Page 1

Extron® AVTrac® Corner Cut Solution

x

Wall

Overview

This guide describes how to cut and install the AVTrac with a 90° bend. Before

starting, read the AVTrac User Guide for important information about selecting

and preparing the installation site, installing the connectivity box, running

cables, and finishing the installation.

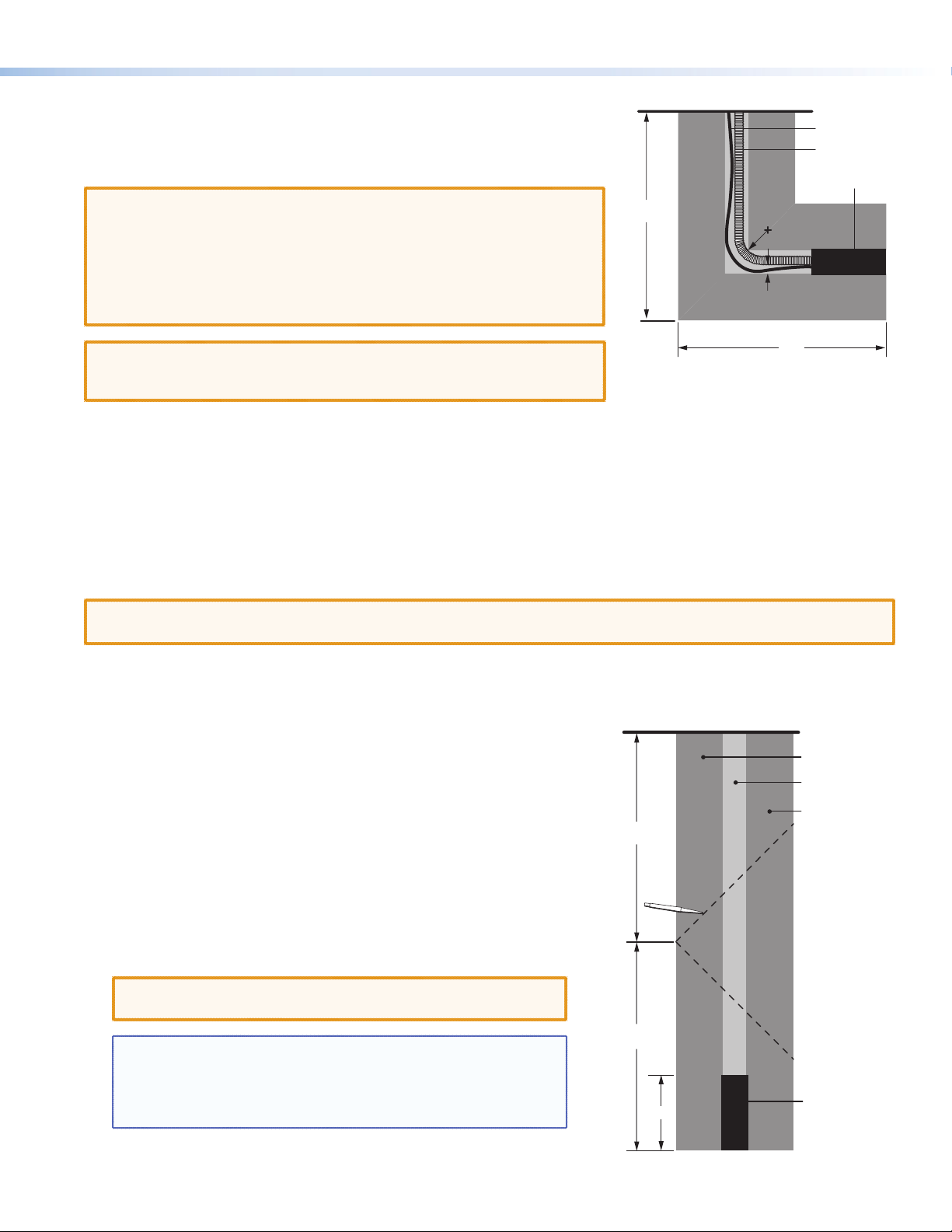

CAUTION: Check the bend radius of your cables (see figure at right),

including the high voltage flex conduit. Ensure that when

multiple cables are present, they can all bend 90° without

damage and without obstructing the passage of other cables.

When the flexible conduit provided is bent through 90° it leaves

a space that is approximately 1 1/2 inches (3.8 cm) wide and

0.67 inches (1.7 cm) high for running AV cables.

