EZ EZ-220, EZ-220V, EZ-420 Hardware Manual

x

TABLE OF CONTENTS

Text Panel Hardware ManualTe

Table of Contents

WARNING/Caution ................................................................... inside cover

Table of Contents...........................................................................................i

EU Information ..........................................................................................iv

1 INTRODUCTION

Manual Organization ...............................................................................2

Introduction to the EZSeries Text Panel ..................................................4

What you need to get started ..................................................................5

Hardware ..........................................................................................5

Software ...........................................................................................5

Need Help? ...........................................................................................5

Onscreen HELP ................................................................................5

PLC HELP.........................................................................................5

Technical Support .............................................................................6

Models ...........................................................................................6

PLCs Supported by EZSeries Text Panels ..............................................8

PLC and Programming Cable Part Numbers ..........................................9

Accessories and Optional Equipment .....................................................9

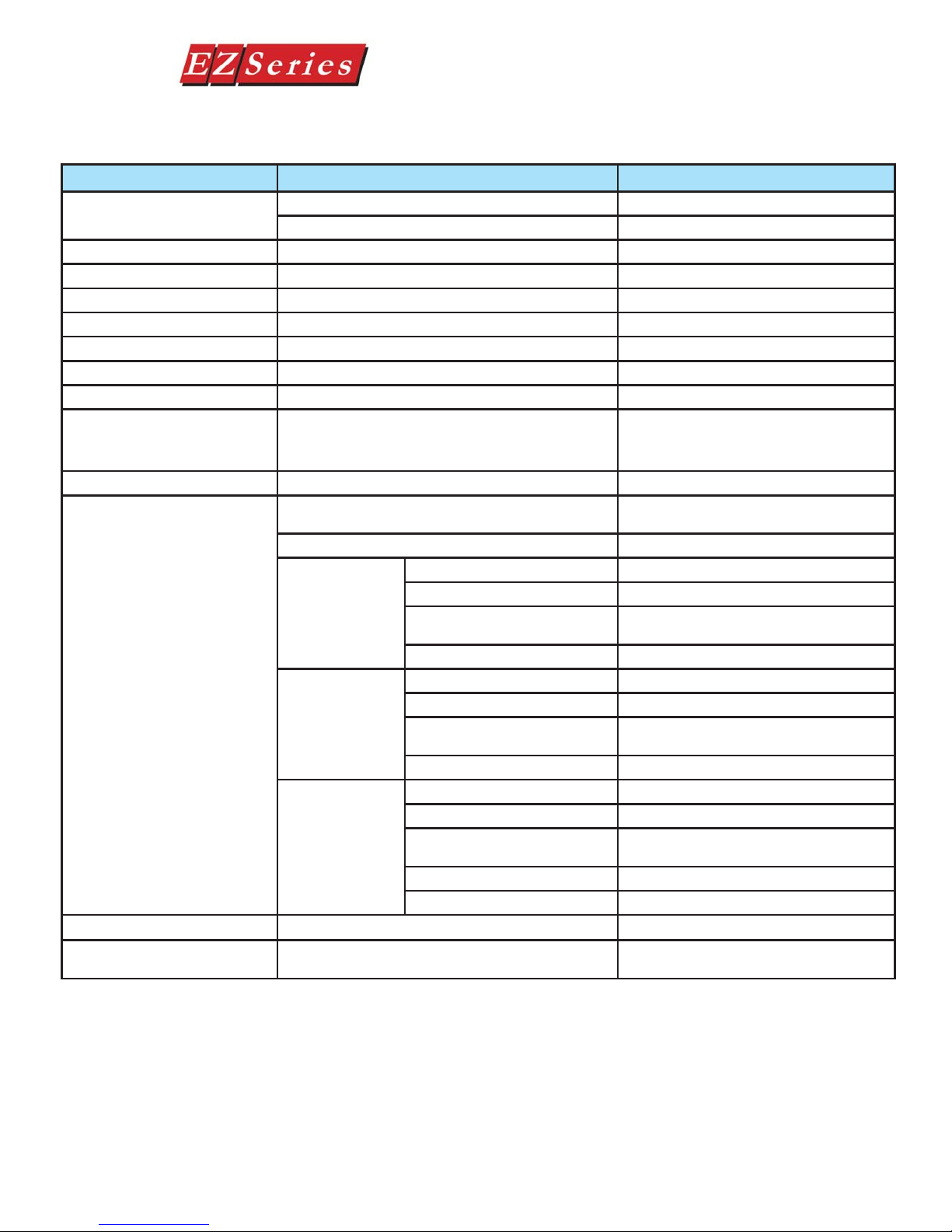

Front Panel Features ............................................................................10

Operator Controls and Indicators ....................................................10

Annunciator Lamps...................................................................11

Data Entry (Keypad) Pushbuttons ............................................11

PLC Message LED ...................................................................11

Control Pushbuttons .................................................................12

Function Pushbuttons ...............................................................12

Pushbutton LEDs......................................................................12

Character LCD Display with LED Backlight ..............................12

Messages .................................................................................13

Rear Panel Indicators............................................................................13

Specifi cations ........................................................................................14

2 HARDWARE INSTALLATION

Custom Labels ......................................................................................16

Create Custom Labels ....................................................................16

Install Custom Labels .....................................................................16

EMI Noise Filter Installation ..................................................................18

Mounting .........................................................................................19

Models EZ-220, EZ-220V, & EZ-420 Outline

Dimensions and Mounting Template .......................................19

Models EZ-220P & EZ-220PV Outline Dimensions

and Mounting Template ............................................................20

Model EZ-220L Outline Dimensions

i

Text Panel Hardware Manual

and Mounting Template ............................................................21

DIN Clip Mounting ...........................................................................22

Connections and Wiring ........................................................................23

EZ-220, EZ-220V & EZ-420 Rear View ..........................................24

EZ-220P & EZ-220PV Rear View ...................................................25

EZ-220L Rear View .........................................................................26

Power Connector ............................................................................27

Serial Port .......................................................................................27

Connect a PLC ...............................................................................28

3 LEARNING THE FEATURES

Learning the Features ...........................................................................30

Memory Mapping/PLC Data Registers..................................................30

Pushbuttons ....................................................................................31

LEDs .........................................................................................31

Annunciator Lamps .........................................................................32

PLC Message Registers .................................................................33

Embedded Data Registers ..............................................................33

PLC Messages and Local Messages ....................................................35

Embedded Data ..............................................................................35

Message Types ...............................................................................36

Displaying PLC Messages ..............................................................36

PLC Message LED .........................................................................35

Arrow Adjustment Entry ..................................................................38

Numeric Keypad Entry ....................................................................38

Annunciator Lamps .........................................................................38

PLC Message LED .........................................................................38

Displaying Local Messages ............................................................39

Local Message File Structure Example ..........................................40

Local Message Menu Structure Example .......................................41

4 TUTORIAL

EZSeries Text Panel Setup ...................................................................44

SETUP Mode ..................................................................................44

Adjust Display Contrast ..................................................................44

Internal Software and Hardware Revisions ....................................44

Preparing for Confi guration .............................................................44

Installing EZSeries Text Panel Programming Software .........................45

Tutorial — Plan the Project using Application Worksheets ...................47

Tutorial — Create the Project using EZSeries Text Panel Programming

Software .........................................................................................51

Tutorial — Confi gure a PLC ..................................................................60

5 CONFIGURATION

Confi gure New System .........................................................................64

ii

Text Panel Hardware ManualTe

x

Confi gure Existing System ....................................................................79

Connect to Panel, View Panel Status and Firmware Version ...............80

Upgrade Firmware ................................................................................81

6 MAINTENANCE and TROUBLESHOOTING

Maintenance .........................................................................................86

Fuse Reset .....................................................................................86

Precautions .....................................................................................86

Screen Overlay/Chemical Compatibility .........................................86

Screen Overlay Cleaning ................................................................88

Gasket Replacement ......................................................................88

Troubleshooting ....................................................................................89

Panel Confi guration Problems ........................................................89

PLC Errors ......................................................................................90

Still Need Help? ....................................................................................91

Warranty Repairs ..................................................................................92

Out of Warranty Repairs .......................................................................92

Frequently Asked Questions (FAQs) .....................................................93

Appendix A .......................................................................................A-1

EZSeries Text Panel Application Worksheet .................................A-2

Appendix B .......................................................................................B-1

Allen-Bradley ..........................................................................B-2

Direct Logic.............................................................................B-3

General Electric ......................................................................B-6

Mitsubishi ................................................................................B-6

Modicon Modbus ....................................................................B-7

Omron .....................................................................................B-8

Siemens..................................................................................B-8

Control Techniques .................................................................B-9

Control Technology Corporation (CTC) ................................B-10

Texas instruments.................................................................B-10

Idec .....................................................................................B-12

Aromat ..................................................................................B-13

EZAutomation EZPLC ..........................................................B-13

Appendix C .......................................................................................C-1

PLC Driver Error Messages ..........................................................C-2

EZSeries Text Panel Error Messages .........................................C-14

EZSeries Text Panel Programming Software Error Messages ...C-15

INDEX ........................................................................................ I-1

iii

Text Panel Hardware Manual

EU INFORMATION

EU Information

The EZ Series Text Panel is manufactured in compliance with European Union (EU) Directives and

carries the CE mark. The EZ Series Text Panel has been tested under CE Test Standard #EN55011,

and is listed under UL File #E209355. The following information is provided to comply with EU documentation requirements.

Please NOTE: Products with CE marks perform their required functions safely

and adhere to relevant standards as specifi ed by EU Directives provided they are

used according to their intended purpose and that the instructions in this manual

are adhered to. The protection provided by the equipment may be impaired if

this equipment is not used in accordance with this manual. Only replacement

parts supplied by EZAutomation or its agents should be used.

Technical

Support

SELV Circuits

Environmental

Specifi cations

Preventative

Maintenance

and Cleaning

If you need assistance, please call our technical support at 1-877-774-EASY or

FAX us at 1-877-775-EASY.

All electrical circuits connected to the communications port receptacle are rated

as Safety Extra Low Voltage (SELV).

Operating Temperature ...................................................................0 to 45 °C

Storage Temperature ................................................................–20 to +60 °C

Operating Humidity .........................................10–95% R.H., noncondensing

Air Composition ..............................................No corrosive gases permitted

No preventative maintenance is required. The EZ Series Text Panel overlay

should be cleaned as needed with warm, soapy water. See Chapter 6, Maintenance and Troubleshooting, for a list of compatible/incompatible chemicals

and compounds.

iv

1

Introduction

In this chapter....

— Manual Organization

— Introduction to the EZSeries Set Point Display Set

Point Display Panel

— What you need to get started

— Need HELP?

— Models

— PLCs Supported by EZSeries Set Point Display Set

Point Display Panel

— Accessories and Optional Equipment

— PLC and Programming Cable Part Numbers

— Front Panel Features

Manual Organization

This manual is all you’ll need to get the EZSeries Set Point Display Set Point

Display Panel installed and confi gured. This manual covers models EZ-220,

EZ-420, EZ-220L, EZ-220P, and two new models with Vacuum Fluorescent

Display EZ-220V, EZ-220PV.

