Page 1

XTP T UWP 202

Two Input XTP Transmitter – Decora® Wallplate

User Guide

XTP Extender

68-2033-01 Rev. A

03 14

Page 2

Safety Instructions

Safety Instructions • English

WARNING: This symbol, , when used on the product, is intended to

alert the user of the presence of uninsulated dangerous voltage within the

product’s enclosure that may present a risk of electric shock.

ATTENTION: This symbol, , when used on the product, is intended

to alert the user of important operating and maintenance (servicing)

instructions in the literature provided with the equipment.

For information on safety guidelines, regulatory compliances, EMI/EMF

compatibility, accessibility, and related topics, see the Extron Safety and

Regulatory Compliance Guide, part number 68-290-01, on the Extron website,

www.extron.com.

Instructions de sécurité • Français

AVERTISSEMENT : Ce pictogramme, , lorsqu’il est utilisé sur le

produit, signale à l’utilisateur la présence à l’intérieur du boîtier du produit

d’une tension électrique dangereuse susceptible de provoquer un choc

électrique.

ATTENTION : Ce pictogramme, , lorsqu’il est utilisé sur le produit,

signale à l’utilisateur des instructions d’utilisation ou de maintenance

importantes qui se trouvent dans la documentation fournie avec le

matériel.

Pour en savoir plus sur les règles de sécurité, la conformité à la réglementation,

la compatibilité EMI/EMF, l’accessibilité, et autres sujets connexes, lisez les

informations de sécurité et de conformité Extron, réf. 68-290-01, sur le site

Extron, www.extron.com.

Sicherheitsanweisungen • Deutsch

WARNUNG: Dieses Symbol auf dem Produkt soll den Benutzer

darauf aufmerksam machen, dass im Inneren des Gehäuses dieses

Produktes gefährliche Spannungen herrschen, die nicht isoliert sind

und die einen elektrischen Schlag verursachen können.

Инструкция по технике безопасности • Русский

ПРЕДУПРЕЖДЕНИЕ: Данный символ, , если указан

на продукте, предупреждает пользователя о наличии

неизолированного опасного напряжения внутри корпуса

продукта, которое может привести к поражению электрическим

током.

ВНИМАНИЕ: Данный символ, , если указан на продукте,

предупреждает пользователя о наличии важных инструкций

по эксплуатации и обслуживанию в руководстве,

прилагаемом к данному оборудованию.

Для получения информации о правилах техники безопасности,

соблюдении нормативных требований, электромагнитной

совместимости (ЭМП/ЭДС), возможности доступа и других

вопросах см. руководство по безопасности и соблюдению

нормативных требований Extron на сайте Extron: www.extron.com,

номер по каталогу - 68-290-01.

Chinese Simplified(简体中文)

警告: 产品上的这个标志意在警告用户该产品机壳内有暴露的危险 电压,

有触电危险。

注意: 产品上的这个标志意在提示用户设备随附的用户手册中有

重要的操作和维护(维修)说明。

关于我们产品的安全指南、遵循的规范、EMI/EMF 的兼容性、无障碍

使用的特性等相关内容,敬请访问 Extron 网站 www.extron.com,参见

Extron 安全规范指南,产品编号 68-290-01。

Chinese Traditional( )

警告: 若產品上使用此符 號,是為了提醒使 用者,產品機殼內存在著

可能會導致觸電之風險的未絕緣危險電壓。

VORSICHT: Dieses Symbol auf dem Produkt soll dem Benutzer in der

im Lieferumfang enthaltenen Dokumentation besonders wichtige Hinweise

zur Bedienung und Wartung (Instandhaltung) geben.

Weitere Informationen über die Sicherheitsrichtlinien, Produkthandhabung,

EMI/EMF-Kompatibilität, Zugänglichkeit und verwandte Themen finden Sie in

den Extron-Richtlinien für Sicherheit und Handhabung (Artikelnummer

68-290-01) auf der Extron-Website, www.extron.com.

Instrucciones de seguridad • Español

ADVERTENCIA: Este símbolo, , cuando se utiliza en el producto,

avisa al usuario de la presencia de voltaje peligroso sin aislar dentro del

producto, lo que puede representar un riesgo de descarga eléctrica.

ATENCIÓN: Este símbolo, , cuando se utiliza en el producto, avisa

al usuario de la presencia de importantes instrucciones de uso y

mantenimiento recogidas en la documentación proporcionada con el

equipo.

Para obtener información sobre directrices de seguridad, cumplimiento

de normativas, compatibilidad electromagnética, accesibilidad y temas

relacionados, consulte la Guía de cumplimiento de normativas y seguridad de

Extron, referencia 68-290-01, en el sitio Web de Extron,www.extron.com.

注意 若產品上使用此符號,是為了提醒 使用者,設備隨附的用戶手冊中有重

要的操作和維護(維修)説明。

有關安全性指導方針、法規遵守、EMI/EMF 相容性、存取範圍和相關主題的詳細資

訊,請瀏覽 Extron 網站:www.extron.com,然後參閱《Extron 安全性與法規

遵守手冊》,準則編號 68-290-01。

Japanese

警告: この記 号 が製品上に表示されている場合は、筐体内に絶縁されて

いない高電圧が流れ、感電の危険があることを示しています。

注意: この記号 が製品上に表示されている場合は、本機の取扱説明書

に 記載さ れて いる重 要な操 作 と保 守 ( 整 備)の 指 示につ いてユーザ ー の 注

意を喚起するものです。

安全上のご注意、法規厳守、EMI/EMF適合性、その他の関連項目に

つ い て は 、エ ク ストロン の ウェ ブ サ イト www.extron.com よ り 『 Extron Safety

and Regulatory Compliance Guide』 ( P/N 68-290-01) をご覧ください。

Korean

경고: 이 기호 가 제품에 사용될 경우, 제품의 인클로저 내에 있는

접지되지 않은 위험한 전류로 인해 사용자가 감전될 위험이 있음을

경고합니다.

주의: 이 기호 가 제품에 사용될 경우, 장비와 함께 제공된 책자에 나와

있는 주요 운영 및 유지보수(정비) 지침을 경고합니다.

안전 가이드라인, 규제 준수, EMI/EMF 호환성, 접근성, 그리고 관련 항목에

대한 자세한 내용은 Extron 웹 사이트(www.extron.com)의 Extron 안전 및

규제 준수 안내서, 68-290-01 조항을 참조하십시오.

Page 3

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part15 of the FCC rules. The ClassA limits provide reasonable

protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and,

if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause interference. This interference must be corrected at the expense of the user.

ATTENTION: The Twisted Pair Extension technology works with shielded twisted pair (STP)

cables only. To ensure FCC Class A and CE compliance, STP cables and STP connectors are

also required.

For more information on safety guidelines, regulatory compliances, EMI/EMF

compatibility, accessibility, and related topics, see the “Extron Safety and Regulatory

Compliance Guide” on the Extron website.

Copyright

© 2014 Extron Electronics. All rights reserved.

Trademarks

All trademarks mentioned in this guide are the properties of their respective owners.

The following registered trademarks

(®)

, registered service marks

(SM)

, and trademarks

(TM)

are the property of

RGBSystems, Inc. or Extron Electronics:

Registered Trademarks

AVTrac, Cable Cubby, CrossPoint, eBUS, EDID Manager, EDID Minder, Extron, Flat Field, GlobalViewer, Hideaway, Inline, IPIntercom,

IPLink, Key Minder, LockIt, MediaLink, PlenumVault, PoleVault, PowerCage, PURE3, Quantum, SoundField, SpeedMount, SpeedSwitch,

SystemINTEGRATOR, TeamWork, TouchLink, V-Lock, VersaTools, VN-Matrix, VoiceLift, WallVault, WindoWall, XTP and XTP Systems

Registered Service Mark

AAP, AFL (Accu-Rate Frame Lock), ADSP (Advanced Digital Sync Processing), Auto-Image, CDRS (Class D Ripple Suppression), DDSP (Digital

Display Sync Processing), DMI (Dynamic Motion Interpolation), DriverConfigurator, DSPConfigurator, DSVP (Digital Sync Validation Processing),

FastBite, FOXBOX, IP Intercom HelpDesk, MAAP, MicroDigital, ProDSP, QS-FPC (QuickSwitch Front Panel Controller), Scope-Trigger, SIS,

Simple Instruction Set, Skew-Free, SpeedNav, Triple-Action Switching, XTRA, ZipCaddy, ZipClip

(SM)

: S3 Service Support Solutions

Trademarks

(®)

(™)

Page 4

Conventions Used in this Guide

Notifications

The following notifications are used in this guide:

WARNING: A warning indicates a situation that has the potential to result in death or

severe injury.

CAUTION: A caution indicates a situation that may result in minor injury.

ATTENTION: Attention indicates a situation that may damage or destroy the product or

associated equipment.

NOTE: A note draws attention to important information.

TIP: A tip provides a suggestion to make working with the application easier.

Software Commands

Commands are written in the fonts shown here:

^AR Merge Scene,,Op1 scene 1,1 ^B 51 ^W^C

[01] R 0004 00300 00400 00800 00600 [02] 35 [17] [03]

E X! *X1&* X2)* X2#* X2! CE}

NOTE: For commands and examples of computer or device responses mentioned

in this guide, the character “0” is used for the number zero and “O” represents the

capital letter “o.”

Computer responses and directory paths that do not have variables are written in the font

shown here:

Reply from 208.132.180.48: bytes=32 times=2ms TTL=32

C:\Program Files\Extron

Variables are written in slanted form as shown here:

ping xxx.xxx.xxx.xxx —t

SOH R Data STX Command ETB ETX

Selectable items, such as menu names, menu options, buttons, tabs, and field names are

written in the font shown here:

From the

Click the OK button.

File menu, select New.

Specifications Availability

Product specifications are available on the Extron website, www.extron.com.

