Page 1

User Guide

Audio Products

XTRA

Half-Rack Audio Power Amplifiers

™

Series

68-2354-01 Rev. A

02 14

Page 2

Safety Instructions

Safety Instructions • English

WARNING: This symbol, , when used on the product, is intended to

alert the user of the presence of uninsulated dangerous voltage within the

product’s enclosure that may present a risk of electric shock.

ATTENTION: This symbol, , when used on the product, is intended

to alert the user of important operating and maintenance (servicing)

instructions in the literature provided with the equipment.

For information on safety guidelines, regulatory compliances, EMI/EMF

compatibility, accessibility, and related topics, see the Extron Safety and

Regulatory Compliance Guide, part number 68-290-01, on the Extron website,

www.extron.com.

Instructions de sécurité • Français

AVERTISSEMENT: Ce pictogramme, , lorsqu’il est utilisé sur le

produit, signale à l’utilisateur la présence à l’intérieur du boîtier du produit

d’une tension électrique dangereuse susceptible de provoquer un choc

électrique.

ATTENTION: Ce pictogramme, , lorsqu’il est utilisé sur le produit, signale

à l’utilisateur des instructions d’utilisation ou de maintenance importantes

qui se trouvent dans la documentation fournie avec le matériel.

Pour en savoir plus sur les règles de sécurité, la conformité à la réglementation,

la compatibilité EMI/EMF, l’accessibilité, et autres sujets connexes, lisez les

informations de sécurité et de conformité Extron, réf. 68-290-01, sur le site

Extron, www.extron.fr.

Sicherheitsanweisungen • Deutsch

WARNUNG: Dieses Symbol auf dem Produkt soll den Benutzer darauf

aufmerksam machen, dass im Inneren des Gehäuses dieses Produktes

gefährliche Spannungen herrschen, die nicht isoliert sind und die einen

elektrischen Schlag verursachen können.

VORSICHT: Dieses Symbol auf dem Produkt soll dem Benutzer in der

im Lieferumfang enthaltenen Dokumentation besonders wichtige Hinweise

zur Bedienung und Wartung (Instandhaltung) geben.

Weitere Informationen über die Sicherheitsrichtlinien, Produkthandhabung,

EMI/EMF-Kompatibilität, Zugänglichkeit und verwandte Themen finden Sie in

den Extron-Richtlinien für Sicherheit und Handhabung (Artikelnummer

68-290-01) auf der Extron-Website, www.extron.de.

Instrucciones de seguridad • Español

ADVERTENCIA: Este símbolo, , cuando se utiliza en el producto,

avisa al usuario de la presencia de voltaje peligroso sin aislar dentro del

producto, lo que puede representar un riesgo de descarga eléctrica.

ATENCIÓN: Este símbolo, , cuando se utiliza en el producto, avisa

al usuario de la presencia de importantes instrucciones de uso y

mantenimiento recogidas en la documentación proporcionada con el

equipo.

Para obtener información sobre directrices de seguridad, cumplimiento

de normativas, compatibilidad electromagnética, accesibilidad y temas

relacionados, consulte la Guía de cumplimiento de normativas y seguridad de

Extron, referencia 68-290-01, en el sitio Web de Extron, www.extron.es.

Инструкция по технике безопасности • Русский

ПРЕДУПРЕЖДЕНИЕ: Данный символ, , если указан на продукте,

предупреждает пользователя о наличии неизолированного опасного напряжения

внутри корпуса продукта, которое может привести к поражению электрическим

током.

ВНИМАНИЕ: Данный символ, , если указан на продукте,

предупреждает пользователя о наличии важных инструкций

по эксплуатации и обслуживанию в руководстве,

прилагаемом к данному оборудованию.

Для получения информации о правилах техники безопасности,

соблюдении нормативных требований, электромагнитной

совместимости (ЭМП/ЭДС), возможности доступа и других

вопросах см. руководство по безопасности и соблюдению

нормативных требований Extron на сайте Extron: www.extron.ru,

номер по каталогу - 68-290-01.

Chinese Simplified(简体中文)

警告: 产品上的这个标志意在警告用户该产品机壳内有暴露的危险 电压,有触电危险。

注意: 产品上的这个标志意在提示用户设备随附的用户手册中有

重要的操作和维护(维修)说明。

关于我们产品的安全指南、遵循的规范、EMI/EMF 的兼容性、无障碍

使用的特性等相关内容,敬请访问 Extron 网站 www.extron.cn,参见 Extron

安全规范指南,产品编号 68-290-01。

Chinese Traditional( )

警告: 若產品上使用此符號,是為了提醒使用者,產品機殼內存在著

可能會導致觸電之風險的未絕緣危險電壓。

注意 若產品上使用此符號,是為了提醒使用者。

有關安全性指導方針、法規遵守、EMI/EMF 相容性、存取範圍和相關主題的詳

細資訊,請瀏覽 Extron 網站:www.extron.cn,然後參閱《Extron 安全性與法

規遵守手冊》,準則編號 68-290-01。

Japanese

警告: この記 号 が製品上に表示されている場合は、筐体内に絶縁されて

いない高電圧が流れ、感電の危険があることを示しています。

注意: この 記号 が製品 上に表 示されてい る場合は、本 機の取 扱説明 書に 記載 されてい

る重要な 操作と保 守(整 備)の 指示につ いてユーザーの 注意 を喚起 するものです。

安全上のご注意、法規厳守、EMI/EMF適合性、その他の関連項目に

つ い て は 、エ ク スト ロ ン の ウェブ サ イト www.extron.jp よ り 『 Extron Safety and

Regulatory Compliance Guide』 ( P/N 68-290-01) をご覧ください。

Korean

경고: 이 기호 가 제품에 사용될 경우, 제품의 인클로저 내에 있는 접지되지 않은 위험한

전류로 인해 사용자가 감전될 위험이 있음을 경고합니다.

주의: 이 기호 가 제품에 사용될 경우, 장비와 함께 제공된 책자에 나와 있는 주요 운영 및

유지보수(정비) 지침을 경고합니다.

안전 가이드라인, 규제 준수, EMI/EMF 호환성, 접근성, 그리고 관련 항목에

대한 자세한 내용은 Extron 웹 사이트(www.extron.co.kr)의 Extron 안전 및

규제 준수 안내서, 68-290-01 조항을 참조하십시오.

Page 3

FCC Class B Notice

This equipment has been tested and found to comply with the limits for a

ClassB digital device, pursuant to part15 of the FCC rules. These limits provide reasonable

protection against harmful interference in a residential installation. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. There is no guarantee that

interference will not occur. If this equipment does cause interference to radio or television reception,

which can be determined by turning the equipment off and on, you are encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

• Consult the dealer or an experienced radio/TV technician for help.