In this manual we will take you through the steps necessary to get your EZSeries

Set Point Display Set Point Display Text Panel up and running in the shortest

possible time. Although your familiarity with programmable operator interface

devices will determine how quickly you move through the steps — it’s as easy

as 1 — 2 — 3. This manual is arranged in chapters. A description of key

Chapter Description

Introduction

1

Provides Manual Organization, and lists what you need to get started, hardware and software. Discusses how to get help with questions or problems you

might encounter through Onscreen Help and Technical Support. Provides you

with a table listing the various models, their part numbers and special features. Lists the important features of all EZSeries Set Point Display Set Point

Display Panels. Lists the PLCs supported by the panels, by brand, model and

protocol. Lists the part numbers for PLC cables and the programming cable.

Tells how to install programming software.

Text Panel Hardware Manual

2

3

4

Hardware Installation

Provides instructions on how to install custom labels and the EMI Noise Filter.

Discusses two mounting techniques — stud mounting and DIN clip mounting. Provides Outline Dimensions and Mounting Template. Provides you with

instructions on connecting the unit to power, a programming PC and a PLC.

Learning the Features

Provides an Overview of the panel features. Front Panel Features, including;

Function Pushbuttons/LEDs, Character LCD Display, PLC Message LED and

Control Pushbuttons are discussed. Local and PLC Messages are described,

along with types of Messages and Embedded Data Variables (DATA 1, 2, and

3).

Tutorial

Provides instructions to create an example (or “demo”) project. Discusses

how to confi gure a PLC ladder logic program to use with the demo project.

Takes you through the steps necessary to create an EZSeries Set Point

Display Set Point Display Panel project using the programming software and

application worksheets. Shows you how to transfer a project to the panel.

Confi guration

2

EZ-TEXT-M-E

Chapter Description

Step-by-step instructions for confi guring the EZSeries Set Point Display Set

5

6

Point Display Panel (new system) using the EZSeries Set Point Display Set

Point Display Panel Programming Software are provided.

Maintenance and Troubleshooting

Instructions for maintaining the EZSeries Set Point Display Set Point Display

panels are provided, including; Fuse Reset, Precautions, Chemical Compatibility, Cleaning, and Gasket Replacement. Troubleshooting section aids in

diagnosing problems you might encounter when installing or operating the

panel. Provides steps to take to isolate and correct problems.

Text Panel Hardware Manual

INTRODUCTION

A

B

C

Appendix A

Application Worksheets are provided to help you plan and implement your

system confi guration.

Appendix B

Wiring diagrams for several PLC cables are provided.

Appendix C

Error Messages for PLC Drivers, EZSeries Set Point Display Set Point Display Panel, and EZSeries Set Point Display Set Point Display Panel Program-

EZ-TEXT-M-E

3

Text Panel Hardware Manual

Introduction to the EZSeries Set Point Display Set Point Display

The EZSeries Set Point Display Set Point Display Panels provide a man-machine

interface to your PLC automation system. The panels provide features such

as 5 user-defi ned pushbuttons with LED indicators, arrow adjust buttons, and

a built-in menu system. The panels communicate with a PLC using either RS232C or RS-422A/485A serial communication. Confi guration software and panel

programming are covered in chapter 5 of this manual.

The panels allow you to confi gure up to 256 20-character text strings confi gured

as PLC Messages and Local Messages. Local Messages are internal panel

messages that the operator can scroll in a menu tree hierarchy . PLC Messages

are displayed when prompted from the PLC program. A PLC Message LED

illuminates whenever a PLC Message is being displayed. Either message type

can have up to three embedded data variables, one of which can be edited by

using the arrow adjust buttons.

The panels have sealed membrane function pushbuttons that allow you to trigger

PLC actions with the push of a button. These pushbuttons are used for input

signals to the PLC. Each pushbutton can be confi gured to function as one of

three switch types:

• ALTERNATE—keeps its current state until the button is pushed

again

• MOMENTARY— is activated only while the button is being pushed

• PANEL SET AND PLC RELEASE —sets a bit in the PLC when

pressed and is reset by either the PLC program or by pressing the

button again.

The LCD display window supports two or four message lines that can display

up to 20 characters each. The messages are programmed using the EZSeries

Set Point Display Set Point Display Panel Programming Software. The message

control type may be either static—text displays that have NO embedded data,

dynamic —text messages that include embedded data (READ access only), or

interactive —text messages that allow the operator to enter data, or change

values that are stored in the PLC registers (READ/WRITE access).

The EZSeries Set Point Display Set Point Display Panel is available in a variety

of models to suit your application. Key features are provided on page 10.

4

EZ-TEXT-M-E

Text Panel Hardware Manual

What you need to get started

Hardware

• EZSeries Set Point Display Set Point Display Panel (Models EZ-220,

EZ-220V, EZ-220L, EZ-420, EZ-220P, & EZ-220PV)

• 24 Volt DC Power Supply (FA-24PS recommended)

• RS-232C Programming Cable (P/N EZTEXT-PGMCBL)

• Appropriate PLC Cables (see page 9 for part numbers)

• Programmable Logic Controller (PLC)

• PC requirements:

— IBM or compatible PC (486 or better) with a mouse

and separate serial port

— VGA display with at least 800 x 600 resolution (1024 x 768

recommended)

— Standard Windows 95/98 (Second Edition)/NT4.0/2000

requirements

— CD ROM Drive

INTRODUCTION

®

Need HELP?

Software

• EZSeries Set Point Display Set Point Display Panel Programming

Software (P/N EZ-TEXTEDIT-E)

PLEASE NOTE: Chapter 6, Maintenance and Troubleshooting, should be

able to help you with most problems you might encounter.

Onscreen HELP

One of the most important features of the EZSeries Set Point Display Set Point

Display Programming Software is the availability of context sensitive onscreen

help. To access the Help windows, simply press the F1 function key while on

the topic where you need help. For example, if you need help while working with

panel confi guration, hit the F1 function key when that dialog box is open and a

pop-up HELP window will be displayed.

PLC HELP

If you need help with the PLC to EZSeries Set Point Display Set Point Display

Panel Interface, consult the EZSeries Set Point Display Set Point Display Panel

Programming Software Help. Each PLC Driver has a Help Topic that lists the

error messages and provides an explanation for each. Also provided are PLC

EZ-TEXT-M-E

5

Models

Text Panel Hardware Manual

to EZSeries Set Point Display Set Point Display Te Panel wiring diagrams.

Technical Support

Although most questions can be answered with EZSeries Set Point Display Set

Point Display Panel HELP or the manuals, if you are still having diffi culty with a

particular aspect of installation or system design, technical support is available

at 1-877-774-EASY, Monday through Friday, 6a.m. to Midnight CST, or FAX us

The EZSeries Set Point Display Text Panels provide a low-cost, easy-to-use

operator interface alternative for your PLC system. With easy to confi gure

Windows-based software and simple installation, you can be connected and

running in minutes. If your application requires pushbuttons, LEDs, or text

display , but your budget is low , check out the complete line of EZSeries Set Point

Display Text Panels. The following features are common to the EZSeries Set

Point Display Text Panel models shown below:

• stores up to 256 20-character messages

• 5 user-defi ned function pushbuttons and LEDs

• 4 control pushbuttons

• up to three embedded PLC data variables per message

• built-in menu system

• EMI fi ltered power supply to reduce communication problems

Part Number

EZ-220P

2 line by 20 character LCD display

Five user-defi ned buttons and LEDs

Numeric keypad

Scroll data entry

Three tri-color LED annunciators

Built-in menu system

EMI fi ltered power supply reduces

communication problems

Character Height 5.55mm (0.22”)

External Dimensions are 10.018” x 5”

****

EZ-220PV

Above with Vacuum Flourescent

Display

6

EZ-TEXT-M-E

FFFFFFEREBVEBEV

Text Panel Hardware Manual

Part Number

EZ-220V

2 lines by 20 characters Vacuum Flourescent Display

Character height of 0.22” (5.55 mm)

External dimensions are 5” x 7.4” x 1.6”

EZ-220

Above with Vacuum with LCD Display

EZ-220L

2 lines by 20 characters LCD display

Character height 0.316” (8.06 mm)

External dimensions are 5” x 10” x 1.6”

INTRODUCTION

EZ-420

4 lines by 20 characters display

Character height of 0.187” (4.75 mm)

External dimensions are 5” x 7.4” x 1.6”

EZ-TEXT-M-E

7

Text Panel Hardware Manual

PLCs Supported by EZSeries Set Point Display Set Point

PLC Brand Model Protocols Supported

Allen Bradley

Aromat Aromat Mewtocol COM

Control Techniques Unidrive 4-wire Binary

Control Technology Corporation (CTC) CTC 2600, 2700, and 5100 CTC Binary

EZAutomation EZPLC EZ Protocol

General Electric 90/30 and 90/70 Versamax SNPX

Idec Idec Computer Link

Mitsubishi FX Series (all) Direct

Modicon

Omron C200, C500, CQM1, CPM1 Host Link

Direct Logic

Siemens Siemens S7300/400 PLCs MPI Adaptor 3964R

Texas Instruments TI5x5 Series, TI505, TI545-1102, TI545-1104

MicroLogix 1000/1200/1500, SLC500, 5/03, /04, and PLC5 DF1 Hlaf Duplex; DF1 Full Duplex

PLC 5 DF1

984 CPU, Quantum 113 CPU, AEG

Modicon Micro Series 110, CPU: 311-xx

411-xx, 512-aa, 612-xx

DL05, DL06

DL105 K-Sequence

D2-230 K-Sequence

D2-240 K-Sequence; DirectNet

DL205

DL305

DL405

D2-250/D2-250 - 1/260

D2-240/250/260 w/DCM DirectNet

D3-330/330P DirectNet

D3-340 DirectNet

D3-350

D3-350 w/DCM DirectNet

D4-430 K-Sequence; DirectNet

D4-440 K-Sequence; DirectNet

D4-450

All with DCM DirectNet

Entivity (Think-n-Do) ModBus RTU

Modbus RTU

K-Sequence; DirectNet;

Modbus (Koyo addressing)

K-Sequence; DirectNet;

ModBus (Koyo addressing)

K-Sequence; DirectNet;

ModBus (Koyo addressing)

K-Sequence; DirectNet

ModBus (Koyo addressing)

TBP (Transparent Byte Protocol) or NITP (NonIntelligent Terminal Protocol)

8

EZ-TEXT-M-E

Text Panel Hardware Manual

INTRODUCTION

PLC Cables and Programming Cable Part Numbers

Part Number Cable Description

EZP-2CBL

EZP-2CBL-1 Direct Logic (VGA Style) 15-pin port, DL250 (RS-232C)

EZP-3CBL Direct Logic PLC RJ11 port, DL340 (RS-232C)

EZP-4CBL-1 Direct Logic PLC 15-pin Dsub port, DL405 (RS-232C)

EZP-4CBL-2

EZP-90-30-CBL GE 90/30 and 90/70 15-pin Dsub port (RS-422A)

EZP-SLC-232-CBL AB SLC 5/03/04/05 DF1 port (RS-232C)

Direct Logic PLC RJ12 port, DL05, DL105, DL205, DL350 & DL450

(RS-232C)

Direct Logic PLC 25-pin Dsub port, DL405, DL350, DL305 DCU, and all

DCM’s (RS-232C)

Accessories and Optional Equipment

Part Number Description

EZ-TEXTEDIT-E EZ Series Text Panel Programming Software

EZ-TEXT-S-GSK Standard Replacement Gasket (small)

