Page 1

User Guide

Matrix Switchers

DMS 1600, DMS 2000,

DMS 3200, and DMS 3600

Configurable Digital Video Matrix Switchers

68-1829-01 Rev. D

09 13

Page 2

Safety Instructions

Safety Instructions • English

WARNING: This symbol, , when used on the product, is intended to

alert the user of the presence of uninsulated dangerous voltage within the

product’s enclosure that may present a risk of electric shock.

ATTENTION: This symbol, , when used on the product, is intended

to alert the user of important operating and maintenance (servicing)

instructions in the literature provided with the equipment.

For information on safety guidelines, regulatory compliances, EMI/EMF

compatibility, accessibility, and related topics, see the Extron Safety and

Regulatory Compliance Guide, part number 68-290-01, on the Extron website,

www.extron.com.

Instructions de sécurité • Français

AVERTISSEMENT: Ce pictogramme, , lorsqu’il est utilisé sur le

produit, signale à l’utilisateur la présence à l’intérieur du boîtier du produit

d’une tension électrique dangereuse susceptible de provoquer un choc

électrique.

ATTENTION: Ce pictogramme, , lorsqu’il est utilisé sur le produit,

signale à l’utilisateur des instructions d’utilisation ou de maintenance

importantes qui se trouvent dans la documentation fournie avec le

matériel.

Pour en savoir plus sur les règles de sécurité, la conformité à la réglementation,

la compatibilité EMI/EMF, l’accessibilité, et autres sujets connexes, lisez les

informations de sécurité et de conformité Extron, réf. 68-290-01, sur le site

www.extron.fr.

Extron,

Sicherheitsanweisungen • Deutsch

WARNUNG: Dieses Symbol auf dem Produkt soll den Benutzer

darauf aufmerksam machen, dass im Inneren des Gehäuses dieses

Produktes gefährliche Spannungen herrschen, die nicht isoliert sind

und die einen elektrischen Schlag verursachen können.

Инструкция по технике безопасности • Русский

ПРЕДУПРЕЖДЕНИЕ: Данный символ, , если указан

на продукте, предупреждает пользователя о наличии

неизолированного опасного напряжения внутри корпуса

продукта, которое может привести к поражению

электрическим током.

ВНИМАНИЕ: Данный символ, , если указан на продукте,

предупреждает пользователя о наличии важных инструкций

по эксплуатации и обслуживанию в руководстве,

прилагаемом к данному оборудованию.

Для получения информации о правилах техники безопасности,

соблюдении нормативных требований, электромагнитной

совместимости (ЭМП/ЭДС), возможности доступа и других

вопросах см. руководство по безопасности и соблюдению

нормативных требований Extron на сайте Extron:

ru, номер по каталогу - 68-290-01.

www.extron.

Chinese Simplified(简体中文)

警告: 产品上的这个标志意在警告用户该产品机壳内有暴露的危险 电压,

有触电危险。

注意: 产品上的这个标志意在提示用户设备随附的用户手册中有

重要的操作和维护(维修)说明。

关于我们产品的安全指南、遵循的规范、EMI/EMF 的兼容性、无障碍

使用的特性等相关内容,敬请访问 Extron 网站 www.extron.cn,参见 Extron

安全规范指南,产品编号 68-290-01。

Chinese Traditional( )

警告: 若產品上使用此符號,是為了提醒使用者,產品機殼內存在著

可能會導致觸電之風險的未絕緣危險電壓。

VORSICHT: Dieses Symbol auf dem Produkt soll dem Benutzer in der

im Lieferumfang enthaltenen Dokumentation besonders wichtige Hinweise

zur Bedienung und Wartung (Instandhaltung) geben.

Weitere Informationen über die Sicherheitsrichtlinien, Produkthandhabung,

EMI/EMF-Kompatibilität, Zugänglichkeit und verwandte Themen finden Sie in

den Extron-Richtlinien für Sicherheit und Handhabung (Artikelnummer

68-290-01) auf der Extron-Website,

www.extron.de.

Instrucciones de seguridad • Español

ADVERTENCIA: Este símbolo, , cuando se utiliza en el producto,

avisa al usuario de la presencia de voltaje peligroso sin aislar dentro del

producto, lo que puede representar un riesgo de descarga eléctrica.

ATENCIÓN: Este símbolo, , cuando se utiliza en el producto, avisa

al usuario de la presencia de importantes instrucciones de uso y

mantenimiento recogidas en la documentación proporcionada con el

equipo.

Para obtener información sobre directrices de seguridad, cumplimiento

de normativas, compatibilidad electromagnética, accesibilidad y temas

relacionados, consulte la Guía de cumplimiento de normativas y seguridad de

Extron, referencia 68-290-01, en el sitio Web de Extron,

www.extron.es.

注意 若產品上使用此符號,是為了提醒使用者。

有關安全性指導方針、法規遵守、EMI/EMF 相容性、存取範圍和相關主題的詳

細資訊,請瀏覽 Extron 網站:www.extron.cn,然後參閱《Extron 安全性與法

規遵守手冊》,準則編號 68-290-01。

Japanese

警告: この記 号 が製品上に表示されている場合は、筐体内に絶縁されて

いない高電圧が流れ、感電の危険があることを示しています。

注意: この記号 が製品上に表示されている場合は、本機の取扱説明書

に 記載さ れて いる重 要な操 作 と保 守 ( 整 備)の 指 示につ いてユーザ ー の 注

意を喚起するものです。

安全上のご注意、法規厳守、EMI/EMF適合性、その他の関連項目に

つ い て は 、エ ク スト ロ ン の ウェブ サ イト www.extron.jp よ り 『 Extron Safety and

Regulatory Compliance Guide』 ( P/N 68-290-01) をご覧ください。

Korean

경고: 이 기호 가 제품에 사용될 경우, 제품의 인클로저 내에 있는

접지되지 않은 위험한 전류로 인해 사용자가 감전될 위험이 있음을

경고합니다.

주의: 이 기호 가 제품에 사용될 경우, 장비와 함께 제공된 책자에 나와

있는 주요 운영 및 유지보수(정비) 지침을 경고합니다.

안전 가이드라인, 규제 준수, EMI/EMF 호환성, 접근성, 그리고 관련 항목에

대한 자세한 내용은 Extron 웹 사이트(www.extron.co.kr)의 Extron 안전 및

규제 준수 안내서, 68-290-01 조항을 참조하십시오.

Page 3

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part15 of the FCC rules. The ClassA limits provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction guide, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause interference; the user must correct the interference at his own expense.

NOTE: For more information on safety guidelines, regulatory compliances, EMI/EMF

compatibility, accessibility, and related topics, see the Extron Safety and

Regulatory Compliance Guide on the Extron website.

FDA/IEC 60825-1 Requirements

CLASS 1 LASER PRODUCT

Complies with FDA performance standards for laser products except for deviations pursuant

to Laser Notice No. 5, dated June 24, 2007.

The product is intended to be used with the fiber optic cables fully installed.

This product meets the applicable requirements of IEC 60825-1, Edition 1 (2007).

Any service to this product must be carried out by Extron Electronics and its qualified

service personnel.

Copyright

© 2013 Extron Electronics. All rights reserved.

Trademarks

All trademarks mentioned in this guide are the properties of their respective owners.

The following registered trademarks®, registered service marks

RGBSystems, Inc. or Extron Electronics:

Registered Trademarks

AVTrac, Cable Cubby, CrossPoint, eBUS, EDID Manager, EDID Minder, Extron, Flat Field, GlobalViewer, Hideaway, Inline, IPIntercom, IPLink,

Key Minder, LockIt, MediaLink, PlenumVault, PoleVault, PowerCage, PURE3, Quantum, SoundField, SpeedMount, SpeedSwitch, System

Integrator, TeamWork, TouchLink, V-Lock, VersaTools, VN-Matrix, VoiceLift, WallVault, WindoWall, XTP, and XTP Systems

Registered Service Mark

AAP, AFL (Accu-Rate Frame Lock), ADSP (Advanced Digital Sync Processing), AIS (Advanced Instruction Set), Auto-Image, CDRS (Class D

Ripple Suppression), DDSP (Digital Display Sync Processing), DMI (Dynamic Motion Interpolation), DriverConfigurator, DSPConfigurator, DSVP

(Digital Sync Validation Processing), FastBite, FOXBOX, IP Intercom HelpDesk, MAAP, MicroDigital, ProDSP, QS-FPC (QuickSwitch Front Panel

Controller), Scope-Trigger, SIS, Simple Instruction Set, Skew-Free, SpeedNav, Triple-Action Switching, XTRA, ZipCaddy, ZipClip

(SM)

: S3 Service Support Solutions

Trademarks

(SM)

, and trademarks

(®)

(™)

(TM)

are the property of

Page 4

Notifications

The following notifications are used in this guide:

WARNING: A warning indicates a situation that has the potential to result in death or

severe injury.

ATTENTION: Attention indicates a situation that may damage or destroy the product or

associated equipment.

NOTE: A note draws attention to important information.

Specifications Availability

Product specifications are available on the Extron website, www.extron.com.