Page 5

Contents

Introduction .................................................... 1

About this Guide ................................................. 1

About the XTP T UWP 202 ................................. 1

Key Features ...................................................... 2

Installation and Operation .............................. 4

Installation Overview ........................................... 4

Installing the Metal Junction Box or Mud Ring .... 5

Cutting an Opening in the Mounting Surface ... 5

Installing the Mud Ring ................................... 6

Installing a UL Listed Metal Junction Box ........ 7

Rear and Side Panel Connectors ........................ 7

Mounting the XTP T UWP 202 ............................ 9

Front Panel Connectors .................................... 10

Making Connections ......................................... 11

HDMI Connection ......................................... 11

TP Cable Termination and

Recommendations ...................................... 12

RS-232 and IR Over XTP Communication .... 13

Power Connection ........................................ 14

Operation ......................................................... 16

Indicators...................................................... 16

EDID ............................................................. 16

Reset Modes ................................................ 17

SIS Configuration and Control ..................... 18

Host Device Connection ................................... 18

SIS Programming Guide ................................... 18

Host-to-Device and Device-to-Host

Communication ........................................... 18

Device-Initiated Message .............................. 18

Error Responses ........................................... 19

Using the Command and Response Tables

for SIS Commands ...................................... 19

Symbol Definitions ........................................ 19

Command and Response Tables for SIS

Commands ..................................................... 20

Input Commands .......................................... 20

Audio Configuration Commands ................... 20

Picture Adjustment Commands

(Analog Only) ............................................... 21

Preset Commands ........................................ 21

EDID Commands .......................................... 22

Advanced Configuration Commands ............ 22

XTP System Configuration Software ........... 23

Installing the XTP System Configuration

Software .......................................................... 23

Using the XTP System Configuration

Software .......................................................... 24

Connections ................................................. 24

Top Menu ..................................................... 25

Device Settings ............................................. 28

Reference Information ................................. 36

Updating Firmware with Firmware Loader ......... 36

Downloading Extron Firmware Loader .......... 36

Installing Firmware Loader ............................ 37

Downloading Firmware ................................. 38

Installing Firmware with Firmware Loader ...... 39

Mounting Template ........................................... 40

XTP T UWP 202 Wallplate Transmitter • Contents

v

Page 6

XTP T UWP 202 Wallplate Transmitter • Contents vi

Page 7

Introduction

This section contains general information about this guide and the Extron XTP T UWP 202

Wallplate Transmitter, and selected device features. Topics in this section include:

• About this Guide

• About the XTP T UWP 202

• Key Features

About this Guide

This guide contains installation, operation, and control procedures, and reference

information for the XTP T UWP 202 Wallplate Transmitter. In this guide, the terms

“XTP T UWP 202” and “transmitter” are used interchangeably to refer to all models of the

XTP T UWP 202 Wallplate Transmitter.

About the XTP T UWP 202

The Extron XTP T UWP 202 is a two-input transmitter that sends HDMI or RGBHV video,

audio, and bidirectional RS-232 and IR up to 330 feet (100 meters) over a single shielded

twisted pair (STP) cable. This two-gang wallplate transmitter supports computer-video

signals up to 1920x1200, including HDTV 1080p/60 Deep Color and 2K. The

XTP T UWP 202 works with XTP Systems for signal distribution and long-distance

transmission between remote endpoints. It comes in a model with a front panel Ethernet

port to enable Ethernet extensions for LAN access and a model without a front panel

Ethernet port.

The XTP T UWP 202 can be powered locally or remotely through an Extron Power Injector

or XTP matrix switcher (see Power Connection on page 14).

To configure and control the XTP T UWP 202, connect a host device, such as a computer,

and enter Simple Instruction Set (SIS) commands (see SIS Configuration and Control on

page 18) or use the XTP System Configuration Software (see XTP System Configuration

Software on page 23).

XTP T UWP 202 Wallplate Transmitter • Introduction 1

Page 8

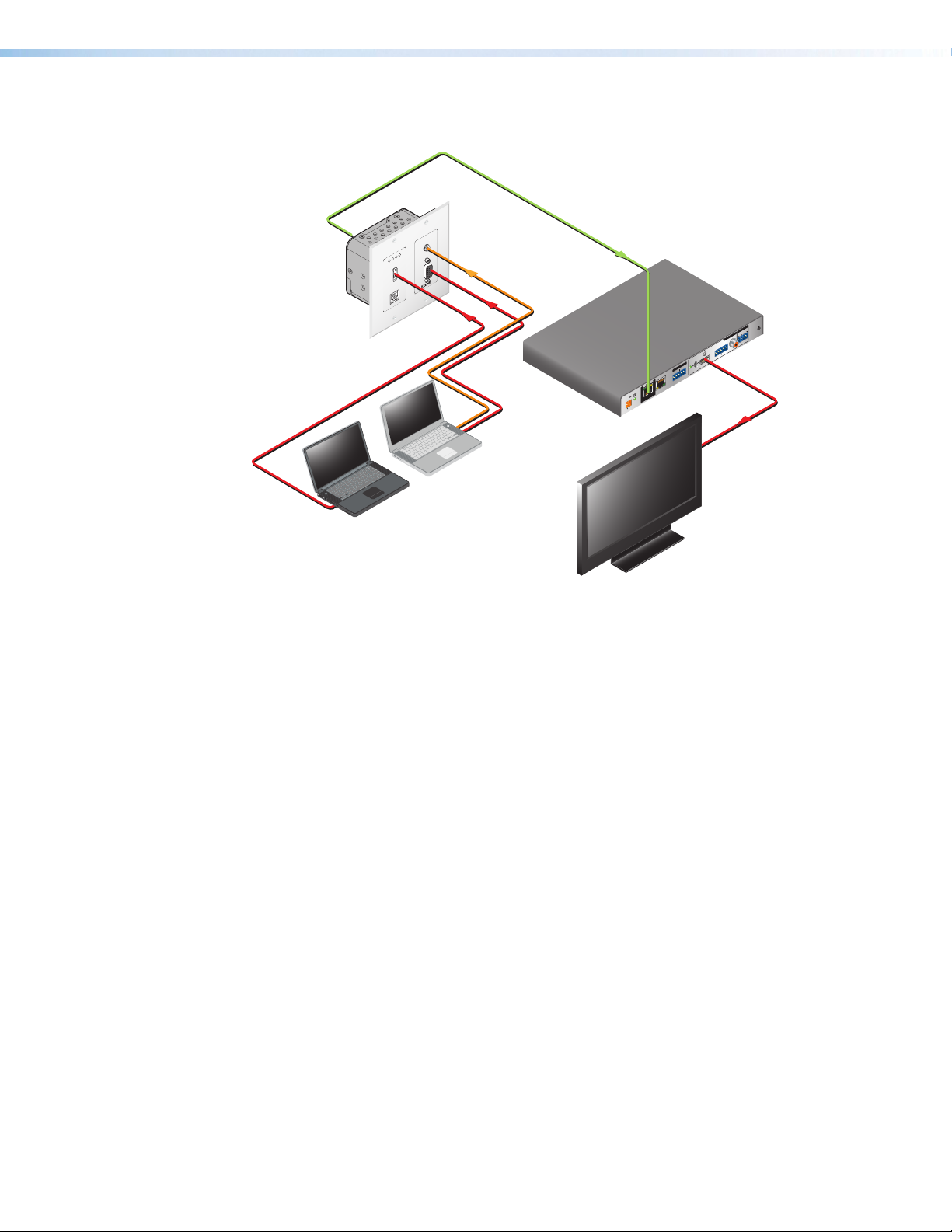

Figure 1 shows a typical point-to-point application of the XTP T UWP 202 with two input

sources.

Key Features

PWR HDCP HDMI

HDMI IN

Extron

XTP T UWP 202

Universal XTP Transmitter

AUDIO IN

RESET

VGA

AUDIO

VGA IN

CLIP

AUTO

SWITCH

CONFIG

LAN

Audio

VGA

Shielded

Twisted Pair

Cable

Extron

XTP R HDMI

XTP Receiver

RESET

RELAYS

2

1

OUTPUTS

RL

AUDIO

S/PDIF

-+ -+

AUDIO

ON

HDMI

OVER XTP

OFF

RS-232 IR

RxTx

Rx G

Tx

LINK

LINK

IG

S

SIG

LINK

LAN

ACT

POWER

XTP IN

XTP IN

12V

--A MAX

HDMI

HDMI

Laptops

Display

Figure 1. Typical Point-to-Point Application Diagram (LAN Model Shown)

Wall mountable — Mounts in a two-gang metal junction box or the provided mud ring.

Inputs — Include one HDMI input and one VGA input.

Support for computer-video to 1920x1200, including HDTV 1080p/60 Deep Color

and 2K signals — Supports digital signal transmission up to 330 feet over a single twisted

pair cable, maintaining superior image quality at the highest resolutions.

Shielded twisted pair cable compatibility — Optimized for use with common shielded

twisted pair cable types. XTP systems fully support a maximum transmission distance of

330 feet (100 meters) for all compatible resolutions when used with shielded twisted pair

cable. Shielded twisted pair cabling with solid center conductor sizes of 24 AWG or better is

recommended for optimal performance.

Digital conversion of analog video and audio input signals — Digitizes analog signals,

ensuring that a reliable, high quality digital video signal is sent to the output destination.

Auto-input switching — Automatically switches to the highest or lowest priority input with

an active video signal for simplified operation.

Bidirectional RS-232 and IR insertion — Allows a remote display to be controlled without

the need for additional cabling through bidirectional RS-232 control and IR signals inserted

into the XTP output.

HDMI specification features — Support data rates up to 6.75 Gbps, Deep Color up to

12-bit, 3D, HD lossless audio formats, and CEC pass-through.

HDCP-compliance — Ensures display of content-protected media and interoperability with

other HDCP-compliant devices.

XTP T UWP 202 Wallplate Transmitter • Introduction 2

Page 9

EDID Minder — Automatically manages EDID communication between connected devices

to ensure that all sources properly power up and reliably display content.

Key Minder — Authenticates and maintains continuous HDCP encryption between input

and output devices to ensure quick and reliable switching in professional AV environments,

while enabling simultaneous distribution of a single source signal to one or more displays.

Remote power capability — To simplify integration, the XTP T UWP 202 can be powered

by an XTP CrossPoint Matrix Switcher or XTP Power Injectors.

Multiple embedded audio formats — Compatible with a broad range of multi-channel

audio signals, providing reliable operation with HDMI sources.

Selectable analog stereo audio input embedding — Supports unbalanced audio for

extended transmission. This feature enables direct connection of separate stereo audio

signals from a laptop, Blu-ray Disc™ player, or other device.

RS-232 control — Features an RS-232 serial port for control and configuration.

Audio input gain and attenuation — Allows the level of gain or attenuation to be set,

eliminating noticeable volume differences when switching between sources.

EDID and HDCP transmission — DDC channels are actively buffered, allowing

continuous communication between source and display.

XTP T UWP 202 Wallplate Transmitter • Introduction 3

Page 10

Installation and Operation

This section contains information for mounting, connecting, and wiring the XTP T UWP 202.