NOTE: For more information on safety guidelines, regulatory compliances, EMI/EMF compatibility,

accessibility, and related topics, see the “Extron Safety and Regulatory Compliance

Guide” on the Extron website.

Conventions Used in this Guide

Notifications

The following notifications are used in this guide:

WARNING: A warning indicates a situation that has the potential to result in death or

severe injury.

CAUTION: A caution indicates a situation that may result in minor injury.

ATTENTION: Attention indicates a situation that may damage or destroy the product or

associated equipment.

NOTE: A note draws attention to important information.

Copyright

© 2014 Extron Electronics. All rights reserved.

Trademarks

All trademarks mentioned in this guide are the properties of their respective owners.

The following registered trademarks

Systems, Inc. or Extron Electronics:

AVTrac, Cable Cubby, CrossPoint, eBUS, EDID Manager, EDID Minder, Extron, Flat Field, GlobalViewer, Hideaway, Inline, IPIntercom,

IPLink, Key Minder, LockIt, MediaLink, PlenumVault, PoleVault, PowerCage, PURE3, Quantum, SoundField, SpeedMount, SpeedSwitch,

SystemINTEGRATOR, TeamWork, TouchLink, V-Lock, VersaTools, VN-Matrix, VoiceLift, WallVault, WindoWall, XTP and XTP Systems

Registered Service Mark

AAP, AFL (Accu-Rate Frame Lock), ADSP (Advanced Digital Sync Processing), Auto-Image, CDRS (Class D Ripple Suppression), DDSP (Digital

Display Sync Processing), DMI (Dynamic Motion Interpolation), DriverConfigurator, DSPConfigurator, DSVP (Digital Sync Validation Processing),

FastBite, FOXBOX, IP Intercom HelpDesk, MAAP, MicroDigital, ProDSP, QS-FPC (QuickSwitch Front Panel Controller), Scope-Trigger, SIS,

Simple Instruction Set, Skew-Free, SpeedNav, Triple-Action Switching, XTRA, ZipCaddy, ZipClip

(SM)

: S3 Service Support Solutions

(®)

, registered service marks

Registered Trademarks

Trademarks

(SM)

, and trademarks

(®)

(™)

(TM)

are the property of RGB

Page 4

Page 5

Contents

XTRA Series Half-Rack Audio Power Amplifiers • Contents

Introduction .................................................. 1

About this Manual............................................ 1

Terms Used in this Manual ........................... 1

Features .......................................................... 1

Installation .................................................... 3

Application Examples

Mounting the XTRA Series Amplifiers

Tabletop Use ............................................... 4

UL Guidelines for Rack Mounting ................. 4

Rack Mounting ............................................ 5

Flexible Conduit Adapter Kit Installation ....... 6

...................................... 3

............... 4

Operation ....................................................... 9

Front Panel Features and Operation ................ 9

Rear Panel Features and Operation ............... 11

Remote Volume Control ............................. 17

Controlling Multiple Amplifiers with One

Volume Controller ..................................... 18

Bridged Mono Output ................................ 19

Troubleshooting ......................................... 20

Amplifier Fails to Exit

Standby Mode Promptly ............................... 20

Amplifier Enters Standby Mode

Too Early ...................................................... 21

Limiter/Protect LED Warning Indicators ......... 21

Over Temp Indicator LED ............................... 21

v

Page 6

Page 7

Introduction

XTRA Series Half-Rack Audio Power Amplifiers • Introduction

About this Manual

This manual contains information about the Extron XTRA Series of power amplifiers.

• XPA 1002 two-channel stereo audio power amplifier

• XPA 1002 Plus two-channel stereo audio power amplifier

• XPA 2001-70V mono audio power amplifier

• XPA 2001-100V mono audio power amplifier

Terms Used in this Manual

The terms “amplifier” and “power amplifier” are used interchangeably in this manual to refer

to all of the XPA models. “XPA 1002” refers to the 1002 and the 1002 Plus. ”XPA2001”

refers to both the XPA2001-70V and the XPA2001-100V.

Features

Inputs — Balanced or unbalanced stereo or mono on a 3.5 mm, 5-pole captive screw

connector.

Speaker outputs — Screw-lock, 5 mm captive screw connectors enable simple, secure

connections with 22 AWG to 12 AWG speaker cables.

Continuous power output for larger rooms —

• XPA1002: 60watts rms per channel at 8 ohms; 100watts rms per channel at 4ohms.

• XPA 1002 Plus: 100 watts rms per channel at 4 and 8 ohms.

• XPA2001-70V: 200watts rms for 70volt speaker systems.

• XPA2001-100V: 200watts rms for 100volt speaker systems.

Professional grade amplifier design —

• The XPA 1002 and 1002 Plus features less than 0.05% total harmonic distortion plus

noise, and better than 105 dB signal-to-noise ratio.

• The XPA 2001 features less than 0.1% total harmonic distortion plus noise, and better

than 100 dB signal to noise ratio.

ENERGY STAR® qualified amplifier — The XTRA Series of amplifiers are energy efficient

products that conserve energy and reduce operating costs.

Highly efficient Class D amplifier design — The XTRA Series of amplifiers generate

substantially less heat than conventional amplifier designs, making them ideal for installation

in equipment racks and lecterns with very limited ventilation. They consume 10watts when

idle and less than 1 watt in standby mode.

1

Page 8

Extron patented CDRS — Class D ripple suppression — A patented, exclusive

XTRA Series Half-Rack Audio Power Amplifiers • Introduction

technology from Extron that eliminates the high frequency switching ripple and EMI

emissions found in typical Class D amplifiers. CDRS enables Extron power amplifiers to be

situated near wireless AV devices without RF interference.

Convection cooled — The XTRA Series of amplifiers are convection cooled without the

need for fans, ensuring quiet, reliable operation.

Ultra low inrush current — no need for power sequencing — Allows many XTRA

series amplifiers to be powered on simultaneously without overloading power circuits.

This eliminates the need for power sequencing.

Flexible Conduit Adapter Kit — Suitable for use in other environmental air space in

accordance with section 300.22, (C) of the National Electrical Code only when used with

optional Flexible Conduit Adapter Kit.

Auto-standby with fast power-up — The amplifiers automatically enter into a standby

mode after 25 minutes of inactivity, + or - 5 minutes, dramatically reducing power

consumption. They quickly return to full power status upon signal detection.

Rear panel attenuation (level) controls — Provide attenuation of input signals for

setting proper audio system gain staging as well as two-zone applications. They are

located on the rear panel to prevent unauthorized or accidental tampering of the level

adjustments.

Multiple protection circuits — Activates during excessive clipping, output shorts,

thermal overload, or DC faults to prevent damage to the amplifier and speakers.

Remote standby port — Enables the amplifiers to be remotely powered down when not

in use, reducing operating cost.