EZ-TEXT-L-GSK Standard Replacement Gasket (large)

EZ-BRK-2 DIN Clips (package of 4)

EZ-TEXT-STUDS Mounting Studs (package of 4)

EZ-TEXT-M-E

9

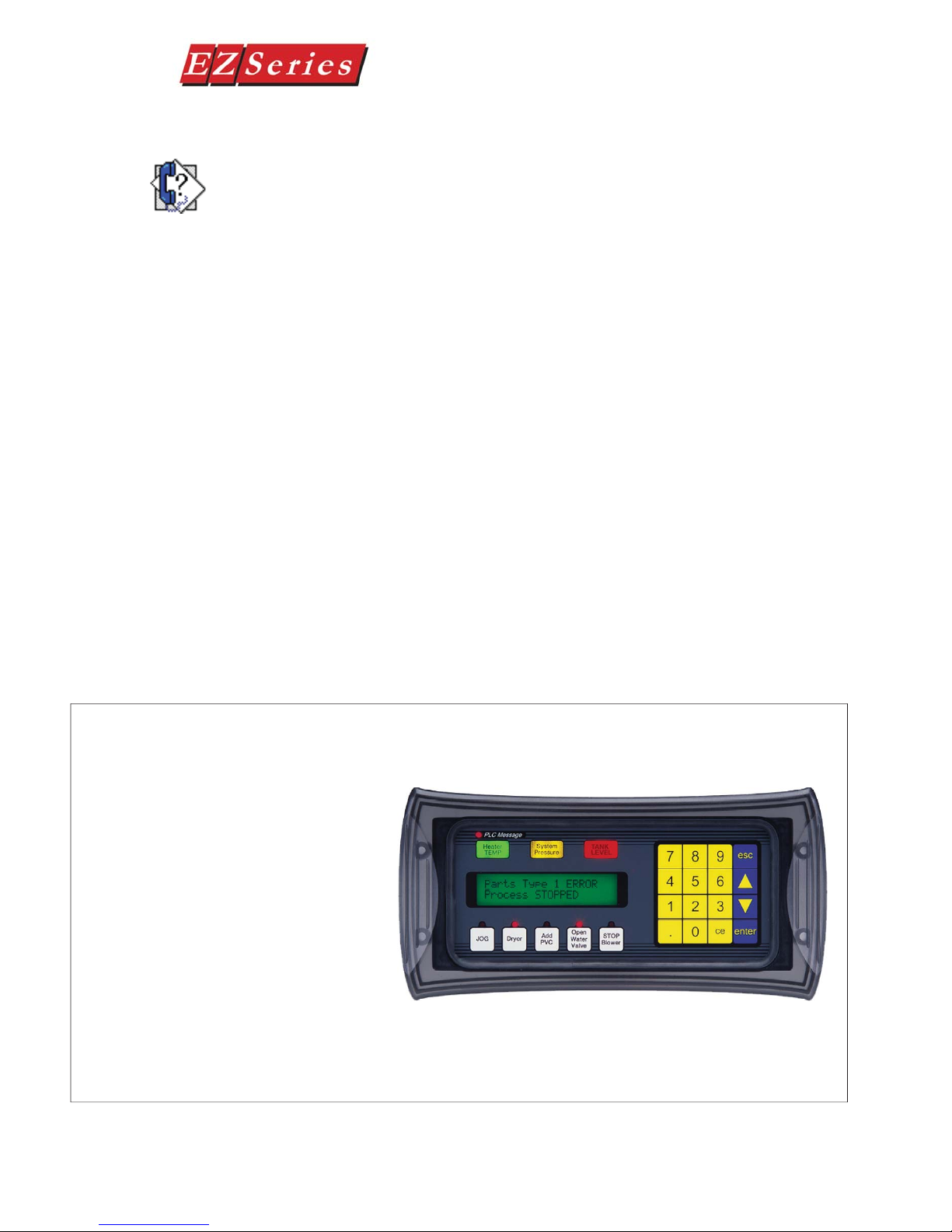

Front Panel Features

In this section, we will describe the front panel features of the EZSeries Set

Point Display Set Point Display Panel. Descriptions of the PLC Message LED,

Pushbuttons, Pushbutton LEDs, PLC Messages, and Local Messages are

provided. To understand the Features, see Chapter 3, Learning the Features.

For a demonstration of how to program the panel indicators and controls, please

refer to Chapter 4, Tutorial.

Operator Controls and Indicators

Each EZSeries Set Point Display Set Point Display Panel provides sealed

membrane Pushbuttons for operator interface with a PLC. Pushbuttons may

be used to begin events or tasks within the PLC, such as Start/Stop Control.

Pushbutton inputs are monitored for ON/OFF conditions in your PLC ladder logic

program. EZSeries Set Point Display Set Point Display Panel Pushbuttons are

Control Pushbuttons or Function Pushbuttons or Data Entry Keypad pushbuttons

available in two models (EZ-220P & EZ-220PV).

Text Panel Hardware Manual

10

EZ-TEXT-M-E

Text Panel Hardware Manual

INTRODUCTION

Annunciator Lamps

The EZ-220P & EZ-220PV models contain 3 tri-color Annunciator Lamps above

the LCD message window. Each of these lamps may be programmed to illuminate

in green, amber, or red and may be labeled to fi t your application. The lamps are

turned ON and OFF through your PLC ladder logic program. They are confi gured

with EZSeries Set Point Display Text Panel Programming Software and may be

confi gured to display status or the condition of any operation being controlled

within the PLC.

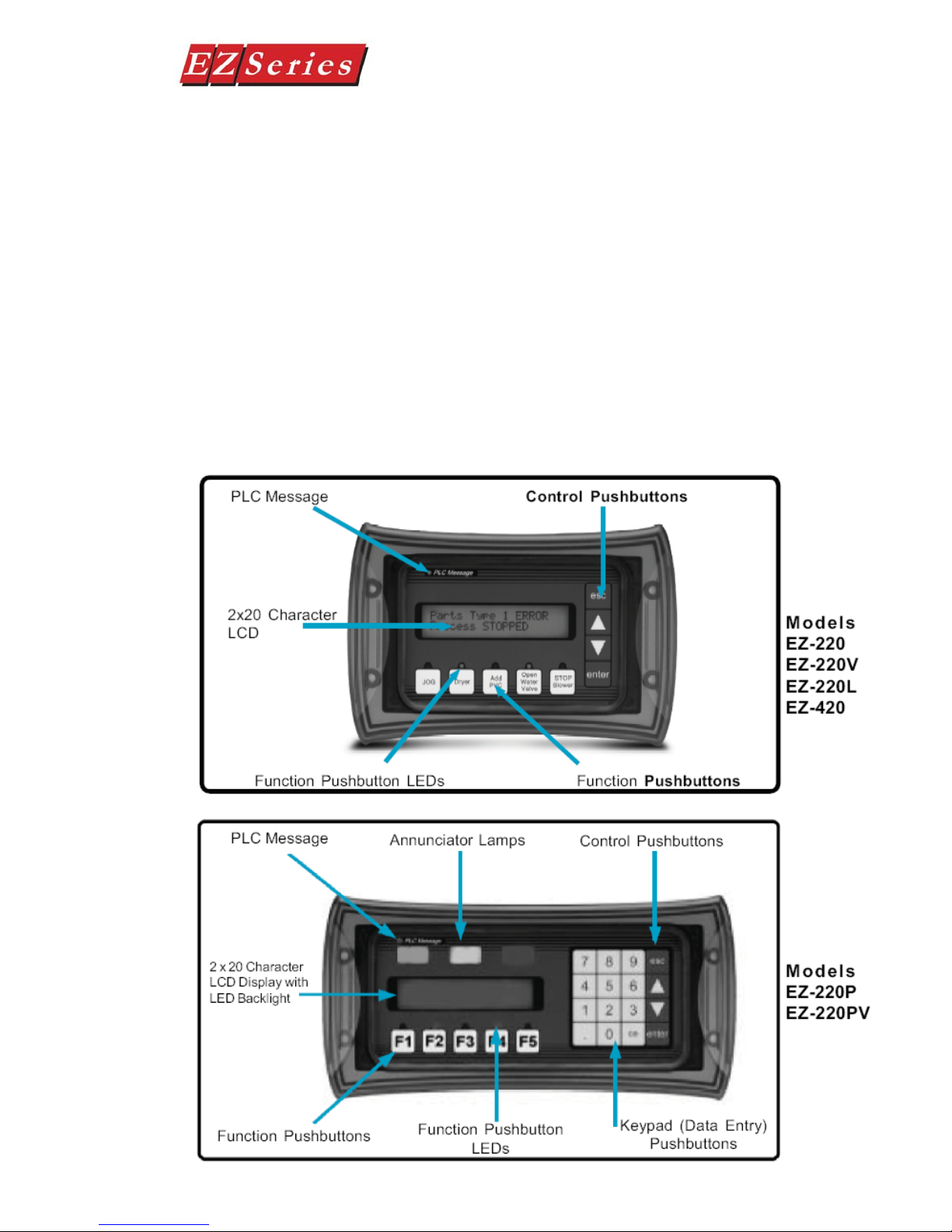

Data Entry (Keypad) Pushbuttons

The EZ-220P & EZ-220PV also feature a numeric keypad.

Use this keypad to enter or change embedded data values.

To update or enter a data value, the enter button must be

pressed to select the data value. Then you may use the

numeric keypad or the UP Arrow (increment) or DOWN

Arrow (decrement) to adjust the value. For the PLC to

acknowledge the change in value, you must press enter

again (sends the updated value to the PLC.) The CE

( Clear Entry) button is used to clear, or set back to zero,

the current value.

PLC Message LED

This LED will illuminate to indicate that the PLC

has triggered a message that will be displayed

in the LCD window. The pushbuttons are

disabled for 3 seconds after a PLC message

is displayed to ensure that the operator sees

the message. The LED will turn OFF when

the operator presses the escape pushbutton,

thereby acknowledging message received.

