Page 1

Installation Guide

PoleVault System

PoleVault Digital Switcher Systems

featuring the PVS 405D Switcher

Includes installation details for the PoleVault (PMK 560),

WallVault (WMK 160 and USFM 100), and

PlenumVault (PVM 220) Mounting Kits.

ALSO AVAILABLE:

The PoleVault

Installation Video.

®

System

View it at www.extron.com.

68-2380-01 Rev. A

03 14

Page 2

Safety Instructions

Safety Instructions • English

WARNING: This symbol, , when used on the product, is intended to

alert the user of the presence of uninsulated dangerous voltage within the

product’s enclosure that may present a risk of electric shock.

ATTENTION: This symbol, , when used on the product, is intended

to alert the user of important operating and maintenance (servicing)

instructions in the literature provided with the equipment.

For information on safety guidelines, regulatory compliances, EMI/EMF

compatibility, accessibility, and related topics, see the Extron Safety and

Regulatory Compliance Guide, part number 68-290-01, on the Extron website,

www.extron.com.

Instructions de sécurité • Français

AVERTISSEMENT: Ce pictogramme, , lorsqu’il est utilisé sur le

produit, signale à l’utilisateur la présence à l’intérieur du boîtier du produit

d’une tension électrique dangereuse susceptible de provoquer un choc

électrique.

ATTENTION: Ce pictogramme, , lorsqu’il est utilisé sur le produit,

signale à l’utilisateur des instructions d’utilisation ou de maintenance

importantes qui se trouvent dans la documentation fournie avec le

matériel.

Pour en savoir plus sur les règles de sécurité, la conformité à la réglementation,

la compatibilité EMI/EMF, l’accessibilité, et autres sujets connexes, lisez les

informations de sécurité et de conformité Extron, réf. 68-290-01, sur le site

www.extron.com.

Extron,

Sicherheitsanweisungen • Deutsch

WARNUNG: Dieses Symbol auf dem Produkt soll den Benutzer

darauf aufmerksam machen, dass im Inneren des Gehäuses dieses

Produktes gefährliche Spannungen herrschen, die nicht isoliert sind

und die einen elektrischen Schlag verursachen können.

Инструкция по технике безопасности • Русский

ПРЕДУПРЕЖДЕНИЕ: Данный символ, , если указан

на продукте, предупреждает пользователя о наличии

неизолированного опасного напряжения внутри корпуса

продукта, которое может привести к поражению электрическим

током.

ВНИМАНИЕ: Данный символ, , если указан на продукте,

предупреждает пользователя о наличии важных инструкций

по эксплуатации и обслуживанию в руководстве,

прилагаемом к данному оборудованию.

Для получения информации о правилах техники безопасности,

соблюдении нормативных требований, электромагнитной

совместимости (ЭМП/ЭДС), возможности доступа и других

вопросах см. руководство по безопасности и соблюдению

нормативных требований Extron на сайте Extron:

com, номер по каталогу - 68-290-01.

www.extron.

Chinese Simplified(简体中文)

警告: 产品上的这个标志意在警告用户该产品机壳内有暴露的危险 电压,

有触电危险。

注意: 产品上的这个标志意在提示用户设备随附的用户手册中有

重要的操作和维护(维修)说明。

关于我们产品的安全指南、遵循的规范、EMI/EMF 的兼容性、无障碍

使用的特性等相关内容,敬请访问 Extron 网站

见 Extron 安全规范指南,产品编号 68-290-01。

www.extron.com,参

Chinese Traditional( )

警告: 若產品上使用此符號,是為了提醒使用者,產品機殼內存在著

可能會導致觸電之風險的未絕緣危險電壓。

VORSICHT: Dieses Symbol auf dem Produkt soll dem Benutzer

in der im Lieferumfang enthaltenen Dokumentation besonders

wichtige Hinweise zur Bedienung und Wartung (Instandhaltung)

geben.

Weitere Informationen über die Sicherheitsrichtlinien, Produkthandhabung,

EMI/EMF-Kompatibilität, Zugänglichkeit und verwandte Themen finden Sie in

den Extron-Richtlinien für Sicherheit und Handhabung (Artikelnummer

68-290-01) auf der Extron-Website,

www.extron.com.

Instrucciones de seguridad • Español

ADVERTENCIA: Este símbolo, , cuando se utiliza en el producto,

avisa al usuario de la presencia de voltaje peligroso sin aislar dentro del

producto, lo que puede representar un riesgo de descarga eléctrica.

ATENCIÓN: Este símbolo, , cuando se utiliza en el producto, avisa

al usuario de la presencia de importantes instrucciones de uso y

mantenimiento recogidas en la documentación proporcionada con el

equipo.

Para obtener información sobre directrices de seguridad, cumplimiento

de normativas, compatibilidad electromagnética, accesibilidad y temas

relacionados, consulte la Guía de cumplimiento de normativas y seguridad de

Extron, referencia 68-290-01, en el sitio Web de Extron,

com.

www.extron.

注意 若產品上使用此符號,是為了提醒使用者,設備隨附的用戶手冊中有重

要 的 操 作 和 維 護( 維 修)説 明。

有關安全性指導方針、法規遵守、EMI/EMF 相容性、存取範圍和相關主題的詳細資

訊,請瀏覽 Extron 網站:

與法規遵守手冊》,準則編號 68-290-01。

www.extron.com,然後參閱《Extron 安全性

Japanese

警告: この記号 が製品上に表示されている場合は、筐体内に絶縁されて

いない高電圧が流れ、感電の危険があることを示しています。

注意: この記号 が製品上に表示されている場合は、本機の取扱説明書

に 記載さ れて いる重 要な操 作 と保 守 ( 整 備)の 指 示につ いてユーザ ー の 注

意を喚起するものです。

安全上のご注意、法規厳守、EMI/EMF適合性、その他の関連項目に

つ い て は 、エ ク ストロ ン の ウェ ブ サ イト

Safety and Regulatory Compliance Guide』 ( P/N 68-290-01) をご覧ください。

www.extron.com よ り 『 Extron

Korean

경고: 이 기호 가 제품에 사용될 경우, 제품의 인클로저 내에 있는

접지되지 않은 위험한 전류로 인해 사용자가 감전될 위험이 있음을

경고합니다.

주의: 이 기호 가 제품에 사용될 경우, 장비와 함께 제공된 책자에 나와

있는 주요 운영 및 유지보수(정비) 지침을 경고합니다.

안전 가이드라인, 규제 준수, EMI/EMF 호환성, 접근성, 그리고 관련 항목에

대한 자세한 내용은 Extron 웹 사이트(

안전 및 규제 준수 안내서, 68-290-01 조항을 참조하십시오.

www.extron.com)의 Extron

Page 3

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part15 of the FCC rules. The ClassA limits provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause interference. This interference must be corrected at

the expense of the user.

NOTE: This unit was tested with shielded I/O cables on the peripheral devices. Shielded cables

must be used to ensure compliance with FCC emissions limits.

For more information on safety guidelines, regulatory compliances, EMI/EMF compatibility,

accessibility, and related topics, see the “

Extron Safety and Regulatory Compliance

Guide” on the Extron website.

Copyright

© 2014 Extron Electronics. All rights reserved.

Trademarks

All trademarks mentioned in this guide are the properties of their respective owners.

The following registered trademarks

®

, registered service marks

(SM)

, and trademarks

(TM)

are the property of

RGBSystems, Inc. or Extron Electronics:

Registered Trademarks

AVTrac, Cable Cubby, CrossPoint, eBUS, EDID Manager, EDID Minder, Extron, Flat Field, GlobalViewer, Hideaway, Inline, IPIntercom, IPLink,

Key Minder, LockIt, MediaLink, PoleVault, PowerCage, PlenumVault, PURE3, Quantum, SoundField, SpeedMount, SpeedSwitch, System

Integrator, TeamWork, TouchLink, V-Lock, VersaTools, VN-Matrix, VoiceLift, WallVault, WindoWall, XTP and XTP Systems

Registered Service Mark

AAP, AFL (Accu-Rate Frame Lock), ADSP (Advanced Digital Sync Processing), Auto-Image, CDRS (Class D Ripple Suppression), DDSP (Digital

Display Sync Processing), DMI (Dynamic Motion Interpolation), DriverConfigurator, DSPConfigurator, DSVP (Digital Sync Validation Processing),

FastBite, FOXBOX, IP Intercom HelpDesk, MAAP, MicroDigital, ProDSP, QS-FPC (QuickSwitch Front Panel Controller), Scope-Trigger, SIS,

Simple Instruction Set, Skew-Free, SpeedNav, Triple-Action Switching, XTRA, ZipCaddy, ZipClip

(SM)

: S3 Service Support Solutions

Trademarks

(®)

(™)

Page 4

Conventions Used in this Guide

Notifications

The following notifications are used in this guide:

DANGER: A danger indicates a situation that will result in death or severe injury.

WARNING: A warning indicates a situation that has the potential to result in death or

severe injury.

CAUTION: A caution indicates a situation that may result in minor injury.

ATTENTION: Attention indicates a situation that may damage or destroy the product or

associated equipment.

NOTE: A note draws attention to important information.

TIP: A tip provides a suggestion to make working with the application easier.

Software Commands

NOTE: For commands and examples of computer or device responses mentioned in

this guide, the character “0” is used for the number zero and “O” is the capital letter

“o.”

Computer responses and directory paths that do not have variables are written in the font

shown here:

Reply from 208.132.180.48: bytes=32 times=2ms TTL=32

C:\Program Files\Extron

Variables are written in slanted form as shown here:

ping xxx.xxx.xxx.xxx —t

SOH R Data STX Command ETB ETX

Selectable items, such as menu names, menu options, buttons, tabs, and field names are

written in the font shown here:

From the File menu, select New.

Click the OK button.

Specifications Availability

Product specifications are available at www.extron.com.

