Page 1

PoleVault Systems

Installation Guide for the PVS 200, 300, and 400

68-1390-01

Rev. C

10 08

Page 2

Precautions

Safety Instructions • English

This symbol is intended to alert the user of important operating and maintenance

(servicing) instructions in the literature provided with the equipment.

This symbol is intended to alert the user of the presence of uninsulated dangerous

voltage within the product’s enclosure that may present a risk of electric shock.

Caution

Read Instructions • Read and understand all safety and operating instructions before using the equipment.

Retain Instructions • The safety instructions should be kept for future reference.

Follow Warnings • Follow all warnings and instructions marked on the equipment or in the user

information.

Avoid Attachments • Do not use tools or attachments that are not recommended by the equipment

manufacturer because they may be hazardous.

Consignes de Sécurité • Français

Ce symbole sert à avertir l’utilisateur que la documentation fournie avec le matériel

contient des instructions importantes concernant l’exploitation et la maintenance

(réparation).

Ce symbole sert à avertir l’utilisateur de la présence dans le boîtier de l’appareil

de tensions dangereuses non isolées posant des risques d’électrocution.

Attention

Lire les instructions• Prendre connaissance de toutes les consignes de sécurité et d’exploitation avant

d’utiliser le matériel.

Conserver les instructions• Ranger les consignes de sécurité afin de pouvoir les consulter à l’avenir.

Respecter les avertissements • Observer tous les avertissements et consignes marqués sur le matériel ou

présentés dans la documentation utilisateur.

Eviter les pièces de xation • Ne pas utiliser de pièces de fixation ni d’outils non recommandés par le

fabricant du matériel car cela risquerait de poser certains dangers.

Sicherheitsanleitungen • Deutsch

Dies es Symbol soll dem Benut zer in der im Liefer umfang ent haltenen

Dokumentation besonders wichtige Hinweise zur Bedienung und Wartung

(Instandhaltung) geben.

Dieses Symbol soll den Benutzer darauf aufmerksam machen, daß im Inneren des

Gehäuses dieses Produktes gefährliche Spannungen, die nicht isoliert sind und

die einen elektrischen Schock verursachen können, herrschen.

Achtung

Lesen der Anleitungen • Bevor Sie das Gerät zum ersten Mal verwenden, sollten Sie alle Sicherheits-und

Bedienungsanleitungen genau durchlesen und verstehen.

Aufbewahren der Anleitungen • Die Hinweise zur elektrischen Sicherheit des Produktes sollten Sie

aufbewahren, damit Sie im Bedarfsfall darauf zurückgreifen können.

Befolgen der Warnhinweise • Befolgen Sie alle Warnhinweise und Anleitungen auf dem Gerät oder in der

Benutzerdokumentation.

Keine Zusatzgeräte • Verwenden Sie keine Werkzeuge oder Zusatzgeräte, die nicht ausdrücklich vom

Hersteller empfohlen wurden, da diese eine Gefahrenquelle darstellen können.

Warning

Power sources • This equipment should be operated only from the power source indicated on the product. This

equipment is intended to be used with a main power system with a grounded (neutral) conductor. The

third (grounding) pin is a safety feature, do not attempt to bypass or disable it.

Power disconnection • To remove power from the equipment safely, remove all power cords from the rear of

the equipment, or the desktop power module (if detachable), or from the power source receptacle (wall

plug).

Power cord protection • Power cords should be routed so that they are not likely to be stepped on or pinched by

items placed upon or against them.

Servicing • Refer all servicing to qualified service personnel. There are no user-serviceable parts inside. To

prevent the risk of shock, do not attempt to service this equipment yourself because opening or removing

covers may expose you to dangerous voltage or other hazards.

Slots and openings • If the equipment has slots or holes in the enclosure, these are provided to prevent

overheating of sensitive components inside. These openings must never be blocked by other objects.

Lithium battery • There is a danger of explosion if battery is incorrectly replaced. Replace it only with the

same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the

manufacturer’s instructions.

Avertissement

Alimentations• Ne faire fonctionner ce matériel qu’avec la source d’alimentation indiquée sur l’appareil. Ce

matériel doit être utilisé avec une alimentation principale comportant un fil de terre (neutre). Le troisième

contact (de mise à la terre) constitue un dispositif de sécurité : n’essayez pas de la contourner ni de la

désactiver.

Déconnexion de l’alimentation• Pour mettre le matériel hors tension sans danger, déconnectez tous les cordons

d’alimentation de l’arrière de l’appareil ou du module d’alimentation de bureau (s’il est amovible) ou

encore de la prise secteur.

Protection du cordon d’alimentation • Acheminer les cordons d’alimentation de manière à ce que personne ne

risque de marcher dessus et à ce qu’ils ne soient pas écrasés ou pincés par des objets.

Réparation-maintenance • Faire exécuter toutes les interventions de réparation-maintenance par un technicien

qualifié. Aucun des éléments internes ne peut être réparé par l’utilisateur. Afin d’éviter tout danger

d’électrocution, l’utilisateur ne doit pas essayer de procéder lui-même à ces opérations car l’ouverture ou le

retrait des couvercles risquent de l’exposer à de hautes tensions et autres dangers.

Fentes et orices • Si le boîtier de l’appareil comporte des fentes ou des orifices, ceux-ci servent à empêcher

les composants internes sensibles de surchauffer. Ces ouvertures ne doivent jamais être bloquées par des

objets.

Lithium Batterie • Il a danger d’explosion s’ll y a remplacment incorrect de la batterie. Remplacer uniquement

avec une batterie du meme type ou d’un ype equivalent recommande par le constructeur. Mettre au reut les

batteries usagees conformement aux instructions du fabricant.

Vorsicht

Stromquellen • Dieses Gerät sollte nur über die auf dem Produkt angegebene Stromquelle betrieben werden.

Dieses Gerät wurde für eine Verwendung mit einer Hauptstromleitung mit einem geerdeten (neutralen)

Leiter konzipiert. Der dritte Kontakt ist für einen Erdanschluß, und stellt eine Sicherheitsfunktion dar. Diese

sollte nicht umgangen oder außer Betrieb gesetzt werden.

Stromunterbrechung • Um das Gerät auf sichere Weise vom Netz zu trennen, sollten Sie alle Netzkabel

aus der Rückseite des Gerätes, aus der externen Stomversorgung (falls dies möglich ist) oder aus der

Wandsteckdose ziehen.

