Page 1

Occupancy Sensor OCS 100C • Setup Guide

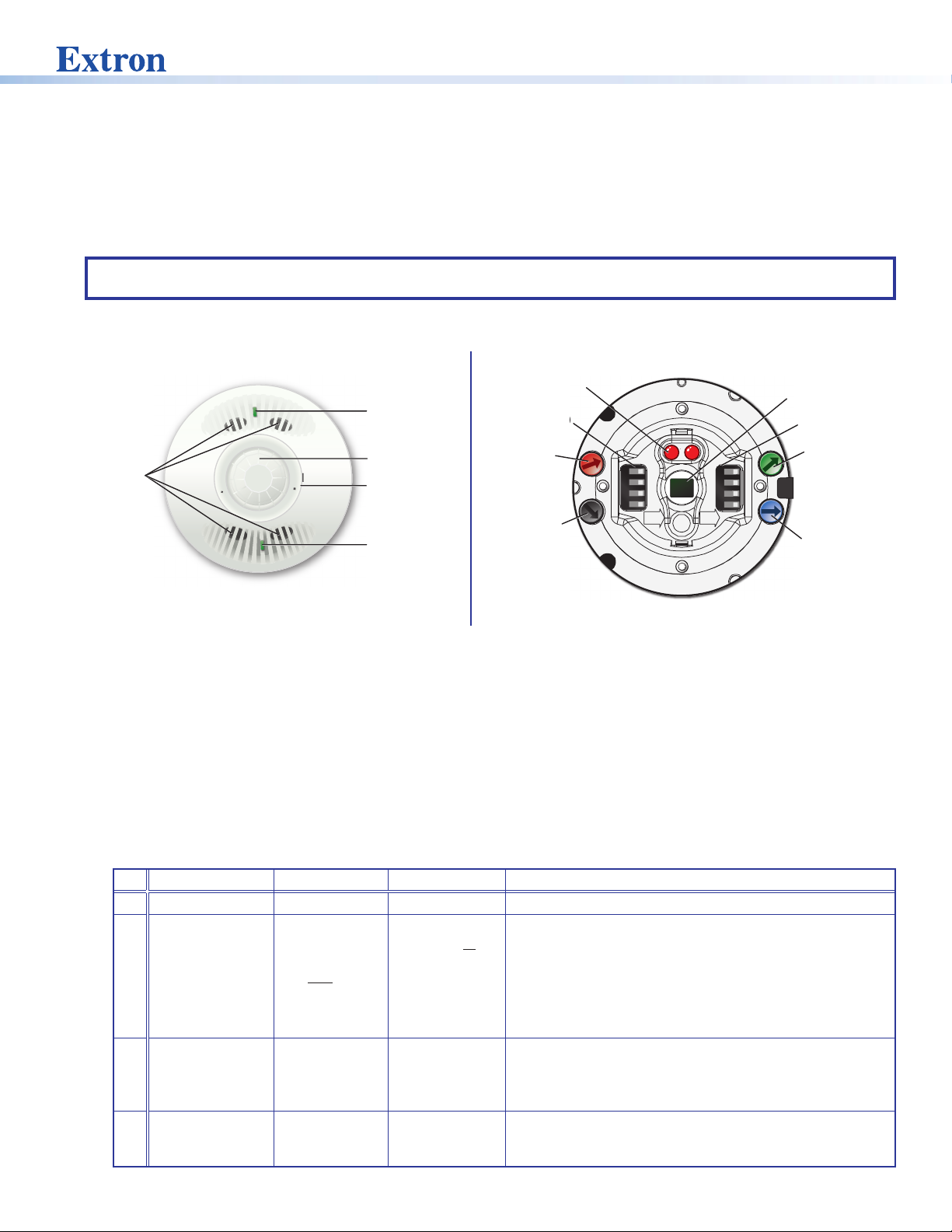

Blue Photocell

Sensitivity Dial

Black Timer

Dial

Green Ultrasonic

Sensitivity Dial

DIP Switches (B)

DIP Switches (A)

1

A

2

3

4

ON ON

1

B

2

3

4

1

2

3

4

1

2

3

4

Infrared Sensor

Red Infrared

Sensitivity Dial

Infrared (PIR)

Red LED

(status indicator)

1

2

3

4

1

2

3

4

Infrared (PIR)

The OCS 100C is a dual technology occupancy sensor that can be used to automate meeting and presentation spaces when

used with Extron control products. The OCS is equipped with ultrasonic (US), infrared (PIR), and photocell sensors that can be

used together to report ambient light conditions and room occupancy. Sensors can be wired directly to Extron controller products

equipped with Digital I/Os ports or via eBUS, when using optional eBUS interface accessories.

