Ez DS-1150, DS-1100, DS-1250 User Manual

Digital Oscilloscope

Digital Oscilloscope

DECLARATION OF CONFORMITY

Manufacture's name : EZ Digital Co., Ltd

Manufacture's Address : 222-28, Nae-dong, Ojeong-gu,

Bucheon-si, Gyeonggi-do

R.O.KOREA, 421-160

Declares that the product :

Product name : Oscilloscope

Model number : DS - 1XXX ( X : 0 ~ 9 )

Date : December, 01, 2001

Conforms to the following product specifications:

Safety : EN 61010-1 : 1993 + A2 : 1995

(IEC 10101 : 1990 + A1 : 1992

+ A2 : 1995, Modified)

EMC : EN 61326/1997 + A1:1998

Supplementary information:

The product herewith complies with the requirements of the

Low Voltage Directive 73/23/EEC and the EMC Directive 89/336/EEC

Bucheon, Gyeonggi

Cheol Young Kim

Location

Quality Assurance Manager

2

WARRANTY

This instrument is warranted against defects in workmanship and materials. If any

failure, resulting from a defect in either workmanship or material should occur under

normal use within a year from the original date of purchase, such failure will be

corrected free of charge to the purchaser by repair or replacement of the defective

part or parts. When the failure is a result of user's neglect, natural disaster or accident,

we charge for repairs regardless of the warranty period.

This warranty is subject to the following conditions and limitations.

The warranty is void and inapplicable if the defective product is not brought or sent

prepaid to our authorized service center or sales outlet within a warranty period.

Defective product is, on EZ Digital Co., Ltd.'s sole judgement, indemnified at a

purchased price, replaced with new one or repaired without charge or with charge.

In the event warranty service is needed, purchaser should get in touch with the service

center or sales outlet, or properly pack and return the product to the service center

or sales outlet at his or her own expense. A returned product must be accompanied

by a written description of the defect. We return the product to the purchaser at his or her

own expense.

In case the warranty does not cover the product on EZ Digital Co., Ltd.'s

sole judgement, we repair the product after obtaining prior permission from the

purchaser who received pro forma statement about repairing charges. In such a

case, EZ Digital Co., Ltd. bears the transportation expenses required to send back all the

repaired products temporarily, and then repair and transportation expenses will be

charged against the purchaser by the statement of accounts.

When the authorized sales agents sell our product, they must notify the purchaser of the

warranty contents, but have no right to stretch the meaning of original warranty contents

or offer additional warranty. EZ Digital Co., Ltd. does not provide any other promise or

suggestive warranty and holds no liability for the damage caused by negligence,

abnormal use or natural disaster. EZ Digital Co., Ltd. is not responsible for damages

though it was notified about the danger in advance.

For more information on service or overall repairs and maintenance of old and decrepit

products, be sure to contact our service center or sales outlet.

3

PRODUCT CONTENTS

OSCILLOSCOPE

- Set 1 set

SUPPLIED ACCESSORIES

- Operation manual

- Power cord

- 100MHz probes x1/x10 2EA (Only DS-1100)

OPTIONAL ACCESSORIES

- RS-232C thermal printer (Printy2 with RS-232C Cable)

- Test probes

150MHz probes x1/x10

250MHz probes x1/x10

- Service manual

- PC Software kit(RS-232C Cable, USB Cable, PC interface Program)

- Interface Card Type A (RS-232C, Centronics, USB)

- Interface Card Type B (RS-232C, Centronics)

4

CONTENTS

1. INTRODUCTION

1-1 KEY FEATURES

1-2 NOTES FOR A SAFETY OPERATION

1-2-1 OPERATING ENVIRONMENT

1-2-2 SAFETY SYMBOLS

1-2-3 POWER SOURCE-RELATED WARNINGS

1-2-4 PLACE-RELATED WARNINGS

1-2-5 OPERATION-RELATED WARNINGS

1-2-6 SERVICE-RELATED WARNINGS

1-2-7 CLEANING AND MAINTENANCE

1-3 NOTES TO USERS

1-3-1 NOTICE FOR PROPER MEASUREMENT

1-3-2 WHEN CONNECTING PERIPHERAL DEVICES

1-3-3 PROBE

1-4 INSTALLATION

1-4-1 POWER CODE

........................................................................................... 18

..................................................................................... 20

...................................................................................7

......................................................................................8

..............................................9

..........................................................9

.........................................................................9

....................................10

......................................................10

.............................................11

..................................................12

.................................................13

................................................................................14

.....................................14

................................................................................ 20

.......................... 15

1-4-2 INTERFACE CARD

2. DESCRIPTION

.................................................................................... 22

2-1 KEY & DISPLAY DESCRIPTION

2-1-1 DISPLAY OVERVIEW

2-1-2 VERTICAL AXIS OPERATION

2-1-3 HORIZONTAL AXIS OPERATION

2-1-4 TRIGGER

2-1-5 MENUS

2-1-6 CONNECTORS

2-1-7 THE MENU BOX BUTTON AND FUNCTION KNOB

2-2 MENUS

2-2-1 AUTOSET

2-2-2 VERTICAL

2-2-3 MATH

2-2-4 HORIZONTAL

2-2-5 TRIGGER

........................................................................................ 27

........................................................................................... 28

.............................................................................. 29

.................................................................................................... 30

.......................................................................................30

......................................................................................31

............................................................................................. 33

............................................................................... 37

....................................................................................... 38

.......................................................................... 20

..................................................... 23

.................................................................... 23

...................................................... 25

................................................. 26

..................... 29

5

2-2-6 MEASURE

..................................................................................... 43

2-2-7 SAVE/RECALL

2-2-8 ACQUIRE

2-2-9 CURSORS

2-2-10 UTILITY

2-2-11 DISPLAY

2-2-12 HARDCOPY

2-3 USING THE FUNCTIONS EFFECTIVELY

2-3-1 USING THE ZOOM FUNCTION

2-3-2 USING THE SINGLE FUNCTION

2-3-3 USING FFT (FAST FOURIER TRANSFORMATION)

........................................................................................ 51

3. APPENDIX

3-1 SPECIFICATIONS

3-2 FACTORY DEFAULTS

.............................................................................. 45

....................................................................................... 47

..................................................................................... 49

...................................................................................... 53

................................................................................. 55

...................................... 56

.................................................... 56

.................................................. 57

............................................................................................. 60

................................................................................ 61

........................................................................ 65

.................... 58

6

1. INTRODUCTION

7

1-1 KEY FEATURES

The 16bit high speed microprocessor adoption enables the scope to acquire

a typical 100,000 points per second and quickly update the picture on

the screen.