Remote volume and mute control port — Allows the XPA 1002 series and the XPA

2001 series to be remotely controlled using the optional Extron VCM100 Series volume

and mute or VC50 volume controllers.

Bridgeable outputs — The power output of the XPA 1002 and XPA 1002 Plus can be

effectively doubled by bridging the output. A mono source is wired to both the left and

right input while the output is wired for bridged operation. Bridging allows power to be

output at 200 watts into 8 ohms. The minimum load impedance when bridging is 8 ohms

(see the wiring instructions on page 19).

Front and rear-mounted signal and protection indication LEDs — Provide

convenient indication of amplifier operation from both sides of an equipment rack.

Internal international power supply — The 100-240 VAC, 50-60Hz universal power

supply provides worldwide power compatibility.

2

Page 9

Installation

XTRA Series Half-Rack Audio Power Amplifiers • Installation

This section discusses how to install the XTRA Series of audio power amplifiers.

Topics that are covered, include:

• Application Examples

• Mounting the XTRA Series Amplifier

WARNING: Failure to follow these instructions may result in serious injury.

Installation and service must be performed by authorized personnel only (see

UL Guidelines for Rack Mounting on page 4).

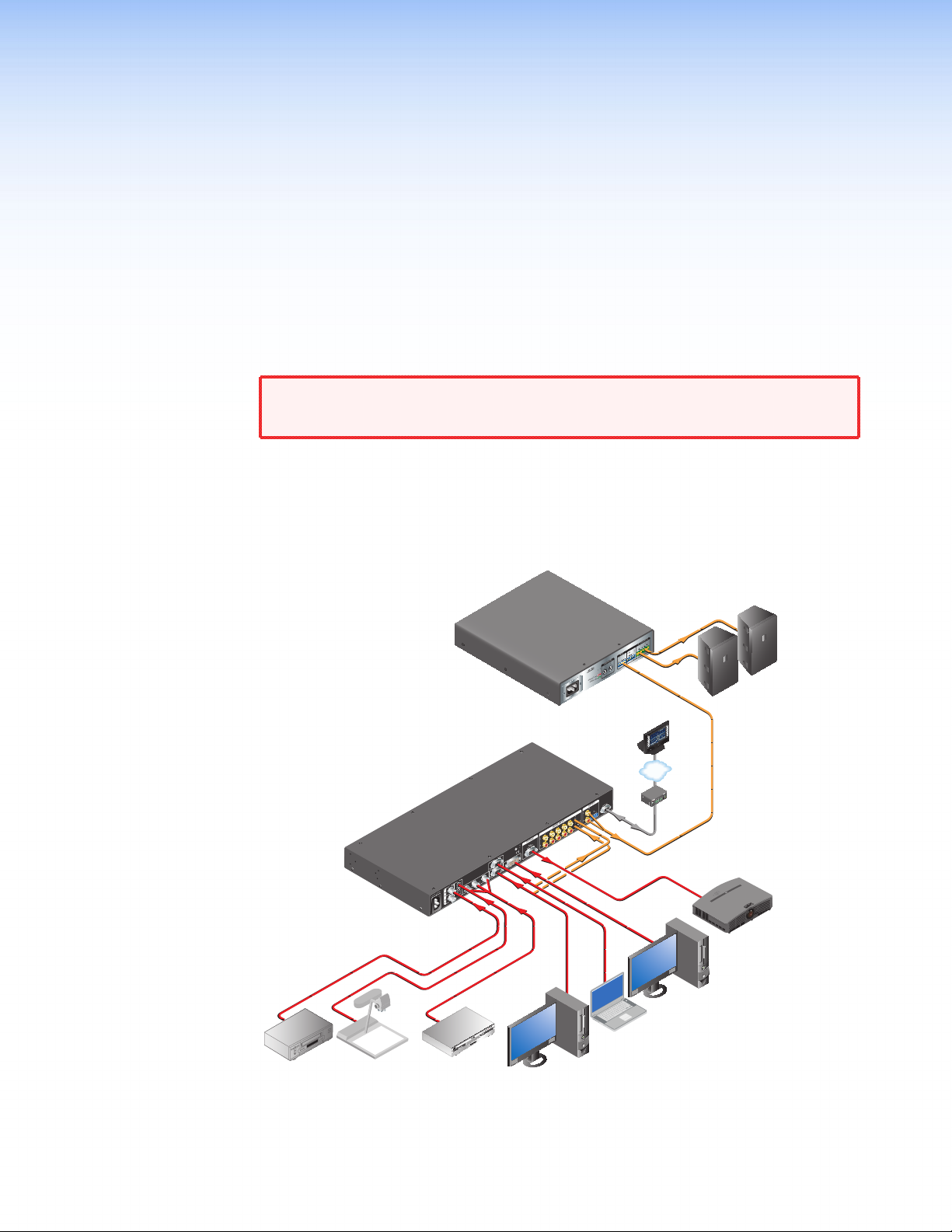

Application Examples

The following illustrations are application examples for the XPA 1002 series and the

XPA 2001 series.

Extron

IN150 8

Scaling Presentation

Switcher

VCR

Document

Camera

Extron

XPA 1002

Power

Amplier

3

YC

1

VID

I

Y

N

VID

100-240V 50-60Hz

4

P

U

2

T

DVD Player

2

8Ω / 4Ω OUTPUTS

1

REMOTE

STANDBY

10V 50mA

G

INPUTS

2

CLASS 2 WIRING

1

GCV

21

ATTENUATION

8

10

6

12

4

8

14

2

10

6

2

12

0

4

1

14

XPA 1002

2

∞

18

0

26

∞

SIGNAL

100-240V 0.5A, 50-60Hz

LIMITER/PROTECT

Extron

SI 28

TouchLink

Control

System

VCR

DVD

DOC

CAM

LAPTOP

PC

ON

OFF

DISPLAY

MUTE

SCREEN

UP

SCREEN

DOWN

Surface-mount

Speake rs

TCP/I P

®

100

RELAY

LINK

ACT

31

INPUT

IR

31

42

31

COM

42

TXRX

IPL 250

1

42

2

R

RS-232

3

RS-232

OUTPUT

A

R

B

L

L

6

R

8

4 5

7

3

AUDIO INPUT

2

1

L

OUTPUT

R

RGB

LISTED

1T23

U S

I.T.E.

