Page 1

PCM 340 • Installation Guide

T-frame

X"

Y"

Minimum and

Maximum

Throw Distance Marks

Projector

Front

IMPORTANT SAFETY INSTRUCTIONS

When using this accessory, basic precautions should always be followed, including the following:

WARNING: Risk of Personal Injury. Maximum setup load for the PCM is 50 lbs (22.7 kg).

SAVE THESE INSTRUCTIONS

NOTE: Refer to local building standards and codes to verify that the installation will meet the regulatory requirements.

Observe all local and national building and safety codes, UL requirements, and ADA accessibility guidelines.

WARNING: Risk of Personal Injury and property damage. Do not exceed specified weight limits of any component of

the installation. Follow the manufacturer's specifications and installation instructions.

Read all instructions before starting installation.

The Extron PCM 340 Drop Ceiling Projector Mount is used for hanging

PoleVault® System AV products and various projectors.

The PCM is installed above the drop ceiling and secures the adjustable

pipe in a pass-through pipe adapter plate. The pipe then supports the

mounting of the Extron PMK 550 and UPB 25 projector bracket.

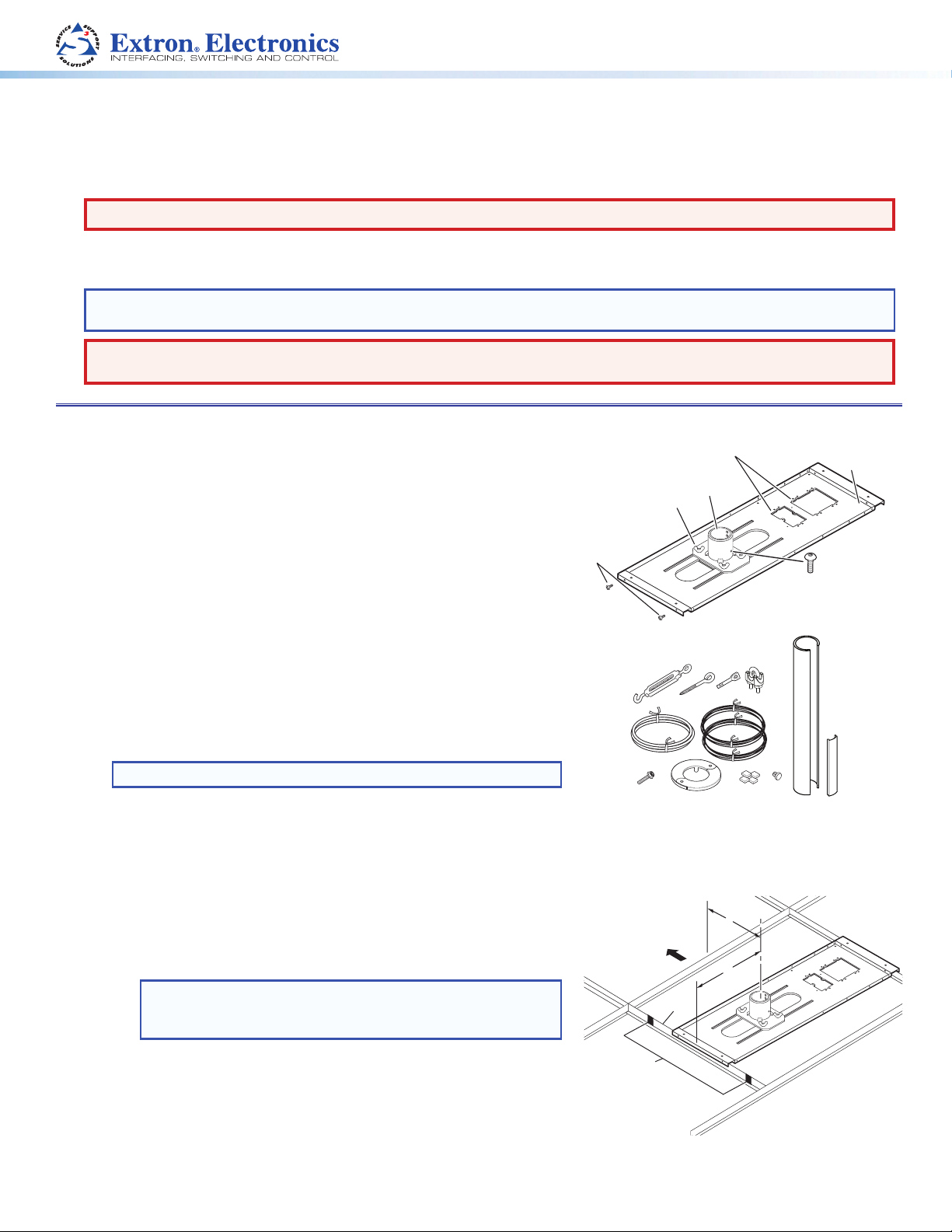

The key components of the PCM 340 are shown in figure 1.

