Page 1

Thank you for choosing

EZ-ACCESS Modular Ramps.

Please visit

www.ezaccess.com

or contact us at 1-800-451-1903

for all of your ramping needs.

INSTALLATION GUIDE

© 2003-2009 HOMECARE PRODUCTS, INC. All rights reserved.

All text and images contained in this document are proprietary and may not be shared, modified, distributed, reproduced, or reused without

the express written permission of EZ-ACCESS, a division of Homecare Products, Inc.

6421 REV A 05-21-09

Proudly made in the USA

Patent Pending

Page 2

INSTALLATION GUIDE

FOR EZ-ACCESS® MODULAR RAMP SYSTEMS

15) FINAL CHECKS:

A) Ensure that all fasteners are in place and secure.

B) Walk on the assembled system, checking for any undue movement.

C) Remove any debris and metal chips.

D) Ensure that the level and slope has not shifted during installation.

E) Check that all handrail ends are covered (either with loops or with end caps).

F) CONGRATULATIONS! Your EZ-ACCESS

®

Modular Ramp System is assembled.

ATTENTION INSTALLER:

• 850 lb. weight capacity

• Read all instructions, including ‘PERIODIC MAINTENANCE AND SAFETY’, prior to

ramp assembly.

• Please leave INSTALLATION GUIDE with the end user.

ATTENTION END USER:

• 850 lb. weight capacity

• Please read and become familiar with the ‘PERIODIC MAINTENANCE AND SAFETY’

section of this manual.

• Fill out and return warranty information.

TOOLS TYPICALLY REQUIRED:

9 ½” SOCKET OR ½" WRENCH

9 9/16” SOCKET OR 9/16” WRENCH

9 5/16” DRILL BIT (IF BRACE ASSEMBLIES ARE USED)

9 ⅛" DRILL BIT

9 5/16” MASONRY DRILL BIT (USED WHEN INSTALLING TO CONCRETE PORCH, STEP, ETC.)

9 5/32” ALLEN WRENCH (SUPPLIED AS NEEDED)

9 3/16” ALLEN WRENCH (SUPPLIED AS NEEDED)

9 #2 PHILLIPS HEAD SCREW DRIVER

9 BOX KNIFE

9 25’ TAPE MEASURE

16) PERIODIC MAINTENANCE AND SAFETY:

A) Caution should be used at all times. Proper maintenance and upkeep to the ramp

surface is vital.

B) IMPORTANT: USE ONLY WITH A QUALIFIED HELPER.

C) Always use your lap belt.

D) It is important that you refer to your equipment’s Owner Guide for the proper

degree of incline/decline and chair direction before attempting ramp use. Never

exceed its recommendations.

E) Periodically check and tighten any loose fasteners to ensure safety.

F) At all times, keep the ramp clear of dirt, leaves, and other debris that may

accumulate on the surface. Simply sweeping the ramp or using a garden hose

will usually suffice, but, if needed, a damp cloth or soft brush with soap and water

can be used (avoid alkaloid detergents

). Rinse well and use extra caution

when the ramp surface is wet.

G) If ramp surface is covered with ice and/or snow, remove before use. Snow

accumulation should be shoveled and the tread surface swept clean. Calcium

Chloride salt substitute may be used to melt snow or ice accumulation on the

ramp, however, after the snow and/or ice threat has cleared, be sure to clean the

tread surface with soap and water (avoid alkaloid detergents

) to remove Calcium

Chloride residue. Rinse well and use extra caution when the ramp surface is

wet.

H) Do not play on or near ramp.

I) Do not use handrails or ramp to support planters, decorations, etc.

J) Ramp surface may become slippery when wet.

K) If any part of the ramp is damaged or loose, DO NOT USE UNTIL REPAIRS

CAN BE MADE BY A CERTIFIED INSTALLER OR OTHER QUALIFIED

PERSON.

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

9 HAMMER

9 LEVEL

9 RUBBER MALLET

9 FILE

9 POWER DRILL

9 HACKSAW (FOR OPTIONAL HANDRAIL KITS)

9 DIGGING TOOLS (IF AN OBSTACLE NEEDS TO BE REMOVED)

9 TWO ABLE-BODIED PERSONS NEEDED FOR INSTALLATION

VIEW PACKING LIST: Each ramp system is shipped with a packing list. Be sure to check

that all items and tools are present before starting installation.

- 2 -

WARRANTY REGISTRATION

EZ-ACCESS®, A DIVISION OF HOMECARE PRODUCTS, INC. y 700 MILWAUKEE AVE N y ALGONA WA 98001-7408

TYPE EZ-ACCESS MODULAR RAMP

NAME PHONE

ADDRESS

NAME OF DEALER DEALER’S CITY, ST, ZIP

PRICE DATE PURCHASED

WHERE WILL RAMP BE USED?

WHAT INFLUENCED YOUR PURCHASE OF THIS RAMP?

MANUFACTURED DATE

CITY, ST, ZIP

SEE LABEL ON SIDE OF RAMP

FRIEND RECOMMENDED DEALER RECOMMENDED WEBSITE ADVERTISING/MAGAZINE

OTHER (PLEASE EXPLAIN)

Please mail warranty information within 10 days of purchase.

