Page 1

ELEVATING TABLE MOUNTABLE INSTALLATION INTERFACE

WITH MODULAR A / V CONNECTOR FACEPLATES

IN2118

IN2118

OPER AT ION MANUAL

Page 2

Installation and Safety Instructions

For Models without a Power Switch:

The socket outlet shall be installed near the equipment and shall be accessible.

For all Models:

No serviceable parts inside the unit. Refer service to a qualified technician.

For Models with Internal or External Fuses:

For continued protection against fire hazard, replace only with same type and rating of fuse.

Instructions d’installation et de sécurité

Pour les modèles sans interrupteur de courant:

La prise de courant d’alimentation sera installé près de l’équipement et sera accessible.

Pour tout les modèles:

Pas de composants à entretenir à l’intérieur. Confiez toute réparation à un technicien qualifié.

Pour les modèles équipés de fusibles internes ou externes:

Afin d’éviter tout danger d’incendie, ne remplacer qu’avec le même type et la même valeur de fusible.

Installations- und Sicherheitshinweise

Für Geräte ohne Netzschalter:

Die Netzsteckdose soll in der Nähe des Gerätes installiert und frei zugänglich sein.

Für alle Geräte:

Keine Wartung innerhalb des Gerätes notwendig. Reparaturen nur durch einen Fachmann!

Für Geräte mit interner oder externer Sicherung:

Für dauernden Schutz gegen Feuergefahr darf die Sicherung nur gegen eine andere gleichen Typs und gleicher Nennleistung

ausgewechselt werden.

Instalacion E Instrucciones de Seguridad

Modelos Sin Interruptor:

Para Todos Los Modelos:

Modelos con Fusibles Internos o Externos:

La conexión debe ser instalada cerca del equipo y debe ser accesible.

Dentro de la unidad , no hay partes para reparar. Llame un tecnico calificado.

Para prevenir un incendio, reemplace solo con el mismo tipo de fusible.

CE COMPLIANCE

All products exported to Europe by Inline, Inc. after January 1, 1997 have been tested and found to

comply with EU Council Directive 89/336/EEC. These devices conform to the following

standards:

EN50081-1 (1991), EN55022 (1987)

EN50082-1 (1992 and 1994), EN60950-92

Shielded interconnect cables must be employed with this equipment to ensure compliance with

the pertinent Electromagnetic Interference (EMI) and Electromagnetic Compatibility (EMC)

standards governing this device.

FCC COMPLIANCE

This device has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC rules. These limits are designed to provide against harmful

interference when equipment is operated in a commercial environment. This equipment generates,

uses and can radiate radio frequency energy and, if not installed and used in accordance with th e

instruction manual, may cause harmful interference to radio communications. Operation of

equipment in a residential area is likely to cause harmful interference, in which case the user will be

required to correct the interference at their own expense.

Page 3

Table of Contents

Product Overview................................................................................................2

Description........................................................................................................ 2

Eighteen Models Available...............................................................................2

Compatibility........................................................................................................3

Input..................................................................................................................3

Output............................................................................................................... 3

Installation............................................................................................................ 4

Mounting the Interface......................................................................................4

