EYS SP series, SP400, SP800, SP600HD, SP800HD User Manual

...

USER MANUAL

“SP” SERIES

EYS SCREW PRESS SEPERATORS

SP400

SP600

SP800

SP600HD

SP800HD

JAN 2012

Congratulations on your purchase of the EYS Screw-Press Separator!

We are glad that you chose EYS separator for your solid-liquid separation solutions and are confident that

you will be more than satisfied with your purchase.

This manual is intended to provide basic information about the operation of the EYS Separator, and to point

out to main areas of consideration while operating and maintaining the machine. Please read this manual

carefully before operating the machinery, and keep it in an easily accessible place for future reference. If

any of your questions or concerns are not covered in this manual, please contact the respective dealer who

had installed the machinery. Your dealer’s contact information is:

If you are not able to reach your dealer and in need of immediate support, then please contact EYS directly

at:

EYS Metal Sanayi ve Ticaret Ltd. Şti.

ASTIM Org. San. Bol. Hurriyet Mah. Havaalanı Bul. No:233, Tepecik/AYDIN - 09100 TURKEY

Tel: +90 (256) 231 05 98

231 11 38

231 05 76

Fax: +90 (256) 231 11 01

e-mail: info@e-y-s.com

internet: www.e-y-s.com

Apart from providing technical and operational instructions, this manual also includes certain safety

warnings that must be followed by the user. The safety instructions and warnings listed in this

manual are by no means a complete list of all safety concerns associated with operating the

machine. Users must apply common sense and abide by the general safety guidelines that govern

operating of machinery.

Contents of this manual refer to the latest product models currently in production at the time of

preparation of the document. EYS reserves the right to make changes in the product design at any

time.

Carefully following the instructions set forth in this manual are essential for maintaining operator

safety as well as the longevity and efficiency of the machinery. Dealers must provide a copy of this

manual to the customer along with the purchased product.

“SP SERIES” USER MANUAL

Page 3 / 34

Please make sure that the operator in charge of operating and/or maintaining this product has full

access to this manual and that he/she has read it entirely prior to running or servicing the machine.

Also please record your product model number and serial number from the machine’s info-tag to the

following section. These info will be necessary and useful when ordering replacement parts in the

future.

Congratulations again on your purchase of the EYS Screw Press Separator!

PRODUCT INFO

Product : Screw Press Separator

Model : SP400 SP600 SP800 SP600HD SP800HD

Serial Number :

Dealer :

Adress :

Tel :

Fax :

Installation Date :

Manufacturer : EYS METAL SANAYİ VE TİCARET LTD. ŞTİ.

ASTİM ORGANİZE SANAYİ BÖLGESİ, HÜRRİYET MAHALLESİ, HAVAALANI BULVARI

NO:233, TEPECİK, AYDIN, TÜRKİYE

TEL: +90 (256) 231 05 98, 231 11 38, 231 05 76, 231 05 77

FAX: +90 (256) 231 11 01

e-mail: info@e-y-s.com

internet: www.e-y-s.com

“SP SERIES” USER MANUAL

Page 4 / 34

HAND-OVER FORM (TO BE SIGNED OFF BETWEEN THE DEALER AND THE CUSTOMER)

Product : SCREW PRESS SEPARATOR

Model : SP400 SP600 SP800 SP600HD SP800HD

Serial Number :

Dealer :

Adress :

Tel :

Fax :

Installation Date :

Manufacturer : EYS METAL SANAYİ VE TİCARET LTD. ŞTİ.

ASTİM ORGANİZE SANAYİ BÖLGESİ, HÜRRİYET MAHALLESİ, HAVAALANI BULVARI

NO:233, TEPECİK, AYDIN, TÜRKİYE

TEL: +90 (256) 231 05 98, 231 11 38, 231 05 76, 231 05 77

FAX: +90 (256) 231 11 01

e-mail: info@e-y-s.com

internet: www.e-y-s.com

This form confirms that the product installation and start-up has been completed

successfully. Basic training has been provided and this manual has been handed over to

the responsible personnel below.

