Page 1

Retractors

Cable Retraction System for Cable Cubby

®

Enclosures

User Guide

Architectural Connectivity

68-1784-01 Rev. B

03 13

Page 2

Safety Instructions

Safety Instructions • English

WARNING: This symbol, , when used on the product, is intended to

alert the user of the presence of uninsulated dangerous voltage within

the product’s enclosure that may present a risk of electric shock.

ATTENTION: This symbol, , when used on the product, is intended

to alert the user of important operating and maintenance (servicing)

instructions in the literature provided with the equipment.

For information on safety guidelines, regulatory compliances, EMI/EMF

compatibility, accessibility, and related topics, see the Extron Safety and

Regulatory Compliance Guide, part number 68-290-01, on the Extron website,

www.extron.com.

Instructions de sécurité • Français

AVERTISSEMENT: Ce pictogramme, , lorsqu’il est utilisé sur le

produit, signale à l’utilisateur la présence à l’intérieur du boîtier

du produit d’une tension électrique dangereuse susceptible de

provoquer un choc électrique.

ATTENTION: Ce pictogramme, , lorsqu’il est utilisé sur le produit,

signale à l’utilisateur des instructions d’utilisation ou de maintenance

importantes qui se trouvent dans la documentation fournie avec le

matériel.

Pour en savoir plus sur les règles de sécurité, la conformité à la réglementation,

la compatibilité EMI/EMF, l’accessibilité, et autres sujets connexes, lisez les

informations de sécurité et de conformité Extron,

réf. 68-290-01, sur le site Extron, www.extron.fr.

Sicherheitsanweisungen • Deutsch

WARNUNG: Dieses Symbol auf dem Produkt soll den Benutzer

darauf aufmerksam machen, dass im Inneren des Gehäuses dieses

Produktes gefährliche Spannungen herrschen, die nicht isoliert sind

und die einen elektrischen Schlag verursachen können.

VORSICHT: Dieses Symbol auf dem Produkt soll dem Benutzer in

der im Lieferumfang enthaltenen Dokumentation besonders wichtige

Hinweise zur Bedienung und Wartung (Instandhaltung) geben.

Chinese Simplified(简体中文)

警告: 产品上的这个标志意在警告用户该产品机壳内有暴露的危险

电 压 ,有 触 电 危 险 。

注意: 产品上的这个标志意在提示用户设备随附的用户手册中有

重要的操作和维护(维修)说明。

关于我们产品的安全指南、遵循的规范、EMI/EMF 的兼容性、无障碍

使用的特性等相关内容,敬请访问 Extron 网站 www.extron.cn,参见 Extron

安全规范指南,产品编号 68-290-01。

Chinese Traditional(繁體中文)

警告: 若產品上使用此符號,是為了提醒使用者,產品機殼內存在著

可能會導致觸電之風險的未絕緣危險電壓。

注意 若產品上使用此符號,是為了提醒使用者。

有關安全性指導方針、法規遵守、EMI/EMF 相容性、存取範圍和相關主題的詳細

資訊,請瀏覽 Extron 網站:www.extron.com,然後參閱《Extron 安全性與

法規遵守手冊》,準則編號 68-290-01。

Japanese

警告: この記 号 が製品上に表示されている場合は、筐体内に絶縁されて

いない高電圧が流れ、感電の危険があることを示しています。

注意: この 記号 が製品上に表示されている場合は、本機の取扱説明書に

記載されている重要な操作と保守(整 備)の指示についてユーザーの

注意を喚起するものです。

安全上のご注意、法規厳守、EMI/EMF適合性、その他の関連項目に

つ い て は 、エク スト ロ ン の ウェ ブ サ イト www.extron.jpより

『Extron Safety and Regulatory Compliance Guide 』 (P/N 68-290-01) をご覧くだ さい 。

Weitere Informationen über die Sicherheitsrichtlinien, Produkthandhabung,

EMI/EMF-Kompatibilität, Zugänglichkeit und verwandte Themen finden Sie in

den Extron-Richtlinien für Sicherheit und Handhabung (Artikelnummer

68-290-01) auf der Extron-Website, www.extron.de.

Instrucciones de seguridad • Español

ADVERTENCIA: Este símbolo, , cuando se utiliza en el producto,

avisa al usuario de la presencia de voltaje peligroso sin aislar dentro

del producto, lo que puede representar un riesgo de descarga

eléctrica.

ATENCIÓN: Este símbolo, , cuando se utiliza en el producto, avisa

al usuario de la presencia de importantes instrucciones de uso

y mantenimiento recogidas en la documentación proporcionada

con el equipo.

Para obtener información sobre directrices de seguridad, cumplimiento

de normativas, compatibilidad electromagnética, accesibilidad y temas

relacionados, consulte la Guía de cumplimiento de normativas y seguridad de

Extron, referencia 68-290-01, en el sitio Web de Extron, www.extron.es.

Korean

경고: 이 기호 , 가 제품에 사용될 경우, 제품의 인클로저 내에 있는

접지되지 않은 위험한 전류로 인해 사용자가 감전될 위험이 있음을

경고합니다.

주의: 이 기호 , 가 제품에 사용될 경우, 장비와 함께 제공된 책자에 나와

있는 주요 운영 및 유지보수(정비) 지침을 경고합니다.

안전 가이드라인, 규제 준수, EMI/EMF 호환성, 접근성, 그리고 관련

항목에 대한 자세한 내용은 Extron 웹 사이트(www.extron.com)의

Extron 안전 및 규제 준수 안내서, 68-290-01 조항을 참조하십시오.

Page 3

Copyright

© 2013 Extron Electronics. All rights reserved.

Trademarks

All trademarks mentioned in this guide are the properties of their respective owners.

The following registered trademarks

(R)

, registered service marks

(SM)

, and trademarks

(TM)

are the property of

RGBSystems, Inc. or Extron Electronics:

Registered Trademarks

AVTrac, Cable Cubby, CrossPoint, eBUS, EDID Manager, EDID Minder, Extron, Flat Field,GlobalViewer, Hideaway, Inline, IP Intercom, IP Link,

Key Minder, LockIt, MediaLink, PoleVault, PowerCage, PURE3, Quantum, SoundField, System Integrator, TouchLink, V-Lock, VersaTools,

VN-Matrix, VoiceLift, WallVault, WindoWall

Registered Service Mark

(SM)

: S3 Service Support Solutions

Trademarks (™

AAP, AFL (Accu-Rate Frame Lock), ADSP (Advanced Digital Sync Processing), AIS (Advanced Instruction Set), Auto-Image, CDRS (Class D

Ripple Suppression), DDSP (Digital Display Sync Processing), DMI (Dynamic Motion Interpolation), Driver Configurator, DSP Configurator, DSVP

(Digital Sync Validation Processing), FastBite, FOXBOX, IP Intercom HelpDesk, MAAP, MicroDigital, ProDSP, QS-FPC (QuickSwitch Front Panel

Controller), Scope-Trigger, SIS, Simple Instruction Set, Skew-Free, SpeedMount, SpeedNav, SpeedSwitch, Triple-Action Switching, XTP, XTP

Systems, XTRA, ZipCaddy, ZipClip

(®)

)

Page 4

Conventions Used in this Guide

Notifications

The following notifications are used in this guide:

DANGER: A danger indicates a situation that will result in death or severe injury.

WARNING: A warning indicates a situation that has the potential to result in death or

severe injury.

CAUTION: A caution indicates a situation that may result in minor injury.

ATTENTION: Attention indicates a situation that may damage or destroy the product or

associated equipment.

NOTE: A note draws attention to important information.

TIP: A tip provides a suggestion to make working with the application easier.

Software Commands

Commands are written in the fonts shown here:

^AR Merge Scene,,Op1 scene 1,1 ^B 51 ^W^C

[01] R 0004 00300 00400 00800 00600 [02] 35 [17] [03]

E X! *X1&* X2)* X2#* X2! CE}

NOTE: For commands and examples of computer or device responses mentioned

in this guide, the character “0” is used for the number zero and “O” is the capital

letter “o.”

Computer responses and directory paths that do not have variables are written in the font

shown here:

Reply from 208.132.180.48: bytes=32 times=2ms TTL=32

C:\Program Files\Extron

Variables are written in slanted form as shown here:

ping xxx.xxx.xxx.xxx —t

SOH R Data STX Command ETB ETX

Selectable items, such as menu names, menu options, buttons, tabs, and field names are

written in the font shown here:

From the File menu, select New.

Click the OK button.

Specifications Availability

Product specifications are available on the Extron website, www.extron.com.

Page 5

Contents

Introduction............................................................ 1

About this User Guide ........................................ 1

About the Cable Retraction System .................... 1

Features ............................................................. 1

Before Getting Started ........................................ 3

Cable Retraction System Overview ..................... 3

Planning ............................................................. 4

Determine Under-table Clearances and

Connections .................................................. 5

CC300, CC600, CC800

Enclosure Clearances .................................... 6

TLP 350CV, TLP 710CV, TLE 350, TLE 710

Enclosure Clearances .................................... 7

All Installations (Except Drop-in) ...................... 8

Prepare the Cable Cubby Enclosure ................... 9

All Installations ................................................ 9

Retrofit Installations ......................................... 9

Prepare the Retractors ..................................... 10

Horizontal or Angular Mounting: .................... 10

Angular Mounting: ........................................ 10

Operation .............................................................. 21

Extend a Cable ................................................ 21

Retract a Cable ................................................ 22

Maintenance and Adjustments ....................... 23

Pulley System Adjustment ................................ 23

To Adjust the Pulley System: ......................... 23

Removing and Replacing the System ............... 25

To Remove the System: ................................ 25

To Replace the System: ................................ 26

Expand the Cable Retraction System ............... 27

Add a Cable Retraction System ........................ 28

Reference Information ...................................... 29

Cable Retraction System Part Numbers ........... 29

Optional Accessories ........................................ 29

Installation ............................................................ 11

Cable Cubby 200 ............................................. 12

CC200 Bracket and Retractor Mounting ...... 13

CC300, CC600, CC800,

TLE, TLP Installation ........................................ 14

Horizontal Bracket Mounting ............................ 15

Locking Screw (Optional) .................................. 17

Alternative Solutions ......................................... 18

Drop-in Installations ...................................... 18

Laptop Power ................................................... 19

Connect the Cables .......................................... 20

Verify Cable Release Operation ......................... 20

vCable Retraction System • Contents

Page 6

Cable Retraction System • Contents vi

Page 7

Introduction

• About this User Guide

• About the Cable Retraction System

• Features

About this User Guide

This guide contains information to install, adjust, and operate Extron Electronics

CableRetractionSystem for CableCubby® Enclosures, and the Extended Length Cable

Retraction System for Cable Cubby

In this guide, the terms “system”, or “retraction system” are used to refer to the

Cable Retraction System for Cable Cubby Enclosures and the Extended Length Cable

Retraction System for Cable Cubby® Enclosures which includes up to three individual

retractors. The term “retractor” refers to an individual retractor in the system, and the term

“enclosure” refers to a Cable Cubby furniture-mountable enclosure. The term “XL” refers to

the XL series. Where differences in preparation, installation, operation, or maintenance may

occur, they are called out.