Topics in this section include:

• Installation Overview

• Installing the Metal Junction Box or Mud Ring

• Rear and Side Panel Connectors

• Mounting the XTP T UWP 202

• Front Panel Connectors

• Making Connections

• Operation

Installation Overview

The XTP T UWP 202 can be installed into the provided mud ring or an UL Listed metal

electrical junction box.

ATTENTION: If using a junction box, use a metal one only.

1. Prepare the mounting surface.

CAUTION: Risk of personal injury. Failure to check the items listed below may

result in personal injury.

ATTENTION: Failure to check the items listed below may result in property

damage.

• Ensure there are no utility cables or pipes at the intended location that might be

damaged or cause injury when installing the device.

• Check that the installation meets building, electrical, and safety codes.

• Ensure there is sufficient space behind the device.

• Choose a location that will allow cable runs without interference.

NOTES:

• Cables may need to be installed in the wall or conduits before installation.

• The mud ring does not require attachment to wall studs.

• For metal junction boxes, refer to the manufacturer for more installation

requirements.

2. Cut a hole in the mounting surface (see Cutting an Opening in the Mounting

Surface on page 5).

3. Install the mud ring or metal junction box in the mounting surface (see Installing the

Mud Ring on page 6 or Installing a UL Listed Metal Junction Box on page 7).

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 4

Page 11

4. Route and connect cables to the rear and side panel connectors (see Rear and Side

Panel Connectors on page 7).

5. Mount the XTP T UWP 202 to the mud ring or metal junction box (see Mounting the

XTP T UPW 202 on page 9).

6. Connect inputs to the front panel connectors (see Front Panel Connections on

page 10).

7. Supply power to all connected devices.

Installing the Metal Junction Box or Mud Ring

Cutting an Opening in the Mounting Surface

1. Using an appropriate template or the mounting enclosure as a guide, mark the area

of the wall with a soft pencil that will be cut (for the provided mud ring, see Mounting

Template on page 40).

NOTE: Check with the manufacturer of the metal junction box for specific

installation requirements.

2. Use a jigsaw or small hand saw to carefully cut away the material within the guidelines

drawn in step 1.

NOTE: If using a template or the mud ring as a guide for cutting the hole in drywall,

cut inside the guidelines to maximize the contact the mud ring makes with the

drywall.

4. If using a mud ring in a wall with insulation inside, remove at least 6 inches of the

insulation in all directions around the cutout.

NOTE: If a wall stud interferes with removing 6 inches of insulation around the

cutout, remove the insulation between the cutout and wall stud.

5. Check the size of the opening by laying the mud ring or metal junction box against it.

The mounting device should fit snugly in the opening.

6. If needed, use a saw, file, or sandpaper to enlarge the hole.

CAUTION: Risk of personal injury. Smooth the edges of the opening to avoid

personal injury during installation.

ATTENTION: Smooth the edges of the opening to avoid damage to the mounting

device or the cables.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 5

Page 12

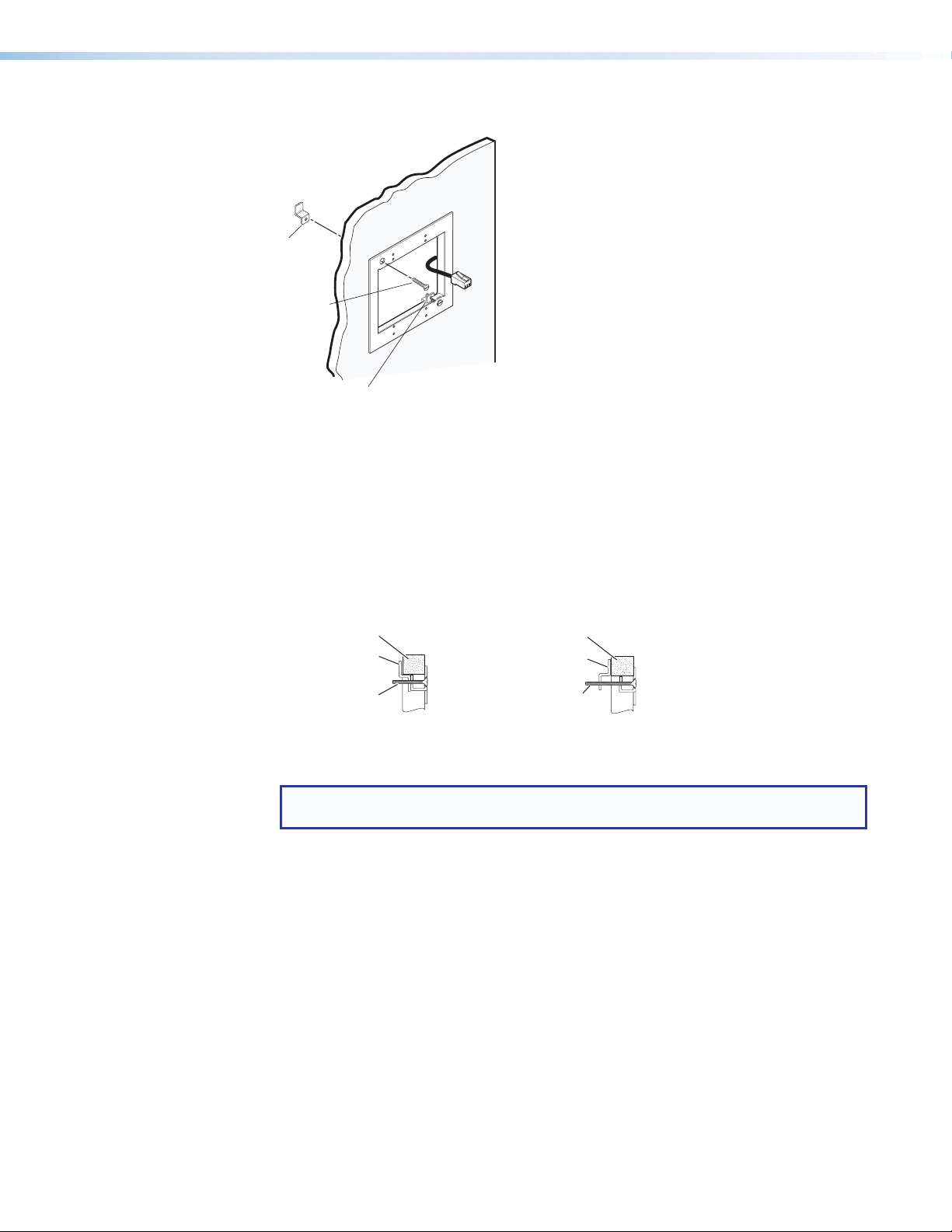

Installing the Mud Ring

Backing Clip

Mounting Sc

Rotate the backing clip

out of the way to insert

the mud ring into the wall.

0.75" #6-32 Scr

Mountint Surface

Mounting Surface

Detail B

rew

Figure 2. Installing the Mud Ring with Backing Clips

1. Place 1.25 inches (3.18 cm) long or 0.75 inch (1.90 cm) #6-32 thread machine screws

through the large holes in the two corners of the mounting bracket. Use the shortest

possible screw needed.

2. Loosely fasten the mounting backing clip on the end of each screw.

3. Insert the mounting bracket into the opening in the wall.

4. Rotate each backing clip so that the tab is behind the installation surface to hold the

bracket snuggly in place when the screw is tightened.

Backing Clip

ew

Detail A

Backing Clip

1.25" #6-32 Screw

Figure 3. Backing Clip Installation

NOTE: The backing clip can be installed as shown in detail A or detail B (see

figure 3).

5. Use a cross-head (Phillips) screwdriver to fasten the screws and backing clips in place.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 6

Page 13

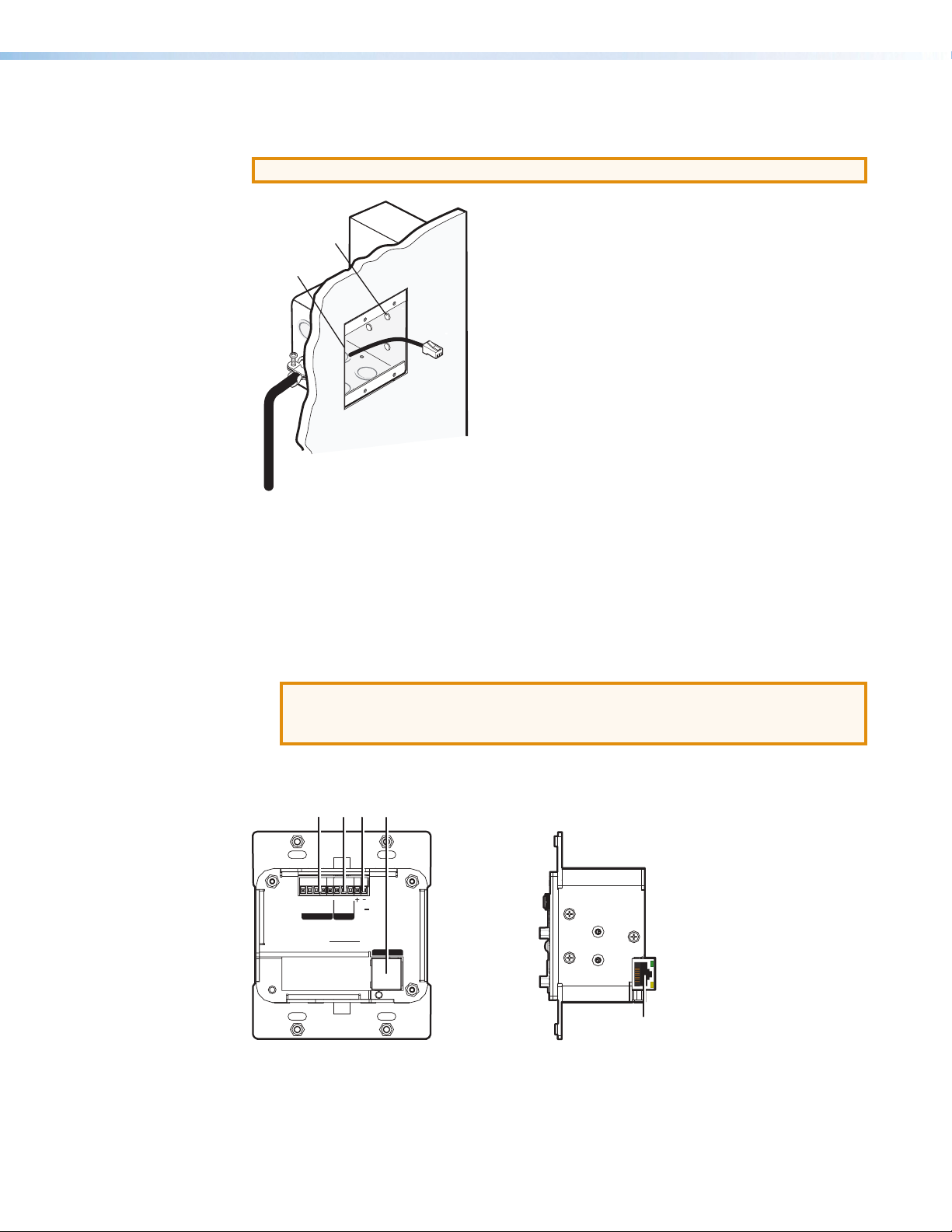

Installing a UL Listed Metal Junction Box

Cable

Cable

Clam

Wall Stud

Rear

Metal junction boxes may differ slightly from model to model. Check with the manufacturer

for specific installation instructions.