Responsible person on behalf of

the dealer/distributor

(date and sign)

Responsible person on behalf of

the customer

(date and sign; please print name)

ATENTION !

Manufacturer’s warranty is not valid unless this form is signed and

dated upon installation!

“SP SERIES” USER MANUAL

Page 5 / 34

INTRODUCTION

Signs And Definitions

The CE sign designating

conformance with the relavant specific EC

Directives as well as the General Machinery Directive, has been

marked on the product by the manufacturer.

WARNING!

This warning box is used to highlight safety related precautions

throughout the document. Remember that there is risk of personal

injury with every “warning” sign topic and it is of utmost importance

to understand and follow the contained instructions carefully.

ATTENTION !

Failure to follow instructions can result in damage to a part or the

whole of the machine, possibly putting the machine out of

commission.

NOTE !

It is especially important to understand and implement the

instructions highlighted therein for the successful long-term

operation of the machine.

Qualified Operators should be properly trained in their assigned area of responsibility, be

knowledgable about general machinery handling precautions and related hazards/risks, capable of

foreseeing and preventing potential damages to the machine before they happen, and be able to apply

necessary first-aid practices as necessary.

Operational Responsibility

Responsibility of operating the machine in accordance with its intended purposes lies with the

customer. The manufacturer is not in anyway responsible for any damages that may be caused by

inappropriate handling of the waste streams resulting form the operation of the product. Likewise, the

manufacturer can not be held responsible for any damages resulting from the use of un-approved

and/or non-original spare parts on the machine.

Second-hand Ownership

In the case of transfer of ownership of the product to a new customer, the original owner is responsible

for handing over this user-manual to the new owner. New owner must be informed and trained about

the basic operation of the product accordingly.

Operational Liability

The entire liability of operating the product properly lies with the customer. The customer is

responsible for making sure that the product is used in accordance with the guidelines set forth in this

document, plus other general machinery operating rules that may not be covered here but are

expected to be known by any machinery operator. The maximum liability of the manufacturer in any

event can not exceed the monetary value of the product itself.

“SP SERIES” USER MANUAL

Page 6 / 34

CONTENTS:

1 SAFETY INSTRUCTIONS………………………………………………………………………………………………… 7

2 GENERAL INSTRUCTIONS……………………………………………………………………………………..……… 8

2.1 Working with slurry………………………………………………………………………………………...….…… 8

2.2 Proper operation…………………………………………………………………………………………..….…….. 8

3 OPERATION PRINCIPLE…………………………………………………………………………………….……….…. 8

4 INSTALLATION & START-UP....………………………………………………………………………..………….… 9

4.1 Delivery ………...............…..………………………………………………………………………………………. 9

4.2 Handling.......………………………………………………………………………………………………..……….... 9

4.3 Typical installation........…………………………………………………………………………………………... 10

4.4 Setup & installation…………………………………………..…………………………………………………….. 10

5 PRE-START-UP CHECKS............................................……………………………………………………… 12

6 START UP…………......................……………………………………………………………………………………… 12

6.1 Counter-pressure on discharge doors…..…………………………………………………………………. 12

6.2 Establishing the solid plug…….....……………………………………………………………………………… 12

6.3 Plug adjustment………………………………………………………………………………………………………. 13

6.4 Other points of consideration...............…………………………………………………………………… 14

7 TROUBLESHOOTING..............................................................…………...………………………….. 16

8 STOPPING THE SEPARATOR…..………………………………………………………………..………………….. 19

9 LONG TERM STORAGE OF THE SEPARATOR…......………………………………………………………… 19

10 CHECKING THE SCREEN AND THE SCREEN GUIDE-RAILS…….…………………..…………………… 19

11 CHECKING THE AUGER……….....……………………………………………………………………………………. 20

12 ACCEPTABLE WEAR AND LIMIT TOLERANCES……………………………………………...……………… 21

13 DISASSEMBLY AND ASSEMBLY…….….…………………………………………………………………………… 22

13.1 Disassembly…..………………………………………………………………………………………………………… 22

13.2 Assembly…..…………………………………………………………………………………………………………….. 23

14 GENERAL MAINTENANCE…………………………………………………………………………………………….. 24

15 STORAGE…….......………………………………..……………………………………………………………………….. 25

16 TECHNICAL SPECIFICATIONS……………....…………..………………………………………………………….. 25

16.1 Technical specifications of the separator……...………………………………………………………… 25

16.2 Machine tags……...........…………………………………………………………………………………………… 27

16.3 Warning signs……....………………………………………………………………………………………………… 27

17 ELECTRIC CONTROL PANEL………......……………………………………………………………..…………….. 28

17.1 Wiring diagrams………………………………………………………………………………………..……………. 28

17.2 Reverse-run of auger at start-up…….......................................……………….......…………… 28

18 SPARE PARTS LIST………......………………………………………………………………………………………….. 29

19 MANUFACTURER’S WARRANTY …....…………....……………………………………………………………. 29

20 EC DECLARATION OF CONFORMITY ………...…….…………………………………………………………… 30

EXHIBITS (Spare Parts List; Wiring Diagrams)………............................................…………… 31-

“SP SERIES” USER MANUAL

Page 7 / 34

1 SAFETY INSTRUCTIONS

Check conformance with safety instructions prior to each start-up!

1. In addition to the specific instructions contained in this document, general machinery operating

rules and precautions must be followed!

2. Safety related signs are marked on the product as necessary. These signs and stickers are

important for personal safety, so do not remove them!

3. Do not operate the machine before replacing/installing all safety and protection related

parts/covers!

4. Make sure you understand the general functioning principle of the machine before operation!

5. Put on relatively snug operational outfit when operating the machine. Loose outfits and long

sleeves can get caught by the moving parts during operation and servicing.

6. Slurry can emit flammable gases under certain conditions; so avoid smoking or carrying open fire

near the machine!

7. Machine should be installed at a properly ventilated area. Avoid spending long periods of time in

poorly ventilated areas around the slurry!

Maintenance

1. Never perform any maintenance, service or cleaning before fully stopping the machine and the

other system components.

2. Always check and verify that the bolts/nuts on the machine are securely tightened.

3. Always wear work gloves when handling sharp and metal objects during maintenace.

4. Always observe local regulations when disposing of lubricants/grease, etc.

5. Never work on the control panel and/or electrical connections without fully cutting off the power

first.

6. Only manufacturer approved spare parts must be used for repairs and replacements.

2 GENERAL INSTRUCTIONS

“SP SERIES” USER MANUAL

Page 8 / 34

2.1 Working with slurry

WARNING !

Slurry can emit flammable and nauseus gase

s

. Always ensure that

there is proper ventilation in the operation area.

2.2 Proper Usage

EYS screw press separator is designed to separate solid and liquid phases of fiber-rich waste materials.

The waste should be free of sand, as well as other foreign objects such as metal, glass, wood, etc. that

have the potential of damaging the internal parts of the separator.

3 OPERATION PRINCIPLE

Slurry can be fed into the EYS Separator either by a pump or gravimetrically through a hopper at the

inlet. The auger inside the separator moves the slurry forward from the inlet section towards the solids

discharge outlet. During this travel of the slurry, the cylindrical screen around the auger continously

dewaters the liquid fraction of the slurry and channels it out through the liquid discharge outlet.

Meanwhile the dewatered solids form into a firm plug as they get closer to the discharge area. At the

solids discharge outlet, there are two hinged doors that apply constant pressure to the solid plug by

means of counterweights attached to the arms that regulate the angle of these doors. As the auger

furthers the solid plug forward, the plug overcomes the backpressure applied by the discharge doors

and exits the machine from the discharge outlet.