The OCS requires 24 VDC for operation. If local 24 V power is not available, use the included 12 V to 24 V power converter.

NOTE: The OCS 100C is designed to detect occupancy using both the PIR and US sensors with their default settings to

avoid false detections.

Front Panel Features and Control

Red LED

Ultrasonic

Sensors

Ultrasonic (US)

Green LED

(status indicator)

Fresnel Lens

Retainer Ring

Ultrasonic (US)

Green LED

(status indicator)

(status indicator)

DIP Switches (A)

Red Infrared

Sensitivity Dial

Black Timer

Dial

A

1

2

3

4

ON ON

B

1

2

3

4

Infrared Sensor

DIP Switches (B)

Green Ultrasonic

Sensitivity Dial

Blue Photocell

Sensitivity Dial

Figure 1. OCS 100C Front Panel Features

Figure 2. OCS 100C Controls

• Ultrasonic sensors (4) — Detect movement in the room, based on ultrasonic sound waves. The US sensor emits ultrasonic

sound waves into an area and measures the speed of their return to detect the presence of people. Frequency changes are

caused by the movement of people, which is detected by the US waves.

• Ultrasonic (US) Green LED status indicators (2) — Flash when the ultrasonic sensors detect occupancy.

• Fresnel lens — Diffracts the incoming light and directs the light to the infrared sensor.

• Retainer Ring — Holds the optional IR mask in place. Remove to access all controls and DIP switches. Insert the at end of

a small screwdriver into the notch in the retainer ring to lever it up and off.

• Infrared (PIR) Red LED status indicator — Located behind the fresnel lens, these LEDs ash when the infrared sensor

detects occupancy.

• Infrared Sensor — The infrared (PIR) sensor detects the presence of people based on the difference between the heat

generated by moving people versus the ambient room temperature.

• DIP Switches A —

A Switch Function OFF ON Note

1 Not used *Not used Not used Switch is not used.

2 Occupancy

detection

behavior - Dual

technology mode

3 Sensor status

indicators

4 Automatic adjust

reset

*Default and recommended settings

*Mutually

exclusive

(requires both

PIR and US

detection

*LEDs enabled LEDs disabled Setting A3 to OFF provides a visual notication whenever

*Retain

learned sensor

adjustments

Independent

(either PIR or US

detection)

Erase all learned

settings (toggle

ON, then OFF)

If A2 is set to OFF, both the PIR and US sensors must

be triggered (simultaneously) before the OCS reports an

occupancy signal. If A2 is set to ON, the OCS reports

occupancy based on only one of the sensors being

triggered. When only one sensor is desired, set A2 to ON

and adjust the dials accordingly. If A2 is ON, false detection

when the room is not occupied increases.

the PIR or US sensors are triggered. When the visual LED

indicators are a distraction or you want to disable the

ashing LEDs, A3 should be set to ON.

Only applicable when Timer (B3) or Sensitivity adjust (B4) or

both are set to Automatic mode (OFF). Toggling A4 ON then

OFF will reset any stored learned adjustments.

1

Page 2

Occupancy Sensor OCS 100C • Setup Guide (Continued)

• DIP Switches B — (see figure2 on the previous page)

B Switch Function OFF ON Note

1 High Airow

compensator

2 Doorway mount *Disabled Enabled

3 Timer adjust Automatic *Manual Applies to the Timer (black), Infrared sensitivity (red), and Ultrasonic

4 Sensitivity adjust Automatic *Manual

*Default and recommended settings

NOTE: B3 and B4 must be set to ON for Manual mode, in order to adjust the timer, infrared sensitivity, and US sensitivity

dials manually.

• Black Timer Dial — The occupancy sensor has a built in timer feature. Use the black timer dial to set the amount of time

before the sensor triggers OFF. The factory default setting is 8 minutes.

• Timer range — 8 minutes to 42 minutes.

