Page 1

User’s Manual

Matrix 200 Switcher

Page 2

Extron’ s Warranty

______ If it has been determined that the product is defective, please call

Extron Electronics warrants the product against defects in materials for

a period of two years and defect in workmanship for a period of two

years from the date of purchase. In the event of malfunction during the

warranty period attributable directly to faulty workmanship and/or

materials, Extron Electronics will, at its option, repair or replace said

products or components, to whatever extent it shall deem necessary to

restore said product to proper operating condition, provided that it is

returned within the warranty period, with proof of purchase and

description of malfunction to:

Extron Electronics

1230 South Lewis Street

Anaheim, CA 92805, U.S.A.

This Limited Warranty does not apply if the fault has been caused by

misuse, improper handling care, electrical or mechanical abuse,

abnormal operating conditions or non-Extron authorized modification to

the product.

Extron and ask for an Applications Engineer at (714) 491-1500 to

receive an RA# (Return Authorization number). This will begin the

repair process as quickly as possible.

Units must be returned insured, with shipping charges prepaid.

If not insured, you assume the risk of loss or damage during shipment.

Returned units must include the serial number and a description of the

problem, as well as the name of the person to contact in case there are

any questions.

Extron Electronics make no further warranties either expressed or

implied with respect to the product and its quality, performance,

merchantability, or fitness for any particular use. In no event will Extron

Electronics be liable for direct, indirect, or consequential damages

resulting from any defect in this product even if Extron Electronics has

been advised of such damage.

Please note that laws vary from state to state, and that some

provisions of this warranty may not apply to you.

Page 3

EXTRON ELECTRONICS / RGB SYSTEMS, INC.

1230 South Lewis Street, Anaheim, CA 92805

(800) 633-9876 (714) 491-1500 FAX (714) 491-1517

U.S.A.

SM

EXTRON ELECTRONICS, EUROPE

Beeldschermweg 6C, 3821 AH Amersfoort

+31-33-453-4040 FAX +31-33-453-4050

The Netherlands

EXTRON ELECTRONICS, ASIA

41B Kreta Ayer Road, Singapore 089003

+65-226-0015 FAX +65-226-0019

Singapore

Page 4

Contents

Chapter 1 - Introduction to the Matrix 200

General.......................................................................................................................... 1-1

I/O Modules ...................................................................................................... 1-1

Configurations................................................................................................... 1-1

Standard Features ......................................................................................................... 1-2

Optional Features .......................................................................................................... 1-3

Front P anel Controller (FPC)............................................................................. 1-3

QuickSwitch Front Panel Controller (QS-FPC) .................................................. 1-4

Redundant Pow er Supply (optional) .................................................................. 1-4

Sample Configuration .................................................................................................... 1-5

Matrix 200 I/O Module Specifications............................................................................. 1-6

Chapter 2 - Hardware Installation

IEC Po wer P anel............................................................................................................ 2-1

Standard Po wer Supply..................................................................................... 2-1

Redundant Pow er Supply (optional) .................................................................. 2-1

Front P anel Controller ....................................................................................... 2-1

QuickSwitch Front P anel Controller................................................................... 2-1

Removing the Matrix 200 Cover..................................................................................... 2-2

Changing Matrix Front P anels........................................................................................ 2-2

Installing a Front P anel Controller ..................................................................... 2-3

Replacing a Blank Panel with a QuickSwitch Front Panel Controller ................. 2-4

Installing a Blank Front P anel............................................................................ 2-5

Installing the FPC for Remote Operation........................................................................ 2-6

Changing the Main Fuse................................................................................................ 2-6

RS-232/RS-422 Communications .................................................................................. 2-7

9-Pin RS-232/RS-422 Connector ...................................................................... 2-7

RS-232/RS-422 Protocol................................................................................... 2-7

Swapping the RS-232/RS-422 P ort Cable......................................................... 2-7

Checksum Disable Jumper ............................................................................................ 2-8

Enabling the Part Number Jumper ................................................................................. 2-8

Installing the Security Jumper ........................................................................................ 2-8

Installing a Redundant (second) Pow er Supply.............................................................. 2-9

Before Installing I/O Modules ......................................................................................... 2-9

Adding an Audio Module ................................................................................. 2-10

Installing I/O Modules in the Rear Panel ......................................................... 2-13

Installing FPC/QS-FPC Software Update........................................................ 2-15

Chapter 3 - Rear Panel Connections

Multi-Output Connection ................................................................................................ 3-1

Genlock Connections..................................................................................................... 3-2

RGB Input Connections ................................................................................................. 3-2

RGB Input Connections with Right & Left Audio............................................................. 3-3

RGBS Input Connections with Right & Left Audio .......................................................... 3-4

RGBHV Input Connections with Right & Left Audio........................................................ 3-5

Composite Video Input Connections .............................................................................. 3-6

Composite Video Input with Right & Left A udio ................................................. 3-6

S-Video Input Connections ............................................................................................ 3-7

Input Connections ............................................................................................. 3-7

Output Connections .......................................................................................... 3-7

S-Video Input Connections with Right & Left Audio........................................................ 3-8

Audio T erminal Connections........................................................................................... 3-9

Audio Wiring Applications.................................................................................. 3-9

Extron • Matrix 200 • User’s Manual

i

Page 5

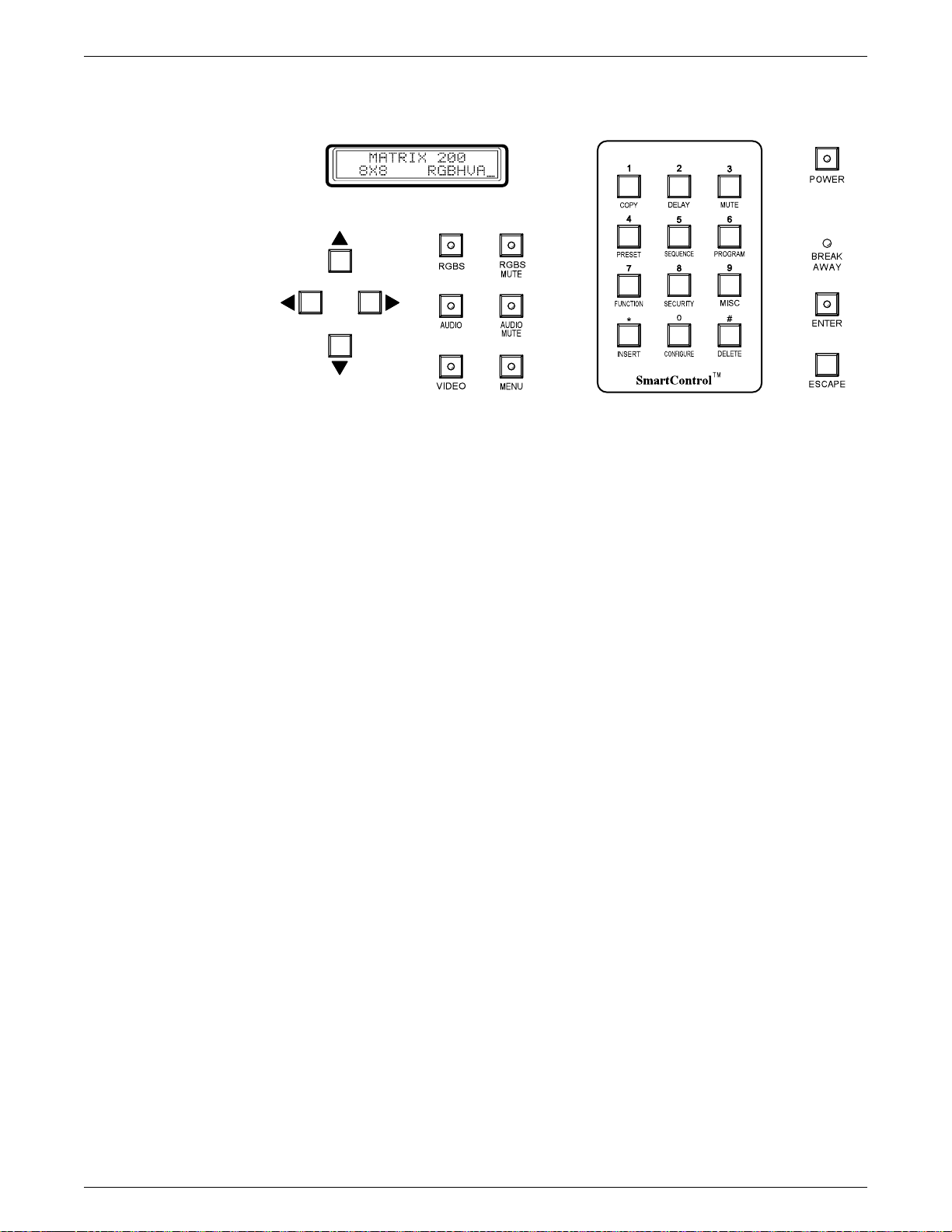

Chapter 4 - Using the Front Panel Controller

Front P anel Controller (FPC) Operation ......................................................................... 4-1

Selecting Menus Using the SmartControl™ Keypad...................................................... 4-2

Po wer On Message........................................................................................................ 4-2

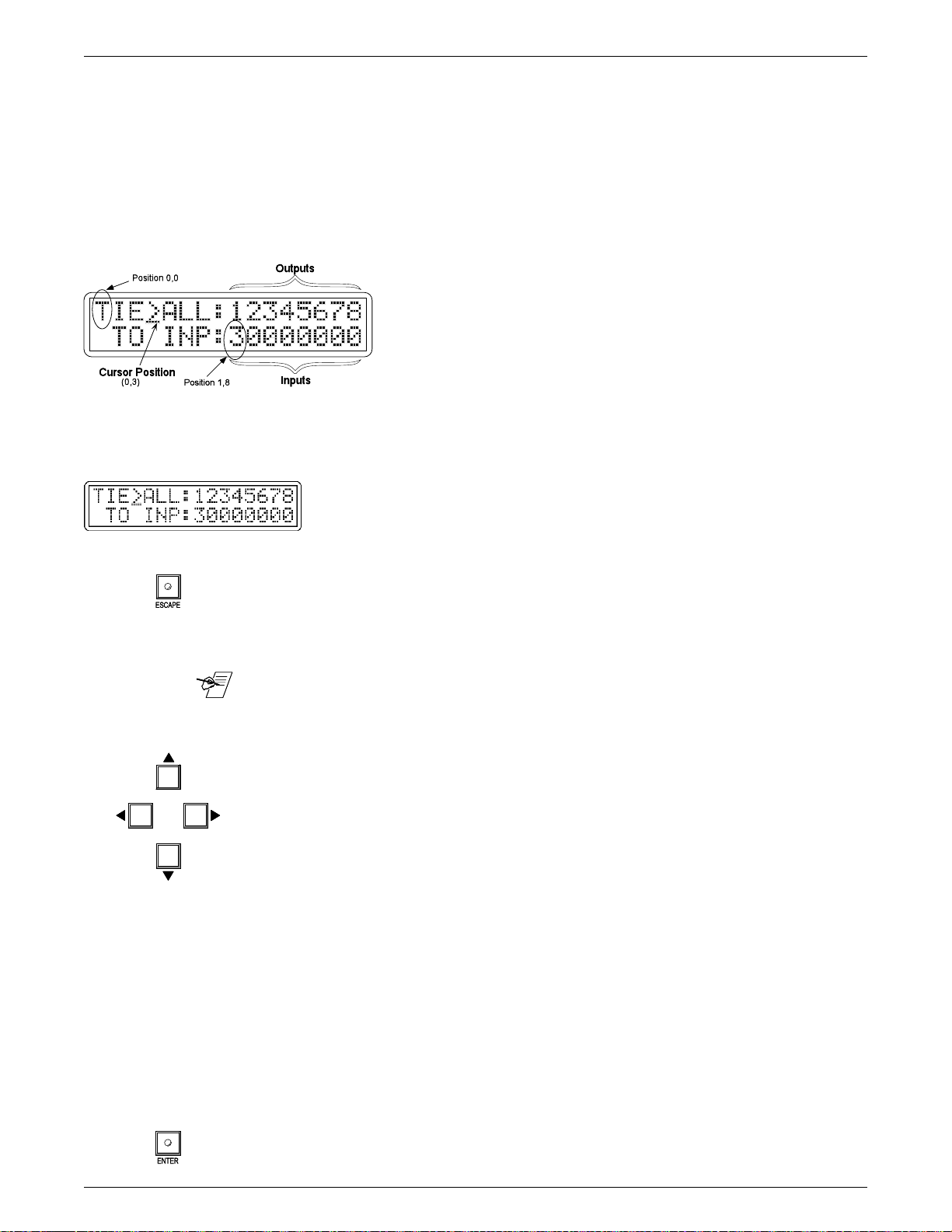

Tie Menu (default menu)................................................................................................ 4-3

Using the LCD Display................................................................................................... 4-3

How I/O Modules Are Handled....................................................................................... 4-4

Changing Tie Submenus................................................................................................ 4-5

Tie All Level....................................................................................................... 4-5

Tie Group Level ............................................................................................................. 4-6

Tie Individual Level ........................................................................................................ 4-7

Menu Selection .............................................................................................................. 4-7

Using the Copy Menu (1) ............................................................................................... 4-8

