Page 1

Occupancy Sensor OCS 100W • Setup Guide

Ultrasonic

Sensors

Green LED

(status indicator)

Red LED

(status indicator)

Infrared Sensor and Lens

Removable Front Cover

DIP Switches (A)

The OCS 100W is a wall-mounted occupancy sensor that incorporates ultrasonic (US) and passive infrared (PIR) into a dualtechnology sensor. The US sensor emits ultrasonic sound waves into an area and measures the speed of their return to detect

the presence of people. Frequency changes are caused by the movement of people, which is detected by the US waves. The PIR

sensor detects the presence of people based on the difference between the heat generated by moving people versus the ambient

room temperature.

The OCS 100W has a 24 VDC power input, ground/common connection, normally open/closed relay, photocell, and occupancy

output connections.

Front Panel Features

• Ultrasonic Sensors — Detect movement in the room, based on

ultrasonic waves.

Green LED

(status indicator)

Ultrasonic

Sensors

Infrared Sensor and Lens

Red LED

(status indicator)

Removable Front Cover

Figure 1. OCS 100W Front Panel Features

• Green LED (status indicator) — Flashes when the ultrasonic

sensors detect occupancy.

• Infrared Sensor and Lens — Diffracts the incoming light and

directs the light to the infrared sensor.

• Red LED (status indicator) — Flashes when the infrared sensor

detects occupancy.

• Removable Front Cover — Conceals all controls and DIP

switches.

Control

• DIP Switches (A) —

DIP Switches (B)

1

2

AB

3

4

1

2

3

4

A OPERATION OFF ON

1 Not used Not used* Not used

2 Not used Not used* Not used

3 LED indicator LED enabled* LED disabled

Timer Test Button

Red Dial

Green Dial

Blue Dial

Notch

4 Automatic adjust

reset

*Default

Toggle to reset (Default: OFF)

Figure 2. OCS 100W Controls

• DIP Switches (B) —

B OPERATION OFF ON

8 minutes:

OFF*

4 minutes:

OFF

15 minutes: ON30 minutes:

ON

1 Timer Setting

(B1 and B2 switches

must be set together)

2 OFF * ON OFF ON

3 Timer adjust Automatic Manual*

4 Sensitivity adjust Automatic Manual*

*Default

• Blue Timer Test Button —

• Push in to enable 8 second timer mode. This will last for 1 hour. Then automatically resets to the dip switch settings.

• Push and hold until the red LED ashes to return the 8 second timer to the dip switch timer settings.

• Red Infrared Sensitivity Dial — Adjust this dial to increase or decrease infrared sensitivity.

• Turn counter clockwise (CCW) to decrease sensitivity.

• Turn clockwise (CW) to increase sensitivity.

• Factory default is 75%.

1

Page 2

Occupancy Sensor OCS 100W • Setup Guide (Continued)