Y, B-Y, R-Y

C

6

8

DVI

RGB

7

RGB

R-Y

5

B-Y

Projector

PC

DVI Outpu t

Laptop

PC

Figure 1. XPA 1002 Series Application Example

3

Page 10

Extron

XTRA Series Half-Rack Audio Power Amplifiers • Installation

MPX 423 A

Media Presentation

Matrix

PC (2)

GlobalViewer

AV Resource

Management and

Remote Control

Application

COMPUTER IN COMPUTER OUT VIDEO IN S-VIDEO INOUT

1

100-240V 0.3A

2

50/60 Hz

Extron

XPA 2001-70V

Power

Amplier

11

12

1 9

10

7

2

5

8

6

1

2

3

4

OUT COMPUTER

1

2

Extron

SI 26CT

Two-way Ceiling

Speake rs

70 V OUTPUT

REMOTE

50mA

STANDBY

10V

G

INPUTS

CLASS 2 WIRING

R

(SUMMED)

HPF

L

GCV

ATTENUATION

80 Hz

8

10

6

OFF

12

4

14

2

XPA 2001-70V

18

0

26

∞

SIGNAL

100-240V 0.5A, 50-60Hz

LIMITER/PROTECT

TCP/I P

Network

RS-232

C

O

O

N

VARIBLE

U

T

T

RESETACT

R

R

O

P

I

3

LINK

O

U

L

U

N

L

T

T

R

S-VIDEO

P

4

P

S

R

L

U

3

U

L

T

T

R

R

S

S

4

1

L

L

VIDEO

R

R

2

3

L

L

R

R

4

1

L

L

R

R

2

3

L

L

I

R

R

4

1

N

L

L

P

R

2

U

L

T

S

S-video

Video

VGA

Video

S-video

VGA

Projector

Laptop (2)

DVD (4)

Flat Panel Display

VCR (4)

Figure 2. XPA 2001 Series Application Example

Mounting the XTRA Series Amplifiers

The XPA 1002 series and XPA 2001 series of audio amplifiers can be set on a table,

Tabletop Use

UL Guidelines for Rack Mounting

mounted on a rack shelf, or mounted in the plenum space above a ceiling-mounted

projector.

Four self-adhesive rubber feet are included with the audio amplifier.

For tabletop use, attach one foot at each corner of the bottom side of the unit and place

the unit in the desired location.

The following Underwriters Laboratories (UL) guidelines pertain to the installation of the

equipment in a rack.

1. Elevated operating ambient — If installed in a closed or multi-unit rack assembly,

the operating ambient temperature of the rack environment may be greater than room

ambient. Therefore, consider installing the equipment in an environment compatible

with the maximum ambient temperature specified by the manufacturer [Tma = +32 to

+122 °F (0 to +50 °C)].

4

Page 11

2. Reduced air flow — Installation of the equipment in a rack should be such that the

XTRA Series Half-Rack Audio Power Amplifiers • Installation

3. Mechanical loading — Mounting of the equipment in the rack should be such that a

4. Circuit overloading — Consideration should be given to the connection of the

5. Reliable earthing (grounding) — Reliable earthing of rack-mounted equipment

Rack Mounting

The XPA 1002 series and XPA 2001 series can be mounted in a rack shelf using the

optional RSU 129 1U Universal rack shelf or the 1U Basic rack shelf, as follows.

1. If feet were installed on the bottom of the amplifier, remove them.

2. Place the amplifier on one half of the rack shelf.

3. Align the front of the amplifier with the front of the shelf, and align the threaded

4. Attach the amplifier to the rack shelf with the two provided 4-40 x 3/16” machine

5. Insert the screws from the underside of the shelf, and securely fasten them into

amount of air flow required for safe operation of the equipment is not compromised.

hazardous condition is not achieved due to uneven mechanical loading.

equipment to the supply circuit and the effect that overloading of the circuits might

have on overcurrent protection and supply wiring. Appropriate consideration of

equipment nameplate ratings should be used when addressing this concern.

should be maintained. Particular attention should be given to supply connections

other than direct connections to the branch circuit (such as the use of power strips).

holes on the bottom of the amplifier with the holes in the rack shelf.

screws.

diagonally-opposite corners.

1U Universal Rack Shelf

1/2 Rack Width Front False

Faceplate

Front false

faceplate

uses 2

screws.

(2) 4-40 x 3/16"

Screws

ATTENTION: Using screws longer than

3/16” will damage the unit and void the

Use 2 mounting holes on

opposite corners.

warranty.

Figure 3. Rack Mounting of the Amplifier

6. Attach the false front panel (provided with rack shelf) to the unoccupied side of the

rack (as shown above), or install a second half-rack-width device in that side by

repeating steps 1 through 5.

7. Attach the rack shelf to the rack using four 10-32 x ¾” bolts (provided). Insert the

bolts through #10 beveled washers, then through the holes in the rack, as shown

above.

5

Page 12

Rack Mounting Ventilation Recommendations

XTRA Series Half-Rack Audio Power Amplifiers • Installation

Excessive heat can decrease the optimal lifetime of the power amplifier. An over temp

indicator LED on the front panel of the amplifier lights red whenever the recommended

operating temperature has been exceeded (see Front Panel Features and Operation

on page 9).

To reduce the chances for an over temp condition, the XPAs should be arranged in a

rack environment so that adequate airflow is available both above and below the XPA

whenever possible. No more than two XPAs should be arranged one-on-top-of-the-other

in a rack without an open space between them, as shown in the following illustration. An

XPA can also be arranged above or below another non-XPA device, but there must be an

open space both above and below those devices.

Vent Space

Vent Space

Vent Space

Vent Space

Vent Space

Vent Space

Figure 4. Allow Sufficient Spacing for Adequate Ventilation

Flexible Conduit Adapter Kit Installation

WARNING: Failure to follow these instructions may result in serious injury.

• The circuit breaker used for this connection should be rated no lower than 20

amps and no greater than 30 amps.

• This unit must be installed in accordance with the National Electrical Code and

with all local codes.

• An ALL-POLE MAINS SWITCH with a contact separation of at least 3 mm in

each pole shall be incorporated in the electrical installation of the building. The

installation shall be carried out in accordance with all applicable installation rules.

• Installation and service must be performed by a qualified electrician only.

• Make sure that the source device and the XPA are turned off and disconnected

from the power source before you begin.

ATTENTION: A UL listed electrical distribution box is recommended for the

termination of the conduit opposite the XPA (see the following UL Requirements

section on page 7).

6

Page 13

The optional Flexible Conduit Adapter Kit consists of:

XTRA Series Half-Rack Audio Power Amplifiers • Installation

• One EMT adapter plate

• One 6-foot long electrical conduit

• Three 7.5 feet, 18-gauge spade connector power wires

• One UL-rated zip tie wrap

• Three auxiliary crimp style spade connectors designed for 14- to 16-gauge wires

NOTE: If needed, Extron recommends using a UL-rated crimp tool to terminate

the spade connectors. One recommended choice is the Molex crimp tool.

The kit provides a convenient means to replace the IEC power cord of the XPA with

conduit, where required by local codes.

UL Requirements

The UL requirements listed below pertain to the installation of the flexible conduit onto a

XPA 1002 or XPA 2001.