Making Changes ............................................................................................... 4-8

Using the RGB Sync Delay Menu (2)............................................................................. 4-8

Mute Output Menu (3).................................................................................................... 4-9

Automating the Matrix 200 ........................................................................................... 4-10

Preset Menus (4) ......................................................................................................... 4-10

Load a Previously Sav ed Preset (menu 4) ...................................................... 4-10

Save the Current Routing as a Preset (menu 4).............................................. 4-11

Sequence Menu (5) ..................................................................................................... 4-11

Create a Timing Sequence (menu 5)............................................................... 4-12

Edit a Timing Sequence (menu 5) ................................................................... 4-12

Copying a Sequence (menu 5)..................................................................................... 4-13

Start a Sequence (menu 5) ............................................................................. 4-13

Stop the Sequence (menu 5) .......................................................................... 4-13

Resume the Sequence (menu 5) .................................................................... 4-14

Delete a Sequence (menu 5) .......................................................................... 4-14

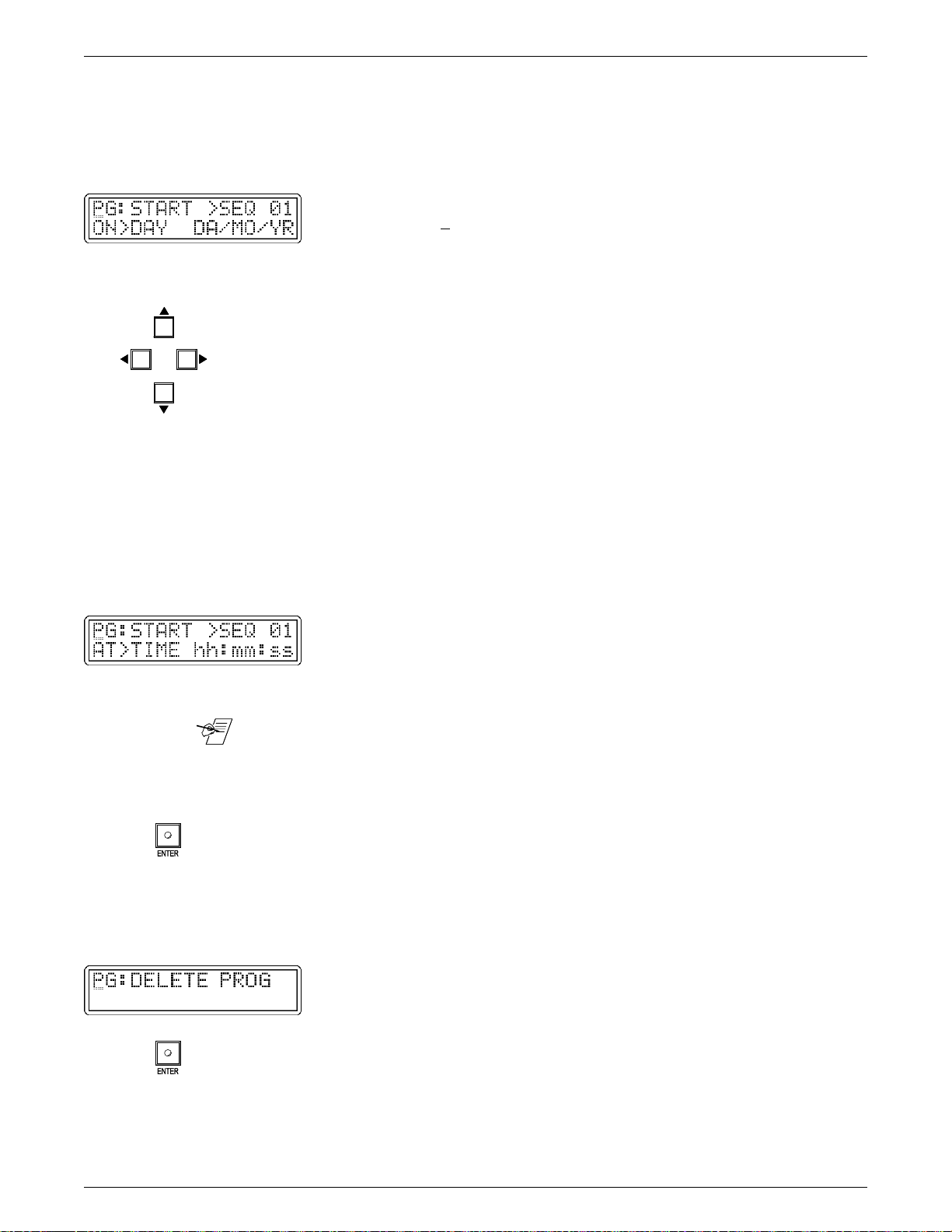

Program Menus (6)...................................................................................................... 4-14

Program Start Time/Date (menu 6) ................................................................. 4-15

Program Delete (menu 6)................................................................................ 4-15

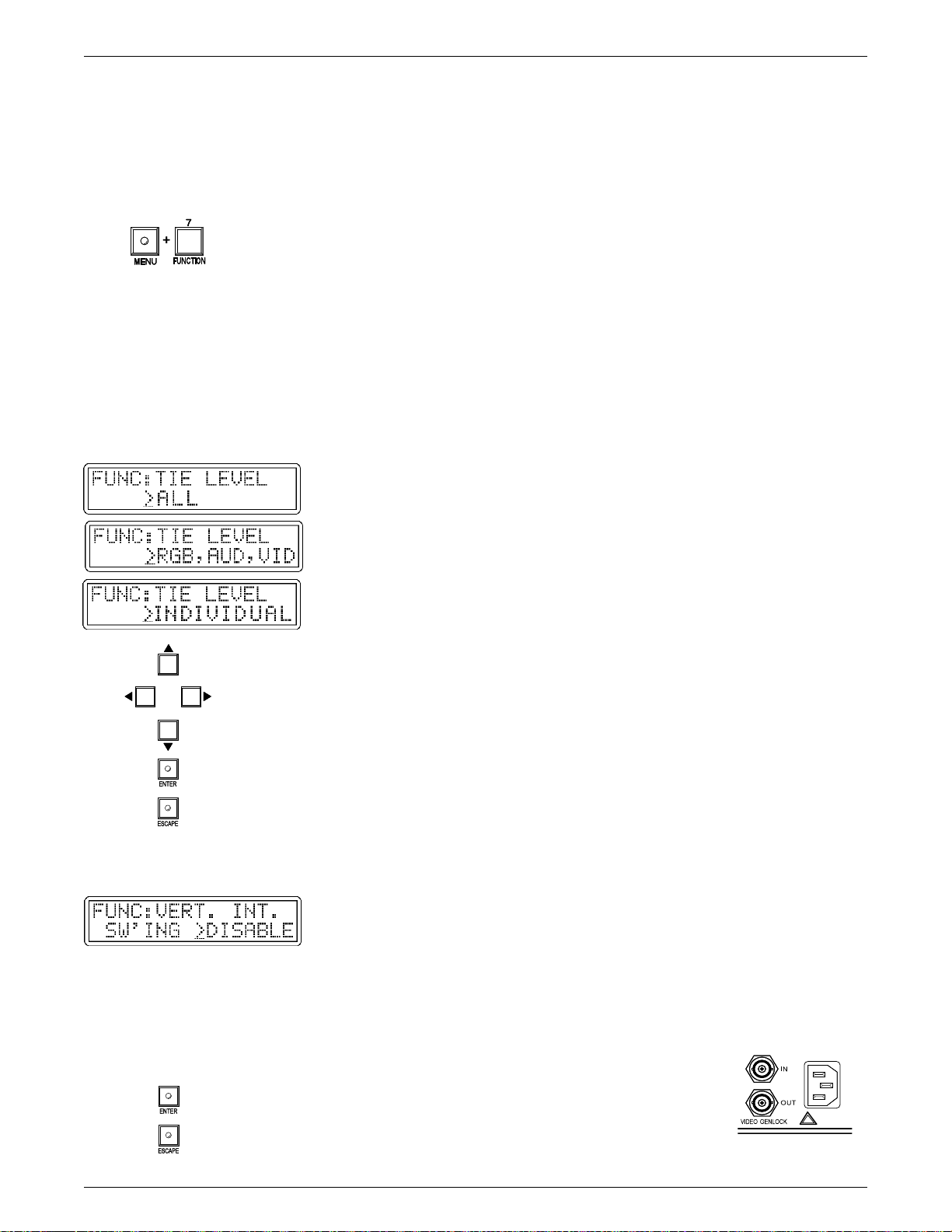

Function Menu (7)........................................................................................................ 4-16

Selecting Function Submenus......................................................................... 4-16

Tie Level Access Submen u (menu 7).............................................................. 4-16

V ertical Interval Switching Submenu (menu 7)................................................ 4-16

Security Menu (8) ........................................................................................................ 4-17

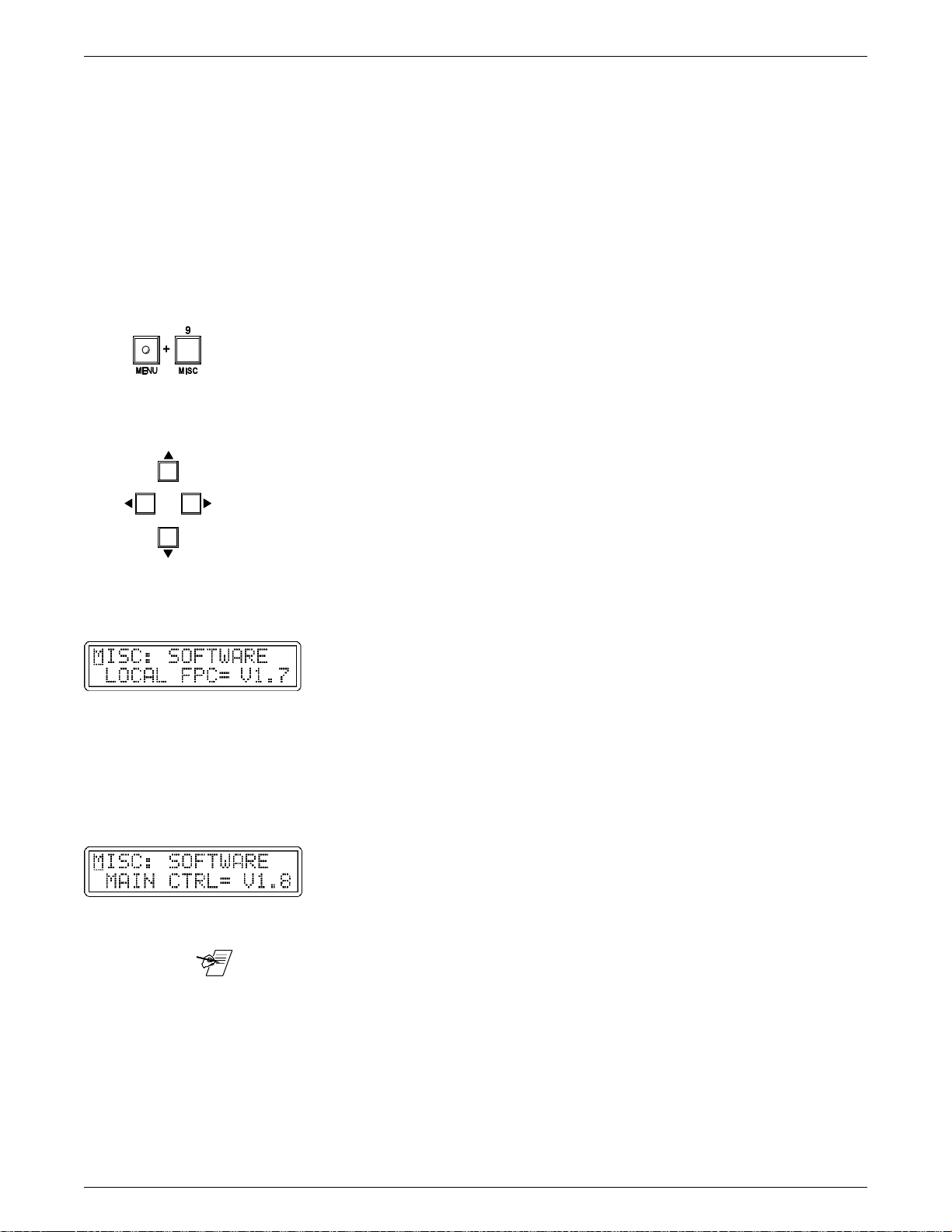

Miscellaneous Menu (9)............................................................................................... 4-18

Selecting Submenus ....................................................................................... 4-18

Display FPC Software Version Submenu (menu 9) ......................................... 4-18

Display Main Controller Software Version Submenu (menu 9) ........................ 4-18

Host Baud Rate Submenu (menu 9) ............................................................... 4-19

Show Clock Time & Date (menu 9) ................................................................. 4-19

Set Clock Time & Date (menu 9)..................................................................... 4-19