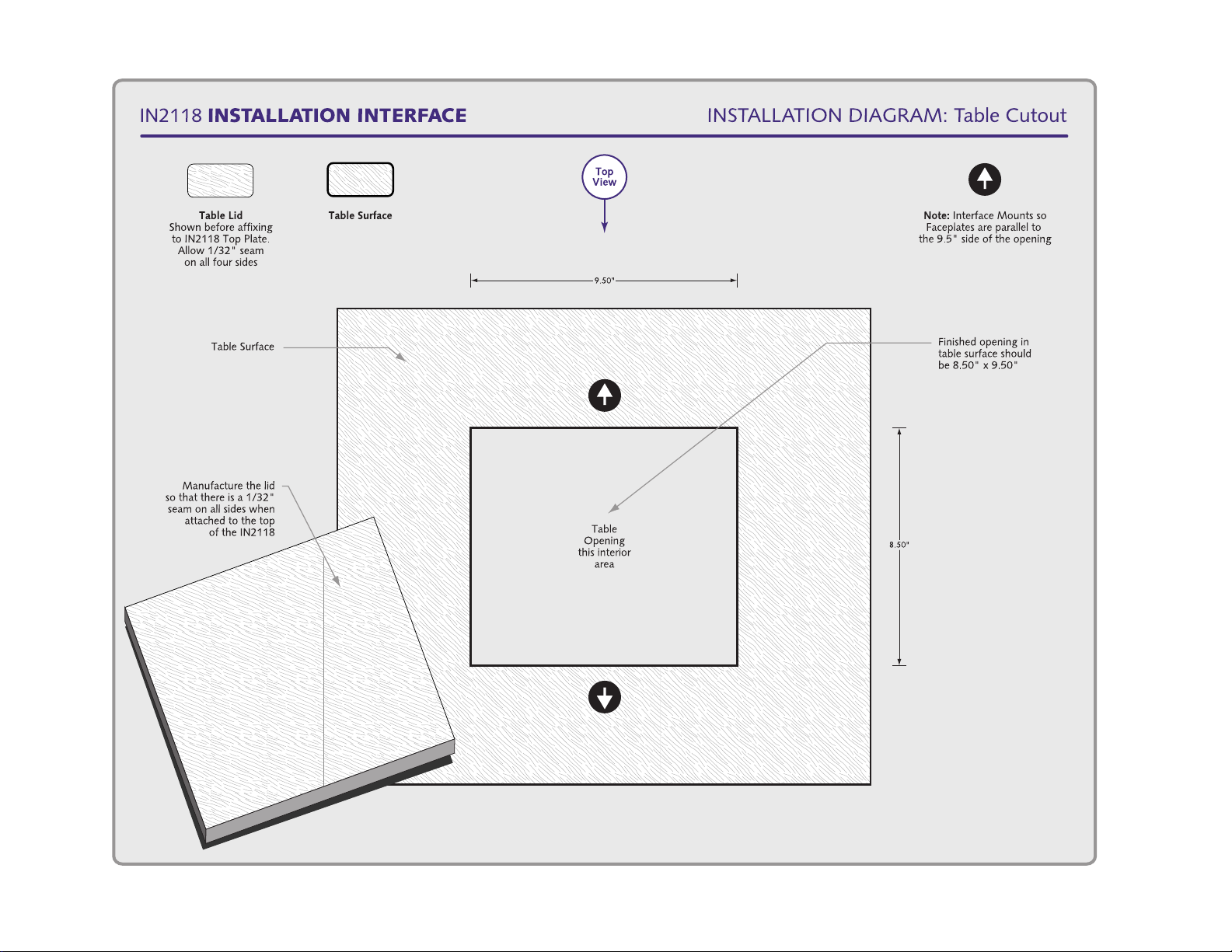

IN2118 Installation Diagram: Table Cutout.....................................................5

Adjusting the IN2118....................................................................................... 7

IN2118 Installation Diagram: Adjustments......................................................8

Maximum Bearing Load................................................................................... 9

Connecting the Interface................................................................................... 9

Adapter / Extension Cables for Input and Local Monitor Output...................11

IN2118 Installation Diagram: (Bottom) Connectors and Controls.................12

IN2118 Application Diagram......................................................................... 13

IN2118 Installation Diagram: (Faceplates) Connectors and Controls............ 14

Operation............................................................................................................ 15

Horizontal Position Control............................................................................15

Dipswitch Settings.......................................................................................... 15

Optimal Settings for LCD / DMD / D-ILA / Plasma Displays.......................16

Remote Control Operation.............................................................................. 16

Contact Closure Devices.................................................................................16

A/V Connector Modules.................................................................................17

Specifications......................................................................................................19

Troubleshooting (IN2118-A, D & G)................................................................20

IN2118 Dimensions Diagrams...........................................................................22

Warranty............................................................................................................25

Page 4

2

Product Overview

DESCRIPTION

The IN2118 is a high performance computer video interface for analog video signals including

VGA, SVGA, XGA, SXGA, UXGA, Macintosh

workstations. The IN2118 flush mounts neatly in a conference room / boardroom table or other

presentation furniture. The IN2118 is a two-sided unit that provides easy access to a highresolution computer video interface, a modular A/V connector faceplate and / or one or two A/C

convenience outlets on either side of the table.

Disappearing Flush Mount Design - When the unit is in the lowered position, it sits

completely flush with the table surface.

Motorized Unit - can be raised and lowered by pressing down on the top surface, or via

contact closure control.

Safety Features - stop the interface from descending if it senses an obstruction such as

attached cables or wayward fingers.

Installation Flexibility - The IN2118 includes several adjustments to help installers

position the unit precisely in a conference table / presentation furniture.

Front Panel A/C Convenience Outlets - are provided to power a laptop computer or

other A/V equipment that will be located on the table.

Modular A/V Connector Plate - The IN2118 simplifies the design and installation pro-

cess since a single unit fills the function of both video interface and A/V connector plate.

Flush mounted in the table and rising into place when needed, the IN2118 provides easy access

for making computer and A/V connections, reducing equipment clutter, and complements the

décor of high tech control rooms, civic / legislative chambers and courtroom installations.

EIGHTEEN MODELS AVAILABLE

The IN2118 is available in several different combinations to match the computer video interface,

A/V connector and A/C power outlet requirements of each installation.

®

, SunTM, SGI

TM

and other high-resolution

Faceplate A: 400 MHz Interface, holds (2) A/V Connector Modules & (1) Edison A/C Outlet

Faceplate D: 400 MHz Interface, holds (2) A/V Connector Modules & (1) IEC A/C Outlet

Faceplate G: 400 MHz Interface, holds (2) A/V Connector Modules & (1) Europlug A/C Outlet

Faceplate B: Holds (6) A/V Connector Modules & (1) Edison A/C Outlet

Faceplate E: Holds (6) A/V Connector Modules & (1) IEC A/C Outlet

Faceplate H: Holds (6) A/V Connector Modules & (1) Europlug A/C Outlet

Faceplate C: Holds (4) A/V Connector Modules & (2) Edison A/C Outlets

Faceplate F: Holds (4) A/V Connector Modules & (2) IEC A/C Outlets

Faceplate K: Holds (4) A/V Connector Modules & (2) Europlug A/C Outlets

Each unit can be ordered with any combination of two (2) faceplates. Complete descriptions of all

available models can be found on pages 26 & 27 of the INLINE 2001 Product Catalog.

Note: A/V Connector Modules are not included and must be ordered separately (see page 17).

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 5

3

The IN2118 Interface is not a scan converter. The data projector, monitor

or other output device must be compatible with the horizontal scan rate,

vertical scan rate and resolution output by the computer video card.

Compatibility

INPUT

The IN2118 Interface will accept high-resolution video signals from virtually any computer that

outputs an analog video signal. The unit will work with signals at virtually any resolution and

refresh rate. Compatible computer video signals include VGA, SVGA, XGA, MAC, SUN, SGI

and other high-resolution computers outputting an analog video signal. Input signal compatibility

parameters are listed below.

Video Signal: Analog RGB Video

Signal Format: RGBHV, RGBS, RGsB*

Horizontal Frequency Range: 30 KHz to 130 KHz

Vertical Refresh Rates: 30 Hz to 120 Hz

* The IN2118 Interface will operate with RGsB input signals. However,

the unit will not strip sync off of the green. RGsB input signals are always

output as RGsB (they cannot be output as RGBS or RGBHV). Also, the

horizontal position control will not operate when used with RGsB input

signals.

OUTPUT

The output signal of the IN2118 Interface is analog RGB video with TTL sync on 3, 4 or 5

female BNC connectors. The output format can be set to RGBHV, RGBS or RGsB using

dipswitches. This output signal is compatible with high-resolution data grade monitors and data /

graphics projectors.