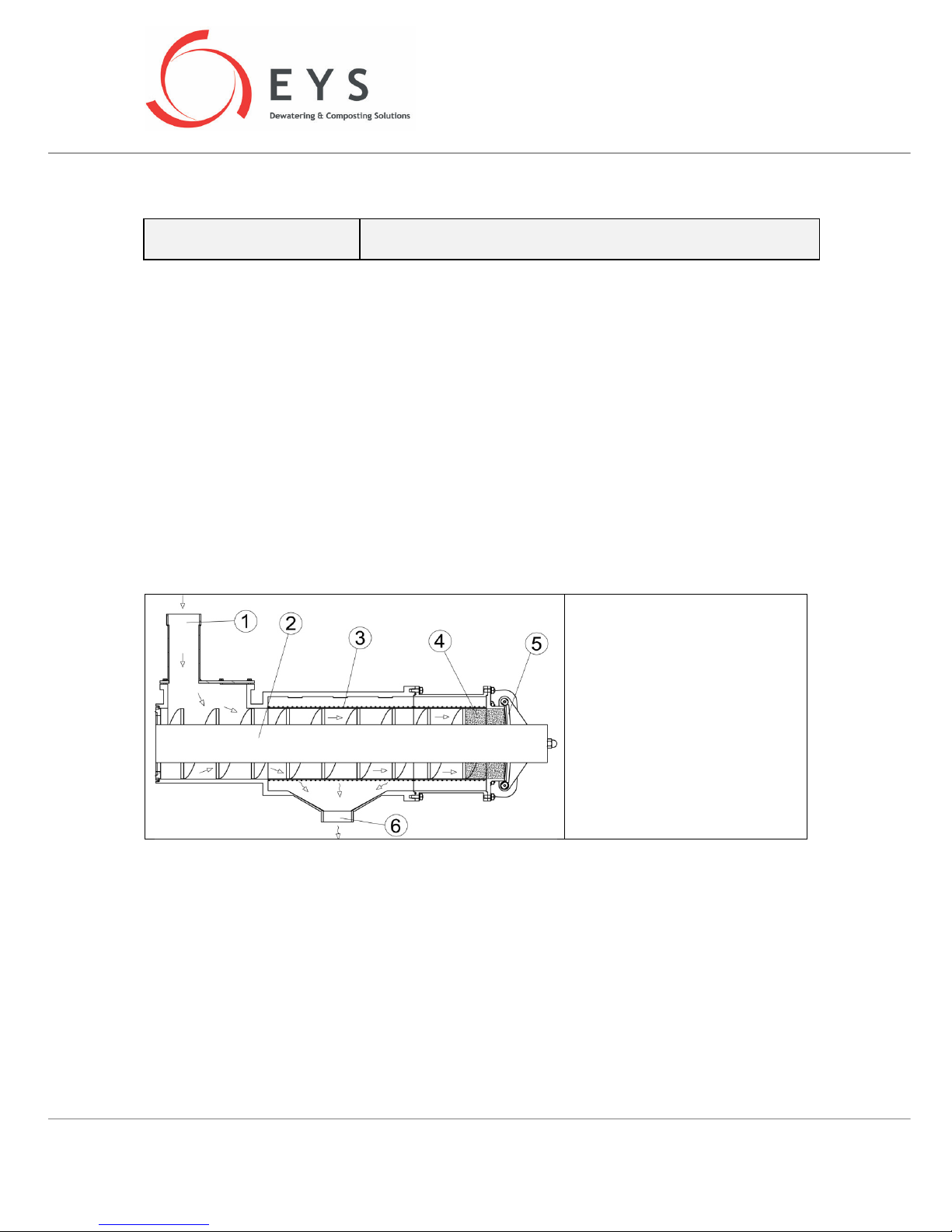

1. Slurry inlet

2. Auger

3. Screen

4. Solid plug

5. Separated solids discharge

6. Separated liquid discharge

Operational efficiency of the separator (throughput and dryness of solids) is greatly affected by the

slurry consistency. Therefore performance results may vary depending on what kind of slurry is being

dewatered. Following principles should be kept in mind when optimizing performance.