• This unit is not to be used beyond its rated voltage range.

• This unit must be wired to a UL listed distribution box.

NOTE: The UL approved electrical distribution box is not included with either

the XPA or the Flexible Conduit Adapter Kit. The installer is responsible for

obtaining and installing the box.

Installing the Flexible Conduit Kit

ATTENTION: Electrostatic discharge (ESD) can damage IC chips even though you

cannot feel it. You must be electrically grounded before touching anything inside the

XPA. A grounding wrist strap is recommended.

Install flexible conduit to the XPA by following the steps below.

1. Unplug the IEC power cord from the power amplifier.

2. Remove the 8 screws from the top and sides of the XPA and lift off the cover (see

figure 5).

Lift Cover Straight Up

Remove (8)

screws

2

8Ω / 4Ω OUTPUTS

1

REMOTE

STANDBY

10V 50mA

G

INPUTS

2

CLASS 2 WIRING

1

GCV

21

ATTENUATION

8

10

6

12

4

8

14

2

10

6

2

12

0

4

1

14

XPA 1002

2

∞

18

0

26

∞

SIGNAL

100-240V 0.5A, 50-60Hz

LIMITER/PROTECT

Figure 5. Removing the Cover

7

Page 14

3. Remove the 2 screws holding the hot (Line) and neutral wires from the terminal block

XTRA Series Half-Rack Audio Power Amplifiers • Installation

on the PCB (see figure 6).

Blue Wire

100-240V 1.3A

50-60Hz

Remove screws

(both sides) to release

IEC connector plate.

Brown Wire

L

N

Remove nut

Figure 6. Removing the IEC Connector

4. Remove the ground wire nut from the grounding stud on the bottom of the enclosure,

as shown above.

5. Remove the 2 screws from the IEC plate, and remove the IEC connector plate and

the attached wires through the rear panel of the XPA, as shown above.

6. Thread the 18-gauge power wires through the length of the electrical conduit tube.

7. Install the EMT adapter plate with conduit attached into the opening from which the

IEC connector was removed in step 5.

8. Slide the conduit nut over the bundle of wires exiting the conduit and onto the conduit

itself. Hand tighten the conduit nut to the conduit.

9. Attach the EMT adapter plate assembly to the XPA using the 2 screws that were

removed in step 5.

10. Connect the black hot (Line) and white neutral wires to the terminal block on the PCB

using the 2 screws that were removed in step 3. Use the included zip tie wrap to

secure the two wires together close to the terminals (see figure 7).

WARNING: Failure to follow these instructions may result in serious

injury.

Ensure that you observe correct wire polarity. The following illustration shows

the location of the hot (Line) and neutral terminals.

Zip-Tie

LINE

NEUTRAL

EMT Adapter Plate

Terminal Block

L

N

Conduit Nut

Hot

Terminal (Black)

Neutral

Terminal (White)

Ground

Wire Nut

Figure 7. Installing the EMT Adapter Plate Assembly

11. Secure the ground wire, as shown above, to the grounding stud on the bottom of the

enclosure using the nut that was removed in step 4.

12. Replace the cover of the XPA by attaching the 8 screws that were removed in step 2.

8

Page 15

Operation

X

X

XTRA Series Half-Rack Audio Power Amplifiers • Operation

This section discusses how to operate the XTRA Series of audio power amplifiers.

Topics covered, include:

• Front Panel Features and Operation

• Rear Panel Features and Operation

Front Panel Features and Operation

2

3

12

OVER

1

XPA 1002

XPA 1002 Plus

Front Panel

TEMP

LIMITER/PROTECT

SIGNAL

4

XPA 1002

2

3

OVER

TEMP

1

PA 2001-70V

PA 2001-100V

Front Panel

Power indicator LED — This LED lights:

a

LIMITER/PROTECT

SIGNAL

4

XPA 2001

• Green when the amplifier is receiving full power.

• Amber when the amplifier is in Standby mode. Standby mode turns off all outputs

from the amplifier, although the amplifier is still receiving power (see f of

Rear Panel Features and Operation on page 13).

Over Temp indicator LED — This LED lights red when the amplifier exceeds the

b

recommended operating temperature for optimal lifetime. The LED turns off after the

amplifier has cooled down sufficiently.

Should the LED light, check the following:

• Verify that the placement of the amplifier allows for adequate ventilation and

airflow.

• Avoid placing other equipment on top of the amplifier.

• Verify that the ambient temperature is within the specified range.

9

Page 16

Limiter/Protect indicator LEDs — These LEDs (representing their respective output

XTRA Series Half-Rack Audio Power Amplifiers • Operation

c

channels) light red under three circumstances:

12

LIMITER/PROTECT

• When the output wiring is shorted together.

• When audio clipping occurs, the LED of the corresponding channel blinks once

per clip occurrence.

• When the amplifier overheats, both LEDs are lit. The LEDs are not lit after the

amplifier recovers from the overheated condition.

NOTE: These LEDs are duplicated on the rear panel.

Signal indicator LEDs — These LEDs (representing their respective output

d

channels) light green only when an input signal is detected on the corresponding

channel.

12

SIGNAL

NOTE: These LEDs are duplicated on the rear panel.

10

Page 17

Rear Panel Features and Operation

XTRA Series Half-Rack Audio Power Amplifiers • Operation

2

100-240V 0.5A, 50-60Hz

1

XPA 1002

XPA 1002 Plus

Rear Panel

XPA 1002

LIMITER/PROTECT

SIGNAL

1

2

ATTENUATION

2

10

12

8

6

14

14

18

4

2

26

0

∞

4 5a 6 7a

3

INPUTS

1

21

10

12

8

0

∞

2

6

4

2

REMOTE

10V 50mA

G

STANDBY

8Ω / 4Ω OUTPUTS

1

2

100-240V 0.5A, 50-60Hz

1

XPA 2001-70V

LIMITER/PROTECT

SIGNAL

ATTENUATION HPF

10

12

8

6

14

80 Hz

18

4

2

26

0

∞

INPUTS

REMOTE

10V

L

(SUMMED)

R

OFF

70 V OUTPUT

50mA

G

STANDBY

GCV

CLASS 2 WIRING

XPA 2001-70V

Rear Panel

3 4 8 5b 6

7b

2

100-240V 0.5A, 50-60Hz

1

XPA 2001-100V

LIMITER/PROTECT

SIGNAL

ATTENUATION HPF

10

12

8

6

14

80 Hz

18

4

2

26

0

∞

100 V OUTPUT

REMOTE

INPUTS

50mA

10V

L (SUMMED)

R

G

OFF

STANDBY

GCV

CLASS 2 WIRING

XPA 2001-100V

Rear Panel

3 4 8 5b 6

7b

NOTE: Control signal ground pins may be labeled as , , or “G”. Audio ground pins

may be labeled as or .