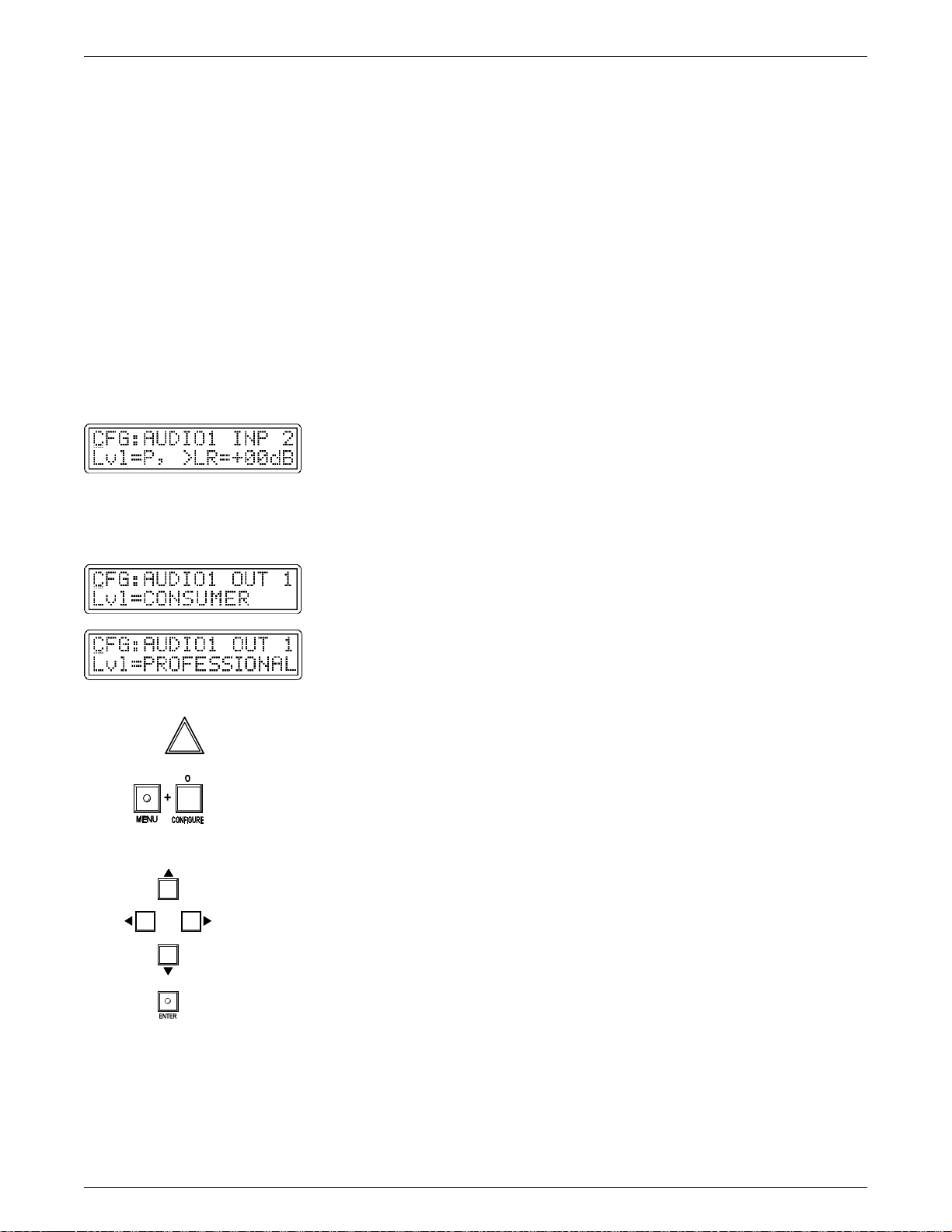

Configure Audio Menu (0)............................................................................................ 4-20

QuickSwitch Front Panel Controller (QS-FPC) Operation ............................................ 4-21

Po wer On Switch and LED.............................................................................. 4-21

Input and Output Buttons ................................................................................ 4-21

I/O Module Select Buttons .............................................................................. 4-22

Control Buttons ............................................................................................... 4-22

Ties, Configurations and Presets .................................................................... 4-24

Matrix 200 Configuration W orksheets .......................................................................... 4-25

Contents

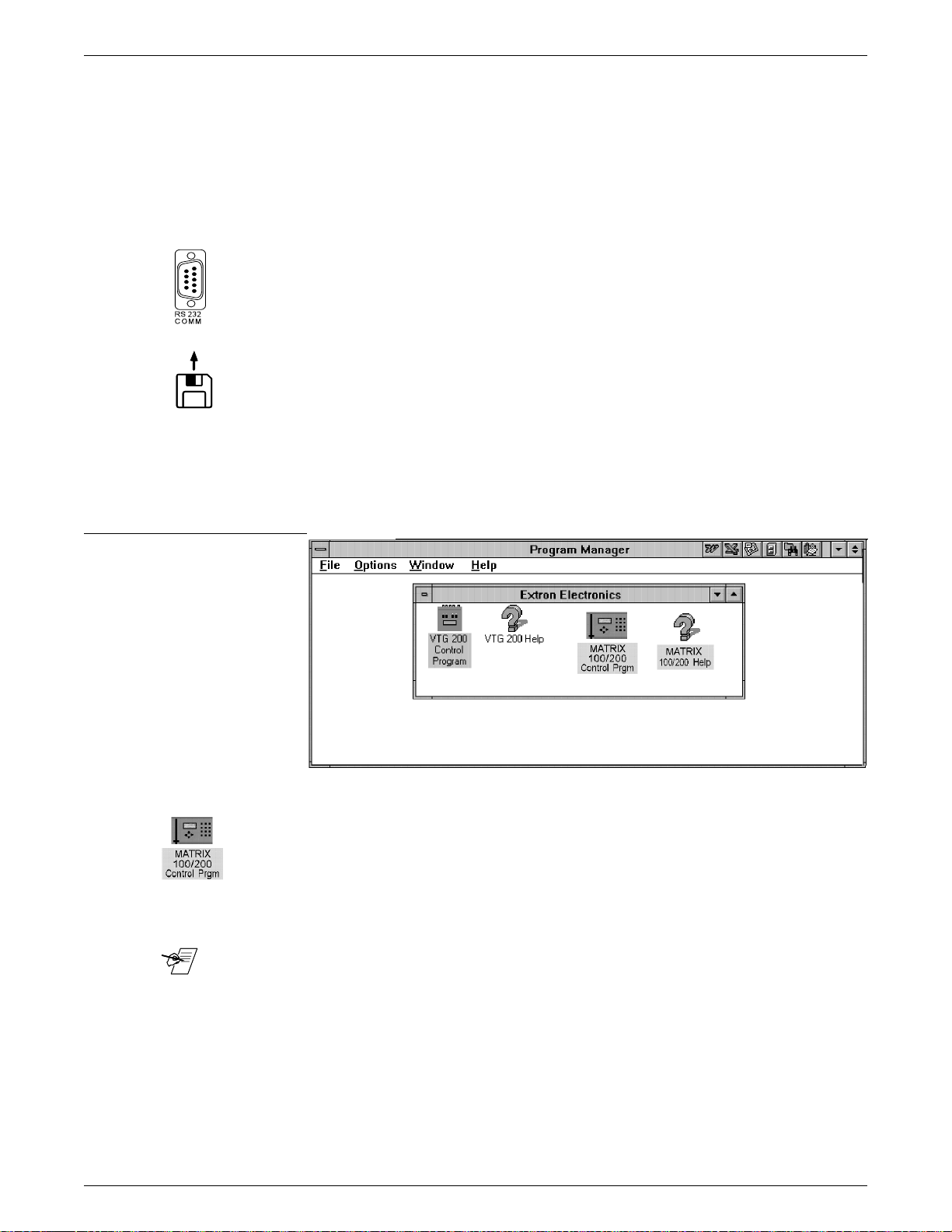

Chapter 5 - Windows® Software Control

Extron Matrix Control Software ...................................................................................... 5-1

Windows Example ............................................................................................ 5-1

Matrix 100/200 Help....................................................................................................... 5-3

ii

Extron • Matrix 200 • User’s Manual

Page 6

Contents

Appendix A - Part Numbers, Glossary and Troubleshooting

Related Part Numbers ...................................................................................................A-1

Switcher Module Part Numbers ........................................................................A-1

Option Kit Part Numbers ...................................................................................A-1

BNC-4 HR Cables (Mini High Resolution BNC Cables).....................................A-2

BNC Mini High Res Cable Specifications .......................................................... A-2

BNC-5 HR Cables.............................................................................................A-2

Matrix 200 Part Numbering System ............................................................................... A-3

Glossary of Terms..........................................................................................................A-4

Troubleshooting............................................................................................................A-12

Appendix B - Programming Guide

Control Ports..................................................................................................................B-1

FPC Port ........................................................................................................... B-1

RS-232/RS-422 Control Port............................................................................. B-1

Program Instruction Lev els: Simple and Adv anced ........................................................B-1

Host/Matrix Data Format................................................................................................ B-2

Binary/hex/decimal Conversion Table................................................................ B-2

Simple Instruction Set .................................................................................................... B-3

Related T erms ...................................................................................................B-3

Simple Instruction List .......................................................................................B-4

Advanced Instruction Set Command Structure .............................................................. B-5

Command Specifier ..........................................................................................B-5

Data ..................................................................................................................B-5

Checksum......................................................................................................... B-5

End of Transmission..........................................................................................B-5

Host-Initiated Communications Protocol ........................................................................B-6

Error Codes (Erc).............................................................................................. B-6

Matrix-Initiated Communications Protocol......................................................................B-6

Timing ............................................................................................................... B-6

Command List (Host-to-Matrix) ......................................................................... B-7

Reports (Matrix-to-Host) ...................................................................................B-7

Communication Control.....................................................................................B-7

Using Commands .......................................................................................................... B-8

CMD0 (30h) - Send Status................................................................................B-8

CMD1 (31h) - Report ID....................................................................................B-9

CMD2 (32h) - Turn Po wer On............................................................................ B-9

CMD3 (33h) - Turn Po w er Off..........................................................................B-10

CMD4 (34h) - Send Software Version .............................................................B-10

Set (Tie) Connection Commands.................................................................................B-11

Planes and Plane Maps .................................................................................. B-11

CMD5 (35h) - Set (Tie) Connection.................................................................B-12

CMD7 (37h) - Set (Tie) All Connections .......................................................... B-12

CMD8 (38h) - Download Status and Presets ..................................................B-13

CMD9 (39h) - Mute All Planes.........................................................................B-13

CMD10 (3Ah) - Save Current as Preset #.......................................................B-13

CMD11 (3Bh) - Load Preset #......................................................................... B-13

CMD12 (3Ch) - Mute Selected Outputs ..........................................................B-14

CMD13 (3Dh) - Request Mute Map.................................................................B-14

CMD14 (3Eh) - Set Sequence ........................................................................B-14

CMD15 (3Fh) - Request a Stored Sequence ..................................................B-15

CMD16 (40h) - Operate Sequence # ..............................................................B-15

CMD17 (41h) - Request a List of Presets .......................................................B-15

CMD18 (42h) - Set Program ........................................................................... B-16

CMD19 (43h) - Request the Current Program.................................................B-16

Extron • Matrix 200 • User’s Manual

iii

Page 7

Contents

CMD20 (44h) - Operate Program.................................................................... B-16

CMD22 (46h) - Set Clock ................................................................................ B-16

CMD23 (47h) - Request the Clock Information................................................B-17

CMD24 (48h) - Turn Executiv e Mode On/Off...................................................B-17

CMD25 (49h) - Set RGB Delay .......................................................................B-17

CMD26 (4Ah) - Request RGB Delay Information ............................................B-17

CMD27 (4Bh) - Set Baud Rate........................................................................ B-18

CMD28 (4Ch) - Download Baud Rate .............................................................B-18

CMD29 (4Dh) - Set Operating Mode...............................................................B-18

CMD31 (4Fh) - Set Slave Coordinates............................................................ B-19

CMD32 (50h) - Request Slave Coordinates .................................................... B-19

CMD33 (51h) - Identify Port ............................................................................ B-19

CMD34 (52h) - Set Security Passcode ...........................................................B-19

CMD35 (53h) - Operate Security ....................................................................B-20

CMD36 (54h) - Set Audio P arameters.............................................................B-20

Configure Audio Inputs....................................................................................B-21

Configure Audio Outputs.................................................................................B-21

CMD37 (55h) - Request Audio Par ameters..................................................... B-22

Reports (Matrix-to-Host) .............................................................................................. B-23

Report0 (70h) - Status ....................................................................................B-23

Report1 (71h) - New Controlling Port ..............................................................B-23

Legend of Icons

___________ Important information – for example, an action or a step that must be done

___________ A Warning – possible dangerous voltage present.

___________ A Warning – possible damage could occur.

___________ A Note, a Hint, or a Tip that may be helpful.

___________ Possible Electrostatic Discharge (ESD) damage could result from touching

___________ Indicates word definitions. Additional information may be referenced in another

The following icons may be used in this manual:

before proceeding.

electronic components.

section, or in another document.

iv

Matrix 200 User’s Manual

68-126-01, Rev. A

Rev. B, 59-03

Rev. C, 69-03, added Chapter 5

Rev. C1, 79-03, new format

Rev. D, 79-08

Written and printed in the USA

Extron • Matrix 200 • User’s Manual

Page 8

Matrix 200

User’s Manual

Chapter One

Introduction to the Matrix 200

1

Matrix 200 Module Specifications

Standard Features

Optional Features

I/O Modules

Configurations

Page 9

General

I/O Modules

Chapter 1 • Introduction to the Matrix 200

Each Extron Matrix 200 is custom designed to the user’s specifications. The

configuration is built from various combinations of ten I/O modules. The I/O

modules and possible configurations are listed below. The Matrix 200 can be

controlled from a host computer, a Front Panel Controller (FPC), or a

QuickSwitch™ Front Panel Controller (QS-FPC).

