Page 1

Installation Guide

Extron Electronics, USA

1230 South Lewis Street

Anaheim, CA 92805

800.633.9876 714.491.1500

FAX 714.491.1517

Extron Electronics, Europe

Beeldschermweg 6C

3821 AH Amersfoort, The Netherlands

+800.3987.6673 +31.33.453.4040

FAX +31.33.453.4050

Extron Electronics, Asia

135 Joo Seng Rd. #04-01

PM Industrial Bldg., Singapore 368363

+800.7339.8766 +65.6383.4400

FAX +65.6383.4664

Extron Electronics, Japan

Kyodo Building, 16 Ichibancho

Chiyoda-ku, Tokyo 102-0082

Japan

+81.3.3511.7655 FAX +81.3.3511.7656

www.extron.com

© 2007 Extron Electronics. All rights reserved.

CVC 200

Component Video and HDTV to RGB Converter

68-437-01 Rev. D

08 07

Page 2

O

U

T

P

U

T

I

N

P

U

T

F

O

R

M

A

T

Extron

CVC 200

Video Converter

HDTV

Set Top Box

Large Screen

Rear Projector

LCD Projector

Video Monitor

DVD

or

or

(2) 4-40 x 3/16" Screws

Use 2 mounting holes on

opposite corners.

False front panel

uses 2 front holes.