®

Enclosures.

About the Cable Retraction System

The Cable Retraction System for Cable Cubby Enclosures is a cable retracting device

installed into, but not limited to, Extron Electronics Cable Cubby products. The cable

retraction system can be mounted into all current Cable Cubby products.

The cable retraction system allows extended cables to be retracted back into the Cable

Cubby enclosure for storage without force or gravity. It also prevents cables from tangling

underneath the table as commonly seen with traditional gravity-fed systems. The retractor is

a compact multi-pulley assembly that provides a smooth consistent return motion with the

push of a button.

Each retractor comes pre-loaded with Extron tested and approved cable, optimized for

the specific cable diameter and flexibility. The standard retractor allows up to three feet of

cable to be extended from the top of the enclosure and provides up to six feet of pigtail for

connection of devices under the table. The XL series allows up to five feet of cable extension

and provides up to four feet of pigtail for under-table connections.

The Cable Retraction System is available in cable types to fit all applications. See

www.extron.com for current models.

Features

• Compatible with most Cable Cubby enclosures— The retraction system is easily

integrated with Cable Cubby 300, 600, and 800 series enclosures, the TLESeries

enclosures, and CableCubby TouchLink™Touchpanels (TLP350CV and TLP710CV

only). An adapter is available for installation into the Cable Cubby 200 enclosure.

• Cables extend up to 3 feet (90 cm) (XL series extend up to 5 feet)— Available

6feet (1.8 m) pigtail on standard retractors and 4 feet (1.2 m) pigtail on XL series

retractors for connection to under-table electronics or floor boxes.

Cable Retraction System • Introduction 1

Page 8

• Flexible installation alternatives— Retractor can be installed under a table or other

work surface in either a vertical or horizontal position.

• DC Laptop Power— Refer to the retraction system DC power compatibility list on the

website for laptop compatibility. Always use the power supply recommended by the

laptop manufacturer.

• Filler Modules (optional)— For mounting fewer than three retractors on each side

(fewer than two for the Cable Cubby 200).

• CC 200 Bracket— For Cable Cubby 200 enclosures allows mounting up to two

retractors total.

Extron

Cable Cubby 300C

Mounted in

Horizontal Position

in Cable Cubby 300C

Extron

Cable Retraction System

Figure 1. Cable Retraction System

Cable Retraction System • Introduction 2

Page 9

Before Getting

Started

This section provides an overview of the retractor installation and suggestions for planning

an installation.

• Cable Retraction System Overview

• Planning

• Prepare the Cable Cubby Enclosure

• Prepare the Retractors

Cable Retraction System Overview

Before beginning an installation, familiarize yourself with the system and the installation to

determine if additional parts or accessories are required.

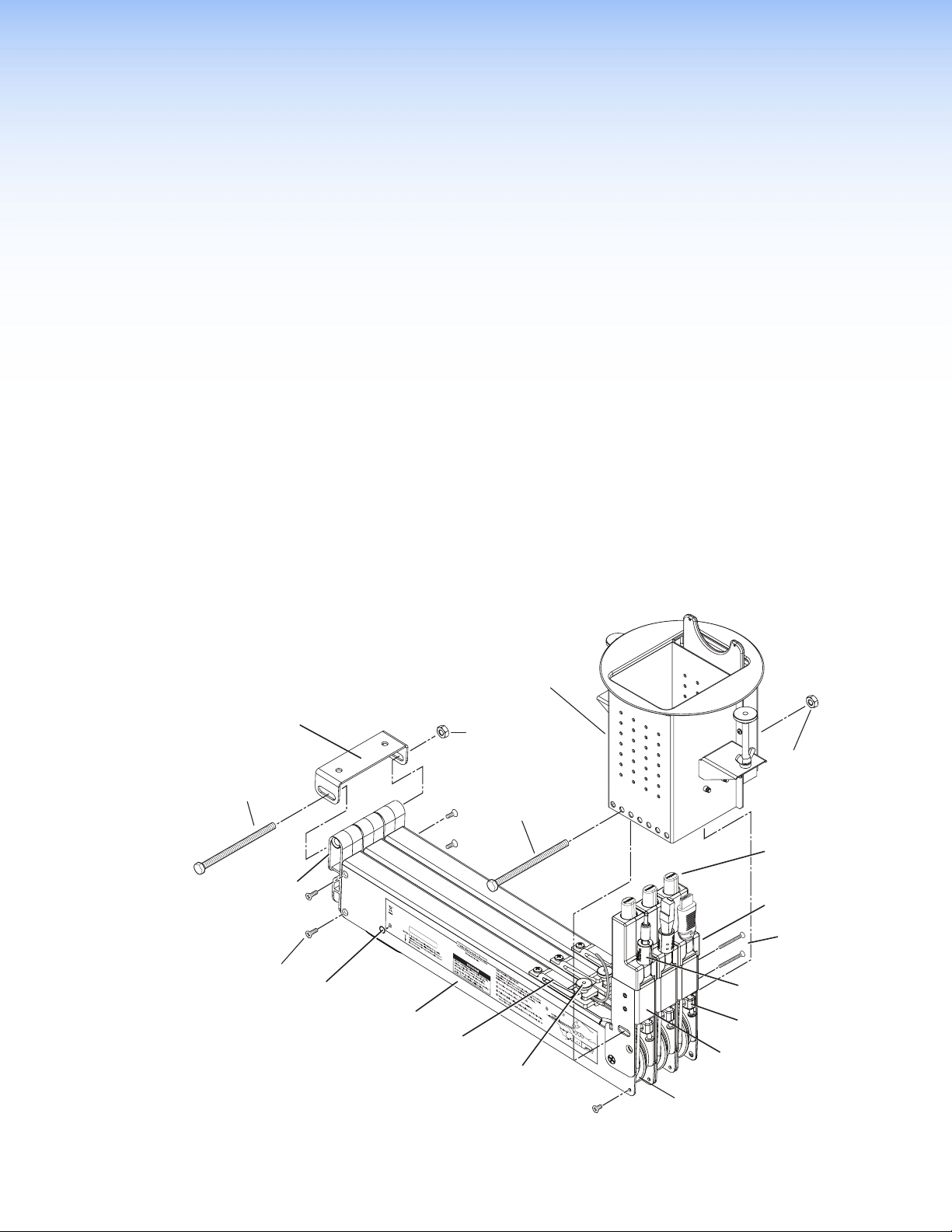

Horizontal Mounting

Bracket

Horizontal

Mounting Bolt

End Cap Assembly,

With Constant

Spring Assembly

End Cap

Screws (4 ea.)

Pulley System

Alignment Port

Retractor Enclosure

Cable Retainer Clamp

The cable and spring assembly have been

tested and optimized for this model.

Contact Extron Electronics for modifications

or repairs.

Cable Cubby

Enclosure

(not included)

Horizontal

Mounting Nut

Enclosure

Mounting Bolt

Anaheim, CA USA

www.extron.com

Thumbnut

Ver tical Mounting

Screws (2 ea.)

Loosen thumbwheel nut.

DO NOT remove

pulley screws

(ea side).

For horizontal mounting

remove this screw (ea side).

Enclosure

Mounting Nut

Cable Release

Button

Cable Stop

Assembly

Cable Stop

Assembly Screws

Cable Stop Collar

Hold cable.

33-1810-10

Rev. A

Adjustment Block

Upper Arm Assembly

Stationary Pulley

Figure 2. Retraction System Components

Cable Retraction System • Before Getting Started

3

Page 10

Planning

Filler modules

(part

take up the same

space as one retractor.

The cable retraction system can be mounted horizontally or vertically depending upon

under-table clearance and accessibility.

Horizontal mounting is recommended to provide maximum legroom and to protect the

retractors against accidental damage.

Vertical mounting is used where insufficient under-table space exists for horizontal

mounting or where under-table access is limited.

Angular mounting (XL models only) is used where insufficient under-table space exists

for horizontal mounting and tabletop to floor clearance prevents vertical mounting. The

XL enclosure has additional mounting holes that enable mounting at an angle between

horizontal and vertical.