- 31 -

Page 3

WARRANTY & REGISTRATION

CONTENTS

BASIC SYSTEM COMPONENTS...................................................................... 4-5

INSTALLING PLATFORMS ...................................................................................6

1. EZ-ACCESS, a division of Homecare Products, Inc., (herein referred to as Manufacturer), warrants that the

equipment shall be free from defects in material and workmanship under normal use and service for a

period of 3-years from the date of original purchase. This limited warranty applies to the original purchaser

only and is non-transferable. This limited warranty is applicable to defective metal structure components

only (excludes powder coated finish, applied non-skid tread, etc.) No part of this warranty will apply to any

equipment which has been subject to misuse, vandalism, negligence, alteration, improper loads, accident,

improper installation, or which has been repaired outside Manufacturer’s place of business in any way as in

the reasonable judgment of Manufacturer, to adversely affect its performance and reliability, nor to normal

deterioration due to wear, tear and exposure, corrosion, or damage caused by rain, fire, earthquake or other

natural causes or acts of nature.

2. Manufacturer’s obligation and purchaser’s sole remedy under this warranty is limited to, at Manufacturer’s

option, repairing or replacing equipment which is returned to its place of business and which, upon

examination, shall disclose to Manufacturer’s reasonable satisfaction to have been defective. Manufacturer

will make the repair or replacement of defective components at its own expense. If Purchaser discovers a

defect, he/she must call Manufacturer at 253-249-1101 to request a Return Authorization (RA) to return the

merchandise to Manufacturer.

3. If Manufacturer determines, in its sole discretion, to replace the equipment with either a new or repaired unit,

purchaser shall be responsible for a charge prorated on the following basis: The purchaser will be allowed a

credit against the purchase price of equivalent equipment at the time of return to Manufacturer, in proportion

to the percentage of the warranted service life remaining at the time of such return. Purchaser will be

responsible to pay the balance of the purchase price of equivalent equipment. Manufacturer reserves the

right to require payment prior to delivery of the repaired/replaced equipment. In calculating available credit,

the remaining warranted service life will be rounded up or down to the nearest whole year. YEARS 0-1: Unit

repaired or replaced; YEARS 1-2: Repair or 50% $ credit (current purchase price multiplied by credit

percentage); YEARS 2-3: Repair or 25% $ credit (current purchase price multiplied by credit percentage).

This limited warranty does not cover removal or reinstallation. Manufacturer reserves the right to require

Purchaser to pay for all shipping charges (Government purchases exempt).

4. DISCLAIMER: THE WARRANTIES AND REMEDIES CONTAINED HEREIN ARE EXCLUSIVE AND IN LIEU OF

ALL OTHER WARRANTIES, WHETHER EXPRESS, IMPLIED OR STATUTORY, INCLUDING ANY LIABILITY

ARISING UNDER ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE,

STATUTORY OR OTHERWISE. HOWEVER, THAT IF ANY IMPLIED WARRANTY CANNOT BE DISCLAIMED

IN ANY TERRITORY WHERE A PRODUCT IS SOLD, THE DURATION OF SUCH IMPLIED WARRANTY IS

LIMITED TO THE DURATION OF THE LIMITED WARRANTY DESCRIBED IN THE FIRST PARAGRAPH.

5. MANUFACTURER SHALL NOT BE LIABLE UNDER ANY CONTRACT, NEGLIGENCE, STRICT LIABILITY OR

OTHER LEGAL OR EQUITABLE THEORY FOR ANY DIRECT, SPECIAL, INCIDENTAL OR CONSEQUENTIAL

DAMAGES, RESULTING FROM THE USE, MISUSE OR INABILITY TO USE THE EQUIPMENT, OR ARISING

OUT OF ANY BREACH OF THIS LIMITED WARRANTY, EVEN IF MANUFACTURER HAS BEEN ADVISED OF

THE POSSIBILITY OF SUCH DAMAGES. THE SOLE REMEDY FOR A BREACH OF THE FOREGOING

LIMITED WARRANTY IS REPLACEMENT OF THE DEFECTIVE OR NON-CONFORMING EQUIPMENT OR

PART. THE MAXIMUM LIABILITY OF MANUFACTURER UNDER THIS WARRANTY IS LIMITED TO THE

PURCHASE PRICE OF THE EQUIPMENT COVERED BY THE WARRANTY.

6. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above

limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also

have other rights which may vary from State to State. Manufacturer reserves the right to change or improve

its products without any obligation to change or improve any Product previously manufactured by it.