Conventions Used in this Guide

Software Commands

Commands are written in the fonts shown here:

^AR Merge Scene,,Op1 scene 1,1 ^B 51 ^W^C

[01] R 0004 00300 00400 00800 00600 [02] 35 [17] [03]

E X! *X1&* X2)* X2#* X2! CE}

NOTE: For commands and examples of computer or device responses mentioned

in this guide, the character “0” is used for the number zero and “O” represents

the capital letter “o.”

Computer responses and directory paths that do not have variables are written in the font

shown here:

Reply from 208.132.180.48: bytes=32 times=2ms TTL=32

C:\Program Files\Extron

Variables are written in slanted form as shown here:

ping xxx.xxx.xxx.xxx —t

SOH R Data STX Command ETB ETX

Selectable items, such as menu names, menu options, buttons, tabs, and field names are

written in the font shown here:

From the File menu, select New.

Click the OK button.

Page 5

Contents

Introduction............................................................ 1

About this Guide ................................................. 1

About the DMS Matrix Switchers ........................ 1

Features ............................................................. 3

Installation .............................................................. 6

Setup and Installation Checklist .......................... 6

Rear Panel Cabling and Features ........................ 7

I/O Boards ...................................................... 9

Remote Port ................................................. 11

Ethernet Port ................................................ 11

Reset Button and LED .................................. 12

Power ........................................................... 13

Cooling fans (DMS 1600 and DMS 3600 only) ..

Front Panel Configuration Port .......................... 13

13

Operation .............................................................. 14

Front Panel Controls and Indicators .................. 14

Input and Output Buttons ............................. 16

Control Buttons ............................................ 18

Power Indicators ........................................... 19

Button Labels ............................................... 20

Rear Panel Power Indicators

(DMS 1600 and DMS 3600) ............................ 20

Front Panel Operations ..................................... 21

Definitions ..................................................... 21

Power ........................................................... 22

Creating a Configuration ............................... 22

Viewing a Configuration ................................ 26

I/O Grouping ................................................. 27

Using Presets ............................................... 30

Muting and Unmuting Outputs ...................... 33

Locking the Front Panel (Executive Mode)..... 34

Performing a System Reset from

the Front Panel ............................................ 35

Background Illumination................................ 35

Selecting the Rear Panel Remote Port

Protocol and Baud Rate .............................. 36

Rear Panel Operations ...................................... 36

Performing Soft System Resets

(Modes 3, 4, and 5) ..................................... 38

Performing a Hard Reset (Mode 1) ................ 39

Troubleshooting ................................................ 39

General Checks ............................................ 39

Digital Signal Guidelines ................................ 40

Configuration Worksheets................................. 41

Worksheet Example 1: System Equipment ... 41

Worksheet Example 2: Daily Configuration .... 42

Worksheet Example 3: Test Configuration ..... 43

Programming Guide ........................................... 46

Local Host-Control Ports .................................. 46

Ethernet (LAN) Port........................................... 47

Host-to-Switcher Instructions ........................... 48

Switcher-Initiated Messages ............................. 48

Switcher Error Responses ................................ 49

Using the Command and Response Tables ...... 49

Command and Response Table for

SIS Commands ........................................... 50

Matrix Software ................................................... 61

Matrix Switchers Control Program .................... 61

Installing the Software ................................... 61

Software Operation via Ethernet ................... 62

Using the Matrix Switcher Control Software .. 63

Starting the program ..................................... 64

Using the program ........................................ 65

IP Settings/Options Window ......................... 67

Updating Firmware ....................................... 72

Uploading HTML Files ................................... 76

Windows Buttons, Drop Boxes,

and Trash Can ............................................. 77

Windows Menus ........................................... 77

Using Emulation Mode .................................. 82

Using the Help System ................................. 82

Button Label Generator Program ...................... 83

Installing the Button Label Generator

Software ...................................................... 83

Using the Button Label Generator Software .. 84

vDMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Table of Contents

Page 6

HTML Operation ................................................. 85

Opening the Embedded Web Pages ................. 85

Status Tab ........................................................ 87

System Status Page ..................................... 87

DSVP and Physical Configuration Page ........ 88

Configuration Tab ............................................. 89

System Settings Page .................................. 89

Passwords Page........................................... 92

Email Settings Page ...................................... 93

Firmware Upgrade Page ............................... 94

File Management Tab ....................................... 96

File Management Page ................................. 96

Control Tab ....................................................... 97

Set and View Ties Page ................................ 97

EDID and Mute Settings Page ...................... 98

Special Characters ........................................... 99

Maintenance and Modifications ................... 100

Mounting the Switcher .................................... 100

UL Guidelines ............................................. 100

Mounting Instructions ................................. 100

Removing and Installing the I/O Board or

Blank Panel ................................................... 101

Removing the I/O Board or Blank Panel ...... 102

Installing the I/O Board or Blank Panel ........ 102

Removing and Installing the Power Supply

Module (DMS 1600 and DMS 3600) .............. 103

Removing the Power Supply Module .......... 103

Installing the Power Supply Module ............ 104

Removing and Installing a Fan Module

(DMS 1600 and DMS 3600) .......................... 104

Removing a Fan Module ............................. 104

Installing a Fan Module ............................... 105

Removing and Installing Button Labels ........... 106

Installing Labels in the Buttons of the

Matrix Switcher .......................................... 106

Ethernet Connection ....................................... 108

Ethernet Link .................................................. 108

Ethernet Connection ................................... 108

Default IP Address ...................................... 108

Pinging to Determine the Extron

IP Address ................................................. 109

Pinging to Determine the Web IP Address .. 109

Configuring the DMS Matrix Switcher for

Network use via the ARP Command .......... 109

Connecting as a Telnet Client ...................... 111

Telnet Tips .................................................. 111

Subnetting — A Primer ................................... 113

Gateways ................................................... 113

Local and Remote Devices ......................... 113

IP Addresses and Octets ............................ 113

Subnet Masks and Octets .......................... 113

Determining Whether Devices are

on the Same Subnet .................................. 114

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Introduction vi

Page 7

Introduction

WARNING: Risk of serious physical injury — The DMS fiber optic I/O boards output

continuous invisible light, which may be harmful to the eyes; use with caution.

• Do not look into the fiber optic cable connectors or into the fiber optic cables

themselves.

• Plug the attached dust caps into the optical transceivers when the fiber cable is

unplugged.

• About this Guide

• About the DMS Matrix Switchers

• Features

About this Guide

This guide contains installation, configuration, and operating information for the Extron

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 Matrix Switchers (see figure 1 on the

next page). These customizable matrix switchers support DVI inputs and outputs and the

fiber optic outputs and inputs of Extron DFX transmitters and receivers. The switchers can

support multiple inputs and outputs, depending on the model:

• DMS 1600 — up to 16 inputs and outputs

• DMS 2000 — up to 20 inputs and outputs

• DMS 3200 — up to 32 inputs and outputs

• DMS 3600 — up to 36 inputs and outputs

NOTE: In this guide, “DMS matrix switcher” refers to any switcher model.

About the DMS Matrix Switchers

The DMS matrix switchers are configurable, modular matrix switchers that distribute a single

link of DVI (or HDMI with suitable adapters) digital video and DFX transmitter and receiver

outputs and inputs. The switchers are assembled from user-installed input and output (I/O)

boards. There are six I/O boards available:

• 4-input x 4-output DVI board • 4-input x 4-output mutimode fiber optic board

• 4-input DVI board • 4-input multimode fiber optic board

• 4-output DVI board • 4-output multimode fiber optic board

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Introduction 1

Page 8

AUDIO

DVI-D INPUT

FOXBOX 4G Tx DVI

RS-232

OVER FIBER

ALARM

Tx Rx 1 2

12V

1.0A MAX

POWER

AUDIO

DVI-D OUTPUT

FOXBOX 4G Rx DVI

RS-232

OVER FIBER

ALARM

Tx Rx 1 2

12V

1.0A MAX

POWER

MODE

AUDIO

DVI-D OUTPUT

FOXBOX 4G Rx DVI

RS-232

OVER FIBER

ALARM

Tx Rx 1 2

12V

1.0A MAX

POWER

MODE

1ON2

AUDIO

DVI-D INPUT

FOXBOX 4G Tx DVI

RS-232

OVER FIBER

ALARM

Tx Rx 1 2

12V

1.0A MAX

POWER

MODE

1ON2

ANAHEIM, CA

RESET

RS232/RS422

REMOTE

LAN

ACT

LINK

100-240V

50/60Hz

1.2A MAX.

100-240V

50/60Hz

1.2A MAX.