ATTENTION: Use metal junction boxes only.

Screws or

Nails

Wall opening is

flush with edge

of box.

p

Signal Output

Figure 4. Installing a Metal Junction Box

1. Insert the metal junction box into the hole in the wall.

2. Secure it to the stud using two screws or nails, as appropriate. The front edge of the

metal junction box must be flush with the front surface of the wall.

3. Feed cables through a metal junction box knockout opening.

4. Secure cables with clamps or ties to provide strain relief.

5. Trim back and insulate shields with heat shrink.

ATTENTION: To prevent short circuits, the outer foil shield can be cut back to the

point where the cable exits the cable clamp. Both braided and foil shields should

be connected to an equipment ground at the other end of the cable.

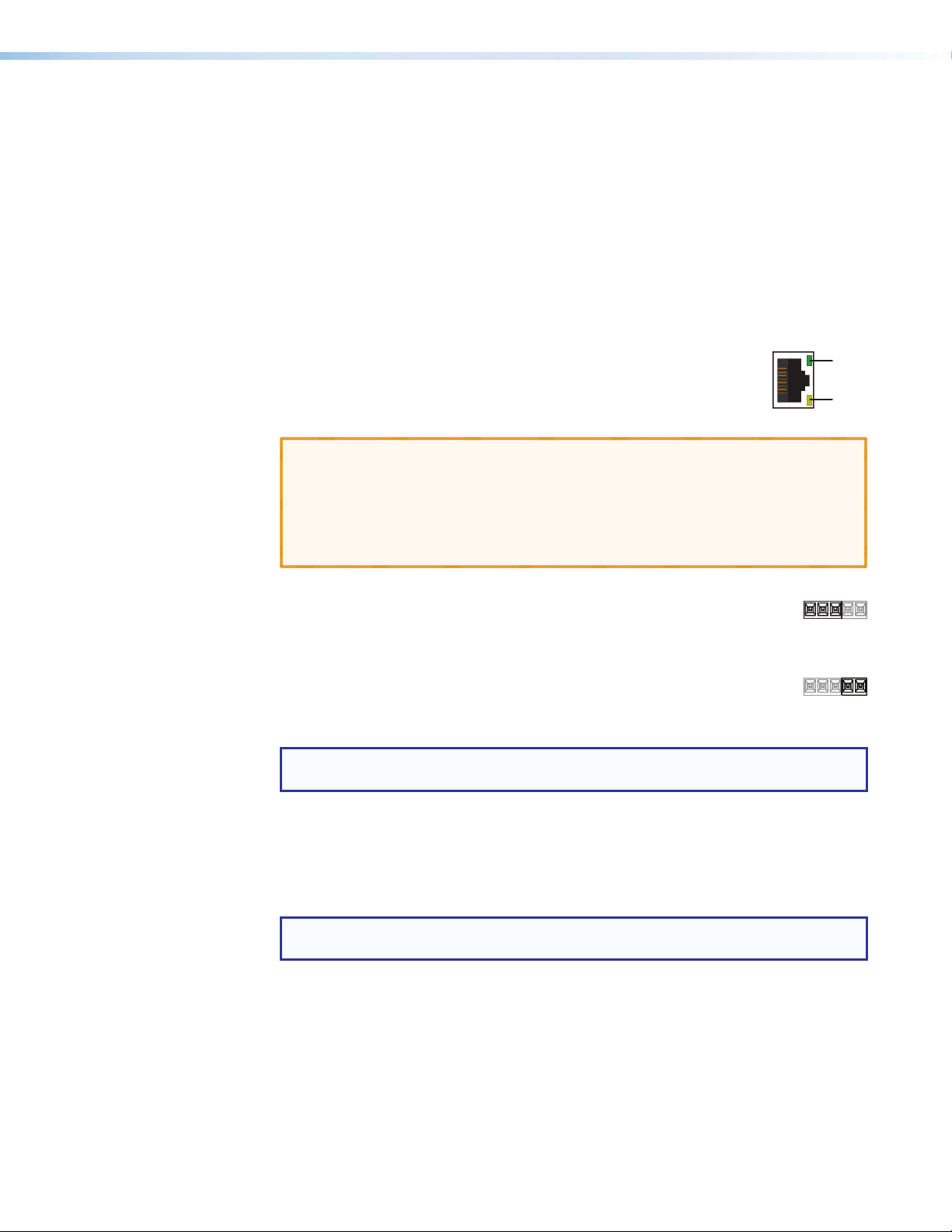

Rear and Side Panel Connectors

BC

Tx

Rx Tx RxGTxRxG

RS-232

RS-232IR

OVER XTP

REMOTE

XTP output connector

A

RS-232 and IR Over XTP connector

B

Figure 5. Rear Panel Connectors

XTP T UWP 202

D

POWER

12V

1.0 A MAX.

A

XTP OUT

A

Side

Remote RS-232 connector

C

DC power connector

D

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 7

Page 14

XTP output connector — Connect a twisted pair cable to the RJ-45 connector

IR

Tx Rx

RS-232

IR

Tx Rx

RS-232

l

A

labeled XTP Out on the XTP T UWP 202 and the XTP input port on another XTP device

to pass all signals (see TP Cable Termination and Recommendations on page 12).

This cable carries the following signals:

• Digital video

• Digital audio

• Bidirectional RS-232 and IR commands

• Remote power

• Ethernet communication

• System communication

Signal LED indicator — Lights green when the transmitter outputs an

XTP signal to a compatible receiver or matrix switcher.

Link LED indicator — Lights yellow when XTP devices are connected

and communication is established.

ATTENTION:

• Do not connect this connector to a computer data or telecommunications

network.

• XTP remote power is intended for indoor use only. No part of the network that

uses XTP remote power should be routed outdoors (see Remote power on

page 15).

Signa

Link

RS-232 Over XTP port — To pass bidirectional serial or other control

B

signals between XTP-compatible devices, connect a control device to the

5-pole direct insertion captive screw connector. The port includes only the 3

Tx Rx G

poles labeled “RS-232.”

IR Over XTP port — To transmit and receive IR signals (up to 40 kHz),

connect a control device to the 5-pole direct insertion captive screw

connector. This port includes only the 2 poles labeled “IR” and shares the

ground pole with the RS-232 port.

Tx Rx G

NOTE: RS-232 and IR data can be transmitted simultaneously (see

RS-232 and IR Over XTP Communication on page 13 for wiring details).

Remote RS-232 connector — Connect a host device to the 3.5 mm, 3-pole direct

C

insertion captive screw connector for serial control of the transmitter.

Power connector and LED — Connect an external power supply to the 2-pole direct

D

insertion captive screw connector. Confirm the polarity of the power supply wires. The

Power LED lights to indicate the device is receiving power.

NOTE: The XTP T UWP 202 can also be powered remotely (see Power

Connection on page 14).

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 8

Page 15

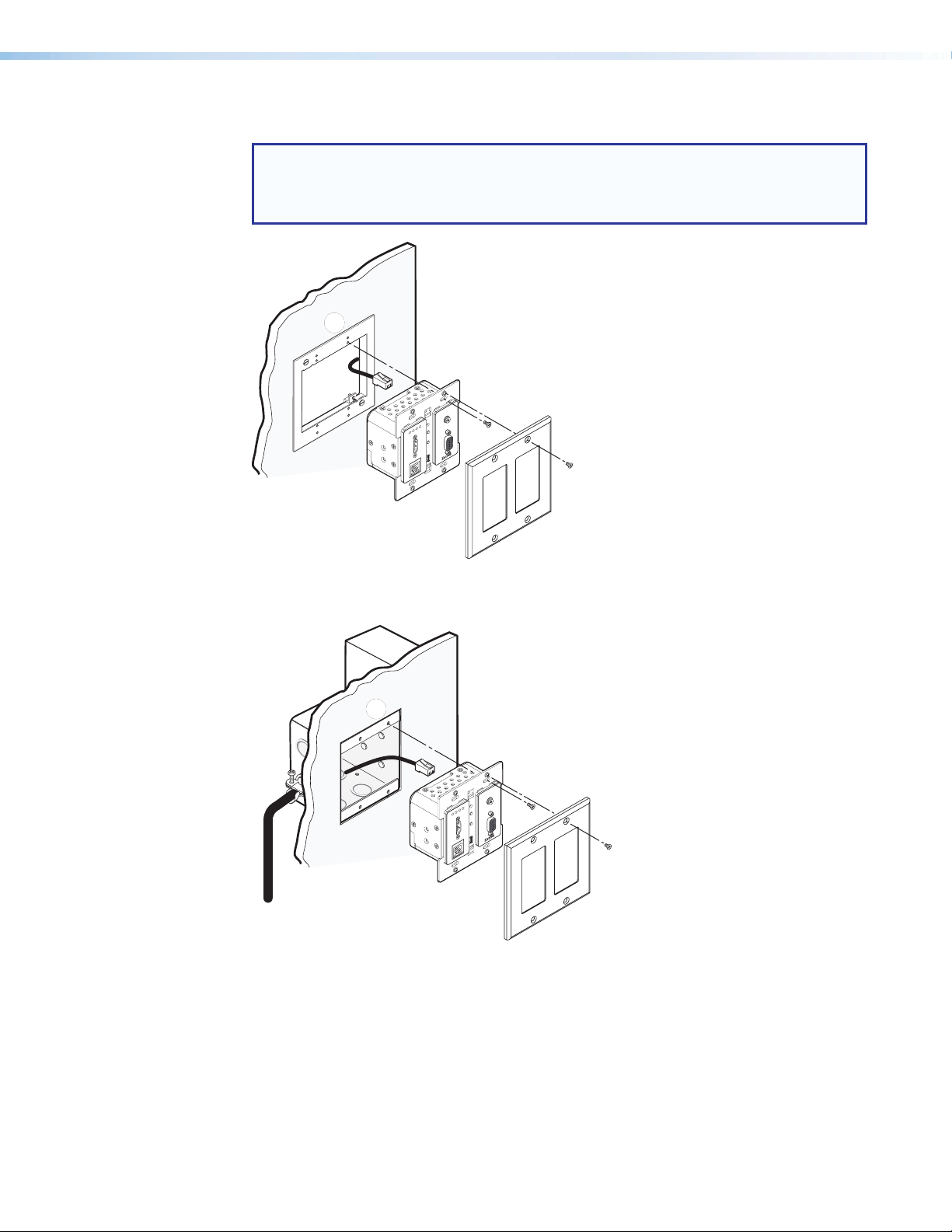

Mounting the XTP T UWP 202

3

Cable

Clam

Wall Stud

3

NOTE: If desired, connect a host device to the front panel Config port (see

figure 8, E) before mounting to configure the transmitter (see SIS Configuration

and Control on page 18 or XTP System Configuration Software on page 23).