VGA, MAC, SUN, SGI and other high-resolution workstations operate in

several video modes encompassing a wide range of resolutions and scan

rates. Many of the video signals from the newest models can run as high

as 70 KHz or more, with the newest VGA cards offering an output resolution of 1600 x 1200 (some can even go as high as 1000 x 1080). The data

projector or monitor connected to the interface output must be compatible

with the horizontal scan rate and vertical refresh rate of the computer’s

video signal. Check the documentation for both the computer graphics

card and the data display device to ensure compatibility.

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 6

4

Installation

MOUNTING THE INTERFACE

WARNING: The IN2118 should only be mounted by licensed and bonded installers. Care

must be taken to avoid scarring or damaging presentation / conference room furniture.

Before installing the IN2118, refer to the Dimensions Diagrams on pages

22 - 24 and make sure the table / installation furniture will accommodate

all

the dimensions of the unit.

In the following example, the IN2118 is installed in a conference room table with a laminated

surface. Depending on the installation, your emplacement may require specialized tools,

additional materials, safety equipment, etc.

Hint: To simplify your installation, make the lid fit the hole

NECESSARY TOOLS & SUPPLIES:

Power Tools: Hand Tools: Miscellaneous:

Drill

Router

Saw (Circular or Saber)

IN9185 Template

Carpenter’s Level

(2) C-Clamps

Wood File

Phillips Screwdriver

1. Locate the desired mounting location on the tabletop / installation furniture surface and

mark the center with a pencil.

2. Attach the extension arms to the optional IN9185 Table Routing Template and position it

around the center mark. Make sure that the 12 flat head screws are countersunk below

the surface of the extension arms. Failure to do so may scar the furniture.

3. Once the Template has been situated properly, use a pair of C-Clamps to secure the

extension arms to the edges of the table. Use a pencil to outline the 9 ½” x 8 ½” inside

edge of the template (see the Installation Diagram on the following page).

Hint: Marking the inside edge of the IN9185 will alert the installer of any accidental

template movement that may occur while routing the hole.

4. Using a router, carefully cut the opening in the table surface (very thick table surfaces

may require additional routing). Use a file to square the round edges. Remove the

template when finished.

When using the IN9185, installers must

(collar) that provides ¼” clearance from the inside edge of the template.

, not vice versa.

Adhesive

Double sided tape

Wood Screws and

Washers

1/32” Feeler Gauge

(Optional)

use a router bit template guide

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 7

5

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 8

6

5. Most installations will require fabrication of a new cover surface (lid). Using the IN9185

template, make another outline on a matching piece of material. Cut out the new lid

using a power / saber saw.

Note: Bear in main that the new surface must accommodate a 1/32” gap on all four sides

between the lid and the table opening.

6. Finish the top and sides of the lid, and the sides of the opening in the table. Again, there

should be a 1/32” seam around all four edges of the lid when it sits flush with the table

surface.

Note: If matching lamina is unavailable, installers may have to completely resurface the

table / presentation furniture, or consider other installation options.

Installers may wish to use 1/32” feeler gauges to achieve precise

equidistant spacing on all four sides of the lid. Hint: A standard size

paper clip (one and one quarter inches long) is almost 1/32” in diameter.

7. The IN2118 is secured to a plate base to prevent damage during shipment. Disconnect

the four screws and remove the plate.

Note: The IN2118 is delivered with the top plate in the lowered position. Do not

raise the

plate until the installation is complete.

8. Loosen the four (4) upper wing nuts and disconnect the mounting flange from the main

housing (see the Adjustments Diagram on page 8).

9. Working from the underside of the table, position the mounting flange so that the gap

between the inside edges of the flange and the table’s opening are roughly equidistant (a

precise adjustment will be done later). The flange contains eight (8) mounting holes: four

oversized primary holes on the corners and four smaller secondary holes on the sides.

The primary holes are used to position the unit, while the secondary holes are used to

permanently attach the IN2118 to the table / installation furniture. Mark the four (4)

primary

Note: Do not

holes only.

drill the secondary holes or permanently attach the flange until the unit has

been positioned properly!

10. Set the flange aside and carefully drill the primary holes. Care must be taken not to

penetrate the surface of the table. Drill the holes in the center of the oversized openings

to provide maximum centering flexibility.

11. Attach the flange to the underside of the table. Do not fully tighten the screws.

12. Attach the main housing to the mounting flange by securing the four (4) upper wing nuts.

Make sure that the top of the housing sits flush with all four sides of the flange before

tightening the nuts.

For applications in which a new table / presentation furniture will be fabricated and / or the IN2118 will be installed at a remote location, the main

housing should not be attached to the mounting flange during shipment.

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 9

7

ADJUSTING THE IN2118

This section offers step-by-step instructions for precisely situating the IN2118 in the table /

presentation furniture. An Adjustment Diagram is provided on the following page.

Do not permanently attach the cover surface (lid) to the top plate until the

IN2118 has been fully installed in the table / presentation furniture.

1. Center the IN2118 until a roughly equidistant gap is achieved between all four sides of the

top plate and the table’s opening (once again, a precise adjustment will be done later).

Once the unit has been properly positioned in the table, tighten the four (4) primary screws.

2. Loosen the upper wing nuts and disconnect the main housing. Carefully drill the (4)

secondary holes and secure the mounting flange to the table. Once again, care must be

taken not to penetrate the surface of the table.

3. Reattach the main housing to the mounting flange. Using the IN9230 IEC Power Cable

(included), apply power to the IN2118, turn it on, and press down on the top plate surface

to raise the unit.

4. With the IN2118 in the raised position, place a Carpenter’s Level across the top of the

plate and level the unit by adjusting the upper wing nuts. When the unit has been

centered, turn the Level 45º and adjust again. This step may have to be repeated several

times until a true level surface is achieved.

Note: Leveling the unit while in the raised position will ensure that the top plate and the table

surface remain parallel (when the IN2118 is in the raised position), and sits flush when the unit

is fully descended.