Basic memory length of DS-1150 is 10kB and that of DS-1150 & DS-1250 is 32kB.

Captured waveforms can be zoomed in and analyzed in detail. Also its built-in

10ns peak detection circuit enables it to capture high frequency noise even at

a low speed time/div and magnify and analyze it using the zoom-in function.

In addition, it can save up to 10 waveforms and provide diversified analysis

function like FFT which is available on high priced products.

General Features

- 100MHz bandwidth(DS-1100), 2 CH dual digitizer

- 150MHz bandwidth(DS-1150), 2 CH dual digitizer

- 250MHz bandwidth(DS-1250), 2 CH dual digitizer

- 100MS/s simultaneous maximum sampling rate per channel,

200MS/s sampling rate for one channel only

25GS/s equivalent sampling rate per channel

- 10ns peak detection for glitch capture even in ROLL mode

- Max. 400Vpk input voltage into all channels

Convenient Functions

- Direct single trigger capture function using a hot-key

- Simultaneous 5 waveform informations auto measurement and FFT analysis

- Auto trigger level setting to 50%

- Saving 10 waveforms & 10 setup parameters

- Convenient inserting interface card for RS-232C, hardcopy and USB

8

1-2 NOTES FOR A SAFETY OPERATION

1-2-1 OPERATING ENVIRONMENT

This instrument will operate to its specifications if the environment is

maintained within the following conditions.

- Indoor use

- Altitude up to 2000m use

- Operating temperature 0 ~ 40

- Relative humidity 80%

- Main supply voltage fluctuations not exceed 10% of the nominal voltage.

- After turning on the instrument, please allow a pre-heating period of as long

as some 15 minutes.

This instrument has been qualified to the following EN61010-1 Category :

- Installation (Over-voltage) category 2

- Pollution Degree 2

1-2-2 SAFETY SYMBOLS

Where these symbols or indications appear on the instrument or in this

manual, they have the following meanings.

Refer to accompanying documents for Safety-related information.

Wherever the symbol is present, see "NOTES FOR A SAFETY OPERATION"

part in this manual.

Ground

Risk of hazard which may cause injury to human body or danger to life.

If a WARNING appears on the instrument , and in this manual, do not

proceed until its suitable conditions are understood and met.

Risk of hazard which causes fire or serious damage to the instrument or

other equipment. Do not proceed until its suitable conditions are met.

9

1-2-3 POWER SOURCE-RELATED WARNINGS

Protection of Power Cord and Unplugging

Power-supply cords should be routed so that they are not likely to be waked

on or pinched by items placed upon or against them, paying particular

attention to cords at plugs, convenience receptacles, and the point where

they exit from the instrument. For added protection for this instrument during

a lightening storm, when it is left unattended and unused for long periods

of time, unplug it from the power source. This will prevent damage to the

instrument due to lightening and power-line surges.

Overloading

Do not OVERLOAD power source and extension cords as this can result in a risk

of fire or electric shock.

1-2-4 PLACE-RELATED WARNINGS

Object and Liquid Entry

Never push objects of any kind into this instrument through openings as they

may touch dangerous voltage points or short out parts that could result in a

fire or electric shock. Never spill liquid of any kind on the instrument. Do not

use this instrument near water- for example, near a bath tub wash bowl,

kitchen sink, or laundry tub, in a wet basement, or near a swimming pool, and

the like. Keep the instrument away from damp air, water and dust.

Unexpected trouble may be caused when the instrument is placed in a damp

or dusty place.

FLAMMABLE AND EXPLOSIVE SUBSTANCE

Avoid using this instrument where there are gases, and where there are

flammable and explosive substances in the immediate vicinity.

Unstable Location

Do not place this instrument on an unstable cart, stand, tripod, bracket, or

table. The instrument may fall, causing serious injury to a person, and serous

damage to the instrument. Do not place or use the instrument in a place

subject to ventilation.

10

1-2-5 OPERATION-RELATED WARNINGS

Power Switch

Before plugging the power cord in be sure to check that the power switch is

set to off for protection of the instrument.

Ground Connection

When connecting a probe , connect the ground side of the probe to the ground

of the signal source. At a floating status, a potential might be produced with

respect to other devices or ground, resulting in damaging the instrument,

probe, other measuring instruments, etc.

CH 1

GND

Excessive Input Voltage

In order to avoid electric shock or fire, the input voltages to the probes, BNC

connectors are specified as follows. Do not apply higher voltages. Before using

probe, check the rated voltage with the naked eye. Remove the unused probe

not to contact with ambient high voltage parts. If you apply a higher voltage

more than 400Vpk , remove the probe out of BNC terminals to ensure against

accidental danger

Maximum input Voltage

- CH1, CH2 all 400Vpk

Do not Use Non-certified Probes

Use the probes certified according to EN 61010-1 and EN 61010-2-031 in europe.

Use the UL listed probes in america.

11

1-2-6 SERVICE-RELATED WARNINGS

Damage Requiring Service

Do not attempt to service this instrument yourself as opening or removing

covers may expose you to dangerous voltage or other hazards.

Unplug this instrument from the power source and after servicing to

qualified service personal under the following conditions

- When the AC power cord or plug is damaged.

- When the LCD is damaged, you must not open the cover during operation.

There is a risk of electric shock.

- If liquid has been spilled, or objects have fallen into the instrument.

- If the instrument does not operate normally by following the operating

instructions. Adjust only those controls that are covered by the operating

instructions as an improper adjustment of other controls may result in

damage and will open require extensive work by a qualified technician to

restore the instrument to instrument to its normal operation.

Unplug the power cord from the power source before opening the cover, and

then remove the probe. Even if the instrument is disconnected from all the

power sources, special attention is required in service as the inside capacity

might be in charged condition. When replacement of fuses or other parts is

required, be sure the service technician has used replacements parts specified

by the manufacturer or have the same characteristics as the original part.

Unauthorized substitutions may result in fire, electric shock or other hazards.