Disconnect the host device after configuration is complete.

1111

XTP T UWP 202

Decora Faceplate

AUDIO IN

RESET

VGA

AUDIO

VGA IN

CLIP

PWR HDCP HDMI

HDMI IN

AUTO

2

SWITCH

CONFIG

LAN

Figure 6. Installing the XTP T UWP 202 (LAN Model Shown) in the Provided Mud

Ring

11111111

p

AUDIO IN

RESET

VGA

HDMI

AUDIO

HDCP

VGA IN

CLIP

PWR

HDMI IN

AUTO

2

SWITCH

CONFIG

LAN

XTP T UWP 202

Decora Faceplate

Signal Output

Cable

Figure 7. Installing the XTP T UWP 202 (LAN Model Shown) in a Metal Junction

Box

1. Align the mounting screws on the XTP T UWP 202 with the available holes on the mud

ring (see figure 6, 1) or metal junction box (see figure 7, 1).

2. Using the provided screws, attach the XTP T UWP 202 to the mud ring (see

figure 6, 2) or metal junction box (see figure 7, 2).

3. Use four mounting screws to attach the Decora faceplate to the XTP T UWP 202 (see

figure 6 or 7, 3).

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 9

Page 16

Front Panel Connectors

A

D

B

C

E

Tip (+)

Sleeve ( )

Sleeve ( )

Ring (-)

Tip (+)

RCA Connector

(balanced)

PWR HDCP HDMI

HDMI IN

VGA

RESET

AUDIO

CLIP

AUTO

SWITCH

AUDIO IN

VGA IN

LAN

HDMI input connector

A

Analog audio input connector

B

Analog video input connector

C

CONFIG

LAN connector (LAN models only)

D

Configuration port

E

Figure 8. Front Panel Connectors (LAN Model Shown without the Decora

Faceplate)

HDMI input connector — Connect a digital video source device to the HDMI

A

connector. It can accept HDMI, DVI (with an appropriate adaptor), or dual mode

DisplayPort video sources.

NOTES:

• The maximum HDMI cable length is 15 feet.

• Use an Extron LockIt lacing bracket to secure the HDMI connector to the

device (see HDMI Connection on page 11).

Analog audio input connector — Connect an analog audio source to the 3.5 mm

B

tip-ring-sleeve (TRS) jack.

Tip (L)

Ring (R)

Sleeve ( )

Figure 9. Wiring a TRS Connector for Audio

By default, audio input is selected automatically (see Audio input selection SIS

commands on page 20 to manually select audio inputs). When the HDMI input is

selected with automatic audio input selections, the transmitter prioritizes embedded

digital audio. The table on page 11 shows the audio format that is sent over the XTP

connection when a specific audio format is not specified.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 10

Page 17

Video Input

HDMI IN

3

HDMI IN

Analog video input connector — Connect a video source to the female 15-pin HD

C

connector. It accepts RGBHV video signals.

LAN connector (LAN model only) — Connect a control device or device to be

D

controlled to this LAN connector for 10/100 Ethernet communication through this

pass-through port. LEDs on this connector indicate link and activity status.

Configuration port — If desired, connect a host device to the front panel USB mini-B

E

Config port for configuring the transmitter.

Making Connections

HDMI Connection

Use an Extron LockIt Lacing Bracket to secure an HDMI cable to each connector. The

following instructions describe how to attach one HDMI LockIt Lacing Bracket. For more

stability, attach a second HDMI LockIt Lacing Bracket to the other mounting screw.

Selected

VGA N/A Yes Analog audio

VGA N/A No No audio

HDMI Yes No HDMI embedded audio

HDMI Yes Yes HDMI embedded audio

HDMI No Ye s Analog audio

HDMI No No No audio

HDMI Embedded

Audio Present

Analog Audio

Present

Audio Sent Over XTP

1

2

Figure 10. Attaching the HDMI Connector and HDMI LockIt Lacing Bracket

1. Plug the HDMI cable into the panel connection (see figure 10, 1).

2. Loosen the HDMI connection mounting screw from the panel enough to allow the

LockIt lacing bracket to be placed over it (see figure 10, 2). The screw does not have

to be removed.

3. Place the LockIt lacing bracket on the screw and against the HDMI connector, then

tighten the screw to secure the bracket (see figure 10, 3).

ATTENTION: Do not overtighten the HDMI connector mounting screw. The shield

it fastens to is very thin and can easily be stripped.

4. Loosely place the included tie wrap around the HDMI

connector and the LockIt lacing bracket as shown (see

the image to the right).

5. While holding the connector securely against the lacing

bracket, use pliers or similar tools to tighten the tie wrap, then

remove any excess length.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 11

Page 18

TP Cable Termination and Recommendations

Connector

Inser

Pins:

Pin

1

2

3

4

5

6

7

8

Wire color

White-green

Green

White-orange

Blue

White-blue

Orange

White-brown

Brown

Wire color

T568A T568B

White-orange

Orange

White-green

Blue

White-blue

Green

White-brown

Brown

Use the following pin configurations for twisted pair cables.

12345678

t Twisted

Pair Wires

RJ-45

Straight-through Cable

(for connection to a switch, hub, or router)

TIA/EIA-T568A TIA/EIA-T568B

Pin Wire Color Pin Wire Color

1 White-green 1 White-orange

2 Green 2 Orange

3 White-orange 3 White-green

4 Blue 4 Blue

5 White-blue 5 White-blue

6 Orange 6 Green

7 White-brown 7 White-brown

8 Brown 8 Brown

Figure 11. TP Cable Termination

Supported cables

The XTP T UWP 202 is compatible with shielded twisted pair (F/UTP, SF/UTP, and S/FTP)

cable.

ATTENTION:

• Do not use Extron UTP23SF-4 Enhanced Skew-Free AV UTP cable or STP201 cable

to link the XTP products.

• To ensure FCC Class A and CE compliance, STP cables and STP connectors are

required.

Cable recommendations

Extron recommends using the following practices to achieve full transmission distances up to

330 feet (100 meters) and reduce transmission errors.

• Use the following Extron XTP DTP 24 SF/UTP cables and connectors for the best

performance:

• XTP DTP 24/1000 Non-Plenum 1000’ (305 m) spool 22-236-03

• XTP DTP 24P/1000 Plenum 1000’ (305 m) spool 22-235-03

• XTP DTP 24 Plug Package of 10 101-005-02

• If not using XTP DTP 24 cable, at a minimum, Extron recommends 24 AWG, solid

conductor, STP cable with a minimum bandwidth of 400 MHz.

• Terminate cables with shielded connectors to the TIA/EIA-T568B standard (see figure 11).

• Limit the use of more than two pass-through points, which may include patch points,

punch down connectors, couplers, and power injectors. If these pass-through points are

required, use shielded couplers and punch down connectors.

NOTE: When using STP cable in bundles or conduits, consider the following:

• Do not exceed 40% fill capacity in conduits.

• Do not comb the cable for the first 20 m, where cables are straightened, aligned, and

secured in tight bundles.

• Loosely place cables and limit the use of tie wraps or hook and loop fasteners.

• Separate twisted pair cables from AC power cables.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 12

Page 19

RS-232 and IR Over XTP Communication

IR Device

RS-232 Device

The RS-232 and IR Over XTP connector is for pass-through transmission of serial signals,

such as projector control signals, and infrared data. To pass bidirectional serial command

signals between XTP-compatible devices, connect a control device to the three leftmost

poles (Tx, Rx, and G) of the 5-pole captive screw connector. To transmit and receive IR

signals, connect a control device to the three rightmost poles (G, Tx, and Rx). The

ground (G) pole is shared.

NOTE: RS-232 and IR data can be transmitted or received simultaneously

(see figure 12 below for wiring considerations).

Tx Rx

Rx Tx

Custom

G

G

Tx/Rx

Pins

Tx Rx G Tx Rx

RS-232 IR

OVER XTP

Figure 12. Wiring the RS-232 and IR Over XTP Connector

ATTENTION: The length of exposed wires is critical.

• The ideal length is 3/16 inch (5 mm).

• Longer bare wires can short together.

• Shorter wires are not as secure in the connectors and could be pulled out.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 13

Page 20

Power Connection

AA

Output Cord

Apply power to the transmitter locally with the provided power supply or remotely with a

power injector or an XTP matrix switcher.

ATTENTION: XTP remote power is intended for indoor use only. No part of the network

that uses XTP remote power should be routed outdoors.

Local power

Smooth

Power Supply

Figure 13. Power Wiring

The XTP T UWP 202 can be connected to a local power supply.

WARNING: Electric shock hazard. The two power cord wires must be kept separate

while the power supply is plugged in. Remove power before wiring.

3/16”

(5 mm) Max.

Ridges

SECTION A–A

ATTENTION:

• This product is intended to be supplied by a Listed Power Unit marked “Class 2”

or “LPS,” rated 12 VDC, 1.0 A minimum. Always use a power supply supplied by

or specified by Extron. Use of an unauthorized power supply voids all regulatory

compliance certification and may cause damage to the supply and the end

product.