Page 5

Contents

Introduction............................................................ 1

Overview ............................................................ 1

The Digital PoleVault, WallVault, and

PlenumVault Systems ........................................ 1

Specifications Availability .................................... 1

Application Diagram ........................................... 2

Before You Begin — Planning the Installation ...... 3

Americans with Disabilities Act (ADA)

Compliance ................................................... 3

Room Layout .................................................. 3

Inventory — PoleVault Digital System ............. 6

Kits ................................................................ 7

Inventory — WallVault Systems

(USFM 100) ............................................. 8

42-209-03 WVS 200D .................................... 8

42-210-03 WVS 400D .................................... 8

Inventory — WallVault Systems

(WMK 160) ....................................................... 9

42-211-03 WVS 210D .................................... 9

42-212-03 WVS 410D .................................... 9

Inventory — PlenumVault Systems

(PVM 220) ....................................................... 10

42-220-03 PLS 200D ................................... 10

42-221-03 PLS 400D ................................... 10

Inventory — PlenumVault Systems

(PVM 220) ....................................................... 11

42-230-03 PLS 210D ................................... 11

42-231-03 PLS 410D ................................... 11

Items Not Included ....................................... 12

Installation Tools ........................................... 12

Optional Items .............................................. 13

Installation ............................................................ 15

Overview .......................................................... 15

Outline of Installation Steps for PoleVault

Digital Systems ................................................ 16

Stage 1:

Installing the Screen and Projector

1. Mark Screen Location ............................... 18

2. Install Projector to Verify Location ............. 18

3. Verify the Image Location .......................... 21

4. Cut the Ceiling Tile .................................... 22

5. Preliminary Safety Hardware Installation .... 22

6. Finish Projector Drop Ceiling Mount

Installation ................................................ 23

7. Secure the Projector Drop Ceiling Mount

to the Ceiling ............................................ 24

8. Install the Electrical Box (if required) .......... 25

9. Install the Screen ...................................... 25

Stage 2:

Mounting the PVT Wallplate and the

MediaLink Controller ......................................... 27

1. Install the Mud Rings ................................ 29

2. Pull the Cables (at the input locations)....... 30

3. Install Wall Plates ...................................... 31

4. Install MediaLink Controller ....................... 32

Stage 3:

Installing the FF 120 Ceiling Speakers ............. 35

1. Cut Ceiling Tile ......................................... 36

2. Install the Speaker on the Drop Ceiling ..... 36

3. Terminate the Speaker Cable for the

PVS Switcher .......................................... 38

Stage 4:

Installing the Switcher Mounting System

and the PVS 405D ............................................. 39

A. PoleVault System

(PMK 560 Pole Mount Kit) ............................. 40

A1. Install the PMK 560 Base Plate ............... 40

A2. Pull the Cables (at the Switcher

location) ....................................................... 41

A3. Secure the HDMI cables using the

LockIt bracket ............................................. 42

A4. Finish installing the Mounting Kit ............. 43

B1. Install the WMK 160 Base Plate ............. 44

B. WallVault System

(WMK 160 Wall Mount Kit) ........................... 44

B2. Install the switcher onto the Base Plate .. 45

B3. Run the cables to the WMK 160

location........................................................ 46

.................. 17

PoleVault Digital Systems • Contents iv

Page 6

B4. Cable the switcher ................................. 46

B5. Final Installation ...................................... 46

C. WallVault System

(USFM 100 Short Throw Wall Mount Kit) ...... 47

C1. Install the USFM 100 Base Plate ............ 48

For drywall with wood studs ......................... 48

For drywall with steel studs ........................... 48

C2. Install the switcher onto the Base Plate .. 48

C3. Run the cables to the

USFM 100 location ................................ 49

If running cable behind the walls: .................. 49

If using a surface raceway or conduit: ........... 49

C4. Cable the switcher ................................. 50

C5. Attach the Boom Arm, Power Supply,

and Projector ......................................... 50

D. PlenumVault System

(PVM 220 PlenumVault Mount Kit) ................ 52

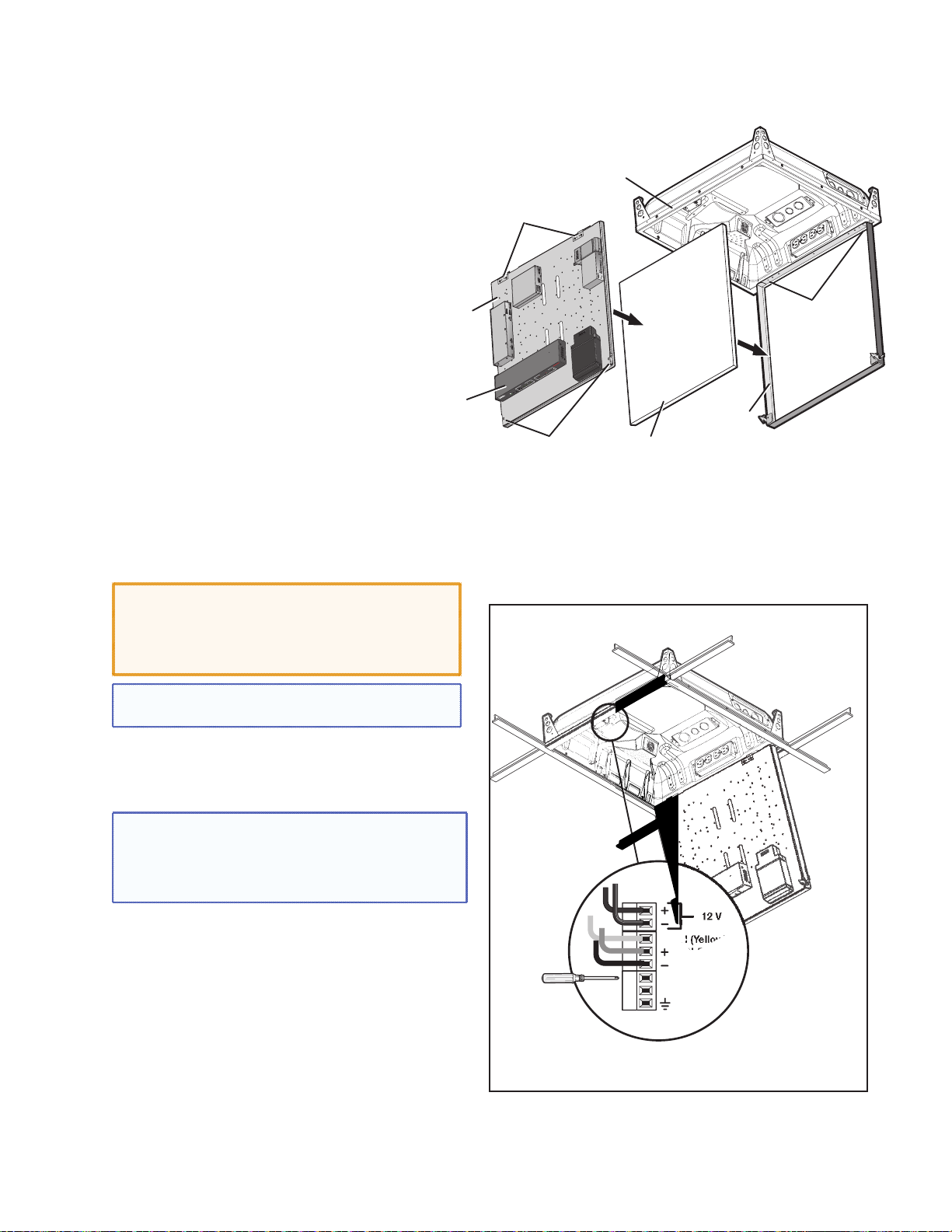

D1. Remove the device mounting plate

from the access door ............................. 53

D2. Remove ceiling tile and install

suspension cables. ................................. 53

D3. Suspend the main PVM 220

enclosure from the ceiling. ...................... 54

D4. Run AC power wiring to the AC module

in the PVM 220 ...................................... 55

D5. Run signal and control cables to the

PVM 220. ............................................... 56

D6. Install devices onto the device mounting

plate. ...................................................... 57

D7. Cut and install the ceiling tile in the

access door. .......................................... 57

D8. Install the device mounting plate onto

the access door. .................................... 58

D9. Cable the switcher ................................ 58

D10. Verify and configure the setup. ............. 59

D11. Attach the door tether to the door. ....... 59

D12. Secure the door latches. ..................... 59

Stage 5:

Configuring the

PVS 405D Switcher ........................................... 61

1. Configure the Switcher —

PCS Product Configuration Software

Program ...................................................... 61

2. Configure the System —

Global Configurator ..................................... 62

3. Test the System ........................................ 63

4. Final Installation ........................................ 65

Optional Accessory Installation —

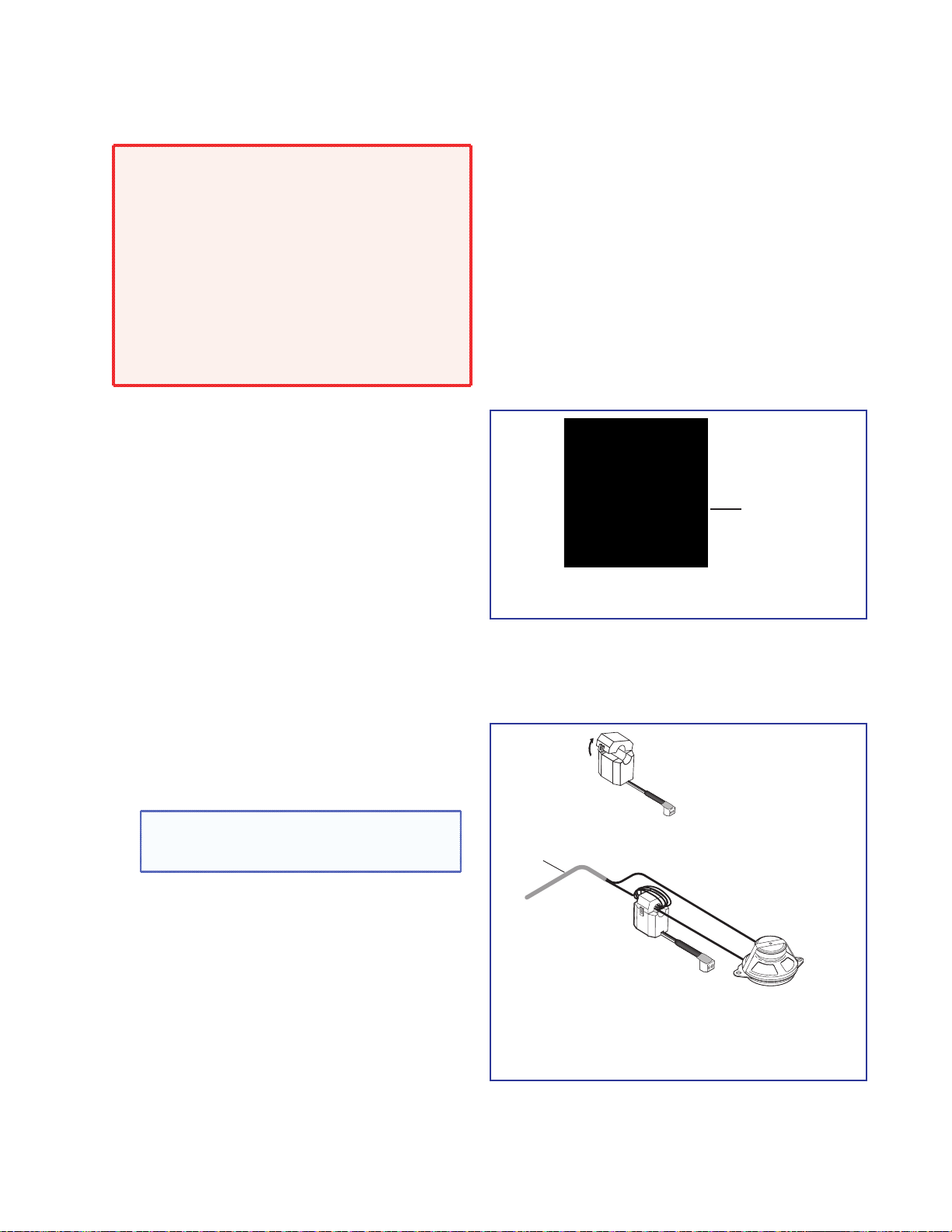

VoiceLift System ............................................ 66

VoiceLift System Included parts: ................... 66

Installation Procedure ................................... 66

Optional Accessory Installation —

Priority Page Sensor (PPS 35) ...................... 67

Installation Procedure ................................... 68

Optional Accessory Installation —

Priority Page Sensor Kit (PPS 25) ................. 68

Priority Page Sensor Kit Included Parts: ........ 69

Installation Procedure ................................... 70

Testing and Adjustment Procedure ............... 72

Outline of Installation Steps for

WallVault Digital Systems (WMK 160) ............... 73

Outline of Installation Steps for

WallVault Digital Systems (USFM 100) .............. 74

Outline of Installation Steps for

PlenumVault Digital Systems (PVM 220)........... 75

Extron Warranty ................................................ 77

Outline of Installation Steps for

PoleVault Digital Systems ................................ 78

PoleVault Digital Systems • Contentsv

Page 7

Introduction

Overview

This guide covers the installation of the Extron PoleVault Digital System, and also the

installation methods for each type of WallVault and PlenumVault enclosure.

NOTE: PoleVault, WallVault, and PlenumVault Digital systems use the same digital PVS

switcher, input source AV devices, control device, and ceiling speakers. However,

the systems have different mounting enclosures, (PMK 560, USFM 100, WMK 160,

and PVM 220), depending on the system type. This guide attempts to use a basic

PoleVault Digital System setup to cover installing the common system components,

and highlights the different enclosure installations separately.

The PoleVault Digital System is used in a drop ceiling room with a wood or concrete

structural ceiling. If the location has a concrete or beam style ceiling, alternative ceiling

mounts can be obtained separately from Extron.

WallVault Systems are specifically developed for classrooms or lecture rooms with a wall

mounted short-throw projector or flat panel display. WallVault Systems utilize either the

USFM 100 or WMK 160 enclosures to securely mount and conceal the system switching

and audio amplification components on the wall.

PlenumVault Systems are designed for rooms with a suspended ceiling. They utilize the

PVM 220 PlenumVault Mounting Kit that securely mounts and conceals system components

in the plenum space above the suspended ceiling.

It is assumed that the installer has some knowledge and experience of AV, electrical,

or electronic device installation. This guide takes the AV installer through the steps for

installation and connection of each of the system component parts.

It may be that the locations for the devices (for example, wall plates, projector, and screen)

have been pre-determined. However, some room installation examples are given to help in

installations where final location is yet to be determined.

The Digital PoleVault, WallVault, and PlenumVault Systems

The Digital PoleVault, WallVault, and PlenumVault Systems are easy-to-use, networkenabled, all-inclusive packages, making them ideal for single-display classrooms. These

Systems use shielded twisted pair cables for transmitting signals and include network

connectivity for Web-based asset management, monitoring, and control.

NOTES:

• The hardware and devices listed on the inventory pages have detailed safety

information, installation, set-up, and configuration instructions which should be

referred to as needed.

• For operation and setup of the projector, screen, and input devices, refer to the

relevant manufacturer manuals supplied with those devices.

• A PoleVault System Installation video is viewable online at www.extron.com.

This video is also a step by step guide to installing PoleVault System and is useful

for first-time installations.

PoleVault Digital Systems • Introduction 1

Page 8

E

VLM 2000H

V

e

w

n

E

xtron

PWR

CHARGEE/CHG ON

Application Diagram

Extron

SPK 18 - 35'

Cable

Extron

PCM 340

Projector Drop

Ceiling Mount

with Adjustable

Pole

Extron

PMK 560

Easy Installation

Pole Mount Kit

Extron

PVS 405D

PoleVault Switcher

Extron

FF 120

Flat Field

Speakers

- 1 Pair

TCP/IP

Network

Ethernet

Extron

VLR 102

VoiceLift

Receiver

TY

I

V

ITI

ENS

S

AL

SIGN

L

SIGNA

AUX

4

1

2

Extron

UPB 25

RS-232

to Switcher

Universal Projector

Mounting Bracket

RS-232

to Projector

Ethernet

Extron

MLC 104 IP Plus

MediaLink Controller

DI

SPLA

Y

ON

OF

F

VOLUME

VCR

1

DVD

2

P

C

CO

N

FI

G

3

4

MLC

104 IP PLUS

Extron

xtron

VLM 2000H

VoiceLift Microphone

oiceLift Microphon

with Charging Station

ith Charging Statio

Extron

Extron

PVT SW HDMI RGB D

HDMI, RGB & Audio

Input Wallplate

Teacher

Laptop

Document

Camera

Legend:

HDMI

VGA

A

U

D

IO IN

HDMI IN

IR OUT

S

G

AU

IN O

DIO

UT

VG

A

IN

LOCA

L

O

U

T

Blu-ray Player

HDMI

AU

D

IO IN

HD

M

I IN

A

U

D

IO IN

IR

OU

T

HD

S

M

I

G

IN

Extron

PVT SW HDMI D

Dual HDMI & Audio

Input Wallplate

VideoAudio ControlCATx

Figure 1. PoleVault System Installation and Wiring Overview

2

PoleVault Digital Systems • Introduction

Page 9

Before You Begin — Planning the Installation

Before installation is started, you must consider several major factors to ensure that the

installation process is as smooth and trouble free as possible, and so that the final finished

project meets the needs of the customers, users, audiences, and installer.

The installation considerations on the following pages, though not comprehensive, should

be consulted to help ensure that key installation aspects have been considered.

Americans with Disabilities Act (ADA) Compliance

When planning where to install the Polevault System, you may need to consider factors

affecting accessibility of the system such as the height of devices from the floor (for example

the MLC controller), distance from obstructions, and how far a user must reach to press any

device buttons.

For guidelines, see sections 307 (“Protruding Objects”) and 308 (“Reach Ranges”) of the

2010 ADA Standards for Accessible Design available at:

http://www.ada.gov/regs2010/2010ADAStandards/2010ADAStandards.pdf.

Room Layout

The Room

The application diagram below shows a typical classroom installation.

PoleVault System

DISPLAY

ON

OFFVCR

1

2

DVD

VOLUME

PC

3

CONFIG

4

Extron

MLC 104 IP Plus

AUDIO

AUDIO IN

INOUT

HDMI IN

VGA IN

LOCAL OUT

IR OUT

G

S

AUDIO

AUDIO IN

IN OUT

HDMI IN

VGA IN

LOCAL OUT

IR OUT

G

S

A

U

DI

O

I

N

HDM

I

I

N

A

U

D

I

I

N

O

O

U

T

I

R

O

U

T

V

G

A

I

N

G

S

L

O

C

A

L

O

U

T

DISPLAY

ON

OFF

VCR

1

2

DVD

VOLUME

PC

3

CONFIG

4

Extron

MLC 104 IP Plus

AUDIO

AUDIO IN

IN OUT

HDMI IN

VGA IN

LOCAL OUT

IR OUT

G

S

Figure 2. Typical Classroom Installation

Room factors to be considered should include, but are not confined to:

• Room size, orientation, and layout:

• Audience factors (for example number, ADA requirements, seating arrangements)

• Existing installed furniture (bookcases, racks, cabinets, workbenches, sinks, and so

forth.)

• Windows, doors, and support pillar locations in relationship to the proposed screen

location

PoleVault Digital Systems • Introduction 3

Page 10

• Ceiling and wall type (important in assessing the hardware needed)

Windows

PVT A/V Wallplate Location

• Ceiling type: dropped, spline, hard lid, and similar. Structural type (wood, concrete,

trusses), plenum or non-plenum

• Wall type: drywall, cement, brick.

WARNING: Structural ceiling failure could cause death serious injury or

death. Check the structural ceiling to ensure that it can handle a load four times

the weight of the final setup.

• Lighting:

• Type and control (important for projector image viewing)

• Ambient light from windows

Student Desks

Speaker

Location

Projector/Switcher

Location

MLC controller

Location

TV / VCR / DVD

Inputs

Screen/White Board

Location

Teacher’s Desk

Figure 3. Example Classroom Installation

Location of the Screen and Projector

• Proposed screen location (normally located at the front center of the room)

• The lowered screen does not cover safety devices, such as fire alarm strobes.

• Dimensions and type of screen (maximum image size, motorized or hanging screen)

• Proposed projector location

• Projector aligned with center of the screen and not an obstruction to viewing

• Projector throw distance (maximum and minimum limits to the screen) of the image

• Horizontal offset (horizontal distance from the center of the lens to the center of the

projector)

• Vertical offset of the projected image (height relationship between the projector and

the screen).

• Projector angle (image projected up, down, or horizontal to screen)

• Power source for the projector: existing and accessible or needing installation

• Projector weight: the Universal Projector Bracket (UPB 25) supports a maximum

weight of 25 pounds.

• Viewing obstructions: pillars, furniture and so forth, window locations for glare

reduction, obstructions between projector and screen.

• Overhead clearances (refer to a copy of ADA Standards for Accessible Design,

Sections 307 and 308, for ADA requirements).