5. Before adjusting the height of the interface, use two-sided tape to temporarily attach the

cover surface material (lid) to the top plate.

6. To adjust the height of the IN2118, press down on the lid and lower the unit. Loosen the

four (4) lower wing nuts. Position the lid so that it sits completely flush with the table

surface and tighten the wing nuts. Raise and lower the interface to ensure that the unit

achieves sufficient clearance when raised, and sits flush when lowered. The IN2118

should ascend and descend smoothly.

The lower wing nuts allow installers to adjust for varying tabletop thickness

(up to two inches) and provide a precise flush-mount installation

7. Using a strong adhesive, permanently attach the lid to the top plate.

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 10

120/230VAC; 10A: 60/50HZ

8

IN2118 Operation Manual - Preliminary 02/05/01 ©2001 - Inline, Inc.

Page 11

9

MAXIMUM BEARING LOAD

In applications where the unit will be raised and lowered by hand or through the contact closure

control port, the maximum weight of the cover surface material affixed to the top of the interface

(the lid) should not exceed 10 pounds / 4.5 kilograms.

The maximum load bearing on the motor is 30 pounds, but exceeding the

10 pound / 4.5 kilogram load limit will shorten the life of the motor and

may compress the activation spring, preventing the unit from operating

properly..

CONNECTING THE INTERFACE

This section offers step-by-step instructions for connecting the IN2118 Interface. A Connectors

and Controls Diagram is included on page 12, and an Application Diagram is on page 13.

CAUTION: Installation of the IN2118 Interface must only be carried out by qualified technicians. Before making any connections, make sure that there is no power connected to the unit.

1. Run the video coax cable(s), power cable, remote cable, and optional accessory cables

(audio / video / phone / data / control cables) to the interface.

Warning: All internal cables and connectors are pre-terminated at the

factory. Removing the connector plate may damage internal components

and will void all warranties. If you have any questions, please call INLINE

technical support at (714) 921-4100.

2. Terminate any Audio, Video and Control Cables to the backside of the A/V Connector

Modules as required by your installation (a complete list of available modules is provided

on pages 17 & 18).

Note: The IN2118 provides a Flexible Cable Conduit to ensure that the accessory cables are

not pinched or damaged while the unit ascends / descends. Before making any terminations,

run all the accessory cables through the bottom of the conduit to the A/V connector plate

opening(s).

3. Using the IN9334 3/32” Allen Wrench (included) - attach the modular connector(s) to

the IN2118 faceplate, making sure that none of the cables are pinched or damaged

(faceplate diagrams are provided on page 14). Once the connectors are securely installed,

tighten the Cable Strain Relief Clamps.

Note: All optional A/C convenience outlet(s) are pre-terminated at the factory.

4. Connect the Video Coax Cable to the (5) BNC female connectors using three, four, or

five high-resolution BNC cables, or a multi-conductor RGBHV, RGBS or RGB "snake.”

The IN7000 / IN7200 / IN7300 and IN7400P Series high-resolution cables are well suited

for this purpose. Take care while making connections to insure that the red output is

connected to the red input, green output to the green input, etc. For dual interface

applications, a second set of BNC connectors is provided.

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 12

10

5LJKW*URXQG

5. Connect the Left, Right and Ground Conductors on the audio cables to the 5-pin

captive screw terminal. This connector will accept stranded or solid cables from 20 - 26

AWG. The IN2118 Interface takes an unbalanced stereo audio input, buffers the signal

and outputs it as balanced stereo audio. This is desirable for systems where the audio

signal will be connected to equipment with balanced audio inputs, and is helpful in

preserving signal integrity and minimizing outside signal interference (which often occurs

while sending the audio signal over lengthy cable runs).

5LJKW

5LJKW

/HIW

/HIW*URXQG

/HIW

6. Access the Dipswitches by removing the screws on the front plate (the IN9334 3/32”

Allen Wrench is included). Use the IN9339 Adjustment Tool to set the switches as

appropriate for your installation (a complete description of the dipswitch settings is

provided on page 15). The factory default output format is RGBS / RGBHV. If your

display device, routing system or cabling requires a different format, use the dipswitches

to change the output signal to RGsB. Replace the front plate and tighten the hex screws.

7. Connect the Remote Device to the 4-pin captive screw terminal (see the Remote Control

Operation Section on page 16).

8. Apply Power to the IN2118 using the IN9230 IEC (USA only) power cable (included).

9. Complete the Installation by turning the interface ON (the power switch is located to the

right of the A/C connector). The front panel LED (on the Interface) will illuminate.

FOR IN2118-A, D & G INSTALLATIONS:

10. Connect the Computer Graphics Card to the IN2118 15-pin video input port (a

Connectors and Controls Diagram is provided on page 14).

• PC / MAC / SGI Computers with 15-pin HD Video Ports - can be connected via

IN8000M-1 / IN8200M-1 Series high-resolution coaxial VGA cables.

• Older Macintosh (15-pin D) / SUN (13W3) / Workstations (4 or 5 BNC) - can be

connected using the appropriate input / output cables listed in the chart on the following

page.

11. Connect the Computer Sound Card Output (if applicable) to the IN2118 3.5mm female

stereo audio input connector using an IN8200-1 Series cable (15-pin HD with 3.5mm stereo

mini male), or an IN9106 audio patch cable (3.5mm stereo mini male to 3.5mm stereo mini

male). For computers with RCA connectors, use the IN9107 audio adapter cable [(1) 3.5mm

stereo mini male to (2) RCA male].

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 13

11

12. Connect the Local Computer Monitor (if applicable) to the local monitor output port of

the IN2118. Monitors with 15-pin VGA connectors will attach directly to the interface.

For other types of monitors, refer to the table below.

If a local monitor is required, the monitor emulation dipswitch must be

disabled (see the Dipswitch Settings Section on page 15 for more details).