Also included in the kit are:

4 turnbuckles, 5 lag eye bolts, 5 concrete anchors, 2 cable clamps,

1 safety wire – 15 feet, 2 tie wires – 30 feet, 4 T-frame screws, 2 set

screws,1 location screw, 4 adhesive pads, 11 hole plugs, 1 escutcheon

ring, (1) 25 inch slotted projector pipe with 1 snap-in trim piece.

1-gang and 2-gang Accessory Mounting

Points (for Power Sockets, for example)

Pipe

Adapter

Pipe Adapter Plate

Wing Nuts (4)

T-frame

Securing

Screws (4)

Base

Plate

Pipe Adapter

Set Screws (2)

Pre-Installation

Determine the exact location of the installation on the drop ceiling.

Consider the following:

• The vertical and horizontal offsets of the projector from the proposed

• The projector dimensions relative to the image target.

Installation

location.

NOTE: See the projector manual for details.

Step 1 — Mark the Frame and Cut the Ceiling Tile.

a. At the location for the projector, identify the ceiling tile and T-frame

where the PCM will be installed.

b. Remove the predetermined ceiling tile and mark the maximum and

minimum throw distances of the projector on the T-frame (see

figure 2).

TIP: Mark the screen direction on the back of the tile to

help with orientation of the tile when replacing it after

cutting�

If it helps, create more working space by removing the adjacent

tiles.

c. Place the PCM base plate over the T-frame, between the two marks.

Lightly tighten the T-frame securing screws (which can be inserted

on the inside or outside of the PCM).

d. Mark the location of the PCM base plate on the T-frame to aid in

replacing it in the correct location.

Figure 1. PCM 340 Parts

Figure 2. Minimum and Maximum

Throw Distances

1

Page 2

PCM 340 • Installation Guide (Continued)