EZ-TEXT-M-E

11

Text Panel Hardware Manual

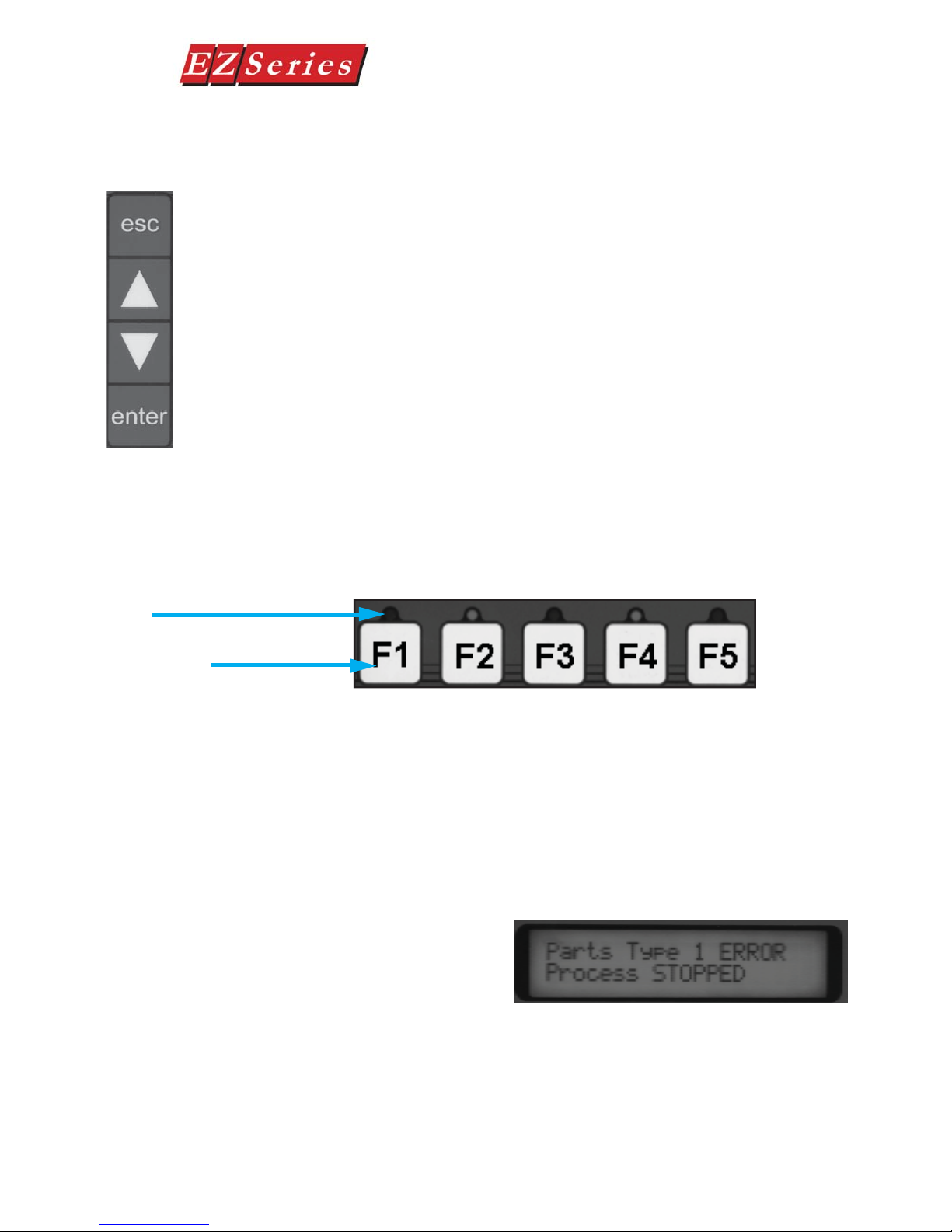

Control Pushbuttons

There are 4 Control Pushbuttons on the front panel. These buttons consist of

an esc ( escape), ( UP Arrow), ( DOWN Arrow), and enter pushbutton. The

arrow buttons are used to scroll through local messages or to change a value

within an interactive message. As the operator presses the buttons, the numeric

value will increment or decrement, respectively. As it is adjusted, the value

WILL NOT BE UPDATED in the PLC data register until the enter pushbutton is

pressed. When completed, the operator will press the enter pushbutton and the

value will be written to the PLC. Press esc to abort or cancel the adjustment

without writing the value to the PLC.

Function Pushbuttons

There are 5 Function Pushbuttons that are user-defi ned. They may be confi gured

as one of three “ switch” types; Alternate, Momentary, or Panel Set & PLC

Release (described on page 69.) They are confi gured as discrete input signals

to the PLC. These pushbuttons are labeled F1 through F5 or may be custom

labeled to suit their function or application.

LEDs

Function Pushbuttons

Pushbutton LEDs

There are LEDs located above each of the user-defi ned pushbuttons. These

LEDs can indicate if the pushbutton status condition is ON or OFF, or it can be

controlled independently by a PLC. You may choose the type of LED Control

while confi guring your panel (see Confi guration, Chapter 5). There are three

different controls— By Button, By Button & Flash, or By PLC, that will determine

LED response when the pushbuttons are pressed.

Character LCD Display with LED

Backlight

Messages display in the Character

LCD Display Window with LED

Backlight. The LCD window supports

two line by twenty characters (EZ220, EZ-220V , EZ-220PV , EZ-220P ,

& EZ-220L models), or four line by

twenty character (EZ-420 models)

messages.

12

EZ-TEXT-M-E

Text Panel Hardware Manual

INTRODUCTION

Messages

PLC Messages can be programmed to display PLC register values and allow

the operator to change a PLC register value. Up to 3 data variables can be

programmed to display in each message. The messages are entered using

EZSeries Set Point Display Set Point Display Panel Programming Software.

Up to 256 PLC Messages may be confi gured and stored in the EZSeries Set

Point Display Set Point Display Panel. PLC Messages are numbered 1 to 256.

The message control type may be static text, dynamic, or interactive. The PLC

logic program controls which messages are displayed. The PLC Message LED

illuminates when a PLC generated message is being displayed.

Local Messages are also displayed in the LCD Display Window. Local Messages

provide pertinent information or instructions to the operator and are displayed

in a menu hierarchy. They can also be programmed to display values from a

PLC register that the operator may change using the EZSeries Set Point Display

Set Point Display Panel control buttons. You may create Folders to group

messages pertaining to the same topic. Local Messages and Folders can be

grouped in up to 3 levels using the EZSeries Set Point Display Set Point Display

Panel Programming Software. The fi rst character in a Folder message display

is a “+” or “–” indicating folder status (closed or open). The next 19 characters

of the display are for the Folder text (Messages do not have a + or -, so all 20

characters can be used for text.) Local Messages allow the operator to select

and initiate user-defi ned interaction. See Chapter 3, Learning the Features, for

more information.

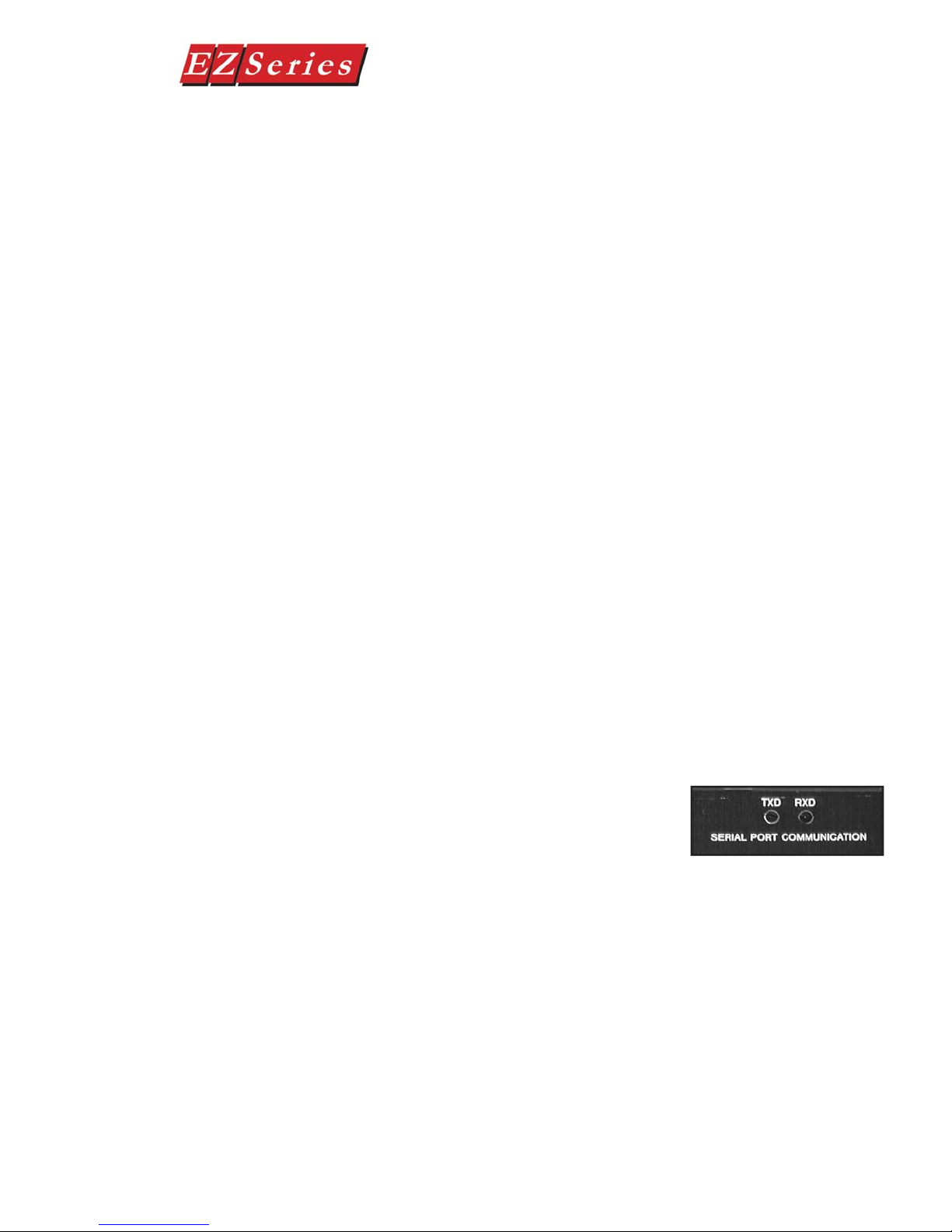

Rear Panel Indicators

EZ-TEXT-M-E

TXD LED

This LED will toggle “on” and “off” to signal activity

on the transmission line.

RXD LED

This LED will toggle “on” and “off” to signal activity

on the receive line.