There is a risk of electric shock. No user

serviceable parts inside. Leave repair to

qualified personnel.

Safety Check

Upon completion of any service or repairs to this instrument, ask the service

technician to perform safety checks to determine that the instrument is proper

operating condition.

12

1-2-7 CLEANING AND MAINTENANCE

Maintenance routines performable by the operator are listed in this section.

More advanced routines (i.e., procedures involving repairs or adjustments

within the instrument) should be referred to service personnel.

Cleaning

If the outside of the case becomes dirty or stained, carefully wipe the surface

with a cloth moistened with detergent, then wipe the cleaned surface with a

dry cloth. In case of severe stain, try cleaning with a cloth moistened with

alcohol. Do not use powerful hydrocarbons such as benzene or paint thinner.

Dust and/or smudges can be removed from the LCD screen. First remove the

front case and filter. Clean the filter (and the LCD face, if necessary) by wiping

carefully with a soft cloth or commercial wiping tissue moistened with a mild

cleaning agent. Take care not to scratch them. Do not use abrasive cleanser

or strong solvents. Let the cleaned parts dry thoroughly before reinstalling

the filter and front case. If it is installed wet, dew may form and blur the

waveforms. Be particularly careful not to get fingerprints on the filter or LCD

face.

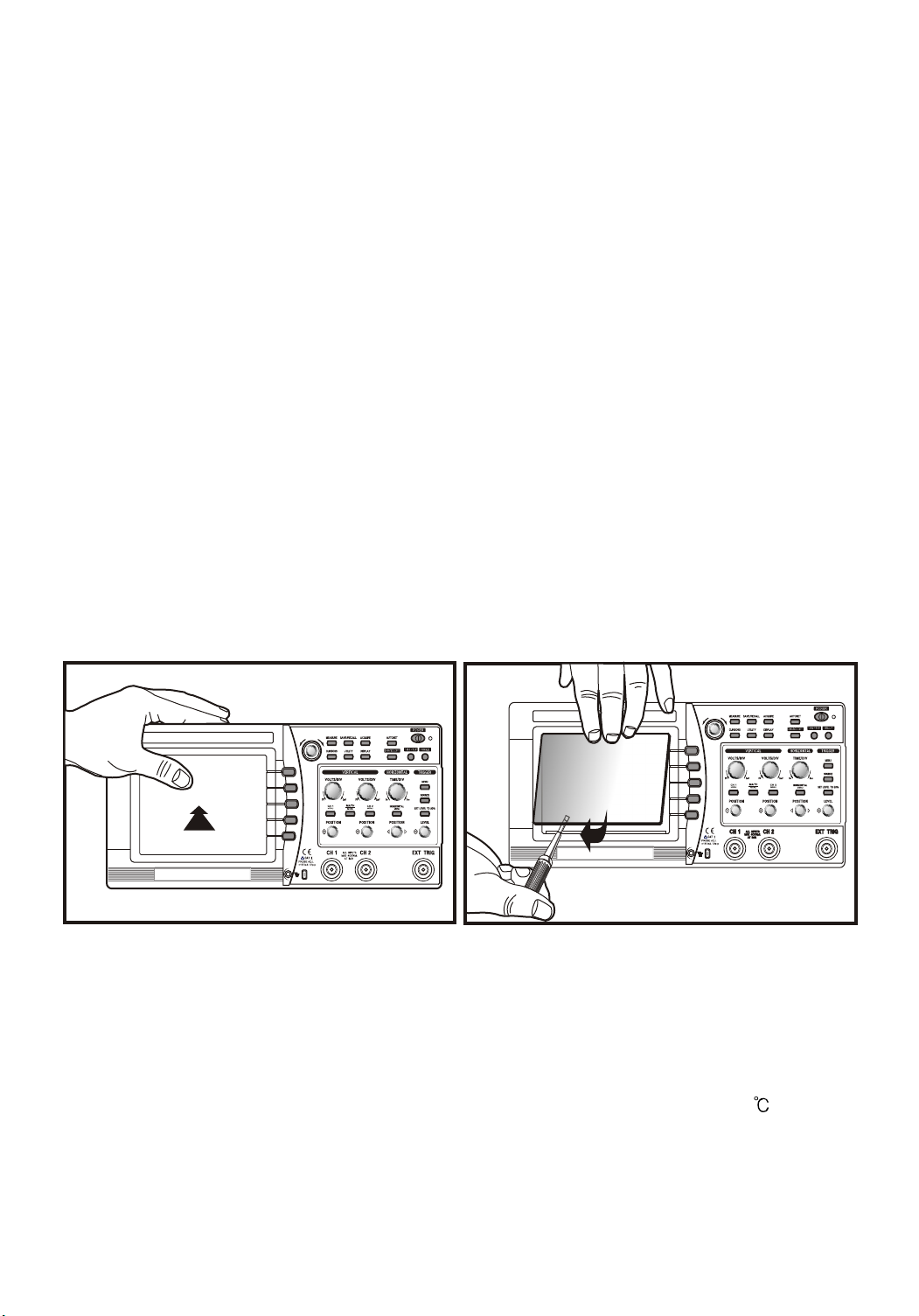

MENU

MENU

Maintenance

This instrument should never be placed in a built-in installation such as a

bookcase or rack unless proper ventilation is provided. Ideal ambient

temperature and relative humidity for storing the instrument are 23 and 60%

13

1-3 NOTES TO USERS

1-3-1 NOTICE FOR PROPER MEASUREMENT

It is recommended to allow about 15 minutes after power on as warm up time

before starting measurement. Traces may drift a little just after power on.

When measuring a signal with high accuracy trace declination, you can correct

the trace position using the automatic calibration function.

Before starting up this function, allow enough warm-up time.

The calibration is classified into software calibration for resorting to the

automatic calibration function in the menu, and hardware calibration for

optimizing the internal circuitry in a wide range.