Schutz des Netzkabels • Netzkabel sollten stets so verlegt werden, daß sie nicht im Weg liegen und niemand

darauf treten kann oder Objekte darauf- oder unmittelbar dagegengestellt werden können.

Wartung • Alle Wartungsmaßnahmen sollten nur von qualiziertem Servicepersonal durchgeführt werden.

Die internen Komponenten des Gerätes sind wartungsfrei. Zur Vermeidung eines elektrischen Schocks

versuchen Sie in keinem Fall, dieses Gerät selbst öffnen, da beim Entfernen der Abdeckungen die Gefahr

eines elektrischen Schlags und/oder andere Gefahren bestehen.

Schlitze und Öffnungen • Wenn das Gerät Schlitze oder Löcher im Gehäuse aufweist, dienen diese zur

Vermeidung einer Überhitzung der empndlichen Teile im Inneren. Diese Öffnungen dürfen niemals von

anderen Objekten blockiert werden.

Litium-Batterie • Explosionsgefahr, falls die Batterie nicht richtig ersetzt wird. Ersetzen Sie verbrauchte

Batterien nur durch den gleichen oder einen vergleichbaren Batterietyp, der auch vom Hersteller

empfohlen wird. Entsorgen Sie verbrauchte Batterien bitte gemäß den Herstelleranweisungen.

Instrucciones de seguridad • Español

Este símbolo se utiliza para advertir al usuario sobre instrucciones importantes

de operación y mantenimiento (o cambio de partes) que se desean destacar en el

contenido de la documentación suministrada con los equipos.

Este símbolo se utiliza para advertir al usuario sobre la presencia de elementos con

voltaje peligroso sin protección aislante, que puedan encontrarse dentro de la caja

o alojamiento del producto, y que puedan representar riesgo de electrocución.

Precaucion

Leer las instrucciones • Leer y analizar todas las instrucciones de operación y seguridad, antes de usar el

equipo.

Conservar las instrucciones • Conservar las instrucciones de seguridad para futura consulta.

Obedecer las advertencias • Todas las advertencias e instrucciones marcadas en el equipo o en la

documentación del usuario, deben ser obedecidas.

Evitar el uso de accesorios • No usar herramientas o accesorios que no sean especificamente recomendados

por el fabricante, ya que podrian implicar riesgos.

安全须知 • 中文

这个符号提示用户该设备用户手册中有重要的操作和维护说明。

这个符号警告用户该设备机壳内有暴露的危险电 压,有触电危险。

注意

阅读说明书 • 用户使用该设备前必须阅读并理解所有安全和使用说明。

保存说明书 • 用户应保存安全 说明书以备将来使用。

遵守警告 • 用户应遵守产品和用户 指南上的所有安全和 操作说明。

避免追加 • 不要使用该产品厂商没有推荐的工具或追加设备,以避免危险。

Advertencia

Alimentación eléctrica • Este equipo debe conectarse únicamente a la fuente/tipo de alimentación eléctrica

indicada en el mismo. La alimentación eléctrica de este equipo debe provenir de un sistema de distribución

general con conductor neutro a tierra. La tercera pata (puesta a tierra) es una medida de seguridad, no

puentearia ni eliminaria.

Desconexión de alimentación eléctrica • Para desconectar con seguridad la acometida de alimentación eléctrica

al equipo, desenchufar todos los cables de alimentación en el panel trasero del equipo, o desenchufar el

módulo de alimentación (si fuera independiente), o desenchufar el cable del receptáculo de la pared.

Protección del cables de alimentación • Los cables de alimentación eléctrica se deben instalar en lugares donde

no sean pisados ni apretados por objetos que se puedan apoyar sobre ellos.

Reparaciones/mantenimiento • Solicitar siempre los servicios técnicos de personal calicado. En el interior no

hay partes a las que el usuario deba acceder. Para evitar riesgo de electrocución, no intentar personalmente

la reparación/mantenimiento de este equipo, ya que al abrir o extraer las tapas puede quedar expuesto a

voltajes peligrosos u otros riesgos.

Ranuras y aberturas • Si el equipo posee ranuras o orificios en su caja/alojamiento, es para evitar el

sobrecalientamiento de componentes internos sensibles. Estas aberturas nunca se deben obstruir con otros

objetos.

Batería de litio • Existe riesgo de explosión si esta batería se coloca en la posición incorrecta. Cambiar esta

batería únicamente con el mismo tipo (o su equivalente) recomendado por el fabricante. Desachar las

baterías usadas siguiendo las instrucciones del fabricante.