The wiring and function are the same, whichever way your product is labeled.

AC power connector — Connect a standard IEC AC power cord here for power

a

input (100 VAC to 240 VAC, 50 to 60 Hz) to the internal, autoswitching power supply.

This connector may be replaced by the Flexible Conduit Adapter Kit as described in

Flexible Conduit Adapter Kit Installation on page 6.

Limiter/Protect indicator LEDs — These LEDs light red under specific

b

circumstances.

NOTE: See c of Front Panel Features and Operation on page 10 for more

details.

Signal indicator LEDs — These LEDs light green only when an input signal is

c

detected on the corresponding channel.

NOTE: See d of Front Panel Features and Operation on page 10 for more

details.

11

Page 18

Attenuation — Use a small screwdriver to adjust the audio input level for the

XTRA Series Half-Rack Audio Power Amplifiers • Operation

d

corresponding channel. The analog potentiometers control the level from = (full

attenuation) to 0 dB (no attenuation).

ATTENUATION

10

12

8

14

18

26

0

∞

21

10

12

8

6

6

14

4

2

2

0

∞

4

ATTENUATION

10

12

8

6

14

18

4

2

26

0

∞

XPA 1002 Series XPA 2001 Series

LEVEL

12

0 0

LEVEL

0

XPA 1002 XPA 2001 Series

NOTES:

• On the XPA 2001 models, the single control adjusts the levels of both

channels simultaneously prior to summing them together.

• On some models, this adjustment is referred to as “level”. The function is the

same, whichever way your product is labeled.

To adjust the attenuation level of the XPA amplifier, do the following:

1. If connecting to a source device with a volume control (variable output), ensure

that the volume on the source device is set to its lowest point, then adjust the

attenuation of the XPA fully counterclockwise.

2. Set the volume of the source device to its maximum volume level. No sound

should be heard.

3. Return to the XPA amplifier and raise the attenuation until sound distortion

occurs, then lower the level slightly to remove any distortion. This setting ensures

that, whatever the source device volume setting is, no clipping occurs.

NOTE: When setting volume control through a source device, ensure that the

volume of the device is set to variable out. Consult the user manual of the

device for detailed instructions on its calibration.

Balanced or unbalanced stereo or mono audio input connector

à

(XPA 1002 series) — Wire the 3.5 mm 5-pin captive screw connector for balanced

or unbalanced input as show in the diagram on the following page.

NOTE: The power output of the XPA 1002 series amplifiers can be effectively

doubled by bridging the output. A mono source is wired to both the left and

right input while the output is wired for bridged operation. Bridging allows

power to be output at 200 watts into 8 ohms. The minimum load impedance

when bridging is 8 ohms (see the wiring instructions beginning on page 19).

12

Page 19

Tip

LR

XTRA Series Half-Rack Audio Power Amplifiers • Operation

Sleeve

Tip

Sleeve

Unbalanced Stereo Input

LR

Sleeves

Tip

Ring

Tip

Ring

Balanced Stereo Input

LR

Tip

Sleeve

Unbalanced Mono Input

LR

Tip

Ring

Sleeve

LR

Balanced Mono Input

Tip

Sleeve

Tip

Sleeve

Unbalanced Stereo Input

Do not tin the wires!

NOTE: The input connector receptacle may be

labeled one of two ways. The wiring and

function are the same, whichever way your

product is labeled.

Balanced or unbalanced stereo or mono audio input connector (XPA 2001) —

â

Wire the 3.5 mm 5-pin captive screw connector for balanced or unbalanced input.

NOTE: For mono input on the XPA 2001, because the left and right channels

are summed, only wire the left channel. No jumpering to the right channel is

needed.

LR

Tip

Ring

Sleeves

Tip

Ring

Balanced Stereo Input

LR

Tip

Sleeve

INPUTS

1

Unbalanced Mono Input

2

LR

1

or

Tip

Ring

Sleeve

Balanced Mono Input

INPUTS

2

Do not tin the wires!

NOTE: The input connector receptacle may be

labeled one of two ways. The wiring and

function are the same, whichever way your

INPUTS

1

2

INPUTS

1

2

or

product is labeled.

Remote control connector — The 3.5 mm 5-pin captive screw port is used to

f

remotely control two functions through contact closure (see the circuit diagram on the

following page).

NOTE: The remote control port may be labeled one of two ways (see the image

on the following page). The wiring and function are the same, whichever way

your product is labeled.

Pins V, C, and G (1, 2, and 3) control volume by varying the DC voltage from 0 V

(full attenuation) to 10 V (maximum volume) with full muting in effect when pin C is

connected to ground (pin G). Use the included 3-pin captive screw connector (see

Remote Volume Control on page 17).

13

Page 20

REMOTE

XTRA Series Half-Rack Audio Power Amplifiers • Operation

10V 50mA

10V 50 mA

VOL/MUTE

G

STANDBY

123

or

45

MAX

10K OHMS

MIN

GCV

2K OHMS

MUTE SWITCH

STANDBY

1 V

2 C

3

G

MUTE

VOLUME

Pin 5 (standby) connected to ground (pin 4) places the amplifier in standby mode.

Standby mode turns off all output, although the amplifier is still receiving power.

Use the included 2-pin, 3.5 mm captive screw connector to remotely ground pin

5. The power indicator LED lights amber when the amplifier is in standby mode.

REMOTE

10V 50mA

10V

V

50mA

GC

G

STANDBY

GCV

or

10V 50 mA

VOL/MUTE

G

STANDBY

Remote Switching to Standby Mode

123 45

STANDBY

Stereo audio output connector — Marked “1” and “2” for the output channels,

å

wire the included 4-pole, 5 mm screw lock captive screw connector to output stereo

audio. Observe the correct polarities for each channel (see the following steps).The

output is designed to power 4 or 8 ohm speaker systems and is rated for 100 watts

per channel at 4 ohms and 60 watts per channel at 8 ohms for the non-Plus model,

and 100 watts per channel at 4 and 8 ohms for the Plus model.

NOTES:

• You must use Class 2 wiring for this output to comply with UL requirements.

• The stereo audio output connector may be labeled one of two ways

(see the images on the following page). The wiring and function are the

same, whichever way your product is labeled.

14

Page 21

8Ω/4Ω OUTPUTS

XTRA Series Half-Rack Audio Power Amplifiers • Operation

2

1

OUTPUT

12

CLASS 2 WIRING

or

XPA 1002

XPA 1002 Plus

ATTENTION: Do not tie channel outputs 1 and 2 to each other or to ground.

Doing so will short the outputs, damage the amplifier, or both.