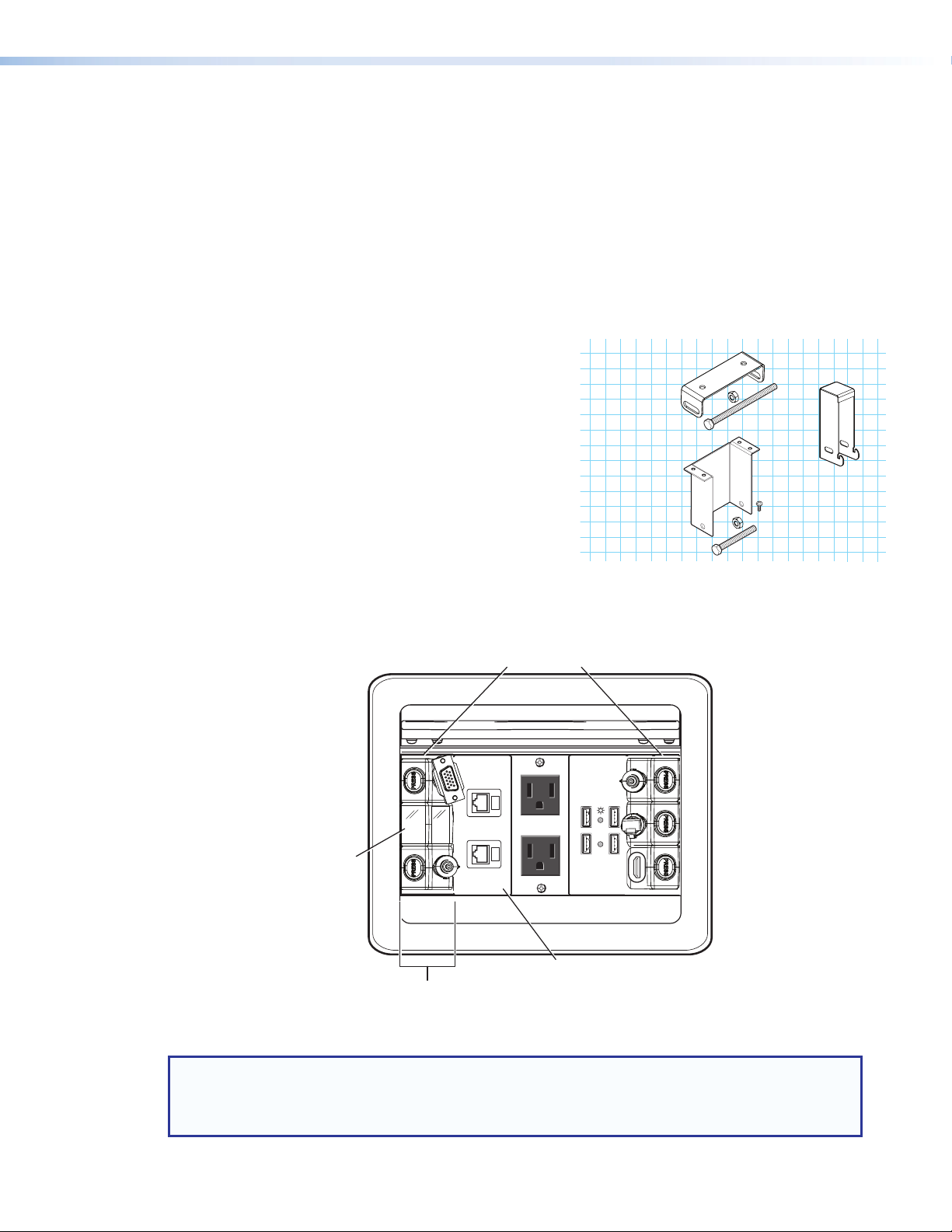

• For horizontal mounting, a mounting

bracket kit, part number 70-678-00, is

required (see Optional Accessories on

Horizontal Mounting

Bracket (Optional)

Part 70-678-00

page29).

• Filler modules, part number 70-678-08,

may be required to occupy unused retractor

space (see Optional Accessories on

page29).

• For Cable Cubby 200 installation, obtain

CC 200 Mounting Bracket

for Cable Cubby 200

(Optional)

Part 70-678-10

(x4)

Filler Module

(Optional)

Part 70-678-08

the CC 200 bracket kit (see Optional

Accessories on page29).

• For DC Power retractors, refer to the list on

the website for laptop compatibiiity. Always

use a power supply recommended by the laptop manufacturer.

The retraction system must be mounted on either

side of the enclosure with the cable release buttons

CC 800 shown

against the enclosure side walls.

UNSWITCHED

100-240V/ 5AMAX

UNSWITCHED

ACTIVITY

#70-678-08)

Retractors take

two AAP spaces.

USP HUB4 AAP

100-240V/ 5AMAX

Check for adequate cable

clearance inside the

Cable Cubby enclosure.

Figure 3. Retraction System Enclosure Locations

NOTE: When AAP modules are relocated or removed to provide space for the retraction system,

associated AAP brackets may require reconfiguration or replacement. Before starting an

installation determine if replacement AAP brackets will be needed. Replacement brackets can be

ordered from the Extron website.

Cable Retraction System • Before Getting Started 4

Page 11

Pigtail Starts

Here

6’ (1.8 m) Std.

4’ (1.2 m) XL

A Cable Cubby Series Installation Guide with details of the AAP bracket requirements,

along with the horizontal mounting bracket, filler module, CC200 mounting bracket kit,

AAPbrackets, and a laptop compatibility list are available at www.extron.com.

CAUTION:

• Do not operate a retractor until it is installed.

• Keep hands away from moving parts.

Determine Under-table Clearances and Connections

For all retractable system installations be certain there is adequate under-table space

and the retractor pigtail can reach under-table devices. The following diagrams show

the under-table clearances required for installation and operation of the retractor system

mounted in a Cable Cubby, TouchLink, or TLE series enclosure.

NOTES:

• To prevent objects from impeding cable retraction, ensure at least 3 inches of

clearance from the exposed cable side of the retractor enclosure.

• Excess cabling may cause clearance issues. Use zip ties to secure under-table

cabling to prevent accidental contact or entanglement with users.

If there is limited under-table access after the Cable Cubby enclosure is mounted, the

retraction system can be installed before the enclosure is mounted

(see Alternative Solutions on page18).

For CC 200 installations, see Cable Cubby 200 on page 12.

Pigtails

To make connections to devices under the table, standard retractors have 6 feet (1.8m) and

XL retractors have 4 feet (1.2m) of pigtail from the exit of the cable retainer as shown below.

Depending on the retractor mounting and the location of the devices, you may require patch

cables to extend the reach of the pigtail.

6’ (1.8 m) Std.

4’ (1.2 m) XL

Pigtail Starts

Here

Figure 4. Pigtail Length

If you need to connect to devices further than the pigtails allow, contact your Extron

representative or go to www.extron.com for a full line of patch cables.

In vertical installations, the pigtail begins 9.5 inches (24.1 cm) below the table top in

CC200/300/600/800 models for both standard and XL models, and 10.5 inches (26.7 cm)

below the table top for TLP 350CV/710CV and TLE 350/710 enclosures (see figure 5 on

page 6 and figure 6 on page 7).

Cable Retraction System • Before Getting Started 5

Page 12

For new Installations:

Choose the optimal mounting location for the CableCubby enclosure. The final location may

require some adjustment depending upon under-table clearances required for the retraction

system. Once the location has been determined, follow the instructions provided with the

enclosure for mounting and installing a power module and AAPs.

For retrofit installations:

For most retrofit installations, the Cable Cubby enclosure does not require removal.

Disconnect all power to the Cable Cubby before retraction system installation.

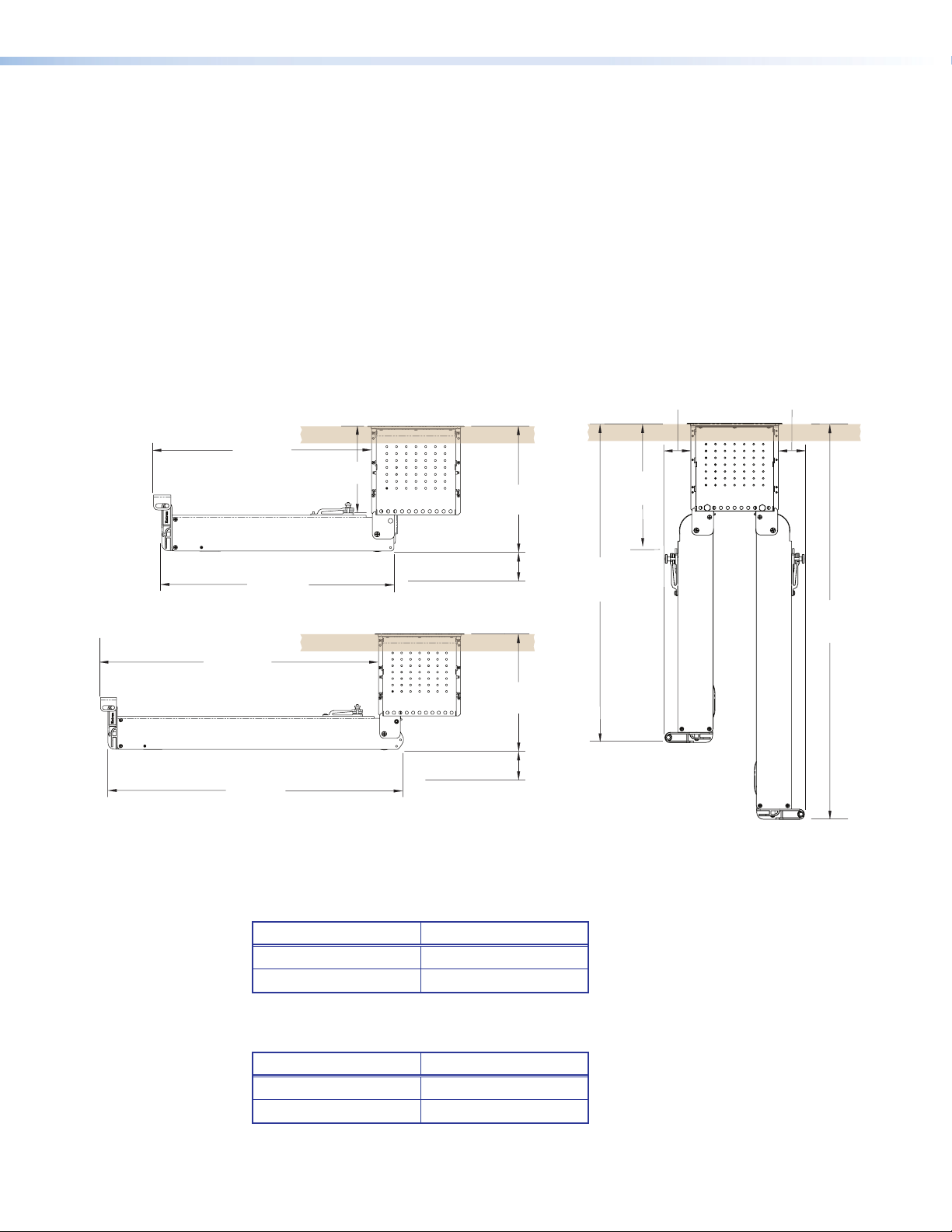

CC300, CC600, CC800 Enclosure Clearances

The following diagrams show the clearance dimensions required for mounting a retractor

system in a CC300, CC600, or CC800 enclosure.