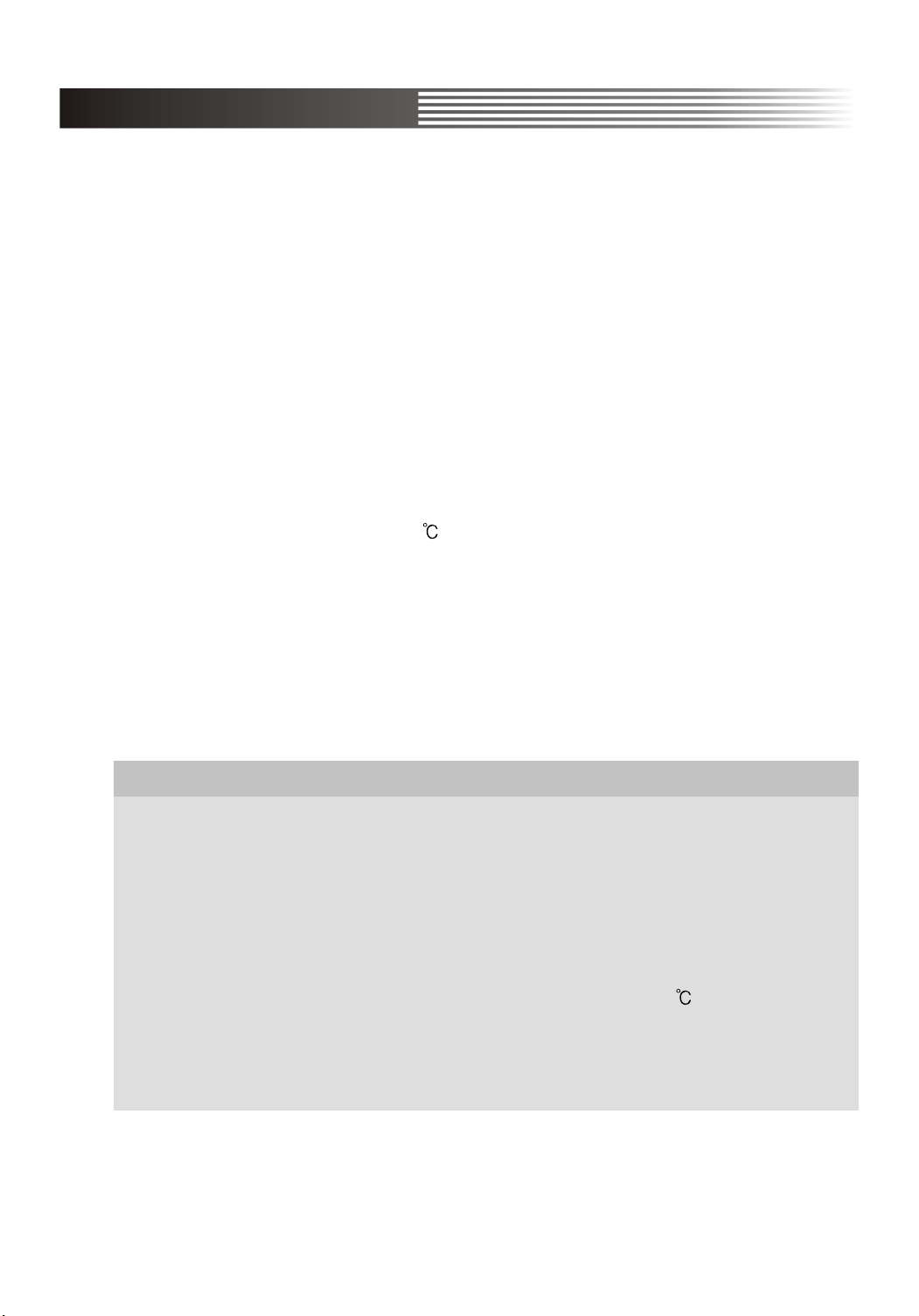

1. The software calibration is recommended when the ambient temperature

has excessively changed (5 ) or when 1000 operating hours or 6 months

has been attained. If the trace is displayed excessively or when it is desired

to optimize the measurement, execute it referring to the automatic

calibration. Before calibration, disconnect all inputs for accurate adjustment.

2. The hardware calibration is necessary to keep the instrument to a stable

operation status. It is recommended to adjust the instrument every 2,000

operating hours or every year.

SOFTWARE CALIBRATION FOR OPTIMUM MEASUREMENT

The changes in measurement accuracy due to use environments

(temperature, humidity, etc) can be optimally corrected automatically

by activating the calibration. It is recommended to perform calibration

when any of the following cases applies.

- Before a customer starts to use this instrument first

- When an ambient temperature changes more than 5 , compared

with that at the time of the previous calibration.