REDUNDANT

PRIMARY

DISCONNECT BOTH POWER

CORDS BEFORE SERVICING

1 - 4

5 - 8

9 - 12

13- 16

17 - 20

21 - 24

25 - 28

29- 32

33 - 36

FAN ASSEMBLY

FAN ASSEMBLY

PRIMARY POWER SUPPLY

REDUNDANT POWER SUPPLY

DVI-D OUTPUTS

ABCD

DVI-D OUTPUTS

ABCD

DVI-D OUTPUTS

ABCD

DVI-D OUTPUTS

ABCD

DVI-D OUTPUTS

ABCD

AB

DVI-D INPUTS DVI-D OUTPUTS

CD ABCD

AB

DVI-D INPUTS DVI-D OUTPUTS

CD ABCD

AB

DVI-D INPUTS DVI-D OUTPUTS

CD ABCD

AB

DVI-D INPUTS DVI-D OUTPUTS

CD ABCD

UPS 507

UNVERSAL SIGNAL PROCESSOR

ADJUST

DETAIL

ZOOM

/PAN

BRIGHT

/CONT

COLOR

/TINT

SIZE

POSITION

MUTE

FREEZE

AUTO

IMAGE

PIP

PRESET

6 754321

MENU

NEXT

INPUTS

CONFIG

HD Camera

FOXBOX 4G Tx DVI

FOXBOX 4G Rx DVI

USP 507

PC

Extron

DMS 3600

Modular DVI Matrix Switcher

Digital Monitors

DVI Projectors

HDTV Monitors

Analog Monitor

DVI Equipped

PCs

Compact HDTV

Camera Systems

Each switcher model supports a different number of I/O boards of any of the above type.

With only one input and output board, each is configured as a 4-input by 4-output matrix.

By adding or removing I/O boards within certain rules that are detailed in I/O Boards, on

page 9, you can expand and contract the DMS matrix as follows:

DMS 1600 — Supports up to four I/O boards, up to a 16-input by 16-output matrix.

DMS 2000 — Supports up to five I/O boards, up to a 20-input by 20-output matrix.

DMS 3200 — Supports up to eight I/O boards, up to a 32-input by 32-output matrix.

DMS 3600 — Supports up to nine I/O boards, up to a 36-input by 36-output matrix.

The matrix switcher routes any input signal to any combination of outputs. The matrix

switcher can route multiple input/output configurations simultaneously.

One or two internal, 100 VAC to 240 VAC, 50-60 Hz, 175-watt power supplies provide

worldwide power compatibility and reliability in the following configurations:

• DMS 3600 — Two replaceable, hot-swappable power supplies

• DMS 1600 — One replaceable, hot-swappable power supply with a second

Figure 1. Typical DMS 3600 Application

• DMS 2000 — One built-in power supply

replaceable supply as an option

• DMS 3200 — One built-in power supply

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Introduction 2

Page 9

The matrix switchers are single box solutions to complex digital video signal routing

applications. Each input and output is individually isolated and buffered, and any input can be

switched to any one or all outputs with virtually no crosstalk or signal noise between channels.

The matrix switchers can be remotely controlled via their rear panel Remote RS-232/RS-422

ports, their rear panel LAN port, and their front panel Configuration (USB) port using either

the Extron Matrix Switchers Control Program or the Simple Instruction Set (SIS). The icondriven Extron software uses a graphical, drag-and-drop interface to make I/O configuration

and other customization functions simple and convenient. The SIS is a set of basic ASCII

code commands that provide simple control through a control system or PC.

The switcher can be operated remotely by any of the following when connected to either a

serial port or the LAN port:

• Control system

• PC

• Extron MKP 2000 or MKP 3000 remote control panel

• (RS-232/RS-422 only) Extron MCP 1000 remote control panel

• (RS-232/RS-422 only) Extron MKP 1000 remote keypad

The matrix switchers are housed in rack-mountable, metal enclosures, of the following sizes,

with mounting flanges for standard 19-inch racks:

• DMS 1600 — 4U high

• DMS 2000 — 3U high

• DMS 3200 — 5U high

• DMS 3600 — 8U high

Features

DVI video inputs and outputs — With DVI I/O boards, the switchers input and output

DVI-D digital video signals on DVI-I connectors.

Fiber optic inputs and outputs — With fiber optic I/O boards, the switchers input and

output fiber optic signals generated and decoded by Extron DFX transmitters and receivers

on LC connnectors.

Automatic input board cable equalization — Typically equalizes greater than 100 feet

(30 m) at 1.65 Gb/s of Extron DVID SL or equivalent high quality cable.

Automatic output board re-clocking — Restores the signal timing and shape allowing for

increased transmission distances.

EDID Minder — Lets you direct the monitor reference of the computer video source and

what resolution to output.

Switching flexibility — The switcher provides individually buffered, independent matrix

switched outputs.

• Tie any input to any or all outputs.

• Quick multiple tie — Multiple inputs can be switched to multiple outputs

simultaneously. This allows all displays (outputs) to change from source to source at the

same time.

Digital Sync Validation Processing (DSVP) — In critical environments or unmanned,

remote locations, it may be vital to know that sources are active and switching. The Extron

DSVP feature confirms that input sources are active by scanning all sync inputs for active

signals. DSVP provides instantaneous feedback via any of the remote control ports on the

switcher.

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Introduction 3

Page 10

E-mail notification — The DMS matrix switchers have a built-in SMTP client feature

AC

Po

Supply

Supply

AC

r

that send out e-mail notifications through an SMTP server. The e-mail notification function

monitors a selected input. If the input loses or regains the sync signal, the switcher sends

out an e-mail regarding the loss or restoration of the input signal to the e-mail recipients. The

matrix switcher can send e-mails to up to 8 e-mail recipients.

Rooming — The switcher can be programmed to group multiple outputs to specific

“rooms” (user-designated groups), allowing them to have their own presets.

Field upgradable, hot-swappable modular design — The architecture of the DMS

matrix switcher allows you to repair, upgrade, reconfigure, or expand the matrix by simply

installing a new I/O board or replacing a board of one type with one of another.

Hot-swappable components let you replace any I/O board at any time without powering

down the switcher.

DMS 1600 and DMS 3600 power redundancy — The DMS 1600 and DMS 3600

have standard and optional power redundancy features. This redundancy, standard for

the DMS 3600 and optional for the DMS 1600, ensures zero downtime and no loss of

functionality through all but catastrophic power failure to support round-the-clock operation

in mission-critical applications.

• Two AC power inputs — Two inputs ensure the switcher operates through any power

interruption short of a simultaneous loss of power from both power sources.

• Two power input circuits — The two complete power circuits, from the plug, through

the power supply, to the power insertion onto the power distribution plane, are separate

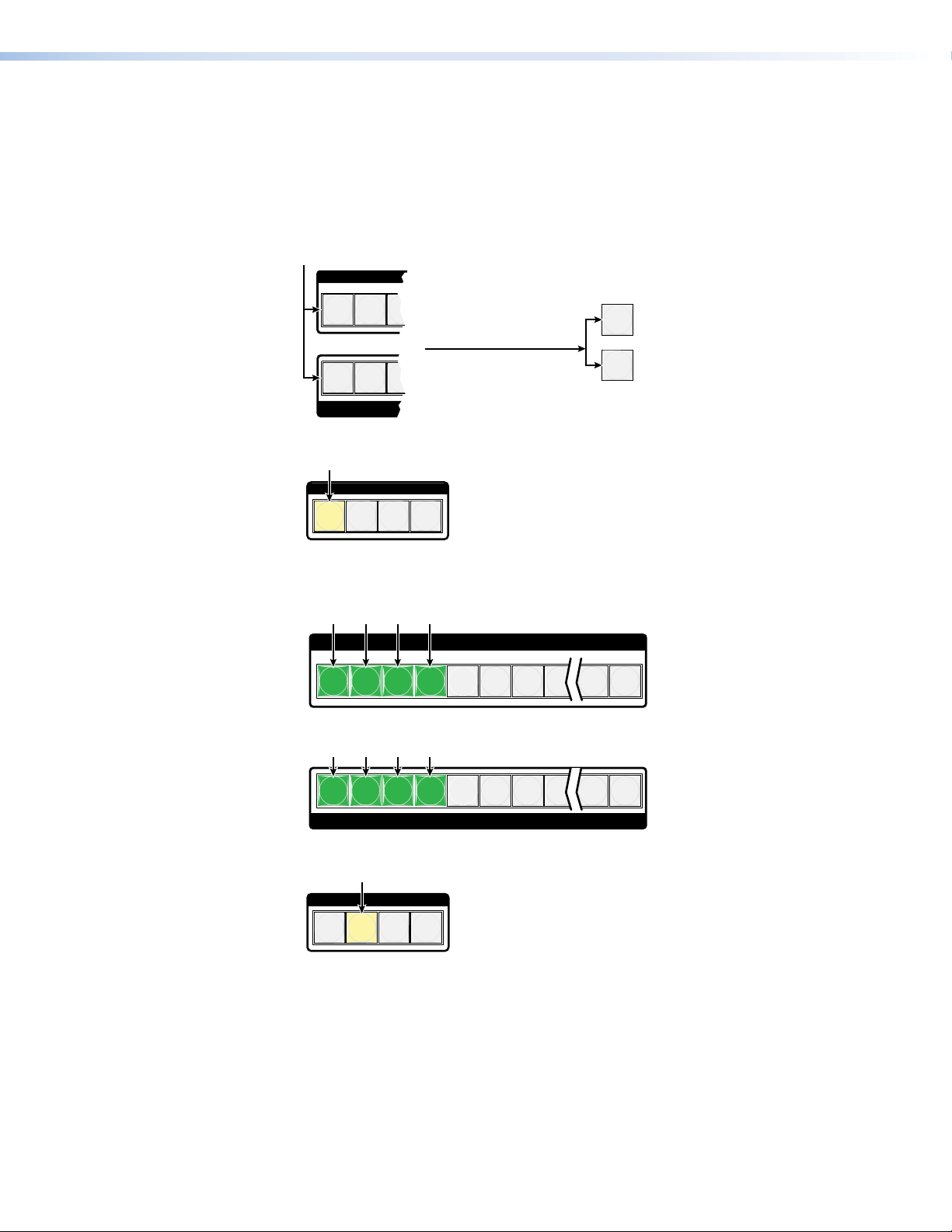

and independent from each other (see figure 2).

wer

Primary

Power

Redundant

Power

Powe

Figure 2. Redundant Power Supply Backs Up Primary Power Supply

• Two hot-swappable power supplies (standard for the DMS 3600 and optional

for the DMS 1600) — The 100 VAC to 240 VAC, 50-60 Hz power supplies of the

matrix switchers provide worldwide power compatibility.