15.7"

(39.9 cm)

See

Table A

9.0"

(22.9 cm)

See

Table B

1.9" (4.8 cm)

1.9" (4.8 cm)

21.7"

(55.0 cm)

16.7"

(42.5 cm)

3.0"

(7.6 cm)

(22.9 cm)

9.0"

23.3"

(59.2 cm)

29.3"

(74.4 cm)

3.0"

(7.6 cm)

23.0"

(58.5 cm)

Horizontal Mounting Clearance

CC300/600/800

XL Models

XL Models

Vertical Mounting Clearance

CC300/600/800

Figure 5. Vertical and Horizontal Clearance Requirements (CC 800 shown)

Enclosure Model Dimension

CC 200 6.2 inches (15.8 cm)

CC 300/600/800 6.4 inches (16.3 cm)

Table A. Vertical Dimension from Table Top To Pigtail

(Horizonal Mounting)

Enclosure Model Dimension

CC 200 9.5 inches (24.1 cm)

CC 300/600/800 9.5 inches (24.1 cm)

Table B. Vertical Dimension from Table Top To Pigtail

(Vertical Mounting)

Cable Retraction System • Before Getting Started 6

Page 13

TLP 350CV, TLP 710CV, TLE 350, TLE 710 Enclosure Clearances

The following diagrams show the clearance dimensions required for mounting a retractor

system in a TouchLink (TLP 350CV and TLP 710CV only) or the TLE series enclosures.

1.9" (4.8 cm)

15.7"

(39.9 cm)

See

Ta ble A

10.0"

(25.4 cm)

See

Table B

1.9" (4.8 cm)

21.7"

(55.0 cm)

23.0"

(58.5 cm)

16.7"

(42.5 cm)

3.0"

(7.6 cm)

3.0"

(7.6 cm)

XL Models

Horizontal Mounting Clearance

TLP 350CV/710CV TLE 350/710

10.0"

(25.4 cm)

24.3"

(61.7 cm)

XL Models

Vertical Mounting Clearance

TLP 350CV/710CV TLE 350/710

30.3"

(77.0 cm)

Figure 6. Vertical and Horizontal Clearance Requirements, TLP 350CV, TLP

710CV, TLE 350, and TLE 710

Retractor installation into the TLP and TLE enclosures is identical to the standard Cable

Cubby enclosures. The enclosures are one inch longer than the CC300/600/800

enclosures, but otherwise the dimensions are the same.

NOTE: Angular mounting requires an additional inch of floor clearance compared to

the Cable Cubby enclosures.

Enclosure Model Dimension

TLP/TLE 7.4 inches (18.8 cm)

Table A. Vertical Dimension from Table Top To Pigtail

(Horizonal Mounting)

Enclosure Model Dimension

TLP/TLE 10.5 inches (29.2 cm)

Table B. Vertical Dimension from Table Top To Pigtail

(Vertical Mounting)

Cable Retraction System • Before Getting Started 7

Page 14

All Installations (Except Drop-in)

Horizontal Mounting: Be certain the horizontal mounting bracket can be fastened

under the table or on a table support without bending the pulley system or forcing it from

perpendicular with the enclosure (see figure 7, “Top View”).

Vertical Mounting: Ensure the retraction system will hang freely without touching the

floor and is not obstructed by anything under the table (see CC300, CC600, CC800

Enclosure Clearances on page6 and TLP 350CV, TLP 710CV, TLE 350, TLE 710

Enclosure Clearances on page7).

Angular Mounting (XL models only): For installations where the tabletop is less than

30inches from the floor, the XL retractor system is too long for vertical mounting and there

may not be adequate under-table clearance for horizontal mounting. An additional mounting

hole has been provided for these installations that allow the retractor system to install at an

angle providing extra floor clearance (see figure 7, right).

Horizontal

Bracket

CC800

CC800

1.9"

(4.7 cm)

UNSWITCHED

100-240V/ 5AMAX

UNSWITCHED

ACTIVITY

USP HUB4 AAP

100-240V/ 5AMAX

10.6"

(27.0 cm)

Top View

26.6"

(70.1 cm)

29.3"

28.0"

(71.1 cm)

30

For minimum table height

requirements of 28 inches

(71 cm) specified by ADA

Section 4.32.

(74.4 cm)

Floor

Figure 7. Horizontal Bracket (Top View) and XL Models Vertical Clearance

Cable Retraction System • Before Getting Started 8

Page 15

Prepare the Cable Cubby Enclosure

The retraction system must be mounted on either

DANGER: SEVERE ELECTRICAL SHOCK. Remove all power from the Cable

Cubby enclosure before beginning a retraction system installation.

All Installations

By now you should be certain the retraction system has adequate under-table clearance

for installation and that proper legroom will be provided to avoid accidental contact with the

system. You should have the required accessories for mounting the retraction system along

with the necessary AAPs and AAP brackets to reconfigure the enclosure.

The retraction system requires two adjacent AAP spaces and must be installed on one side

of the enclosure or the other with the cable release buttons against the enclosure side walls

(see figure8). Filler modules, when used, take up the same space as one retractor. Where

the retraction system is installed in the enclosure is based on under-table clearance, the

mounting orientation of the retractors, and operation preferences.

Install or reconfigure the power module and AAP modules and brackets before beginning

the installation of the retraction system.

Retrofit Installations

Prepare the AAP spaces for the retraction system ensuring sufficient under-table clearance

for the retraction system.

Relocate, remove, or replace existing AAPs and reconfigure associated AAP brackets to

make room for the retraction system.

side of the enclosure with the cable release buttons

CC 800 shown

against the enclosure side walls.

Filler modules

(part #70-678-08)

take up the same

space as one retractor.

Retractors take

two AAP spaces.

UNSWITCHED

100-240V/ 5AMAX

UNSWITCHED

ACTIVITY

USP HUB4 AAP

100-240V/ 5AMAX

Check for adequate cable

clearance inside the

Cable Cubby enclosure.

Figure 8. Retraction System AAP locations

Cable Retraction System • Before Getting Started 9

Page 16

Prepare the Retractors

Remove two enclosure screws

(front and back) from this position

for horizontal or angular mounting.

Cable Stop Assembly

Enclosure

Each retractor is delivered ready to mount vertically. No further modifications are required.

See CC300, CC600, CC800, TLE, TLP Installation on page 14 for vertical installation

details.

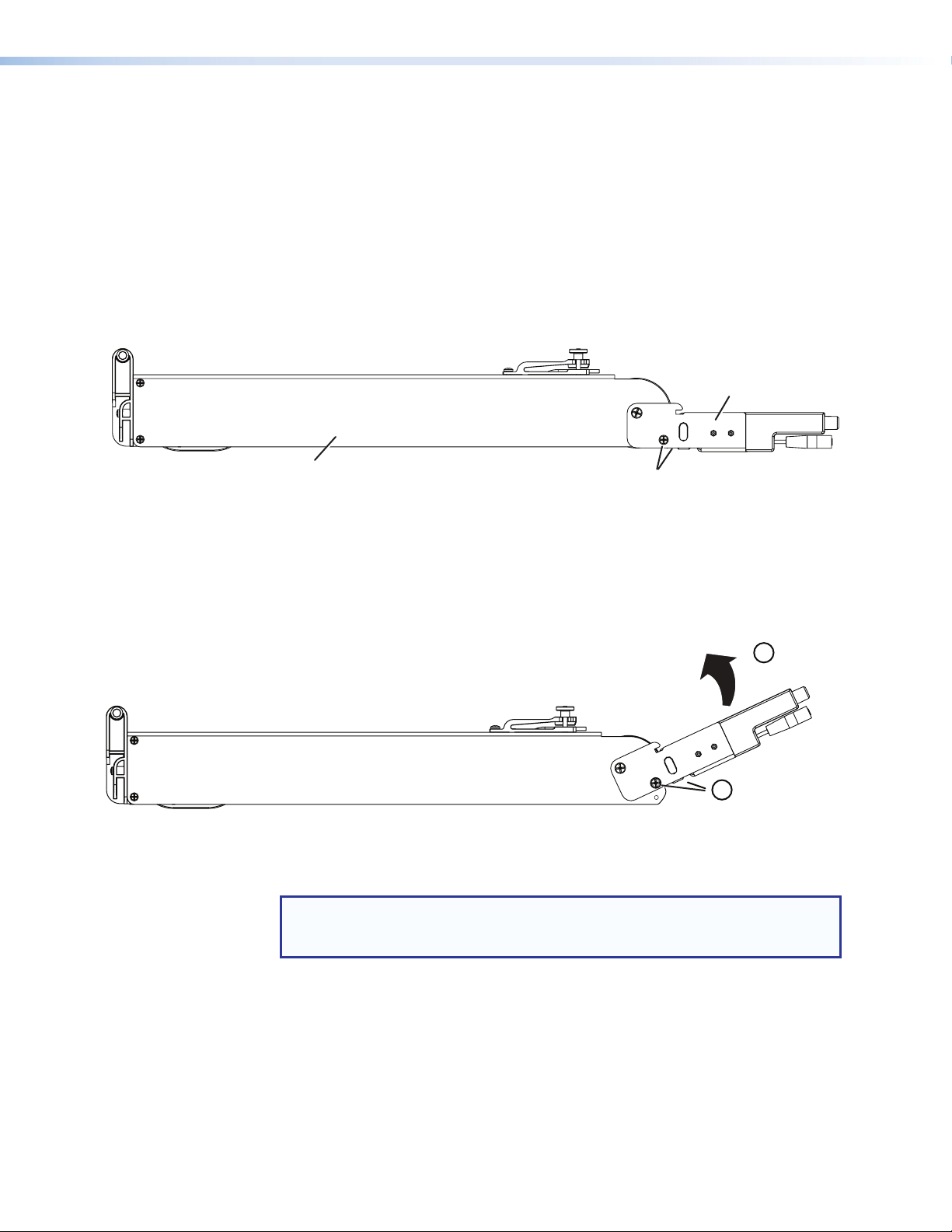

Horizontal or Angular Mounting:

To mount the retractors horizontally or at an angle, remove the two enclosure screws

from the retractor (see figure 9).