• Unless otherwise stated, the AC/DC adapters are not suitable for use in air handling

spaces or in wall cavities. The installation must always be in accordance with the

applicable provisions of National Electrical Code ANSI/NFPA 70, article 75 and

the Canadian Electrical Code part 1, section 16. The power supply shall not be

permanently fixed to a building structure or similar structure.

• Power supply voltage polarity is critical. Incorrect voltage polarity can damage the

power supply and the unit. The ridges on the side of the cord identify the power

cord negative lead.

• The length of the exposed (stripped) copper wires is important. The ideal length is

3/16 inch (5 mm).

TIP: Do not tin the stripped power supply leads. Tinned wires are not as secure in the

captive screw connectors and could be pulled out.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 14

Page 21

Remote power

The XTP T UWP 202 can be powered remotely through an XTP Power Injector or through

an XTP matrix switcher.

ATTENTION: XTP remote power is intended for indoor use only. No part of the network

that uses XTP remote power should be routed outdoors.

Power injector

To power the XTP T UWP 202 remotely with an XTP Power Injector, power one device

locally (see Local power on page 14) and connect an XTP Power Injector to the XTP

cable run along the XTP ports (see the XTP Power Injector User Guide for more installation

information).

Tx

Rx Tx RxGTxRxG

RS-232

RS-232IR

POWER

12V

OVER XTP

REMOTE

1.0 A MAX.

XTP T UWP 202

XTP OUT

Remote

Extron

XTP T UWP 202

XTP Transmitter

Power

100-240V

50/60 Hz

---A MAX

Power

XTP

XTP PWR

PWR

Extron

XTP PI 100

XTP Power

Injector

POWER

12V

1A MAX

12V Local Power

Supply

Extron

XTP R HDMI

XTP Receiver

Shielded Twisted Pair

Cable

SIG LINK

XTP IN

LAN

OVER XTP

RS-232 IR

Rx GTx

AUDIO

ON

OFF

RxTx

HDMI

AUDIO

LR

−+−+

OUTPUTS

S/PDIF

1

2

RESET

XTP R HDMI

RELAYS

Figure 14. Typical Pont-to-point Application with Remote Power

NOTE: The power injector provides remote power up to 330 feet with a shielded twisted

pair cable with 24 AWG wire.

Direct power from an XTP matrix switcher

XTP matrix switchers have a fixed amount of power available to provide remote power

to connected XTP devices (see the XTP matrix switcher user guide for more details). To

manage available power from the XTP matrix switcher, use the XTP System Configuration

Software with the XTP matrix switcher.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 15

Page 22

Operation

B

C

Indicators

After all transmitters, all receivers, and their connected devices are powered up, the system

is fully operational. If any problems are encountered, verify that the cables are routed and

connected properly. If problems persist, call the Extron S3 Sales & Technical Support

Hotline. See the contact numbers on the last page of this guide for the nearest Extron

office.

A

PWR HDCP HDMI

VGA

HDMI IN

RESET

AUDIO

CLIP

AUTO

SWITCH

AUDIO IN

VGA IN

LAN

CONFIG

Figure 15. Front Panel Indicators (LAN Model Shown without the Decora

Faceplate)

Signal LED Indicators:

A

Power LED indicator — Lights when power is applied to the unit.

HDCP LED indicator — Lights when the input signal is encrypted.

HDMI LED indicator — Lights when an HDMI input video signal is detected.

VGA LED indicator — Lights when a video signal is detected on the VGA input.

Audio clipping LED indicator — Lights when the analog audio input signal is -3 dBFS

B

or above. The light remains lit for 200 ms after the audio input signal drops below

-3 dBFS.

Auto switch LED indicator — Lights when the transmitter is in auto switch mode.

C

EDID

To manage EDID on the XTP T UWP 202, use the XTP System Configuration Software

(see EDID Minder on page 34). The XTP T UWP 202 can record and save EDID in a user

memory location, select a pre-defined EDID, or use EDID from a display connected to a

receiver. EDID stored in the user memory location can come from the display connected to

a receiver or a custom EDID imported through the XTP System Configuration Software.

NOTE: In matrix applications, EDID on the transmitter is assigned by the matrix

switcher using the XTP System Configuration Software.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 16

Page 23

Reset Modes

A

PWR HDCP HDMI

HDMI IN

VGA

RESET

AUDIO

CLIP

AUTO

SWITCH

AUDIO IN

VGA IN

LAN

CONFIG

Figure 16. Reset Button (LAN Model Shown without the Decora Faceplate)

Use the recessed Reset button on the front panel of the transmitter to return the device to

default settings or to restore factory-shipped firmware. To access the Reset button, the

faceplate may need to be removed (see figure 16, A).

Reset Mode Summary

Mode Activation Result Purpose/Notes

Press the recessed Reset button while

applying power to the device.

NOTE: After a mode 1 reset,

update the device with the

latest firmware version. DO

(Mode 1)

Factory Reset

NOT operate the firmware

version that results from this

mode reset.

The device reverts to the factory

default firmware.

NOTE: If you do not want to

update the firmware or if you

perform a mode 1 reset by

mistake, cycle power to the

device to return the firmware

version running prior to the

Use mode 1 to roll back

to factory firmware for a

single power cycle if an

incompatibility issue arises.

reset.

XTP T UWP 202 Wallplate Transmitter • Installation and Operation 17

Page 24

SIS Configuration and Control

The XTP T UWP 202 can be configured and controlled using Extron Simple Instruction Set

(SIS) commands or the XTP System Configuration Software (see XTP System Configuration

Software on page 23). This section contains basic SIS communication details and SIS

commands and responses when connected directly to the XTP T UWP 202. Topics in this

section include:

• Host Device Connection

• SIS Programming Guide

• Command and Response Tables for SIS Commands

Host Device Connection

Use a computer running the HyperTerminal or Extron DataViewer utility, or a control system to

enable serial control of the transmitter. To connect directly to an XTP T UWP 202, connect the

computer to the XTP T UWP 202 through the front panel USB Config port or the rear panel

RS-232 connector. The protocol for the serial port is as follows: 9600 baud, no parity, 8 data

bits, 1 stop bit, no flow control.

SIS Programming Guide

Host-to-Device and Device-to-Host Communication

SIS commands consist of one or more characters per field. No special characters are

required to begin or end a command sequence. When the XTP T UWP 202 determines that

a command is valid, it executes the command and sends a response to the host device. All

responses from the switcher to the host end with a carriage return and a line feed

(CR/LF = ]), which signals the end of the response character string. A string is one or more

characters.

Device-Initiated Message

When the transmitter is connected through the serial port only and a local event occurs, the

device responds by sending a message to the host.

The following copyright messages are displayed after a power cycle via RS-232. The specific

message displayed depends on the XTP T UWP 202 model.

NOTE: Black and white models are not differentiated in the displayed part number.

© Copyright YYYY, Extron Electronics XTP T UWP 202 Vx.xx, 60-1216-12]

© Copyright YYYY, Extron Electronics XTP T UWP 202 NL, Vx.xx, 60-1410-12]

YYYY is the year. Vx.xx is the firmware version number.

XTP T UWP 202 Wallplate Transmitter • SIS Configuration and Control 18

Page 25

Error Responses

Space

When the XTP T UWP 202 receives an SIS command and determines that it is valid, it

performs the command and sends the corresponding response to the host device. If the

command is determined invalid or contains invalid parameters, the switcher returns an error

response to the host. The error response codes are:

E01 = Invalid input number E12 = Invalid port number

E06 = Invalid switch attempt in this mode E13 = Invalid parameter

E10 = Invalid command E14 = Not valid for this configuration

E11 = Invalid preset number E17 = Invalid command for signal type

Using the Command and Response Tables for SIS Commands

The command and response tables begin on page 20. Figure 17 shows the hexadecimal

equivalent of ASCII characters used in the command and response tables.

NOTE: Upper and lowercase text can be used interchangeably unless otherwise stated.

ASCII to Hex Conversion Table

•

Figure 17. ASCII to Hexadecimal Conversion

Symbol Definitions

= Carriage return and line feed

]

| or }

W or

= Carriage return with no line feed

= Space

•

= Escape key

E

XTP T UWP 202 Wallplate Transmitter • SIS Configuration and Control 19

Page 26

Command and Response Tables for SIS Commands

Command ASCII Command

(Host to Device)

Input Commands

Input selection

Select input

View the selected input

Auto switch mode

Disable auto switch mode

Set priority to the highest

numbered active input

Set priority to the lowest

numbered active input

View setting

X!! In X!] Select input X!.

!

E0AUSW} Ausw0]

E1AUSW} Ausw1]

E2AUSW} Ausw2]

EAUSW} AuswX#]

Audio Configuration Commands

Audio gain and attenuation

NOTE: Gain and attenuation commands are case-sensitive.

Set gain

Set attenuation

Increment audio level

Decrement audio level

View audio level

Audio input selection

Set audio input format

View audio input format

Black video signal resolution

Set black signal resolution

View black signal resolution

X%G Aud X&] Set gain to X%.

X^g Aud X&] Set attenuation to X^.

+G or +g

-G or -g

G or g

EIX@AFMT} AfmtIX@] Set the audio input format to X@.

EIAFMT} AfmtIX@]

EAX*AFMT} AfmtAX*] Set the black signal resolution to X*.

EAAFMT} AfmtAX*]

Response

(Device to Host)

X!]

In

Aud

X&]

Aud

X&]

Aud

X&]

Additional Description

View the selected input.

Switch inputs manually.

When available, automatically switch

to the HDMI input (default).

When available, automatically switch

to the VGA input.

View the auto switch mode.

Increase the audio level.

Decrease the audio level.

View the audio level.

View the audio input format.

View the black signal resolution.

NOTE: X! = Input selection 1 = VGA

2 = HDMI (default)

X@ = Audio input format 0 = auto (default)

1 = digital embedded

2 = analog

X# = Auto switch mode 0 = disable

1 = priority to the HDMI input (default)

2 = priority to the VGA input

X% = Audio gain adjustment 0 - 24 = decibels above 0

X^ = Audio attenuation adjustment –18 - 0 = decibels below 0

X& = Audio level adjustment –18 - +24 (0 dB = default)

X* = Black signal resolution 2 = 720p @ 50 Hz

4 = 720p @ 60 Hz (default)

6 = 1080p @ 60 Hz

XTP T UWP 202 Wallplate Transmitter • SIS Configuration and Control 20

Page 27

Command ASCII Command

(Host to Device)

Black signal for audio only

NOTE: The switcher uses a black signal to simulate a 720p or 1080p, 50 Hz or 60 Hz signal so audio can be

passed without video.