警告

电源 • 该设备只能使用产品上标明的电源。 设备必须使用有地线的供电系统供电。 第三条线

(地线)是安 全设 施,不能不用或跳过 。

拔掉电源 • 为安全地从设备拔掉电源,请拔掉所有设备后或桌面电源的电源线,或任何接到市

电系统的电 源线。

电源线保护 • 妥善布线, 避免被 踩踏,或重 物挤压。

维护 • 所有维修必须由认证的维修人员进行。 设备内部没有用户可以更换的零件。为避 免出现

触电危险不要自己试图打开设备盖子维修该设备。

通风孔 • 有些设备机壳 上有通风槽或孔,它们是用来防止机内敏感元件过 热。 不要用任何 东

西挡住通风 孔。

锂电池 • 不正确的更换电池会有爆炸的危险。必须使 用与厂家推荐的相同或相近 型号的电池。

按照生 产厂的建议处 理废弃电池。

Page 3

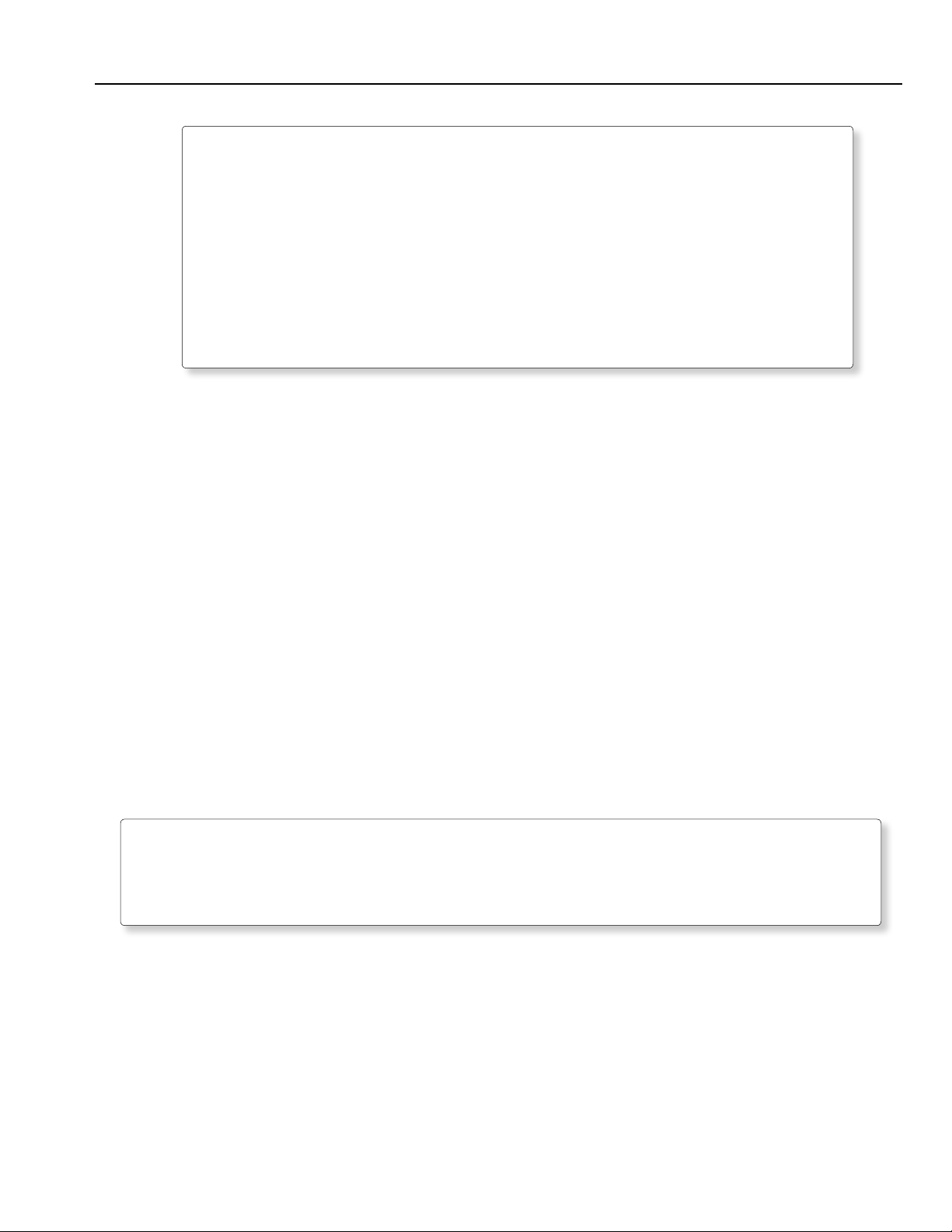

Introduction

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation. The Class A limits are designed to provide reasonable protection against

harmful interference when the equipment is operated in a commercial environment.

This equipment generates, uses, and can radiate radio frequency energy and, if not

installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area

is likely to cause harmful interference, in which case the user will be required to correct

the interference at his own expense.

Overview

This manual covers the installation of the Extron PoleVault™ System in a drop ceiling room with a wood or concrete

structural ceiling. If the location has a concrete or beam style ceiling, alternative ceiling mounts can be obtained

separately from Extron (see 2c, "Optional items", later in this chapter). For those types of installation, refer to the

individual mounting hardware user's manuals for method.

It is assumed that the installer has some knowledge and experience of A/V, electrical, or electronic device

installation. This manual guides the A/V installer through the steps for installation and connection of each of the

system’s component parts.

It may be that the locations for the devices (e.g., wall plates, projector, and screen) have been pre-determined.

However, some room installation examples are given to help in installations where nal location is yet to be

determined.

The PoleVault System

Extron PoleVault Systems are easy-to-use, network-enabled, all-inclusive packages, making them ideal for singleprojector K-12 classrooms. PoleVault Systems use economical twisted pair cables for transmitting signals and

include network connectivity for Web-based asset management, monitoring, and control.

N

The hardware and devices listed on the inventory pages have individual user manuals which have detailed safety

information, installation, set-up, and configuration instructions, and should be referred to as needed.

For operation and set up of the projector, screen, and input devices, refer to the relevant manufacturer's manuals

supplied with those devices.