13

Text Panel Hardware Manual

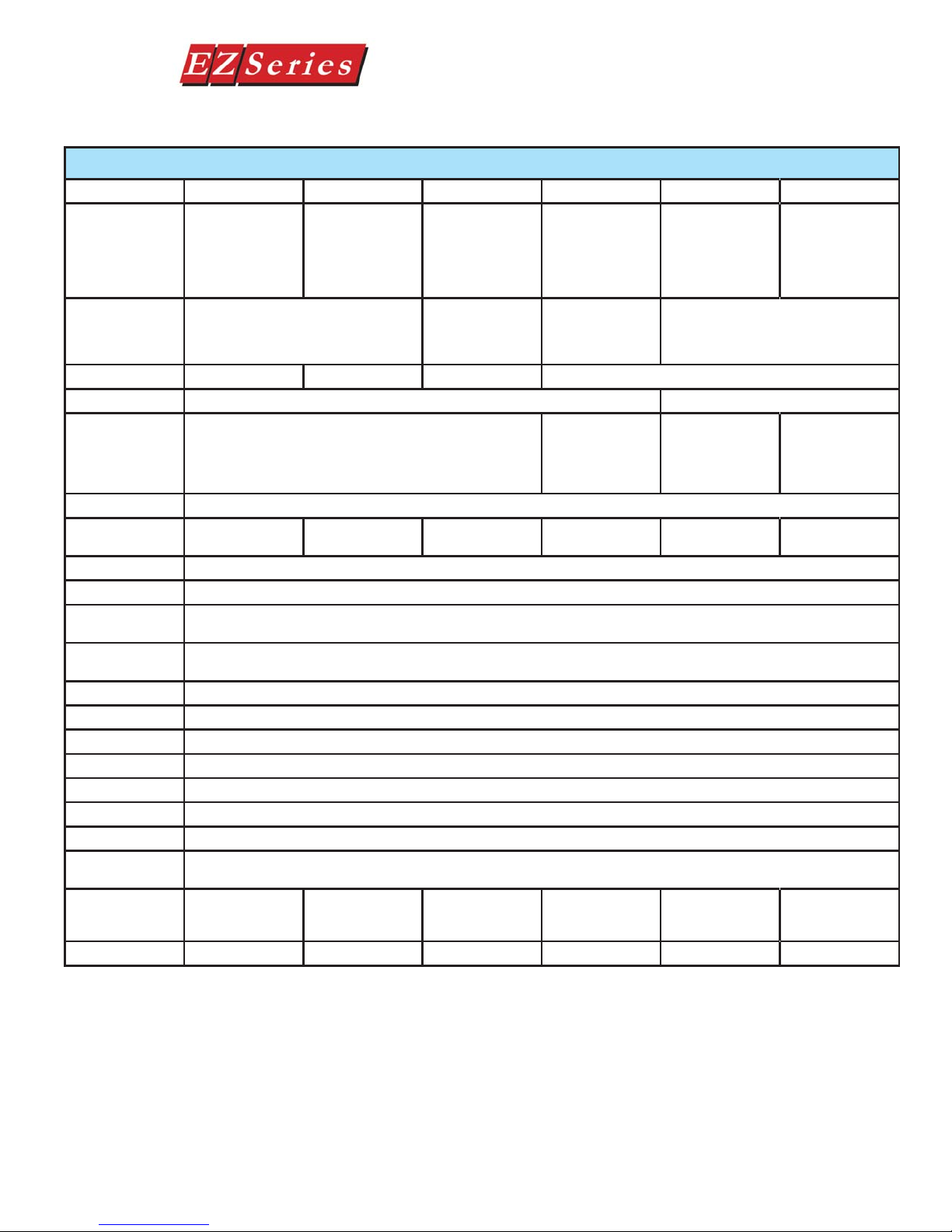

Specifi cations

EZSeries Set Point Display Set Point Display Panel Specifi cations

Part Number EZ-220 EZ-220L EZ-420 EZ-220P EZ-220V EZ-220PV

2x20 LCD display,

Description

Display Type

Character Height 5.55mm (0.22”) 8.06mm (0.316”) 4.75mm (0.187”) 5.55mm (0.22”)

Viewing Angle + or - 15 degrees horizontal + or - 60 degrees horizontal

Keypad Overlay Five user defi ned pushbuttons and four control pushbuttons

Service Power 24 VDC (20-30VDC operating range)

Power

Consumption

Enclosure NEMA 4, 4X (indoor)

Agency Approval UL, CUL, CE

Operating

Temperature

Storage

Temperature

Humidity 10 - 95% R.H., (non-condensing)

Electrical Noise NEMA ICS 2-230 showering arc ANSI C3790a-1974 SWC Level C Chattering Relay Test

Withstand Voltage 1000 VDC (1 minute) between power supply input terminal and protective ground (FG)

Vibration 5 - 55Hz 2 G for 2 hours in the X, Y, and Z axes

Shock 10 G for under 12 ms in the X, Y, and Z axes

Burn-in Temperature cycled 96 hours and then fully functional tested

LED/LCD Life 100,000 hours

Serial

Communications

Dimensions

Weight (lbs) .65 .85 .65 .85 .65 .85

fi ve user defi ned

pushbuttons, fi ve

LEDs

Character LCD, 2 lines by 20 characters

w/LED backlight

4 Watts @ 24 VDC

7.418 x 5.00

(188.419 x

126.9989)

2x20 LCD display,

large characters,

fi ve user defi ned

pushbuttons, fi ve

LEDs

4.5 Watts @ 24

VDC

Download/Program/PCS Port TS-232/RS422/RS485 15-pin D-sub (female)

10.018 x 5.00

(254.458 x

126.998)

4x20 LCD display,

fi ve user defi ned

pushbuttons, fi ve

LEDs

Character LCD,

4 lines by 20

characters w/LED

backlight

4 Watts @ 24 VDC

0 to 45 °C (32 to 113 °F)

-20 to 60 °C (-4 to 140 °F)

7.418 x 5.00

(188.419 x

126.9989)

2x20 LCD display,

numeric keypad,

fi ve user defi ned

pushbuttons, three

tri-color LED

annunciators

Character LCD,

2 lines by 20

characters w/LED

backlight

Numeric keypad,

fi ve user defi ned

pushbuttons and

four control push-

buttons

5.5 Watts @ 24

VDC

10.018 x 5.00

(254.458 x

126.998)

2x20 LCD display,

fi ve user defi ned

pushbuttons, fi ve

LEDs

Character VFD (Vacuum Fluorescent

Display), 2 lines by 20 characters w/LED

Five user defi ned

pushbuttons and

four control push-

buttons

6 Watts @ 24 VDC

7.418 x 5.00

(188.419 x

126.9989)

2x20 VFD display,

numeric keypad,

fi ve user defi ned

pushbuttons, three

tri-color LED

annunciators

backlight

Numeric keypad,

fi ve user defi ned

pushbuttons and

four control push-

buttons

8.5 Watts @ 24

VDC

10.018 x 5.00

(254.458 x

126.998)

14

EZ-TEXT-M-E

Hardware Installation

In this chapter....

— Custom Labels

— EMI Noise Filter Installation

— Mounting

— DIN Clip Mounting

— Connections and Wiring

2

Custom Labels

Text Panel Hardware Manual

Create Custom Labels

You may create custom labels for the EZSeries Set Point Display Text Panel

Function Pushbuttons that are particular to their function within your application. The labels slide into an existing slot in the panel overlay so that the text or

numbers you have printed will rest over the pushbuttons.

A Microsoft Word® document ( EZ-TEXT_INSERTS.doc) is installed in the

EZSeries Set Point Display Text Panel Program folder on your computer

when you installed your programming software. You must have Word

installed on your computer to open this document. This document will help

you create your labels. Two sheets of cover stock have also been shipped with

your panel.

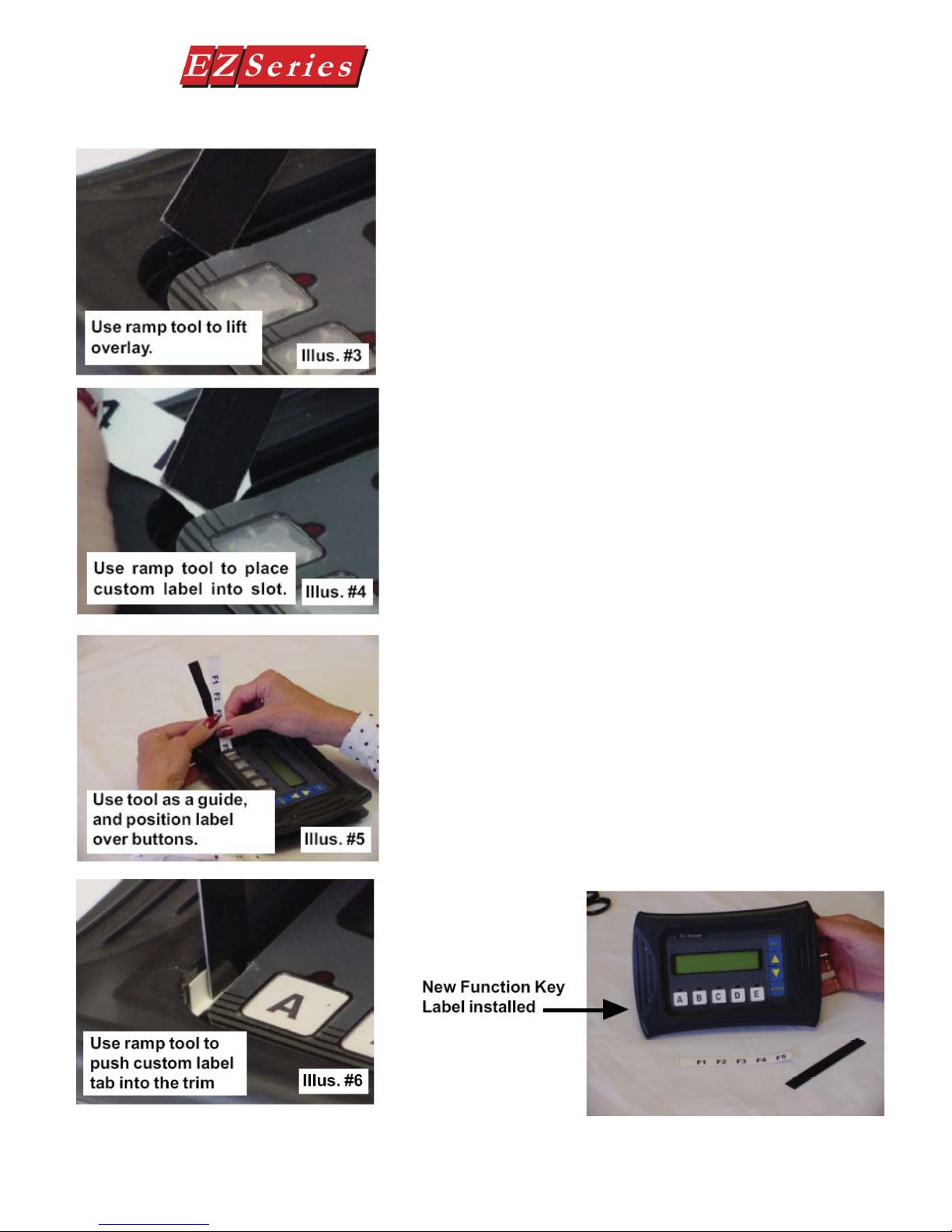

Install Custom Labels

A 1/2-inch x 4-inch fl at metal tool ( ramp tool) is shipped with each unit to

aid in the installation of the label inserts.

To install the pushbutton labels into the slots, perform the following steps.

1. Carefully remove rubber trim mold from panel front to access label

slots. (The trim has a barbed retaining rib that is pressed securely into

a channel in the front panel housing.) The ramp tool can be used to

help lift the trim (see illustration #1).

16

EZ-TEXT-M-E

Text Panel Hardware Manual

2. The recessed slot(s) where the labels are inserted

should now be visible.

3. Remove the factory installed label insert.

4. Use the corner of the ramp tool to lift the top layer of the

overlay (shown in illustration #3), just enough to

place the custom label into the slot. Hold the overlay

up with the ramp tool and start the custom label into

the slot (illustration #4).

5. Once the label has been placed into the slot, move the

ramp tool behind the label insert and use as a ramp to

guide the label insert into the slot until properly

positioned (illustration 5).

6. Push label tab down into trim channel with the ramp

tool (illustration 6).

7. Replace the rubber trim by fi rmly pressing the barbed

rib into the molded channel in the front panel housing.