ner Mount

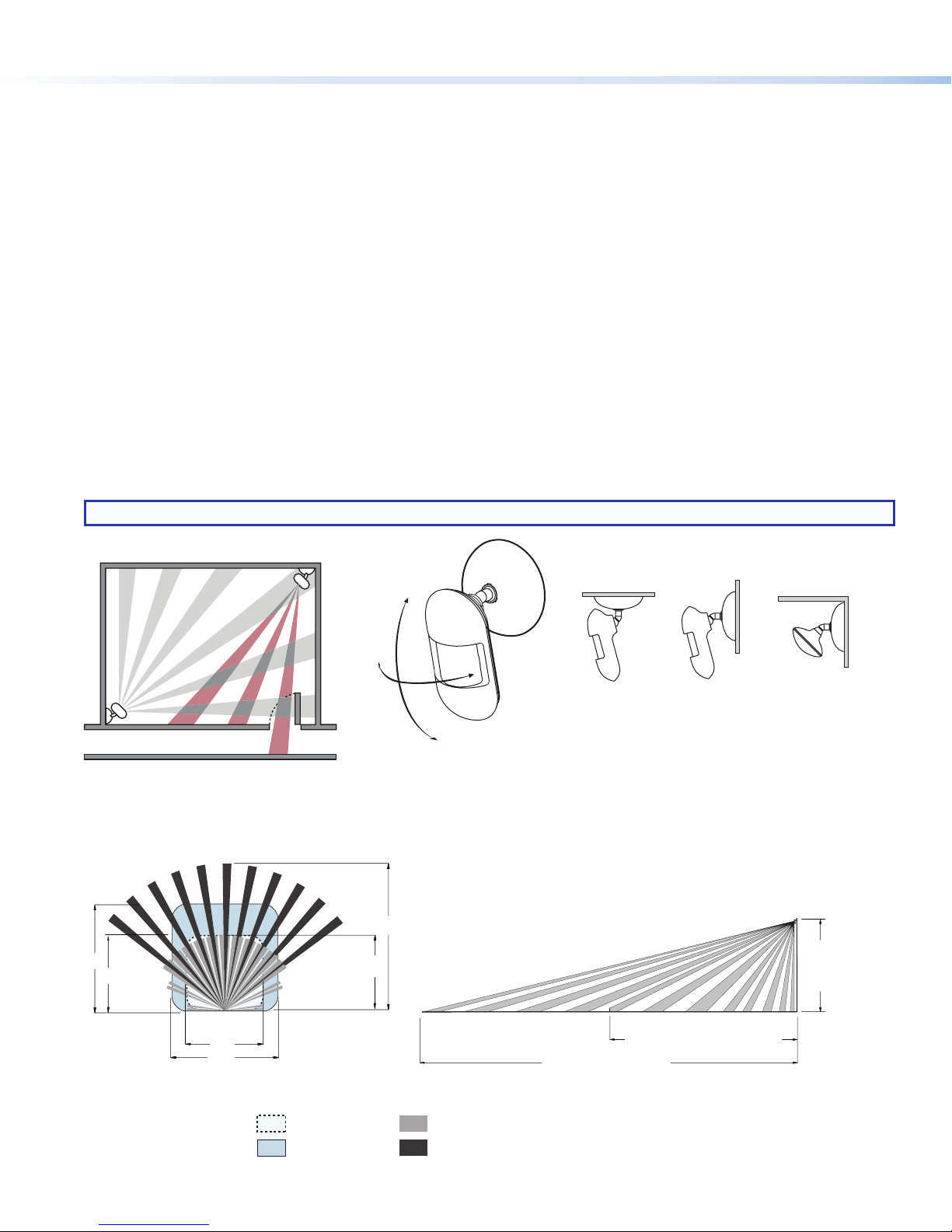

Sensor Placement

32'

Mounting

US Major Motion

IR Major Motion

• Green Ultrasonic Range Dial (see figure2 on the previous page) — Adjust this dial to increase or decrease ultrasonic

sensitivity.

• Turn counter clockwise (CCW) to decrease sensitivity.

• Turn clockwise (CW) to increase sensitivity.

• Factory default is 50%.

• Blue Photocell Dial — Photocell prevents the sensor from triggering on when the area is adequately lit with natural light and

when motion is detected. The sensor must be mounted directly over an area that is representative of the average, natural

room lighting. Before setting the photocell control, wait until the natural light is brightest (optional). Adjust this dial to increase

or decrease photocell sensitivity.

• Turn counter clockwise to decrease photocell sensitivity.

• Turn Clockwise to increase photocell sensitivity.

• Factory default is 100% (full clockwise).

• Full CW — Photocell is disabled.

• Range — 10 to 1000 LUX

Sensor Placement and Installation Options

When placing the sensor in a room, be sure the sensor is not aimed out through a door. The sensor can detect hallway trafc,

causing false triggers. PIR sensors trigger in response to changes in the amount of IR arriving from any of their segments of view

within a direct line of sight from the sensor. US sensors trigger in response to changes in the pitch of reected ultrasonic waves,

caused by movement within the space.

NOTE: See Troubleshooting on page5 if you experience false triggers.

Wrong

60˚

Correct

Figure 3. Sensor Placement and Installation Diagrams

Hallway

Sensor Coverage

23'

20'

40'

80˚

Ceiling Mount Wall Mount Top View

Cor

Installation OptionsRotation

10'

Height

23'

32'

US Minor Motion

Figure 4. Sensor Coverage Diagrams

2

Sensor Coverage

IR Minor Motion

20' Minor Motion Coverage

40' Major Coverage

Page 3

OCS 100W Parts

Cover

Pull

Cover

Body

Bracket

Cover

Wiring

Harness

Mounting

Bracket

Mounting Bolt,

Washer and nut. (2)

32'

23'

32'

23'

40'

20'

40' - 0" Major Coverage

20' - 0" Minor Motion Coverage

10' - 0"

Mounting

Height

Sensory Coverage

US Minor Motion

US Major Motion

IR Minor Motion

IR Major Motion

Mounting

Bracket

Installation

Pull

Figure 5. OCS 100W Parts

Wall

1

Insert wiring through

Mounting Bracket.