AV Cables

Conduit

Connectivity Bo

A

Bend (turn)

Radius

1.5" (typ)

CAUTION: If the total of lengths A plus B (see figure at right) is greater

than 8 feet, you will need additional 4 foot AVTrac extension

kits (part number 70‑645‑04).

Required Tools and Equipment

To cut and prepare the 90° track, you may need some or all of the following items that are not provided by Extron:

• Tape measure • Blades for cutting plastic ramps and aluminum

• Marker

• Rafter tool or angle measuring tool • Safety glasses

• 10 inch sliding compound miter saw • File or deburring tool

IMPORTANT: By this point, the installation site must be prepared. If necessary, remove carpeting. For

complete information, consult the AVTrac User Guide, available at www.extron.com.

Preparing the 90° AVTrac

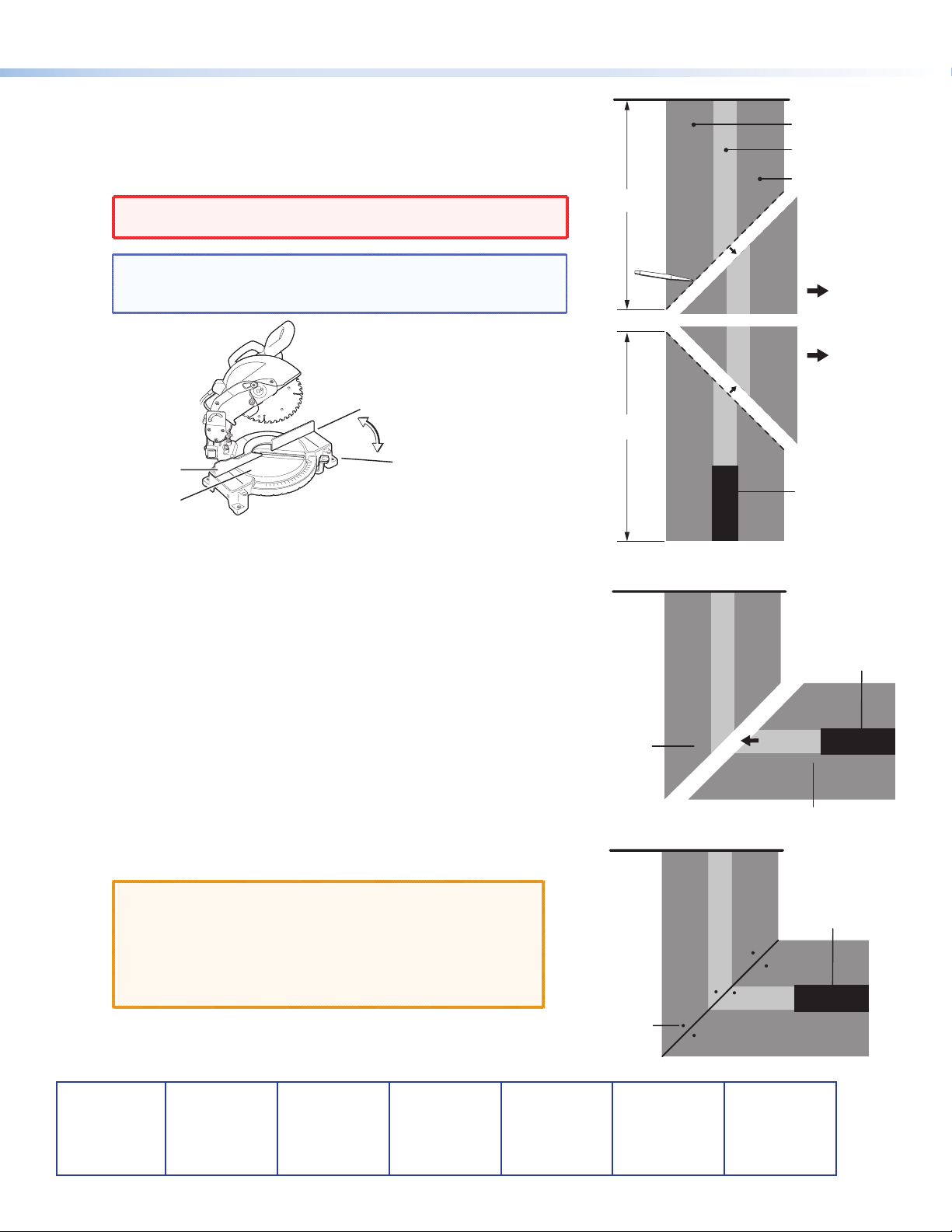

1. Decide where the first section of the AVTrac (from the wall to the bend)

will run. Assemble the track components, ensure they are all level at one

end and measure the maximum length along the outside edge (A).