EZ-TEXT-M-E

17

Text Panel Hardware Manual

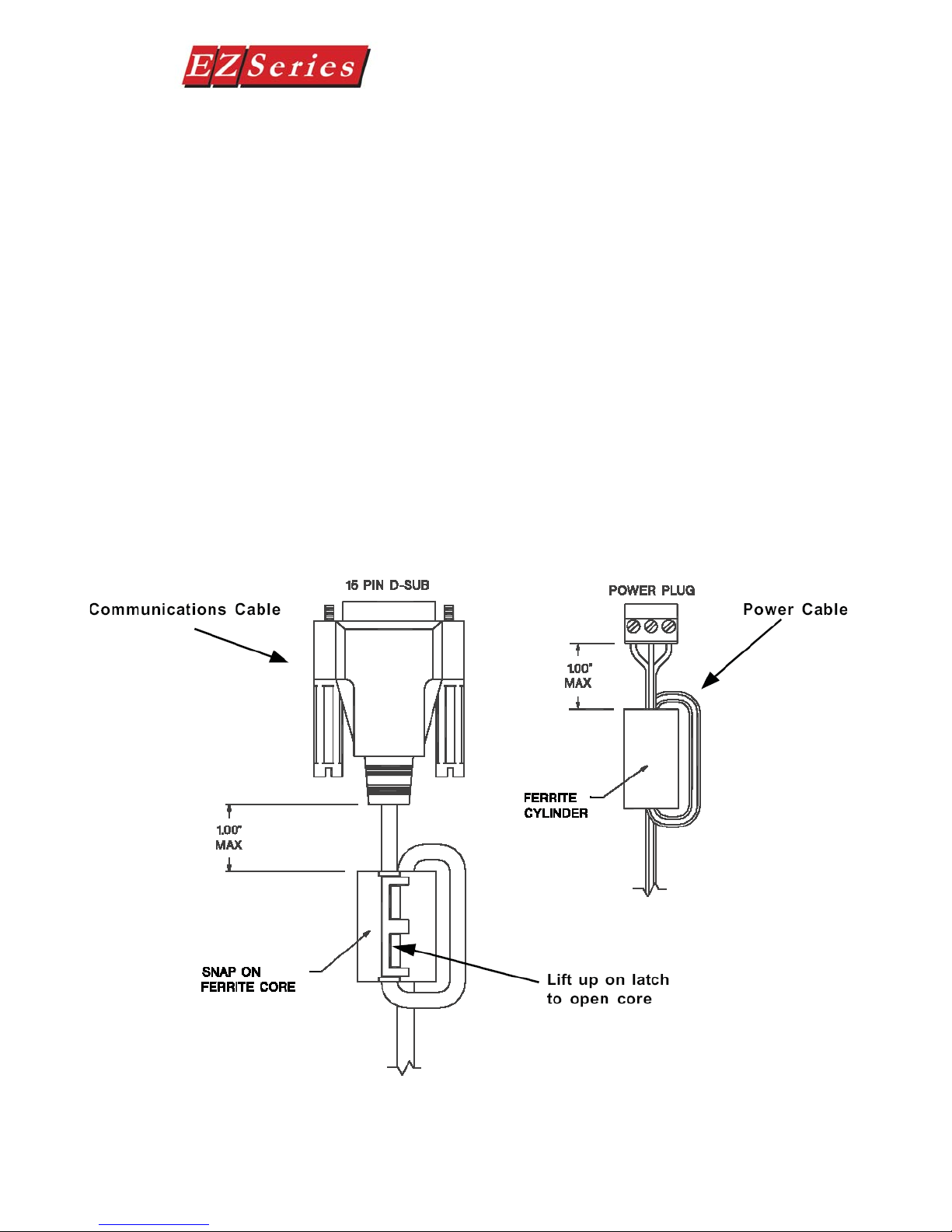

EMI Noise Filter Installation

EZSeries Set Point Display Text Panels are supplied with two ferrite cores that

should be attached to the cables prior to installation of the EZSeries Set Point

Display Text Panel. These cores are required to suppress EMI emissions that

are conducted through the Power Cable and the Communications Cable. The

fi gure, below, shows the ferrite cores properly installed. Attach the cores within

one inch of the EZSeries Set Point Display Text Panel connector. The cable

should be snugly wrapped once around the core, providing two passes through

the core.

The Power Cable Core is a solid ferrite cylinder . The Power Cable should pass

once through the core, be looped around and pass through a second time. Pull

the excess cable so that it rests snugly against the outside of the core.

The Communications Cable Core is a snap-together, split, ferrite core. This

core can be installed on a fi nished cable. Lift the latch to open the core. Wrap

the wire through the core center, snugly around the outside, and again through

the center. Close the core until the latch snaps. Ensure that the cable jacket is

not pinched between the two halves of the core. The fi nished cable should look

similar to the drawing shown below.

18

EZ-TEXT-M-E

Mounting

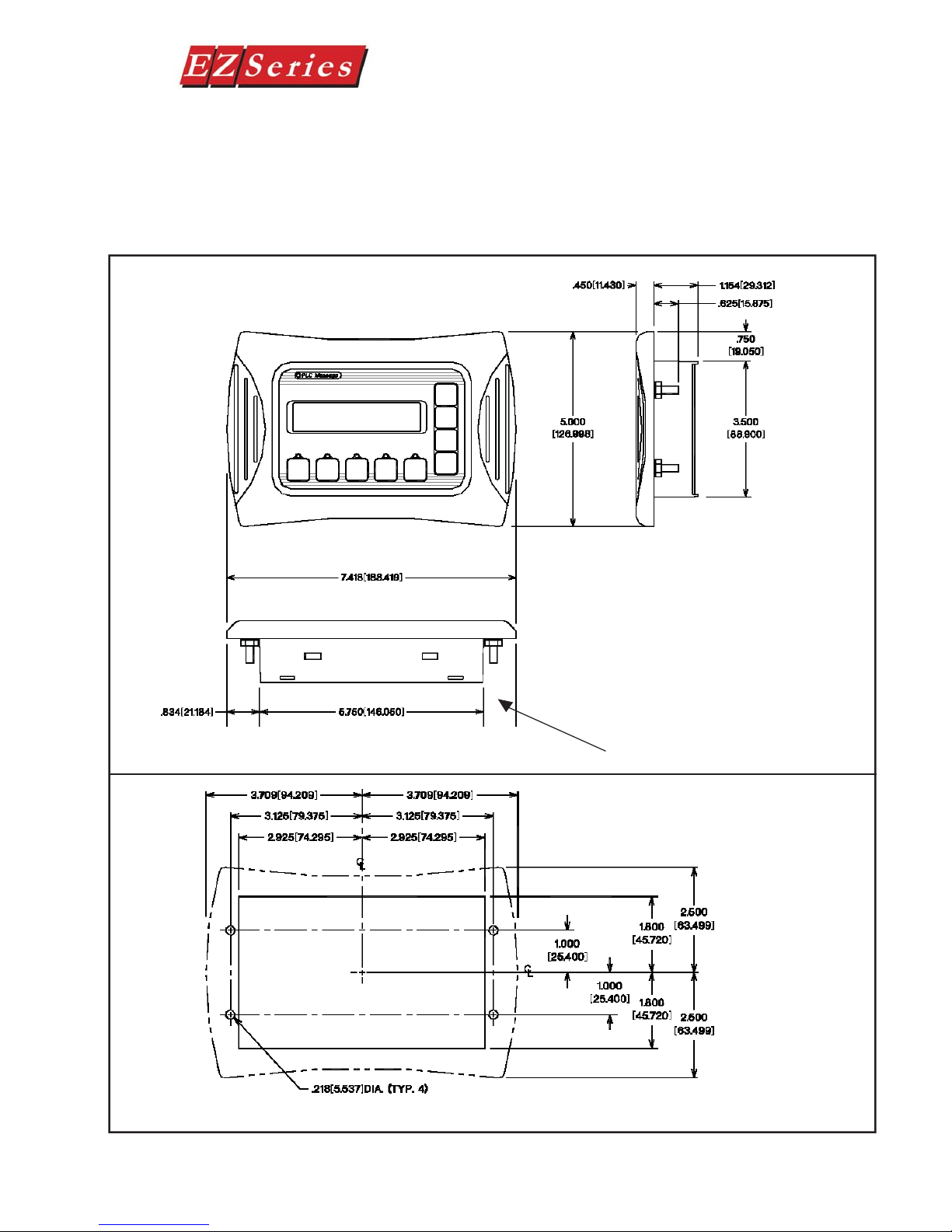

Models EZ-220, 200V, & 420 Outline

Dimensions and Mounting Template

Text Panel Hardware Manual

EZSeries Set Point Display Text Panels can be mounted in two different ways:

Stud Mounting and DIN Clip Mounting. The panel comes with all the necessary

mounting hardware required for stud mounting. DIN Clips (P/N EZP-BRK-2) must

be ordered separately.

STUD Mounting:

Use the 4 studs and 4 nuts

with captive washers to secure the unit to the mounting surface. Requires a

5/16” wrench.

Mounting Studs (4 total)

EZ-TEXT-M-E

Mounting Template

19

Text Panel Hardware Manual

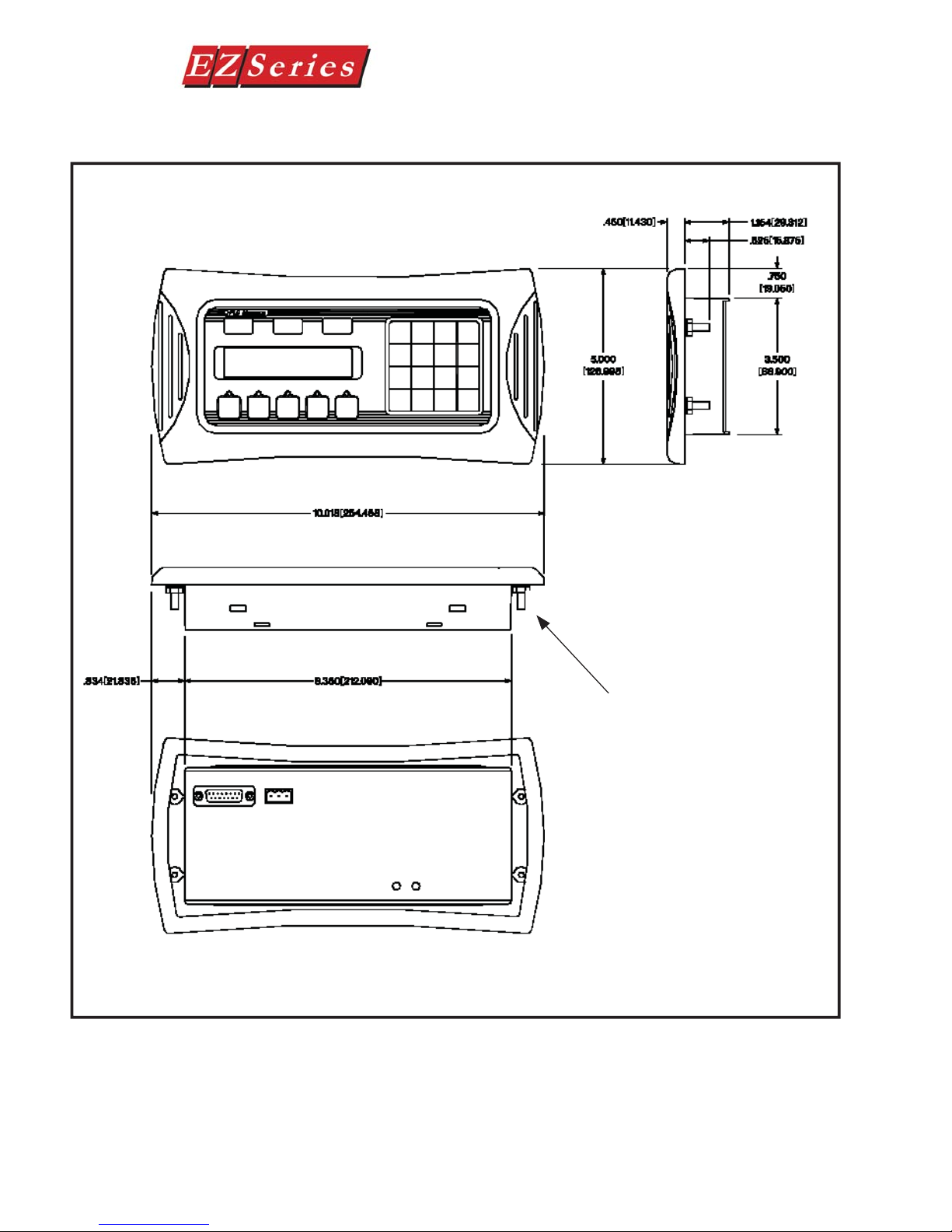

Model EZ-220P/EZ-220PV

Outline Dimensions

STUD Mounting:

Use the 4 studs and 4 nuts

with captive washers to

secure the unit to the mounting surface. Requires a 5/16”

wrench.