NOTE: The power output of the XPA 1002 series can be effectively doubled by

bridging the output. A mono source is wired to both the left and right input

while the output is wired for bridged operation. Bridging allows power to be

output at 200 watts into 8 ohms. The minimum load impedance when bridging

is 8 ohms (see the wiring instructions beginning on page 19).

To wire the stereo audio output connector:

Step 1: Strip and insert the speaker wires into the connector and tighten the

captive screws. Be sure to observe the correct polarity.

Do not tin the wires!

Step 2: Insert the wired connector into the amplifier output and secure the locking

screws on either side.

2

8Ω / 4Ω OUTPUTS

1

CLASS 2 WIRING

15

Page 22

Mono audio output connector — Wire the included 2-pole, 5 mm screw lock

XTRA Series Half-Rack Audio Power Amplifiers • Operation

ç

captive screw connector for mono audio (see the steps below). Output is designed to

power 70 V (XPA 2001-70V) or 100 V (XPA 2001-100V) line distribution systems and

is rated at 200 watts.

NOTES:

• You must use Class 2 wiring for this output to comply with UL requirements.

• The mono audio output connector may be labeled one of two ways

(see the images below). The wiring and function are the same, whichever

way your product is labeled.

70 V OUTPUT

CLASS 2 WIRING

XPA 2001-70V

OUTPUT

70V

or or

100 V OUTPUT

CLASS 2 WIRING

XPA 2001-100V

OUTPUT

100V

ATTENTION: Do not tie channel outputs 1 and 2 to each other or to ground.

Doing so will short the outputs, damage the amplifier, or both.

To wire the mono audio output connector:

Step 1: Strip and insert the speaker wires into the connector and tighten the

captive screws. Be sure to observe the correct polarity.

Do not tin the wires!

Step 2: Insert the wired connector into the amplifier output and secure the locking

screws on either side.

70 V OUTPUT

CLASS 2 WIRING

16

Page 23

High pass filter (HPF) toggle switch (XPA 2001 series) — Use a small

HPF

HPF

XTRA Series Half-Rack Audio Power Amplifiers • Operation

h

screwdriver to toggle this recessed two-position switch. Setting the switch to 80 Hz

(default) prevents the saturation of 70 V and 100 V speaker input transformers by

low frequency signals. Saturation can result in severe distortion of the speaker output

signal.

80 Hz

80 Hz

OFF

or

NOTES:

• The filter may be safely turned off if high pass filtering is applied to the

source input signal upstream of the amplifier. Otherwise, it should be left on.

• The high pass filter toggle switch may be labeled one of two ways. The

wiring and function are the same, whichever way your product is labeled.

Remote Volume Control

Options for the remote control of the XPA amplifiers include the Extron VCM 100 and

VC 50 volume controllers. Third party 10k potentiometer volume controllers can also be

connected to this port.

As shown in the following illustration, pin V (1) on the XPA is a 10 VDC reference voltage.

Pin C (2) is the volume control DC voltage input. The range is 0 to 10 V, where 0 V is mute

and 10 V provides maximum volume. Pin G (3) is ground.

NOTE: All nominal levels are at ±10%.

OFF

REMOTE

10V 50mA

G

STANDBY

Extron

STP 22

Cable

10V

VOL/

MUTE

VOLUME

MUTE

VCM 100

or

10V 50 mA

GCV

Red

Black

Ground

VOL/MUTE

12345

STANDBY

Figure 8. Pinout Diagram for VCM 100 MAAP Connection to XPA Remote

Connector

17

Page 24

Controlling Multiple Amplifiers with One Volume Controller

XTRA Series Half-Rack Audio Power Amplifiers • Operation

Several XPA 1002 and XPA 2001 series units can be daisy-chained so that one volume

controller can simultaneously regulate the volume of all the amplifiers.

NOTES:

• As additional amplifiers are added to the daisy chain, the sensitivity of the

volume potentiometer will change. The maximum volume level (fully clockwise)

will not be affected. However, the effectiveness of the minimum volume level

(fully counterclockwise) in reducing the volume to inaudible levels decreases as

more amplifiers are added to the daisy chain.

• When more than two XPA Half-Rack units are attached to the chain, sound may

be heard even if the levels have been set to their lowest. If complete muting is

required, use a contact closure switch attached between the C (Vol/Mute) and

the G (ground) pins of the first XPA Half-Rack unit in the chain.

To regulate multiple amplifiers with a single volume controller:

1. Attach all three pins of the volume controller to the corresponding pins on the first

XPA Half-Rack unit only — Ground to G (ground), Vol/Mute to C (Vol/Mute),

and 10 V to V (10 V).

2. Use jumper wires to connect the C (Vol/Mute) pins of the first amplifier and each

successive amplifier.

3. Use jumper wires to connect the G (ground) pins of the first amplifier and each

successive amplifier.

Extron

VCM 100 AAP

10V

VOL/

MUTE

REMOTE

10V 50mA

G

GCV

10V 50 mA

VOL/MUTE

12345

STANDBY

STANDBY

Extron

XPA Half-Rack

daisy chain

REMOTE

10V 50mA

G

GCV

10V 50 mA

VOL/MUTE

12345

STANDBY

STANDBY

REMOTE

10V 50mA

G

GCV

10V 50 mA

VOL/MUTE

12345

STANDBY

STANDBY

or

Figure 9. Regulating Multiple Amplifiers with a Single Volume Controller

NOTE: The 10 V pin of the volume controller connects to the first XPA Half-Rack

unit only. There are no jumper wires linking it to subsequent amplifiers.

18

Page 25

Bridged Mono Output

T

ATTENTION: Failure to follow these instructions may result in damage to the unit.

Electrostatic discharge (ESD) can damage IC chips even though you cannot feel it. You must be electrically grounded before touching anything inside the XPA. A grounding wrist strap is recommended.

XTRA Series Half-Rack Audio Power Amplifiers • Operation

The power output of the XPA 1002 and XPA 1002 Plus can be effectively doubled by

bridging the output. Bridging allows power to be output in mono at 200 watts at 8 ohms.

NOTES:

• The bridging instructions that follow apply only to the XPA 1002 series.

• The minimum load impedance when bridging is 8 ohms.

To bridge the output, follow the steps and refer to the diagram below:

1. Unplug the IEC power cord from the power amplifier.

2. Fully attenuate the potentiometer.

3. Wire the output as shown in the following diagram.

4. Wire the input as shown in the following diagram.

5. Connect the IEC power cord and power up the amplifier.

6. Adjust the input levels of channels 1 and 2 identically.

NOTE: See d (Attenuation) of Rear Panel Features and Operation on page

12 for more details.

100-240V 0.5A, 50-60Hz

Balanced Wiring

From

Mono

Source

Un-Balanced Wiring

From

Mono

Source

XPA 1002

LIMITER/PROTECT

Levels should be set

identically.