• Full counter clock wise (CCW) = 8 minutes

• Full clock wise (CW) = 42 minutes

• Timer operation —

• When the sensor detects motion, it instantly triggers ON.

• Once occupancy is no longer detected, the timer begins. If no motion is detected and the timer expires, then the

sensor triggers OFF.

*Disabled Enabled If enabled (set to ON) the sensor will not detect minor changes

and movement. This could result in missed detection, with a low

trigger-on threshold.

sensitivity (green) adjustment dials.

• Setting to Manual mode allows for more predicted behavior

and is better suited for automating AV applications.

• Setting to Automatic mode allows the sensor to learn over

time the ideal timer and sensitivity adjustments for the space

and usage trends. This is better suited for automating lighting

applications.

• All adjustment dials are disabled when set to Automatic (OFF).

NOTE: If it takes too long for the OCS to turn off when the room is unoccupied, adjust the timer to 8 minutes and

extend the timer via the configuration of the connected control processor. This setup reduces false detection.

• Test mode (8 second timer):

• Red Infrared Sensitivity Dial — Adjust this dial to increase or decrease infrared sensitivity.

• Green Ultrasonic Sensitivity Dial — Adjust this dial to increase or decrease ultrasonic sensitivity.

• Blue Photocell Sensitivity Dial — The photocell prevents the sensor from triggering on when the area is adequately lit with

2

1. Open the retainer ring.

2. Rotate the black timer dial to about midway (50% or 12 o’clock).

3. Return to minimum setting (full CCW).

4. The timer will remain in the 8 second test mode for 1 hour, then automatically reset to 8 minutes.

5. To manually force the timer out of the 8 second test mode, turn the timer adjustment approximately 1/16 inch

clockwise. The setting is slightly above minimum (just above the 8 minute setting).

• Turn clockwise (CW) to increase sensitivity. Minor movements are detected as occupancy.

• Turn counter clockwise (CCW) to decrease sensitivity. Major movements are needed to detect occupancy.

• The factory default setting is at 75%.

• Turn clockwise (CW) to increase sensitivity. Minor movement are detected as occupancy.

• Turn counter clockwise (CCW) to decrease sensitivity. Major movements are needed to detect occupancy.

• The factory default setting is at 50%.

natural light and motion is detected. The sensor must be mounted directly over an area that is representative of the average,

natural room lighting. Before setting the photocell control, wait until the natural light is brightest (optional).

Adjust this dial to increase or decrease photocell sensitivity.

• Turn counter clockwise to decrease photocell sensitivity, causing it to activate with less light.

• Turn clockwise to increase photocell sensitivity, requiring brighter light to activate the sensor.

• Factory default is 100% (full clockwise) — Photocell sensor is disabled.