For horizontal mounting proceed to the “Installation” section beginning on page 11.

For angular mounting, see below.

Cable Stop Assembly

Enclosure

Remove two enclosure screws

(front and back) from this position

for horizontal or angular mounting.

Figure 9. Remove Enclosure Screws (Horizontal or Angular Mounting Only)

Angular Mounting:

1. To prepare an XL retractor for angular mounting move the cable stop assembly upward

as shown until the mounting hole is visible.

Move cable stop assembly

1

upward until the angular

mounting hole is visible.

Install two enclosure screws

2

(front and back) in angular

mounting location.

Figure 10. Install Angular Mounting Enclosure Screws

2. Reinstall the two screws removed in the preparation above.

NOTE: For Cable Cubby 200 installations, mount the retractor onto the CC 200

mounting bracket before installing in the enclosure (see CC200 Bracket and

Retractor Mounting on page13).

Cable Retraction System • Before Getting Started 10

Page 17

Installation

This section provides details of the retractor system installation, cable connection, and

verification of operation.

• Cable Cubby 200

• CC300, CC600, CC800, TLE, TLP Installation

• Horizontal Bracket Mounting

• Locking Screw (Optional)

• Alternative Solutions

• Laptop Power

• Connect the Cables

• Verify Cable Release Operation

By now you should have determined there is adequate under-table clearance, have all the

required accessories for installation, the enclosure should be prepared, and the retractor

system properly configured.

Cable Retraction System • Installation 11

Page 18

Cable Cubby 200

10.7" (27.2 cm)

The CC200 Mounting Bracket, part number 70-678-10,

allows one or two retractors (standard or XL) to be installed in

a CableCubby200 enclosure. The bracket kit adapts an AAP

opening for retraction system mounting similar to other Cable

Cubby enclosures.

Before installing the adapter, be certain there is adequate space

under the table for the retraction system with the attached

bracket.

NOTE: To prevent objects from impeding cable retraction,

ensure at least 3 inches of clearance from the exposed

cable side of the retractor enclosure.

CC 200 Mounting

Bracket Kit

Determine the retractor mounting orientation: horizontal, vertical, or angular (see Planning

on page4).

0.3" (7.6 mm)

2.0" (5.0 cm)

(x4)

27.5"

(69.9 cm)

XL Models

30

CC 200

Vertical Mounting Clearance

Standard Models

CC 200 Bracket

23.3" (59.1 cm)

3.0"

(7.6 cm)

21.8" (55.3 cm)

15.7" (39.9 cm)

CC 200 Bracket

8.9" (22.6 cm)

3.0" (7.6 cm)

Standard Models

8.9" (22.6 cm)

Figure 11. CC 200 mounting dimensions

3.0" (7.6 cm)

CC200 Horizontal Mounting Clearance

XL Models

Cable Retraction System • Installation 12

Page 19

CC200 Bracket and Retractor Mounting

1. Using the supplied mounting bolt (1/4-20 x 3 inch), mount the CC200 bracket to the

retractor as shown.

NOTE: If only one retractor is mounted, use a filler module (part number

70-678-08) in place of the second retractor.

Once the retractor is mounted to the bracket, the assembly may be installed.

2. The cable stops and connectors may be too large to fit through the AAP opening at the

same time as the retractor. Pull a short amount of cable out of the retractor and push it

through the AAP opening prior to installing the bracket and retractor assembly.

3

Mounting Screw

w / Washer (4 plcs)

2

CC 200

Bracket

Bracket and

Retractor Assembly

1

Mounting Bolt

and Nut

Figure 12. Install the Bracket and Retractor Assembly

3. Press the bracket and retractor assembly against the bottom of the enclosure, lining up

the bracket holes with the AAP mounting holes on the enclosure. Fasten from the top

using the four supplied screws.