PoleVault Systems Installation • Introduction

1-1

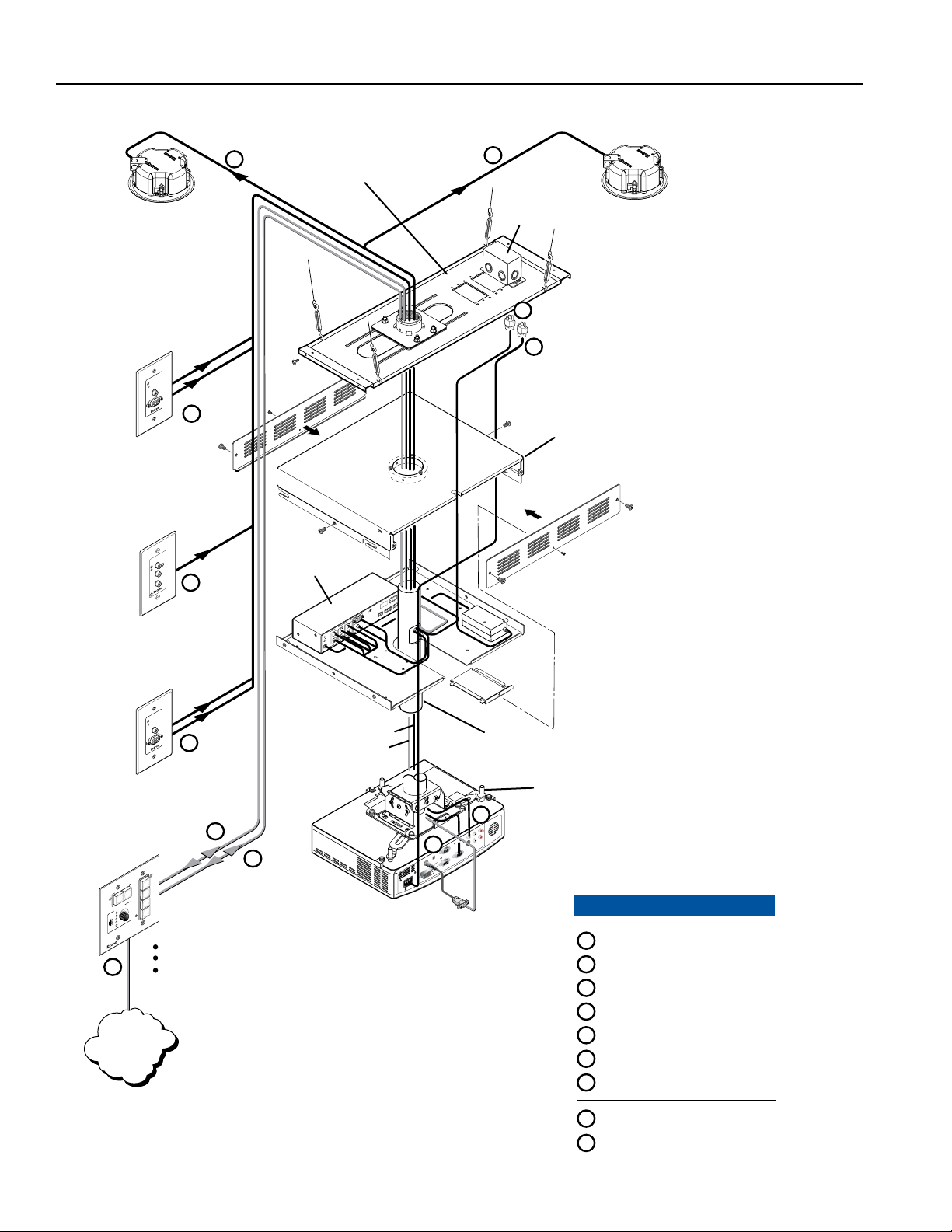

Page 4

Introduction, cont'd

L

R

AUX/MIX IN

DO NOT GROUND

OR SHORT

SPEAKER OUTPUTS!

1B

1A

I

N

P

U

T

S

O

U

T

P

U

T

S

2B

2A

3B

3A

RS-232 MLC/IR

DC VOL

4/8 Ohms

AMPLIFIED OUTPUTS

VOL/MUTE

Tx

A

B

C

Rx

IR

12V

10V

POWER

12V

3A MAX

US

LISTED

17TT

AUDIO/VIDEO

APPARATUS

®

RGB

VIDEO

RGB

VIDEO

PMK 450

Multi-product Pole

Mount Kit

PVT CV D

1 Gang

PVT RGB D

1 Gang

PVT RGB D

1 Gang

AC for Projector

AC for PoleVault

System

Ceiling Mounted

AC Outlet

RGB and Audio Input

RGB and Audio Input

Video and Audio Input

(x2)

(x2)

MLC 104 IP Plus

Projector on/off control

Projector input switching

Projector volume control

2 Gang (depth: 1.78”)

PCM 240

Projector Drop Ceiling

Mount

PV SI 3C LP

Full Range

Single Driver

Ceiling Speakers

AUDIO IN

L

R

VIDEO IN

COMPUTER IN

AUDIO IN

COMPUTER IN

AUDIO IN

4

4

7

1

1

1

3

2

8

9

CONFIG

DISPLAY

VOLUME

1

2

3

4

ON

OFF

TCP/IP

Network

PVS 204SA

PoleVault Switcher

Extron PoleVault™ System

UPB 25

Universal Projector

Mounting Bracket

AC in

RS-232

PMP 6

Projector Mounting Pole

Comm Adapter

(depending on

projector type)

6

5

7

8

6

5

4

3

2

1

9

Video In

Video In

Video In

Video Out

Audio

Audio

Communication

Extron Cables & Notes

CAT 5 T568A cable - 50'

Projector control cable - 50'

MLC power and control cable - 50'

18 AWG Speaker cable - 25'

Composite Video cable - 3'

VGA Video cable - 3'

PoleVault Switcher power cable - 25'

Projector power cord - not included

UTP network cable - not included

PoleVault System installation and wiring overview

1-2

PoleVault Systems Installation • Introduction

Page 5

CONFIG

DISPLAY

VOLUME

1

2

3

4

ON

OFFVCR

DVD

PC

Extron

MLC 104 IP Plus

PoleVault System

CONFIG

DISPLAY

VOLUME

1

2

3

4

ON

OFF

VCR

DVD

PC

Extron

MLC 104 IP Plus

Before you Begin Installation - Planning

Before installation is started, several major factors must be considered to ensure that the overall installation is as

smooth and trouble free as possible, and that the final finished project meets the needs of the customers, users,

audiences, and installer.

The installation consideration on the following pages, though not comprehensive, should be consulted to help ensure

that key aspects have been considered.