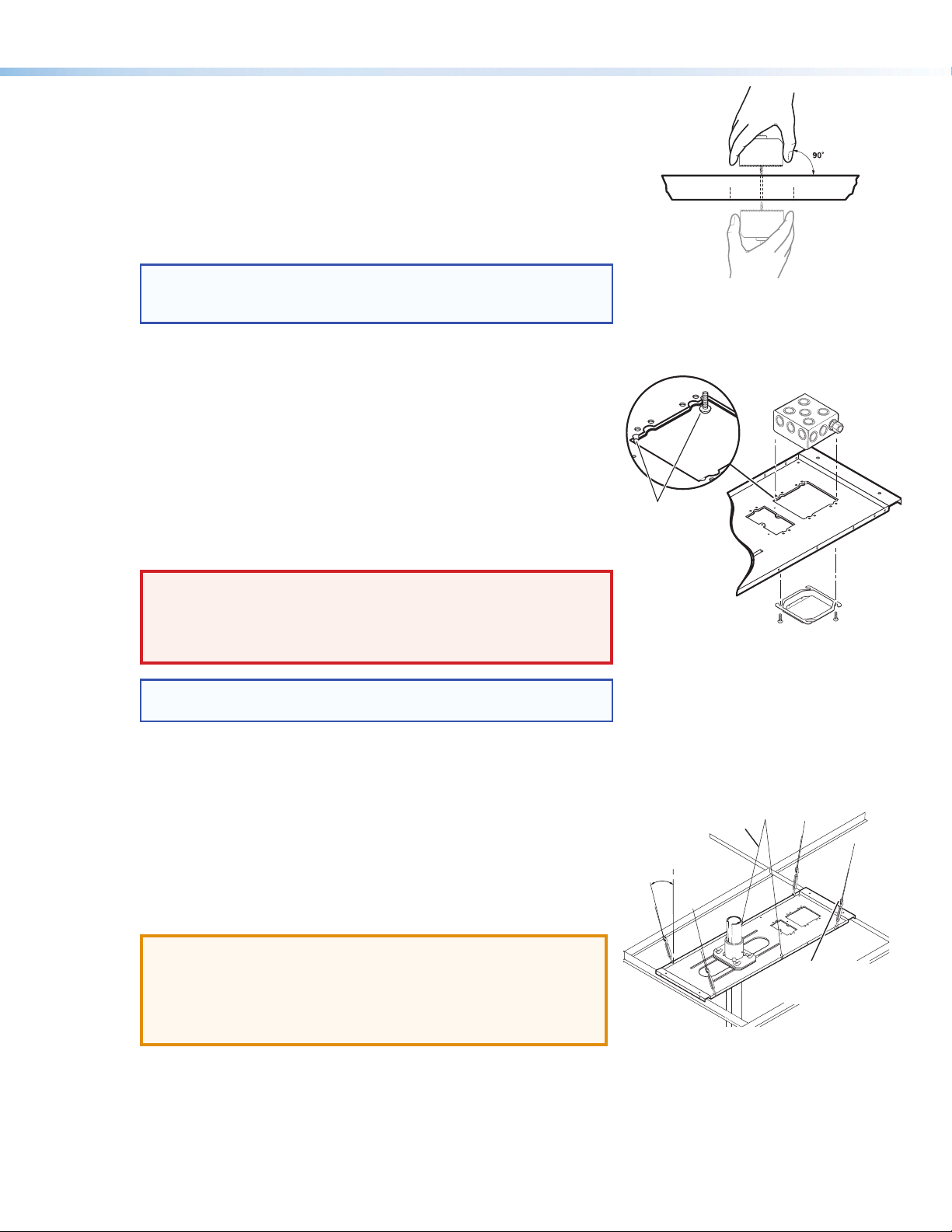

e. Measure the distances X and Y (see figure 2) from the inner vertical

section of the front and left T-frame runners to the center of the Pipe

Adapter Plate.

f. Using these dimensions, mark and cut a hole (using a 2 inch

hole saw) for the projector pipe in the removed ceiling tile (see figure 3).

g. If required, to prepare the ceiling tile for a power outlet, use the PCM

plate to trace and cut out the 2-gang hole in the ceiling tile for a

UL approved RACO® junction box.

If this is not required, proceed to step 3.

TIP: Install any optional power outlets in the 2-gang opening on the

mounting plate, towards the outside edge of the mount, so

they do not interfere with the PMK 550 when installed.

Step 2 — Install the Electrical Box.

The following method is recommended for integrating a 4S RACO electrical

box (not supplied) on the PCM base plate (such as a RACO 231, 2 1/8 inch

deep, 4 x 4 inch electrical box and a RACO 778, 1/2 inch raised, 4 x 4 inch

plaster ring.

Install the RACO box on the PCM plate as follows:

a. Attach the box to the plate, using the smallest notches in opposite

corners of the cut-out (see figure 4). Do not tighten the screws fully

at this time.

b. On the room side of the tile, slide the plaster ring under the screws.

c. Fully tighten the screws

Top Side

Underside

Figure 3. Mark and start cutting on

underside. Finish on top

side.

Raco 231

Use the smallest

notches when

attaching the

Raco box.

WARNING: Risk of Personal Injury. For safety, complete all wiring

of the electrical boxes and accessories after the plate

is installed and secure.

All electrical installation should be done by a qualified

electrician.

NOTE: If installing a single-gang electrical box, use a Raco 503

junction box�

Step 3 — Secure the PCM Base Plate to the Ceiling.

Tie wire installation

a. Replace the cut ceiling tile, and temporarily replace the PCM base plate

over the ceiling tile.

b. Check the orientation and tile hole alignment hole(s) with the PCM

adapter plate by pushing the slotted pipe up through the hole into the

adapter plate.

c. When adequately satisfied the plate and hole align, remove the pipe.

d. Attach the four turnbuckles to the mounting plate, one at each corner.

ATTENTION: Risk of Personal Injury and property damage.

• DO NOT rest or lean on the mounting plate or

suspended ceiling when attaching the turnbuckles

and tie wire, or when drilling into the ceiling.

• For safest installation, insert the turnbuckle from

the outside so that it hooks inwards.

e. Mark and drill four holes, approximately 1¼ inch (32 mm) deep into

the ceiling joists, using a 1/4 inch (6.4 mm) diameter drill bit. Do this at

10 degrees out from vertical. Drill a fifth hole centered above the PCM

for the safety cable (see figure 5). The minimum joist size used should

be 2 inches by 4 inches.

Figure 4. Install RACO Box and

Plaster Ring.