#10-32 Screw

w/ Nylon Captive

Cap Washer

C

V

C

2

0

0

Introduction

Mounting

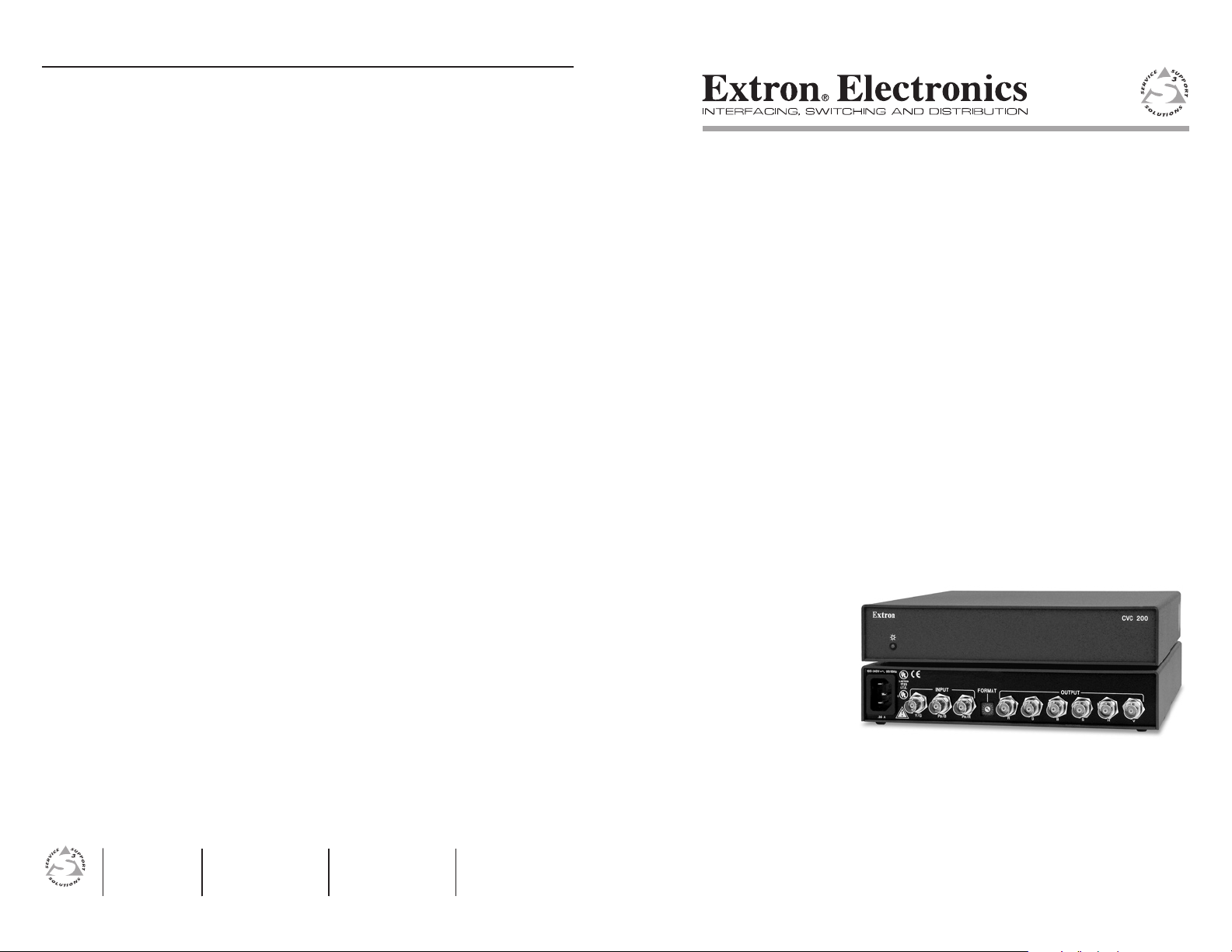

The CVC 200 Component Video Converter converts all SMPTE

standard component video formats to RGBS or RGBHV video. The

CVC 200 can also strip sync-on-green (SOG) from RGsB video.

The converter outputs converted RGBS or RGBHV video on BNC

connectors. Figure 1 shows a typical CVC 200 application.

Figure 1 — Typical CVC 200 application

The component video input formats include DVD, Betacam® video, and

HDTV component video. The RGsB video input can be computer video

or NTSC/PAL video.

3. Mechanical loading — Mount the equipment in the rack so that

a hazardous condition is not achieved due to uneven mechanical

loading.

4. Circuit overloading — Connect the equipment to the supply

circuit and consider the effect that circuit overloading might

have on overcurrent protection and supply wiring. Appropriate

consideration of equipment nameplate ratings should be used

when addressing this concern.

5. Reliable earthing (grounding) — Maintain reliable grounding

of rack-mounted equipment. Pay particular attention to supply

connections other than direct connections to the branch circuit

(e.g. use of power strips).