4. See Locking Screw (Optional) on page17 for final installation instructions.

Cable Retraction System • Installation 13

Page 20

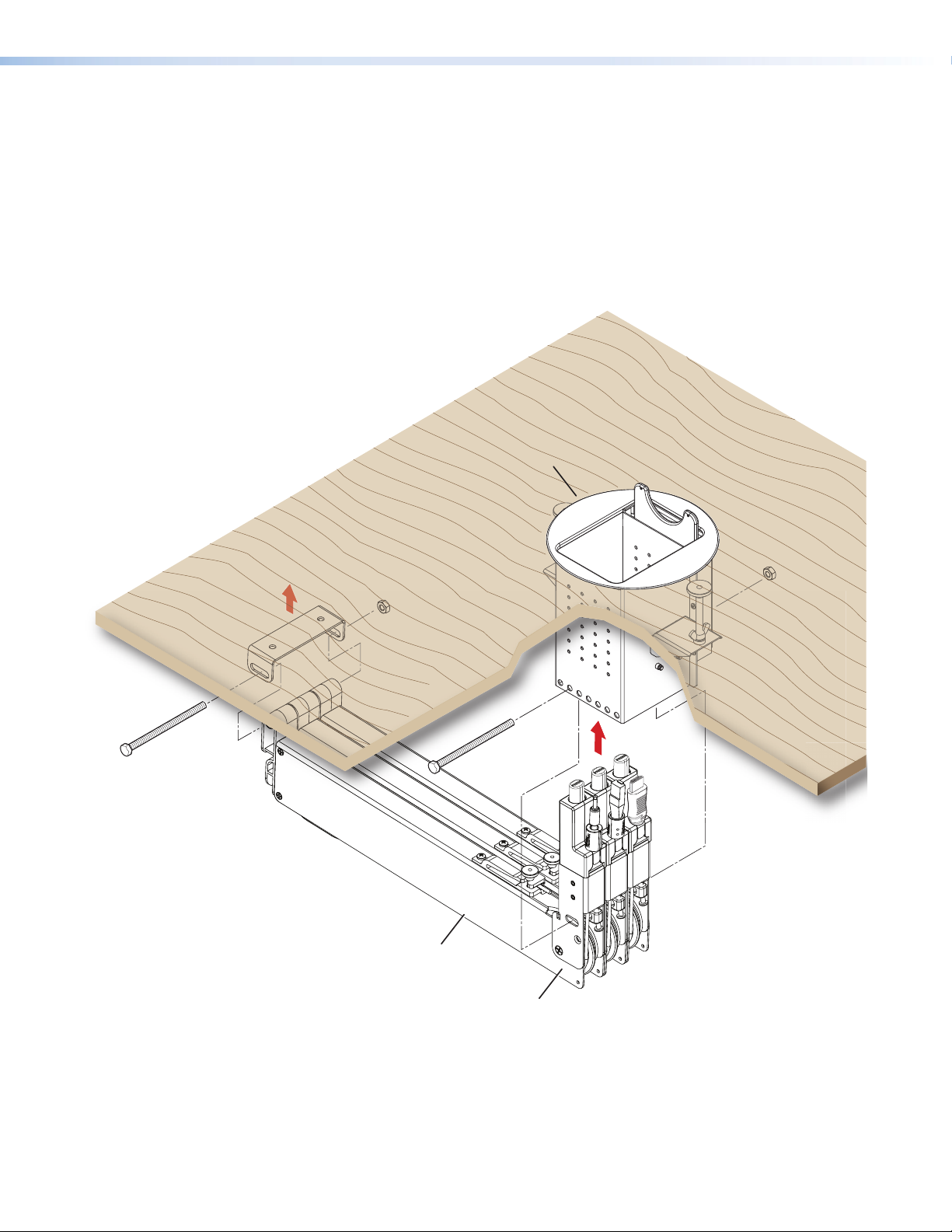

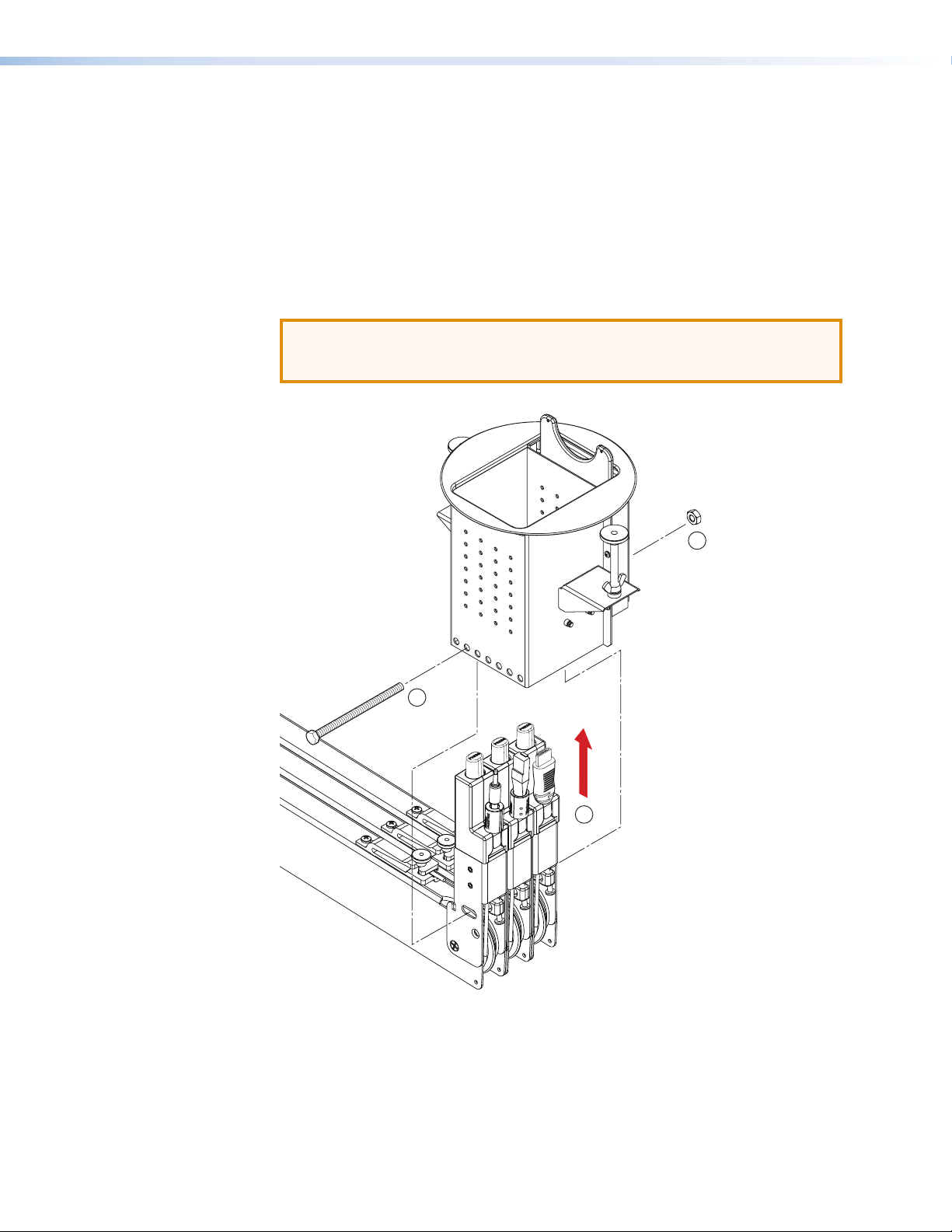

CC300, CC600, CC800, TLE, TLP Installation

The enclosure must be installed and properly configured before beginning the retraction

system installation.

1. With the cable release buttons against the enclosure wall, install the retraction system

by pushing the system up and into the enclosure (see figure 13).

2. With the retraction system against the sidewall, press the mounting bolt through the

second hole from the edge of the Cable Cubby enclosure, through the retraction

system, then out the other side of the enclosure.

3. Thread the nut on the bolt and tighten.

ATTENTION: Do not overtighten the enclosure mounting bolt. It only needs

to be snug. Overtightening could deform the retractor housing and cause

misalignment of the pulley wheels resulting in malfunction.

3

2

1

Figure 13. Retraction System Installation

4. Connect the retraction system cables and other AAP cables (if installed).

5. If horizontally mounting the retractors, proceed to Horizontal Bracket Mounting on

page15.

For vertical and angular mounting, see Locking Screw (Optional) on page17 for

final installation details.

Cable Retraction System • Installation 14

Page 21

Horizontal Bracket Mounting

Top View

For horizontal mounting, the horizontal mounting bracket (part number 70-678-00) must be

used. The slotted holes in the mounting bracket allow for tolerance in placing the bracket.

To ensure accurate bracket location, follow these procedures:

1. Attach the horizontal mounting bracket to the retractor end caps using the provided bolt

and nut.

TIP: Hand tighten the nut only enough to keep the bracket from easily moving.

The bolt and nut will be removed later.

Horizontal Bracket

Mounting Holes

Slotted Hole

Horizontal Mounting

Bolt

End Caps

Figure 14. Attach Horizontal Bracket to End Caps

2. Raise the retraction system with attached bracket to the desired mounting location.

NOTE: Be certain the system is perpendicular to the enclosure to prevent

binding of the pulley system.

UNSWITCHED

100-240V/ 5AMAX

UNSWITCHED

100-240V/ 5AMAX

USP HUB4 AAP

CC800

ACTIVITY

Horizontal

Bracket

Figure 15. Align Retraction System Perpendicular to Cable Cubby Enclosure

Cable Retraction System • Installation 15

Page 22

3. Ensure the bracket is flush with the surface and trace a line around the bracket

perimeter.

Trace Around

Bracket Perimeter

Figure 16. Mark Bracket Location

4. Lower the assembly and remove the horizontal bracket from the retractors.

5. Position the bracket inside the lines drawn in step 3 and fasten with the supplied

screws.

ATTENTION: Ensure the supplied screws do not pierce through the top of the

table. If necessary, use appropriate screws based on the table material and

thickness.

5

5

8

7

6

Figure 17. Position Bracket and Mount

6. Raise the retractor system up into the installed bracket.

7. Run the bolt through the bracket and end caps.

8. Secure the bolt with the nut supplied in step 1.

ATTENTION: Do not overtighten the horizontal mounting nut. It only needs to

be snug. Overtightening could deform the end caps and cause misalignment

of the system resulting in poor cable extension and retraction.

Cable Retraction System • Installation 16

Page 23

Locking Screw (Optional)

w (1 each).

If the retraction system is mounted next to an unused location in the Cable Cubby

enclosure, a locking screw is provided to prevent the retractors from rotating on their

mounting bolt during operation.

If needed, tighten the locking screws to prevent movement of the retractor. There is one

locking screw for each retractor.

NOTE: Do not overtighten. The locking screw only needs to be snug.

Tighten locking

scre

Locking

Screw

Figure 18. Locking Screws

Cable Retraction System • Installation 17

Page 24

Alternative Solutions

Drop-in Installations

For installations with limited under-table access, the retractors must be installed before

dropping the enclosure into the table. All drop-in installations must be mounted vertically or

using angular mounting.

1. For retrofit installations, remove the Cable Cubby enclosure from the furniture.

For new installations follow the Cable Cubby enclosure preparation instructions but

do not mount the enclosure.

2. Install the retraction system in the enclosure following the installation instructions (see

CC300, CC600, CC800, TLE, TLP Installation on page14) and locking screw

instructions (see Locking Screw (Optional) on page17).

3. Once the retraction system is installed, lower the

enclosure and retraction system into the cutout ensuring

that kinking or bending of the cables is prevented.

If the bottom of the retractors will not be accessible,

connect the pigtails before lowering the system.

4. After the enclosure has been dropped into the opening,

lift it just enough to allow the two screw clamps to be

installed.

NOTE: Connect all cables before lowering the enclosure into the cutout.

Screw Clamp

(both sides)

NOTE: In drop-in type installations, it is not

possible to adjust the screw clamps for an

exact fit and will take some trial and error

to adjust it for the tightest fit.

Figure 19. Drop-in Installation

Cable Retraction System • Installation 18

Page 25

Laptop Power

1.4"

(35.56 mm)

0.0"

(7.5 mm)