INSTALL SADDLE BRACKETS TO PLATFORM ......................................7

CONNECTING TWO PLATFORMS TOGETHER......................................8

ATTACH SUPPORT TUBES TO PLATFORM SADDLE BRACKETS .......9

INSTALL BASE FEET AND ADJUST HEIGHT........................................10

INSTALL PLATFORM BRACE ASSEMBLY ............................................10

INSTALL RAMP SECTIONS.......................................................................... 11-16

INSTALLING A SINGLE RAMP RUN ............................................................ 16-17

ANCHOR TOP TRANSITION PLATE..................................................................18

ANCHOR BOTTOM TRANSITION PLATE..........................................................18

PRE-ASSEMBLE HANDRAILS ...........................................................................19

INSTALLING RAMP HANDRAILS .......................................................................20

INSTALLING PLATFORM HANDRAILS..............................................................21

INSTALLING LOOPS...........................................................................................22

INSTALLING END CAPS.....................................................................................22

OPTIONAL INSIDE CORNER HANDRAIL KIT ............................................. 22-23

CORNER POCKET PROTECTIVE CAP .............................................................23

OPTIONAL HANDRAIL CLOSURE KIT......................................................... 24-25

OPTIONAL TOP SUPPORT ASSEMBLY............................................................26

OPTIONAL LIGHTNING ROD GROUNDING KIT ...............................................27

OPTIONAL HURRICANE TIE DOWN KIT..................................................... 28-29

WARRANTY .................................................................................................. 30-31

FINAL CHECKS...................................................................................................31

- 30 -

PERIODIC MAINTENANCE & SAFETY ..............................................................31

- 3 -

Page 4

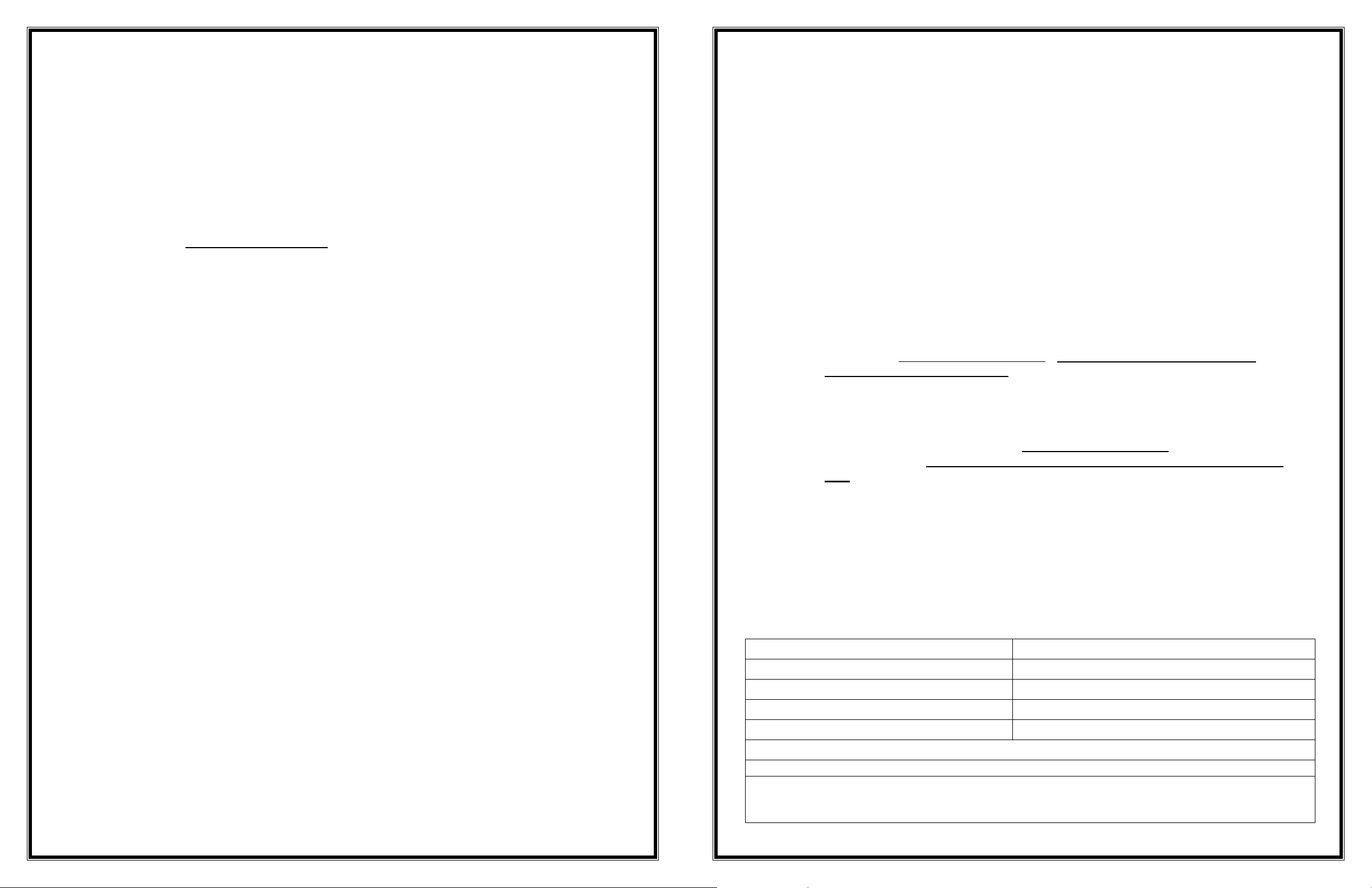

BASIC SYSTEM COMPONENTS: Because each ramp configuration will differ from one

another, your system may or may not contain all of these basic system components:

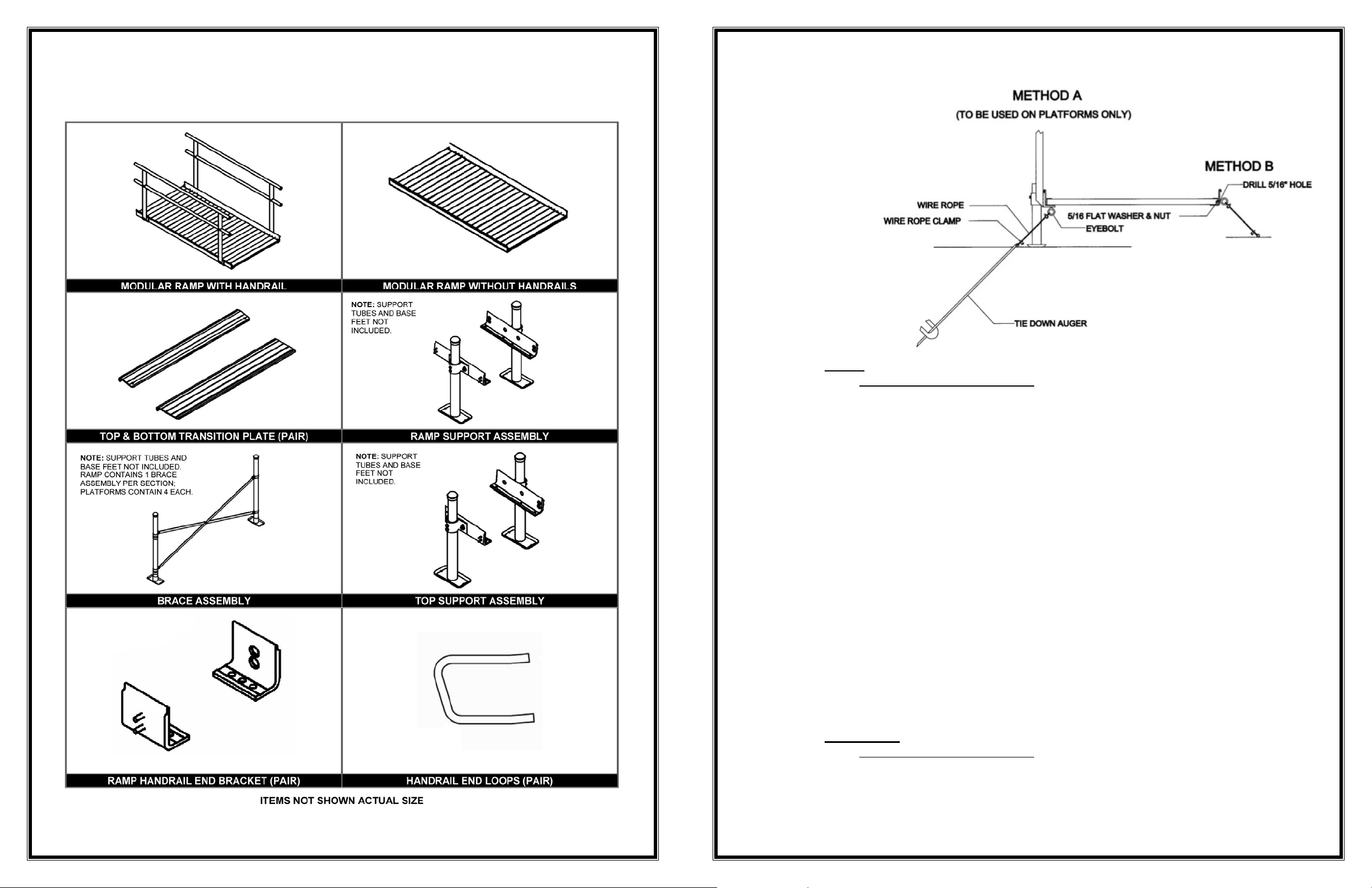

FIG. 44

A) RAMP

i) Refer to FIG. 44, METHOD B.

ii) Install one TIE DOWN KIT per each 10-feet of ramp (e.g., 8' of ramp

requires one TIE DOWN KIT, but 12’ of ramp requires two). See FIG. 43

for acceptable locations.

iii) Drill a 5/16” hole below the tread surface and between the ribs underneath

the treads in each of the side rails at the center of the ramp.

iv) In this drilled hole, install one of the 5/16” eyebolts and secure to the ramp

using one 5/16” flat washer and one 5/16” nut.

v) Install the tie down anchor augers into the ground, inline with the eyebolts

and perpendicular to the ramp at an approximate angle of 30 degrees.

Use a ½” steel rod (or similar item) through the eye of the anchor auger to

turn the anchor auger into the ground. Keep turning the auger until only

the eye is exposed.

vi) Secure one end of the wire rope to one of the eyebolts using the supplied

3/16” wire rope clamps. Thread the other end of the wire rope through the

eye of the anchor auger and secure the wire rope to itself using the

supplied 3/16” wire rope clamps. NOTE: Ensure that the wire rope has

been pulled taut and all slack has been removed prior to securing it to the

anchor auger.

vii) Cut the excess wire rope as required using a cable cutter or other

appropriate tool. Wrap vinyl electrical tape at the cut end to keep the wire

rope from fraying.

viii) Repeat on the opposite side of ramp section.

B) PLATFORM

i) Refer to FIG. 44, METHOD A.

ii) Install one TIE DOWN KIT per Platform.

iii) Install eyebolts by removing the 5/16” x 1½” bolt, then inserting the eyebolt

in its place (see FIG. 43 for acceptable locations).

- 4 -

- 29 -

Page 5

14) INSTALL OPTIONAL HURRICANE TIE-DOWN KIT:

The installer, based on field conditions, will determine the exact location of the tie downs.