• Separation efficiency is typically increased when a larger screen slot-size is used. This in turn

will result in more solid particles to escape into the separated liquid phase.

• Smaller screen slot-size typically results in less solids percentage in the separated liquid phase.

However throuhput will be lower with smaller screen slot-sizes.

• Moisture content of the separated solids is typically reduced with increased back-pressure at

the discharge doors.

4 INSTALLATION AND START-UP

“SP SERIES” USER MANUAL

Page 9 / 34

4.1 Delivery

EYS Seperator is delivered fully assembled; in a secure crate. Net weight of each model is as follows.

SP400

SP600

SP800

SP600HD

SP800HD

Net Weight [kg]

450 700 850 950 1100

4.2 Handling

The machine must be handled and lifted with a safe and proper method as required by the specific

circumstances of the installation location. A suitable crane and/or forklift must be utilized. Please

refer to the above figure for proper lifting arrangements by forklift or crane.

WARNING !

A properly chosen forklift can be used for transferring and/or lifting of the

separator to short distances or heights. Use the specifically designed forklift

openings on the legs of the separator. Make sure that the forks of the forklift

are fully through these openings on both legs. A crane should be employed

when lifting the separator to higher locations (such as while installing on an

elevated platform). When lifting with a crane, use two slings of 3m length and

1ton lifting capacity each, together with proper shackles. Apply the slings as

shown in the above figure. Never lift with chain or steel cable. These lifting

procedures must be followed not only for initial installation but for subsequent

liftings also, whenever necessary.