Attach safety cable

to center holes and

secure with cable

10

clamps.

o

Attach tie wire

to the turnbuckles

and eye bolts.

Drill holes and

attach tie wires

10° out from

vertical.

Figure 5. Attach Tie Wire and Safety

Cable.

Raco 778

2

Page 3

f. Install appropriate anchors or lag eye bolts for the structural

ceiling into each drilled hole.

g. Loop the safety cable through the center anchor or lag eye bolt,

attach it to the plate center holes (figure 6) and secure it with the

cable clamps.

h. Cut appropriate lengths of the supplied tie wire.

Loop the wire through the anchors or lag eye bolts and the

turnbuckles, then twist the wire around itself at least five times.

i. Tighten the turnbuckles by hand (see figure 6), and level the plate

so that it just rests on the grid.

ATTENTION: Potential Damage to Property.

• The four hanging wires should be taut, taking

the full weight of the completed installation.

• Overtightening the turnbuckles could cause

the T-bar assembly to be lifted, making the

suspended ceiling bowed and unsafe.

j. Tighten the four T-frame securing screws on the PCM.

k. Push the slotted pipe up through the hole into the adapter plate

and tighten the location and set screws to secure the pipe in place.

Secure PCM to frame

(from either side)

PCM

Adjust the turnbuckles to take

up any slack in the hanging wire.

Figure 6. Adjust Turnbuckles.

T-frame

Step 4 — Final Installation.

a. Install the projector assembly and lock it into place.

b. Tuck the signal cables into the slotted pipe and firmly snap

the trim piece into place (see figure 7).

NOTE: The trim piece can be cut to the desired length.

c. Open the escutcheon ring and, with the tabs uppermost,fit the ring

around the slotted pipe (see figure 8), then close it. Slide the ring

up until it is snug against the ceiling tile.

d. Insert the hole plugs into the remaining open holes in the visible

part of the pipe.

e. Complete any further device installation according to the relevant

device manual.

Snap-in

Tr im Piece

Device Cables

Figure 7. Snap in Trim Piece.

Hole Plug

Escutcheon

Ring

Slotted

Projector Pipe

Figure 8. Fit Ring and Hole Plugs.

3

Page 4

PCM 340 • Installation Guide (Continued)

Specications

General

Maximum load capacity ������������������ 50 lbs (22�7 kg)

Material ����������������������������������������� Baseplate and pipe: aluminum,

Tie wire: steel, 14 AWG, 70,000 psi tensile strength

Dimensions

Base plate �������������������������������� 1�2" H x 26�4" W x 8�0" D (2�9 cm H x 67�0 cm W x 20�3 cm D)

Pipe ����������������������������������������� 25" length, 1�5"-11�5 NPT

Adjustment ranges ������������������������� 1�5" - 23�0" drop, 21�5", adjustable in 0�5" steps

NOTE: Drop distances are measured from the bottom of the hanger plate.

Product weight ������������������������������� 4�5 lbs (2 kg)

Shipping weight ����������������������������� 9 lbs (5 kg)

NOTE: Weights include the pipe.

Vibration ���������������������������������������� ISTA 1A in carton (International Safe Transit Association)

Regulatory compliance

Safety �������������������������������������� CE; c-UL, UL for use with UL Listed mount and projector; OSHPD anchorage pre-approval

Warranty ���������������������������������������� 3 years parts and labor

NOTE: Specifications are subject to change without notice.

26.39" (670.3 mm)

2X 1.00" (25.4)

8.00"

(203.2 mm)

2X 6.00"

(152.4)

Drop

2X 24.72" (627.8 mm)

23.71" (602.3 mm)

25.00"

(635.0 mm)

2.42"

(61.4)

1.15"

(29.2 mm)

THREADED HOLES APPEAR

ON THIS SIDE ONLY

2.00" (50.8 mm)

(TYP. SPACING)

Extron Headquarters

+1�800�633�9876 (Inside USA/Canada Only)

Extron Europe

+31�33�453�4040

© 2012 Extron Electronics — All rights reserved. All trademarks mentioned are the property of their respective owners. www.extron.com

4

(1 1/2"-11.5 NPT)

Extron Asia

+65�6383�4400

Extron Japan

+81�3�3511�7655

Extron China

+86�21�3760�1568)

Extron Middle East

+971�4�2991800

Extron Korea

+82�2�3444�1571

Extron India

+91�80�3055�3777

68-1573-01

Rev E

08 12

Loading...

Loading...