As a rule, they should be positioned opposite one another and near the center of ramp as

shown in FIG. 43. (METHOD A, as shown in FIG. 44 is to be used for securing platforms

only.)

The Tie Down Installation Kit meets the requirements of Section 6.0 of ASCE 7-02 (wind

loads) for ensuring that all EZ-ACCESS Ramp systems are properly restrained against

hurricane strength winds.

Install the EZ-ACCESS® Modular ramp system ramp system to establish layout and

locations. It may be necessary to temporarily reposition components in order to install

anchor augers.

WARNING: Prior to installing the anchor augers into the ground, ensure that any

underground electrical conductors, natural gas lines, water/drain lines, and/or other

interferences are located and will not hinder the installation.

WARNING: The tie down installation should be completely inspected for any loose

wire ropes, fasteners, anchor augers, etc. after being subjected to strong winds.

FIG. 43

- 28 -

- 5 -

Page 6

1) INSTALLING PLATFORMS: If your system does not include a platform, skip to ‘INSTALL

RAMP SECTIONS’ of this instruction guide. Generally, we suggest installing all platforms

and ramps before installing handrails (see ‘HANDRAIL INSTALLATION’).

A) There are three types of platforms (you may be installing one or more of these

types). All three require the same procedure for assembly except for FIG. 3

which requires an additional platform connector kit.

FIG. 1 5' x 5' Universal Platform (straight configuration)

FIG. 2 5' x 5' Universal Platform (turn configuration)

FIG. 3 5' x 4' Universal Platform (2 shown combined to make 5' x

8’ turn back platform)

13) INSTALL OPTIONAL LIGHTNING ROD GROUNDING KIT:

A) The Lightning Rod Grounding Kit provides a path for lightning strikes into the

ground.

WARNING: Prior to installing the grounding rod, ensure that any underground

electrical conductors, natural gas lines, water/drain lines, and/or other interferences

are located and will not hinder the installation.

i) Install the EZ-ACCESS

ii) Drive the grounding rod straight into the ground as close as possible (at

®

Modular ramp system.

least within 1½') to one of the support tubes, leaving approximately 2"

exposed.

FIG. 1 FIG. 2

iii) Install the hose clamp around support tube. Place #8 copper wire under

hose clamp and tighten so that wire is in good contact with support tube.

iv) Install 5/8” grounding rod clamp to grounding rod. Place #8 wire between

clamp and rod, then tighten clamp.

FIG. 42

FIG. 3

- 6 -

- 27 -

Page 7

12) INSTALL OPTIONAL TOP SUPPORT ASSEMBLY:

A) The top support assembly provides supplemental support at the upper end of the

ramp. When used, the top support assembly replaces the Ramp Handrail End

Brackets.

i) Attach top support brackets with two each 5/16” x 1½" bolts and two each

5/16” flat washers.

NOTE: There is a left and right top support bracket. The two 3/8” studs

aligned horizontally should be toward the end of the ramp (FIG. 39).

B) The following steps are done AFTER the ramp is resting on a supporting surface

and the top transition plate is installed. IMPORTANT: Read “INSTALLING A

SINGLE RAMP” and “ANCHOR TOP TRANSITION PLATE” sections and ensure

all steps are completed before proceeding with the steps that follow.

i) Install support tube bracket on each top ramp support bracket using two

each 3/8” nylock nuts into the threaded holes and two each 3/8” flat

washers. DO NOT TIGHTEN (FIG. 40).

ii) Install two each 3/8” x ½” hex bolts into the threaded holes on the support

tube bracket.

B) INSTALL SADDLE BRACKETS TO PLATFORM:

i) Place the surface of the platform face down, onto cardboard or a lawn so

that the platform is not damaged (scratched or dented).

ii) Each platform has two different configurations at each corner into which

the platform saddle brackets and support legs can be installed. To account

for obstacles, either position can be used as long as one platform saddle

bracket is installed in each corner.

iii) Position the platform saddle bracket over the threaded inserts located on

each outside corner of the platform (FIG. 4).

iv) Slide the platform saddle brackets into position (one end of the bracket will

slide into the groove). NOTE: If there are space limitations, the saddle

brackets can be installed under the platform as shown in FIG. 7 (if

necessary, support tubes can be cut to fit).

v) Using a ½” socket wrench, attach a platform saddle bracket to the platform

with two 5/16” x 1½” bolts and two 5/16” flat washers. DO NOT OVER

TIGHTEN

(FIG. 5). Repeat this step for all four platform saddle brackets.

NOTE: The 4 x 4, 5 x 4, and 5 x 5 platforms each use 4 (four) platform

saddle brackets.

vi) Once installed, start two each ⅜” x ½” bolts into the threaded holes in each

platform saddle bracket (FIG. 6) in order to secure the support tube.

iii) Slide support tube into support tube bracket and onto base foot.

iv) Level support tube and then tighten 3/8” nylock nuts to secure support tube

bracket (FIG. 41).

v) Adjust height as needed, and then tighten bolts.

vi) Place end caps on support tube.