Building Wiring

Wiring

Harness

Body

Bracket

Cover

Mounting Bolt,

Washer and nut. (2)

Wiring

Harness

3

Connect building wiring to

Wiring Harness with wire nuts.

Push

Wall

2

Secure Mounting

Bracket to the wall.

Loosen

“POP”

4

Snap Bracket Cover in place to

conceal wiring and Mounting

Bracket.

5

Snap sensor into mounting post. Plug Wiring Harness into

connector located on the left side, opposite exit slot and

place wiring under wire tabs. Align sensor and tighten

position locking screw.

Tighten

Position

Locking

Screw

“SNAP”

6

Replace Cover.

Figure 6. OCS 100W Installation

ATTENTION:

• All structural steps and electrical installation must be performed by qualied personnel in accordance with local and national

building codes and electrical codes.

• Toute étape structurelle et installation électrique, doit être effectuée par un personnel qualié, conformément aux codes du

bâtiment, aux codes incendie et sécurité, et aux codes électriques, locaux et nationaux.

3

Page 4

Occupancy Sensor OCS 100W • Setup Guide (Continued)

Ext

ECM DI

eBUS

Sensor

Occupancy

OCS 100W Wiring

100-240V ~ 50-60Hz

Extron

1 1 2 3 72 1 2 3 4 1 2 3 4PWR OUT = 9W

SWITCHED 12 VDC

40W MAX TOTAL

4 5 6

3 4

5A MAX

RTSCTS

5 6 7 8 5 6 7 83214G

8

RTSCTS

SGSG SGSGTxRx GTxRxGTxRx GTxRxG

IPCP PRO 550

Control Processor

Dual Zone

Sensor w/ 12 VDC

Power Supply

BUS ID

M

S

B

24 GG-S+S+V

ron

O8

Control Module

Single Zone

Sensor w/ 24 VDC

Power Supply

L

S

B

eBUS

+ V OUT

ECM DIO8

+12V (Red)

Ground

(Black)

Ground (Black)

DIGITAL I/O

Control Signal #1 (Blue)

1234GG6578

Ground (Black)

+24V (Red)

NOTE: The Ground dash line is optional.

Control Signal #1 (Blue)

12V

1.5 A MAX

IN

PC 1224

33-2671-01 A

Extron

PC 1224

Power Module

Figure 7. OCS 100W Wiring Diagram

OUT

1.25 A MAX

12V

OUT

75 mA MAX

24V

Ground

(Black)

+24V (Red)

IPCP PRO 550

00-05-A6-XX-XX-XX

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

+V +S -S GTxRx GTxRxGTxRx GTxRxG SGSG SGSG

eBUS

LAN

FLEX I/ORELAYSIR/SERIALCOM12 VDC

Control Signal #2 (Blue)

Black Ground

Red +24 VDC

Connections

Blue Occupancy control output

Gray Occupancy and photocell

control output

NOTE: Gray wire is used when the

control system needs to know

when the area is adequately

Extron

OCS 100W

Occupancy

Sensor 1

Extron

OCS 100W

Occupancy

Sensor 2

Extron

OCS 100W

Occupancy

lit with natural light and when

motion is detected (For example,

automatic lighting through Extron

control system).

Relay Contacts

Blue/

Common

White

Black/

White

Yellow/

White

Normally closed when

unoccupied

Normally open when

unoccupied

NOTE: Relay contacts could

be used to trigger third party

devices, such as HVAC, based

on occupancy.

PC 1224 Wiring

ATTENTION:

• Do not connect power until you have read the ATTENTIONS: notices on the next page.

• Ne branchez pas l’alimentation avant d’avoir lu les mises en garde «ATTENTIONS» de la page suivante.

• Remove power from the system before making any connections.

• Mettez le système hors tension avant d’effectuer tout raccordement.

