosening the

outer set screws in the platform corner pockets. Using a level, adjust the platform height

and re-tighten.

2.2.9. Once the final height has been adjusted, tighten the second, lower set screw in each

platform corner pocket.

2.2.10. To allow access to the lowermost hole in the platform post, the support tubes must not

extend more than 1/2” above the platform corner pockets. Trim the support tubes as

needed before installing plugs.

2.2.11. Insert a plug into the top of each support tubes. Use a rubber mallet or similar tool as

needed (FIG.2.5).

2.2.12. Ensure all set screws are tightened securely.

2.3. CONNECT TWO PLATFORMS TOGETHER

2.3.1. Assemble the first platform as described in the previous steps except on the side where the

second platform will connect, install two PPPC (CONNECTOR – PLATFORM TO PLATFORM)

before installing feet onto the support tubes.

2.3.2. Make sure the platform connector set screws are oriented outward so they will be

accessible.

Any two platforms of the same width can be connected. However, two 5' x 4’

platforms are usually connected to make a turn back platform.

2.3.3. Slide the platform connectors up until they contact the bottom of the platform and tighten

the set screws securely (FIG. 2.6).

2.3.4. Install a support tube stub into the open pocket in each connector until the bottom of the

stub is flush with the bottom of the connector and tighten the set screws securely.

2.3.5. Install a plug in the top of each support tube stub.

2.3.6. Assemble the second platform as described in the previous section except only install

support tubes, plugs, and feet on the opposite side of where the platforms will connect

(FIG. 2.7).

2.3.7. Lift the second platform and slide the open corner pockets over the support tube stubs

extending up from the platform connectors. Tighten the set screws in the platform corner

pockets securely.

2.3.8. Adjust the platform heights and level as needed.

Make sure all the set screws in both the platform corner pockets and the platform

connectors are tightened securely before proceeding with the installation.

Page 14 of 72

FIG. 2.6

FIG. 2.7

Page 15 of 72

2.4. 45° ANGLE PLATFORM

This platform is used between two ramps to make a 45-degree turn and features a symmetrical design,

making it usable in either direction.

2.4.1. There are two options for 45° Angle Platform handrails, Two-Line and Vertical Pickets.

The platform includes the handrail components needed for the option ordered.

Platform handrails are shown for clarity of how to orient platforms in various

configurations. It is strongly suggested that all platforms and ramps be installed

before installing handrails (see ‘HANDRAILS’ section).

2.4.2. Set platform on one of the sides where the ramp will attach and install legs and feet and

adjust height as described previously in this section. The two legs on the short side must

be installed in the orientation shown (FIG. 2.8)

Use “low profile foot for platform heights under 4”.

It is sometimes helpful to lay platform on its side when inserting the legs.

2.4.3. Install ramps on both sides of the platform where there are no curbs. Refer to Section 3.2

for installing ramps on platforms and Section 4 for installing ramp handrails.

2.5. 8’ X 5’ TURN BACK PLATFORM

This platform is used to create a turn back (or switchback) instead of connecting two 5’ x 4’ platforms.

It includes two standard 5’ platform handrails and handrails for the 8’ side with a curb.

2.5.1. Install the support tubes and feet as described in the ‘INSTALL SUPPORT TUBES AND

FEET, THEN ADJUST PLATFORM HEIGHT’ section.

FIG. 2.8

Page 16 of 72

2.6. INSTALL UNIVERSAL ANGLE BRACE - PLATFORMS

For added stability, any platform with a walking surface over 36″ high requires bracing. The PUAB

(PATHWAY ANGLE BRACE) is used for surfaces 36″ up to 72″. Walking surfaces 72″ and higher requires

cross braces in addition to the angle braces.

2.6.1. Angle braces come in pairs. Use four pairs per platform (one pair per support tube, or

side) or six pairs when two platforms are connected.

2.6.2. Use two brace bands to secure the ends of the two angle braces nearest the twist to the

support tube using a 5/16" bolt, flat washer, and nut (FIG. 2.9).

2.6.3. Opposite ends of the braces are attached to the bottom of the platform side rail at 90° to

each other using a 1/4″x 1” long self-drilling screw (FIG. 2.9).

FIG. 2.9

2.7. INSTALL UNIVERSAL CROSS BRACE

2.7.1. Install UNIVERSAL CROSS BRACES on all support tubes when the walking surface is 72″ or

more above the ground. Cross braces are normally installed on all four sides (FIG. 2.10)

unless two platforms are connected.

2.7.2. Ensure that all cross braces are secured before using platform.

FIG. 2.10

Page 17 of 72

3. RAMPS

3.1. CONNECT RAMP SECTIONS

3.1.1. Place the walking surface side of the ramp sections face down, onto cardboard or lawn so

that the ramp is not damaged (scratched or dented).

When installing a single ramp section, skip to 'INSTALL A SINGLE RAMP RUN TO AN

EXISTING STRUCTURE’.

3.1.2. Butt the sections together end-to-end and ensure there is no gap, then position the two

center saddle brackets, included in the PRRC (CONNECTOR – RAMP TO RAMP), over the

threaded inserts at the end of each ramp section (FIG. 3.1).

3.1.3. One edge of the center saddle bracket will slide into the groove of the ramp sections.

To create a run, ramp sections are connected using two interchangeable center

saddle brackets per joint. The center saddle brackets are also where the handrails

and ramp legs are attached.

FIG. 3.1

(BOTTOM VIEW)

3.1.4. Attach the center saddle brackets using four each 5/16″-18 x 1-1/2″ bolts and 5/16″

washers per bracket. Tighten all eight bolts (four each per center saddle bracket).

Although a system can have multiple ramps per run, it is recommended that a

3.1.5. If necessary, install optional PRST (RAMP SUPPORT – TOP) at this time (see ‘OPTIONAL

EQUIPMENT’ section).