- Every 6 months or 1000 operating hours

- Optimization of measurement accuracy is required

14

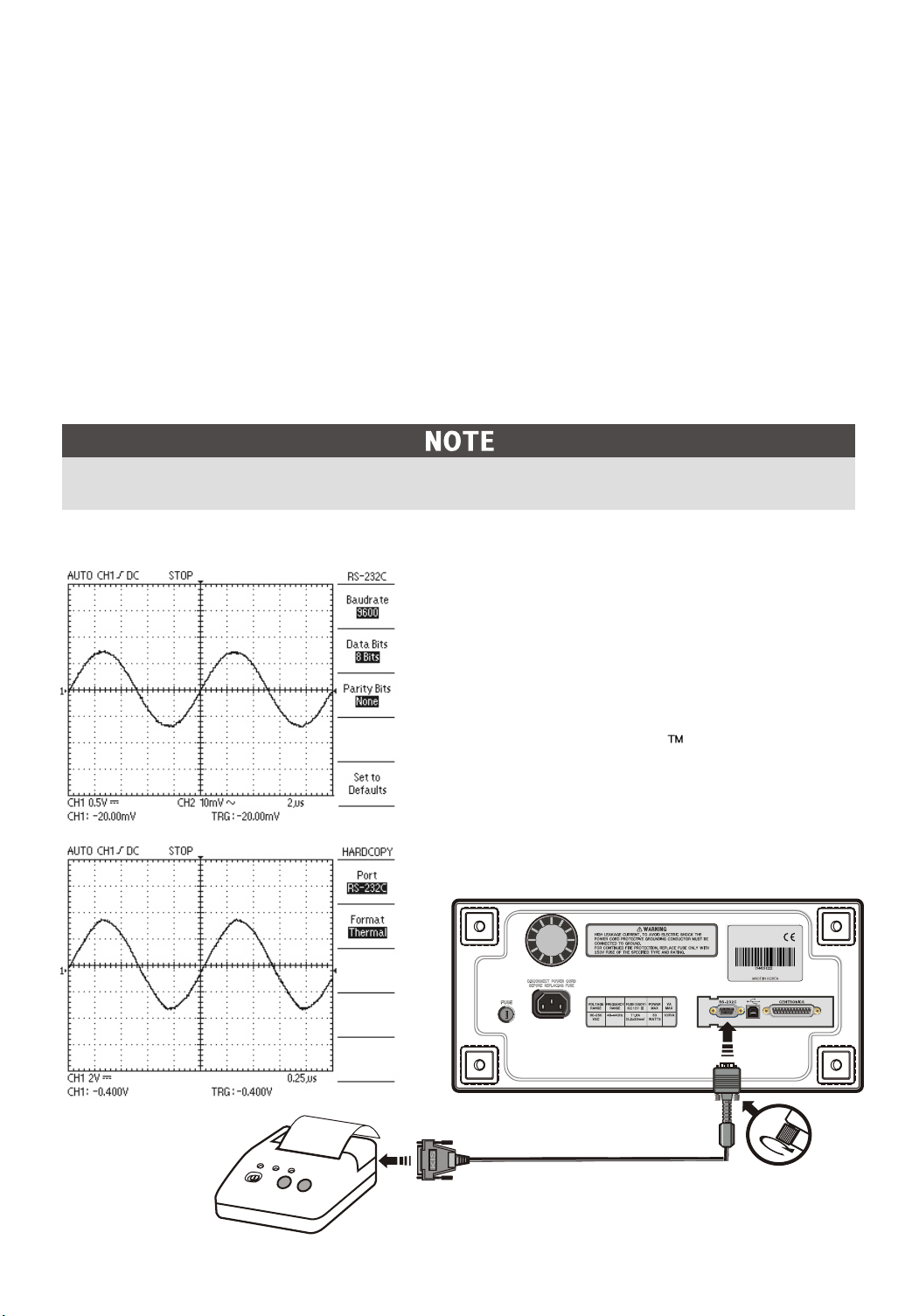

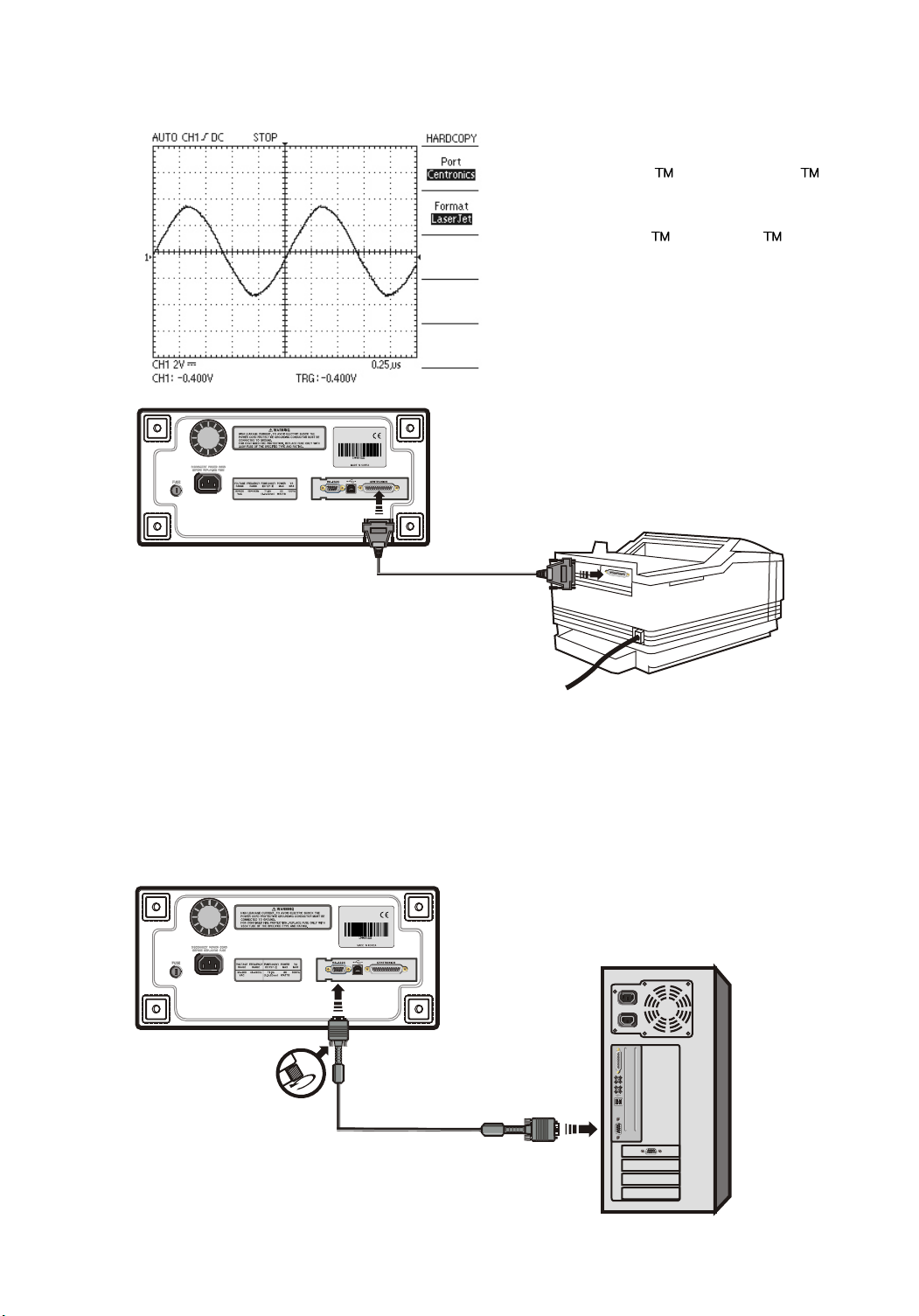

1-3-2 WHEN CONNECTING PERIPHERAL DEVICES

When connecting a printer and a personal computer to the oscilloscope, be

sure that the oscilloscope, the printer and the personal computer are all off,

and then connect them. Pay attention to the direction of the cables and the

ports of the peripheral devices. Before operation, be sure to carry out the

setting necessary for the printer and the personal computer. (For the setting

of the printer and the personal computer, refer to the operation manual for

each) If you operate the printer and the personal computer which are

improperly set, abnormal operation will occur. In this case, turn off the

instrument, the printer and the personal computer at once, and set them

properly again and operate them.