• Primary and redundant circuits — The power supply circuitry is configured to

automatically switch over. Should the primary power supply fail, the hot redundant

power supply immediately assumes the load of the failed primary supply, meaning zero

downtime and no loss of functionality.

• Ease of maintenance — A failed power supply can be easily replaced from the rear at

any time without powering down the matrix, and with no tools required.

• Power supply status LEDs — Front panel and rear panel LEDs indicate the status of

the primary and redundant power supplies.

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Introduction 4

Page 11

Operational flexibility — Operations such as input/output selection and setting of presets

can be performed using a variety of local and remote control mechanisms:

• Front panel controller

• Matrix Switchers Control Program

• Simple Instruction Set (SIS)

• HTML pages

• Remote control panels and keypads (see the list on page 3)

The serial ports allow remote control via a PC or a control system. The Ethernet link

allows multiple remote links with two levels of password protection.

Upgradeable firmware — The firmware that controls all switcher operation can be

upgraded in the field via RS-232/RS-422 or Ethernet, without taking the switcher

out of service. Firmware upgrades are available for download on the Extron website,

www.extron.com, and can be installed using the Matrix Switchers Control Program or the

built-in HTML pages.

Labeling — The included Button Label Generator software lets you create labels to place in

the front panel I/O buttons, with names, alphanumeric characters, or color bitmaps for easy

and intuitive input and output selection. Alternatively, labels can be made with any Brother

®

P-Touch® or comparable labeler.

Global memory presets — 32 global memory presets are available as a time-saving

feature that lets you set up and store input/output configurations in advance. You can then

recall those configurations, when needed, with a few simple steps. The presets are available

via front panel operation or serial port or Ethernet control.

Rack mountability — The DMS matrix switchers are housed in rack-mountable metal

enclosures with mounting flanges for standard 19-inch racks.

Front panel security lockout modes (Executive mode) — If a matrix switcher is

installed in an open area, where operation by unauthorized personnel may be a problem, a

security lockout mode can be implemented. When the front panel is locked, a special button

combination or SIS command is required to unlock the front panel controller and make the

front panel fully operational.

I/O grouping — Allows the matrix switcher to be virtually divided into smaller subswitchers,

making installation and control easier. I/O grouping limits the selection of inputs and outputs

to members of the same group. I/O grouping allows specific outputs, such as those

designated for a specific purpose, to be grouped together.

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Introduction 5

Page 12

Installation

This section describes the installation of the DMX matrix switchers, including:

• Setup and Installation Checklist

• Rear Panel Cabling and Features

• Front Panel Configuration Port

Setup and Installation Checklist

Get ready

c Familiarize yourself with the DMS matrix switcher.

c Obtain IP setting information for the matrix switcher from the local network administrator

(see Ethernet Connection on page 108).

Configure the matrix switcher

c Install the desired I/O boards (page 101).

Perform physical installation

c Create (page 83) and replace (page 106) button labels (optional).

c Install the switcher in a rack (page 100) (optional).

c Cable input and output devices to the I/O boards (page 9).

c Connect computers or control systems to any of the remote control ports (a serial

[RS-232/RS-422] port [page 11], a USB port [page 13], and a LAN port [page 11]) on

the switcher (optional).

c Connect power (page 13).

c Test the switcher by creating a tie (page 23).

Ancillary operations

c Install the Matrix Switchers Control Program (page 61).

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Installation 6

Page 13

Rear Panel Cabling and Features

Figure 3, below, shows a DMS 1600. Figure 4, below, shows a DMS 2000. Figure 5, on the

next page, shows a DMS 3200. Figure 6, on the next page, shows a DMS 3600. The four

models have similar features, but different-sized enclosures and a different arrangement of

the features.The DMS 2000 and DMS 3200 do not have swappable power supplies or fan

assemblies. The DMS 3600 has two fan assemblies.

10

1

A B

1 - 4

ANAHEIM, CA

5

6

REMOTE

RS-232/RS-422

LAN

LINK ACT

RESET

5 - 8

9 - 12

13 - 16

REDUNDANT

REDUNDANT

100-240V

100-240V

1.2A MAX.

1.2A MAX.

PRIMARY

PRIMARY

100-240V

100-240V

1.2A MAX.

1.2A MAX.

50-60Hz

50-60Hz

50-60Hz

50-60Hz

A B

AB

AB

DISCONNECT BOTH POWER

DISCONNECT BOTH POWER

CORDS BEFORE SERVICING

CORDS BEFORE SERVICING

1

1

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

CD

TMDS

FIBER

INPUTS

CD

TMDS

FIBER

INPUTS

PRIMARY POWER SUPPLY

AB

DVI-D OUTPUTS

DVI-D OUTPUTS

1

2

CD

TMDS

FIBER

OUTPUTS

REDUNDANT POWER SUPPLY

DMS 44 DVI

DMS 44 DVI

DMS FIBER 44

1

8

1

3 4

9 97

Figure 3. DMS 1600 Matrix Switcher Rear Panel

1

1

A B

7

6

5

RESET

LAN

REMOTE

100-240V 50/60Hz

1 - 4

A B

5 - 8

A B

9 - 12

AB

13- 16

2.0A MAX

AB

17 - 20

8

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

CDAB

TMDS

FIBER

INPUTS

CDAB

TMDS

FIBER

INPUTS

1

3 4

1

2

DVI-D OUTPUTS

DVI-D OUTPUTS

DVI-D OUTPUTS

CD

TMDS

FIBER

OUTPUTS

CD

TMDS

FIBER

OUTPUTS

DMS 44 DVI

DMS 44 DVI

DMS 44 DVI

DMS FIBER 44

DMS FIBER 44

Figure 4. DMS 2000 Matrix Switcher Rear Panel

a DVI input connectors (see page 10) e Remote (RS-232/RS-422) port (see page 11)

b DVI output connectors (see page 10) f LAN (Ethernet) connector (see page 11)

c Fiber optic input connectors (see page 11) g Reset button and LED (see page 12)

d Fiber optic output connectors (see page 11) h Power connectors (see page 13)

i Power indicator LEDs (DMS 1600 and DMS 3600 only) (see page 13)

j Cooling fan assemblies (DMS 1600 and DMS 3600 only) (see page 106)

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Installation 7

Page 14

1

1

1

2

A B

5

6

7

1 - 4

REMOTE

LAN

RESET

3.0A MAX

100-240V 50/60Hz

A B

5 - 8

A B

9 - 12

A B

13- 16

A B

17 - 20

A B

21 - 24

AB

ABCDABCD

25 - 28

29- 32

8

Figure 5. DMS 3200 Matrix Switcher Rear Panel

1

10

A B

1 - 4

FAN ASSIMBLY

FAN ASSIMBLY

ANAHEIM, CA

A B

5 - 8

A B

9 - 12

A B

13- 16

A B

17 - 20

AB

21 - 24

25 - 28

29- 32

29- 32

33 - 36

33 - 36

N

DISCONNECT BOTH POWER

CORDS BEFORE SERVICING

REDUNDANT

100-240V

50/60Hz

1.2A MAX.

PRIMARY

100-240V

50/60Hz

1.2A MAX.