1. Room layout

a. The room

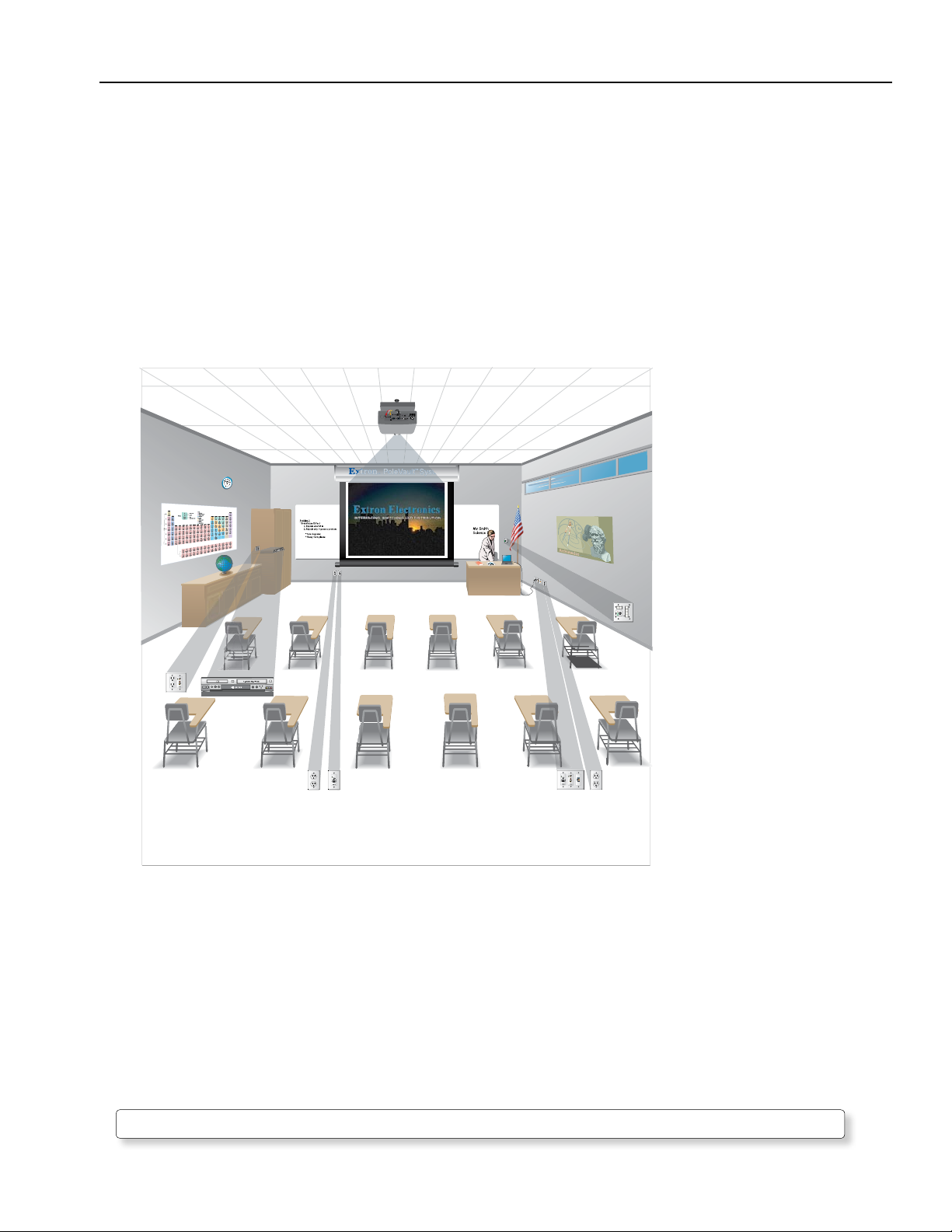

The application diagram below shows a typical classroom installation.

Typical classroom installation

Room factors to be considered should include, but are not confined to:

• Room size, orientation, and layout:

Audience factors (e.g. number, ADA requirements, seating arrangements)

Existing installed furniture (bookcases, racks, cabinets, workbenches, sinks, etc.)

Windows, doors, and support pillar locations in relationship to the proposed screen location

• Ceiling and wall type (important in assessing the installation hardware needed)

Ceiling type: dropped, spline, hard lid etc., structural type (wood, concrete, trusses), plenum or

non-plenum

Wall type: drywall, cement, brick etc.

W

Check the structural ceiling to ensure that it can handle a load four times the weight of the final setup.

PoleVault Systems Installation • Introduction — Planning

1-3

Page 6

Introduction — Planning, cont’d

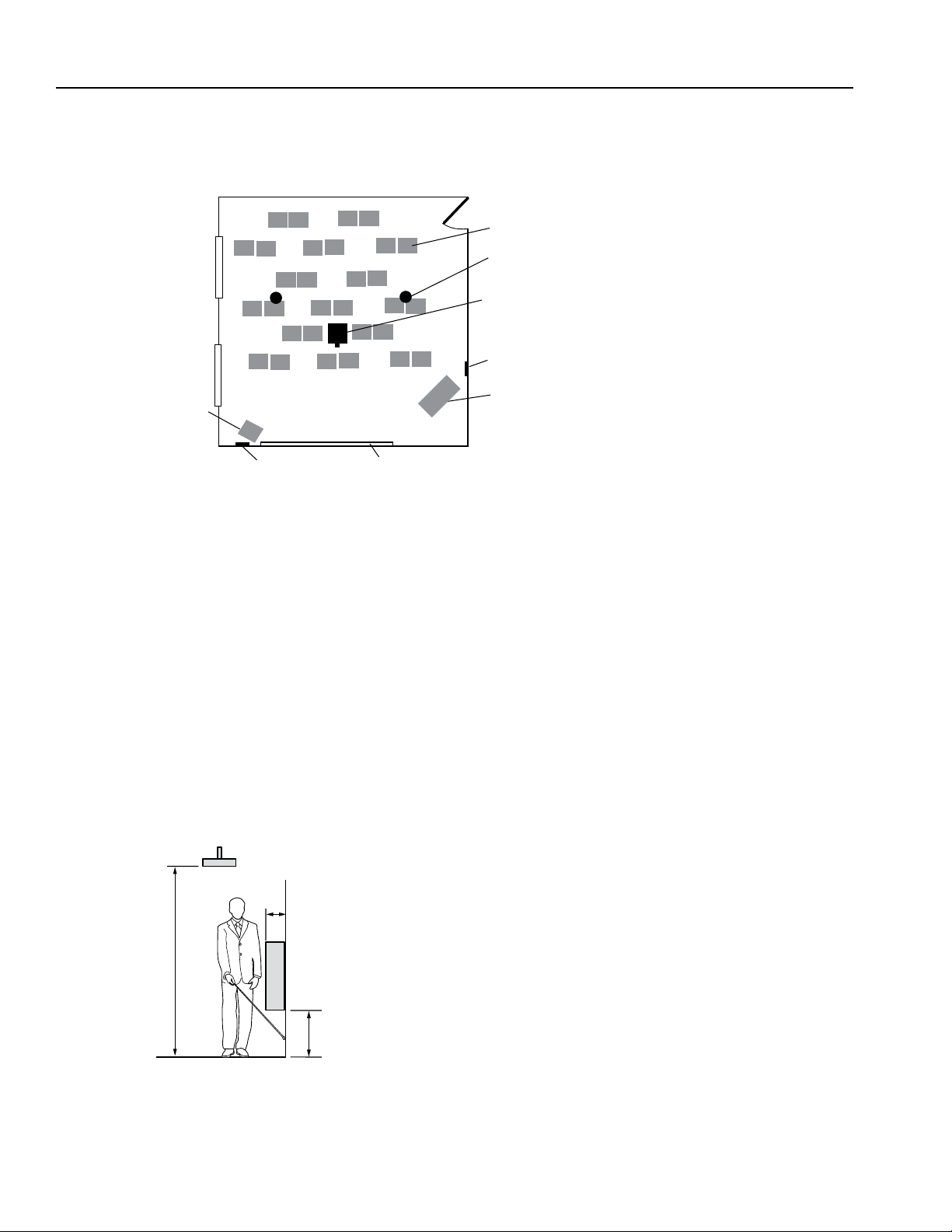

Student Desks

Teacher’s Desk

TV / VCR / DVD

Inputs

Screen/White Board

Location

Windows

MLC Controller

Location

PVT A/V Wallplate

Location

Projector/Switcher

Location

Speaker

Location

Greater than

27"