Matrix units can also be interconnected to expand the switching capabilities for

up to 48 inputs by 48 outputs. This allows for multiple switching combinations.

Matrix 200 Switchers are ordered for a specific application with a combination of

I/O modules. Each module switches one type of video signal – one for red, one

for blue, etc. One audio module switches both left and right stereo channels.

• 4 x 4 High-Resolution Analog Module (HRAM), with 250 MHz video bandwidth

• 8 x 4 High-Resolution Analog Module (HRAM), with 250 MHz video bandwidth

• 8 x 8 High-Resolution Analog Module (HRAM), with 250 MHz video bandwidth

• 4 x 4 Sync Module

• 8 x 4 Sync Module

• 8 x 8 Sync Module

• 4 x 4 Video Module

• 8 x 4 Video Module

• 8 x 8 Video Module

• 8 x 8 Stereo Audio Module

For example: a Matrix 200 designed to switch RGB, separate horizontal and

vertical sync, and stereo audio, will require the following modules: three HRAM,

two Sync and one audio modules.

Configurations

Depending upon the configuration of I/O modules (above), the Matrix 200

Switcher can have up to 16 different input/output configurations. The

configuration determines how many modules are required.

• RGsB Red, Green, (sync on green), Blue

• RGBS Red, Green, Blue and separate composite Sync

• RGBHV Red, Green, Blue and separate H&V Sync

• RGsBCv Red, Green, (sync on green), Blue, and Composite video

• RGsBYC Red, Green, (sync on green), Blue and S-Video

• RGBSCv Red, Green, Blue, composite Sync, and Composite video

• RGsBA Red, Green, (sync on green), Blue, and stereo Audio

• RGBSA Red, Green, Blue, Sync, and stereo Audio

• RGBHVA Red, Green, Blue, separate H&V sync, and stereo Audio

• RGsBCvA Red, Green, (sync on green), Blue, Composite video, & stereo

Audio

• RGsBYCA Red, Green, (sync on green), Blue, S-Video, & stereo Audio

• RGBSCvA Red, Green, Blue, composite Sync, Composite video, & stereo

Audio

• CvA Composite video, and stereo Audio

• YCA S-Video with stereo Audio

• Cv Composite video

• YC S-Video

1-1

Extron • Matrix 200 • User’s Manual

Page 10

Chapter 1 • Introduction to the Matrix 200

Standard Features

• Microprocessor control, with battery backup

• RS-232/RS-422 control

• Complete breakaway

• Composite and S-Video Genlock

• RGB video delay switching

• Separate video and audio mute

• Security Lockout

• 250 MHz bandwidth

Microprocessor Control The Matrix 200 is programmable from a host system, or from the optional Front

Panel Controller. It uses memory to store configurations and a calendar/clock to

activate these preset configurations at a specific date and time. The battery

backup prevents loss of preset information.

RS-232/RS-422 Control The Matrix 200 can be controlled by any remote control system or computer with

RS-232/RS-422 serial communications capability. Refer to Appendix B for

programming guidelines including a complete listing of RS-232/RS-422

communications protocol.

Complete Breakaway The complete breakaway feature of the Matrix 200 allows the user to program

any Video, S-Video or Audio Channel to be controlled separately (breakaway) or

as a group (follow one or more inputs, or all RGB inputs). A fully populated

RGBS composite video and audio switcher can be controlled as three separate

switchers.

Complete breakaway allows individual video or audio outputs to follow any one

or more RGBS inputs when switched to an output channel. This makes the

Matrix 200 capable of adding audio to any or all RGBS or video channels, as well

as allowing switchable video and audio to follow any switched RGBS channel.

Video Genlock The Matrix 200 features a broadcast quality NTSC/PAL/SECAM Composite

Video or S-Video Genlock for synchronized switching of signals. The Matrix 200

will Genlock as many composite video signals as are installed in the switcher.

RGB Delay Switching The Matrix 200 can be programmed to delay switching the RGB video for 1 to 9

seconds after the sync is switched. This allows the display device to be in sync

before the picture arrives, providing seamless switching of the RGBS signals

when switching between various frequencies.

Video and Audio Mute The Matrix 200 provides separate mute controls to easily mute (turn off) the

RGBS or audio signals. Mute can be programmed to operate independently on

different outputs, or all outputs can be muted simultaneously with a single button.

Security Lockout Matrix 200 programs can be protected by denying access through the RS-232

port, as well as through the Front Panel. Access is allowed only with a security

passcode.

Executive Mode The Matrix 200 front panel buttons can be enabled/disabled to restrict Matrix 200

configuration changes.

250 MHz Bandwidth Even when fully populated, the Matrix 200 has a bandwidth of no less than 250

MHz (-3 dB).

Extron • Matrix 200 • User’s Manual

1-2

Page 11

Optional Features

Chapter 1 • Introduction to the Matrix 200

• Front Panel Controller (FPC)

• SmartControl microprocessor

• QuickSwitch™ Front Panel Controller (QS-FPC)

• Redundant power supply

Front Panel Controller (FPC)

The Front Panel Controller (FPC) provides local control of all Matrix 200 Switcher

functions. It is supplied as an optional accessory to the Matrix 200 and is

intended for users who wish to supplement normal RS-232/RS-422 computer

control with local or remote operator control. For even greater flexibility, two

FPCs can be connected to the same Matrix 200 - one mounted to the front of the

Matrix 200 and the other located remotely. Refer to Chapter 2 for instructions on

mounting the FPC, and to Chapter 4 for FPC operation. The FPC includes the

following features:

Control Microprocessor “SmartControlTM” is the Front Panel’s built-in microprocessor. It determines the

Matrix 200 input/output configuration, what presets are saved, as well as all other

switcher settings. SmartControl effectively configures the Matrix 200.

Trouble Status Indication The SmartControl microprocessor continuously monitors Matrix status, and also

alerts the user to any problems that may have occurred, such as: loss of power

(if the Matrix 200 has the optional redundant power supply) or loss of front panel

control when using the optional FPC. This helps isolate any equipment

malfunction quickly.

Configuration Memory SmartControl can store up to 20 different connection configurations (called

presets). This can save hours of reprogramming each I/O configuration. The

Front Panel Controller (FPC) allows for easy configuration of inputs and outputs,

as well as the control of additional system features.

Two separate FPCs can be used to control one Matrix 200 switcher. For

example, a second FPC could be used to control the switcher from as far away

as 200 feet. When controlling the switcher via RS-232/RS-422, the FPC may or

may not be needed.

LCD Menu-driven The Front Panel includes a lighted, liquid crystal display (LCD) that is used to

SmartControl step through the setup and program functions necessary to install and operate

the Matrix 200. A full complement of function buttons makes setup and

programming of the unit fast and easy.

1-3

Extron • Matrix 200 • User’s Manual

Page 12

Chapter 1 • Introduction to the Matrix 200

1

1

2

234567

INPUTS

34 567

OUTPUTS

8

8

QuickSwitch™ Front Panel Controller (QS-FPC)

The QuickSwitch Front Panel Controller (QS-FPC) provides local control of all

Matrix 200 Switcher functions. It is supplied as an optional accessory to the

Matrix 200 and is intended for users who wish to supplement normal RS-232

computer control with local or remote operator control. Refer to Chapter 2 for

instructions on mounting the QS-FPC, and to Chapter 4 for QS-FPC operation.

The QS-FPC includes the following features:

Control Microprocessor SmartControlTM is the Front Panel's built-in

microprocessor. With it, the user determines the Matrix 200 input/output

configuration, what presets are saved, as well as all other switcher settings.

ENTER

PRESET

VIEW

RGBS

ESC

VIDEO AUD 1 AUD 2

QS - FPC

MATRIX SWITCHER

Redundant Power Supply

Configuration Memory SmartControl can store up to eight different matrix

configurations (called presets). This can save hours of reprogramming each I/O

configuration. The QuickSwitch Front Panel Controller (QS-FPC) allows for easy

configuration of inputs and outputs, as well as the control of additional system

features.

QuickSwitch SmartControl The Front Panel’s full complement of function buttons

makes setup and programming of the unit fast and easy.

The Matrix 200 can be ordered with an optional redundant (backup) power

supply to prevent signal loss if input power to the primary power supply should

suddenly be lost or interrupted.

Extron • Matrix 200 • User’s Manual

1-4

Page 13

Sample Configuration

Chapter 1 • Introduction to the Matrix 200

The picture here shows one example of the I/O modules that could be installed in

six planes of a Matrix 200. See page 1-1 for I/O modules and possible

configurations.

For example, an 8 x 8 RGBS switcher requires: three 8 x 8 high-resolution

analog modules (HRAM) and one 8 x 8 sync module (Syn). This would occupy

the Red, Green, Blue and one Sync/Video planes. The fifth plane could have a

composite video module (Cv), and the sixth plane could have an audio switching

module (Aud).

This configuration is capable of being

controlled and routed as three

separate switchers:

• one 8 x 8 RGBS matrix switcher

• one 8 x 8 video switcher

• one 8 x 8 audio switcher

In addition, SmartControl™ allows

the Matrix 200 to group these

functions as a single RGBS

composite video switcher with stereo

audio.

The bottom of the diagram illustrates

how the Main Controller (and the

optional Front Panel Controller)

routes the various inputs to the

outputs.

1-5

Extron • Matrix 200 • User’s Manual

Page 14

Chapter 1 • Introduction to the Matrix 200

Matrix 200 I/O Module Specifications

Power . 100 - 240 VAC, 50/60 Hz, 60 Watts

Dimensions . 17" W, 15" D, 6.8" H

Shipping Weight. 22 lbs (10 kg)

Operating Temperature. 0° C - 50° C

Storage Temperature. -20°C - 70° C

MTBF . 35,000 Hours (demonstrated)

Approved . CE, UL, CUL Listed

Warranty . 2 years, parts and labor

HRAM Video (High Resolution Analog Module)

Connectors . BNC

Bandwidth . 250 MHz (-3 dB)

Crosstalk:

at 10 MHz . -50 dB(typical) See note 1.

Note 1: Crosstalk is the

attenuation of all hostile

signals relative to a given

input-output connection.

Note 2: Isolation is the

attenuation of an input signal

relative to an unselected

output when all inputs have

the same signal applied

simultaneously.

Composite Video Module

Sync Module

Return Loss:

Output Impedance . 75 ohms

Frequency Response . -0.5 dB @ 5 MHz; -3.0 dB @ 15 MHz

Isolation Between Outputs. Greater than 40 dB @ 5 MHz

Propagation Delay . 10 ns

Output Impedance . 75 ohms

Max. Input Voltage . ±5 V

Max. Propagation Delay. 64 ns H to L (41 ns L to H)

Max. Rise/Fall Time . 8 ns H to L (3.6 ns H to L)

at 100 MHz . -30 dB

at 200 MHz . -30 dB

Isolation:

at 10 MHz . -60 dB (typical) See note 2.

at 100 MHz . -55dB

at 10 MHz . -20 dB

at 200 MHz . -50 dB

Input Impedance . 75 ohms

Switching Speed . 200 ns (nominal)

Input Signal . 0.3-1.0 V p-p (max dc offset ± 0.30 V)

Gain . Unity ±1%

Differential Gain . 0.5%

Differential Phase . 1.3°

Line and Field Tilt . Less than 0.1%

Crosstalk . Greater than 40 dB @ 5 MHz

CMRR . -60 dB

Input Signal . 75 ohms, analog, 0-1.0 V p-p

Gain . Unity

Input Impedance . 510 ohms

Input Sensitivity . 500 mV p-p

Output Level . 4.5 V p-p not terminated;

Polarity . Follows input

. 43 cm W, 38 cm D, 17 cm H

. (max dc offset ±0.30 V)

. 2.2 V p-p terminated at 75 ohms

Extron • Matrix 200 • User’s Manual

1-6

Page 15

Audio Module, General

Total Harmonic Distortion + Noise . Worst case 0.03% @ 20kHz, 30 V p-p

Common Mode Rejection Ratio . -55 dB worst case @ 20kHz (-65 dB Typical)

Audio Input Specifications

Professional Mode Attenuation . 20 dB

Chapter 1 • Introduction to the Matrix 200

Input Impedance . High Z (>10k ohms, typical)

Input Voltage Level . To 6 V p-p into 600 ohms

Output Impedance . Low, capable of driving 600 ohms, balanced

Output Level . Near zero to unity gain

Connectors . 6-conductor, Phoenix® Captive Screw Terminal

Signal to noise . Better than 110 dB, 20Hz-20kHz

. (Differential Output)

Adjacent Channel Crosstalk . Better than -85 dB @ 20kHz

Stereo Channel Separation . Greater than 60 dB 20 Hz - 20kHz

Bandwidth . 20Hz - 20kHz, Flat ± 0.1 dB

Consumer Mode Attenuation . 0 dB

Maximum Input Level:

Professional Mode . 60 V p-p Differential; 60 V p-p Single-ended

Consumer Mode . 6 V p-p Differential; 6 V p-p Single-ended

Nominal Input Program Level:

User Controllable Input Gain . +31.5 dB Gain

Audio Output Specifications

Nominal Output Program Level:

Professional Mode . +4 dBu (1.2 V rms)

Consumer Mode . -10 dBu (300 mV rms)

. -95.5 dB Attenuation

(In 1 dB steps, using FPC; in 0.5 dB steps, using Serial interface)

Input Impedance . 10 k ohms, Differential to Ground

Professional Mode Gain . 14 dB

Consumer Mode Gain . 0 dB

Maximum Output Level:

Professional Mode . 60 V p-p Differential; 30 V p-p Single-ended

Consumer Mode . 12 V p-p Differential; 6 V p-p Single-ended

Professional Mode . +4 dBu (1.2 V rms)

Consumer Mode . -10 dBu (300 mV rms)

Stereo Channel Directing: . Left Input to Left & Right Output

. Right Input to Left & Right Output

Channel swap . Right Input to Left Output;

. Left Input to Right Output

1-7

Output Impedance . 50 ohms, Differential to Ground

Extron • Matrix 200 • User’s Manual

Page 16

Chapter 2 • Hardware Installation

Matrix 200

User’s Manual

Chapter T wo

Hardware Installation

IEC Power Panel

Removing the Matrix 200 Cover

Installing Front Panels (local & remote)

2

RS-232/RS-422 Connections

Installing Redundant Power Supply

Extron • Matrix 200 • User’s Manual

Installing Security Feature

Installing I/O Modules

Page 17

IEC Power Panel

Standard Power Supply

REDUNDANT POWER FUSE: 250V ~0.8A TT AC POWER INPUT

Chapter 2 • Hardware Installation

This chapter covers only the installation of the Matrix 200 hardware. Connecting

its inputs and outputs is covered in Chapter 3 and setup is covered in Chapter 4.

The IEC Power Panel consists of an On/Off switch, a fuse cover and two male

power connectors. The second connector is provided for a redundant power

supply.

The Matrix 200 Series switcher/router has an auto-switching power supply that

operates from any input voltage from 90 to 260 VAC, 50/60 Hz. No equipment

changes are necessary.

Fuse

Fuse Type = 5mm x 20mm

Fuse Rating = 250V, 0.8A Super Slo Blo

!

100-240V ~0.5A MAX 50/60 Hz

DISCONNECT ALL POWER CORDS BEFORE SERVICING

Redundant Power Supply (optional)

To improve equipment reliability in critical applications, the Matrix 200 can be

configured with a redundant internal power supply. With this option, the

Matrix 200 will automatically switch to the backup supply if the primary supply

fails. If the Matrix 200 switches to the backup power supply, it continues to

operate without interruption and sends a command to the Host system to

indicate a change in status. If the Matrix has a Front Panel Controller or

QuickSwitch Front Panel Controller, the Power LED will flash to alert the user

that a power failure has occurred.

_______ To install this optional power supply, see procedure on page 2-9.

Front Panel Controller

The Front Panel Controller (FPC) provides local control of all Matrix 200

functions. This optional feature is intended to supplement normal RS-232/

RS-422 computer control with a local or remote operator control. As described in

the following pages, the FPC can either be mounted on the front of the

Matrix 200 or installed remotely, up to 200 feet, by means of an RJ45 cable

connected to the rear panel.

Power Switch

Power Switch - 1 = On

0 = Off

Two FPCs can be connected to the same Matrix 200 - one on the front and the

other located remotely and connected to the rear panel of the Matrix 200. Refer

to the following pages for instructions for mounting and connecting the FPC to

the Matrix 200.

_______ The following pages include procedures for panel installation.

QuickSwitch Front Panel Controller

The QuickSwitch Front Panel Controller (QS-FPC) provides local control of all

Matrix 200 functions. This optional feature is intended to supplement normal

RS-232 computer control with a local or remote operator control.

2-1

Extron • Matrix 200 • User’s Manual

Page 18

Chapter 2 • Hardware Installation

Removing the Matrix 200 Cover

As a preliminary step, follow this procedure when making any hardware

changes which require access to the interior of the Matrix 200 unit.

Caution: The ambient temperature of the rack should not exceed 50° C. To insure proper

ventilation, we recommend that you allow a minimum of one rack unit spacing

above and one below the Matrix 200 if forced air cooling is not used.

1. Turn off input power to the Matrix 200; disconnect power cord(s).

2. If the Matrix 200 is rack-mounted, remove it and place it on a clean

workspace.

3. Remove the six screws that hold the top half of the Matrix cover. Lift the

cover-half straight up to expose the main controller board inside. (See

picture)

Note: When changing a front panel, the

side panels may move when the panel is

off, misaligning the panel screws with the

mounting holes. With the top cover off,

move the sides, if necessary, to align the

holes. After the new front panel is

mounted, replace the top cover.

Changing Matrix Front Panels

All Matrix 200 units ship with either a Front Panel Controller (FPC), a

QuickSwitch Front Panel Controller (QS-FPC), or a Blank Front Panel. There

may be a need to change this configuration, such as:

• If the FPC or QS-FPC is to be removed, for example to install it remotely, a

blank front panel must be installed in its place.

• If the Matrix 200 Series Switcher is presently configured with the blank front

panel and the optional FPC or QS-FPC is to be installed.

4. Go to the appropriate installation

procedure.

Caution:

Take care to remove the four spacers

from the rear of the panel.

If there is a need to change this configuration, refer to “Removing the Matrix 200

Cover” (above), and use the appropriate procedure from the following page.

Extron • Matrix 200 • User’s Manual

2-2

Page 19

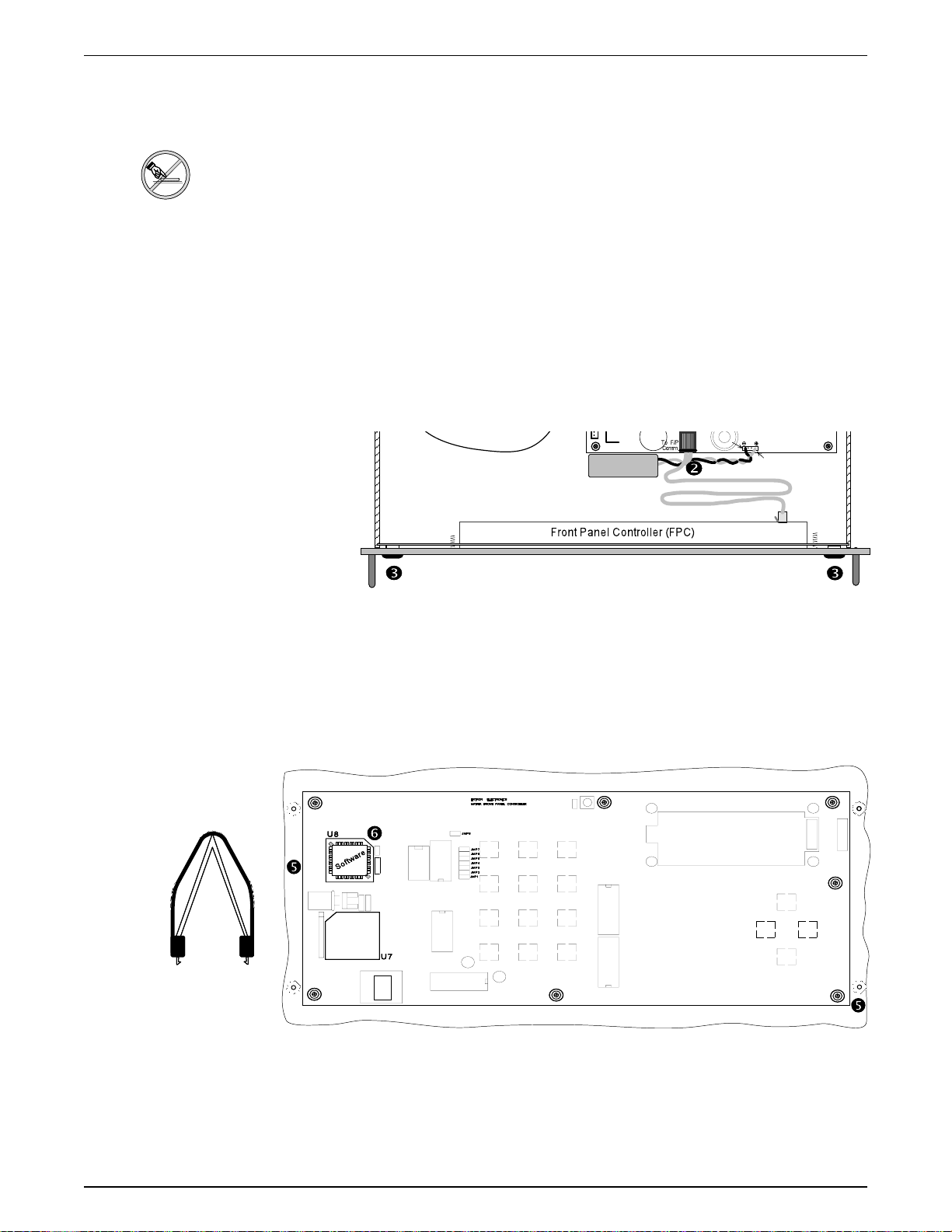

Installing a Front Panel Controller

Remove the cover (see “Removing the Matrix 200 Cover” on page 2-2) and then

do the following:

1. Remove the four

No.10 screws and

dress washers (items

& ) from the

Blank Front Panel.

Caution:

Take care to remove the four spacers from the rear of the panel. See picture

below, left.

2. Disconnect the Power Indicator cable from J13 on the right side of the main

controller board and remove the panel. See in the picture below right.

3. Position the FPC on the front of the Matrix 200, with a spacer behind each

screw. Install the four screws and dress washers (items & ). This may

be made easier by placing the Matrix face-up, being careful to protect the

BNC connectors from damage.

Chapter 2 • Hardware Installation

4. Connect the modular

cable from the plug on

the FPC to the RJ45

connector on the

Matrix 200 main

controller board. See

in the picture to the right

for connector location.

5. Reverse the above

procedure to put the

Matrix back together.

_______ When installing a new front

panel, it may be necessary to reposition the side panels to align the screw

holes.

The mounted Front Panel Controller.

Black

Red

2-3

Extron • Matrix 200 • User’s Manual

Page 20

Chapter 2 • Hardware Installation

Replacing a Blank Panel with a QuickSwitch Front Panel Controller

_______ Installing a front panel may be easier by placing the Matrix face-up, being

careful to protect the BNC connectors from damage.

After removing the Matrix 200 cover, remove the Blank Front Panel as follows:

1. Remove the four screws

and dress washers (items

& at left) from the existing

front panel. Take care to

remove the four spacers

from the rear of the panel.

2. When removing the blank

panel, disconnect the Power

Indicator cable from J13 on

the right side of the Main

Controller board. See at

right.

LITHIUM

BATTERY

3. Remove the Blank Front and set it aside.

4. Position the QS-FPC on the front of the Matrix 200, with a spacer behind each

screw. Install the four screws and dress washers (items & ).

5. Connect the modular cable from the plug on the QS-FPC to the RJ45 connector

on the Matrix 200 Main Controller board. See in the picture above for the

RJ45 connector location.

___ Circuits may be damaged by using the wrong RJ45 cable. See figure below for

correct orientation of cable conductors.

6. Refer to page 2-2 when reassembling the Matrix 200.

Operating instructions for the QS-FPC are found in Chapter 4.

Extron • Matrix 200 • User’s Manual

2-4

Page 21

Installing a Blank Front Panel

Remove the cover (see “Removing the Matrix 200 Cover” on page 2-2) and then

do the following:

1. Disconnect the modular cable from the plug on the FPC to the RJ45 connector

2. Remove the four

Caution:

Take care to remove the four spacers from the rear of the panel. See picture

below, left.

Chapter 2 • Hardware Installation

on the Matrix 200 main controller board. See in the picture below for the

connector location.

No.10 attaching

screws and dress

washers (items &

in pictures below)

from the front panel

and remove the

panel.

3. Position the blank panel on the front of the Matrix 200 with a

spacer behind the panel for each screw. Install the four screws and

dress washers. (See & in left picture.) This may be made

easier by placing the Matrix face-up, being careful to protect the

BNC

connectors

from damage.

4. Connect the

Power Indicator

cable from the

Blank Front Panel to J13

on the right side of the

main controller board.

See in the picture to

the right.

5. Reverse the procedure for

removing the cover to

reassemble the Matrix.

_______ When installing a new front

panel, it may be necessary to reposition the side panels to align the screw

holes.

Black

Red

2-5

If the FPC is to be installed remotely, refer to

the following procedure.

Extron • Matrix 200 • User’s Manual

Page 22

Chapter 2 • Hardware Installation

Installing the FPC for Remote Operation

The rear panel of the Matrix 200 has an 8-conductor RJ45 connector used to

plug a cable from a remote FPC. The remote FPC can be used independently, or

as a second FPC, in parallel with one mounted to the front of the Matrix 200. The

use of one or more FPCs does not interfere with normal RS-232/RS-422 control

of the Matrix 200 switcher.

