Eye Lighting H572D, H566D, H566S, H570D Installation & Maintenance

Installation & Maintenance

H572D / H570D / H566D / H566S

CLASS I, IP65

EL-IM004.00 Page 1 of 2

Installation

The Eye Lighting H572D, H570D and H566 series’ are

floodlights for outdoor (permanent) use, designed to be

operated in conjunction with remote control gear appropriate

for the lamp type and wattage in use.

The floodlight is designed to be securely mounted on a suitably

solid horizontal surface using 2x M16 bolts.

Screw the lamp in to its full extent, ensuring that it’s secure,

but not over tightened.

Ensuring the gasket and joining surfaces are clean, secure the

lamp carrier to the main body by pivoting the three screws and

tightening the wing nuts evenly. Ensure the chain is attached.

Incoming supply cables from the control gear are terminated in

the termination box via the 20mm threaded entry.

To maintain the integrity of the enclosure’s protection against

dust and moisture ingress, cable glands or conduit fittings

rated at least IP65 must be used.

Check that the cable glands are tightened correctly.

Floodlights must be installed within the maximum

recommended distance to the control gear, as applicable to

the type used.

These instructions should be retained by the floodlight owner

for reference, and made available as necessary, to ensure

future maintenance is carried out correctly.

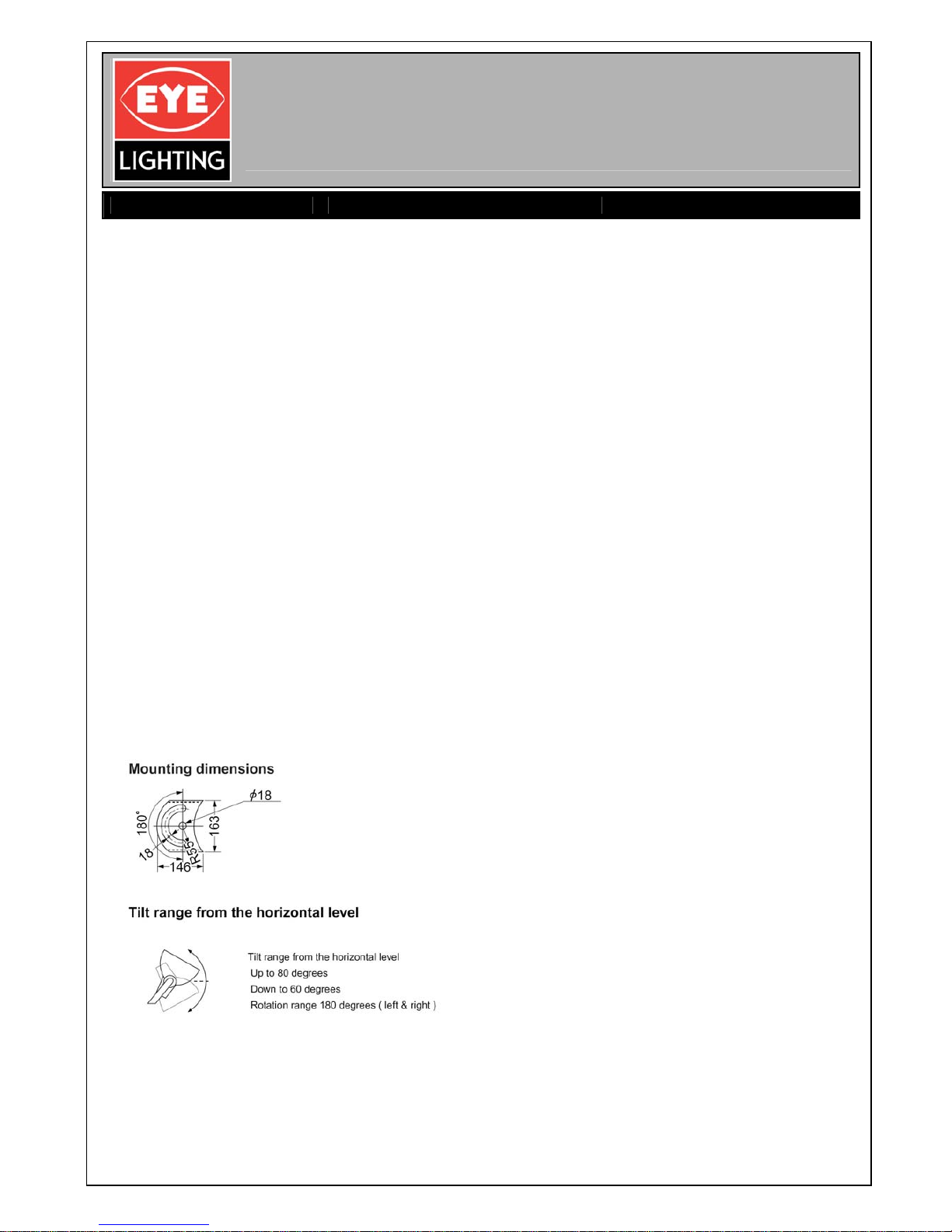

Aiming

Adjust the horizontal aiming of the floodlight by loosening the

anchor and swivel screws (not supplied) fixing the base to the

mounting surface. Using the markings on the base plate as a

guide, adjust to the required angle and tighten the screws.

Adjust the tilt by loosening the screws at the pivot point and

releasing the locking lever. Using the markings on the pivot

plate, adjust the floodlight to the required tilt angle and hold in

place by tightening the lever. Check the tilt angle is correct

and tighten the screws.

As an alternative to using the markings on the base and pivot

plates, the included aiming device may be used during this

process to aim at a specific point.