(68.5 cm)

80"

(203 cm)

Min

Walking Parallel to a Wall

4"

(10 cm)

Max

(ADA referenced figure 8a, redrawn)

• Lighting

Type and control (important for projector image viewing)

Ambient light from windows

Example classroom installation

b. Location of the screen and projector

• Proposed screen location

Normally located at the front center of the room (not covering fire alarm strobes when screen is lowered)

Dimensions and type of screen (maximum image size, motorized or hanging screen)

• Proposed projector location

Aligned with center of the screen. Not an obstruction to viewing

Projector's throw distance (maximum and minimum limits to screen) of the image

Horizontal offset (horizontal distance from the center of the lens to the center of the projector)

Vertical offset of the projected image (height relationship between the projector and the screen)

Projector angle (image projected up, down, or horizontal to screen)

Power source for the projector: existing and accessible or needing installation

Projector weight. The Universal Projector Bracket (UPB 25) supports a maximum weight of 25 lbs.

Overhead clearances (refer to a copy of "ADA Standards for Accessible Design", "Section 4-4", "Head Room"

for ADA requirements)

1-4

ADA overhead and side clearance requirements

PoleVault Systems Installation • Introduction — Planning

Page 7

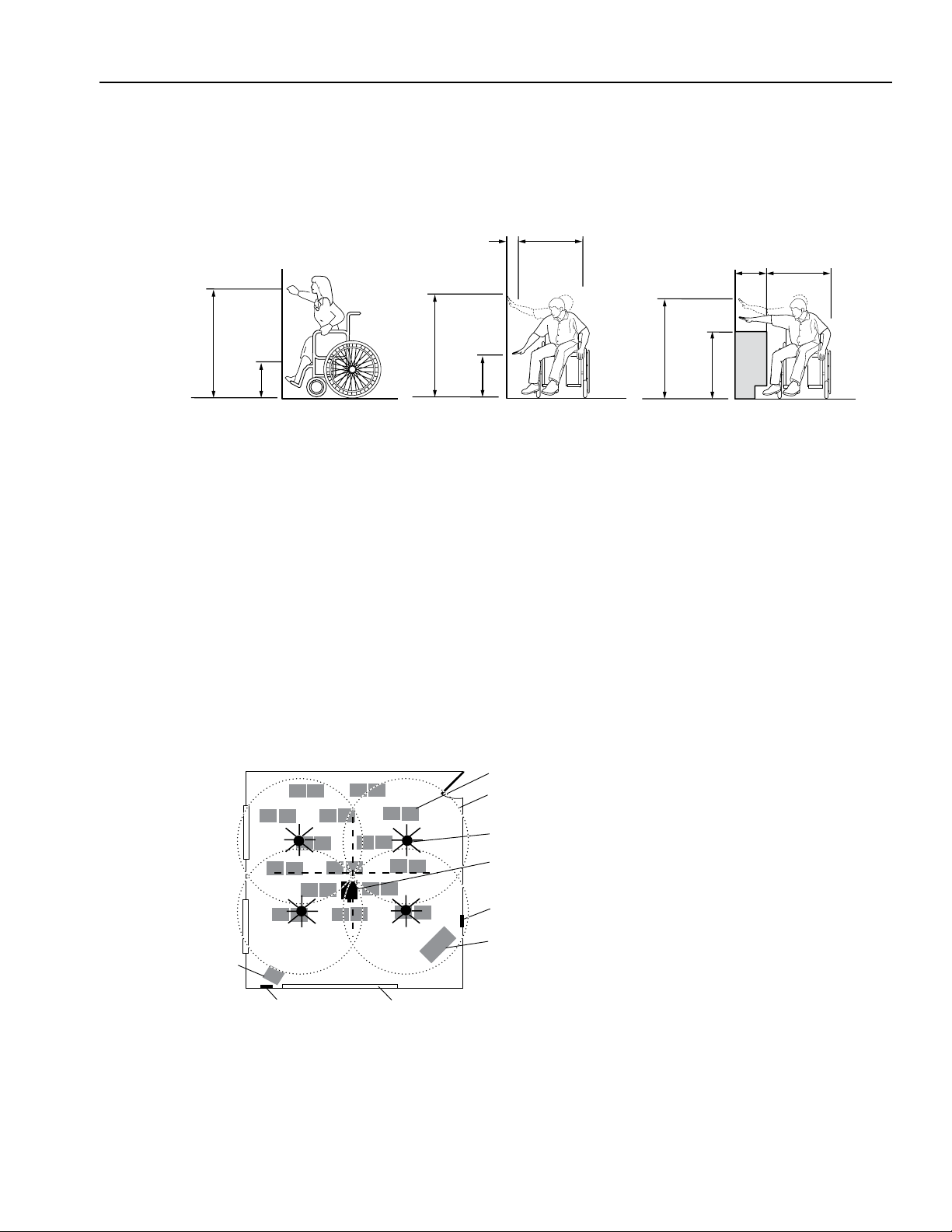

30"

(76 cm)

10"

(25.5 cm)

Max

54"

(137 cm)

Max

High / Low Side Reach Limits

9"

(23 cm)

Min

30"

(76 cm)

24"

(61 cm)

Max Side Reach over Obstruction Limits

46"

(117 cm)

Max

34"

(86.5 cm)

(ADA referenced figure 6c, redrawn)

(ADA referenced figure 6b, redrawn)

High Forward Reach Limits

48"

(122 cm)

Max

15"

(38 cm)

Min

(ADA referenced figure 5a, redrawn)

Student Desks

Teacher’s

Desk

TV / VCR / DVD

Inputs

Screen/White board

Location

Windows

MLC Controller

Location

PVT A/V Wallplate

Location

Projector/Switcher

Location

Speaker

Location

Each speaker covers

one-fourth of

listening area.