ADAPTER / EXTENSION CABLES FOR INPUT AND LOCAL MONITOR OUTPUT

The IN2118 Interface has 15-pin HD VGA-type input and local monitor output connector ports.

The following cables / adapters are available:

Computer 3’ 6’ 12’ 25’ 35’ +

VGA: 15-Pin HD

Input Cable (M-M)

Output Cable (M-F)

VGA with Stereo Audio: 15-Pin HD with 3.5mm (M-M) mini DIN

Input Cable (M-M)

Output Cable (M-F)

MAC with 15-Pin D:

Input Cable (M-M)

Output Cable (M-F)

MAC G3, G4 and PowerBook with 15-Pin HD*:

Input Cable (M-M)

Output Cable (M-F)

SUN: 13W3 (may also be used with SGI with RGsB output)

Input Cable (M-M)

Output Cable (M-F)

Workstation: 5 BNC / RGBHV

Input Cable (M-M)

Output Cable (M-M)

Workstation: 4 BNC / RGBS

Input Cable (M-F)

*Newer Mac G3 models (with translucent cases) have 15-Pin HD connectors (pins arranged in 3 rows).

Older G3 models (with solid white enclosures) incorporate 15-Pin D connectors (pins arranged in 2 rows).

IN8003M-1 IN8006M-1 IN8012M-1 IN8025M-1 IN80xxM-1

IN8006-1 IN8012-1 IN8025-1 IN80xx-1

IN8203M-1 IN8206M-1 IN8212M-1 IN8225M-1 IN82xxM-1

IN8203-1 IN8206-1 IN8212-1 IN8225-1 IN82xx-1

IN9140M IN9144M

IN9141 IN9145

IN8006M-1 IN8012M-1 IN8025M-1 IN80xxM-1

IN8006-1 IN8012-1 IN8025-1 IN80xx-1

IN9142M IN9146M

IN9143 IN9147

IN9045-L6 IN9045-L12 IN9045-L25 IN9045-Lxx

IN9045-L6 IN9045-L12 IN9045-L25 IN9045-Lxx

IN9100

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 14

12

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 15

13

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 16

14

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 17

15

Operation

HORIZONTAL POSITION CONTROL

The location of the horizontal position control is shown in the Faceplate A Connectors and

Controls Diagram on the previous page. This control adjusts the position of the image on the

data display device. The horizontal position control has no effect on the local computer monitor.

If the horizontal position adjustment is set to an extreme position on either the display device or

the IN2118 Interface, the output image may appear dark and / or the colors may be displayed

improperly. To position the video image and achieve optimum picture quality:

1. Set the display device’s horizontal position control to the center of its adjustment range.

2. Adjust the horizontal position control on the IN2118 Interface until the picture is

centered properly on the display device.

Note: The horizontal position control does not work with RGsB input signals.

DIPSWITCH SETTINGS

Most installations will not require any changes to the dipswitch settings. The factory default and

specialized dipswitch settings are indicated below.

Note: The switches are located under the Dipswitch access plate (see the diagram on the previous

page).

Factory Default Settings:

Dipswitches ON: 2 & 4

Signal Format: Red / Green / Blue / Horizontal and Vertical Sync

Horizontal Position Control: Enabled

H & V Sync Polarity: Negative, Negative

Monitor Emulation: Disabled

The following table lists the functions of the 6 dipswitches:

DIPSWITCH FUNCTION SETTING

*If monitor emulation is desired when using a MAC G3 (with 15-pin HD connector) or G4, dipswitch #6 must be set to 1.

1

2

3

4

5

6

Horizontal Position

RGsB Output (sync on green)

RGBS or RGBHV Output (dip

switch 2 must be set to 1)

RGBHV Output Sync Polarity

Serration Pulse Removal (for

RGBS or RGsB output)

Monitor Emulation (VGA color /

MAC* 640 x 480)

1 = Disabled

0 = Enabled

1 = RGBS or RGBHV

0 = RGsB

1 = RGBS

0 = RGBHV

1 = Negative, Negative

0 = Mirror Input Polarities

1 = Remove Serration Pulses

0 = Pass Serration Pulses

1 = Emulation Disabled

0 = Emulation Enabled

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 18

16

OPTIMAL SETTINGS FOR LCD / DLP / D-ILA / PLASMA DISPLAYS

The following output sync settings provide maximum signal preservation and are recommended

for the best image quality with LCD, DLP, D-ILA and Plasma Display devices. Depending on

the design of the display device’s sync processing circuitry, you may be able to set the horizontal

position control (dipswitch #1) to the enabled position. However, experimentation with your

display device is the best way to determine whether you can achieve a stable image with the

horizontal position enabled. Many LCD displays include a fine phase control, which can be

adjusted to optimize picture quality.

Dipswitches ON: 1 & 2

Signal Format: Red / Green / Blue / Horizontal and Vertical Sync

Horizontal Position Control: Disabled

H & V Sync Polarity: Mirror Input Polarities

REMOTE CONTROL OPERATION

The IN2118 can be raised and lowered by pressing down on the top surface, or via remote control.

The remote port is a 4-pin captive screw terminal on the connector plate that allows the interface to

be controlled by any device that is capable of providing a latching contact closure, or by an RS-232

control device (when used with an optional IN6901 / IN6902 RS-232 to contact closure converter).

Contact Closure Control: The interface can be raised or

lowered via the remote port by providing a latching contact

closure between pin 1 and pin 2 on the remote jack.

Opening / closing the contact closure causes the unit to

ascend / descend. The manual control (pressing down on the

top surface) and the contact closure switch work

independently. Therefore, an open or closed status between

pins 1 & 2 on the remote port could select either the raising

or lowering of the interface, depending on the current

position of the unit.

Status: The remote connector status pins (3 & 4) can be used to provide feedback to a control

system to indicate whether the IN2118 is in the raised or lowered position. The status pin will be

open or closed depending on the current position:

Closed: Unit is in the raised position

Open: Unit is in the lowered position

CONTACT CLOSURE DEVICES

Any device capable of providing a latching contact closure may be used to control the IN2118.