FIG 7

FIG. 39 FIG. 40 FIG. 41

- 26 -

- 7 -

Page 8

C) CONNECTING TWO PLATFORMS TOGETHER:

i) Place the surface of the platform face down, onto cardboard or a lawn so

that the platform is not damaged (scratched or dented).

ii) Places edges to be joined against one another.

iii) Attach platform connector saddle bracket (two each) into existing threaded

inserts using 5/16” x 1½” hex bolts (four per bracket) and 5/16" flat

washers (four per bracket) as shown in FIG. 8. DO NOT OVER TIGHTEN.

NOTE: Any two platforms with the same width can be connected.

However, generally two 5' x 4’ platforms are connected to make a turn

back platform.

iv) FIG. 9 shows completed assembly. CAUTION: Although platforms are now

connected, four support tubes must be installed per platform.

FIG. 36

FIG. 8 FIG. 9

FIG. 37 FIG. 38

- 8 -

- 25 -

Page 9

11) INSTALL OPTIONAL HANDRAIL CLOSURE KIT:

A) This kit will connect the handrails on a platform to the handrails on one side of

the ramp.

i) If needed, drop square tube post into corner pocket on platform and

tighten two set screws with supplied 3/16” allen wrench (FIG. 33).

ii) Using an adjustable elbow with a threaded insert in one end, pass 5/16” x

2” buttonhead screw through the hole in square tube into threaded insert on

adjustable elbow. Tighten lightly (FIG. 34).

iii) Insert ring joiner into each end of other elbows (FIG. 35).

iv) Insert ring joiner/adjustable elbow assembly into tube end on ramp handrail

and position both assemblies until they are aligned (FIG. 36).

v) Measure the distance between the ring portions of the ring joiner

assemblies. HELPFUL HINT: Use the supplied 5/32” and 3/16” allen

wrenches to lightly tighten the ring joiner/adjustable elbow assembly so they

hold their position while measuring.

vi) Cut round tube to the length measured (FIG. 37).

vii) Using a metal file, smooth any sharp edges from the cutting.

viii) Insert cut tube into place and tighten all setscrews on ring joiners and

adjustable elbows (FIG 38).

NOTE: If difficult to install, disassemble adjustable elbows.

D) ATTACH SUPPORT TUBES TO PLATFORM SADDLE BRACKETS:

i) Tip the platform on its side. Have one person support the platform while the

other person slides the support tubes into the platform saddle brackets.

Adjust the support tubes to the approximate height needed (FIG. 10).

FIG. 34

FIG. 33

FIG. 10

ii) Using a 9/16” socket wrench, secure each of the support tubes with one of

the two bolts on each platform saddle bracket (the second bolt will be

tightened after final height adjustments are complete). The universal

platform configured as a turn back platform (FIG. 3) will have eight tubes to

adjust.

CAUTION: Do not attempt to walk on the platform without both bolts in

each platform saddle bracket tightened securely.

iii) Place the platform with support tubes attached into the upright position.

IMPORTANT: Do not let the weight of the platform bear on the support

tubes while tipping the platform upright as it may bend the outer rail.

FIG. 35

- 24 -

- 9 -

Page 10

E) INSTALL BASE FEET AND ADJUST HEIGHT:

i) Slip the base foot under each support tube (FIG. 11).

NOTE: If installing on soft soil it may be necessary to set the base foot on

a concrete pad or stepping stone.

ii) Adjust the final height of the platform.

a. Adjust each leg one at a time by loosening the bolt in the platform

saddle bracket. Using a level, adjust the platform height and

retighten (FIG. 12).

iii) Once the final height has been adjusted, tighten the second bolt in each

platform saddle bracket.

iv) Ensure that all bolts are secure.

v) Cut round tube to the length measured (FIG. 31).

vi) Using a metal file, smooth any sharp edges from the cutting.

vii) Insert cut tube into place and tighten all set screws on ring joiner/adjustable

elbows assemblies (FIG. 32).

NOTE: If difficult to install, disassemble adjustable elbows and reconfigure.

10) INSTALL CORNER POCKET PROTECTIVE CAP:

A) Some platform configurations will have unused corner pockets on which corner

pocket protective cap will need to be installed (FIG. 32a).

FIG. 31

FIG. 11 FIG. 12

F) INSTALL PLATFORM BRACE ASSEMBLY:

i) Install platform brace assemblies on all support tubes when the walking

surface is 36” or more above the ground. The platform brace assemblies

are normally installed on all four sides (FIG. 13).

ii) Platform brace assemblies need to be cut to desired length and 5/16” holes

to attach the brace bands will need to be drilled at both cut ends.

iii) Ensure that all platform brace assemblies are secured before using

platform.

FIG. 32

FIG. 32a

FIG. 13

- 10 -

- 23 -

Page 11

7) INSTALL LOOPS:

A) Install loops using same procedure as handrail with joiner assemblies.

8) INSTALL END CAPS:

A) Use end caps when there are any remaining open ends on the handrails.

i) Push them in by hand or by using a rubber mallet, then twist caps once

they are in place.

9) INSTALL OPTIONAL INSIDE CORNER HANDRAIL KIT:

A) Because each installation is unique, the components must be cut at the job site.

i) Slide a ring joiner into both ends of the adjustable elbow (FIG. 28).

ii) Slide a ring joiner/adjustable elbow assembly into each ramp handrail tube

(FIG. 29).

iii) Position both assemblies until they are aligned (FIG. 30).

iv) Measure the distance between the two ring portions of the ring

joiner/adjustable elbow assembly.