The diagram below shows the cable connection from the remote FPC to the

Matrix 200. The remote panel can be mounted in another rack, or any convenient

location.

OO

UU

TT

PP

UU

TT

SS

Changing the Main Fuse

8-conductor

LISTED

1T23

c

ITE

OO

UU

TT

PP

UU

TT

SS

OO

UU

TT

PP

UU

TT

SS

8-conductor

cable, up to

cable, up to

100 feet

200 feet

To change the AC power fuse, you must first unplug the IEC power cable. This

allows access to the fuse holder. Use a small, flat

AC POWER INPUTFUSE: 250V ~0.8A TT

screwdriver to press into the notch and pull the holder

straight out. There is a storage place for a spare fuse.

Replace the blown fuse* (see picture right) and slide the

fuse holder until it snaps in place.

There is also an AC fuse on each of the two boards that

make up the power supply. Each fuse is located next to

the AC input connector. These fuses are accessible by

removing the top cover of the Matrix.

Extron • Matrix 200 • User’s Manual

* Use 250V, 0.8A Super Slo Blo Fuse

2-6

Page 23

RS-232/RS-422 Communications

T

The Matrix 200 can be controlled by a host system through an RS-232/RS-422

interface. The interface allows the user to write programs to configure and

automate the operation of the Matrix 200. This includes making changes

dynamically when commanded by the host controller and when informing the

host of the Matrix status. Certain important changes in status are reported to the

host automatically. For additional programming information, refer to Appendix B.

9-Pin RS-232/RS-422 Connector

The RS-232/RS-422 connector is a standard 9-pin D subminiature female

receptacle with the following pin designations:

Pin RS-232 Description RS-422 Description

REDUNDANT POWER

DISCONNEC

1

!

Chapter 2 • Hardware Installation

1 — No Connection TxD (-) Transmit Data (-)

2 Tx Transmit Data TxD (+) Transmit Data (+)

3 Rx Receive Data Rx (+) Receive Data (+)

4 — No Connection Rx (-) Receive Data (-)

5 Gnd Signal Ground Gnd Ground

6 — No Connection — No Connection

7 — No Connection — No Connection

8 — No Connection — No Connection

9 — No Connection — No Connection

RS-232/RS-422 Protocol

The RS-232/RS-422 baud rate is selectable from the Miscellaneous Menu, see

Chapter 4. The default protocol is 9600-baud, 8-bits, no parity, 1 stop bit, X-On/

X-Off.

Swapping the RS-232/RS-422 Port cable

The rear panel of the matrix has a single 9-pin connector labeled “RS-232”. The

Main Controller board provides two connectors – one for RS-232 and the other

for RS-422. Each matrix ships with the cable connected to the RS-232 port on

the Main Controller board. If your system uses RS-422, you may change this

connection on the Main Controller board as shown below. See page 2-2 for

instructions on removing the Matrix 200 cover.

2-7

Extron • Matrix 200 • User’s Manual

Page 24

Chapter 2 • Hardware Installation

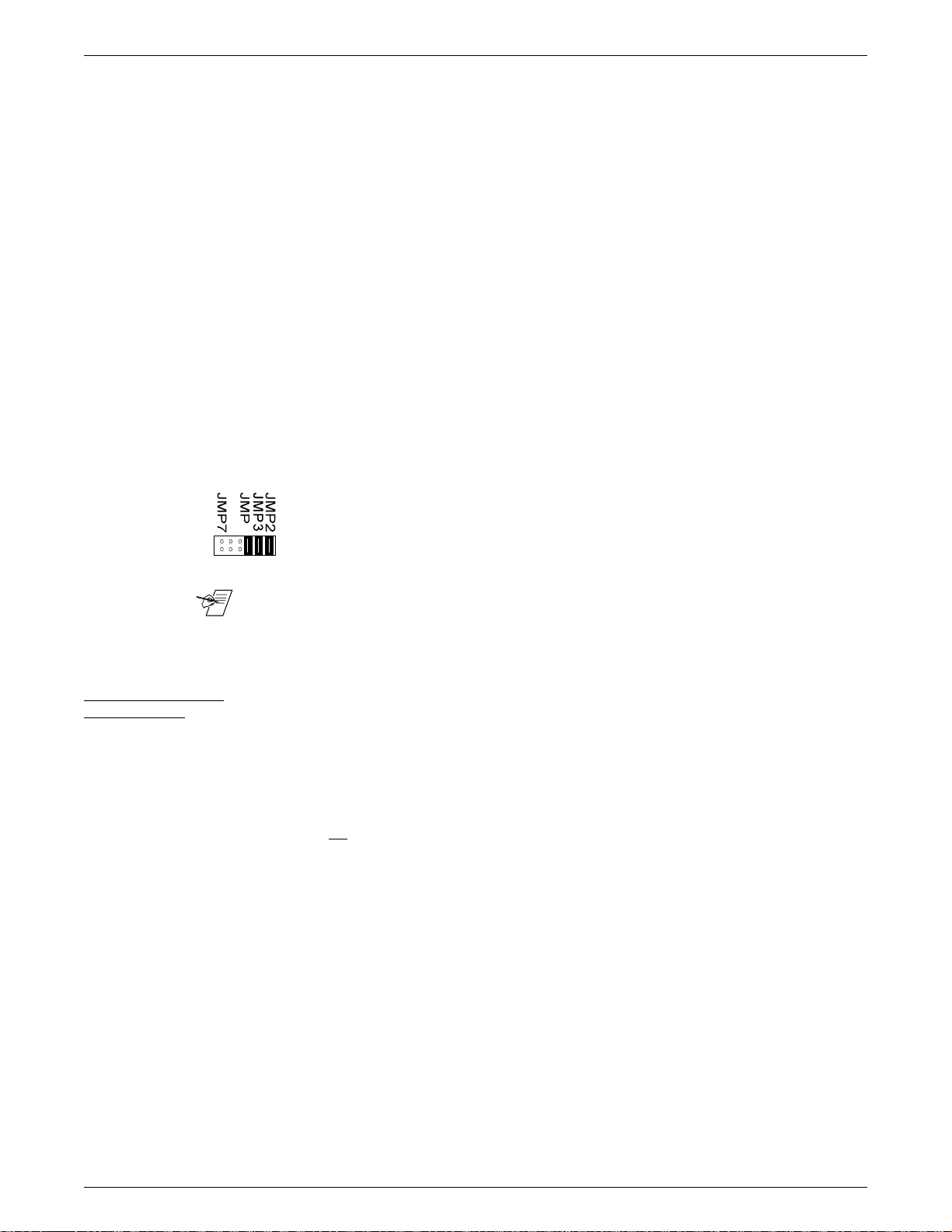

Checksum Disable Jumper

The Matrix 200 is shipped with JMP3 installed to disable the Checksum feature.

To enable it, remove the top cover (page 2-2) and remove JMP3. See picture

below.

_______ Note: When Checksum is disabled, the Cks1 and Cks2 bytes must still be

included. They must be data bytes (have a value between 80h and FFh).

Enabling the Part Number Jumper

The Matrix 200 reports its unit part number if the JMP4 jumper on the main board

is installed. This jumper has no other effect on the system and is factory set.

Installing the Security Jumper

The security code feature is described in Chapter 1, and implemented in Chapter

4, menu 8. It can only be used if JMP2 is installed.

Note: If the security is set and the code is not known, you cannot access the

Matrix. Remove this jumper and reinstall it to unlock the Matrix and reset the

code. At some point in time, power must be applied with the jumper out for the

controller to recognize this change. To reactivate the security feature, reinstall

JMP2 before putting the cover back on.

Extron • Matrix 200 • User’s Manual

4

Black

Red

4

2-8

Page 25

Installing a Redundant (second) Power Supply

To install a redundant power supply in a Matrix 200, disconnect the power

source, remove the Matrix from its rack mount, and place it on a clean

workspace. Refer to page 2-2 to remove the cover. With the cabinet open, do the

following:

1. Mount the new power supply on the four bolts projecting up from the bottom of

the cabinet and secure it with four nuts. This position is parallel to that of the

primary power supply. (See dotted lines in picture.)

2. Connect the two twisted power cables from the second IEC connector to the

inputs on the new power supply boards. See dotted lines in picture below.

3. Connect the two black power output connectors to the two vacant connectors

on the main controller board - next to the connectors from the primary power

supply.

4. Check the mounting and connections by comparing them with those for the

primary power supply.

5. Put the Matrix 200 back together and connect both AC power sources.

Chapter 2 • Hardware Installation

UNDANT POWER FUSE: 250V ~0.8A TT AC POWER INPUT

100-240V ~0.5A MAX 50/60 Hz

!

DISCONNECT ALL POWER CORDS BEFORE SERVICING

Like the primary

power supply, the

redundant supply

has a 2-amp, fastblo fuse at the AC

input of each

board.

6. To check the operation of the redundant supply, turn the AC switch Off. The

Matrix should function normally using the redundant power supply. If using an

RS-232/RS-422 interface, the Matrix Status Bytes will indicate this condition.

Black

Before Installing I/O Modules

Before adding an I/O Module to an existing Matrix 200, you must know the

revision status of the Matrix. Page A-1 has a list of option kits and their part

numbers. It also explains what upgrades may be required before adding

modules.

_______ If the serial number has an “A” after it, the Matrix is ready for an Audio Module.

If the unit does not meet these requirements, go to the appropriate procedure to

bring it up to date and then do the Audio Installation.

2-9

Extron • Matrix 200 • User’s Manual

Page 26

Chapter 2 • Hardware Installation

Adding an Audio Module

_______ Do not use this procedure unless your Matrix 200 is up to date. See previous

Tools for Installation:

3/16" flat screwdriver

#4 Phillips screwdriver

#6 Phillips screwdriver

Wire cutters

Audio Option Kit:

Qty Description

6 Internal Tooth Lock

Washers

1 Audio Module with:

1 3" Ribbon Cable

6 1-5/8 Screws

16 Phoenix Connectors

page.

1. Remove the Matrix top cover (procedure on page 2-2).

2. Locate the gray ribbon cables that connect the Main Controller board to the

existing I/O modules (Red, Green, Blue and Sync/Composite Video). Note the

orientation of the red stripe on each ribbon cable and unplug both ends. If

necessary, cut the ties that bind them together. It is not necessary to mark the

cable connections; this will be covered later. Place the ribbon cables

aside.

3. On the rear panel, remove the two screws (See below)

that hold the right end of the blank cover. (Tabs hold the

left end.) Remove the cover and put the screws back in

the same holes. This reveals two long, parallel

access slots. These will

accommodate the upper

and lower sections of the

Audio Module.

4.Check the installation

parts list and identify

them by their location in

the picture to the right.

Lock Washers

Extron • Matrix 200 • User’s Manual

Black

Red

2-10

Page 27

Chapter 2 • Hardware Installation

5. Unpack the Audio Matrix module and locate the following:

· The bracketed attachment is the power supply.

· Two rows of female Phoenix audio connectors,

eight in each row. Six pins per connector.

· Board address DIP switches. (See at right.)

· 3-inch ribbon cable attached. (Not visible in the

picture to the right.)

_______ The address DIP switches are factory-set. See right end of picture above. They

should be set to represent an address of five (0101 binary).

6. Remove the six nuts from the screws that hold the two boards together. Set

the screws and washers aside; the nuts will not be needed. (See above.)

7. Slide the rear panel upward about 3/4", while keeping it in the

cabinet grooves. (See right.)

8. Orient the Audio Module above the nylon

spacers, with the audio connector

strips to the rear. Tilt the module

slightly and slip the audio connectors

through the parallel openings in the

rear panel and lower it to a

horizontal position.

(See right.)

9. While holding the Audio Module in position

with the rear panel, lower them both

carefully until the module rests on the six nylon spacers. (See

below.)

10. With the Audio Module loosely in position, lift the corner by

the power supply slightly and plug the ribbon cable

into the nearest slot (J4) on the Main

Controller board.

2-11

_______ The I/O connectors on the Main Controller

board are on a parallel bus, therefore it

doesn't matter which module is plugged to

which connector. Because of its cable length,

the Audio Board must plug into the closest

connector.

Extron • Matrix 200 • User’s Manual

Page 28

Chapter 2 • Hardware Installation

11. Plug the remaining I/O Ribbon cables from each module to a connector on

the Main Controller board (See below). Since the Main Board connectors

are the same, connect the cables for neatness and convenience. For

example, the illustration below shows the Red I/O module connected to J5,

the Green to J6, etc.

Warning: When working close to the other I/O modules, be careful that you do not change any

other DIP switch settings.

12. Be sure the cables are securely plugged into the Main board, and then drop

the six screws into the six holes in the Audio Module (See below). Wiggle

each screw by hand to align it with the threads below and tighten them with a

screwdriver.

Audio

Black

Red

_______ The red stripe on the ribbon cables (pin 1) is to the right, on the Main Controller

and Audio boards. (See the picture below.) It must point up on the other I/O

modules.

13. With all connections and screws secure, route the cables away from the

power supplies. Use tie wraps to tie cables together where they follow the

same path.

14. If no other modifications are required, put the top cover back on the

Matrix 200 and put it back in its working position.