4

PoleVault Digital Systems • Introduction

Page 11

Location of MediaLink Controller and Wall Plates

Windows

PVT AV Wallplate Location

• Forward and side reach (for full details refer to a copy of ADA Standards for

Accessible Design, Sections 307 and 308, for ADA requirements).

• Location of source devices:

Desk, table, or rack mounted, and proximity to proposed transmitter location (wall,

podium, or furniture)

• Cabling obstacles:

Studs, utility pipes, power supply location (raceway installation needed?)

• Network drop for MediaLink Controller:

Wall or floor cabled

Type and Location of the Speakers

• Speaker type based on room ceiling and wall type

• Total number and spacing of speakers

Based on ceiling height and room size

Audience seating and room acoustics

Desired spread and evenness of sound coverage and ambient noise level compensation

Each speaker covers

one-fourth of

listening area.

Speaker

Location

Projector/Switcher

Location

MLC controller

Location

TV / VCR / DVD

Inputs

Screen/White board

Location

Student Desks

Teacher’s

Desk

Figure 4. Example Classroom with Four Speaker Installation

PoleVault Digital Systems • Introduction 5

Page 12

Inventory — PoleVault Digital System

NOTE: The PoleVault Digital System inventory is shown on this and the next page. For WallVault and

PlenumVault Digital Systems, see the inventory lists on pages 8 to 11.

The PoleVault Digital System (PVS xxx) ships in two boxes. The larger box contain the devices and hardware,

individually boxed and labeled. The smaller box contains only the FF 120 speakers.

Carefully check all the received items against the lists on this and the next page..

PoleVault Digital System Devices

and Hardware

PoleVault Digital System

42-207-03 or 42-208-03

PCM 340

PCM 340 White

70-656-23

PCM 340

Projector Drop Ceiling Mount

Accesories

UPB 25

UPB 25 White

60-773-03

UPB 25

Universal Projector Bracket

Accesories

PMK 560

PMK 560 White

70-1034-03

Cables

(1) SPK 18, 35 ft

(1) MLC, PW/RS232/VC, 50 ft

(1) MLC IR, 50 ft

PMK 560

Pole Mount Kit

(1) HDMI Micro, 3 ft

STP 201P Patch, 35 ft

Quantity varies depending

on PVS system ordered.

These may be boxed separately

or loose inside larger box.

(1) Snap-in trim piece

(4)Turnbuckles

(5) Lag eye bolts

(5) Concrete anchors

(2) Cable clamps, Galv steel

(1) Safety wire (15 ft. 1/8 in. dia)

(2) Tie wire (30 ft., 14 AWG)

(4) T-frame screws

(2) Set screws

(1) Location screw

(11) Hole plugs

(4) Adhesive pads

(1) 25 in. Slotted pipe

(1) Escutcheon ring

(4) M6 x 40 mm screws

(4) M5 x 40 mm screws (4)

M4 x 40 mm screws (4) M3

x 40 mm screws

(4) 0.328 inch ID washers

(4) #10 washers

(4) #6 washers

(4) Adhesive pads

(1) Hex key

The PVS 405D may come

pre-installed on the PMK 560

Accesories

(4) 10-32 Cover screws

(3) 4-40 screws

(2) Velcro

(1) Tie wrap

®

pads

NOTE�Items not drawn to scale

6

PoleVault Digital Systems • Introduction

Page 13

Kits

PoleVault Digital System Devices

• PVS 200D (part number 42-207-03) includes one PVT SW HDMI D

• PVS 400D (part number 42-208-03) includes one PVT SW HDMI RGB D and one PVT SW HDMI D.

NOTE: If any items in the PoleVault Digital System boxes are damaged or missing, contact the Extron Technical

Support Hotline (see rear cover for contact numbers).

and Hardware, cont’d

PoleVault Digital System

42-207-03 or 42-208-03

PVS 405D

This item may come pre-installed

on the PMK 560

SELECT

R

CONFIG

AUDIO

1

345

2

AUX

PVS 405D

PoleVault Digital Switcher

60-1235-01

(1) 2-pole connector

(3) 3-pole connector

(2) 5-pole connector

(1) Audio connector, 4-pole

(2) Securing screws

(7) Tie wraps

(1) LockIt

(1) Power supply

(1) Power cord

AUDIO LEVEL ADJUSTINPUTS

PEAK

INPUT

PEAK

VOICELIFT

NORMAL

NORMAL

SIGNAL

SIGNAL

PAGING

SENSOR

SENSITIVITY

PVS 405D

POLEVAULT SWITCHER

PVT SW HDMI RGB D

White

®

Faceplate

IN OUT

VGA IN

LOCAL OUT

AUDIO

AUDIO IN

HDMI IN

IR OUT

S

G

PVT SW HDMI RGB D

60-1335-03

(1) Mud ring

(4) PVT mounting screws

(1) Decora

(4) Faceplate screws

(1) 2-pole connector

(1) Tie wrap

or optional

PVT SW HDMI D

60-1270-03

MLC 104 IP Plus

DISPLAY

ON

VOLUME

MLC 104 IP Plus

(1) Mud ring

(8) Mounting screws

(4) Faceplate screws

(2) Faceplates (1) White (on unit)

(1) Black

OFF

CONFIG

60-818-03

VCR

DVD

PC

MLC 104 IP Plus

FF 120

1

2

3

4

FF 120

42-120-03

(2) Cable clamps - Anchor ring

(2) T-rails

PoleVault Digital Systems • Introduction 7

Page 14

Inventory — WallVault Systems (USFM 100)

Extron

Plastic Enclosure Cover

USFM 100

Arm Cover (top)

Arm Cover (front)

Arm Cover (buttom)

Boom Arm

Base Plate

Device Mounting Plate

Figure 5. USFM 100 for WVS 200D and WVS 400D WallVault Systems

42-209-03 WVS 200D

Part Number Description Quantity

26-621-50 MLC IR cable, 50 ft 1

26-626-50 MLC PW/RS-232 cable, 50 ft 1

26-627-35 Speaker cable, 35 ft 2

26-667-03 Micro HDMI cable, 3 ft 1

26-696-35 STP 201P cable, 35 ft 1

42-120-03 FF 120 speakers 1 pair

60-773-03 UPB 25 1

60-818-03 MLC 104 IP Plus 1

60-1235-01 PVS 405D 1

60-1335-03 PVT SW HDMI RGB D 1

70-744-03 USFM 100 1

42-210-03 WVS 400D

Part Number Description Quantity

26-621-50 MLC IR cable, 50 ft 1

26-626-50 MLC PW/RS-232 cable, 50 ft 1

8

PoleVault Digital Systems • Introduction

26-627-35 Speaker cable, 35 ft 2

26-667-03 Micro HDMI cable, 3 ft 1

26-696-35 STP 201P cable, 35 ft 2

42-120-03 FF 120 speakers 1 pair

60-773-03 UPB 25 1

60-818-03 MLC 104 IP Plus 1

60-1235-01 PVS 405D 1

60-1270-03 PVT SW HDMI D 1

60-1335-03 PVT SW HDMI RGB D 1

70-744-03 USFM 100 1

Page 15

Inventory — WallVault Systems (WMK 160)

Se

M

)

"

Ass

v

o

M

lat

e

K

Figure 6. WMK 160 for WVS 210D and WVS 410D WallVault Systems

42-211-03 WVS 210D

Part Number Description Quantity

26-621-50 MLC IR cable, 50 ft 1

26-626-50 MLC PW/RS-232 cable, 50 ft 1

26-627-35 Speaker cable, 35 ft 2

26-692-15 HDMI Plenum M-M cable, 15 ft 1

26-696-35 STP 201P cable, 35 ft 1

42-120-03 FF 120 speakers 1 pair

60-818-03 MLC 104 IP Plus 1

60-1235-01 PVS 405D 1

60-1335-03 PVT SW HDMI RGB D 1

70-1030-03 WMK 160 1

(1) WMK 160 Base Plate

160 Base P

1) WM

(1) WMK 160 Cover

(4) 1/4" KapToggle®

(4) 1/4

Assemblies

4

(4) 1/4-20 x 2"

Pan Head Bolts

(2) #14 x 1 3/4"

2) #14

Self-tapping

Metal/Wood Screws

(4) Cover Screws

Co

(1) PoleVault Switcher

(1) P

Mounting Plate

42-212-03 WVS 410D

Part Number Description Quantity

26-621-50 MLC IR cable, 50 ft 1

26-626-50 MLC PW/RS-232 cable, 50 ft 1

26-627-35 Speaker cable, 35 ft 2

26-692-15 HDMI Plenum M-M cable, 15 ft 1

26-696-35 STP 201P cable, 35 ft 2

42-120-03 FF 120 speakers 1 pair

60-818-03 MLC 104 IP Plus 1

60-1235-01 PVS 405D 1

60-1270-03 PVT SW HDMI D 1

60-1335-03 PVT SW HDMI RGB D 1

70-1030-03 WMK 160 1

PoleVault Digital Systems • Introduction 9

Page 16

Inventory — PlenumVault Systems (PVM 220)

Figure 7. PVM 220 for PLS 200D, PLS 210D, PLS 400D, and PLVS 410D

PlenumVault Systems

42-220-03 PLS 200D

Part Number Description Quantity

26-621-50 MLC IR cable, 50 ft 1

26-626-50 MLC PW/RS-232 cable, 50 ft 1

26-627-35 Speaker cable, 35 ft 1

26-692-15 HDMI Plenum M-M cable, 15 ft 1

26-696-35 STP 201P cable, 35 ft 1

42-120-03 FF 120 speakers 1 pair

60-773-03 UPB 25 1

60-818-03 MLC 104 IP Plus 1

60-1335-03 PVT SW HDMI RGB D 1

70-656-23 PCM 340 1

70-1072-01 KTS, PVM 220/PVS 405D/PS 1

E

HER

SA IP

TC

5

I

SW

40

T

S

L

U

V

A

P

EV

POL

NG

OR

GI

S

Y

T

A

N

P

IT

V

SE

I

IT

S

N

E

S

L

EL ADJUS

K

MA

PEA

R

L

O

EV

A

N

N

L

G

SI

T

F

I

L

UDIO

E

A

VOIC

L

MA

R

O

K

N

L

A

A

E

N

P

G

SI

T

U

P

IN

O

5

AUDI

AUX

UTS

P

N

I

3

4

1

2

ELECT

S

FIG

N

O

C

R

10

42-221-03 PLS 400D

Part Number Description Quantity

26-621-50 MLC IR cable, 50 ft 1

26-626-50 MLC PW/RS-232 cable, 50 ft 1

26-627-35 Speaker cable, 35 ft 1

26-692-15 HDMI Plenum M-M cable, 15 ft 1

26-696-35 STP 201P cable, 35 ft 2

42-120-03 FF 120 speakers 1 pair

60-773-03 UPB 25 1

60-818-03 MLC 104 IP Plus 1

60-1270-03 PVT SW HDMI D 1

60-1335-03 PVT SW HDMI RGB D 1

70-656-23 PCM 340 1

70-1072-01 KTS, PVM 220/PVS 405D/PS 1

PoleVault Digital Systems • Introduction

Page 17

Inventory — PlenumVault Systems (PVM 220)