Several contact closure type devices are available:

IN6901 / IN6902 RS-232 to Contact Closure Converter - allows the IN2118 and other

INLINE devices with contact closure control ports to be regulated by RS-232 sources.

Control System - many control systems are capable of providing contact closures.

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 19

17

A/V CONNECTOR MODULES

Connector Module Black / White Description Type Size

Video Modules

IN9351B / IN9351W (2) BNC Female Barrel Single

IN9352B / IN9352W (1) 4-Pin Mini DIN Female (S-Video) Installation Single

IN9357B / IN9357W (2) F-Connector Female Barrel Single

IN9363B / IN9363W

(1) 4-Pi n Mini DIN Female (S-Video)

(1) BNC Female Barrel

IN9381B / IN9381W (1) BNC Female Barrel Single

IN9382B / IN9382W (1) F-Connector Female Barrel Single

IN9383B / IN9383W (1) RCA Female - White Barrel Single

IN9390B / IN9390W 4-Pin Mini DIN Female (S-Video) Barrel Single

IN9468B / IN9468W (2) 4-Pin Mini DIN Female Barrel (S-Video) Barrel Single

Audio Modules

IN9353B / IN9353W (2) RCA Female - Red / White Installation Single

IN9354B / IN9354W (2) ¼” Stereo Phono Female Installation Single

IN9355B / IN9355W (2) 3.5mm Mini Stereo Female Installation Single

IN9360B / IN9360W

(1) Contact Closure Switch (Single Pole) with

Internal LED

(1) 3.5mm Stereo Mi ni Female

IN9365DB / IN9365DW (1) XLR 3-Pin Female (Neutrik) Installation Double

IN9373B / IN9373W (2) RCA Female - Red / White Barrel Single

IN9384B / IN9384W (1) ¼” Stereo Phono Female Installation Single

IN9385B / IN9385W (1) 3.5mm Mini Stereo Female Installation Single

IN9395DB / IN9395DW (1) XLR 3-Pin Female (Switchcraft) Installation Double

IN9398DB / IN9398DW (1) XLR 3-Pin Male (Cannon) Installation Double

IN9450B / IN9450W (1) Mini XLR 3-Pin Male (Switchcraft) Installation Single

IN9451B / IN9451W (2) Mini XLR 3-Pin Male (Switchcraft) Installation Single

IN9456B / IN9456W (2) RCA Female - Red / White Quick Connect Single

IN9457B / IN9457W (2) 3.5mm Mini Stereo Female Quick Connect Single

IN9458B / IN9458W (1) 3.5mm Mini Stereo Female Quick Connect Single

IN9459B / IN9459W (1) ¼” Stereo Phono Female Quick Connect Single

IN9460B / IN9460W

(1) Contact Closure Switch (Single Pole) with

External LED

(1) 3.5mm Mini St ereo Female

IN9463B / IN9463W (1) Mini XLR 3-Pin Male (Switchcraft) Quick Connect Single

IN9473DB / IN9473DW (1) 4-Pole Speakon Male (Neutrik) Installation Double

Audio / Video Modules

IN9372DB / IN9372DW

A/V Super Module:

(2) RCA Female - Audio: Red / White

(1) RCA Female - Video: Yellow

(1) 4-Pi n Mini DIN Female - S-Video

IN9376DB / IN9376DW

IN9377DB / IN9377DW

IN9386B / IN9386W

IN9387B / IN9387W

IN9388B / IN9388W

IN9461DB / IN9461DW

IN9462DB / IN9462DW

IN9469B / IN9469W

A/V Super Module:

(2) RCA Female - Audio: Red / White

(1) RCA Female - Video: Yellow

(1) 4-Pi n Mini DIN Female - S-Video

(2) RCA Female - Audio: Red / White

(1) RCA Female - Video: Yellow

(1) BNC Male

(2) 3.5mm Stereo Mi ni Female

(1) 4-Pi n Mini DIN Female - S-Video

(1) 3.5mm Stereo Mi ni Female

(1) RCA Female - Video: Yellow

(1) 3.5mm Stereo Mi ni Female

A/V Super Module:

(2) RCA Female - Audio: Red / White

(1) RCA Female - Video: Yellow

(1) 4-Pi n Mini DIN Female - S-Video

(2) RCA Female - Audio: Red / White

(1) RCA Female - Video: Yellow

(2) RCA Female - Audio: Red / White

(1) RCA Female - Video: Yellow

Barrel

Installation

Quick Connect

Installation

Barrel

Installation

BNC: Barrel

3.5mm Mini: Installation

Installation

Installation

Quick Connect

Quick Connect

Installation

Single

Single

Single

Double

Double

Double

Single

Single

Single

Double

Double

Single

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 20

18

Connector Module Black / White Description Type Size

Control / Computer M odules

IN9356B / IN9356W (1) 5-Pin Captive Screw Terminal Installation Single

IN9360B / IN9360W

(1) Contact Closure Switch (Momentary - Single

Pole with LED)

Installation

Single

(1) 3.5mm Stereo Mi ni Female

IN9361B / IN9361W (1) 15-Pin HD Female Barrel Single

IN9362B / IN9362W (1) 15-Pin HD Male Barrel Single

IN9364DB / IN9364DW (1) XLR 4-Pin Female (Neutrik) Installation Double

IN9366DB / IN9366DW (1) XLR 6-Pin Female (Neutrik) Installation Double

IN9374B / IN9374W (1) 9-Pin D Female Barrel Single

IN9375B / IN9375W (2) 6-Pin Mini DIN Female - Keyboard / Mouse Barrel Single

IN9378B / IN9378W (1) 9-Pin D Male Barrel Single

IN9379B / IN9379W (1) 6-Pin Mini DIN Female - Keyboard / Mouse Installation Single