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

CDAB

TMDS

FIBER

INPUTS

1

3 4

1

1

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

DVI-D INPUTS

C D A B C D

CDAB

TMDS

FIBER

INPUTS

PRIMARY POWER SUPPLY

AB

AB

AB

AB

DVI-D OUTPUTS

DVI-D OUTPUTS

DVI-D OUTPUTS

DVI-D OUTPUTS

DVI-D OUTPUTS

DVI-D OUTPUTS

CD

TMDS

FIBER

OUTPUTS

CD

TMDS

FIBER

OUTPUTS

1

2

DVI-D OUTPUTS

DVI-D OUTPUTS

DVI-D OUTPUTS

DVI-D OUTPUTS

DVI-D OUTPUTS

CD

TMDS

FIBER

OUTPUTS

CD

TMDS

FIBER

OUTPUTS

CD

TMDS

FIBER

OUTPUTS

CD

TMDS

FIBER

OUTPUTS

LAN

REMOTE

RS232/RS422

ACT

LINK

REDUNDANT POWER SUPPLY

DMS 44 DVI

DMS 44 DVI

DMS 44 DVI

DMS 44 DVI

DMS 44 DVI

DMS 44 DVI

DMS 44 DVI

DMS FIBER 44

DMS FIBER 44

DMS 44 DVI

DMS 44 DVI

DMS 44 DVI

DMS 44 DVI

DMS 44 DVI

DMS FIBER 44

DMS FIBER 44

DMS FIBER 44

DMS FIBER 44

RESET

1

8 4

1

3

9 5 6 7 9

Figure 6. DMS 3600 Matrix Switcher Rear Panel

a DVI input connectors (see page 10) e Remote (RS-232/RS-422) port (see page 11)

b DVI output connectors (see page 10) f LAN (Ethernet) connector (see page 11)

c Fiber optic input connectors (see page 11) g Reset button and LED (see page 12)

d Fiber optic output connectors (see page 11) h Power connectors (see page 13)

i Power indicator LEDs (DMS 1600 and DMS 3600 only) (see page 13)

j Cooling fan assemblies (DMS 1600 and DMS 3600 only) (see page 106)

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Installation 8

Page 15

I/O Boards

Input

Location D

Output

Location A

rd

ATTENTION: Use electrostatic discharge (ESD) precautions (be electrically grounded)

when making connections. Electrostatic discharge can damage equipment, even if

you cannot feel, see, or hear it.

Remove system power before making all connections.

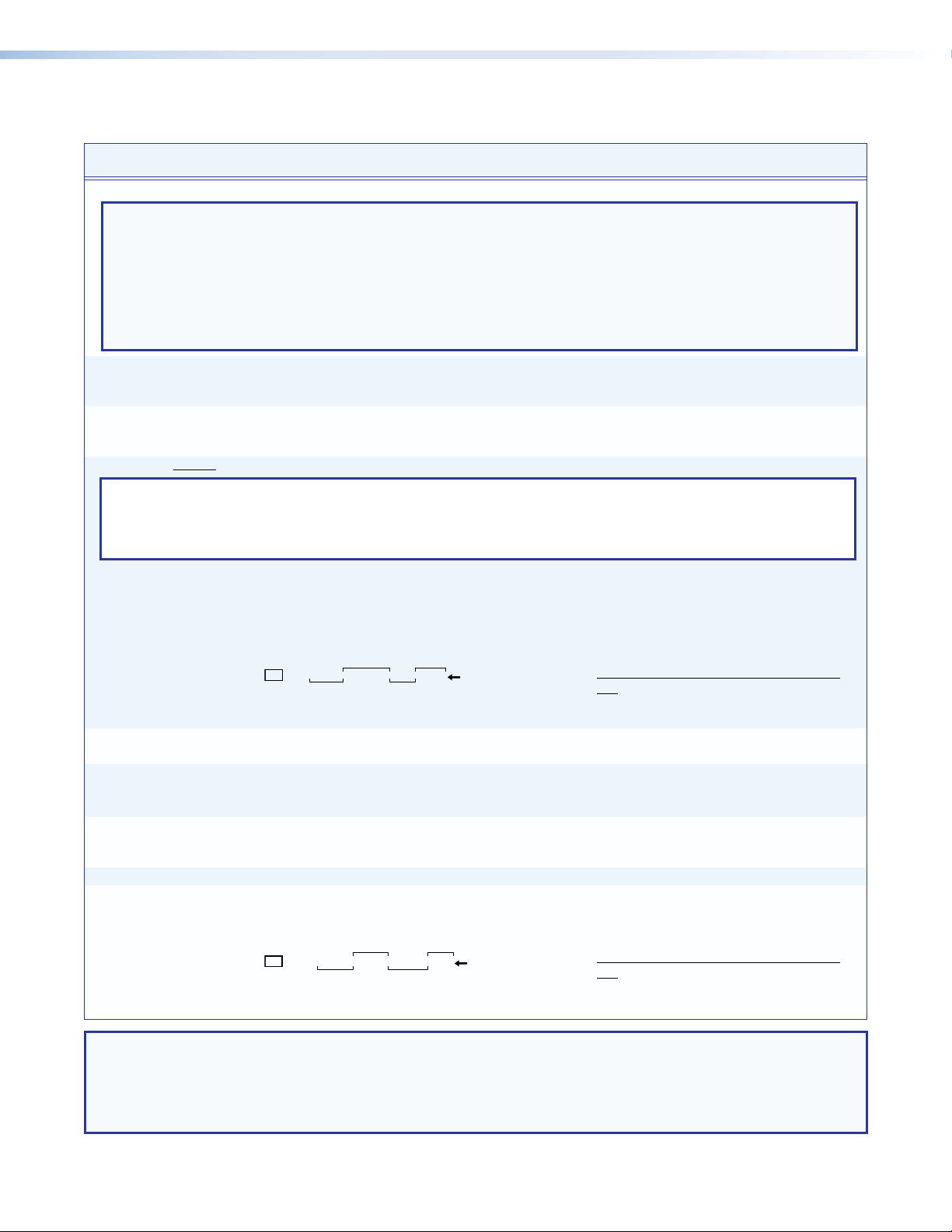

I/O board configuration overview

Figure 7 shows a mix of I/O boards. On the boards, the input and output DVI connectors

are identified as A through D. Each I/O board is identified by the input and output numbers

supported by the board position (1 - 4, 5 - 8, and so on).

Input

ANAHEIM, CA

1 - 4

5 - 8

9 - 12

13 - 16

100-240V 50/60Hz 1.2A MAX.

Input 1

Input 2 Input 3 Input 4

A B

AB

DVI-D INPUTS DVI-D OUTPUTS

C D A B C D

CDAB

TMDS

FIBER

INPUTS

PRIMARY POWER SUPPLY

Output 1

Output 2 Output 3 Output 4

CD

TMDS

FIBER

OUTPUTS

ABCD

DVI-D OUTPUTS

REDUNDANT POWER SUPPLY

DMS FIBER 44

Output

Slot 1

(1-4) Input/Output

Board

Slot 2

(5-8) Input/Output

Board

Slot 3

(9-12) Output Boa

Slot 4

No board installed

Location A

Input 5 Input 6Input 7Input 8

Output 9

Output 10

Output 11

Output 12

Location D

Figure 7. Arrangement of Inputs and Outputs on the I/O Boards

Slot Inputs and outputs Slot Inputs and outputs

1 1 through 4 5* 17 through 20

2 5 through 8

3 9 through 12

4 13 through 16

6

7

8

9

21 through 24

25 through 28

29 through 32

33 through 36

* DMS 2000, DMS 3200, and DMS 3600 only

DMS 3200 and DMS 3600 only

DMS 3600 only

Locations A through D correspond to the input and output numbers identified by the board

position numbers. (For example, the input and output numbers supported by the I/O board

in slot 2 [location 5 - 8] are as follows: A = 5, B = 6, C = 7, and D = 8.) Inputs and outputs

are grouped separately, with inputs A through D on the left and outputs A through D on the

right.

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Installation 9

Page 16

Below are installation guidelines for the switcher configuration; if you incorrectly order the

Pin Signal

1

TMDS data 2–

TMDS data 2+

TMDS data 1–

TMDS data 1+

DDC clock +5 V power

DDC dataTMDS clock+Ground (+5 V)

CEC control* TMDS clock–Hot Plug Detect

TMDS data 0–

TMDS data 0+

Spare

Spare

Spare

Spare

Spare

Spare

TMDS data 2

shield

TMDS data 1

shield

TMDS data 0

shield

TMDS clock

Shield

Pin PinSignal Signal

2

9

10

17

41220

51321

61422

71523

8

* CEC control on pin 8

is a proprietary usage,

not the industry

standard.

16 24

18

31119

1

9

8

17 24

Female Connector

Male Connector

I/O boards, the switcher will not recognize some inputs, outputs, or both.

• You must install a 4x4 DVI or fiber optic input and output board in the top slot (slot 1).

• You can install any of the six board types (a 4x4 DVI or fiber optic input and output

board, a 4 DVI or fiber optic input board, or a 4 DVI or fiber optic output board) or a

blank panel in the next slot (slot 2).

• You can install any of the board types in the slot directly underneath a 4x4 input and

output board.

• After you install a 4-input board or 4-output board, all active boards underneath it must

be the same size (4-input or 4-output).

• Within these size guidelines (4-input must follow 4-input or 4-output must follow

4-output), you can follow a DVI board with a fiber optic board or follow a fiber optic

board with a DVI board.

• If you install a blank panel, all slots under it must contain blank panels (you cannot skip

a slot).

I/O connections

WARNING: Risk of serious physical injury — The DMS fiber optic I/O boards output

continuous invisible light, which may be harmful to the eyes; use with caution. For

additional safety, plug the attached dust caps into the optical transceivers when the

fiber cable is unplugged.

NOTES:

• Fiber optic boards: Ensure that you use multimode fiber cable for your I/O board.

Typically, multimode cable has an orange or aqua jacket.

• DVI boards: Although the DVI I/O boards use DVI-I connectors, the switchers

handle only DVI-D (digital) video and the boards are labeled “DVI-D.”

a DVI-D Inputs ports — Connect DVI cables between these ports and the DVI output

ports of the digital video sources (see figure 8).

b DVI-D Outputs ports — Connect DVI displays for the routed direct digital image

(see figure 8).