General Operation and Maintenance

Failed lamps are to be replaced promptly, or the circuit

isolated, to avoid possible control gear damage. Continual

operation on supply voltage above that nominated on the

control gear will reduce expected lamp and component life.

Clean excessive build up of foreign material from outer

surfaces of the body. Clean the lens as required with warm

water and mild detergent.

Screws requiring loosening for future service and lamp

replacement should be greased for ease of maintenance. Use

silicone base grease only as oil base grease may damage

some components.

Luminaires with damaged or cracked glass shall be removed

from service immediately.

Continuously operated lamps should be turned off at least

once a week for 1 hour.

Lamp Replacement

The floodlight is to be wiped clean of all dust and debris prior

to disassembly.

Loosen the three wing nuts and pivot the fixing screws away

from the lamp carrier. Carefully withdraw the lamp carrier.

Replace the lamp only with a type and wattage suitable for the

control gear in use. Screw the lamp in to its full extent,

ensuring that it’s secure, but not over tightened.

Ensure gasket and joining surfaces are clean, return the lamp

carrier to its position and evenly tighten the wing nuts.

EL-IM004.00 Page 2 of 2

Important – Safety

Before carrying out any servicing on this luminaire, ensure

that the mains supply is fully isolated. High voltages,

greater than mains voltage, can be present during

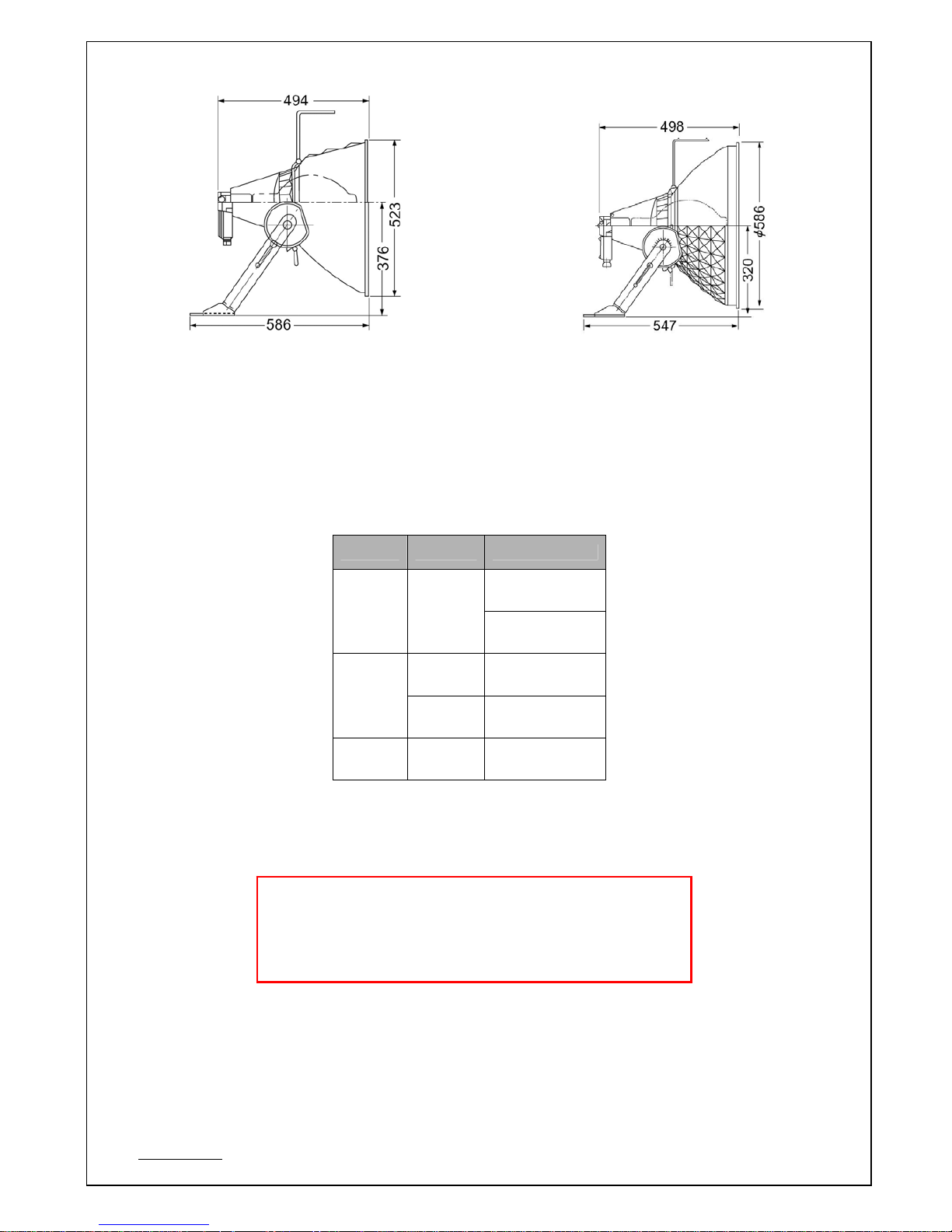

LAMP TABLE

Type Wattage Lamp

M1000LE/BUH

MF1000LE/BUH

Metal

Halide

1000W

M1000B X/U

MF1000B X/U

940W

NH940LX

NH940FLX

High

Pressure

Sodium

1000W

NH1000

NH1000F

Mercury 1000W HF1000PD

For further enquiries, please contact:

Eye Lighting

15 Industrial Ave, Wacol QLD Australia 4076

Tel: (617) 3335 3588 Fax: (617) 3335 3533

Email: info@eli.com.au

H572D / H570D

Max weight = 9.2 kg

Projected Area = 0.23 m

2

H566D / H566S

Max weight = 8.8 kg

Projected Area = 0.27 m

2

Loading...

Loading...