Mounting Studs (4 total)

20

EZ-TEXT-M-E

Text Panel Hardware Manual

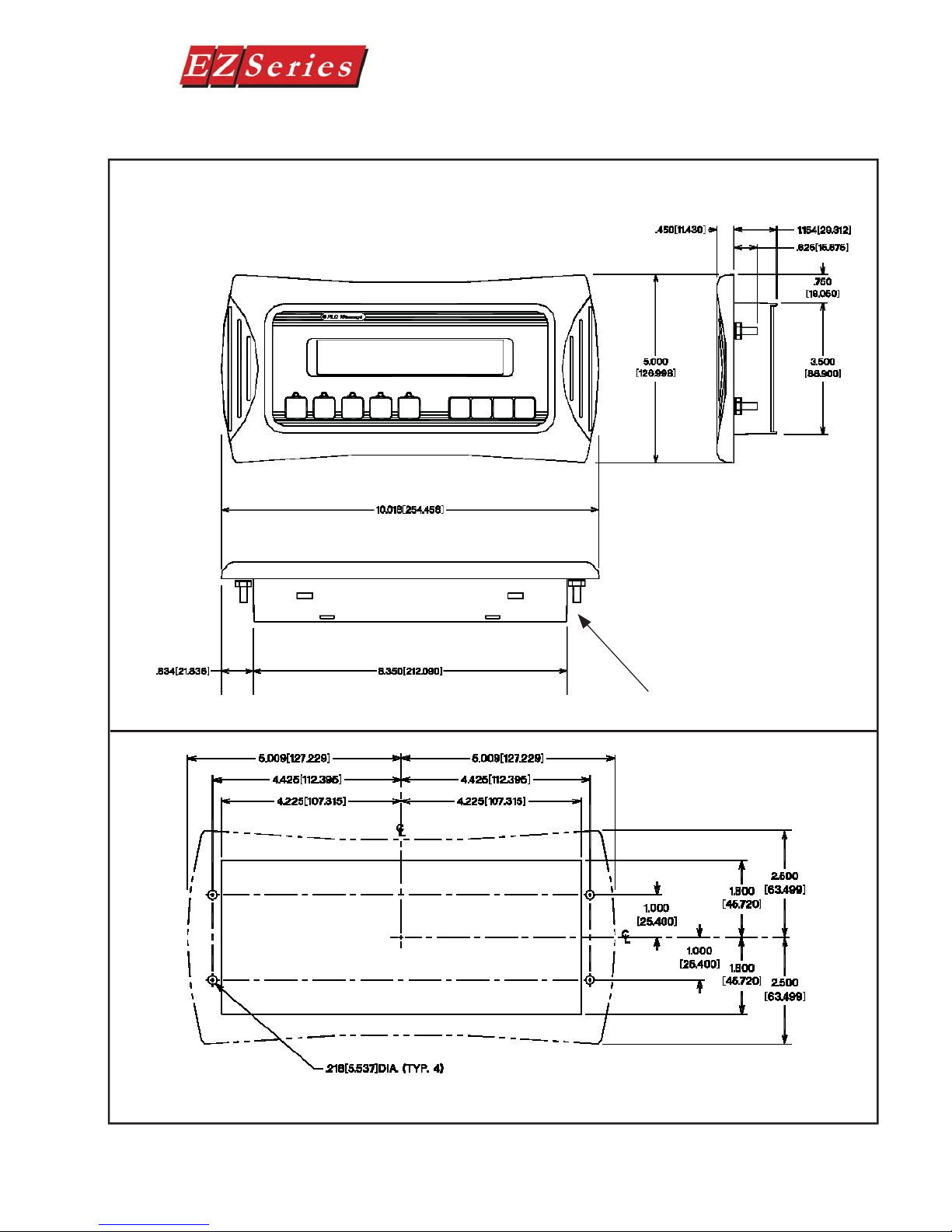

Model EZ-220L Outline

Dimensions and Mounting Template

STUD Mounting:

Use the 4 studs and 4 nuts

with captive washers to secure the unit to the mounting surface. Requires a

5/16” wrench.

Mounting Studs (4 total)

EZ-TEXT-M-E

Mounting Template

21

DIN CLIP Mounting

DIN Clips (P/N EZ-BRK-2) are metal brackets that attach to the panel and secure

the front bezel to a mounting surface with a screw. They provide an alternative

to bolting the panel into the mounting surface. There are 4 square holes in the

chassis (two on the top and two on the bottom). Insert the clip fl ange into this

hole and secure the EZSeries Set Point Display T ext Panel by tightening the DIN

CLIP screw until the front bezel is fi rmly pressed to the mounting surface.