IN9389B / IN9389W (1) 6-Pin Mini DIN Female - Keyboard / Mouse Barrel Single

IN9391DB / IN9391DW (1) XLR 5-Pin Female (Neutrik) Installation Double

IN9394DB / IN9394DW (1) XLR 4-Pin Female (Switchcraft) Installation Double

IN9396DB / IN9396DW (1) XLR 6-Pin Female (Switchcraft) Installation Double

IN9397DB / IN9397DW (1) XLR 7-Pin Female (Switchcraft) Installation Double

IN9399B / IN9399W (1) Mini XLR 6-Pin Male (Switchcraft) Installation Single

IN9452B / IN9452W (1) Mini XLR 4-Pin Male (Switchcraft) Installation Single

IN9460B / IN9460W

(1) Contact Closure Switch (Momentary - Single

Pole with LED)

Quick Connect

Single

(1) 3.5mm Stereo Mi ni Female

IN9464B / IN9464W (1) Mini XLR 4-Pin Male (Switchcraft) Quick Connect Single

IN9465B / IN9465W

(1) Rocker Switch (Latc hing - Single Pole),

Max Voltage: 10A / 125VAC, 6A / 250VAC

Installation

Single

Approvals: UL / CSA

IN9466B / IN9466W (2) 6-Pin Mini DIN Female - Keyboard / Mouse Installation Single

IN9467B / IN9467W (1) USB Connector Quick Connect Single

IN9470B / IN9470W

(1) Switch with Integral LED

(Latching, Single Pole, Single Thr ow)

Max. Voltage: 5A / 125VAC, 3A / 250VAC

Installation

Single

Approvals: CSA

IN9471B / IN9471W

(1) Switch ( Latching, Single P ole, Double Throw)

Max. Voltage: 15A / 125VAC,

10A / 250VAC, 10A / 28VDC

Installation

Single

Approvals: CSA

IN9472DB / IN9472DW

(1) Switch (Latching, Double Pole, Double Throw)

Max. Voltage: 15A / 125VAC,

10A / 250VAC, 10A / 28VDC

Installation

Double

Approvals: CSA

Data / Phone Modules

IN9358B / IN9358W (1) RJ11 Female - Phone Installation Single

IN9358DB / IN9358DW (1) RJ11 Female - Phone Installation Double

IN9359B / IN9359W (1) RJ45 Female - Data Installation Single

IN9359DB / IN9359DW (1) RJ45 Female - Data Installation Double

IN9453B / IN9453W (1) RJ11 Female - Phone Barrel Single

IN9453DB / IN9453DW (1) RJ11 Female - Phone Barrel Double

IN9454B / IN9454W (1) RJ45 Female - Data Barrel Single

IN9454DB / IN9454DW (1) RJ45 Female - Data Barrel Double

Blank Plate

IN9350B / IN9350W Blank Plate - Single Single

IN9367DB / IN9367DW Blank Plate - Double Double

IN9368TB / IN9368TW Blank Plate - Triple Triple

IN9369QB / IN9369QW Blank Plate - Quad Quad

IN9474QB / IN9474QW (1) Grommet - 1” ID Quad

Note: When ordering INLINE equipment, please specify the necessary A/V Connector modules.

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 21

19

Specifications

IN2118 Installation Video Interface

Input (IN2118-A, D & G only)

Connector Type (1) 15-pin HD female

RGB Video Signals Analog, 1.5 Vp-p max.

Sync Signals TTL compatible

Horizontal Scan Rate 30 KHz - 130 KHz

Vertical Sync Range 30 Hz - 120 Hz

Stereo Audio Connector (1) 3.5mm stereo mini female

Stereo Audio Signal Unbalanced Stereo Audio - Impedance: 10 K

Output (IN2118-A, D & G only)

Local Monitor (Buffered) (1) 15-pin HD female

Main Outputs 1 or 2 sets of 5 female BNC - Located on Bottom of Unit

Output Sync Format RGBHV, RGBS or RGsB format

Bandwidth 400 MHz @ -3 dB with 0.7 volt input signal

Balanced Audio Outputs (2) 5-pin Captive Screw Connectors, Impedance: 50

Controls (IN2118-A, D & G only)

External Horizontal Position Control

Internal 10 Dip Switches

Dimensions

Overall Including Flange

Interface Top Plate 8.15” x 9.15” / 20.7 cm. x 23.2 cm.

Interface Elevation Rises approximately 3.4” / 8.64 cm. above top of table

Shipping Weight 20 lbs. / 9 Kg.

Product Weight 15 lbs. / 6.8 Kg.

Power

Power Supply Internal Switch Mode: 90 to 260 VAC; 47 - 63 Hz

General

Paint Finish Black

Front Panel A/C Outlets 1 or 2 Edison / IEC / Europlug Female - 800 Watts Max.

Remote Control 4-pin Captive Screw - Contact Closure Type

Regulatory Compliance

EMI & Safety

14” x 12.15” x 11.15” / 35.6 cm. x 30.9 cm. x 28.3 cm.

(see the Dimensions Diagrams on pages 22-24)

UL 1950, CAN/CSA-22.2 No. 950 3

FCC class A; CE: EN50022 (1987), EN50081-1 (1991),

EN50082-1 (1992 & 1994), EN60950-92

rd

Ed.