HELPFUL HINT: Use the supplied 5/32” and 3/16” allen wrenches to

lightly tighten the ring joiner/adjustable elbow assembly so they hold their

position while measuring.

A) INSTALL RAMP SECTION(S):

i) Turn the ramp sections upside down on a flat surface (so that the ramps do

not get scratched or dented, it is recommended that this be done either on

the lawn or on a piece of cardboard).

NOTE: If you are installing a single ramp section, skip to 'INSTALLING A

SINGLE RAMP RUN’.

ii)

iii) Position the two center saddle brackets over the threaded inserts found on

Butt the sections together end-to-end and ensure there is no gap.

the end of each ramp section (FIG. 14).

iv) One edge of the center saddle bracket will slide into the groove of the ramp

section.

NOTE: Ramp sections are connected to create a ramp run using two

interchangeable center saddle brackets per joint. The center saddle

brackets are also where the handrails and support tube brackets are

attached, and are a part of the ramp support assembly. (FIG. 14).

FIG. 28

FIG. 30

FIG. 29

FIG. 14

v) Attach the center saddle brackets using four each 5/16” x 1½” bolts and

washers per center saddle bracket.

vi) Tighten all eight bolts (four each per center saddle bracket).

NOTE: A maximum of three ramp sections may be joined in this manner.

vii) If necessary, install optional top support assembly at this time. See

- 22 -

'OPTIONAL TOP SUPPORT ASSEMBLY'.

- 11 -

Page 12

FIG. 15a FIG. 15b

viii) Install four ramp handrail end brackets (these will be used to attach

handrails in a later step).

a. For 4’, 6’, and 8’ ramps, use one at each outside corner of the

ramp section using one 5/16” x 1½” bolt & washer into the

threaded insert second from the end of the ramp (FIG. 15a).

b. For 10' ramps, two additional ramp handrail end brackets are

installed using one 5/16” x 1½” bolt and washer at the center of

each ramp section (FIG. 15b). NOTE: Ensure holes in ramp

handrail end bracket align with threaded inserts in ramp. Install

one fastener into either of the two inserts.

ix) Turn the joined ramps to the upright position.

x) Place the upper end of the ramp onto the supporting surface, i.e., platform,

porch, etc.

xi) Once the ramp is resting on the porch or platform, lift the upper end of the

ramp and install the top transition plate (top transition plate is the smaller

of the two) into what will be the upper end of the ramp.

NOTE: When used with an MTSA, the bottom transition plate (the larger

of the two) can be installed at what will be the upper end of the ramp to

compensate for minor angular misalignment (about 10 degrees) between

the porch, deck, or platform.

xii) Install the bottom transition plate (larger of the two) into what will be the

lower end of the ramp (FIG. 16).

6) INSTALL PLATFORM HANDRAILS:

NOTE: Depending on your configuration, refer to FIG. 26 and 27, as needed.

i) Drop platform handrails into corner pockets on straight platform

configuration. NOTE: If the handrails do not fit, it may be necessary to

remove the washers between the vertical post and round tubes.

ii) To connect handrails on turn and turn back platform configurations, remove

one vertical post per platform and retain for reuse. Pass three each 5/16” x

2” buttonhead screws through the holes in square post and into threaded

insert in round tube/square tube end. Tighten with supplied 3/16” allen

wrench. If the handrails do not fit in the corner pocket, it may be necessary

to remove/add washers between the vertical post and round tubes.

iii) Tighten two each set screws in each corner pocket on platform with

supplied 3/16” allen wrench.

iv) Use a rubber mallet to install square plastic end caps into the top of

handrail posts.

v) Install plastic protective cap over unused corner pocket.

vi) Using the supplied 3/16” allen wrench, tighten the setscrews on the outside

of the square corner pockets.

NOTE: Straight platform handrails simply drop into the square pockets and

require no assembly other than tightening the set screws (FIG. 26).

FIG. 16

- 12 -

FIG. 26

- 21 -

FIG. 27

Page 13

5) INSTALL HANDRAILS:

A) Install pre-assembled handrail section to side of ramp run (FIG. 22).

i) The vertical posts of the handrails each have two holes that correspond

with studs on the saddle brackets that were installed earlier.

ii) Attach handrails to these studs using two each 5/16” flat washers and two

each 5/16” hex nuts per handrail post.

NOTE: If the studs do not align with the posts and are off by 6”, the Ramp

Handrail End Bracket was installed into the wrong threaded insert on the

ramp. (See FIG. 15a for location of the correct insert).

FIG. 25

a) Maneuver the ramp to its desired position (FIG. 17).

IMPORTANT: Make sure the top transition plate overlaps the supporting surface

as far as possible.

CAUTION: DO NOT use the ramp until all support tubes and ramp brace

assemblies (if needed) are installed and secured!

FIG. 17

- 20 -

xiii) So that no sharp edges are exposed, install protective caps over side rail

corners as shown in FIG. 18. Place one cap on each side at both the top

and bottom of ramp.

NOTE: If necessary, use silicone adhesive to bond cap to ramp.