42-230-03 PLS 210D

Part Number Description Quantity

26-621-50 MLC IR cable, 50 ft 1

26-626-50 MLC PW/RS-232 cable, 50 ft 1

26-627-35 Speaker cable, 35 ft 2

26-692-15 HDMI Plenum M-M cable, 15 ft 1

26-696-35 STP 201P cable, 35 ft 1

42-120-03 FF 120 speakers 1 pair

60-818-03 MLC 104 IP Plus 1

60-1335-03 PVT SW HDMI RGB D 1

70-1072-01 KTS, PVM 220/PVS 405D/PS 1

42-231-03 PLS 410D

Part Number Description Quantity

26-621-50 MLC IR cable, 50 ft 1

26-626-50 MLC PW/RS-232 cable, 50 ft 1

26-627-35 Speaker cable, 35 ft 2

26-692-15 HDMI Plenum M-M cable, 15 ft 1

26-696-35 STP 201P cable, 35 ft 2

42-120-03 FF 120 speakers 1 pair

60-818-03 MLC 104 IP Plus 1

60-1270-03 PVT SW HDMI D 1

60-1335-03 PVT SW HDMI RGB D 1

70-1072-01 KTS, PVM 220/PVS 405D/PS 1

PoleVault Digital Systems • Introduction 11

Page 18

Items Not Included

The following items are not included in the systems. However, input and display devices are

essential parts of the system, and at any installation they may vary depending on their use.

This list suggests various devices that may be used.

• Projector (or display device)

• Screen (and mounting hardware)

• Input devices, such as:

• Installation hardware needed (may vary per installation):

• Blu-ray, DVD/CD/VCR combo player (and cables)

• Document camera (and cables)

• PC or Mac computer (with keyboard, mouse, local monitor, VGA cables,

RJ-45 network cables, power cords, and, where desired, a P/2 DA2 or distribution

amplifier (DA) for PC signal to local monitor)

• Bolts for concrete structural ceilings where needed

• Toggle bolts (used for screen mounting on dry wall)

• S-hooks for hanging the screen

• Spare ceiling tiles in case of accidental damage during installation

• Electrical box, where installation of a box on the PCM 340 is desired

• Safety wire, lag eye bolts, and strain reliefs for installation and securing ceiling

speakers

• Heat shrink, extension cord

Installation Tools

• Laser level, or two levels (large for screen

installation, small for wall plates and projector

mounts)

• Tape measure

• Stud finder

• Drill and drill bit set including a unibit to cut

through metal studs

• Extension drill bit (3/4 inch min., 4 to 8 foot

length, to drill through fire breaks)

• Socket set

• Pipe strap or wrapped pipe wrench

• Pliers and wire strippers

• Standard screwdriver set and Extron Tweeker

• Cable cutters (to cut safety wire)

To aid the professional installer, this checklist gives the tools recommended to complete

the installation. Tools should include, but are not confined to:

• Drywall saw and hacksaw blade mounted on

handle (for cutting ceiling tiles)

• Flashlight and safety goggles

• Razor knife

• 2 inch hole saw

• Painter’s tape (to mark up walls), pencil, and

marker pen

• RJ-45 crimpers and RJ-45 connectors

• Voltage tester

• Fish tape, pull string, and electrical tape (for

taping fish tape to pull string)

• Zip ties

• Vacuum cleaner

• Heat gun

12

PoleVault Digital Systems • Introduction

Page 19

Optional Items

The optional Extron products suggested below can be added to or substituted for items

in the standard Digital PoleVault System. Some of these items may also be suitable for the

Digital WallVault or PlenumVault Sytems.

• Optional accessories:

Wall mount speakers (for example, SI 26) or extra ceiling speakers

MLC 104 IP Plus DV+ controller (includes DVD/VCR IR control)

MLC 104 IP Plus L controller (with lectern faceplate)

MLC 104 IP Plus AAP controller (with AAP opening)

MLC 226 IP controller

PPS 25 Priority Page Sensor Kit

PPS 35 Priority Page Sensor

P/2 DA2

VLM 1000 VoiceLift Microphone System or VLM 2000 System

• Optional installation hardware:

FCMP (flat ceiling mount)

ACMP (angled ceiling mount)

SMB (surface mount boxes for installing the MLC on a podium or desk)

EWB (external wall boxes to mount devices for a surface raceway system)

• Optional speakers:

SM 3 (Compact Full-Range Surface Mount Speakers)

SI 3C LP ( Full-Range Ceiling Speakers with 4” Low Profile Back Can)

PoleVault Digital Systems • Introduction 13

Page 20

14

PoleVault Digital Systems • Introduction

Page 21

Installation

Overview

This section outlines the basic steps for installing the PoleVault System. An outline and

checklist of the stages (Stages One through Five), listing the relevant steps within each

stage, is given on pages 16 and the rear cover. A fully detailed description of these steps is

given in the five corresponding sections.

Carefully check inventory of PoleVault System packages, input and output devices, any

optional accessories, and installation hardware before commencing.

NOTES:

• Additional installation hardware is needed for this installation, and should be

supplied by the installer. See Items Not Included on page 12 for a list of items that

you may need.

• Refer to local building standards and codes to verify that the installation will meet all

the regulatory requirements.

• Observe all local and national building and safety codes, UL requirements, and

ADA accessibility guidelines.

Similar outline lists of steps for installing WallVault (WMK 160 or USFM 100) and

PlenumVault (PVM 220) Digital Systems can be found on pages 73 through 76.

PoleVault Digital Systems • Installation Overview 15

Page 22

Outline of Installation Steps for PoleVault Digital Systems

Stage 1 — Install the Screen and Projector

c Mark the screen location (page 18).

c Install projector to verify location (page 18).

c Verify the image location (page 21).

c Cut the ceiling tile (page 22).

c Preliminary safety hardware installation (page 22).

c Finish projector drop ceiling mount installation (page 23).

c Secure the projector drop ceiling mount to the ceiling (page 24).

c Install the electrical box (if required) (page 25).

c Install the screen (page 25).

Stage 2 — Mount the PVT Wall Plates and the MLC 104 IP Plus.

Install the mud rings (page 29).

c

c Pull cables (at the input locations) (page 30).

c Install the wall plates (page 31).

c Install the MediaLink Controller (page 32).

Stage 3 — Install the FF 120 Speakers.

c Cut the ceiling tile (page 36).

c Install the speaker on the drop ceiling (page 36).

c Terminate the speaker cable for the PVS switcher (page 38).

Stage 4A — Install the PMK 560 and PVS 405D.

c Install the PMK 560 base plate (page 40).

c Pull the cables (at the switcher location) (page 41).

Stage 5 — Configure the PoleVault Switcher and the System.

Optional Accessory Installation

The pages listed above contain instructions for installing the PoleVault Digital System. Where possible, line

drawings and photos from an actual installation are used to clarify some of the steps discussed in the text. Most

images have a number corresponding to the step that is being described (for example, Ñ).

NOTE: Similar outline lists of steps for installing WallVault (WMK 160 or USFM 100) and PlenumVault

(PVM 220) Digital Systems can be found on pages 73 through 76.

c Finish installing the pole mount kit (page 43)

c Configure the switcher — PCS Configuration program (page 61).

c Configure the system — Global Configurator (page 62).

c Test the system (page 63).

c Final installation (page 65).

c

VoiceLift System (page 66).

c Priority Page Sensor PPS 35 (page 67).

c Priority Page Sensor Kit PPS 25 (page 69).

PoleVault Digital Systems • Installation Overview16

Page 23

T

Secur

Scre

1-gang and 2-gang Accessory Mounting

Stage 1: Installing the Screen and Projector

Stage 1 Involves installing the three pieces of hardware shown below.

PCM 340 Projector Drop Ceiling Mount

• Where it goes: Attaches to a structural ceiling,

rests on the suspended ceiling.

• What it does: Holds the slotted pipe, PoleVault pole

mount kit (PMK 560), and projector.

Slotted Pipe

• Where it goes: Locks into place in the PCM 340 adapter.

• What it does: Holds the PMK 560 pole mount kit,

UPB 25 Projector Bracket, and projector.

b

a

Pipe Adapter Plate

Wing Nuts (4)

-bar

ing

ws (4)

1

PCM 340

Points (Power Sockets)

Pipe

Adapter

2

Slotted

Pipe

Base

Plate

Pipe Adapter

Set Screws (2)

UPB 25 Universal Projector Bracket

(separated into two sections) c

• Where it goes: Adjuster Plate screws onto the base of

the slotted pipe, and the Projector

Bracket attaches to the projector.

• What it does: Attaches the projector to the PCM 340.

Allows proper projector positioning and

orientation.

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector)

3

UPB 25

Adjuster Plate

(Top Section)

Projector Bracket

(Bottom Section)

17

Page 24

1. Mark Screen Location.

PCM 340

Minimum/Maximum

Throw Distance Marks

TIPS:

• When marking the location of screens,

devices, or the site for installing transmitters

and MediaLink control devices, use painters

tape to avoid wall surface damage.

• When marking the center line of the

screen, where possible, keep it aligned

with the center of the ceiling tile. This

makes the projector installation and

alignment easier.

a. Mark the center line and the outer edges of the

screen.

b. Mark any structural studs, utility pipes, conduits,

or fire breaks before drilling the hardware holes.

Do not drill the holes yet.

2. Install Projector to Verify Location.

a. Remove the ceiling tiles at the location, and

mark the maximum and minimum throw

distances on the T-frame. See the projector

installation manual for more information.

Mark the screen location.

Ä

TIP: For ease of working on the T-frame,

remove the adjacent tiles.