• Viewing obstructions

Pillars, furniture etc., window locations for glare reduction, obstructions between projector and screen

c. Location of MediaLink Controller and Wall Plates

• Forward and side reach (for full details refer to a copy of "ADA Standards for Accessible Design", "Section 4-2",

"Space Allowance and Reach Ranges")

ADA high/low forward, side and over obstruction reach limit requirements

• Location of source devices

Desk, table, or rack mounted, proximity to proposed transmitter location (wall, podium, or furniture)

• Cabling obstacles

Studs, utility pipes, power supply location (raceway installation needed?)

• Network drop for MediaLink Controller

Wall or floor cabled

d. Type and location of the speakers

• Speaker type based on room ceiling and wall type

• Total number and spacing of speakers

Based on ceiling height and room size

• Audience seating and room acoustics

Desired evenness of sound coverage and ambient noise level compensation

Example classroom with four speaker installation

PoleVault Systems Installation • Introduction — Planning

1-5

Page 8

Introduction — Inventory Overview

UPB 25 White

60-773-03

UPB 25

Universal Projector Bracket

PCM 240

Projector Ceiling Mount

PCM 240 White

60-772-03

(4)Turnbuckles

(5) Lag eyes screws

(5) Concrete anchors

(2) Cable clamps, Gal Steel

(1) Safety wire (15 ft 1/8” dia)

(2) Tie wire (30 ft, 14 AWG)

(4) Locking Screws

(4) Adhesive pads

(1) Hex key

PoleVault System

42-108-03 (or 42-109-03, or 42-110-03*)

(4) M6 x 40 mm screws

(4) M5 x 40 mm screws

(4) M4 x 40 mm screws

(4) M3 x 40 mm screws

0.328 ID washers (4)

#10 washers (4)

#6 washers (4)

Adhesive pads (4)

Hex key (1)