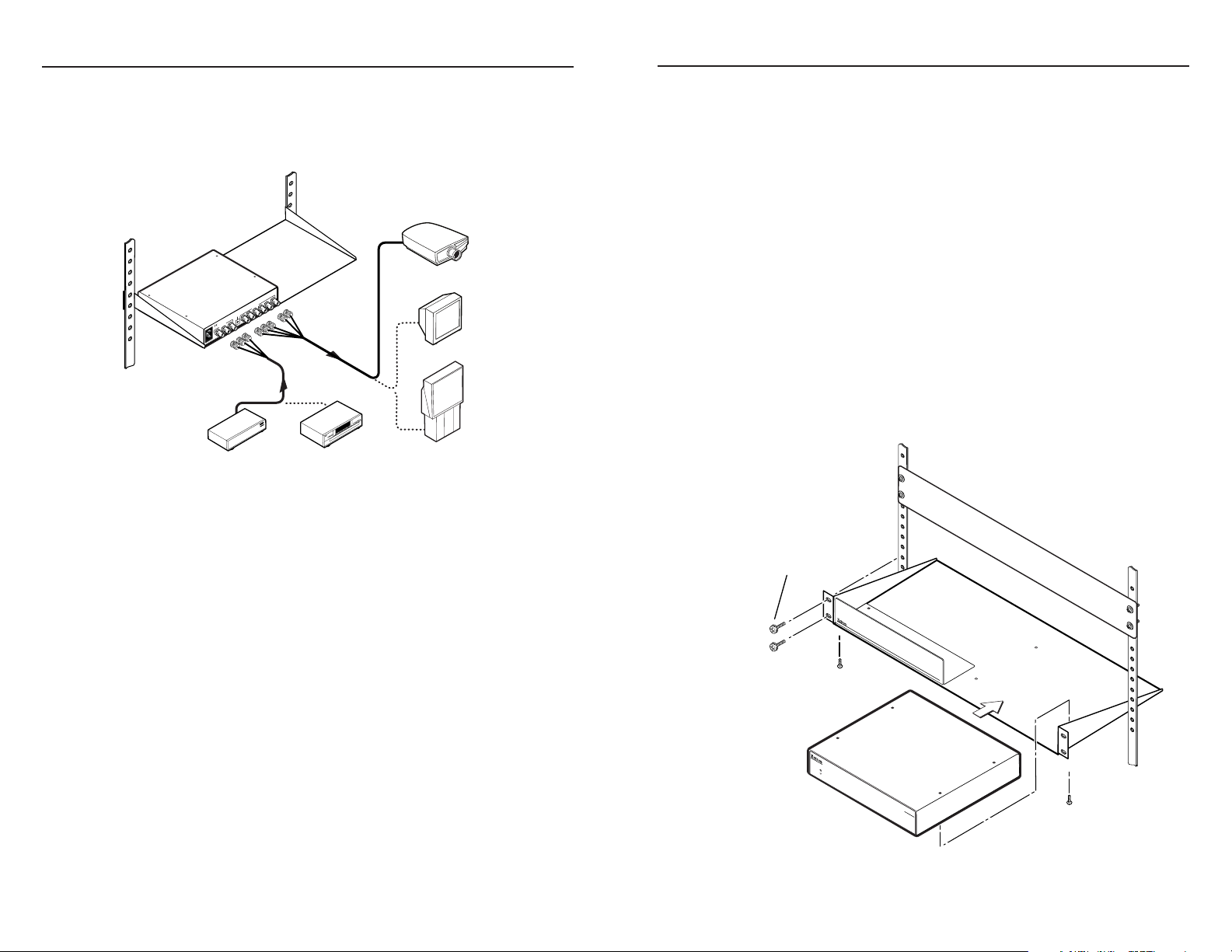

Mounting instructions

Rack mount the CVC 200 as follows:

1. Remove the feet from the CVC, if they were previously installed.

2. Mount the CVC 200 on the rack shelf, using two 4-40 x 3/16”

screws in opposite corners (under the shelf) to secure the CVC to

the shelf (figure 2).

Mounting

1

The CVC 200 can be rack mounted using one side of a 1U Universal

Rack Shelf (part #60-190-01) or 1U Basic Rack Shelf (part #60-604-01).

UL requirements

The following Underwriters Laboratories (UL) requirements pertain to

the installation of the CVC into a rack.

1. Elevated operating ambient temperature — If the equipment

installed in a closed or multi-unit rack assembly, the operating

ambient temperature of the rack environment may be greater

than room ambient temperature. Therefore, install the CVC in an

environment compatible with the maximum ambient temperature

(Tma = +122 °F, +50 °C) specified by Extron.

2. Reduced air flow — Install the equipment in a rack so that the

amount of air flow required for safe operation of the equipment is

not compromised.

CVC 200 • Installation

Figure 2 — Rack mounting the CVC 200

CVC 200 • Installation

2

Page 3

Cable Connection and Rate Selection

OUTPUT

R

G B

S

H V

PR/R

PB/B

Y/G

INPUT FORMAT

LIST ED

1T23

I.T. E.

C

.35A

100-240V 50-60Hz

2 4

1

3

PR/R

PB/B

Y/G

PR/R

PB/B

Y/G

Y, PB, P

R

RGsB

(SOG)

video

Y, B-Y, R-Y

video

video

PR/R

PB/B

Y/G

(R-Y)

(B-Y)

Position

0

1

2

3

4

5

6

7

8

9

A

B-F

Input

format(s)

Not used

Y, Pb, Pr

Y, Pb, Pr

Y, Pb, Pr

Not used

RGsB

RGsB

Y, Pb, Pr

Y, Pb, Pr

Y, Pb, Pr

Y, Pb, Pr

Not used

Standard or rate

NTSC/PAL

HDTV (480p, 576p, 720p, 1035i, 1080i)

Betacam

NTSC/PAL

Computer rates

NTSC/PAL

HDTV (720p)

HDTV (1080i)

HDTV (1080p)