3.1.6. Locate PRHBPR (RAMP HANDRAIL END BRACKET PAIR). Install four end brackets (these

will be used to attach handrails in a later step). Use one end bracket at each outside

corner of the ramp or ramp run using one 5/16″ x 1-1/2″ bolt and washer into the

threaded insert closest to the end of the ramp (FIG. 3.2).

3.1.7. Turn the joined ramps to their upright position, being careful not to damage the threaded

studs.

FIG 3.2

(BOTTOM VIEW)

maximum of three ramp sections at a time be joined in this manner.

Page 18 of 72

3.2. INSTALL RAMPS ON PLATFORMS

FIG. 3.3

(TOP VIEW)

FIG. 3.4

(BOTTOM VIEW)

3.2.1. The following will address attaching a ramp or ramp run to a platform. If the ramp needs

to be angled with respect to the platform or is going to be attached to an existing porch,

skip to ‘ANGLE RAMPS WITH RESPECT TO PLATFORMS, PORCHES, OR DECKS’ in this

section.

3.2.2. Ramps are most commonly located toward either the left or right side of the platform or

centered but can be placed in any location on a platform side except when using a

‘VERTICAL PICKET CLOSURE’ (outlined in SECTION 5). When the ramp is located toward

the side of a platform, the ramp handrail post should be positioned 1-1/2” (minimum) to

2” from the inside of the platform post. When using other locations, a second closure

(Single-Line, Two-Line or Horizontal Picket) must be ordered to connect the ramp and

platform handrails. When centering ramps using a Vertical Picket Closure additional

components are needed. The additional components will come with the closure if

specified at the time of order. The closure can also be converted in the field by ordering a

second set of hardware.

3.2.3. Locate a PRHP (RAMP HANGER PAIR) and install the two hangers in the platform side rail

where the ramp will be attached.

3.2.4. Hold the hanger perpendicular (approximately) to the platform side rail then bring the

hanger upward until it is against the side rail lip. Rotate the hanger and continue pushing

upward in such a manner that the “hook″ at the top of the hanger goes behind and

catches on the lip in the top of the platform side rail and the hanger sits on the ledge at

the bottom (FIG. 3.3).

3.2.5. Set the ramp on the hangers. The hangers should be positioned as close as possible to the

ramp side rails. The procedure is the same at both the top and bottom of ramp runs

which end at a platform unless a transition plate is used (FIG. 3.4).

Do not attempt to walk on ramps until installation is complete.

Page 19 of 72

3.3. ATTACH RAMP LEGS TO RAMPS

3.3.1. Locate the appropriate PRLxxPR (RAMP LEG PAIR where “xx” denotes the leg length) for

the location. Insert the leg into a foot. Make sure the leg is fully engaged in the foot and

the foot will be oriented so it extends under the ramp once installed. Tighten the thumb

screw on each foot securely (FIG. 3.5).

If installing on soft soil it may be necessary to set the foot on a concrete pad.

FIG. 3.5

3.3.2. Place the slot in the ramp leg over the two shorter studs in the middle of the center

saddle bracket, install the support plate over both studs then install 5/16”-18 nylon insert

locknuts and 5/16” flat washers on each stud but do not tighten fully. Repeat on the

opposite side (FIG 3.5)

In situations where the lower end of a ramp or ramp run is too close to the ground

to install normal feet and feet are needed due to ground or other conditions, special

welded low profile feet (part no. PRLPRLP). are available (FIG 3.6).

3.3.3. Remove the 5/16”-18 nylon insert locknuts and 5/16” flat washers attaching the ramp

handrail post (if already installed), position the low profile foot so the foot is oriented

under the ramp and the channel leg wraps around the ramp post. Reinstall the locknuts

and flat washers, adjust height as described below then tighten fasteners securely.

Repeat on the opposite side (FIG. 3.6).

Page 20 of 72

FIG. 3.6

3.3.4. Adjust the ramp legs one at a time.

ADA guidelines call for a maximum slope of 1:12 (approximately 5°) and this is the

ideal slope for the PATHWAY 3G system. However, the ramps can be installed from

1:14 to 1:8 (approximately 4° to 7°). Do not attempt to install the ramps outside this

range.

NOTE if the ramp is installed at the maximum angle (approximately 7°) longer legs

may be required.

3.3.4.1. Raise the ramp sections (at the center saddle bracket) to take any sag

out of the ramp run, then tighten the two locknuts in each leg.

Adjusting sections can be accomplished by having someone sight down the ramp

while another person adjusts the ramp height.

It’s important to ensure that the ramp sections are parallel to each other. If they

are not, it may be difficult to install the handrails (FIG. 3.7).

3.3.4.2. Insert a plug into the top of each leg (FIG. 3.5).

3.3.5. Ensure that all bolts are tight and the ramp sections are aligned parallel to one another.

FIG. 3.7

Page 21 of 72

FIG. 3.8

INSTALL UNIVERSAL ANGLE BRACE - RAMPS

If the ramp walking surface is over 36″ high, a PUAB (UNIVERSAL ANGLE BRACE) must be installed

under the ramp (FIG. 3.8).

3.3.6. The opposite end of the angle brace is attached to the bottom of the ramp (near the

3.3.7. Ensure that all angle braces are secured before using the ramp.

center of the tread at the end of the ramp) using a 1/4″ x 1” long self-drilling screw.

Walking surfaces over 72″ or more above the ground require UNIVERSAL CROSS

BRACES in addition to the angle braces (see ‘INSTALL UNIVERSAL CROSS BRACE’

section). The process for installing cross braces to ramp legs and platform support

tubes is the same.

Page 22 of 72

Loading...

Loading...