• Range — 10 to 1000 LUX

Page 3

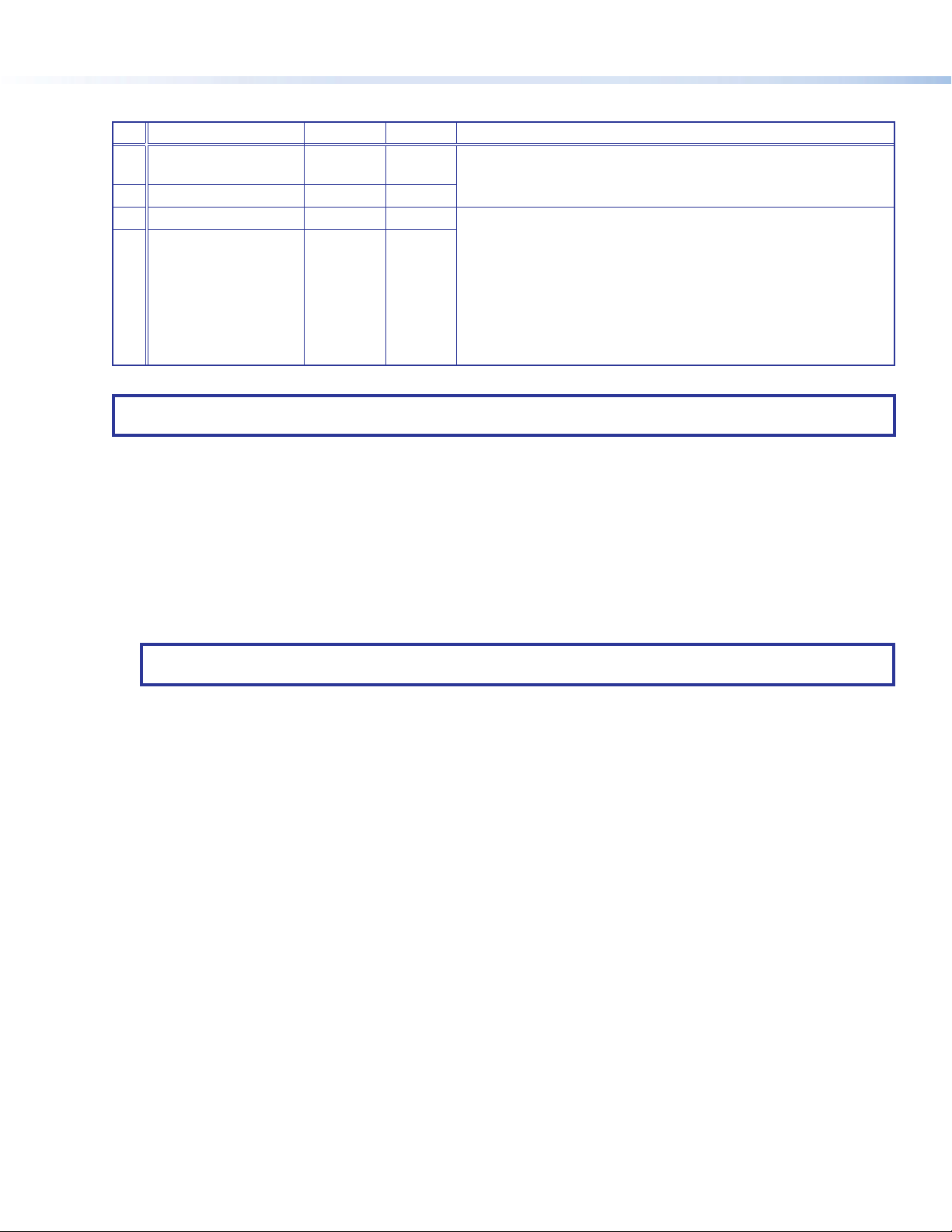

Recommended Setup

Blue Photocell

Sensitivity Dial

Red Infrared

Sensitivity Dial

Green Ultrasonic

Sensitivity Dial

DIP Switches (B)

DIP Switches (A)

1

A

2

3

4

ON ON

1

B

2

3

4

1

2

3

4

1

2

3

4

Infrared (PIR)

Red LED

(status indicator)

Black Timer Dial

1

2

3

4

1

2

3

4

Infrared (PIR)

Red LED

Ultrasonic (US)

Green LED

(status indicator)

Ultrasonic (US)

Green LED

(status indicator)

DIP Switches (A)

Red Infrared

Sensitivity Dial

Black Timer Dial

A

1

2

3

4

ON ON

B

1

2

3

4

Figure 3. OCS 100C Front Panel Features and Controls

With the OCS in the default or recommended settings (A2 OFF), the OCS requires both the IR sensor AND the US sensor to

detect occupancy to turn ON. Only one sensor (PIR or US) needs to trigger to reset the timer for the OCS to remain ON while the

room is still occupied. When the OCS is in the OFF state, no occupancy is detected.

Follow these steps to setup the OCS to detect occupancy with minimal false detection:

NOTE: We recommend using the OCS 100C in the default settings when beginning the setup or the test mode. If needed,

make slight adjustments at a time from the default sensitivity settings.

1. Keep all the DIP switches and rotary dials in the default positions.

2. Set the OCS in Test Mode.

3. Enter the room several times to verify if the IR detector is detecting movement (red LEDs ash).

• If the red LEDs ash when entering the room, the default red infrared sensitivity dial is set correctly.

• Verify the red LEDs ash with movement throughout the room.

• If the red LEDs do not ash, turn the red infrared sensitivity dial to decrease or increase IR sensitivity, until the red LEDs

always ash when entering the room or making movements throughout the room.

• To avoid false detections when the room is unoccupied, do not adjust the sensor too sensitively.