Figure 8. DVI Connectors

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Installation 10

Page 17

Remote Port

RS-232FunctionPin Function

9

—

Not used

—

ansmit data (–)

ansmit data (+)

Not used

RS-422

REMOTE

LAN

T

c Fiber optic input ports — Connect fiber optic cables to the Input LC

connectors.

Connect the opposite ends of these fiber optic cables to the Output connectors on

DFX 100 Tx transmitters.

Input LEDs — Amber indicates fiber connections.

Green indicates input signal detection.

d Fiber optic output ports — Connect fiber optic cables to the Input LC

connectors.

Connect the opposite ends of these fiber optic cables to the Input connectors on

DFX 100 Rx receivers.

Input LEDs — Amber indicates fiber connections.

Green indicates signal transmission.

e Remote RS-232/RS-422 port — Connect a host device, such as a computer, touch

panel control, or RS-232 capable PDA to the switcher via this 9-pin D connector for

serial RS-232/RS-422 control (see figure 9).

1

—

9

5

RS-232/RS-422

6

1

TX

RX

—

Gnd

—

—

—

Not used

Transmit data

Receive data

Not used

Signal ground

Not used

Not used

Not used

2

3

4

5

6

7

8

—

Not used

TX–

Tr

Receive data (–)

RX–

Not used

—

Signal ground

Gnd

Not used

—

Receive data (+)

RX+

Tr

TX+

Figure 9. Remote RS-232/RS-422 Port

See Programming Guide, starting on page 46 for definitions of the SIS commands

and Matrix Software starting on page 61 for details on the control software.

NOTE: The switcher can support either the RS-232 or RS-422 serial protocol, and

can operate at 9600, 19200, 38400, or 115200 baud rates.

See Selecting the Rear Panel Remote Port Protocol and Baud Rate on page 36

to configure the RS-232/RS-422 port from the front panel.

If desired, connect an MKP 2000 or MKP 3000 remote control panel to the rear panel

Remote port on the switcher. See the MKP 2000 Remote Control Panel User Guide or

the MKP 3000 User Guide for details.

Ethernet Port

f LAN port — If desired, for IP control of the system, connect the matrix

switcher to a PC or to an Ethernet LAN via this RJ-45 connector. You can use

a PC to control the networked switcher with SIS commands from anywhere in

the world. You can also control the switcher from a PC that is running the Extron Matrix

Switchers Control Program or has downloaded HTML pages from the switcher.

Link LED indicator — Indicates that the switcher is properly connected to an

Ethernet LAN. This LED should light steadily.

Act LED indicator — Indicates transmission of data packets on the RJ-45 connector.

This LED should flicker as the switcher communicates.

LINK AC

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Installation 11

Page 18

Cabling

reversed) is a "crossover" cable.

no pin/pair assignments are swapped.

Inser

Crossover Cable Straight-through Cable

RESET

It is vital that your Ethernet cables be the correct cable type and that they be properly

terminated with the correct pinout. Ethernet links use Category (CAT) 3, 5e, or CAT 6,

unshielded twisted pair (UTP) or shielded twisted pair (STP) cables, terminated with RJ-45

connectors. Ethernet cables are limited to a length of 328 feet (100 m).

NOTES:

• Do not use standard telephone cables. Telephone cables do not support Ethernet

or Fast Ethernet.

• Do not stretch or bend cables. Transmission errors can occur.

The cable used depends on your network speed. The switcher supports both

10 Mbps (10Base-T — Ethernet) and 100 Mbps (100Base-T — Fast Ethernet), half-duplex

and full-duplex Ethernet connections.

• 10Base-T Ethernet requires CAT 3 UTP or STP cable at minimum.

• 100Base-T Fast Ethernet requires CAT 5e UTP or STP cable at minimum.

RJ-45 connector wiring

The Ethernet cable can be terminated as a straight-through cable or a crossover cable and

must be properly terminated for your application (see figure 10).

• Crossover cable — Direct connection between the computer and the DMS matrix

switcher

• Patch (straight) cable — Connection of the DMS matrix switcher to an Ethernet LAN

Pins:

12345678

Pin

t Twisted

Pair Wires

RJ-45

Connector

A cable that is wired as T568A at one end

and T568B at the other (Tx and Rx pairs

End 1 End 2 End 1 End 2

Wire color

1

White-green

2

Green

3

White-orange

4

Blue

5

White-blue

6

Orange

7

White-brown

8

Brown

T568A T568B

Wire color

White-orange

Orange

White-green

Blue

White-blue

Green

White-brown

Brown

Pin

Wire color

1

White-orange

2

3

White-green

4

Blue

5

White-blue

6

7

White-brown

8

Brown

A cable that is wired the same at both ends is

called a "straight-through" cable, because

Wire color

White-orange

OrangeOrange

White-green

Blue

White-blue

GreenGreen

White-brown

Brown

T568BT568B

Figure 10. RJ-45 Connector and Pinout Tables

Reset Button and LED

g Reset button — The Reset button initiates four levels of reset of the matrix

switcher. For four different reset levels, press and hold the button while the

switcher is running or while you power up the switcher (see Rear Panel

Operations on page 36 for details).

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Installation 12

Page 19

Power

h Primary and Redundant AC power connectors —

NOTES:

• Redundant power connectors are present on the DMS 1600 and DMS 3600

only.

• A redundant power supply is optional for the DMS 1600 and standard for the

DMS 3600.

• For the most reliable power with your DMS 1600 and DMS 3600, connect

a power cord between the Redundant power connector and either an

uninterruptible power source or to a power source that is completely

independent from the primary power source.

Plug standard IEC power cords into these connectors to connect the switcher to

100 VAC to 240 VAC, 50-60 Hz power sources.

i Primary and Redundant power supply indicator LEDs (DMS 1600 and

DMS 3600 only) —

Green — Indicates that the associated power supply is operating normally.

Red — Indicates that the associated power supply is operating outside the normal

tolerances or has failed (see Removing and Installing the Power Supply Module

(DMS 1600 and DMS 3600)) on page 103 to replace the power supply).

Cooling fans (DMS 1600 and DMS 3600 only)

NOTE: DMS 2000 and DMS 3200 cooling fans are fixed in place and not field

replaceable.

j Cooling fan or fans (DMS 1600 and DMS 3600 only) — See Removing and

Installing a Fan Module (DMS 1600 and DMS 3600) on page 104.

Front Panel Configuration Port

ENTER PRESET

CONFIG

PRIMARY

REDUNDANT

POWER SUPPLY

1 1

Figure 11. Front Panel Configuration Port

a Config(uration) port — This mini USB B port serves a similar communications

function as the rear panel Remote port, but it is easier to access than the rear port after

the matrix switcher has been installed and cabled.

CONTROL

ESC

VIEW

DMS 1600

TMDS DIGITAL MATRIX SWITCHER

CONFIG

ENTER PRESET

POWER

TMDS DIGITAL MATRIX SWITCHER

CONTROL

DMS 2000

VIEW

ESC

NOTE: A front panel Configuration port connection and a rear panel Remote

port connection can both be active at the same time. If commands are sent

simultaneously to both, the command that reaches the processor first is handled

first.

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Installation 13

Page 20

Operation

DMS 1600

TMDS DIGITAL MATRIX SWITCHER

POWER SUPPLY

PRIMARY

REDUNDANT

INPUTS

OUTPUTS

CONTROL

ENTER PRESET

VIEW

ESC

1

2

3

4

5

6 7 8

9

10

11 12

13 14 15 16

1

2

3

4

5

6 7 8

9

10

11 12

13 14 15 16

CONFIG

6

5

3

4

7

1

2

This section describes the front panel operation of the DMS matrix switchers, including:

• Front Panel Controls and Indicators

• Rear Panel Power Indicators (DMS 1600 and DMS 3600)

• Front Panel Operations

• Rear Panel Operations

• Troubleshooting

• Configuration Worksheets

Front Panel Controls and Indicators

The front panel controls (see figure 12 and figure 13, figure 14, and figure 15 on the

next page) are grouped into two sets. The input and output buttons are grouped on the left

side of the control panel. The control buttons are grouped on the right side of the panel.