Before using peripheral devices, Interface card should be installed in this instrument.

When using thermal printer opertion, RS-232C settings are as follows

- BAUD RATE : 9600 bps

- PARITY BIT : None

- DATA BIT : 8 bit

* RS-232C Serial cable is 9pin

(male) to 25pin(male) null cable.

* RS-232C thermal printer is

Printy 2 of SANEI Electric INC

15

When using printer operation, Centronics settings are as follows

* This instrument supports

DeskJet and LaserJet with

PCL level 3

* DeskJet , LaserJet is

registered trade mark of HP.

K.I.S

When using PC communication operation, RS-232C settings are as

follows

Before communicating with a PC, the PC software kit(option) should be

installed in your PC. If you want to have more detailed information, refer to the

PC software kit manual.

16

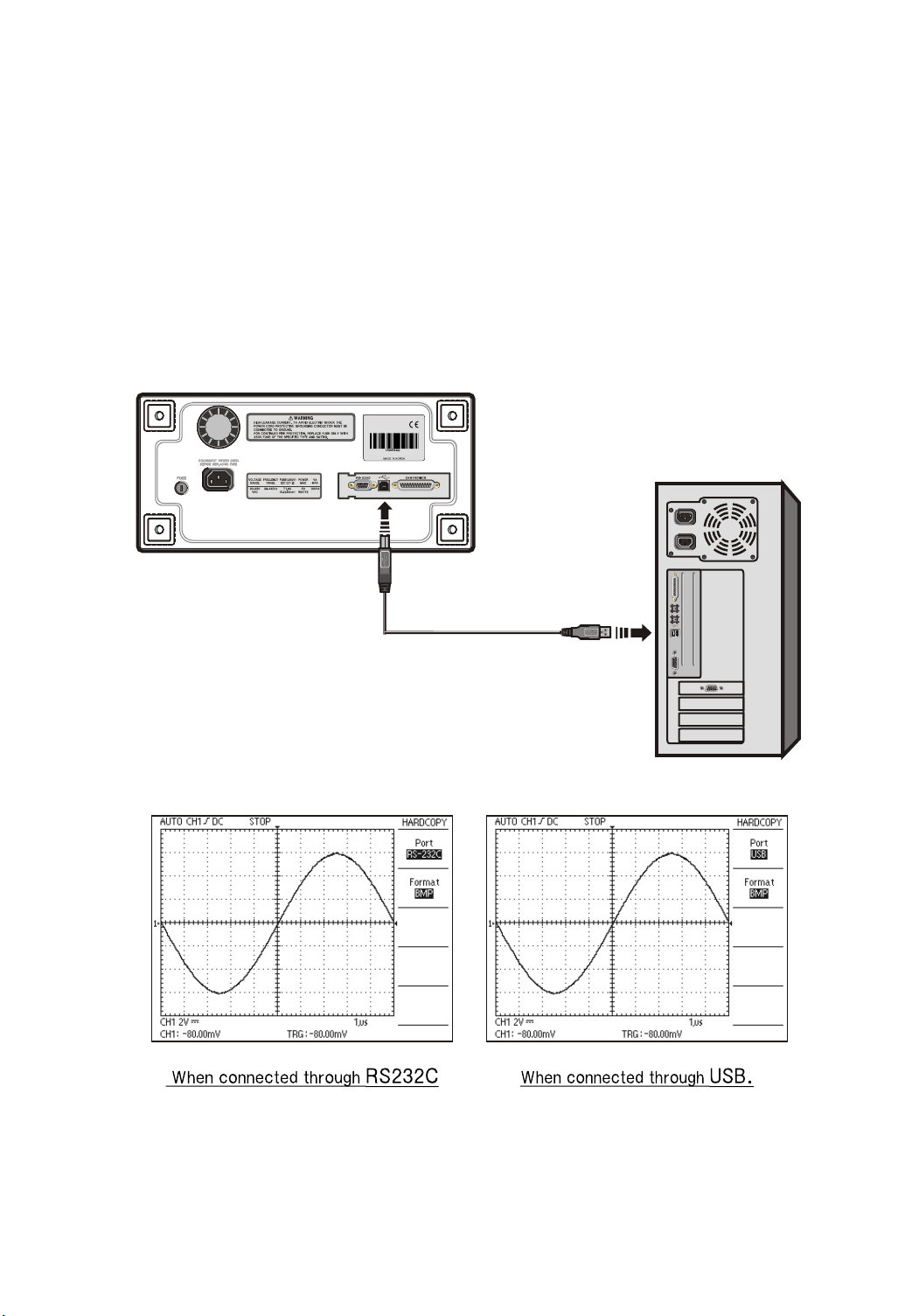

When using PC communication operation, the USB settings are as follows

Before communicating with a PC, the PC software kit (optio ) should be

installed in your PC, an interface card with USB should be installed in

your instrument. The USB protocol is spec V1.1

For more detailed information, refer to the PC software kit manual.

If users want to connect the instrument with the computer and use it, the port

needs to be set to the connection format between them and the transmission

format needs to be set to the BMP format.