Response

(Device to Host)

Additional Description

Enable black signal

Disable black signal

View black signal setting

EB1AFMT} AfmtBX(]

EB0AFMT} AfmtBX(]

EBAFMT} AfmtB X(]

Picture Adjustment Commands (Analog Only)

Pixel phase

Horizontal shift

Vertical shift

Image reset

Set a pixel phase value

Increment value

Decrement value

View pixel phase value

Set horizontal shift value

Increment value

Decrement value

View horizontal shift value

Set vertical shift value

Increment value

Decrement value

View vertical shift value

Execute an image reset

EX1# PHAS} PhasX1#] Adjust the pixel phase to X1#.

E+PHAS} Phas X1#]

E-PHAS} Phas X1#]

EPHAS} PhasX1#]

EX1$ HCTR} HctrX1$]

E+HCTR} Hctr X1$]

E-HCTR} Hctr X1$]

EHCTR} HctrX1$]

EX1$ VCTR} VctrX1$]

E+VCTR} Vctr X1$]

E-VCTR} Vctr X1$]

EVCTR} VctrX1$]

1A

Preset Commands

Input presets

Save an input preset

Recall an input preset

X1%, SprX1% ]

X1%. RprX1% ] Recall the preset X1% configuration.

Aadj1

]

Enable a black signal for audio only.

Disable the black signal.

View the black signal setting.

Increase the pixel phase value.

Decrease the pixel phase value.

Show the pixel phase value.

Set the horizontal location of the first

active pixel in the active window.

Increase the shift value (move the

image to the right).

Decrease the shift value (move the

image to the left).

Show the horizontal location of

the first active pixel in the active

window.

Set the vertical location of the first

active pixel in the active window.

Increase the shift value (move the

image down).

Decrease the shift value (move the

image up).

Show vertical location of the first

active pixel in the active window.

Set picture adjustment settings to

the default values.

Save the current configuration to

preset X1%.

NOTE: X( = Enable or disable 0 = disable

1 = enable (default)

X1# = Pixel phase 0-255 (128 = default)

X1$ = Horizontal or vertical shift 0-65535 (32768 = default)

X1% = Preset number 1-8

XTP T UWP 202 Wallplate Transmitter • SIS Configuration and Control 21

Page 28

Command ASCII Command

(Host to Device)

EDID Commands

NOTE: For EDID management, use the XTP System Configuration Software (see EDID Minder on page 34).

Advanced Configuration Commands

HDCP authorized device (HDMI input only)

HDCP authorized device On

HDCP authorized device Off

Query HDCP authorized

device status

Test pattern

Set a test pattern

View the current test pattern

Factory defaults

System reset

Status

View input signal presence

Query HDCP input status

Query firmware version

Query full firmware version

Query part number

EE1HDCP} HdcpE1]

EE0HDCP} HdcpE0]

EEHDCP} HdcpE X$ ]

X1)J Tst X1)]

J

EZXXX} Zpx]

0LS

EIHDCP} HdcpI0X1@]

Q

*Q

N

Response

(Device to Host)

X1)]

Tst

X1!X1!]

Frq

]

x.xx

x.xx.xxxx

60-1216-12

60-1410-12]

]

] or

Additional Description

Designate the transmitter as

an HDCP authorized device

(default).

Do not designate the

transmitter as an HDCP

authorized device.

View the HDCP authorized

device status.

Set a test pattern or disable

one.

View the current test pattern

setting.

Resets unit to factory default.

View the input signal presence

of each input. In the response,

the first X1! is the VGA input.

The second X1! is the HDMI

input.

View the HDCP status of the

HDMI input.

View the firmware version.

View the full firmware version.

View the device part number.

The response is based on

the model. Black and white

models are not differentiated.

NOTE: X$ = HDCP authorization 0 = HDCP authorization off

1 = HDCP authorization on (default)

X1) = Color bars test pattern 0 = disable (default)

1 = 720p @ 50 Hz

3 = 720p @ 60 Hz

5 = 1080p @ 60 Hz

X1! = Video signal status 0 = video or TMDS not detected

1 = video or TMDS detected

X1@ = HDCP status 0 = no source connected

1 = HDCP compliant source

2 = non-HDCP compliant source

XTP T UWP 202 Wallplate Transmitter • SIS Configuration and Control 22

Page 29

XTP System Configuration Software

This section contains installation and configuration procedures for the XTP System

Configuration Software for configuring and controlling the XTP T UWP 202. It can also be

controlled with SIS commands (see SIS Configuration and Control on page 18). Topics in

this section include:

• Installing the XTP System Configuration Software

• Using the XTP System Configuration Software

Installing the XTP System Configuration Software

The program is available for download on the Extron website, www.extron.com.

Figure 18. Extron Website Download Page

1. On the Extron website, click the Download tab (see figure 18, 1).

2. From the left sidebar, click the XTP System Configuration Software link

(see figure 18, 2).

3. Click the Download Now button (see figure 18, 3).

4. Submit any required information to start the download. Note where the file is saved.

5. Open the executable (.exe) file from the location where it was saved.

6. Follow the instructions that appear on the screen. By default, the installation creates a

directory in the appropriate Program Files folder named “Extron Electronics\XTP System

Configuration.”

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 23

Page 30

Using the XTP System Configuration Software

The XTP T UWP 202 can be controlled directly from the front panel Config port or remotely

from an XTP matrix switcher.

Connections

When opening the XTP System Configuration Software, the Connections screen opens

first. This screen is used to establish communication with an XTP device through USB

connection (see Configuration port on page 11). Ensure the transmitter is connected and

powered on before attempting to connect to it.

Figure 19. Connections Screen

1. From the Connections screen in the software, select the USB radio button (see

figure 19, 1).

2. Select the connected device to be controlled from the displayed list (see figure 19, 2).

3. Click the Connect button (see figure 19, 3). The Device Settings screen opens.

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 24

Page 31

Top Menu

The top menu bar contains three menus for configuring software settings.

File menu

The File menu contains options for disconnecting from the transmitter and exiting the

program. To access the menu, click the File menu.

Figure 20. File Menu

Disconnect

This option disconnects the connected device from the XTP System Configuration Software.

From the File menu, select Disconnect. The Connections screen opens.

NOTE: If the device is already disconnected, the Disconnect option is disabled until a

device is connected.

Exit

This option disconnects the transmitter from the software and closes the application.

From the File menu, select Exit. The application closes.

Tools menu

The Tools menu contains an option for updating firmware. To access this menu, click the

Tools menu.

Figure 21. Tools Menu

NOTE: The Backup and Restore and Software Preference options are not

available when directly connected to the XTP T UWP 202.

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 25

Page 32

Update Firmware

This option uploads firmware from the host device to the connected device.

NOTE: If necessary, download new firmware from the Extron website (see

Downloading Firmware on page 38).

1. From the Tools menu, select Update Firmware. A dialog box opens to ask permission

to disconnect from the device.

Figure 22. Confirm Disconnect Dialog Box

2. Click the Yes button to disconnect from the device and continue with the firmware

update process. The Update Firmware dialog box opens.

Figure 23. Update Firmware Dialog Box

3. Click the Check network for updates icon to search the LAN or WAN for firmware

files or click the Select file from computer icon to select a firmware file from the

connected host device. The Browse dialog box opens.

4. Select the desired firmware file and click the Open button.

5. Click the Close button after the firmware finishes updating.

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 26

Page 33

Help menu

The Help menu contains a way to access XTP System Configuration Software information,

a link to the help file, and a link to the Extron website.

Figure 24. Help Menu

NOTE: The Tutorial (System Configuration) option is not available when directly

connected to the XTP T UWP 202.

About the Software

This option provides basic information about the XTP System Configuration Software,

including version number and copyright information.

Figure 25. About - XTP Dialog Box (Example)

1. From the Help menu, select About the Software. The About - XTP dialog box opens.

2. Click the Details button for more information.

3. Click the Ok button to close the dialog box.

Help

This option opens the XTP System Configuration Software help file in a Web browser.

From the Help menu, select Help.

Extron Website

This option opens the Extron website in a Web browser.

From the Help menu, select Extron Website.

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 27

Page 34

Device Settings

The Device Settings screen allows a user to view and edit various device settings for the

device directly connected to the PC running the XTP software. Click the Device Settings

icon (see figure 26, 1) on the Global Navigation bar to open the Device Settings screen.

Figure 26. Transmitter Device Settings Screen

AV Controls panel

The AV Controls panel, located on the left, is used to selection an input.

Input selection — Click an Input button to select an input. As a new

2

input is selected, the summary within the device information panel (to

the far right in figure 26) changes to reflect the currently selected input.

NOTE: The signal indicators on the AV input buttons display green

when a signal is present on the corresponding input or gray

when there is no signal present.

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 28

Page 35

Input/Output tab

Click the Input/Output tab (see figure 27, 1) to open the Input/Output screen. It contains

input information and options to apply automatic settings to individual inputs.

Figure 27. Input/Output Tab

Input — Displays the input name.

2

Signal Type — Displays the signal type of each input. Input 1 is analog. Input 2 is

3

HDMI/DVI.

Auto-Image — Attempts to size and center the input signal based on the aspect ratio

4

setting. Auto-Image is applied whenever there is a change in the input sync.

Auto Memory — Recalls input and image settings for signals that have previously been

5

applied. When it is disabled, the XTP T UWP 202 treats every newly applied input as a

new source.

HDCP Authorization — Select the HDCP Authorized check box to have input 2

6

report as an HDCP authorized device. If the box is not checked, the source will be

blocked from encrypting its output. This may result in some content not being passed

by the source device.

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 29

Page 36

Analog Video tab

Click the Analog Video tab (see figure 28, 1) to open the Analog Video screen. It contains

signal sampling, image shifting, and saving and recalling input preset options.

Figure 28. Analog Video Tab

Image Settings panel

Signal sampling optimizes the input signal to the transmitter for the currently selected input.

Signal Sampling — To adjust signal sampling settings, enter a value within acceptable

2

range displayed in parentheses to the right of the corresponding field or click the Up and

Down arrows.

Horizontal and Vertical Shift — To adjust the horizontal and vertical shift settings,

3

enter a value within the Min and Max values displayed to the right of the corresponding

field or click the Up or Down arrows.