4. Enter the room and verify if the US detector is detecting movement (green LEDs ash).

• If the green LEDs ash when entering the room, the default green ultrasonic range dial is set correctly. This sensor is very

sensitive.

• Verify the green LEDs ash with movement throughout the room.

• If the green LEDs do not ash, turn the green ultrasonic range dial to decrease or increase US sensitivity, until the green

LEDs always ash when entering the room or making movements throughout the room.

• To avoid false detections when the room is unoccupied, do not adjust the sensor too sensitively.

5. Leave the room and close the door. Wait until the Digital output state, relay or red and green LEDs stay OFF. Wait several

minutes to ensure there are no false detections.

• If the door remains open, the US sensor may detect changes.

• If possible, wait longer, to conrm no IR or US change is registered.

6. Enter the room again, to conrm the Digital input state relay, red and green LEDs turn ON.

(status indicator)

DIP Switches (B)

Green Ultrasonic

Sensitivity Dial

Blue Photocell

Sensitivity Dial

NOTE: After going through these steps and verifying the OCS is setup to accommodate the room, do not adjust the DIP

switches or dials.

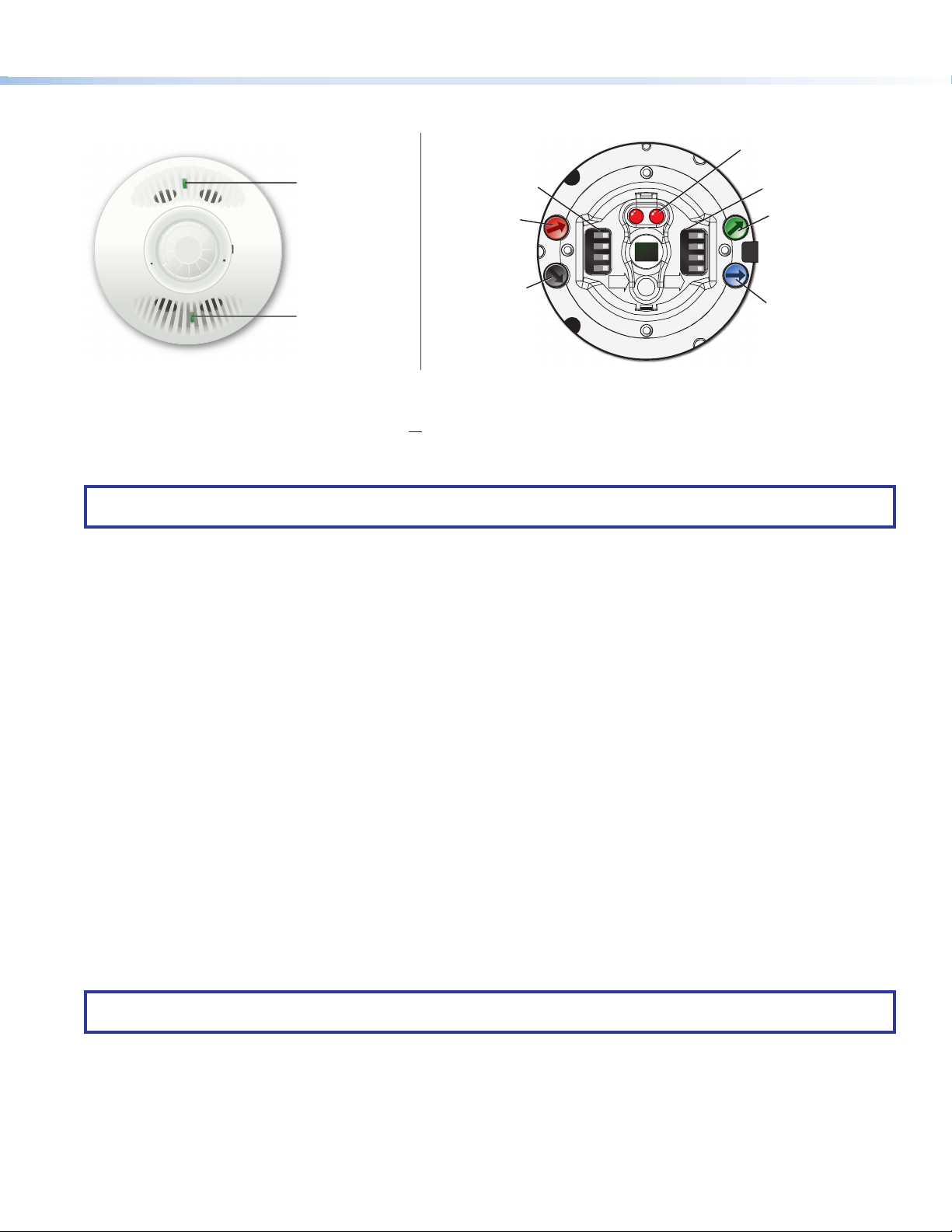

Automatic Mode

Out of the box, the OCS 100C can be setup in Automatic Mode, where no manual sensitivity adjustments are needed and

sensitivity learning and adjustments are made automatically. For simple setup, we recommend keeping the OCS in the default

settings and ipping the B4 Dip switch to the OFF (Auto) position. The OCS is ready to mount (see Installation on page5).

3

Page 4

Occupancy Sensor OCS 100C • Setup Guide (Continued)

Mask Patterns and Sensor Coverage

An included infrared mask may be needed to achieve the desired sensory coverage. Any area masked will block the PIR sensor

from detecting motion in that area.

NOTE: Mount the OCS 6 to 8 feet (1.8 to 2.4 m) away from HVAC vents and high air flow areas

Hallway

Center Ceiling Mount

(mask blocks sensor seeing

out doorway into hallway)

Conference

Room Mask

Full Mask with

selected areas

cut out

180º Mask Full Mask

Hallway

Corner Ceiling Mount

(no mask needed)

No Mask Needed

Using the Infrared Mask (included)

Rectangular

Areas

Over the Door Specific Areas to Mask

Typical Mask Patterns

22'

(7 m)

12'

(4 m)

(max Disabled)

3