d the

nal

17

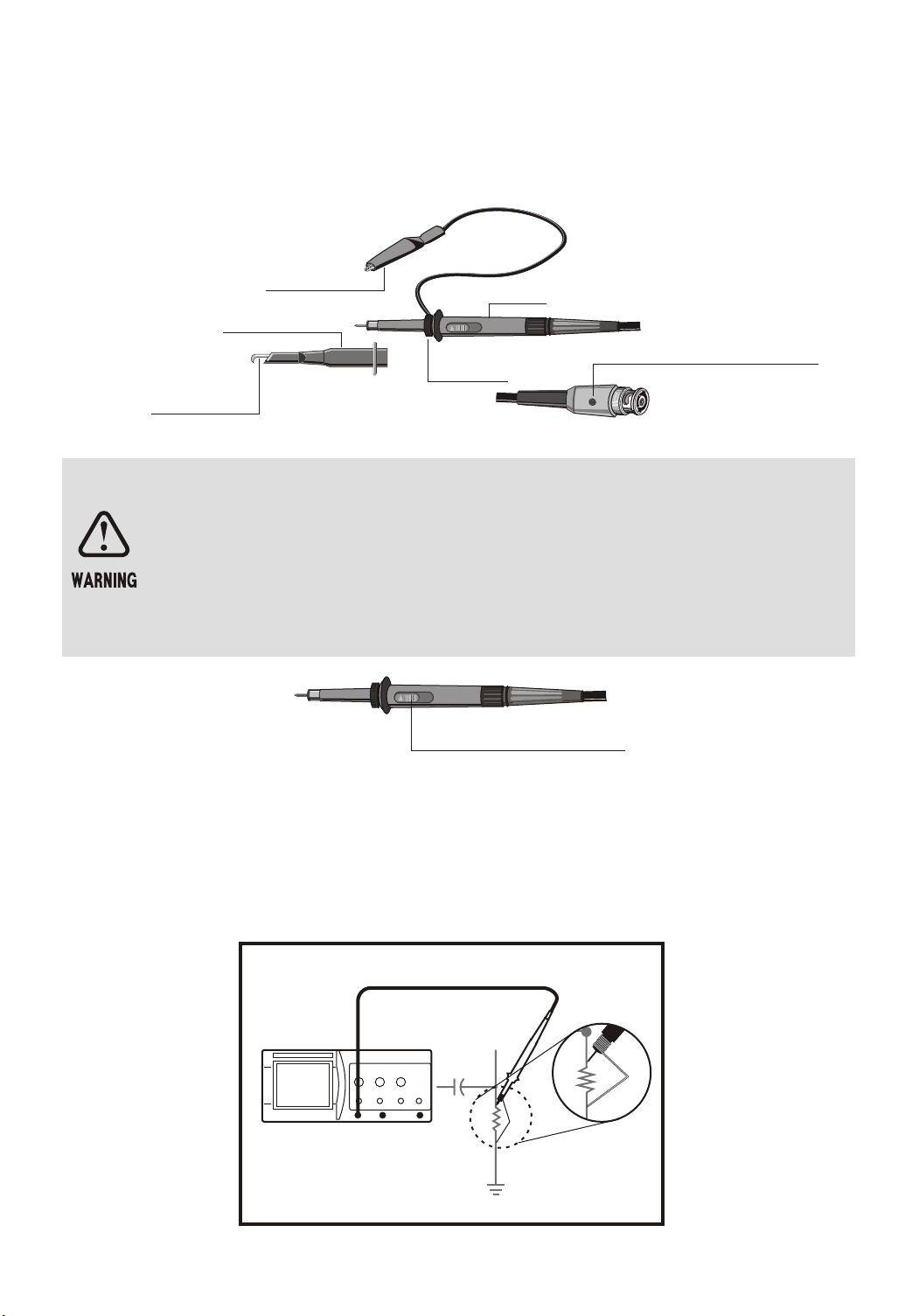

1-3-3 PROBE

The first step of measurement is to connect the signals to the instrument

properly.

GROUND CLIP

HOOK COVER

RETRACTABLE

HOOK TIP

GROUND

COVER

BODY

CAPACITANCE

CORRECTION

TRIMMER

Probe Attenuation Setting

When the optional probe is used with the x10 / x1 select switch set to x10,

the input signal to the instrument is attenuated to 1/10. When a signal is

too small to be measured with x10, use the mode x1. In this case, note

that the input impedance of x1 is different from that of x10, and the measurable frequency band becomes very low.

Attenuation switch

Probe Grounding

Connect the probe ground lead as close as possible to the point being

measured especially when measuring a signal with a fast rise time or a

high frequency signal. Long probe ground leads may cause waveform

distortions, such as ringing and overshoot.