Image Reset — Click the Image Reset button to set pixel phase, horizontal shift, and

4

vertical shift to the default values.

Input Presets panel

Input presets save signal sampling and shift settings to be recalled later.

Save Preset — To save a preset, select one from the list of presets and click the Save

5

Preset

Recall Preset — To recall a saved preset, select the desired preset from the list of

6

presets and click the Recall Preset button.

button.

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 30

Page 37

Audio tab

Click the Audio tab (see figure 29, 1) to open the Audio screen. It contains settings for

audio input format and analog audio gain.

Figure 29. Audio Tab

Input format panel

Input format — From the Audio Format drop-down list, select the format for input 2.

2

It can be Auto, HDMI, or Analog.

Analog audio gain — Click and drag the handle of the Gain slider, enter a value in the

3

field, or click the Up or Down arrow to adjust the analog input gain.

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 31

Page 38

General tab

Click the General tab (see figure 30, 1) to open the General screen. It contains settings for

auto switch mode and factory reset.

Figure 30. General Tab

Auto-input Switching panel

Auto-input Switching — Click the Enable Auto-Input Switching check box to

2

enable auto switch mode. Two settings are available for this mode:

Click the Priority to highest active input number radio button to

Õ

automatically switch to the highest numbered active input (HDMI).

Click the Priority to lowest active input number radio button to

Ö

automatically switch to the lowest numbered active input (VGA).

Factory reset

Factory Reset — Click the Factory Reset button to reset the transmitter to factory

3

settings except for firmware.

NOTE: This is the same as the E ZXXX SIS command (see the System reset

command on page 22).

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 32

Page 39

Device Information panel

The Device Information panel on the right side of the software screen displays device

information and settings.

General Information section

Model — Displays the device model.

1

Firmware version — Displays the full firmware

2

version.

Signal Information section

Selected input — Displays the input number of

3

the currently selected input (1 = VGA input and

2 = HDMI input).

Auto-input switching — Displays the On or Off

4

status of auto switch mode.

Signal present — Displays the signal presence

5

of both inputs.

HDCP — Displays the HDCP status of input 2.

6

Audio Information section

Selected audio input — Displays the format of

7

the currently selected audio input.

Analog audio gain — Displays the analog audio gain in dB.

8

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 33

Page 40

EDID Minder

Use the EDID Minder screen to assign unique EDID to the input or match current output

resolutions to the input. Click the EDID Minder icon (see figure 31, 1) on the global

navigation bar. The EDID Minder screen opens.

The EDID Minder screen displays a table of EDID options and connected output devices,

which are each represented by output display icons.

• Factory default EDID options are displayed in blue.

• Connected output resolutions and devices are displayed in green.

• Custom loaded or saved EDID options are displayed in yellow.

Figure 31. EDID Minder Screen

Assign EDID

To assign EDID to selected inputs:

1. Select an available EDID setting (represented by a blue, green, or yellow output display

icon) from the Favorites, Connected Outputs, or Available EDID panel (see

figure 30, 2-4).

2. In the list of inputs on the right side of the screen, select the check box of the

connected input (see figure 30, 5).

3. Click the Assign button below the input area (see figure 30, 6).

TIP: Alternatively, EDID can be assigned by dragging and dropping the desired EDID

onto the input.

To assign EDID to all inputs:

1. Select an available EDID setting (represented by a blue, green, or yellow output display

icon) from the Favorites, Connected Outputs, or Available EDID panel (see figure 30,

).

2-4

2. Below the list of inputs on the right side of the screen, click the Assign to All button

(see figure 30, 7).

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 34

Page 41

Import EDID

1. On the EDID Minder screen, click the Add EDID to Library button (see figure 31, 8).

The Browse window opens.

2. Select the desired EDID file and click Open. The EDID appears in the Available EDID

panel (see figure 31, 4).

3. Assign the EDID from the Available EDID panel to import the EDID setting to the device.

Save output EDID

1. On the EDID Minder screen, right-click on the desired EDID setting in the Connected

Outputs

2. Select the Save EDID to PC option. The EDID setting is saved to the connected PC.

Alternatively, right-click on the desired EDID, select Copy, and then Paste the EDID into

the Favorites or Available EDID panel.

panel (see figure 31, 3).

Set favorite EDID

Commonly used EDID settings can be added to the Favorites panel for quick access.

1. Click and drag the desired EDID from the Connected Outputs or the Available EDID

panel to the Favorites panel. The EDID setting is copied to the Favorites panel (see

figure 31, 2). Alternatively, right-click the desired EDID and select Copy. Then Paste the

EDID setting into the Favorites panel.

EDID filters

The filters can be used to easily locate a specific EDID setting. Selectable filters include:

Resolution

1

Refresh Rate

2

Video Format

3

Audio Format

4

Figure 32. EDID Minder Filters

To use a filter or combination of filters:

1. Select an EDID setting from one of the drop-down lists of the associated filter (see

figure 32, 1-4). The available EDID options that match the filter selection are displayed

in their respective panels.

2. Repeat step 1 to apply more filters.

To clear the currently applied filters:

1. Click the Clear button next to the filters (see figure 32, 5). All filters are reset.

Common timings

This function automatically displays available EDID settings that are common among multiple

selected outputs.

1. Hold <Ctrl> and click the desired outputs in the Connected Outputs panel. The Common

Timings

2. Select the desired common EDID setting. The EDID will be shown in the Available EDID

panel.

tab appears, listing the EDID settings common among the selected outputs.

XTP T UWP 202 Wallplate Transmitter • XTP System Configuration Software 35

Page 42

Reference Information

This section contains mounting information and instructions for updating firmware. Topics in

this section include:

• Updating Firmware with Firmware Loader

• Mounting Template

Updating Firmware with Firmware Loader

To upload and update firmware for the XTP T UWP 202, download the new firmware to a

connected computer and upload the firmware with the Firmware Loader utility.

Downloading Extron Firmware Loader

Figure 33. Locating Software on the Extron Website

1. On the Extron website, click the Download tab (see figure 33, 1).

2. On the left sidebar, click the Software link (see figure 33, 2).

XTP T UWP 202 Wallplate Transmitter • Reference Information 36

Page 43

Figure 34. Navigating to Firmware Loader

3. Click the F link and navigate to Firmware Loader (see figure 34, 3).

4. Click the Download link on the right that corresponds with the program (see

figure 34, 4).

5. Submit any required information to start the download. Note where the file is saved.

Installing Firmware Loader

1. Once Firmware Loader has been downloaded, run the .exe file from the location where

the file was saved. The installation wizard window opens.

2. Follow the instructions on the Installation Wizard screens to install Firmware Loader on

the computer.

XTP T UWP 202 Wallplate Transmitter • Reference Information 37

Page 44

Downloading Firmware

Figure 35. Downloading Firmware from the Extron Website

1. On the Extron website, click the Download tab (see figure 35, 1).

2. On the left sidebar, click the Firmware link (see figure 35, 2).

3. Navigate to the XTP T UWP 202.

4. Ensure the available firmware version is a later version than the current one on the

device.

NOTE: The firmware release notes are a PDF file that provides details about the

changes between different firmware versions. The file can be downloaded from the

same page as the firmware.

5. Click the Download link to the right of the desired device.

6. Submit any required information to start the download. Note where the file is saved.

XTP T UWP 202 Wallplate Transmitter • Reference Information 38

Page 45

Installing Firmware with Firmware Loader

Use the Firmware Loader utility to upload firmware to the transmitter when connected

directly to the device.

1. Connect the host device to the front panel USB port.

2. Open Firmware Loader and establish a connection between the computer and the

device. The Add Device... dialog box opens.

Figure 36. Add Device... Dialog Box

3. From the Device Name drop-down list, select XTP T UWP 202.

4. From the Connection Method drop-down list, select the method of connection.

5. Depending on the connection method, additional options appear. Make the appropriate

selections for the current connection method.

6. Click the Connect button.

7. Click the Browse button in the New File Firmware (Optional) section. The Open dialog

box opens.

8. In the Open dialog box, navigate to the new firmware file, which has an .S19 extension,

and select it.

ATTENTION: Valid firmware files must have the file extension .S19. A file with any

other extension is not a firmware upgrade for this device and could cause the

device to stop functioning.

9. Click the Open button. The Browse dialog box closes.

10. Click the Add button. The Add Device... dialog box closes and the device and firmware

are listed in the Firmware Loader main window.

11. Click the Begin button to start the upload process.

12. Close Firmware Loader when the Remaining Time field shows 00.00.00, the

Progress column is 100%, and the Status field is completed.

XTP T UWP 202 Wallplate Transmitter • Reference Information 39

Page 46

Mounting Template

or the installation

Template for the 2-gang

mounting bracket

Figure 37 is a example of a mounting template for preparing mounting surfaces. It is not to

full size.

4.28"

(10.87 cm)

(7.78 cm)

3.06"

4.26" (10.83 cm)

3.75" (9.53 cm)

Recommended

cut-out area

f

surface.

SURFACE

CUT-OUT AREA

FOR WALL MOUNT

Top Panel

Figure 37. Mounting Template for 2-gang Mud Rings

NOTE: Measure the template before cutting.

XTP T UWP 202 Wallplate Transmitter • Reference Information 40

Page 47

Extron Warranty

Extron Electronics warrants this product against defects in materials and workmanship for a period of three years

from the date of purchase. In the event of malfunction during the warranty period attributable directly to faulty

workmanship and/or materials, Extron Electronics will, at its option, repair or replace said products or components,

to whatever extent it shall deem necessary to restore said product to proper operating condition, provided that it is

returned within the warranty period, with proof of purchase and description of malfunction to:

USA, Canada, South America,

and Central America:

Extron Electronics

1230 South Lewis Street

Anaheim, CA 92805

U.S.A.

Europe and Africa:

Extron Europe

Hanzeboulevard 10

3825 PH Amersfoort

The Netherlands

Japan:

Extron Electronics, Japan

Kyodo Building, 16 Ichibancho

Chiyoda-ku, Tokyo 102-0082

Japan

China:

Extron China

686 Ronghua Road

Songjiang District

Shanghai 201611

China

Asia:

Extron Asia Pte Ltd

135 Joo Seng Road, #04-01

PM Industrial Bldg.

Singapore 368363

Middle East:

Extron Middle East

Dubai Airport Free Zone

F12, PO Box 293666

United Arab Emirates, Dubai

Singapore

This Limited Warranty does not apply if the fault has been caused by misuse, improper handling care, electrical