Format

switch

R

V

G B

S

H

R

V

G B

S

H

RGBHV

video

RGBS

video

Cable Connection and Rate Selection (Cont’d)

Cable Connection and Rate Selection

See figure 3 to identify the rear panel connections and Format rotary

switch

Figure 3 — CVC 200 rear panel features

Power connector — Plug a standard IEC power cord into this

a

connector to connect the CVC 200 to a 100 to 240VAC, 50 Hz or

60 Hz power source.

Input connectors — Connect a component video input device

b

(HDTV, W-VHS [Y, Pr, Pb], SMPTE [Y, R-Y, B-Y]), Betacam®

[Y, R-Y, B-Y]) or an RGsB input device to these female BNC

connectors. Use high-resolution cable, such as Extron’s BNC4 mini HR, RG59/HR, or RG6/SHR cable. Connect the input

device as shown in figure 4.

Format rotary switch — Use an Extron Tweeker or other small

c

screwdriver to set the Format rotary switch to match the video

input format. The table below shows the switch settings and their

assigned input video formats.

Output connectors — Connect an RGBHV or RGBS display to

d

these female BNC connectors. Use high-resolution cable, such

as Extron’s BNC-4 or BNC-5 mini HR, RG59/HR, or RG6/SHR

cable. Connect the display as shown in figure 5.

Figure 4 — Input connections

Figure 5 — Output connections

3

CVC 200 • Cable Connection and Rate Selection

CVC 200 • Rate Selection

4

Page 4

Specifications

Specifications (Cont’d)

Specifications

Video

Gain ................................................ Unity

Bandwidth ..................................... 55 MHz (-3 dB)

Video input

Number/signal type ..................... 1 component video [HDTV, W-VHS (Y, Pr, Pb),

SMPTE (Y, R-Y, B-Y), and Betacam®

(Y, R-Y, B-Y)] or RGsB

Connectors .................................... 3 BNC female

Nominal level ................................ 1V p-p for Y of component video

0.3V p-p for R-Y and B-Y of component video

0.7V p-p for PB PR

Minimum/maximum levels ........ Y: 0.5 V to 1.5 Vp-p with no offset at unity gain

PB PR: 0.4 V to 1.0 Vp-p with no offset at unity

gain

Impedance ..................................... 75 ohms

Horizontal frequency .................... 15.75 kHz to 100 kHz according to selected mode

Vertical frequency .......................... 60 Hz

Return loss ..................................... <-25 dB @ 5 MHz

DC offset (max. allowable)........... ±2 V (maximum)

Video output

Number/signal type ..................... 1 RGBHV, RGBS

Connectors .................................... 6 BNC female

Nominal level ................................ 0.7 Vp-p for RGB

Minimum/maximum levels ........ RGB: 0.4 V to 1.0 Vp-p

Impedance ..................................... 75 ohms

Return loss ..................................... <-30 dB @ 5 MHz

DC offset ........................................ 0.1 V with input at 0 offset

General

Power ............................................. 100 VAC to 240 VAC, 50/60 Hz, 12 watts,

internal, autoswitchable

Temperature/humidity ................ Storage -40° to +158°F (-40° to +70°C) / 10% to

90%, noncondensing

Operating +32° to +122°F (0° to +50°C) / 10% to

90%, noncondensing

Rack mount .................................... Yes, with optional rack shelf,

part #60-190-01 or #60-604-01

Enclosure type .............................. Metal

Enclosure dimensions .................. 1.6” H x 8.75” W x 9.4” D

(1U high, half rack wide)

4.1 cm H x 22.2 cm W x 23.9 cm D

(Depth excludes connectors.)

Product weight .............................. 2.8 lbs (1.3 kg)

Shipping weight ........................... 5 lbs (3 kg)

Vibration ........................................ ISTA 1A in carton

(International Safe Transit Association)

Listings............................................ UL, CUL

Compliances ................................... CE

MTBF ............................................... 30,000 hours

Warranty ........................................ 3 years parts and labor

N

N

All nominal levels are at ±10%.

Specifications are subject to change without notice.

5

CVC 200 • Specifications

CVC 200 • Specifications

6

Loading...

Loading...