Parts Included

(1) IN2118 Installation Unit

(1) IN9230 IEC Power Cable, 6’ long (USA only)

(1) IN9334 3/32” Allen Wrench

(1) IN9339 Adjustment Tool with Technician’s Blade

(1) Operation Manual

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 22

20

Required Accessories (Ordered Separately)

Input and Local Monitor Adapter and Extension Cables:

VGA: IN8000 Series 15-pin HD female to 15-pin HD female, various lengths from 3’ to 100’

For Other Computers: Refer to the table on page 11

Optional Accessories

Table Routing Template

IN9185: Provides a guide to make a precision cut when mounting the IN2118 in a table /

presentation furniture

Remote Equipment:

IN6901 / IN6902: RS-232 to contact closure converter

IN9465: Rocker Switch Module

Audio Input Cables:

IN9106: 3.5mm stereo mini male to 3.5mm stereo mini male, 6’ long

IN9107: (1) 3.5mm stereo mini male to (2) RCA male, 6’ long

Installation Cables:

IN7000P-5 Series RGBHV Cable: Standard Resolution, Plenum Cable available in bulk

lengths

IN7000P-5K Series RGBHV Cable: Standard Resolution, Plenum Cable available in 1000’

bulk length

IN8800: 18 Conductor Super High-Resolution Cable: (3) Super High-Resolution Coax., (3)

Mini Coax., (5) 26 Gauge Twisted Pairs, (1) Gauge Pair

Connectors and Tools:

IN9301: BNC Connectors

IN9320: Crimp Tool Frame

IN9321: Die (IN9320 and IN9321 are used to terminate bulk cables)

RGB Installation Cables

Coaxial Cables 3-Conductor 4-Conductor 5-Conductor

Standard Resolution

Standard Resolution, Plenum

Super High Resolution

Super High Resolution, Plenum

Ultra High Resolution

All cable grades are available in lengths from 3’ to 250’ pre-terminated with high quality BNC connectors or as bulk cable.

IN7000-4 IN7000-5

IN7000P-4 IN7000P-5

IN7300-3 IN7300-4 IN7300-5

IN7400P-5

IN7200-3 IN7200-5 IN7200-6

Troubleshooting (IN2118-A, D & G)

Problem: The display device connected to the IN2118 output has a bad / scrambled image.

Solution 1: Verify that the correct input cable is being used.

Solution 2: The display device connected to the output of the interface may not be

compatible with the computer output. PC, MAC, SUN and other high-resolution

workstations have new and ultra high-resolution modes such as 1600 x 1200 and 1800 x

1440, and can output a video signal with a horizontal scan rate of over 100 KHz! Many

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 23

21

data monitors and data projectors are not compatible with these resolutions and

frequencies.

Solution 3: Check the dipswitch settings to make sure the unit is putting out a sync

format that the display device can use. For most applications, the default dipswitch

settings (see page 15) will work best.

Solution 4: The RGBS or RGBHV cable may have a bad sync line. Try running the

sync through another cable.

Problem: The output image is very dark.

Solution: The horizontal position control may be set off to an extreme setting or may

be interacting poorly with the horizontal position control on the display device. Follow

the horizontal position adjustment procedure on page 15.

Problem: The local monitor looks fine but the image on the LCD projector is wavy or has

vertical bars in the picture.

Solution 1: LCD / DMD / D-ILA / Plasma Display devices work best when the sync

signal has minimum sync processing. Set the interface dipswitches to the factory default

positions (see page 15). In some cases, disabling the horizontal position control may

alleviate this problem.

Solution 2: LCD / DMD displays often have an adjustment called Phase Adjust or Fine

Phase Control. This control should be adjusted to provide the best image.

Problem: The output image is missing a color.

Solution: Possibly the RGBS or RGBHV cable is bad. Try switching connections on

the output to verify that the bad color’s cable is OK (Example: If there is no red, try

running the green output through the red cable and see if the green is displayed or not).

Problem: The output image is too green.

Solution: The dipswitch settings may be set for sync on green output and the display

device doesn’t like that format. Try changing the dipswitches to output an RGBS or

RGBHV signal (see Dipswitch Settings Section on page 15).

Problem: The horizontal position control is not working.

Solution 1: Check the dipswitch settings to see if the horizontal position control has

been disabled.

Solution 2: The input setting may be RGsB (sync on green). The horizontal position

control does not work with RGsB input signals.

Problem: The output image is doubled, with two images displayed side-by-side.

Solution: The display device may not be compatible with the horizontal scan rate of

the computer. This problem often occurs when a 31.5 KHz VGA signal is sent into an

RGB monitor that is only compatible with signals at 15.75 KHz.

If problems persist, call INLINE Technical Services at (714) 921-4100 for further assistance.

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 24

22

0.625"

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 25

23

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Page 26

24

BOTTOM VIEW

IN2118 Operation Manual - Preliminary 01/31/01 ©2001 - Inline, Inc.

Page 27

25

Warranty

♦

INLINE warrants the equipment it manufactures to be free from defects in materials and

workmanship.

♦

If equipment fails because of such defects and INLINE is notified within two (2) years

from the date of shipment, INLINE will, at its option, repair or replace the equipment at

its plant, provided that the equipment has not been subjected to mechanical, electrical or

other abuse or modifications.

♦

Equipment that fails under conditions other than those covered will be repaired at the

current price of parts and labor in effect at the time of repair. Such repairs are warranted

for ninety (90) days from the day of re-shipment to the Buyer.

♦

T his warranty is in lieu of all other warranties expressed or implied, including without

limitation, any implied warranty or merchantability or fitness for any particular purpose,

all of which are expressly disclaimed.

The information in this manual has been carefully checked and is bel ieved to be accurate. However,

INLINE, Inc. assumes no responsibility for any inaccuracies that may be contained in this manual. In

no event will INLINE, Inc. be liable for direct, indirect, special, incidental, or consequential damages

resulting from any defect or omission in this manual, even if advised of the possibility of such

damages. The technical information contained herein regarding IN2118 features and specifications is

subject to change without notice.

Apple, Mac and Macintosh are registered trademarks of Apple Computer, Inc. Sun, Sun

Microsystems, and the Sun Logo are trademarks or registered trademarks of Sun Micro systems, Inc. in

the United States and other countries. SGI is a trademark of Silicon Graphics, Inc. All other

trademarks and registered trademarks are the property of their respective companies.

All Rights Reserved © Copyright 2001

©

(800) 882-7117 ♦ (714) 450-1800 ♦ Fax (714) 450-1850 ♦ www.inlineinc.com

INLINE, INC. ♦ 810 West Taft ♦ Orange, CA 92865

©2001 - Inline, Inc . IN2118 Operation Manual - Preliminary 01/31/01

Loading...

Loading...