Appliance Control

Threshold

Not Used

U.S. Patents: 6151529, 5946209, 5699243, 5640143, 6415205,

32'

(10 m)

23'

(7 m)

67E4

6078253, D404326, 6222191, 5986357, 6759954

Extron Headquarters

+1.800.633.9876 (Inside USA/Canada Only)

Extron USA - West

+1.714.491.1500 +1.714.491.1517 FAX

OCS 100C

www.extron.com

68-3155-52 Rev. A

45'

(14 m)

64'

(20 m)

Sensor Coverage

Center of

Figure 4. Mask Patterns and Sensor Coverage Diagrams

4

Sensory Coverage

US Minor Motion

US Major Motion

NOTE: These coverage dimensions are achieved when the

OCS100C is installed 10 feet (3 m) above the coverage area.

IR Minor Motion

IR Major Motion

Page 5

Installation

y

e nuts.

Installation Method 1

OCS 100C Parts

S

C

Nut

Washer

Cutting End

Threaded

Mounting Post

Cover Plate

Ceiling

Mounting

Post

Cover Plate

2

Secure mounting

post to the ceiling tile with

nut and washer.

1

Twist and lock threaded

mounting post into the

cover plate. Drill into

ceiling tile.

30˚ Adjustment

Adjustment Knobs

Red: Infrared Range - 75% Default

Black: Timer - 8 min to 42 max - min Default

Green: Ultrasonic Range -50% Default

Blue: Photocell - max Default

Switch Settings: All switches OFF for full automatice oper

A1 Not Used

A2 Threshold: OFF = low sensitivity, ON = high sensitivity

A3 LED Control: OFF = LEDs active, ON = LEDs disabled

A4 Automatic Adjust Reset: Toggle to reset

B1 Strong Airow Compensator: OFF = disable, ON = enable

B2 Over Doorway Mounting: OFF = disable, ON = enable

B3 Timer Adjust: OFF = automatic, ON = manual

B4 Sensitivity Adjust: OFF = automatic, ON = manual

Appliance Control

67E4

Extron Headquarters

+1.800.633.9876 (Inside

Ext

+1.714.491.1500 +1.714.

r

on USA - West

www.extron.com

68-3155-52 Rev. A

U

S

A/

C

anada

491.1517

FAX

U.S. Patents: 6151529, 5946209, 5699243, 5640143, 6415205,

6078253, D404326, 6222191, 5986357, 6759954

OCS 100C

Only)

Made in China

Sensor Coverage

Center of

R

a

n

g

with the arrow on the twist-lock cover

e

Match either arrow shown here

o

f

a

d

plate. Then inserts the tabs into

j

u

s

t

m

e

n

t

the slots. Twist until

ratchet action indicates

(

c

l

i

c

k

t

engagement.

u

Blue: Occupancy control output

Connections

Black : Ground

Grey: Occupancy &

Red: +24VDC

Photocell control

Blue/White = co

Relay Conta

Black/White = N.C

Yello

outp

ation

w/Wh

ut

cts:

mmon

ite = N.O.