Text Panel Hardware Manual

22

EZ-TEXT-M-E

Connections and Wiring

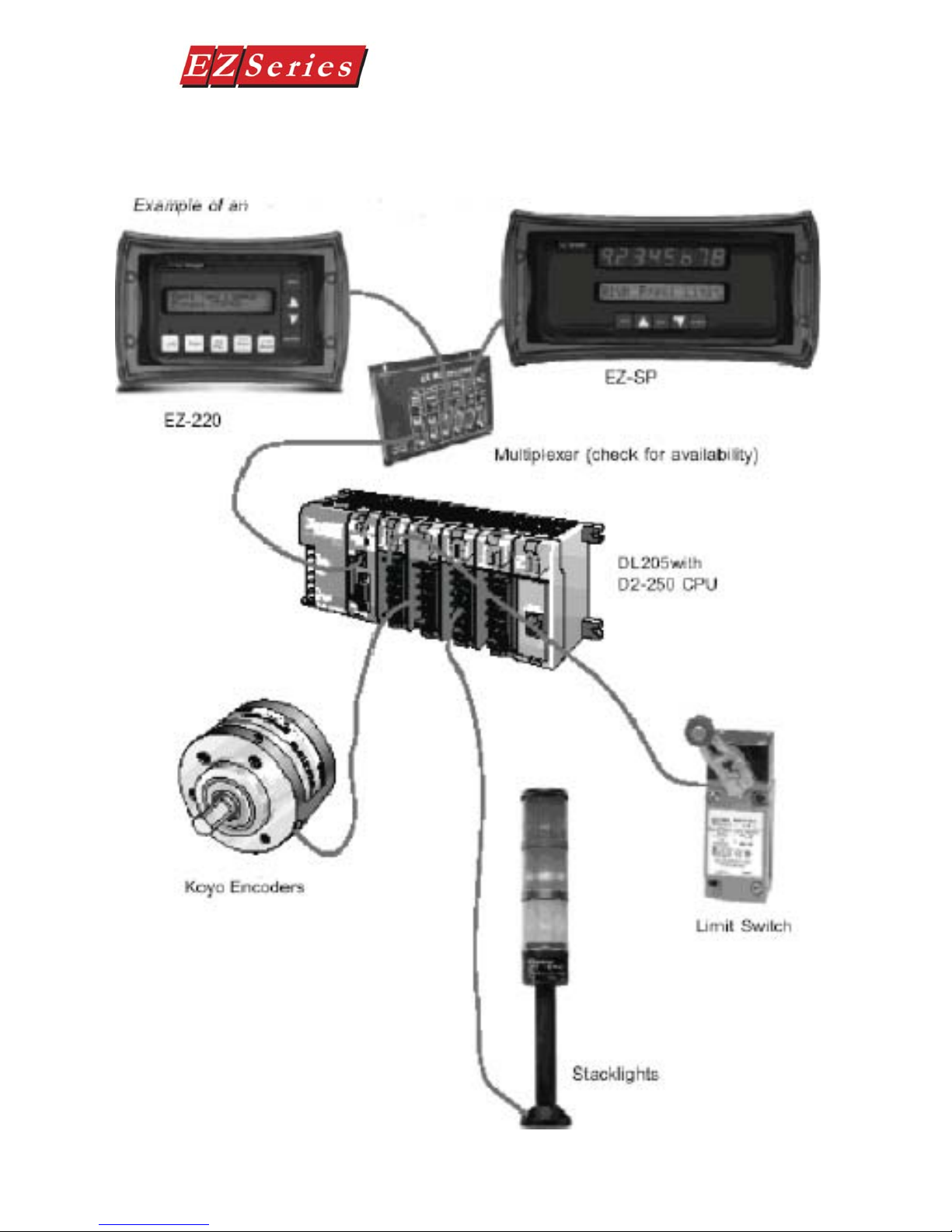

EZSeries Text Panel Application

Text Panel Hardware Manual

EZ-TEXT-M-E

23

Text Panel Hardware Manual

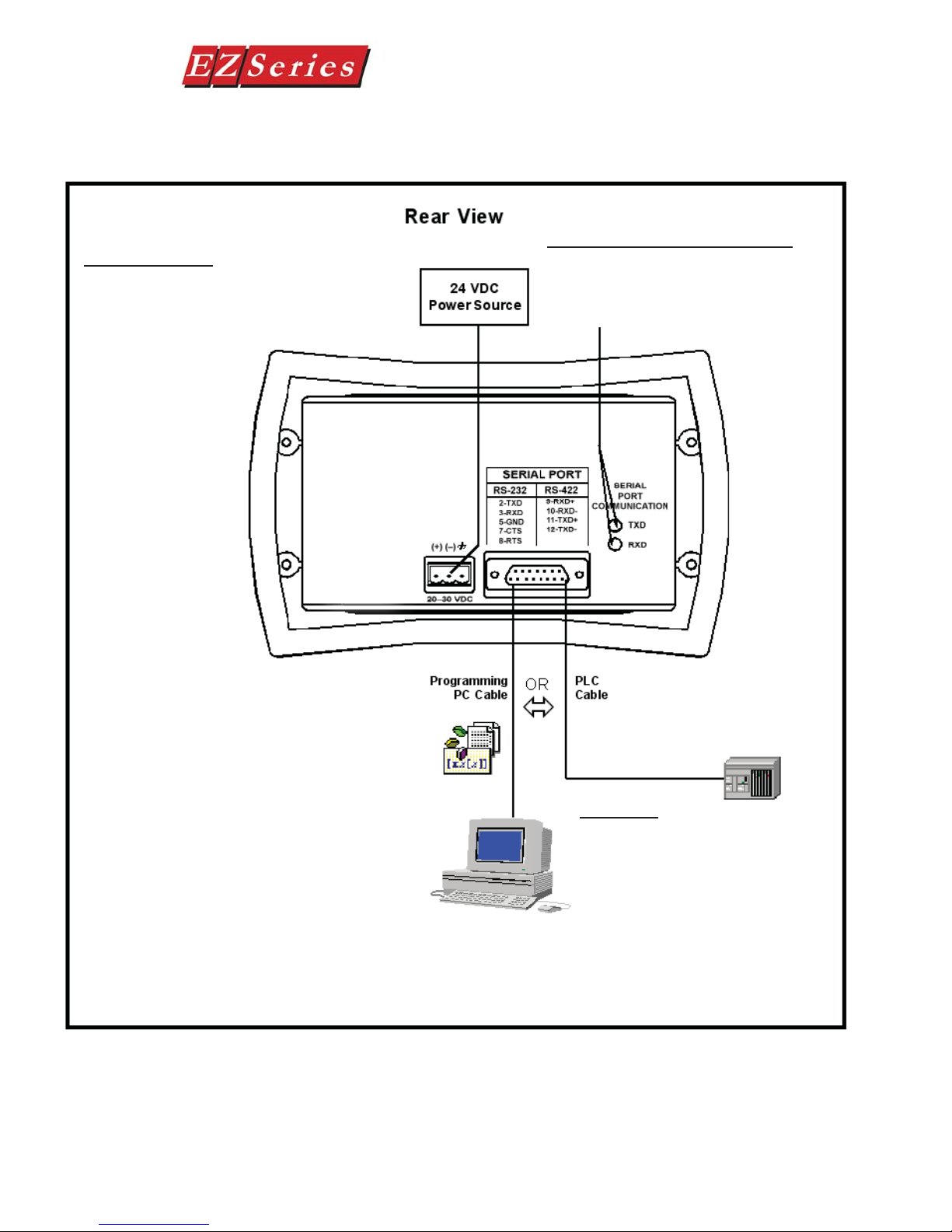

EZ-220, EZ-220V & EZ-420 Connections and Wiring

Power Connector

Block style connector is used to connect an

external 24VDC power supply . See Power Connector Pinout on page 27.

Serial Port Communication LEDs

These LEDs illuminate to show whether

the unit is sending or receiving data. See

page 91.

24

Serial Port

This port may be used to connect the

programming computer or a PLC (see

page 27). Use programming cable P/N

EZTEXT-PGMCBL to connect the PC. See

PLC Cable Part Number table, page 9 for

the appropriate PLC cable used by your

application. Block style connector is used

to connect an external 24VDC power

supply. See Power Connector Pinout

on page 27.

EZ-TEXT-M-E

Text Panel Hardware Manual

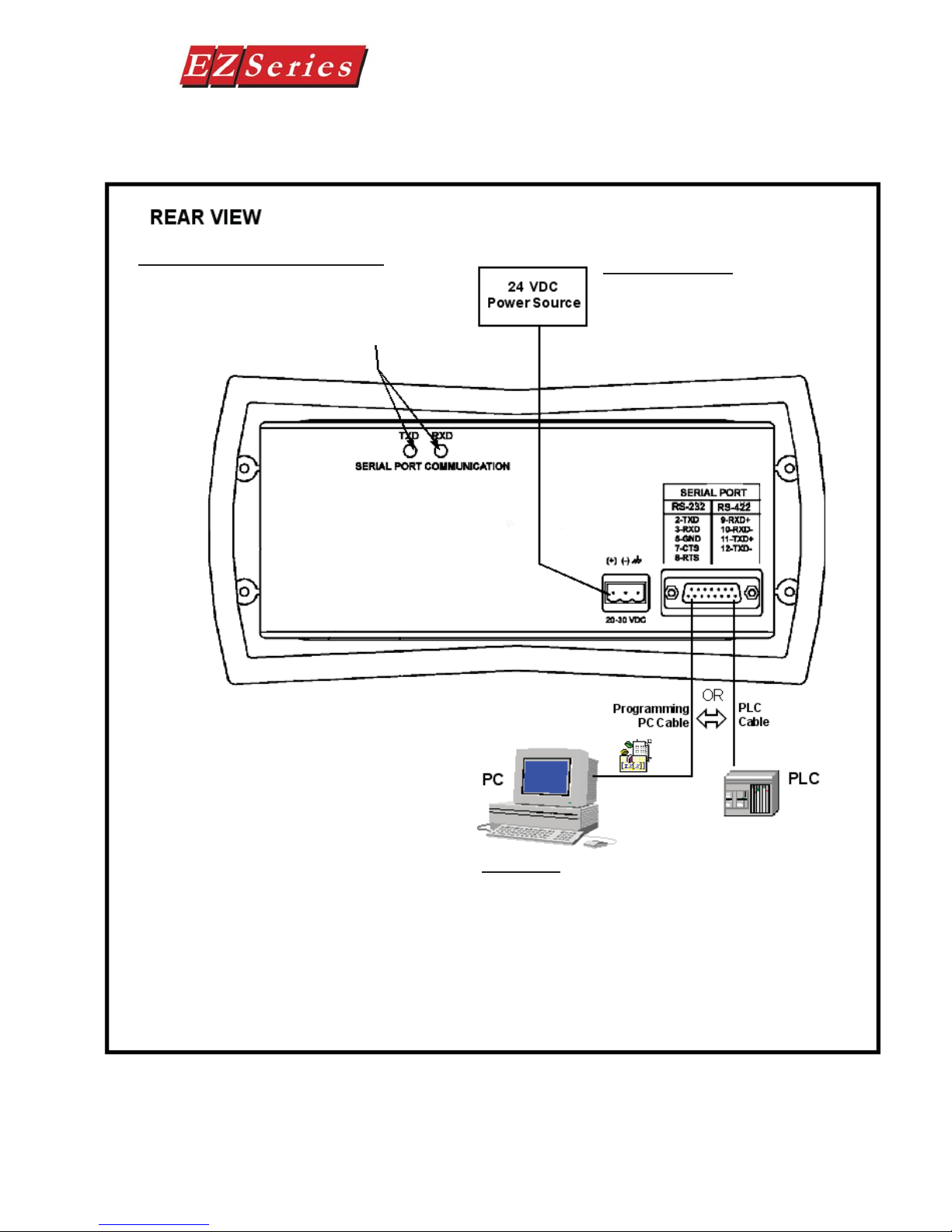

EZ-220P & EZ-220PV Connections and Wiring

Serial Port Communication LEDs

These LEDs illuminate to show whether

the unit is sending or receiving data. See

page 91.

Power Connector

Block style connector is used to

connect an external 24VDC power

supply . See Power Connector Pinout

on page 27.

EZ-TEXT-M-E

Serial Port

This port may be used to connect the programming

computer or a PLC (see page 27). Use programming cable

P/N EZTEXT-PGMCBL to connect the PC. See PLC Cable

Part Number table, page 9 for the appropriate PLC cable

used by your application. Block style connector is used

to connect an external 24VDC power supply. See Power

Connector Pinout on page 27.

25

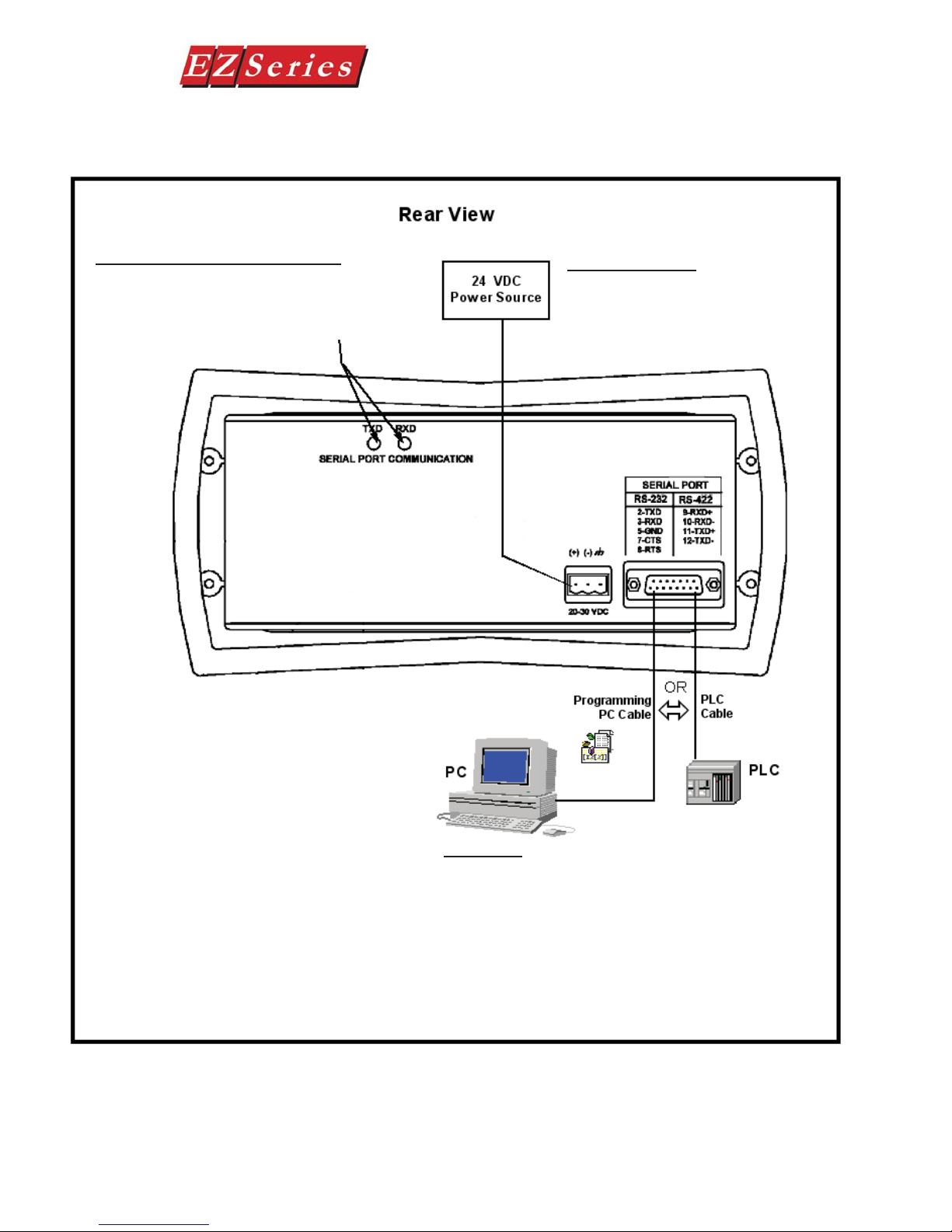

EZ-220L Connections and Wiring

Text Panel Hardware Manual

Serial Port Communication LEDs

These LEDs illuminate to show whether

the unit is sending or receiving data. See

page 91.

Power Connector

Block style connector is used to

connect an external 24VDC power

supply . See Power Connector Pinout

on page 27.

26

Serial Port

This port may be used to connect the programming computer or a PLC (see page 27). Use programming cable P/N

EZTEXT-PGMCBL to connect the PC. See PLC Cable Part

Number table, page 9 for the appropriate PLC cable used by

your application. Block style connector is used to connect an

external 24VDC power supply. See Power Connector Pinout

on page 27.

EZ-TEXT-M-E

Loading...

Loading...