DC Power Cable

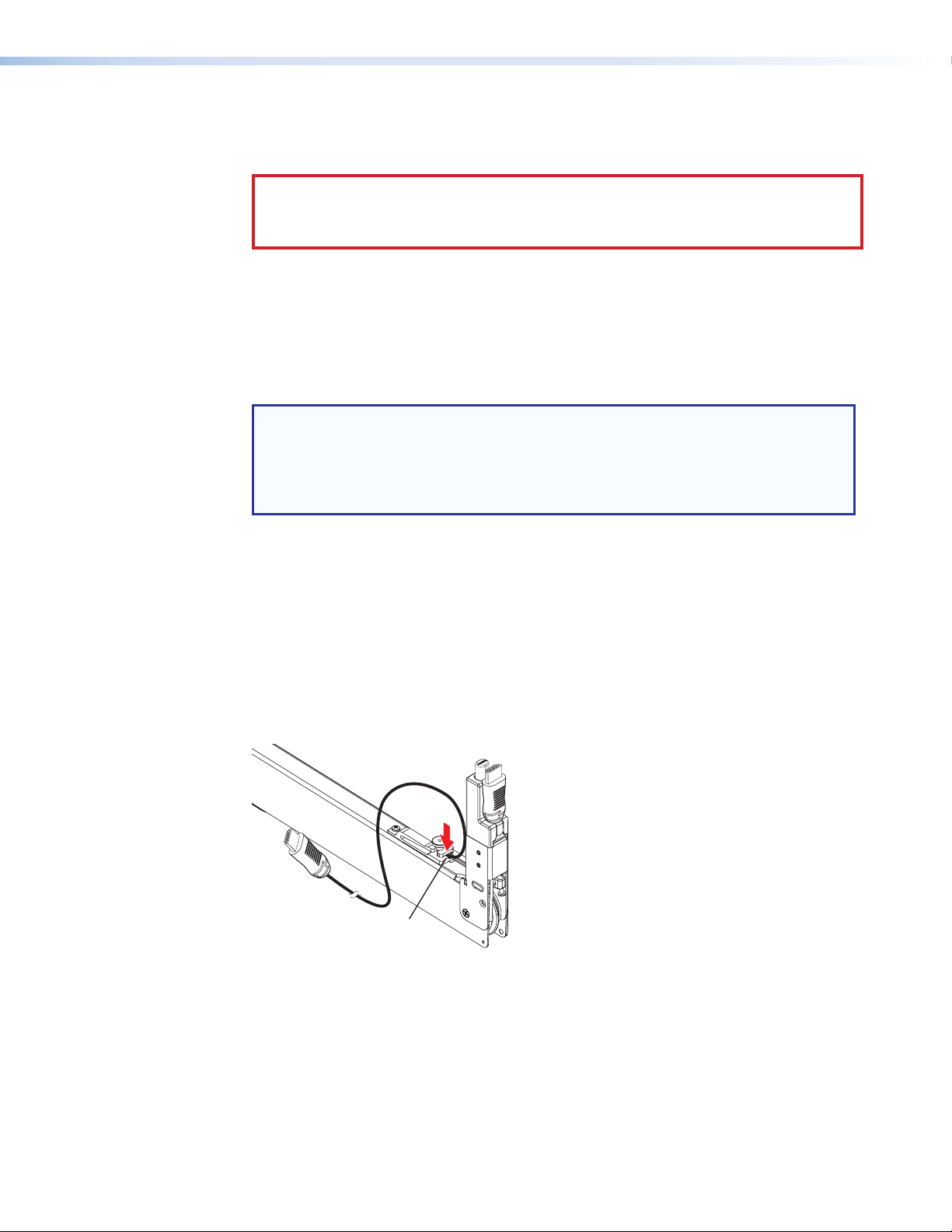

The DC power retractor provides a connection for a laptop on the tabletop to a compatible

laptop power supply (not supplied) under the furniture. Installation of the retractor is

identical to other retractors.

The cable has a female connector under the furniture (b) for connection to a laptop

power supply(a), and male connector on the topside (c) of the table for connection to a

compatible laptop.

ATTENTION:

• Use only the power supply recommended by the manufacturer of

the laptop.

• The cable connectors may not be compatible with all models

of Dell and HP laptop computers and power supplies. See

www.extron.com for a current compatibility list.

DC Power

3

Connector

Laptop

(not supplied)

1

Power Supply

(not supplied)

2

Under-table

Connector

Figure 20. DC Power Retractor Connection

Under-furniture space for the retractor and power must be available for the OEM laptop

power supply. The power supply module should be safely located and supply leads should

be dressed to avoid entanglements and accidental contact.

The power supply (a) must be compatible with both the laptop power requirements and the

female connector (b) on the under-table end of the retractor cable.

The DC power connector (c) must be compatible with the laptop power connection.

Three labels (Dell, HP, and blank-printable) are provided for the

topside connector to identify the laptop it is compatible with.

Affix the appropriate label as shown at right.

Cable Retraction System • Installation 19

Page 26

Connect the Cables

Connect the under-enclosure cables to the proper device.

If additional cable length is needed use Extron cable as required.

Excess cabling may cause clearance issues. Use wire ties to secure under-table cabling to

prevent accidental contact or entanglement with users.

Verify Cable Release Operation

After installation, check the operation of the cable release assembly. Pull a length of cable

from the system. The cable release button stops the cable from retracting back into the

system when pulling ceases.

Make certain the cable pulls freely without jerking or requiring excessive force. If it does,

check under the enclosure to determine if something has fallen into the retraction system

to cause tangling of the cable or is jamming the pulley

system. Also be certain the cable is properly routed

around the pulleys (see figure 22 on page 20).

Release the cable. Hold the connector and press the

release button. When retracting, hold the cable end

as the release button is pressed. Restrict the cable

retraction to a slow, controlled motion.

Ensure the cable retracts completely into the system.

The stop collar (or connector if there is no stop collar)

will rest on the seat of the cable stop assembly, stopping

cable travel. If it does not, proceed to Pulley System

Adjustment on page 23.

Cable Release

Button

Cable Release

Assembly

Stop collar

seated.

Cable Retraction System • Installation 20

Page 27

Operation

This section provides details of the retractor system operation.

• Extend a Cable

• Retract a Cable

Once installed, the retractors are ready for operation.

CAUTION:

• Do not operate a retractor until it is installed.

• When retracting, hold the cable with one hand and press the release button with

• Retraction should be a slow, controlled motion.

• Keep hands away from moving parts.

the other.

Extend a Cable

To connect a cable, grip it by the connector and pull enough cable from the retractor to

connect to the device. There is no need to press the cable release button when extending

a cable. When you stop pulling the cable, the cable release assembly will fix the length

automatically.

Cable Retraction System • Operation 21

Page 28

Retract a Cable

1. Disconnect the cable from the device and with one hand hold it firmly by the connector

to keep the cable taught.

2. With your other hand, press and hold the cable release button.

CAUTION: Use one hand to control the cable as it retracts. A cable allowed to

retract too quickly and without control can cause possible injury to the user or

damage the furniture surface, Cable Cubby, and nearby items.

3. With one hand pressing the release button, continue to hold the cable with the other

hand and allow it to slowly be pulled back into the retractor.

4. When the stop collar (or connector if the cable does not have a stop collar) is seated

against the cable release assembly, release the cable and button.

Press and hold the

2

cable release button.

Hold the cable taught

1

by the connector.

Slowly allow the cable

3

to be pulled until the

stop collar (or connector)

seats against the cable

release assembly.

Release the cable

4

and button.

22

Figure 21. Cable Retraction

Cable Retraction System • Operation 22

Page 29

Maintenance and Adjustments

• Pulley System Adjustment

• Removing and Replacing the System

• Expand the Cable Retraction System

• Add a Cable Retraction System

ATTENTION:

• Each Extron retractor model is designed with custom-made cable and a unique matching spring that work

together to maintain cable signal integrity and preserve consistent cable retraction pull force over the life of

the product. Alterations to the retractor will cause premature failure of the retractor system and cables.

• Modifications to the Retractor System are prohibited and will void the Extron warranty for this product.

Consult your Sales representative for more information.

Pulley System Adjustment

The tension on the cable that provides constant force during cable extension and retraction

is maintained by proper adjustment of the pulley system. Too little tension and the cable will

have slack or may slip out of the pulley tracks, and will not retract properly.

To Adjust the Pulley System:

1. Before beginning pulley system adjustments, ensure the cable routing around the pulley

system is correct (see below) and the cable is completely retracted into the enclosure.

Cables should be in the correct

pulley track, taught, and parallel

to each other.

Figure 22. Cable Routing

Cable Retraction System • Maintenance and Adjustments 23

Page 30

2. Hold the cable to prevent movement.

Anaheim, CA USA

www.extron.com

Cable Retractable System

ARNING!: When retracting, hold the cable end as

the release button is pressed. Restrict

the retraction to a slow, controlled motion.

Keep hands and fingers away from

moving parts.

Do not operate retractor until installed.

Cable Tension Adjustment

For optimum performance, proper cable tension must be

maintained. Follow the steps below or refer to the Cable

Retractable System User Guide for procedures.

1. Hold the cable to prevent movement.

2. Loosen thumbwheel nut on cable retainer.

3. Adjust cable to align tension pulley screw to this hole.

4. When tension is correct, re-tighten the thumbnut to

secure the cable.

Adjust.

Adjust.

4

4

Retainer Clip

Retainer Clip

Loosen thumbwheel

Loosen thumbwheel

3

3

nut.

nut.

Align pulley screw.

Align pulley screw.

Figure 23. Pulley System Adjustment

Hold cable.

Hold cable.

2

2

1

1

Cable stop collar

Cable stop collar

(or connector on

(or connector on

some models) must

some models) must

be seated.

be seated.

3. Loosen the thumbwheel nut on the retainer clip until the cable can be moved. Do not

allow it complete freedom of movement.

4. Adjust the cable to align the bottom pulley screw with the alignment hole on the

enclosure (designated c on the product label in figure24).

24

Alignment

c

Hole

Alignment Hole (pulley screw visible)

The cable and spring assembly have been

tested and optimized for this model.

Contact Extron Electronics for modifications

or repairs.

NOTE: To prevent objects from impeding

cable retraction, ensure at least

three inches of clearance from the

exposed cable side of the enclosure.