2. Mark the maximum length on the outside edge of the track (be sure you

are marking the correct side of the track) and draw a line at 45° across

all the pieces to mark the outside edges of the outside plastic ramp, the

aluminum track, and the inside plastic track.

3. Determine where the second section of the AVTrac (from the bend to the

connectivity box) will run and measure the maximum length along the

outside edge (B).

4. Mark the maximum length on the outside edge of the track (be sure you

are marking the correct side of the track) and draw a line at 45° across

all the pieces to mark the outside edges of the outside plastic ramp, the

aluminum track, and the inside plastic track.

CAUTION: Mark the pieces before making any cuts, and make

sure that the cuts will be in the correct orientation.

B

track (one for each)

Wall

Outside Plastic Ramp

Aluminum Track

Inside Plastic Ramp

A

NOTE: The aluminum base track runs under the connectivity

box. The cover track runs up to (but not under) the

connectivity box. Cut the cover track 12 inches shorter

than the base track to accommodate the connectivity box

(see the figure at right).

B

Connectivity Box

12"

Page 2

Extron® AVTrac® Corner Cut Solution (Continued)

Wall

Cutting the AVTrac

1. Use a power miter saw with a blade that is appropriate for the material

you are cutting (plastic or aluminum) to make a 45° cut through each

individual track pieces (see figure below). Make sure the start of the cut

aligns with the marks you made in step 4 of "Preparing the 90° AVTrac".

WARNING: Always use safety goggles when using power

equipment.

TIP: Place the thick edge of the plastic ramp against the back

support of the miter saw. The thin edge may slide into the

gap between the base and back support of the miter saw.

45˚

Back Support

Base

Miter Saw

2. Deburr the edges of the metal track using a file.

3. Safely discard the track sections that have been cut out.

Wall

Outside Plastic Ramp

Aluminum Track

Inside Plastic Ramp

A

Discard

Discard

B

Connectivity Box

Installing the AVTrac

1. Remove the aluminum cover tracks and place them to one side.

2. Assemble the side ramps and aluminum base track from section 1 of the

track (from the wall to the bend) where it will be installed.

3. Follow instructions in the AVTrac User Guide (available at www.extron.com)

to drill the pilot holes and secure the track to the floor. All track pieces

should be secured to the floor by screws that are at least 1 inch and no

more than 3 inches from the cut (see the bottom figure at right).

4. Assemble section 2 of the track (from the bend to the connectivity box)

where it will be installed so that the cut ends are aligned with the cut ends

of section 1.

5. Follow instructions in the AVTrac User Guide to secure the track to

the floor.

IMPORTANT: Finish the installation by securing the

connectivity box, populating the box with

Architectural Adapter Plates, running cables to

the connectivity box, replacing the cover track,

and covering the track with carpet or plastic. For

complete information, consult the AVTrac User

Guide.

Section 1

Wall

Secure the track with

masonry screws at

least 1" and no more

than 3" from the cut edge.

Connectivity Box

Section 2

Connectivity Box

Extron USA ‑ West

Headquarters

+800.633.9876

Inside USA/Canada Only

+1.714.491.1500

+1.714.491.1517 FAX

Extron USA ‑ East

+800.633.9876

Inside USA/Canada Only

+1.919.863.1794

+1.919.863.1797 FAX

Extron Europe

+800.3987.6673

Inside Europe Only

+31.33.453.4040

+31.33.453.4050 FAX

© 2010 Extron Electronics. All Rights Reserved. www.extron.com

Extron Asia

+800.7339.8766

Inside Asia Only

+65.6383.4400

+65.6383.4664 FAX

Extron Japan

+81.3.3511.7655

+81.3.3511.7656 FAX

Extron China

+400.883.1568

Inside China Only

+86.21.3760.1568

+86.21.3760.1566 FAX

Extron Middle East

+971.4.2991800

+971.4.2991880 FAX

68-1981-01

Rev A

09 10

Loading...

Loading...