Figure 12. Front Panel, DMS 1600 Switcher

a Input buttons (see page 17)

b Output buttons (see page 17)

c Enter button (see page 18)

d Preset button (see page 18)

e View button (see page 19)

f Esc button (see page 19)

g Power Supply indicators (DMS 1600 and DMS 3600) (see page 19)

h Power indicators (DMS 2000 and DMS 3600) (see page 19)

The illuminated buttons can be labeled with either text or graphics. The buttons can be set

to provide amber background illumination all the time or the background illumination can

intensity (depending on the operation) when selected.

be turned off (see Background Illumination on page 35). The buttons blink or are lit at full

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 14

Page 21

I

2

3

1

2

2

1

12

11

2

1

12

11

E

13

3

13

6

5

4

14

4

14

78

16

17 18

15

6

5

78

16

15

17 18

N

10

9

P

U

T

20

19

S

O

U

10

9

P

T

U

T

20

19

S

Figure 13. Front Panel, DMS 2000 Switcher

1

2

1

2

2

17 18

17 18

1

1

1

17 18

3

19

19

2

2

2

3

3

3

19

6

5

4

20

20

4

4

4

20

7

23

23

22

22

21

21

6

6

6

5

5

7

5

7

7

23

22

21

10

12

9

8

25

25

24

24

26 27

26 27

10

10

10

9

9

9

8

8

8

26 27

25

24

13

11

11

11

11

14

29

28

28

29

30

30

12

13

12

13

12

13

14

14

14

28

29

30

3

4

5

6

CONFIG

CONTROL

ENTERPRESET VIEW ESC

POWER

8

DMS 2000

TMDS DIGITAL MATRIX SWITCHER

3

I

N

16

15

P

U

T

32

32

31

31

S

O

U

16

16

16

15

15

15

T

P

U

T

32

31

S

CONFIG

CONTROL

ENTERPRESET VIEW ESC

POWER

4

5

6

8

E

DMS 3200

TMDS DIGITAL MATRIX SWITCHER

Figure 14. Front Panel, DMS 3200 Switcher

3

4

5

6

7

25

7 8

25

INPUTS

10

9

11 12 13 14 15 16

28 29 30 31 32 33 34 35 36

27

26

10

9

27

26

OUTPUTS

12 13 14 15 16

11

28 29 30 31 32 33 34 35 36

17

17

18

18

CONTROL

ENTER PRESET VIEW PRESET

POWER SUPPLY

CONFIG

PRIMARY

REDUNDANT

DMS 3600

TMDS DIGITAL MATRIX SWITCHER

2

1

19 20

1

19 20

3 4

21

2

3 4

21

1

2

22

22

5

23 24

5

24

23

6 7 8

6

Figure 15. Front Panel, DMS 3600 Switcher

a Input buttons (see page 17) e View button (see page 19)

b Output buttons (see page 17) f Esc button (see page 19)

c Enter button (see page 18) g Power Supply indicators (DMS 1600 and DMS 3600) (see page 19)

d Preset button (see page 18) h Power indicator (DMS 2000 DMS 3600) (see page 19)

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 15

Page 22

Input and Output Buttons

Primary functions

Action Select input or output for tie being created.

Indication Blink: potential tie/untie.

NOTE: See Front Panel Operations, beginning on page 21, for detailed descriptions

of the following operations.

Lit: current tie

DMS 1600

DMS 2000

DMS 3200

DMS 3600

Secondary functions

I/O Grouping Action 1 Input 1 and Output 1:

Select I/O Group mode.

Action 2 Assign an input or output to the selected group.

Indication Lit: Input or output is assigned to the selected group.

Presets Action Select a preset in Preset mode.

Indication Lit: A preset has already been saved to this location.

Output mutes Action Outputs: Press and hold to mute the output.

Indication Outputs, blink: Output is muted.

Port

configuration

Background

illumination

Action 1 Inputs shown above: Select

Action 2

Indication Blink: selected Blink: selected

Action Input 1 and Input 2:

NOTE

Toggle between background

illumination or buttons unlit.

1 2 3

through

1 2 3

through

11

through

1 2 3

through

17

through

1 2 3

through

19

through

Blink: Preset location is selected to be saved.

: DMS 1600, 3200 — Input 15 (232) / 16 (422)

DMS 2000 — Input 9 (232) / 10 (422)

DMS 3600 — Input 17 (232) / 18 (422)

15

and

9

and

15

and

17

and

Configuration mode

Input defined

at left:

Select RS-232

16

10

20

16

32

18

36

Input defined

at left:

Select RS-422

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 16

Page 23

a Input buttons — The input buttons have one primary function (❏) and five secondary

functions (•):

❏ Select and identify an input.

• Input 1 only — Press simultaneously with the Output 1 button to select I/O Group

mode.

• Select a preset.

• Input 1 and Input 2 only — Toggle background illumination of the buttons on and

off.

• Input 15 and 16 (DMS 1600 and DMS 3200), Input 9 and 10 (DMS 2000), or

Input 17 and 18 (DMS 3600) — Select Serial Port Selection and Configuration

mode.

• Input 15 (DMS 1600, DMS 3200), Input 9 DMS 2000), or Input 17 (DMS 3600) —

Select the RS-232 protocol for the RS-232/RS-422 port in Serial Port Selection and

Configuration mode and indicate its selection.

• Input 16 (DMS 1600, DMS 3200), Input 16 (DMS 2000), or Input 18

(DMS 3600) — Select the RS-422 protocol for the RS-232/RS-422 port in Serial

Port Selection and Configuration mode and indicate its selection.

b Output buttons — The output buttons have one primary function (❏) and three

secondary functions (•):

❏ Select and identify output.

• Output 1 only — Press simultaneously with the Input 1 button to select I/O Group

mode.

• DMS 1600 and DMS 2000 — Select a preset.

• Mute the output.

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 17

Page 24

Control Buttons

Primary functions

Action Save changes. Select Preset

Indication Blink: A save is

needed.

mode.

Blink: Save preset.

Lit: Recall preset.

Select View

View mode

Cancel/escape.

mode.

Flashes once.

selected.

ENTER PRESET

Secondary functions

I/O Grouping Action Select group 1. Select group 2. Select group 3. Select group 4.

Port

configuration

Front panel

lock

Indication Lit: group

selected.

Action Select 9600

baud.

Indication Blink: selected Blink: selected Blink: selected Blink: selected

Action With Esc, toggle

front panel lock

Lit: group

selected.

Select 19200

baud.

VIEW

Lit: group

selected.

Select 38400

baud.

toggle front panel

on and off.

ESC

Lit: group

selected.

Select 115200

baud.

With Enter,

lock

on and off.

Indication Flash twice to indicated the front

panel has been locked or unlocked.

c Enter button — The Enter button has three primary functions (❏) and three secondary

functions (•):

❏ Saves configuration or preset changes that you make on the front panel. To create

a simple configuration:

• Press the desired input button (item

• Press the desired output buttons (item

• Press the Enter button.

❏ Indicates that a potential tie has been created but not saved.

❏ Indicates that a global preset has been selected to be saved or recalled but that the

preset action has not been accomplished.

• In the I/O Group mode, selects group 1 and indicates its selection.

• Selects 9600 baud for the RS-232/RS-422 port in Serial Port Selection and

Configuration mode and indicate its selection.

• With the Esc button, toggles the front panel lock on and off.

a

on page 17).

b

on page 17).

d Preset button — The Preset button has two primary functions (❏) and three secondary

functions (•):

❏ Activates Save Preset mode to save a configuration as a preset and Recall Preset

mode to activate a previously-defined preset.

❏ Blinks when Save Preset mode is active and lights steadily when Recall Preset

mode is active.

• In the I/O Group mode, selects group 2 and indicates its selection.

• Selects 19200 baud for the RS-232/RS-422 port in Serial Port Selection and

Configuration mode and indicates its selection.

• With the View button, indicates that the front panel lock has been toggled on or off.

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 18

Page 25

e View button — The View button has one primary function (❏) and four secondary

POWER

functions (•):

❏ Selects and indicates View-only mode, which displays the current configuration.

NOTE: View-only mode also provides a way to mute and unmute the outputs.

• In the I/O Group mode, selects group 3 and indicates its selection.

• With the Esc button, commands the front panel system reset.

• Selects 38400 baud for the RS-232/RS-422 port in Serial Port Selection and

Configuration mode and indicates its selection.

• With the Preset button, indicates that the front panel lock has been toggled on or

off.

f Esc button — The Esc button has two primary functions (❏) and three secondary

functions (•):

❏ Cancels operations or selections in progress and resets the front panel button

indicators.

NOTE: The Esc button does not reset the current configuration or any presets.

❏ Flashes once to indicate that the escape function has been activated.

• In the I/O Group mode, selects group 4 and indicates its selection.

• Selects 115200 baud for the RS-232/RS-422 port in Serial Port Selection and

Configuration mode and indicates its selection.

• With the Enter button, toggles the front panel lock on or off.

Power Indicators

DMS 1600 and DMS 3600

g Primary and Redundant Power Supply LEDs —

Green — Indicates that the associated power supply is operating

within normal tolerances.

Red — Indicates that the associated power supply is operating

outside the normal tolerances, has failed, or (DMS 3600 only) is not

installed (see Removing and Installing the Power Supply Module (DMS 1600 and

DMS 3600), on page 103, to replace the power supply).

Unlit (DMS 1600 Redundant LED) — No power supply is installed.

POWER SUPPLY

REDUNDANT

DMS 2000 and DMS 3200

h Power LED — Indicates that the power supply is operating within normal

tolerances.

PRIMARY

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 19

Page 26

Button Labels

32

k

Panel is Standard

The numbered translucent covers on the input and output buttons can be removed and

replaced to insert labels behind them.

Input and output labels can be created easily with the Extron Button Label Generator

software, which ships with every Extron matrix switcher. Each input and output can be

labeled with names, alphanumeric characters, or color bitmaps for easy and intuitive input

and output selection (see figure 16) (see Button Label Generator Program, on page 83,

for details on using the labeling software, see Removing and Installing Button Labels,

on page 106, for blank labels and a procedure for removing and replacing the translucent

covers).