W

Figure 24. Product Label on Retractor

5. Hand tighten the thumbwheel nut on the retainer clip to secure the cable.

Cable Retraction System • Maintenance and Adjustments 24

Page 31

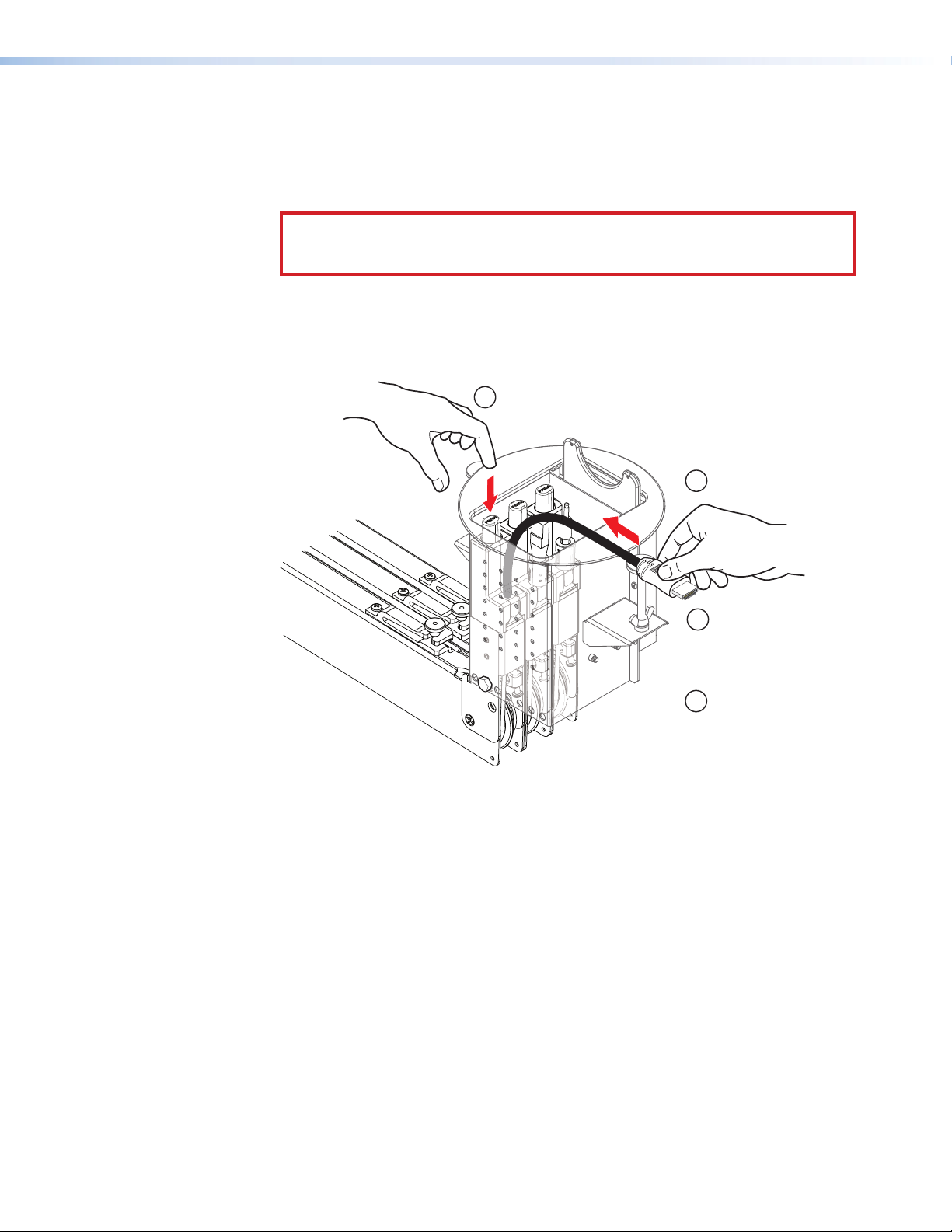

Removing and Replacing the System

To Remove the System:

DANGER: Ensure that AC power is disconnected before servicing the system.

1. Remove both ends of all retractor cables from connected devices.

NOTE: Drop-in installations require removal of the enclosure and retraction

system at the same time.

2. If necessary, loosen the locking screw on all retractors. If the system is mounted

vertically, proceed to step 6.

Loosen locking

screw (1 ea).

Figure 25. Loosen Locking Screws

25

3. Hold or otherwise support the cable retraction system near the horizontal bracket.

4. Remove the nut and slide the bolt from the horizontal mounting bracket.

CAUTION: All cable retractors attached to the horizontal mounting bracket will

drop when the bolt is removed.

Remove bolt.

4

Support the

3

retractor system.

Figure 26. Remove Horizontal Mounting Bolt

Cable Retraction System • Maintenance and Adjustments 25

Page 32

5. Slowly lower the system and allow it to hang vertically. If the system was mounted

vertically, it is already in this position.

6. Make certain the retractors are supported so they will not drop unexpectedly.

CAUTION: All retractors attached to the enclosure mounting bolt will drop when

the enclosure mounting bolt is removed.

7. Remove the enclosure mounting bolt. The retraction system is now detached from the

Cable Cubby.

Remove enclosure

7

mounting bolt.

Slide system

8

down and out.

Support the

6

retraction system.

Figure 27. Removing the Cable Retraction System

26

8. Slide the system down and out to remove it from the Cable Cubby.

To Replace the System:

Reverse the previous steps making certain the system is correctly oriented to the Cable

Cubby enclosure.

Cable Retraction System • Maintenance and Adjustments 26

Page 33

Expand the Cable Retraction System

Up to three retractors on each side, six total, (two total for the Cable Cubby 200), can

be mounted in a retraction system installation. If fewer than the maximum are installed

and additional retractors are desired, remove the filler module and replace it with the new

retractor (see Removing and Replacing the System on page25).

Filler

Module

Figure 28. Two Retractors in Cable Cubby Enclosure

27

Cable Retraction System • Maintenance and Adjustments 27

Page 34

Add a Cable Retraction System

The retraction system must be mounted on either

Depending upon the Cable Cubby enclosure, an additional retraction system with up to

three more retractors may be installed. As in the initial retraction system installation, existing

AAPs and their brackets may need to be relocated, removed, or replaced to allow room for

the additional system. The additional system does not have to mount the same as the first,

but proper under-table clearance for both systems, as well as clearances from each other

must be considered.

Filler modules

(part #70-678-08)

take up the same

space as one retractor.

CC 800 shown

side of the enclosure with the cable release buttons

against the enclosure side walls.

UNSWITCHED

100-240V/ 5AMAX

UNSWITCHED

ACTIVITY

USP HUB4 AAP

100-240V/ 5AMAX

Check for adequate cable

Retractors take

two AAP spaces.

clearance inside the

Cable Cubby enclosure.

Figure 29. Add a Retraction System

28

No matter which mounting method used, adequate space must be available inside the

Cable Cubby enclosures for the addititonal cables.

As shown in a typical horizontal mounting installation in figure 30, the second retraction

system will extend the opposite direction as the first.

UNSWITCHED

100-240V/ 5AMAX

UNSWITCHED

ACTIVITY

USP HUB4 AAP

100-240V/ 5AMAX

Existing System Additional System

CC800

Figure 30. Two Retraction Systems (Horizontal Mount)

Cable Retraction System • Maintenance and Adjustments 28

Page 35

Reference

Information

• Cable Retraction System Part Numbers

• Optional Accessories

Cable Retraction System Part Numbers

Retractors are available in versions to support most AV and data signal types including

VGA, Network, PC Audio, USB, DisplayPort, HDMI, and others. Each standard retractor

provides cable that extends up to 3 feet (90cm) from the enclosure. A 6 foot (1.8 m) pigtail

is provided on the input side of the retractor for connection to under-table electronics, floor

boxes, or an Extron AVTrac® floor mounted raceway system.

XL retractors extend up to 5 feet (152cm) from the enclosure and provide a 4 foot (1.2 m)

pigtail.

See the website at www.extron.com for the complete line of the Cable RetractionSystem

for Cable Cubby® Enclosures and Extended Length Cable Retraction System for

CableCubby® Enclosures.

Optional Accessories

Cable Retraction System, All Systems Part number

Retractor Mounting Kit for Horizontal Mounting 70-678-00

Retractor Filler Module 70-678-08

Cable Cubby 200 Mounting Bracket Kit 70-678-10

Cable Retraction System • Reference Information 29

Page 36

Extron Warranty

Extron Electronics warrants this product against defects in materials and workmanship for a period of three years

from the date of purchase. In the event of malfunction during the warranty period attributable directly to faulty

workmanship and/or materials, Extron Electronics will, at its option, repair or replace said products or components,

to whatever extent it shall deem necessary to restore said product to proper operating condition, provided that it is

returned within the warranty period, with proof of purchase and description of malfunction to:

USA, Canada, South America,

and Central America:

Extron Electronics

1230 South Lewis Street

Anaheim, CA 92805

U.S.A.

Europe and Africa:

Extron Europe

Hanzeboulevard 10

3825 PH Amersfoort

The Netherlands

Japan:

Extron Electronics, Japan

Kyodo Building, 16 Ichibancho

Chiyoda-ku, Tokyo 102-0082

Japan

China:

Extron China

686 Ronghua Road

Songjiang District

Shanghai 201611

China

Asia:

Extron Asia Pte Ltd

135 Joo Seng Road, #04-01

PM Industrial Bldg.

Singapore 368363

Middle East:

Extron Middle East

Dubai Airport Free Zone

F12, PO Box 293666

United Arab Emirates, Dubai

Singapore

This Limited Warranty does not apply if the fault has been caused by misuse, improper handling care, electrical

or mechanical abuse, abnormal operating conditions, or if modifications were made to the product that were not

authorized by Extron.

NOTE: If a product is defective, please call Extron and ask for an Application Engineer to receive an RA (Return

Authorization) number. This will begin the repair process.

USA: 714.491.1500 or 800.633.9876 Europe: 31.33.453.4040

Asia: 65.6383.4400 Japan: 81.3.3511.7655

Units must be returned insured, with shipping charges prepaid. If not insured, you assume the risk of loss or damage

during shipment. Returned units must include the serial number and a description of the problem, as well as the

name of the person to contact in case there are any questions.

Extron Electronics makes no further warranties either expressed or implied with respect to the product and its quality,

performance, merchantability, or fitness for any particular use. In no event will Extron Electronics be liable for direct,

indirect, or consequential damages resulting from any defect in this product even if Extron Electronics has been

advised of such damage.

Please note that laws vary from state to state and country to country, and that some provisions of this warranty may

not apply to you.

Extron Headquarters

+1.800.633.9876 (Inside USA/Canada Only)

Extron USA - West Extron USA - East

+1.714.491.1500 +1.919.850.1000

+1.714.491.1517 FAX +1.919.850.1001 FAX

Extron Europe

+800.3987.6673

(Inside Europe Only)

+31.33.453.4040

+31.33.453.4050 FAX

© 2013 Extron Electronics All rights reserved. www.extron.com

Extron Asia

800.3987.6673

(Inside Asia Only)

+65.6383.4400

+65.6383.4664 FAX

Extron Japan

+81.3.3511.7655

+81.3.3511.7656 FAX

Extron China

+4000. 398766

(Inside China Only)

+86.21.3760.1568

+86.21.3760.1566 FAX

Extron Middle East

+971.4.299.1800

+971.4.299.1880 FAX

Extron Korea

+82.2.3444.1571

+82.2.3444.1575 FAX

Extron India

1800.3070.3777

(Inside India Only)

+91.80.3055.3777

+91.80.3055.3737 FAX

Loading...

Loading...