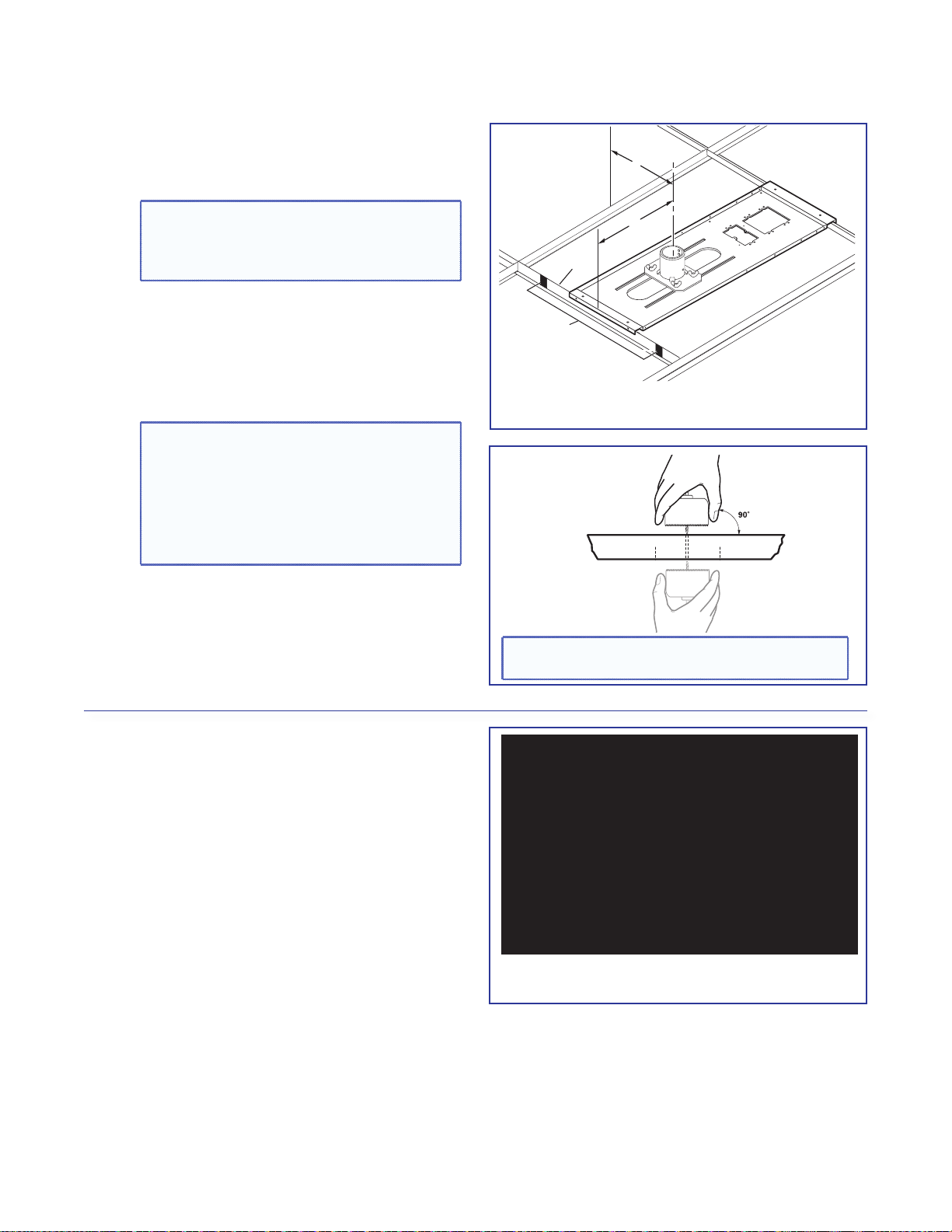

b. Place the PCM 340 over the T-frame, between

the two marks. Lightly tighten the T-frame

securing screws. The T-frame screws can be

used on the outside or the inside to secure the

PCM to the T-frame.

NOTE: Place the PCM 340 on the T-frame

so that the pipe adapter slides left to right

in relation to the proposed screen location,

rather than towards and away from it. This

makes it easier to align and center the

image.

c. Slide the slotted pipe up into the pipe adapter.

Adjust to the desired height and align the

location holes and pipe holes. Insert the location

screw, lightly tightening it down using a

5/32 inch hex wrench. Insert and lightly tighten

down the set screws onto the pipe. Do not

overtighten. The pipe is removed and replaced

later during installation.

Place the PCM 340 on the T-bar

É

Slotted

Pipe

Pipe

Adapter

Align Pipe holes with

location screw holes.

Insert location screw

and secure.

Insert and secure the slotted pipe.

î

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector)18

Page 25

d. Using a 3/32 inch hex wrench, back out the

set screws on the top portion of the adjuster

plate (see a in the image below) of the UPB 25.

Screw the plate onto the base of the pipe. Align

it so the security flange is at the rear

a

Adjuster

Plate

Pivot Screws

Security Flange

Set Screws (2)

Loosen the four adjuster plate

locking screws and slide the

adjuster plate away from the

projector bracket.

Adjuster Plate

Locking Screws (4)

e. Carefully follow the steps below to install the

projector bracket on the projector.

i. Invert the projector on a flat surface to access

the mounting points. Use a blanket or a

similar item under the projector to protect the

projector and the surface.

ii. On each arm, rotate the barrel (on the end

of the arm) so that it only just protrudes from

the base of the arm (see the figure at right).

iii. Select the correct sized mounting screws and

the appropriately sized washers that fit the

projector mounting point inserts.

iv. To attach the arms to the projector:

The next step is critical as it provides a

flat surface for the bracket to sit on, and

must be done for each mounting point.

• Place a washer on a mounting point

(see the figure at right).

• Position the arm so the barrel is over the

washer.

• Insert the mounting screw down through

the barrel and washer, and into the

threaded insert (mounting point). Lightly

tighten the screw by hand.

b

Projector

Bracket

ï Screw the adjuster plate onto the base of

the pipe.

Rotate the barrel

until it just protrudes

ii

Barrel

below the arm.

ATTENTION:

iv

Ü

Place washer on

mounting point.

Mounting Point

on Projector Base

This is critical as it provides a flat surface

for the bracket to sit on.

NOTE: If using the 3- or 4-millimeter

screws, place an additional small washer

under each screw head, on top of the

barrel, as well as one on the top of the

mounting point.

v. Repeat step iv for all projector mounting

points.

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector) 19

Place the washer. Align the barrel. Insert the screw.

Page 26

vi. Pivot the arms so that they extend towards

the center of the projector (see the figure at

right). Adjust the arms as needed for your

projector model.

NOTE: Avoid overlapping the arms where

possible.

Washer

vii. With the security flange towards the rear of

vi. Pivot arms towards center of projector.

the projector, place the projector bracket on

top of the arms and adjust for slot alignment.

• Using the slots on the bracket that are

closest to the barrel on each arm, place

the clamp under the arm and lightly secure

it to the bracket with the adjustment screws

(see the figure at right). Loosely secure all

the mounted arms.

Using the slot closest

to the barrel, secure the

arms to the bracket with

the clamp and screw.

NOTE: Where arms are unavoidably

crossed, replace the original adjustment

vii. Secure arms with clamp.

screw with a supplied 10-32 ¾ inch

adjustment screw and secure both

arms to the bracket using one clamp. In

addition, the barrels on the arms must be

raised to compensate, keeping the arms

Where arms cross, use the

supplied screw to secure

both arms to the bracket.

See note at left.

Bracket

level and reducing stress.

Clamp

viii. As close as possible, balance the weight

Arms

Note: If arms cross, secure both with clamp.

of the projector evenly across the projector

bracket. Lift the bracket at opposite corners

to assess if the configuration is approximately

balanced.

ATTENTION: Take into consideration the

uneven weight distribution of the projector

when lengthening or shortening the arms.

Distribute the projector weight evenly on

the arms.

Adjust the bracket on the arms as needed.

The projector shown at right is as close as

possible to being evenly balanced.

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector)20

viii. Evenly balanced configuration

Page 27

ix. Check for stress on the arms. To do this

Projector

Center Line

⊗

loosen the mounting screws (do not remove).

If the arm or the barrel lifts, this indicates

stress on the arm. Adjust the height of the

threaded barrels to reduce or eliminate

any torque or stress that might be caused

by crossed arms or by projector mounting

points with differing heights. It is important to

keep the arms level and as close (low) to the

projector base as possible.

x. Check that the projector weight is still as

evenly distributed as possible.

Hand tighten the screws until snug.

ATTENTION: Do not overtighten the

mounting screws as this may damage the

projector. See the projector manual for the

threaded insert torque setting.

f. Lift the projector up to the adjuster plate and

slide it into place. Tighten down the locking and

pivot screws.

Loosen the screw and adjust

the barrel height to reduce torque

on the arms and bracket.

Tighten down all the

mounting screws.

Washer

INCORRECT CORRECT

Arm not level, causing stress Arm level, no stress

on mounting point on mounting point

3. Verify the Image Location.

a. Connect a power cable to the projector and

turn it on.

b. Verify image size and location by loosening the

PCM 340 pipe adapter plate wing nuts, and

adjust the plate (left-right) to center the image.

TIP: Remember to include the vertical

and horizontal offsets when aligning the

projector. See the projector manual for

information

c. When satisfied, tighten down the plate wing

nuts.

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector) 21

Slide and lock the projector onto the

ß

adjuster plate.

Center Line

Measure the

horizontal offset

Lens

Page 28

4. Cut the Ceiling Tile.

T-bar

X"

Y"

Minimum and

Maximum

Throw Distance Marks

a. Mark the location of the PCM 340 on the

T-frame. This aids putting it back in the correct

location when the tile is replaced.

TIP: Mark the screen direction on back

of the tile (for example with an arrow or

“to front”) to help orientation of tile when

replacing it after cutting

b. Measure the distances X and Y (see the figure

at right) from the inner vertical section of the

front and left T-frame runners to the center of

the Pipe Adapter Plate.

Using the X and Y dimensions, mark and cut a

hole for the slotted pipe in the ceiling tile.

TIP: Place the tile on a box and mark the

center of the hole on the underside of the

tile. Use a hole saw bit to start to cut the

hole by hand (turning bit counter clockwise) to avoid damaging the tile. When the

drill bit is through the tile, turn the tile over

and finish cutting from the top side

Take the measurements with the PCM 340

á

on the T-frame.

Top Side of Tile

Underside of Tile

TIP: Mark and start cutting the hole on the

underside. Finish on the top side.