VCR

Computer Computer

Document

D

Camera

13 15

29 28 30 31

VTG 200

Figure 16. Sample Button Labels and Icons

Rear Panel Power Indicators (DMS 1600 and DMS 3600)

NOTE: The DMS 2000 and DMS 3200 each have a built-in, non-removeable power

supply, which does not have the Power Supply LEDs (a), below.

The primary and redundant power supply modules on the DMS 1600 and DMS 3600

(see figure 17) each have a 2-color LED.

1

100-240V 50/60Hz 1.2A MAX.

RESET

REMOTE

RS-232/RS-422

LAN

ACT LINK

DISCONNECT BOTH POWER

100-240V 50/60Hz 1.2A MAX.

CORDS BEFORE SERVICING

REDUNDANT

PRIMARY

PRIMARY POWER SUPPLY

1

REDUNDANT POWER SUPPLY

Redundant Power

1

Supply is Optional

for DMS 1600, Blan

Figure 17. Rear Panel Power Supply Indicators

a Primary and Redundant Power Supply LEDs —

Green — Indicates that the associated power supply is operating within normal

tolerances.

Red — Indicates that the associated power supply has failed (see Removing and

Installing the Power Supply Module (DMS 1600 and DMS 3600), on page 103, to

replace the power supply).

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 20

Page 27

Front Panel Operations

Definitions

The following paragraphs detail the power-up process and provide sample procedures for

the following actions:

• Creating ties, sets of ties, and configurations

• Changing a configuration

• Viewing ties, sets of ties, and configurations

• Creating I/O groups

• Saving a preset

• Recalling a preset

• Muting and unmuting outputs

• Locking and unlocking the front panel

• Performing a front panel reset

• Toggling background illumination on and off

• Reading and setting the Remote RS-232/RS-422 port settings

The following terms, which apply to Extron matrix switchers, are used throughout this guide:

• Tie — An input-to-output connection.

• Set of ties — An input tied to two or more outputs. (An output can never be tied to

more than one input.)

• Configuration — One or more ties or one or more sets of ties.

• Current configuration — The configuration that is currently active in the switcher (also

called configuration 0)

• Global memory preset — A configuration that has been stored. Up to 32 global

memory presets can be stored in memory. When a preset is retrieved from memory, it

becomes the current configuration. Presets can be saved and recalled from the front

panel and any of the serial or LAN ports. For front panel operations, preset locations are

assigned to the input buttons.

• Room — A subset of outputs that are logically related to each other, as determined by

the operator. The switchers support up to 10 rooms, each of which can consist of from

1 to 16 outputs.

• Room memory preset — A configuration consisting of outputs in a single room that

has been stored. When a room preset is retrieved from memory, it becomes the current

configuration.

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 21

Page 28

Power

Apply power by connecting one or both power cords between the one or two AC power

connectors (depending on the model) and the AC power sources. The switcher performs

a self-test that flashes the front panel buttons several times and then turns them either off

or to background illumination. An error-free power up self-test sequence leaves all control

buttons either unlit or showing background illumination.

The current configuration and all presets are saved in non-volatile memory. When power is

applied, the most recent configuration is retrieved. The previous presets remain intact.

If an error occurs during the self-test, the switcher locks up and fails to respond to

commands or button pushes. If your switcher locks up on power-up, call the Extron S3

Sales and Technical Support Hotline (see the last page of this guide for the phone number

in your region of the world).

Creating a Configuration

The current configuration can be changed using the front panel buttons. Change the current

configuration as follows:

1. Press the Esc button to clear any front panel button indications that may be lit.

2. Select the desired input and one or more outputs by pressing the input and output

buttons. Input buttons and output buttons light or blink green to indicate ties.

• To indicate potential ties, output buttons blink when an input is selected.

• To indicate current ties, output buttons light steadily when an input is selected.

3. To clear unwanted outputs, press and release the associated lit output buttons.

To indicate potential unties, output buttons blink when an output is deselected but

not untied from the input.

4. Press and release the Enter button to accept the tie.

5. Repeat steps 1 through 4 to create or delete additional ties until the desired

configuration is complete.

NOTES:

• Only one input can be tied to an output.

• If a tie is made between an input and an output, and the selected output was

previously tied to another input, the older tie is broken in favor of the newer tie.

• If an input with no tie is selected, only the button for that input lights.

• As each input and output is selected, the associated output button blinks to

indicate a tentative tie. Buttons for outputs that were already tied to the input

light steadily. Outputs that are already tied can be left on, along with new

blinking selections, or toggled off by pressing the associated output button.

• If you press the input button for an input that is I/O grouped

(see I/O Grouping on page 27), you cannot select the output button for an

output in a different group. The associated input button remains lit.

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 22

Page 29

Example 1: Creating a set of ties

Press the button.

C O N T R O L

PRESET

ENTER ESCVIEW

1 2 3 4 5 6 7 8 15 16

OUTPUTS

1

Press and release the buttons.

The buttons blink to indicate that the selected input will be tied

to these outputs.

The Enter button blinks

to indicate the need to

confirm the change.

ENTER

All input buttons and output buttons

return to unlit or background illumination.

Press the button.

The Enter button returns to

unlit or background

illumination.

Input 5 tied

to outputs 3, 4, and 8

Input

Output

3

4

8

5

In the following example, input 5 is tied to outputs 3, 4, and 8. The steps show the front

panel indications that result from your action.

NOTE: This example assumes that there are no ties in the current configuration.

1. Clear all selections: Press and release the Esc button. The button flashes once.

2. Select an input: Press and release the input 5 button.

The button lights.

INPUTS

1 2 3 4 5 6 7 8 15 16

3. Select the outputs: Press and release the output 3, output 4, and output 8 buttons.

NOTE: You can cancel the entire set of ties at this point by pressing and releasing

the Esc button. The Esc button flashes once and all selected input and output

buttons return to unlit or background illumination.

4. Confirm the change: Press and release the Enter button.

The current configuration is now input 5 tied to output 3, output 4, and output 8 (see

figure 18).

Figure 18. Example 1: Create Ties

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 23

Page 30

Example 2: Adding a tie to a set of ties

1 2 3 4 5 6 7 8 15 16

1 2 3 4 5 6 7 8 15 16

INPUTS

OUTPUTS

Press the button.

The button lights.

The Output 3, Output 4, and Output 8 buttons light

to indicate the ties created in example 1.

C O N T R O L

PRESET

ENTER

ESCVIEW

1 2 3 4 5 6 7 8 15 16

OUTPUTS

The Enter button blinks

to indicate the need to

confirm the change.

Press the button.

The button blinks to indicate that the

selected input will be tied to this output.

ENTER

All input buttons and output buttons

return to unlit or background illumination.

Press the button.

The Enter button returns to

unlit or background

illumination.

Input 5 tied

to outputs 1, 3, 4, and 8

Input

Output

1

3

4

8

5

In the following example, a new tie is added to the current configuration. The steps show

the front panel indications that result from your action.

NOTE: This example assumes that you have performed example 1.

1. Clear all selections: Press and release the Esc button. The button flashes once.

2. Select an input: Press and release the input 5 button.

3. Select the output: Press and release the output 1 button.

4. Confirm the change: Press and release the Enter button.

The current configuration is now input 5 tied to output 1, output 3, output 4, and output 8

(see figure 19).

Figure 19. Example 2: Add a Tie

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 24

Page 31

Example 3: Removing a tie from a set of ties

1 2 3 4 5 6 7 8 15 16

1 2 3 4 5 6 7 8 15 16

INPUTS

OUTPUTS

Press the button.

The button lights.

The Output 1, Output 3, Output 4, and Output 8 buttons light

to indicate the ties created in example 1 and example 2.

OUTPUTS

C O N T R O L

PRESET

ENTER

ESCVIEW

1 2 3 4 5 6 7 8 15 16

The Enter button blinks

to indicate the need to

confirm the change.

Press and release the Output 4 button.

The button blinks to indicate that the

selected input will be untied from this output.

ENTER

All input buttons and output buttons

return to unlit or background illumination.

Press the button.

The Enter button returns to

unlit or background

illumination.

Input 5 tied

to outputs 1, 3, and 8

Input

Output

1

3

8

5

In the following example, an existing tie is removed from the current configuration. The steps

show the front panel indications that result from your action.

NOTE: This example assumes that you have performed example 1 and example 2.

1. Clear all selections: Press and release the Esc button. The button flashes once.

2. Select an input: Press and release the input 5 button.

3. Select the output: Press and release the output 4 button.

4. Confirm the change: Press and release the Enter button.

The current configuration is now input 5 tied to output 1, output 3, and

output 8 (see figure 20).

Figure 20. Example 3: Remove a Tie

DMS 1600, DMS 2000, DMS 3200, and DMS 3600 • Operation 25

Page 32

Viewing a Configuration

C O N T R O L

PRESET

ENTER

ESCVIEW

1 2 3 4 5 6 7 8 15 16

OUTPUTS

Until you select an input, only the buttons for untied outputs light.

Press the button. It lights.

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8 15 16

INPUTS

15 16

OUTPUTS

The output buttons for outputs that are not tied to