CH 1

Spring GND

18

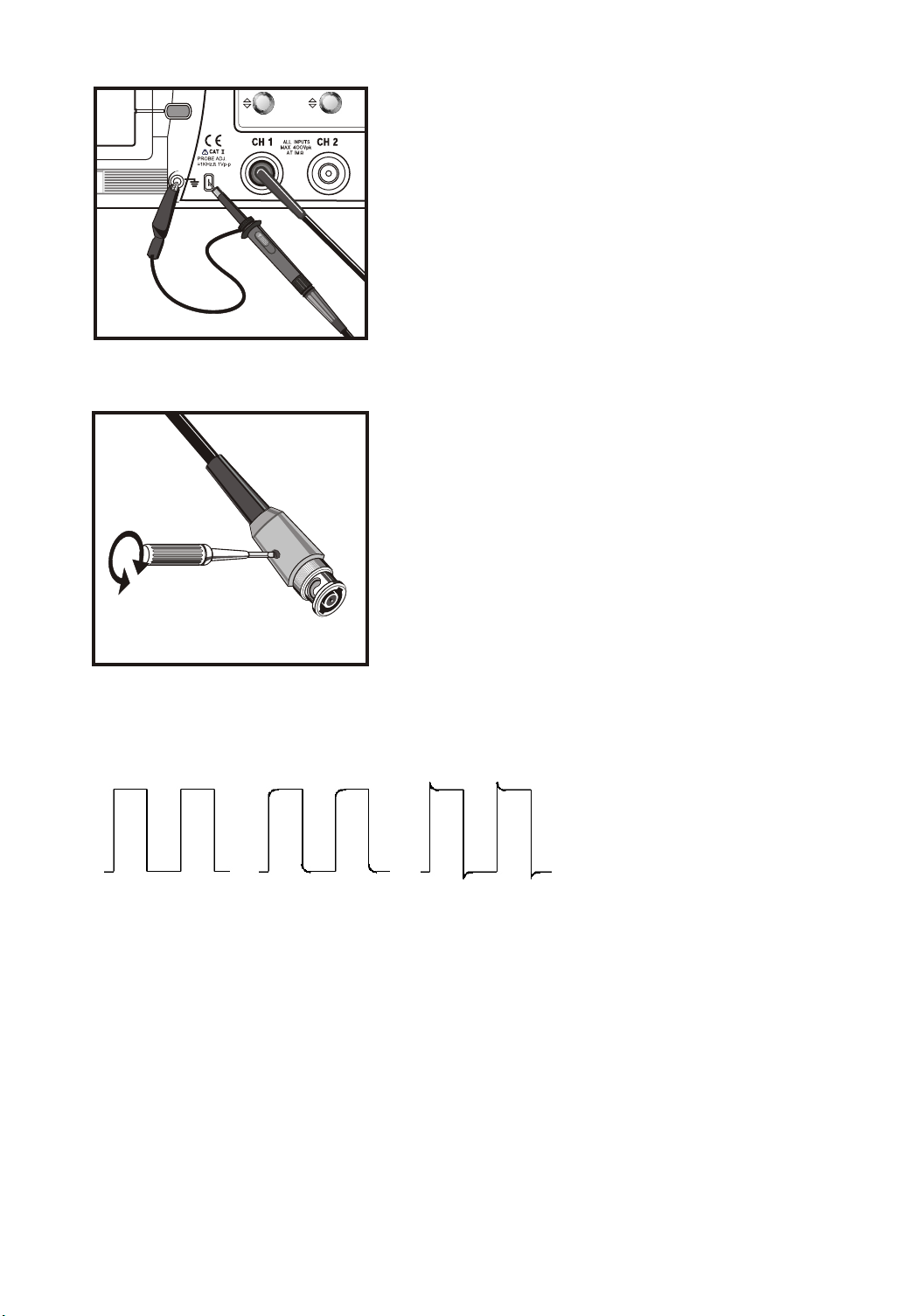

Probe Compensation

The probe switch setting is 10X.

To avoid a measurement error, probe

compensation must be done. Especially when

the probe is charged.

Connect the probe tip to the CAL 1V output

terminal. A 1 kHz square wave should be

displayed with flat tops.

Any distortion in the left presentation is

caused by incorrect probe compensation.

If overshoot or undershoot is present, turn the

screwdriver adjustment in the probe for a

flat-top presentation.

This adjustment remains in effect until changed

again.

Be sure that the attenuation switch on the

probe is set to match with the probe menu

selection in the oscilloscope.

CORRECTLY

COMPENSATED

PROBE COMPENSATION BY CORRECTION SQUARE-WAVE

UNDER

COMPENSATED

OVER

COMPENSATED

19

1-4 INSTALLATION

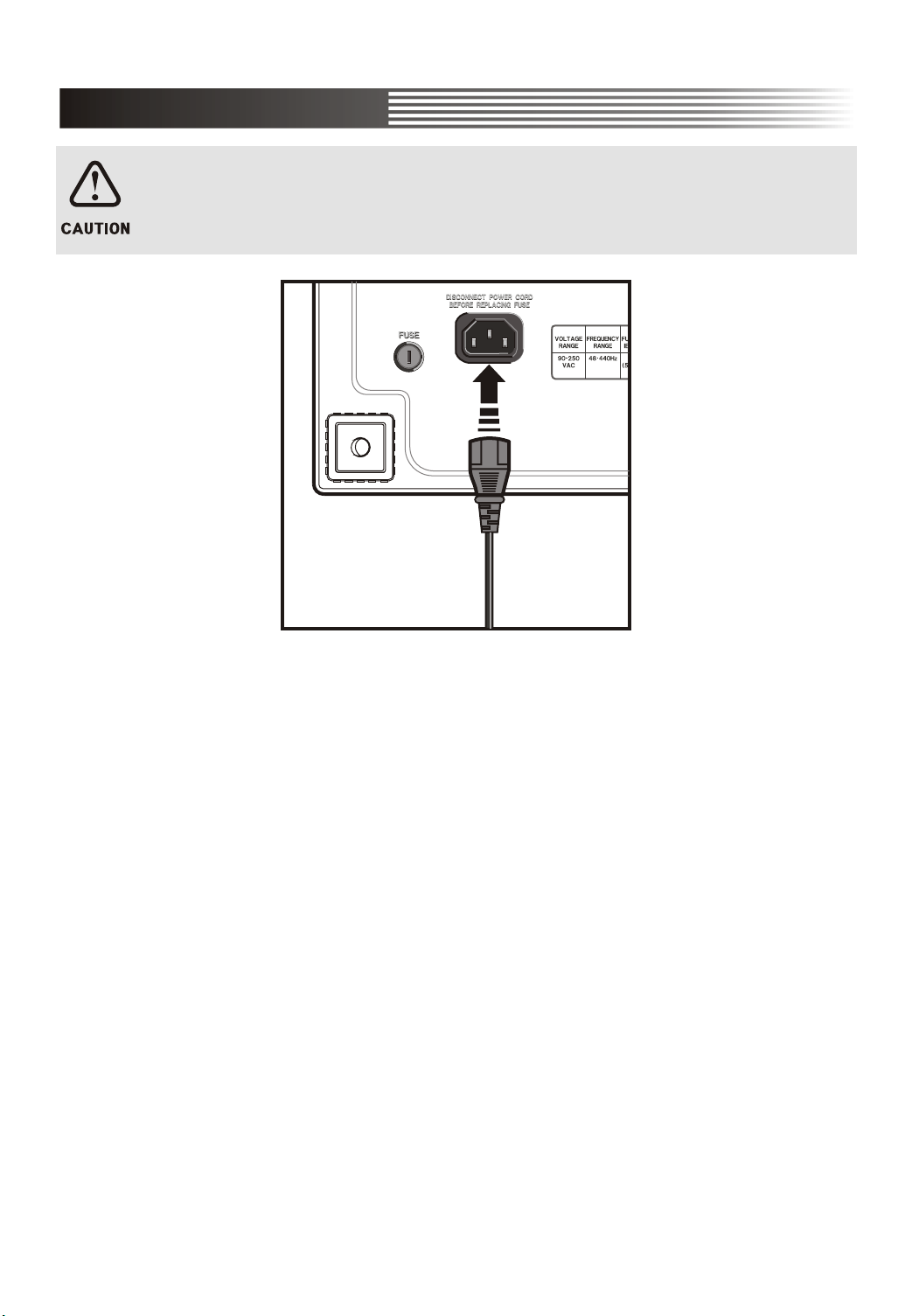

1-4-1 POWER CORD

Use only power cords designed for your oscilloscope. Use a power source

that delivers 90 to 250 VACRMS, 48 to 440 Hz.

1-4-2 INTERFACE CARD

You can increase the feature set of your oscilloscope by inserting an interface

card.

Refer to the "NOTES TO USERS" section in this manual and the PC software

Kit manual for detailed description. Install the interface card into the rear of

DS-1000 series as following procedures.

Two types of interface card (optional) are available. Be sure of which one you

need when you place an order.

20

Loading...

Loading...