The OCS100W requires 24 VDC. If the sensors are connected to a device that does not provide 24 VDC:

1. Connect a 12 VDC power source to the 12 VDC input on the supplied PC 1224 power converter,

using a 2-pole captive screw connector (see image on the right).

2. Wire the PC 1224 24 VDC 2-pole captive screw connector to the black and red wires on the

OCS100W.

A 12 VDC pass-through is available to power additional 12 VDC devices.

Power

Source

12V

1.5 A MAX

OUT

IN

1.25 A MAX

12V

PC 1224

OUT

75 mA MAX

24V

33-2671-01 A

Extron

PC 1224

Power Module

Additional

Devices

Sensor

4

Page 5

Troubleshooting

Problem Possible Cause Test Result

Sensor remains on. Constant noise. Reduce both green and red

knobs by 15% and remove

noise source.

Sensor remains on too long. Timer setting too high. Check dip switch settings. Reduce timer setting.

Hallway trafc turns sensor

on.

Infrared sensor can see into

the hallway.

Put in timer test mode and

walk the hallway.

Move sensor to a less noisy

area within the room.

Move the sensor, so the

sensor cannot see into the

hallway.

Safety Instructions

For information on safety guidelines, regulatory compliances, EMI/EMF compatibility, accessibility, and related topics, see the

Extron Safety and Regulatory Compliance Guide, part number 68-290-01, on the Extron website.

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC rules. The Class A limits provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause interference. This interference must be corrected at the expense of the user.

NOTE: For more information on safety guidelines, regulatory compliances, EMI/EMF compatibility, accessibility, and related

topics, see the Extron Safety and Regulatory Compliance Guide on the Extron website.

Power Attentions

ATTENTIONS:

• These products are intended for use with a UL Listed LPS type power source.

• Ces produits doivent être utilisés avec une source d’alimentation de type LPS certiée UL.

• Use of a non-LPS or unlisted power supply will void all regulatory compliance certication.

• L’utilisation d’une source d’alimentation non-listée ou non-listéeLPS annulera toute certication de conformité

réglementaire.

• Unless otherwise stated, the AC/DC adapters are not suitable for use in air handling spaces or in wall cavities. The power

supply is to be located within the same vicinity as the Extron AV processing equipment in an ordinary location, Pollution

Degree 2, secured to the equipment rack within the dedicated closet, podium, or desk.

• Sauf mention contraire, les adaptateurs CA/CC ne conviennent pas à une utilisation dans les espaces d’aération ou dans

les cavités murales. La source d’alimentation doit être placée à proximité de l’équipement Extron dans un emplacement

ordinaire soumis à un degré de pollution de catégorie II, solidement xé au rack d’équipement d’une baie technique, d’un

pupitre.

• The installation must always be in accordance with the applicable provisions of National Electrical Code ANSI/NFPA 70,

article 725 and the Canadian Electrical Code part 1, section 16.

• Cette installation doit toujours être conforme aux dispositions applicables du Code américain de l’électricité (National

Electrical Code) ANSI/NFPA 70, article 725, et du Code canadien de l’électricité, partie1, section16.

• The power supply shall not be permanently xed to building structure or similar structure.

• La source d’alimentation ne devra pas être xée de façon permanente à la structure de bâtiment ou à d’autres structures

similaires.

5

Page 6

Extron Headquarters

+800.633.9876 Inside USA/Canada Only

Extron USA - West Extron USA - East

+1.714.491.1500 +1.919.850.1000

+1.714.491.1517 FAX +1.919.850.1001 FAX

Extron Europe

+800.3987.6673

Inside Europe Only

+31.33.453.4040

+31.33.453.4050 FAX

© 2017 Extron Electronics All rights reserved. All trademarks mentioned are the property of their respective owners. www.extron.com

6

Extron Asia

+65.6383.4400

+65.6383.4664 FAX

Extron Japan

+81.3.3511.7655

+81.3.3511.7656 FAX

Extron China

+86.21.3760.1568

+86.21.3760.1566 FAX

Extron Middle East

+971.4.299.1800

+971.4.299.1880 FAX

Extron Australia

+61.8.8113.6800

+61.8.8351.2511 FAX

Extron India

1800.3070.3777

(Inside India Only)

+91.80.3055.3777

+91.80.3055.3737 FAX

68-3155-50 Rev. B

09 17

Loading...

Loading...