FIG. 18

- 13 -

Page 14

FIG. 19

xiv) Attach support tube bracket to the center saddle bracket using ⅜” nylock

nuts and ⅜” washers (FIG. 19).

a. To ensure plumb support tubes, level the support tube brackets

(FIG. 20).

b. Secure and tighten the ⅜” nylock nuts.

c. Start two each ⅜” x ½” bolts without washers into the threaded

holes on each support tube bracket. DO NOT TIGHTEN.

4) PRE-ASSEMBLE HANDRAILS:

A) One pair of handrails is required for each ramp section. Handrails are

interchangeable.

B) When used in a multiple ramp run, joiner assemblies are used to connect

handrails together. Refer to FIG. 24 for following steps:

i) One end of the handrail tube is notched to accept the joiner assembly.

Locate the notched end on each upper and lower handrail tube.

ii) Slide joiner assembly into the notched end of handrail tube. Repeat

process for both upper and lower handrail tube.

iii) Slide the next handrail section over the joiner assembly.

iv) Ensure that the tube ends are pushed firmly towards each other.

v) Using the supplied 5/32” allen wrench, tighten setscrews in both joiner

assemblies.

vi) Join all handrails together in this manner.

FIG. 20

FIG. 24

- 14 -

- 19 -

Page 15

2) ANCHOR TOP TRANSITION PLATE: The top transition plate must be anchored to a

substantial surface to assure the ramp will not be dislodged. Use the pre-drilled holes at

each corner of the top transition plate as guides.

A) IF RESTING ON A WOODEN SURFACE:

i) Drill two ⅛” holes into the wooden surface and secure by installing a #10 x

1½” stainless screw and #10 stainless washer into each hole (FIG. 23).

B) IF RESTING ON A CONCRETE SURFACE:

i) Using a marker, transfer the hole locations from the top transition plate to

the concrete surface then remove the top transition plate.

ii) Using a 5/16” masonry bit, drill two 1½” deep holes at the marked surface.

iii) Lightly set lead concrete anchor into holes with a hammer.

iv) Re-attach the top transition plate and align over the drilled holes.

v) Secure the top transition plate by installing a #10 x 1½” stainless screw and

#10 stainless washer into each hole.

C) IF RESTING ON AN ALUMINUM PLATFORM:

i) Drill two ⅛" holes and secure by installing a #10 x 1½” stainless screw and

#10 stainless washer into each hole.

NOTE: If the hole you are drilling is not coming out between two ribs on the

underside of the platform, drill a new ⅛" hole through the top transition plate

and platform in a position that will allow the screws to be installed between

the ribs.

xv) Place a base foot under each support tube bracket, then slide support tube

through the bracket and onto the base foot (FIG. 21).

NOTE: If used on very soft soil it may be necessary to set the base foot on

a concrete pad.

xvi) Adjust the legs one at a time.

a) Raise the ramp sections (at the center saddle bracket) to take any

sag out of the ramp run.

b) Tighten the two bolts in each support bracket.

c) Place end cap on support tube (FIG. 21).

NOTE: Adjusting sections can be accomplished by having someone

sight down the ramp while another person adjusts the ramp height.

IMPORTANT: Ensure that the ramp sections are parallel to each

other. If they are not, it may be difficult to install the handrails.

d) Double check that all bolts are tight, the support tubes are plumb, and

the ramp sections are aligned parallel to one another.

FIG. 23

3) ANCHOR BOTTOM TRANSITION PLATE:

A) If the bottom transition plate (end of ramp system) is resting at ground level, then

anchoring the ramp is optional.

B) If a bottom transition plate is resting on any type of raised area (i.e., a platform),

it must be anchored using the same procedures as used to ‘ANCHOR TOP

TRANSITION PLATE’.

- 18 -

FIG 21

- 15 -

Page 16

e) If the ramp tread surface is over 36” in height, connect the brace

assembly under the ramp as shown in FIG. 22.

f) The brace assembly ends will need to be cut to desired length, and

5/16” holes to attach the brace bands will need to be drilled at both

cut ends.

g) Ensure that all platform brace assemblies are secured before using

platform.

FIG 22

iii) Turn the ramp over to the upright position.

a) Place the upper end of the ramp onto the supporting surface, i.e.,

platform porch, etc.

iv) Once the ramp is resting on the porch or platform, lift the upper end of the

ramp and install the top transition plate into what will be the upper end of the

ramp and the bottom transition plate into what will be the lower end of the

ramp (FIG. 16).

NOTE: The bottom transition plate is the larger of the two.

a) Maneuver the ramp to its desired position (FIG. 17).

FIG. 16

H) INSTALLING A SINGLE RAMP RUN:

i) Turn the ramp section upside down on a flat surface. Do this on cardboard

or a lawn so that the ramp is not damaged (scratched or dented).

ii) Install four ramp handrail end brackets (these will be used to attach handrails

in a later step).

a) For 4’, 6’, and 8’ ramps, use one at each outside corner of the ramp

section using one 5/16” x 1½” bolt & washer into the threaded insert

second from the end of the ramp (FIG. 15a).

b) For 10' ramps, two additional ramp handrail end brackets are installed

using one 5/16” x 1½” bolt and washer at the center of each ramp

section (FIG. 15b).

NOTE: Ensure holes in ramp handrail end bracket align with threaded

inserts in ramp. Install one fastener into either of the two inserts.

FIG. 17

FIG. 15a FIG. 15b

- 16 -

- 17 -

Loading...

Loading...