4.3 Typical Installation

“SP SERIES” USER MANUAL

Page 10 / 34

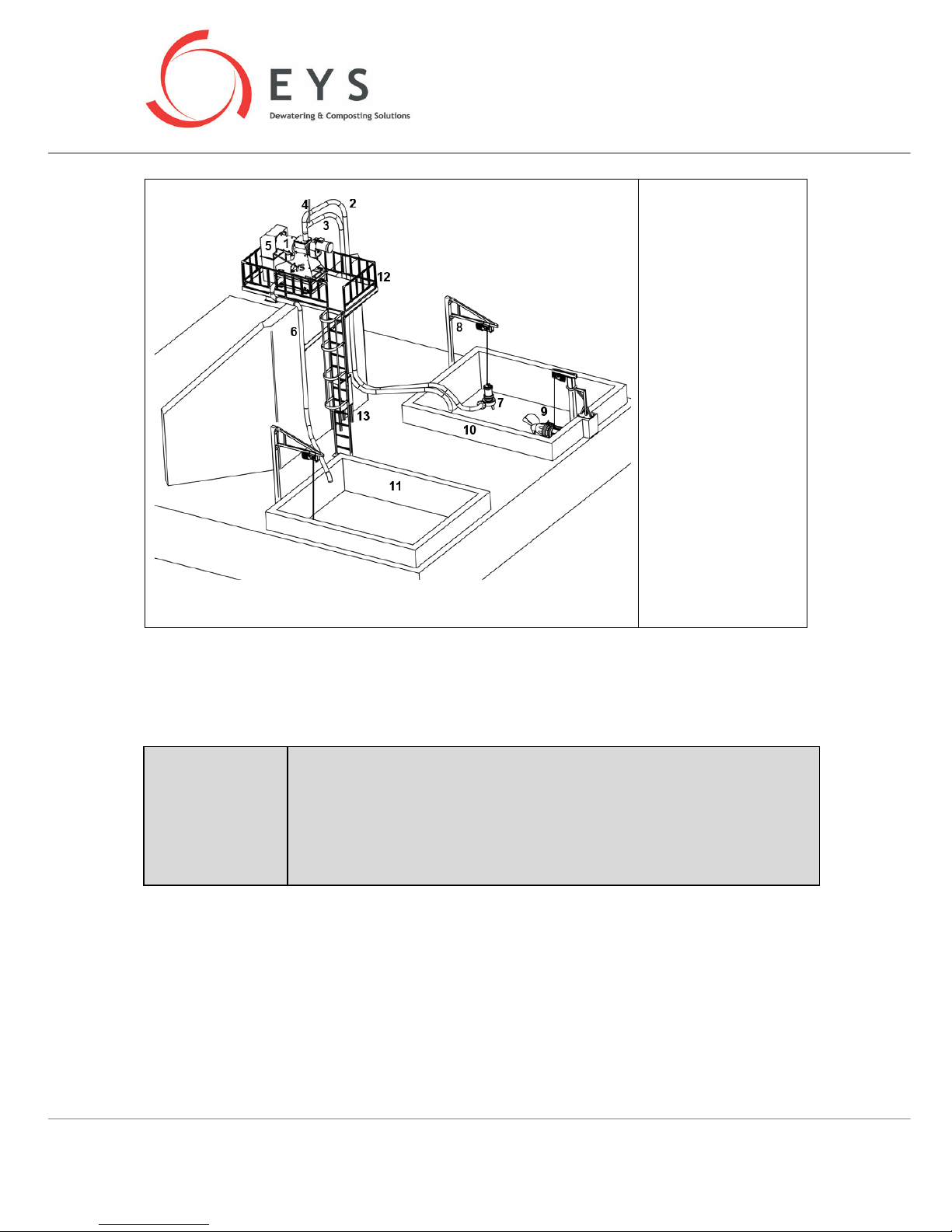

1. Separator

2. Inlet pipe (from

pump)

3. Overflow pipe

4. Air-vent pipe

5. Solids cover

(optional)

6. Liquid effluent

drainage pipe

7. Pump

8. Pump inst. fixture

9. Agitator & inst. pole

10. Slurry pit

11. Liquid effluent pit

12. Separator platform

13. Electric control

panel

4.4 Set-up and Installation

ATTENTION !

Separato

r should be installed at a reasonable height to allow separated solids

to accumulate easily underneath. Otherwise the separator may become buried

under accumulated solids.

The separated liquid fraction will be drained to a separate lagoon (other than

the slurry pit where the separator is being fed from) gravimetrically. Therefore

this lagoon should be planned close to the separation system in order to allow

for easy drainage of the liquid.

Follow the below steps for setting up the separator:

“SP SERIES” USER MANUAL

Page 11 / 34

• Mount the F-Pipe to the inlet pipe of the separator.

• Mount the pump outlet pipe to the 6” upper inlet of the F-Pipe using the quick coupling

connectors.

• Mount a 6” over-flow pipe to the lower branch of the F-Pipe using the quick coupling connectors.

This overflow line will go directly back to the slurry pit where the pump is.

• Connect the 1,5” air-vent pipe to the over-flow line. This line will prevent a possible vaccum effect

on the over-flow line. This air-vent pipe should extend at least 1m above the upper branch of the

F-Pipe (pump line). Make sure that the valve on the air-vent pipe is free and open.

• Mount a 6” pipe to the liquid discharge outlet of the separator. This pipe will extend to the

separated liquid lagoon. The layout of this pipe should not cause dips along the path, which would

prevent the liquid to drain completely and may cause freeze-ups in the pipe.

• All electric work and connections must be carried out by a qualified electrician.

ATTENTION!

Overflow and separated liquid drainage lines must extend in a linear fashion to allow

easy flow of the slurry. Overflow line must not be submerged into the slurry pit,

otherwise it might creaate siphoning effect and divert all slurry flow from the pump

back into the same pit through the overflow line.

ATTENTION !

If the pump feeding the separator is not an EYS pump, then a suitable pump must be

used to supply the minimum flow rates as per the below table. Otherwise the

Loading...

Loading...