.

Conference Room

Mask

Full Mask

r

n

)

Sensor Body

*

*

180º Mask

Infrared Lens w/

Retainer Ring

*

NOTE: *Only use a mask if the PIR sensor needs to be blocked.

Only one mask should be installed at any given time.

Ceiling

Cover Plate

Sensor Body

od

5

Attach sensor body to cover plate

by aligning arrows and twist lock

into place.

Installation Method 2

Ceiling

4

Connect building wiring to

wiring harness with wire nuts.

3

Insert wiring through

mounting post.

Nut and Washer (2 ea)

1

Secure cover

plate to the ceiling.

Mounting Bolts (2)

ATTENTION:

• All structural steps and electrical installation must be performed

by qualied personnel in accordance with local and national

Ceiling

3

Connect building wiring to

wiring harness with wir

building codes and electrical codes.

• Toute étape structurelle et installation électrique, doit être

effectuée par un personnel qualié, conformément aux codes

du bâtiment, aux codes incendie et sécurité, et aux codes

électriques, locaux et nationaux.

• Only connect to Class III SELV systems.

• Connectez l’unité uniquement à des systèmes fonctionnant en

2

Insert wiring through

cover plate.

Sensor Body

4

Screw and mount the

twist-lock cover plate.

très basse tension de sécurité (TBTS) de classe III.

Figure 5. Installation Diagram

5

Page 6

Occupancy Sensor OCS 100C • Setup Guide (Continued)

Extron

Mod

Gr

Devices

PC 1224 Wiring

ATTENTION:

• Do not connect power to the device until you have read the ATTENTION: notices on the next page.

• Ne branchez pas l’alimentation à l’appareil avant d’avoir lu les mises en garde «ATTENTION: » de la page suivante.

• Remove power from the system before making any connections.

• Mettez le système hors tension avant d’effectuer tout raccordement.

• The controller and the OCS 100C must share a common ground connection to avoid ground loops and a difference in

grounding potential.

• Le contrôleur et l’OCS 100C doivent partager une connexion de mise à la terre commune pour éviter les risques de

boucles de terre et une différence dans le potentiel de terre.

The OCS 100C requires 24 VDC to power. If the sensor is connected to a device that does not provide 24VDC, use the included

PC1224 power module:

1. Connect a 12 VDC power source to the 12 VDC input on the supplied PC 1224 power converter (see gure6).

2. Wire the PC 1224 24 VDC, 75 mA max connector to the black and red wires on the OCS100C.

A 12 VDC, 1.25 A max pass-through is available to power additional 12 VDC devices.

OCS 100C Wiring Diagram

PC 1224

Power Module

PC 1224

External Power

Supply (12 VDC)

Ground

(Black)

+12 V (Red)

ound all

Ground (Black)

+12 V (Red)

12V

1.5 A MAX

IN

www.extron.com

POWER

12V

1.0A MAX

OUT

24V

75 mA MAX

OUT

33-2665-01 B

1.25 A MAX

12V

COM 1 DIGITAL I/OCOM 2

G

G

RTSCTS

Tx Rx

Tx Rx

VOL

RELAYS

VCG-S+V +S GC12

IPCP PRO 250

Control Processor

12 4G

PWR OUT = 6W

+24 V (Red)

Ground (Black)

Occupancy Control

Signal (Blue)

IPCP PRO 250

MAC: 00-05-A6-XX-XX-XX

S/N: ####### E######

3

eBUS

IR/S

SG

l

Extron

OCS 100C

Occupancy Sensor

LAN

Figure 6. OCS 100C Wiring Diagram

Wire Color Connections Note

Power

Black Ground Shared with all of the outputs.