5. Preliminary Safety Hardware Installation

a. Mark and drill holes at 10 degrees out from

vertical for each turnbuckle. Drill a fifth hole

directly centered above the PCM 340 for the

safety cable.

b. Install an appropriate anchor or lag eye bolt for

the structural ceiling into each drilled hole.

à Mark the structural ceiling for lag eye

bolt installation.

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector)22

Page 29

6. Finish Projector Drop Ceiling Mount

Installation.

a. Detach the projector bracket and projector

from the adjuster plate. DO NOT remove the

projector bracket from the projector.

b. Unscrew the adjuster plate from the mounting

pole.

c. Loosen the pipe adapter set screws on the

PCM 340 and the pipe location screw and

remove the mounting pole, then loosen the

T-frame securing screws and remove the PCM

340 from its marked location.

d. Replace the cut ceiling tile, checking the

orientation to align the hole with the

PCM 340.

e. Replace the PCM 340 over the ceiling tile, slide

the slotted pipe up through the tile and into

the adapter plate. Realign the location holes

with the pipe holes, insert and tighten down the

location screw. Tighten the set screws.

f. Tighten the four T-frame securing screws on the

PCM 340. The T-frame securing screws can be

used on either side of the frame.

J Slide the pipe up through the ceiling tile and

into the pipe adapter plate. Shown as viewed

from below.

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector) 23

Page 30

7. Secure the Projector Drop Ceiling Mount

to the Ceiling.

a. Attach the four turnbuckles to the base plate,

one at each corner.

WARNING: May result in serious injury.

DO NOT rest or lean on the mounting

plate or suspended ceiling when attaching

turnbuckles, tie wire, or when drilling into

the ceiling.

NOTE: For safest installation, insert the

turnbuckle from the outside so that it

hooks inwards

b. Cut four equal lengths of the supplied hanging

wire, and loop the wire through the anchors or

lag eye bolts, and the turnbuckles, then twist

å Attach the turnbuckles at the corners

of the PCM 340.

the wire around itself at least five times tightly at

each end.

c. Hand tighten the turnbuckles and level the plate

so it just rests on the T-frame.

Secure PCM to T-frame

(from either side)

CAUTIONS:

• The four hanging wires should be taut,

PCM

taking the full weight of the completed

installation.

• Do not overtighten the turnbuckles

T-frame

or the T-frame assembly could be lifted,

making the suspended ceiling bowed

and unsafe

Adjust the turnbuckles to take

up any slack in the hanging wire.

e. Pass the braided safety cable through the fifth

and center anchor and attach it to the center

holes on either side of the plate. Ensure the

K Hand tighten all four turnbuckles.

cable is of equal length on both sides of the

anchor and secure the cable using the cable

clamps.

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector)24

Page 31

8. Install the Electrical Box (If required).

WARNING: Improper installation may result in

electrical shock or serious injury.

All electrical installation should be performed by

qualified personnel in accordance with local and

national building codes, fire and safety codes, and

local and national electrical codes.

RACO box

If required, the following method is recommended for

integrating a 4S RACO

®

electrical box (not supplied) on

the PCM base plate (for example, a RACO 232, 2 1/8

inch deep, 4x4 inch electrical box and a RACO 778,

1/2 inch raised, 4x4 inch plaster ring or similar).

Install the RACO box on the PCM plate as follows:

a. Attach the box to the plate, using the smallest

notches in opposite corners of the cut-out (see

figure at right). Do not tighten the screws fully at

this time.

b. On the opposite side of the PCM plate, slide

the plaster ring under the screws. The plaster

ring anchors the box in place with PCM plate

sandwiched between.

c. Fully tighten the screws.

WARNING: May result in electrical

shock or serious injury. For safety,

complete all wiring of the electrical boxes

and accessories after the plate is fully

installed and secured.

Use the smallest

notches when

attaching the

RACO box.

RACO 778

Plaster Ring

é Install the RACO box and plaster ring onto

the PCM 340.

d. Mark and cut a hole in the ceiling tile for the

electrical box opening.

9. Install the Screen.

a. Following the guidelines given by the screen

manufacturer, continue to install the screen

mounting brackets and then hang the screen.

TIP: Use S-hooks to hang the screen

from the brackets. Bend the ends of the

S-hooks so the screen does not fall when

it is rolled up.

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector) 25

Page 32

PoleVault Digital Systems • Installation — Stage 1 (Screen and Projector)26

Page 33

Stage 2:

Audio Input

Mounting the PVT

Wallplate and the

MediaLink Controller

Stage 2 Involves installing and cabling the devices shown below.

NOTE: The installation must conform to national and local electrical codes and UL requirements. See the

device user guide for details.

PVT SW HDMI RGB D AV Source Input Wallplate

PVT SW HDMI RGB D

AUDIO IN

HDMI IN

IR OUT

G

S

LOCAL OUT

Decora

Faceplate

• Where it goes: Installs in a wall near input source location.

• What it does: Transmits an input source HDMI or RGB video and audio signals to the switcher.

NOTES:

• The PVT SW HDMI RGB D is a 2-gang wallplate.

• The PoleVault Digital System incorporate EDID Minder. This allows the transmitter to communicate the

appropriate EDID information to the source, ensuring correct video output resolution.

• The EDID settings on the PVT wallplates are set during switcher configuration. See the PVS 405D

PoleVault Digital Switcher User Guide (available at www.extron.com),or the PCS Help file for setup and

operating details.

AUDIO

IN OUT

VGA IN

Mounting

Screws (4)

Signal/Power

Status LED

Audio and

HDMI input

Connectors

IR Output

Connector

AUDIO IN

HDMI IN

IR OUT

G

S

AUDIO

IN OUT

VGA IN

LOCAL OUT

Audio Output

Connector

VGA Input

Connector

Local Monitor

Output

Audio Input

Connector (at Rear)

PVT Output Port

(at Rear)

L R -

IN

AUDIO

SIG LINK

PVT SW HDMI RGB D

PVT OUT

PoleVault Digital Systems • Installation — Stage 2 (Wallplates and MLC) 27

Page 34

MLS 104 IP Plus MediaLink Controller

PVT SW HDMI D

Audio Input Connector

Mounting

screws (4)

DISPLAY

ON

VOLUME

OFF

CONFIG

VCR

DVD

PC

1

2

3

4

RS-232/IR

COMM LINK

I/O

RS-232

12V

Captive screw connectors for:

Display/RS-232/IR

Comm. Link

Digital I/O,

MLS/RS-232

Power

Tx

DISPLAY

Rx

GROUND

IR OUT

A B C D E

+12V OUT

GROUND

DIGITAL

GROUND

MLS

POWER

IR IN

A B

GROUND

GROUND

+12V IN

CM

SCP

1

2

3

Rx

Tx

LAN

TWEEKER TO REMOVE

PRESS TAB WITH

Ethernet

port

RUN

100

00-05-A6-01-6B-F5

MLC 104 IP PLUS

Right Side

• Where it goes: Installs in a wall at a location convenient to user.

• What it does: Provides remote control of switcher and projector.

Cabling for the Wallplates and MediaLink Controller

PVT transmitter installation

• Sheilded twisted pair (STP) signal transmission cables

(connects PVT input wallplates to PVS 405D switcher)

MLC 104 IP Plus installation

• MLC power and RS-232 control cable

(connects the MLC controller to the MLC control

port on the PVS 405D switcher)

• IR/RS-232 communications cable control cable

(connects the MLC controller to the projector via

RS-232 or to an IR emitter)

• LAN network cable

(not supplied - connects the MLC controller to LAN)

Optional Wallplate

Signal/Power

Status LED

AUDIO IN

HDMI IN

IR OUT

G

S

IR OUT

AUDIO IN

HDMI IN

G

S

AUDIO IN

HDMI IN

Audio and

HDMI input

Connectors

IR Output

Location of

MAC address

AUDIO IN

HDMI IN

HDMI Input

Connector

Rear View

STP201P cable, 35 ft

26-696-35

MLC PW/RS-232, 50 ft

26-626-50

IR Serial Comm, 50 ft

26-621-50

PVT SW HDMI D

SIG LINK

PVT OUT

Decora

Faceplate

Mounting

Screws (4)

PVT Output Port

(at Rear)

• Where it goes: Installs in a wall near input source location.

• What it does: Transmits an input source HDMI and audio signals to the switcher.

PoleVault Digital Systems • Installation — Stage 2 (Wallplates and MLC)28

Page 35

NOTE: The installation must conform to national and local building and electrical codes, and

UL requirements. See the device user guides for details.

1. Install the Mud Rings.

NOTE: These devices can be installed using the

supplied mud ring or a wall box. If installing a

box, allow enough depth for the plate and the

cables. The box should be at least 2.5 inches

(6.4 cm) deep to accommodate the connectors

and cables.

If a suitable wall box is already installed, follow

step 2 onwards.

a. Using an appropriate template or the PVT

mounting enclosure as a guide, with a soft

pencil, mark the area of the wall that will be cut

out.

NOTE: If installing a metal junction box,

check with the manufacturer of the box for

specific installation requirements.

b. Use a jigsaw or small hand saw to carefully

cut away the material within the marked area.

c. If using a mud ring in a wall with insulation

inside, remove at least 6 inches of the insulation

in all directions around the cutout.

NOTE: If a wall stud interferes with

removing 6 inches of insulation around the

cutout, remove the insulation between the

cutout and wall stud.

Wall

Mud Ring

4.00"

3.75"

û Insert the mud ring into the wall.

CAUTION: Risk of personal injury. Smooth

the edges of the opening to avoid

personal injury during installation.

ATTENTION: Smooth the edges of the

opening to avoid damage to the mounting.

d. Insert the mud ring into the opening. The

mud ring locking arms should fit easily into

the opening. If needed, use a saw, file, or

sandpaper to enlarge the hole.

e. Rotate the mud ring locking arms and secure

with the screws provided.

TIP: Use a level when fitting the mud ring.

Repeat steps a to c for each additional input wall

plate that needs to be installed.

f. At the desired location mark the opening for the

MLC 104 IP Plus mud ring.

g. Repeat steps b to e.

PoleVault Digital Systems • Installation — Stage 2 (Wallplates and MLC) 29

Page 36

2. Pull the Cables (at the input locations)

Fasten the WHITE section to the cable

The following cables need to be installed:

• STP cables for signal transmission from the

AV wallplates to the PVS 405D

NOTES:

• Maximum distance from the

PVS 405D to the Wallplate is 150 feet.