If the Matrix has an FPC, the new Power On message will show “A” in position

6. See example. Other digits depend on the configuration. The new

configuration will also appear in Request ID information sent to the Host

system via the RS-232/RS-422 port.

If other modifications are required, go to the appropriate procedure.

Extron • Matrix 200 • User’s Manual

2-12

Page 29

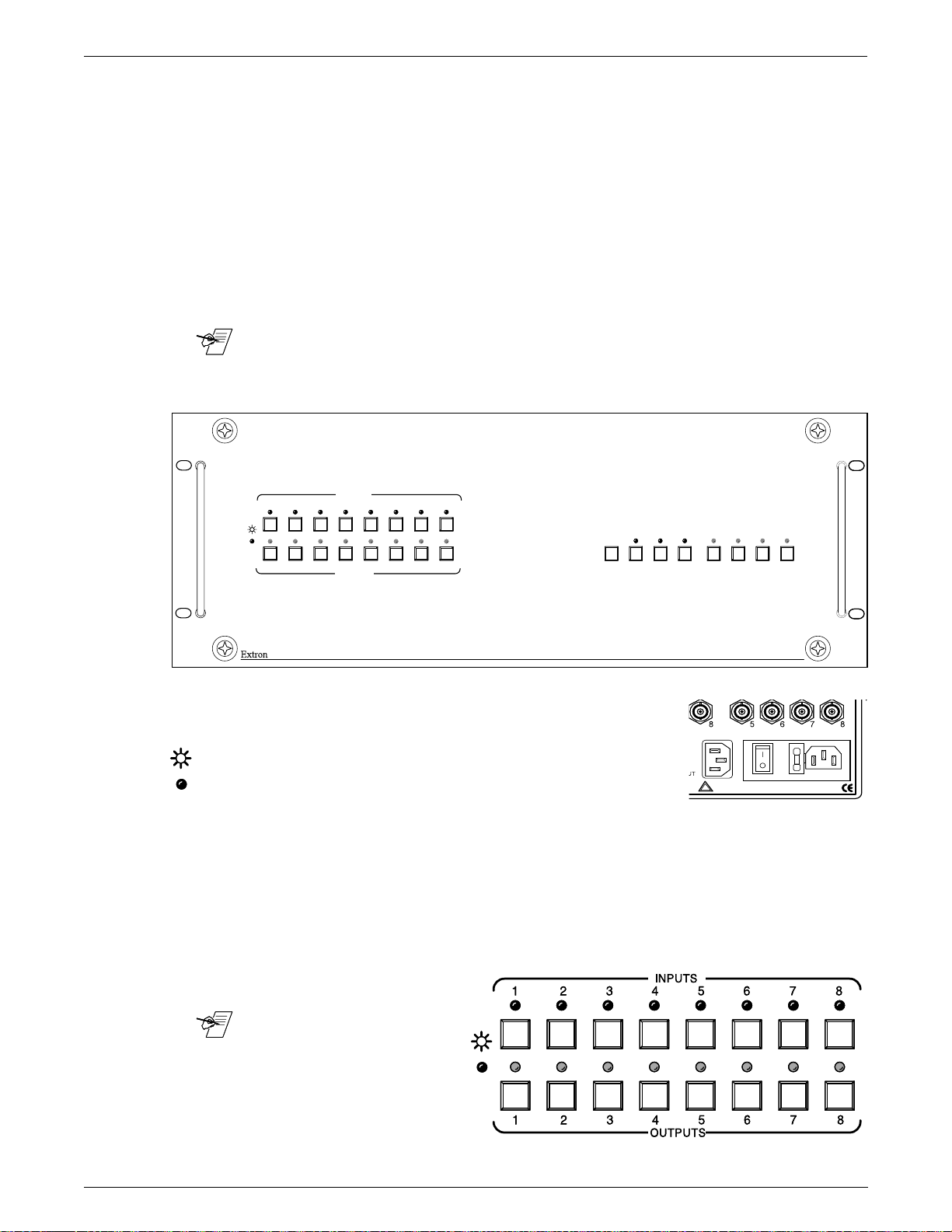

Installing I/O Modules in the Rear Panel

Tools for Installation:

3/16" flat screwdriver

#4 Phillips screwdriver

#6 Phillips screwdriver

9/16" Socket/nutdriver

Configuration plane 1 plane 2 plane 3 plane 4 plane 5

There are three types of modules that can be installed in the rear panel of the

Matrix 200: HRAM module, for RGB; Sync module, for Horizontal and/or Vertical

Sync; and Composite Video module for Composite Video or S-Video. Positions,

or “planes” 1, 2, and 3 will accommodate only HRAM modules. Planes 4 and 5

will accommodate either Sync or Composite video modules, but not HRAM. A

Matrix unit cannot have one or two HRAM modules; it must have three (for red,

green and blue) or none.

Use this procedure to install any HRAM, Sync or Composite Video module.

Locate the position on the back panel for the new module. An HRAM can only be

installed in the locations marked Red, Blue or Green. A Sync module or a

Composite Video module can only be mounted in the positions marked as such.

If there is one sync module, it must be in the first position after the Blue, or

Plane 4.

RGsB HRAM HRAM HRAM - RGBS HRAM HRAM HRAM Sync RGBHV HRAM HRAM HRAM Sync Sync

RGBSCv HRAM HRAM HRAM Sync C-Video

1 Cv - - - C-Video 2 Cv or 1 YC - - - C-Video C-Video

Audio can be included with any of these combinations.

Chapter 2 • Hardware Installation

_______ Address switches are set according to the physical location.

The illustration here shows the modules already installed.

BLUE

SYNC/

VIDEO

OO

UU

TT

PP

UU

TT

SS

1

2

1

2

4

4

OO

UU

TT

PP

UU

TT

SS

OO

UU

TT

PP

UU

TT

SS

1. Remove the Matrix top cover (procedure on page 2-2).

2. Locate the gray ribbon cables that connect the Main Controller board to the

existing I/O modules and determine where the new module will be connected.

If cables from adjacent modules are in the way, they may be unplugged and

reconnected later.

SYNC/

VIDEO

LISTED

1T23

c

ITE

3

12

REDUNDANT POWER FUSE: 250V ~0.8A TT AC POWER INPUT

100-240V ~0.5A MAX 50/60 Hz

!

DISCONNECT ALL POWER CORDS BEFORE SERVICING

43

3. On the rear panel, remove the 16 round plastic plugs that cover the holes

where the new module will be installed.

4. On the new module, remove the nuts from the 16 BNC connectors.

______ If installing both a Sync module and a Composite Video module, the Sync module must be in

Plane 4 and the Composite Video in Plane 5.

2-13

Extron • Matrix 200 • User’s Manual

Page 30

Chapter 2 • Hardware Installation

The picture to the right shows some

physical differences between these

two modules. The Sync module has

some components placed on the

insides of the boards, while the

Composite Video module has none.

The Sync termination DIP switches

below will be set for 75 ohms (on) or

510 ohms (off). The switches (1 - 8)

correspond to the inputs on the right

(1 - 8).

12

5678

INPUTS

OUTPUTS

3

4

on

off

7

8

123456

Sync termination DIP switches

on = 75 ohms

off = 510 ohms

Configuration examples:

8 x 8 = 8 switches on (1 - 8)

8 x 4 = 8 switches on (1 - 8)

4 x 4 = 4 switches on (1 - 4)

Red

Green

Blue

Sync/Video

Sync/Video

12

56

3

7

4

Sync termination DIP switches

ê

8

5. Mount the module by inserting the BNC connectors through the

holes in the rear panel and secure it in place with the 16 nuts. (Use

9/16" socket.)

6. Verify that the address DIP switches are set for the correct

Plane number. These switches are set at the factory, but their

settings should be confirmed.

The address switch settings are shown to the left, with their orientation as seen

from the front of the Matrix 200.

7. Carefully support the I/O board while pushing the ribbon cable onto its

connector (Red stripe up). Connect the other end to the Main Controller

board. The connectors on the Main Controller board are the same, therefore

the cables can be arranged for neatness. Note the orientation of the red stripe

(pin 1) is to the right when looking from the front of the Matrix.

8. After rechecking all connections, replace the cover on the Matrix 200 and

secure it with the six screws. (See page 2-2.)

9. If the Matrix has a Front Panel Controller, when power is applied the LCD

message will indicate the new configuration. The example here shows Red,

Green, Blue, Horizontal & Vertical Sync and Audio. If the Matrix had only

RGB, and one Sync module

and one Composite Video

module had been added, the

display will read:

RGBSC_ _.

The new configuration will also

appear in Request ID information

sent to the Host system via the

RS-232/RS-422 port.

The picture to the right is for an

HRAM module.

Extron • Matrix 200 • User’s Manual

2-14

Page 31

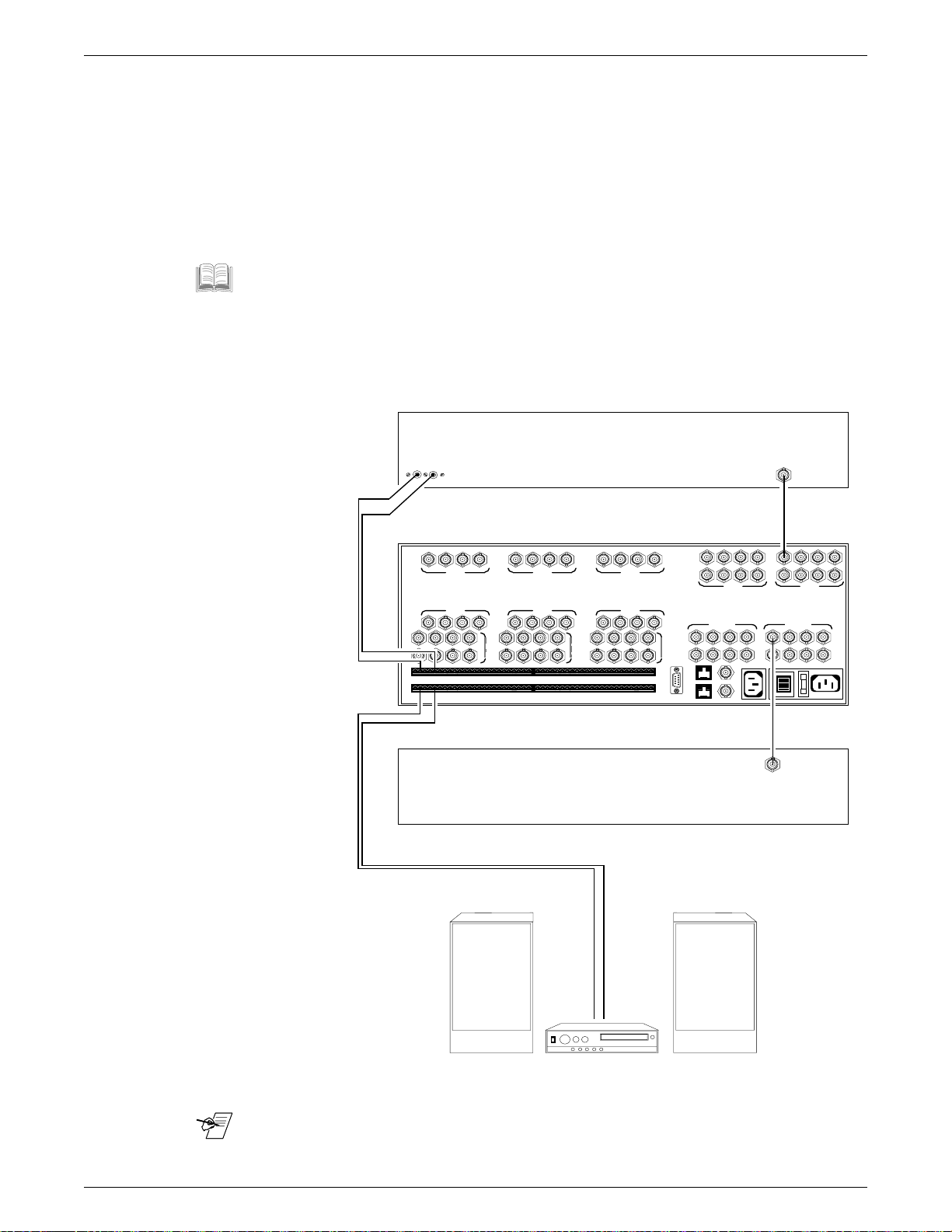

Installing FPC/QS-FPC Software Update

1. If the FPC/QS-FPC is mounted on the Matrix 200, refer to the procedure on

page 2-2 to open the cabinet and then continue with step 2.

___________ Electro-Static Discharge (ESD) can damage IC chips, even when it is not

enough to be humanly detected (felt, heard or seen). Do NOT touch IC chips

without being electrically grounded.

2. With the top cover off the Matrix, unplug the cable that connects the FPC/QSFPC to the Main Controller board and put it aside.

3. Remove the four (4) screws that hold the FPC/QS-FPC to the Matrix cabinet.

4. Place the FPC/QS-FPC face down on a clean workspace. If necessary, place

it on a soft pad to prevent damage.

5. Using a 1/4" nut driver, remove four (4) 1/4" nuts that hold the cover on the

back of the FPC/QS-FPC.