Captive Screw

1

SIGNAL

3.5 mm

1

2

1

2

5 mm

Captive Screw

2

ATTENUATION

12

14

18

26

∞

1

21

10

12

8

6

14

4

2

0

∞

2

10

8

6

4

2

0

Input

10V 50mA

1

2

G

STANDBY

Amplified

Output

8Ω / 4Ω OUTPUTS

REMOTE

INPUTS

1

o 8 Ohm Minimum

Speaker Load

2

NOTE: During bridged mono output, the + output

from channel 1 becomes the positive terminal and

the + output from channel 2 becomes the

negative terminal

Figure 10. Bridging the Output of the XPA 1002 Series

19

Page 26

Troubleshooting

XTRA Series Half-Rack Audio Power Amplifiers • Troubleshooting

The front and rear panels have LED warning indicators, as described in the following

diagnostic information.

Amplifier Fails to Exit Standby Mode Promptly

The input channel (channels 1 and 2) Signal LED lights green per indicated input channel

when an input signal is detected.

Power LED

Color

Amber Not lit No output signal No input detected, verify the

Green or

Amber

Amber Lit No output signal Amplifier has been placed in

Amber Lit DC Fault is detected

Signal LED

State

Lit

intermittently

Problem Description Problem Solution

input signal.

If input is present, raise input

level until signal LED lights.

Does not promptly exit

standby mode with

signal present.

on either channel. Unit

does not exit standby.

The output signal level of the

source may be too low to cross

the signal detection threshold

of the amplifier (see amplifier

specifications for details).

Increase the signal level of the

source until the signal LED

lights consistently.

standby mode and output has

been turned off. Check remote

port. DC Fault may have been

detected (see below).

Disconnect power then

disconnect the remote port (if

connected). Next, reconnect

power to the unit to determine

if the unit continues to go

into immediate standby upon

power up. In such a case, the

unit should be serviced.

20

Page 27

Amplifier Enters Standby Mode Too Early

XTRA Series Half-Rack Audio Power Amplifiers • Troubleshooting

The input channel (channels 1 and 2) Signal LED lights green per indicated input channel

when an input signal is detected.

Power LED

Color

Green or

Amber

Signal LED

State

Lit

intermittently

Problem Description Problem Solution

Enters standby mode

early.

Limiter/Protect LED Warning Indicators

The output channel (channels 1 and 2) Limiter/Protect LED lights red per indicated output

channel as shown in the following diagnostic information.

LED State Problem Description Problem Solution

Blinks Audio clipping is occurring at the rate

of one blink per clip.

Lights steady The amplifier may be overheating. Determine the reason for the

Output channel leads are shorted Check speakers and speaker

The output signal level of the

source may be too low to cross

the signal detection threshold

of the amplifier (see amplifier

specifications for details).

Increase the signal level of the

source until the signal LED

lights consistently.

Reduce the power output to

avoid overdriving the amplifier,

causing clipping.

overheated state and allow the

amplifier to cool. The LED will not

be lit after the amplifier recovers

from the overheated state.

wiring for shorts.

Over Temp Indicator LED

This indicator does not represent a hard failure of the unit. It is meant as a warning that

the amplifier has exceeded the recommended operating temperature for optimal product

lifetime.

LED State Problem Description Problem Solution

Lights steady Amplifier has exceeded the

recommended operating

temperature. The LED turns off after

the amplifier cools down sufficiently.

• Verify that the placement of the

amplifier allows for adequate

ventilation and airflow.

• Avoid placing equipment on top

of the amplifier.

• Verify that the ambient

temperature is within the

specified range.

21

Page 28

Extron Warranty

Extron Electronics warrants this product against defects in materials and workmanship for a period of three years

from the date of purchase. In the event of malfunction during the warranty period attributable directly to faulty

workmanship and/or materials, Extron Electronics will, at its option, repair or replace said products or components,

to whatever extent it shall deem necessary to restore said product to proper operating condition, provided that it is

returned within the warranty period, with proof of purchase and description of malfunction to:

USA, Canada, South America,

and Central America:

Extron Electronics

1230 South Lewis Street

Anaheim, CA 92805

U.S.A.

Europe and Africa:

Extron Europe

Hanzeboulevard 10

3825 PH Amersfoort

The Netherlands

Japan:

Extron Electronics, Japan

Kyodo Building, 16 Ichibancho

Chiyoda-ku, Tokyo 102-0082

Japan

China:

Extron China

686 Ronghua Road

Songjiang District

Shanghai 201611

China

Asia:

Extron Asia Pte Ltd

135 Joo Seng Road, #04-01

PM Industrial Bldg.

Singapore 368363

Middle East:

Extron Middle East

Dubai Airport Free Zone

F12, PO Box 293666

United Arab Emirates, Dubai

Singapore

This Limited Warranty does not apply if the fault has been caused by misuse, improper handling care, electrical

or mechanical abuse, abnormal operating conditions, or if modifications were made to the product that were not

authorized by Extron.

NOTE: If a product is defective, please call Extron and ask for an Application Engineer to receive an RA (Return

Authorization) number. This will begin the repair process.

USA: 714.491.1500 or 800.633.9876 Europe: 31.33.453.4040

Asia: 65.6383.4400 Japan: 81.3.3511.7655

Units must be returned insured, with shipping charges prepaid. If not insured, you assume the risk of loss or damage

during shipment. Returned units must include the serial number and a description of the problem, as well as the

name of the person to contact in case there are any questions.

Extron Electronics makes no further warranties either expressed or implied with respect to the product and its quality,

performance, merchantability, or fitness for any particular use. In no event will Extron Electronics be liable for direct,

indirect, or consequential damages resulting from any defect in this product even if Extron Electronics has been

advised of such damage.

Please note that laws vary from state to state and country to country, and that some provisions of this warranty may

not apply to you.

Extron Headquarters

+1.800.633.9876 (Inside USA/Canada Only)

Extron USA - West Extron USA - East

+1.714.491.1500 +1.919.850.1000

+1.714.491.1517 FAX +1.919.850.1001 FAX

Extron Europe

+800.3987.6673

(Inside Europe Only)

+31.33.453.4040

+31.33.453.4050 FAX

© 2014 Extron Electronics All rights reserved. www.extron.com

Extron Asia

+800.7339.8766

(Inside Asia Only)

+65.6383.4400

+65.6383.4664 FAX

Extron Japan

+81.3.3511.7655

+81.3.3511.7656 FAX

Extron China

+4000.398766

Inside China Only

+86.21.3760.1568

+86.21.3760.1566 FAX

Extron Middle East

+971.4.2991800

+971.4.2991880 FAX

Extron Korea

+82.2.3444.1571

+82.2.3444.1575 FAX

Extron India

1800.3070.3777

Inside India Only

+91.80.3055.3777

+91.80.3055.3737 FAX

Loading...

Loading...