• STP cables supplied are terminated to

the TIA 568B standard.

• PoleVault switcher communication cable

from the MediaLink controller (MLC PW/

RS-232/VC, 50 feet, part number

26-626-50)

• Projector communication cables from the

MediaLink controller (IR Serial Comm,

50 feet, part number 26-621-50)

a. Drill cable pathways through any obstructions

(for example, wall caps, fire-breaks, or

horizontal studs).

b. Label the signal cables at both ends with the

supplied labels.

c. Pull the cabling through the wall from the ceiling

space down to the location of the transmitters

and other wall devices, and out through the

openings.

TIP: Secure cables with cable clamps to

provide strain relief.

NOTE:

first, then wrap the clear section around it.

INPUT 1/2

Use the supplied labels for clear cable

É

identification during installation.

PoleVault Digital Systems • Installation — Stage 2 (Wallplates and MLC)30

Pull the cables at each location.

î

Page 37

3. Install the Wallplates.

VGA IN

AUDIO

IN OUT

LOCAL OUT

S G

HDMI IN

AUDIO IN

IR OUT

S

G

Decora

®

Faceplate

Wall

Mud Ring

Extron

PVT SW HDMI RGB D

STP Cable

from PoleVault® Switcher

Audio Input Cable

a. Connect the cables to the rear of the input

devices.

b. If desired, wire an IR emitter to the unit using a

two conductor cable. Wire the ground to G and

signal lead to S. IR signals are transmitted over

the STP cables.

NOTE: For podcasting or recording

applications, use a three conductor audio

cable and connect the audio return to

the connector marked G (ground wire),

R (black wire), and L (red wire). The other

end will be connected to the “Line Out”

connection on the PVS 405D switcher.

This option is available only with

PVT SW HDMI RGB D wallplates.

c. Mount the device into the mud ring, using the

supplied screws.

d. Attach the supplied Decora® faceplate.

e. Label the Decora plate with the supplied label,

using the appropriate input number. This makes

inputs easier to identify when configuring the

switcher.

f. Repeat steps a through e for other AV

wallplates.

Connect the cables to the AV source

Ñ

input devices at each location.

PoleVault Digital Systems • Installation — Stage 2 (Wallplates and MLC) 31

AUDIO IN

HDMI IN

IR OUT

G

S

Mount the PVT in the mud ring then õ attach

ñ

AUDIO

IN OUT

VGA IN

LOCAL OUT

the Decora faceplate.

Page 38

4. Install the MediaLink Controller.

Wire Bared

(22 mm)

Heat Shr

Drain

LAN 2 LAN 3

STPUTAUDIO OUT

5D

GENSO

IN

AUX

VOIC

5

T

1 2

3

OT

DR SHO

R

S

T

G

TIP: Before cabling and installing the

MLC 104 IP Plus, locate the device MAC

address printed on a label on the bottom of

the controller. Write down the 12 character

alphanumeric address, (for example,

00-05-A6-03-9G-H4) and use when

configuring the IP address.

When cabling, the length of exposed wire is

critical to avoid transmission problems. Ensure

the lengths given here are adhered to when

stripping the cables for connection.

NOTE: If a drain wire is used, both ends of the

wire must be covered by heat shrink to avoid

accidental grounding.

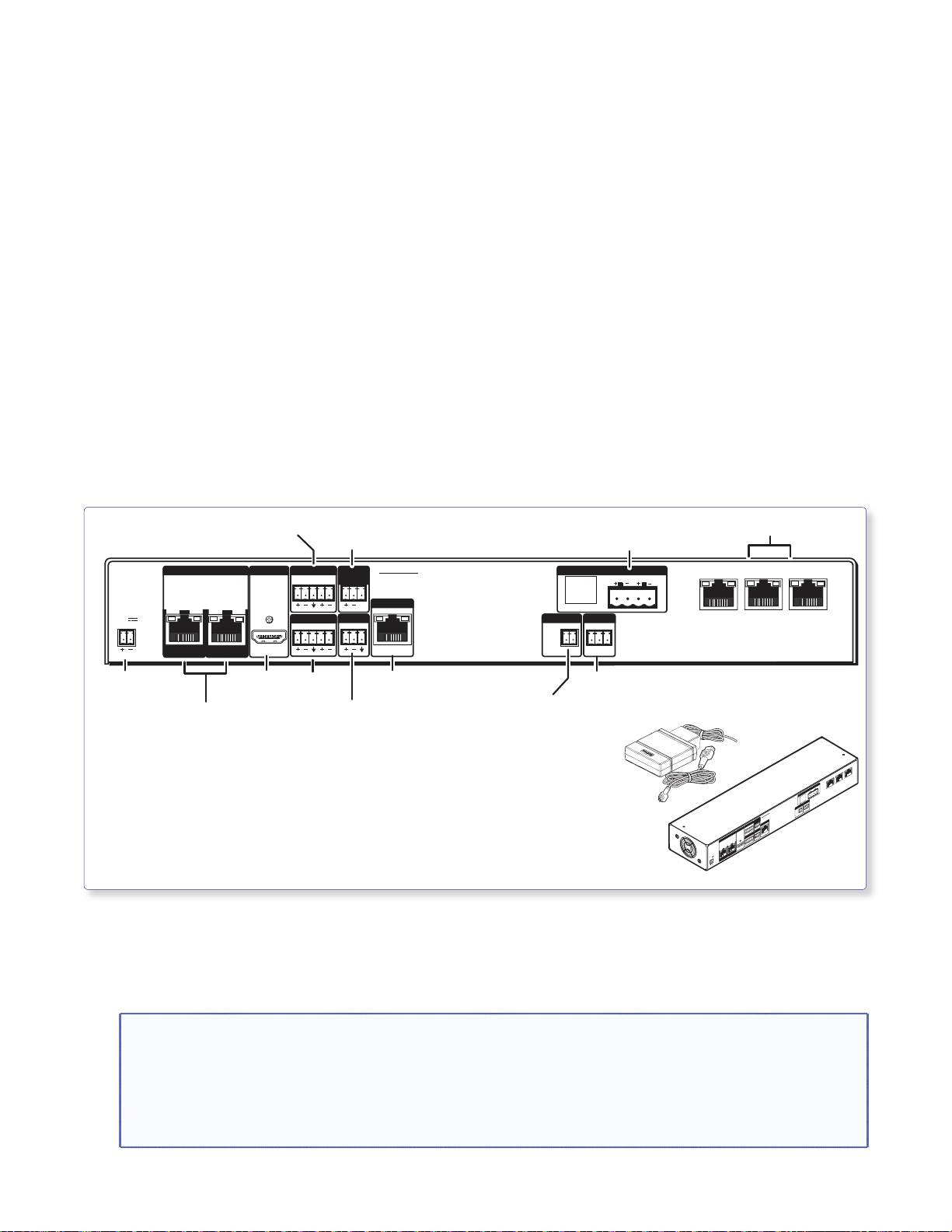

a. Connect the MLC power and RS-232 control

cable (part number 26-626-50) as shown at

right. To do this, strip the outer jacket back

to the length appropriate to get the red and

black leads to the switcher power supply. Trim

the white/purple/drain short enough to plug

directly in to the switcher, keeping most of the

drain covered in the jacket.

Wire

ink on

3/16"

(5 mm)

Max.

Heat Shrink on

Outer Jacket to

Inner Conductor

Transition

7/8"

TIP: Observe wire stripping lengths.

PVS 405D

PVS 40

PAGING

PAGIN

SENSOR

R

L

R

VOICELIFT

ELIFT

+V

+V

AUX OVER PVT REMOTE

INPUT 5

L

R

POWER

12V

3A MAX

INPUTS OUTPUT AUDIO OUT

INPUT

1/2

3/4

2

4

SIG LINKSIG LINK

IG

HDMI

IG

PVT IN PVT IN

IN

Included power supply is used for both

PVS 405D and MLC 104 IP Plus

AMPLIFIED AUDIO OUT

AMPLIFIED AUDIO OU

DO NOT

N

ROUN

GROUND

OR SHORT

PEAKE

SPEAKER

UTPUT

OUTPUTS

CLASS 2 WIRING

LASS 2 WIRIN

VER PV

RT

4/8

RS-232

TxRxIRSG G

Rx

AB

MLS PWR

RS-232 12V

8

Ω

Tx

LR

GROUND

GROUND

+12V IN

LAN 1

MLC 104 IP Plus

right side panel

MLS and Power ports

REMOTE

RS-232

Tx Rx G

NOTE:

PVS 405D

Remote RS-232

Port

From MLC 104 IP Plus

terminal

A - (Rx on the MLS port) White (Tx on the RS-232 port)

B - (Tx on the MLS port) Violet (Rx on the RS-232 port)

MLS RS-232 Ground Drain wire

Wire color To PVS 405D terminal

Ground

Power Ground Black To PVS 405D Power Supply

12 V In Red To PVS 405D Power Supply

NOTE:

You must connect

a ground wire between

the MLC and PVS 405D.

G

Ground (Gnd)

B

Receive (Rx)

A

Transmit (Tx)

If you use cable that has

a drain wire, tie the drain wire

to ground at both ends.

Transmit (Tx)

Receive (Rx)

B

A

Tx

Rx

AB

GROUND

MLS PWR

RS-232 12V

MLC 104 IP Plus

right side panel

MLS and

+12V IN

Power

GROUND

ports

G

Ground

+12 VDC input

External Power Supply

(12 VDC, 4 A)

Ground all devices.

NOTE: The MLC 104 IP Plus is powered from the PVS 405D associated power supply.

Connect the MLC 104 IP Plus to the PVS 405D Switcher and Power Supply.

Ü

PoleVault Digital Systems • Installation — Stage 2 (Wallplates and MLC)32

Page 39

b. Connect the IR/RS-232 projector

Connecting IR Cable

k

Connecting RS-232 Cable

LR

DO NOT

GROUND

OR SHORT

SPEAKER

OUTPUTS

4/8

Ω

3A MAX

POWER

12V

HDMI

1/2

SIGLINKSIG LINK

3/4

INPUTS OUTPUT AUDIO OUT

PVS 405D

AMPLIFIED AUDIO OUT

PAGING

SENSOR

PVT IN PVT IN

L

R

AUX OVER PVT REMOTE

VOICELIFT

LAN 1LAN 2LAN 3

INPUT 5

+V

L

R

RS-232

TxRxIRSG G

123

GROUND

+12V OUT

CM

GROUND