Red +24 VDC Power input

Occupancy Control Outputs

Blue Occupancy control output When wiring the blue wire of the OCS to Extron products with Digital or FLEX

Blue/White Common Relay contacts could be used to trigger third party devices, such as HVAC, based on

Black/White Normally closed when unoccupied

Yellow/White Normally open when unoccupied

Occupancy and Lighting Output

Gray Occupancy and photocell control

output

6

Input ports, congure the ports as Input without pull up. The sensor provides

approximately 21 VDC in the ON state and 0 VDC in the OFF state. Use the shared

black ground wire

occupancy.

Typically used for lighting applications. When wiring the gray wires of the OCS to

Extron products with Digital or FLEX Input ports, congure the ports as Input without

pull up. The output state will remain OFF 0 VDC when occupancy is detected but

there is high amount of ambient or natural light in the room. Only when there is low

or no ambient or natural light in the room and occupancy is detected will the output

state trigger ON 21 VDC. Use the shared black ground wire.

Page 7

Troubleshooting

Problem Possible Cause Test Solution

Sensor remains ON. Constant noise. Reduce both green and red

knobs by 1/8 (15%) turn or

remove noise source.

Sensor remains OFF Sensitivity is set too low. Increase both green and red

knobs by 1/8 (15%) turn.

Sensor remains on too long. Timer setting is too high. Check DIP switch settings. Reduce timer setting.

Hallway trafc turns sensor

on.

Infrared sensor can see into

the hallway.

Put sensor in timer test mode

and walk the hallway.

Move sensor to a less noisy

area within the room.

Move the sensor. If the A2

DIP switch is set to OFF,

set green and red knobs to

normal levels.

Move sensor, so it cannot see

into the hallway or install the

IR blocks.

Safety Instructions

For information on safety guidelines, regulatory compliances, EMI/EMF compatibility, accessibility, and related topics, see the

Extron Safety and Regulatory Compliance Guide on the Extron website.

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the

FCC rules. The Class A limits provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used

in accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment

in a residential area is likely to cause interference. This interference must be corrected at the expense of the user.

NOTE: For more information on safety guidelines, regulatory compliances, EMI/EMF compatibility, accessibility, and related

topics, see the Extron Safety and Regulatory Compliance Guide on the Extron website.

Power Attention

ATTENTION:

• These products are intended for use with a UL Listed LPS type power source.

• Ces produits doivent être utilisés avec une source d’alimentation de type LPS certiée UL.

• Use of a non-LPS or unlisted power supply will void all regulatory compliance certication.

• L’utilisation d’une source d’alimentation non-listée ou non-listéeLPS annulera toute certication de conformité

réglementaire.

• Unless otherwise stated, the AC/DC adapters are not suitable for use in air handling spaces or in wall cavities. The

power supply is to be located within the same vicinity as the Extron AV processing equipment in an ordinary location,

Pollution Degree 2, secured to the equipment rack within the dedicated closet, podium, or desk.

• Sauf mention contraire, les adaptateurs CA/CC ne conviennent pas à une utilisation dans les espaces d’aération ou dans

les cavités murales. La source d’alimentation doit être placée à proximité de l’équipement Extron dans un emplacement

ordinaire soumis à un degré de pollution de catégorie II, solidement xé au rack d’équipement d’une baie technique,

d’un pupitre, ou d’un bureau.

• The installation must always be in accordance with the applicable provisions of National Electrical Code ANSI/NFPA 70,

article 725 and the Canadian Electrical Code part 1, section 16.

• Cette installation doit toujours être conforme aux dispositions applicables du Code américain de l’électricité (National

Electrical Code) ANSI/NFPA 70, article 725, et du Code canadien de l’électricité, partie1, section16.

• The power supply shall not be permanently xed to building structure or similar structure.

• La source d’alimentation ne devra pas être xée de façon permanente à la structure de bâtiment ou à d’autres structures

similaires.

7

Page 8

For information on safety guidelines, regulatory compliances, EMI/EMF compatibility, accessibility, and related topics, see the

Extron Safety and Regulatory Compliance Guide on the Extron website.

© 2017-2019 Extron Electronics — All rights reserved. www.extron.com

All trademarks mentioned are the property of their respective owners.

Worldwide Headquarters: Extron USA West, 1025 E. Ball Road, Anaheim, CA 92805, 800.633.9876

68-3155-51 Rev. G

01 19

Loading...

Loading...