Chapter 2 • Hardware Installation

Black

Red

PLCC Chip Puller

6. After first properly grounding yourself, use the PLCC IC puller to remove the

old Software chip. Squeeze the tool to align the hooks with the slots provided

in opposite corners of chip socket U8. Insert the hooks, squeeze gently and

pull the IC straight out of the socket. Set the chip aside.

7. Note the orientation of the angled corner of the new Software chip. Position

this to match the angled corner of the socket and carefully press it in place.

8. Reinstall the cover on the back of the FPC/QS-FPC and reverse the above

procedure to put the Matrix back in place.

2-15

Extron • Matrix 200 • User’s Manual

Page 32

Matrix 200

User’s Manual

Chapter Three

Rear P anel Connections

Multiple Output Connections

Genlock Connections

3

RGB Input Connections

Composite Video Input Connections

S-Video Input Connections

Audio T erminal Connections

Page 33

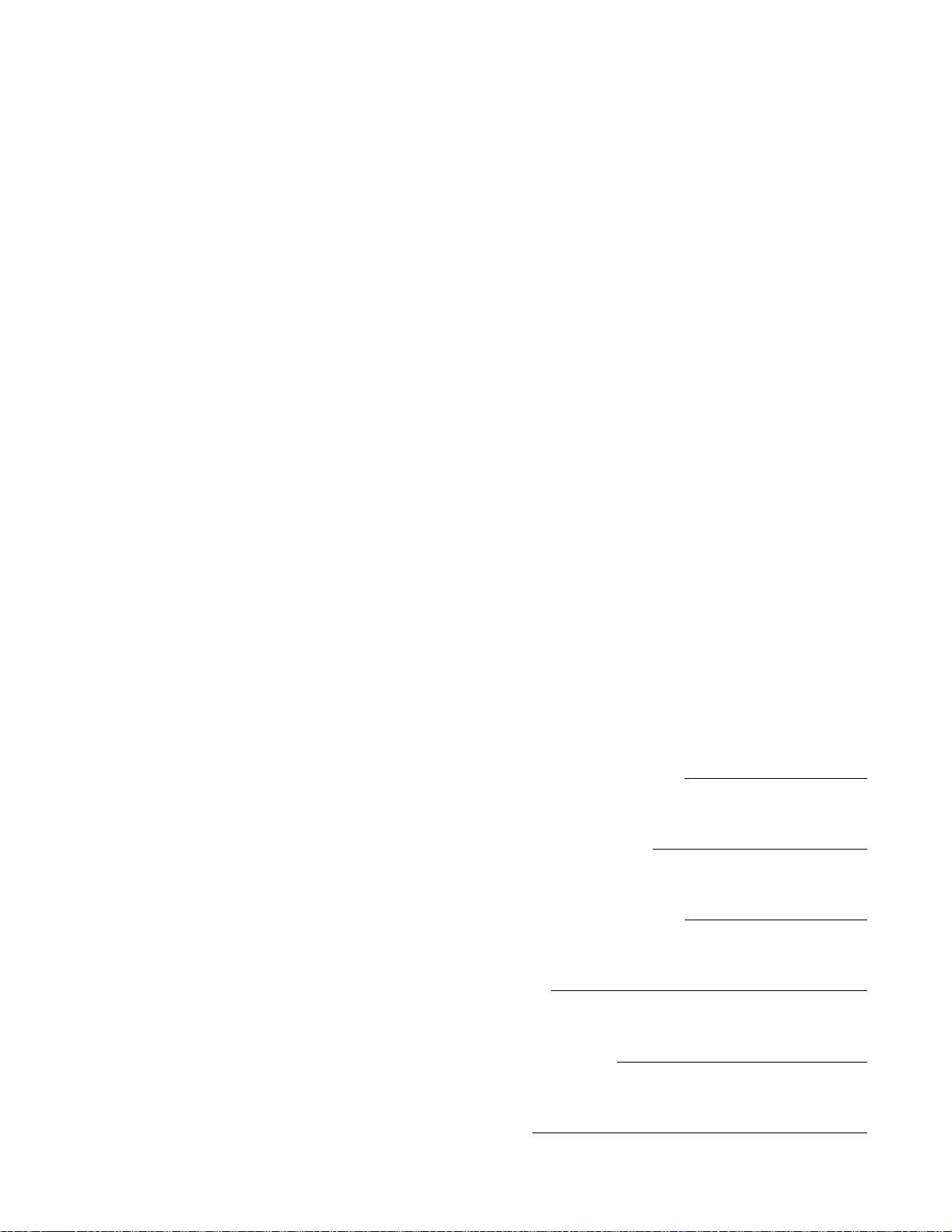

Multi-Output Connection

Chapter 3 • Rear Panel Connections

When using the Matrix 200 to switch different types of video signals, the signal

output from the switcher is in the same format as the corresponding input. That

is, RGB and Sync (composite or separate H&V) signals will pass through the

RGB and SYNC output; NTSC and PAL video signals will pass through the

composite video output; and S-Video will pass through the S-Video output.

Therefore, if multiple input signal types are used in the same switcher, the same

multiple outputs must also be directed to the output devices.

In the diagram below, the Matrix 200 supplies RGB output for large screen

projectors and data monitors, composite video output for an LCD projector, and

audio output for a stereo audio system.

The following pages show possible connections.

3-1

Extron • Matrix 200 • User’s Manual

Page 34

Chapter 3 • Rear Panel Connections

Genlock Connections

The Matrix 200 is

designed to use an

external Genlock signal

to synchronize composite

video or S-video

switching. If connected,

Genlock can be

programmed either from

the optional Front Panel

Controller, or from a Host

system (through the RS-232/

RS-422 port).

OO

UU

TT

PP

UU

TT

SS

REDUNDANT POWER

FUSE: 250V ~0.8A TT

AC POWER INPUT

RGB Input Connections

The illustration here shows the

Genlock connections. The

100-240V ~0.5A MAX 50/60 Hz

!

DISCONNECT ALL POWER CORDS BEFORE SERVICING

Genlock Out connector simply

allows the signal to be passed

on to another video device; it

does not have to be connected

for Matrix operation.

All RGB input and output connections to the Matrix 200 are made with BNC type

connectors. Many types of RGB output devices (scan doublers, document

cameras, etc.), including most computers, do not have BNC video output

connectors. If not, a suitable adapter or an Extron computer-video interface

should be used to adapt the device output to the BNC input of the Matrix 200.

With the proper adapter, the RGB and Sync signals can be connected directly to

the R, G, B, H, V inputs of the switcher. If the RGB signal is using the Sync-onGreen channel, connect the RGB cables to the switcher without using the sync

channels.

RGB input connections to the Matrix 200 can be made using the following

combinations:

Without Audio

RGsB - Red, Sync-on-Green, Blue

RGBS - Red, Green, Blue, and Composite Sync

RGBHV - Red, Green, Blue, H&V Sync

With Audio

RGsB with R&L Audio - Red, Green, Blue, and Audio Follow

RGBS with R&L Audio - Red, Green, Blue, Sync and Audio Follow

RGBHV with R&L Audio - Red, Green, Blue, H&V Sync and Audio Follow

The following three pages illustrate examples for the above combinations with

Right and Left Audio connections.

Extron • Matrix 200 • User’s Manual

3-2

Page 35

RGB Input Connections with Right & Left Audio

Chapter 3 • Rear Panel Connections

AUDIO

OUTPUT VIDEO OUTPUT

RGBLR

INPU TS

RED GREEN

INPU TS INPU TS

(SYNC)

RGB

VIDEO INPUT

AV SOURCE UNIT

BLUE

INPU TSIN P U TSINPU TS

THIS SWITCHER IS CONFIGURED FOR 8 X 8 RGBS,

8 X 8 COMPOSITE VIDEO, AND 8 X 8 AUDIO.

VIDEO DESTINATION UNIT

INPU TS INP UTS

SYNC/

VIDEO

OUTPU TS

OUTPU TS

SYNC/

VIDEO

3-3

AUDIO DESTINATION UNIT

_______ Audio Connections may or may not be used. See page 3-9 for wiring.

Extron • Matrix 200 • User’s Manual

Page 36

Chapter 3 • Rear Panel Connections

A

RGBS Input Connections with Right & Left Audio

AUDIO

OUTPUT VIDEO OUTPUT

R G B H&VLR

INPU TS

RED GREEN

INPU TS INPU TS

(SYNC)

R G B H&V

AV SOURCE UNIT

BLUE

INPU TSIN P U TSINPU TS

VIDEO DESTINATION UNIT

SYNC OUTPUT

INPU TS INP UTS

SYNC/

VIDEO

OUTPU TS

THIS SWITCHER IS CONFIGURED FO

8 X 8 COMPOSITE VIDEO, AND 8 X 8

SYNC INPUTVIDEO INPUT

VIDEO

OUTPU TS

SYNC/

_______ Audio Connections may or may not be used. See page 3-9 for wiring.

Extron • Matrix 200 • User’s Manual

AUDIO DESTINATION UNIT

3-4

Page 37

Chapter 3 • Rear Panel Connections

RGBHV Input Connections with Right & Left Audio

AUDIO

OUTPUT VIDEO OUTPUT

RGB H VLR

INPU TS

RED GREEN

INPU TS INPU TS

(SYNC)

RGB H V

AV SOURCE UNIT

BLUE

INPU TSIN P U TSINP U TS

THIS SWITCHER IS CONFIGURED FOR

THIS SWITCHER IS CONFIGURED FOR 8 X 8 RGBS,

8 X 8 COMPOSITE VIDEO, AND 8 X 8 AUDIO.

8 X 8 RGBHV, AND 8 X 8 AUDIO

VIDEO DESTINATION UNIT

SYNC OUTPUT

INPU TS IN PU TS

SYNC/

VIDEO

OUTPU TS

SYNC INPUTVIDEO INPUT

OUTPU TS

SYNC/

VIDEO

3-5

AUDIO DESTINATION UNIT

_______ Audio Connections may or may not be used. See page 3-9 for wiring.

Extron • Matrix 200 • User’s Manual

Page 38

Chapter 3 • Rear Panel Connections

Composite Video Input Connections

NTSC and PAL are television or VCR type signals on a single coax cable,

which may or may not have stereo audio. For this application, the Matrix 200

uses one Composite Video module, shown below in the right-most position.

Possible uses include: NTSC or PAL, with or without right & left audio follow.

Connect the output of an NTSC/PAL video source to a Video module input.

(See illustration below.) Connect the video output from the Matrix to a

destination device that uses Composite Video.

_______ NTSC - National Television Standards Committee

PAL - Phase Alternation Line

Composite Video Input with Right & Left Audio

AUDIO

OUTPUT

INPUTS

RED GREEN

AV SOURCE UNIT

INPUTS INPUTS

(SYNC)

THIS SWITCHER IS CONFIGURED FOR 8 X 8 RGBS,

8 X 8 COMPOSITE VIDEO, AND 8 X 8 AUDIO.

BLUE

INPUTSINPUTSIN P U TS

VIDEO DESTINATION UNIT

VIDEO OUTPUTLR

INPUT S IN PUTS

SYNC/

VIDEO

OUTPUTS

VIDEO INPUT

OUTPUTS

SYNC/

VIDEO

_______ Audio Connections may or may not be used. See page 3-9 for wiring.

Extron • Matrix 200 • User’s Manual

AUDIO DESTINATION UNIT

3-6

Page 39

S-Video Input Connections

S-Video (S-VHS) is typically the output from the AV source on a 4-pin miniature

din-type connector and must be converted to 2 BNC type connectors - one for

Chroma (C) and the other for Luminance (Y).

_______ For S-VHS to BNC interface, use Extron cable 26-353-01.

To connect S-Video to the Matrix 200, the Matrix must be ordered with two

composite video modules. Use one for Luminance (Y) and the other for Chroma

(C). The Y and C signal lines are then connected to the two video modules. See

illustration on facing page.

_______ When connecting Y and C cables, be sure to use the same input numbers on the

two video modules for each source. This example uses number 1 inputs. Also,

use the same output number pair for each destination. This example uses

number 1 outputs, but we could have used outputs number 2, or 3, etc.

Input Connections

Choose which input number to use to connect the S-Video source device to the

Matrix 200. Connect the Luminance (Y) to the input connector on the first (left)

Video module and the Chroma (C) to the same input number on the second

(right) Video module.

Chapter 3 • Rear Panel Connections

Output Connections

If audio is used, connect the right and left audio source outputs to the right and

left inputs on the back of the Matrix. See page 3-9 for details on audio

connections.

Choose which Matrix 200 output number to use for the S-Video destination unit.

Connect the Luminance (Y) output from the first (left) Video module to the

Luminance input of the destination unit. Connect the Chroma (C) from the same

output number on the second (right) Video module to the Chroma input of the

Video destination unit.

If audio is used, connect the right and left audio output from the Matrix connector

to the right and left inputs of the audio destination unit. See page 3-9 for details

on audio connections.

_______ A Matrix 200 can be configured with RGsB (sync on green) and S-Video.

3-7

Extron • Matrix 200 • User’s Manual

Page 40

Chapter 3 • Rear Panel Connections

S-Video Input Connections with Right & Left Audio

AUDIO

OUTPUT

LR

INPU TS

RED GREEN