PMK 450

Pole Mount Kit

PMK 450 White

70-618-03

(7) Replacement screws

(2) Velcro

™

pads

(1) Set screw Hex wrench

(1) Security screw Hex wrench

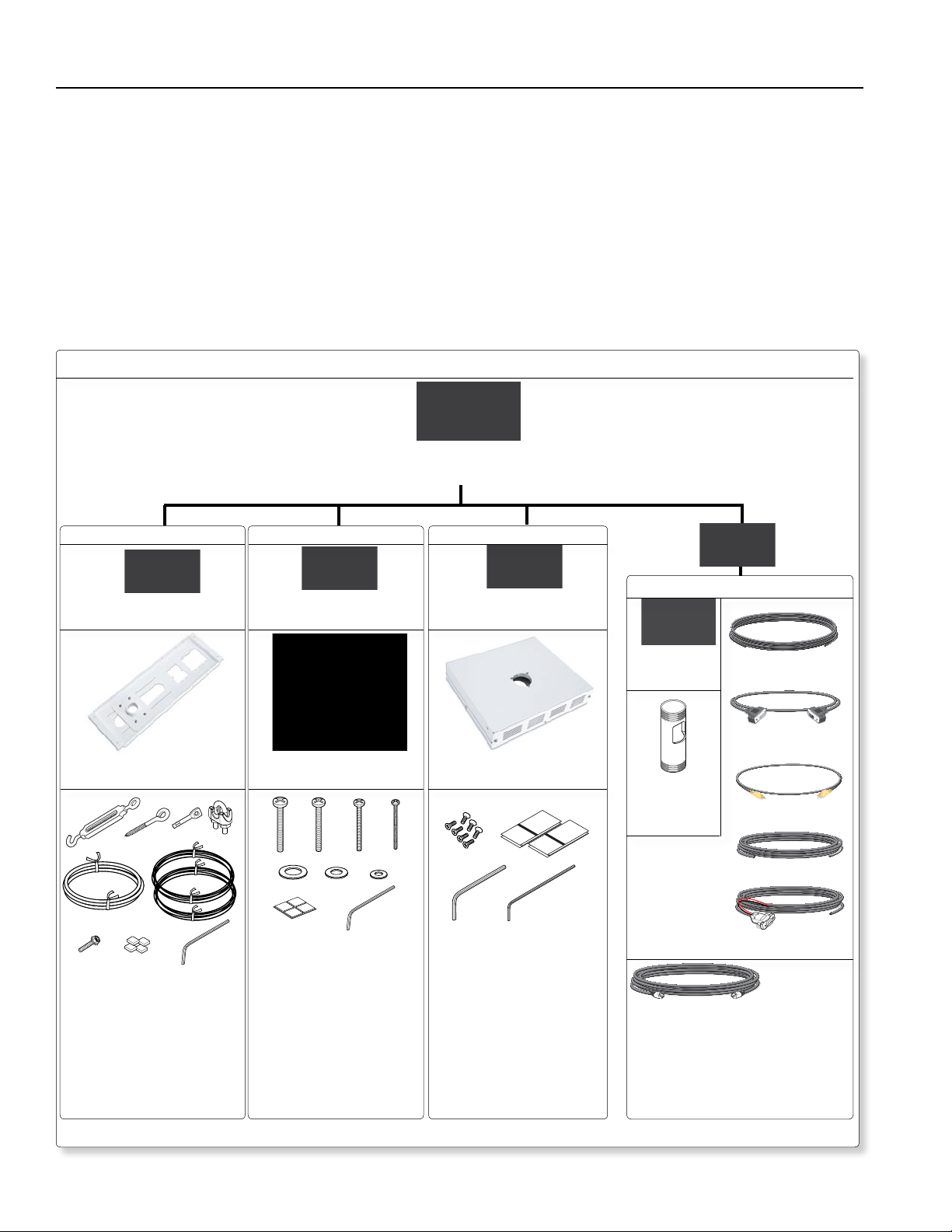

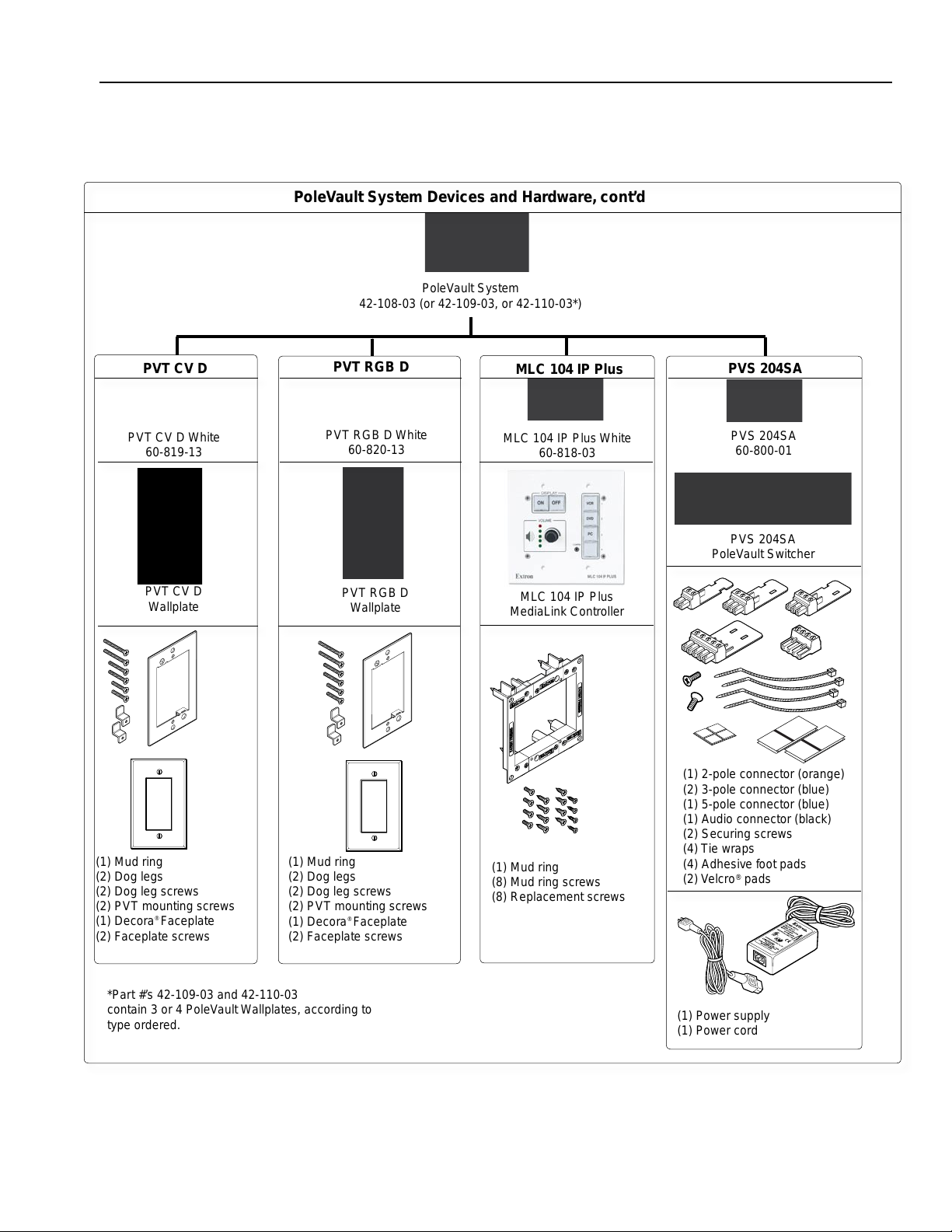

PoleVault System Devices and Hardware

PMP

Projector

Mounting Pole

PMP 6 White

70-511-13

PCM 240

UPB 25

PMK 450

PMP

CABLES

(1) SPK 18, 25’

(1) MLC, PW/RS232/VC, 50’

(1) IR SERIAL COMM, 50’

(1) MVGA M-M, 3’

(1) V RCA, 3’

CAT5 T568A Patch, 50’

Quantity varies depending on

PVS system ordered.

These may be boxed separately or

loose inside larger box.

2. Inventory

a. Included items

The PoleVault System (PVS xxx) ships in two boxes. The larger box (42-1xx-xx) contain the devices and

hardware, individually boxed and labeled. The smaller box (42-103-13) contains only the PV SI 3C LP speakers.

Each PVS system has the same quantities of speakers, hardware and devices, but differ in the number and type of

PoleVault A/V Source Input Wall Plates, and are shipped as follows:

• PVS 200 (part # 42-108-03) includes one PVT RGB D and one PVT CV D

• PVS 300 (part # 42-109-03) includes two PVT RGB D and one PVT CV D

• PVS 400 (part # 42-110-03) includes two PVT RGB D and two PVT CV D (see front cover of this manual)

Carefully check all the received items against the following lists.

1-6

PoleVault Systems Installation • Introduction — Inventory Overview

Page 9

PVT CV D

Wallplate

PVT CV D White

60-819-13

(1) Mud ring

(2) Dog legs

(2) Dog leg screws

(2) PVT mounting screws

(1) Decora® Faceplate

(2) Faceplate screws

*Part #’s 42-109-03 and 42-110-03

contain 3 or 4 PoleVault Wallplates, according to

type ordered.

PoleVault System

42-108-03 (or 42-109-03, or 42-110-03*)

PoleVault System Devices and Hardware, cont’d

PVT CV D

PVT RGB D

Wallplate

PVT RGB D White

60-820-13

(1) Mud ring

(2) Dog legs

(2) Dog leg screws

(2) PVT mounting screws

(1) Decora® Faceplate

(2) Faceplate screws

PVT RGB D

MLC 104 IP Plus

MediaLink Controller

MLC 104 IP Plus White

60-818-03

(1) Mud ring

(8) Mud ring screws

(8) Replacement screws

MLC 104 IP Plus

PVS 204SA

60-800-01

PVS 204SA

PoleVault Switcher

(1) 2-pole connector (orange)

(2) 3-pole connector (blue)

(1) 5-pole connector (blue)

(1) Audio connector (black)

(2) Securing screws

(4) Tie wraps

(4) Adhesive foot pads

(2) Velcro

®

pads

PVS 204SA

(1) Power supply

(1) Power cord

PoleVault System Devices and Hardware, (cont'd)

PoleVault Systems Installation • Introduction — Inventory Overview

1-7

Page 10

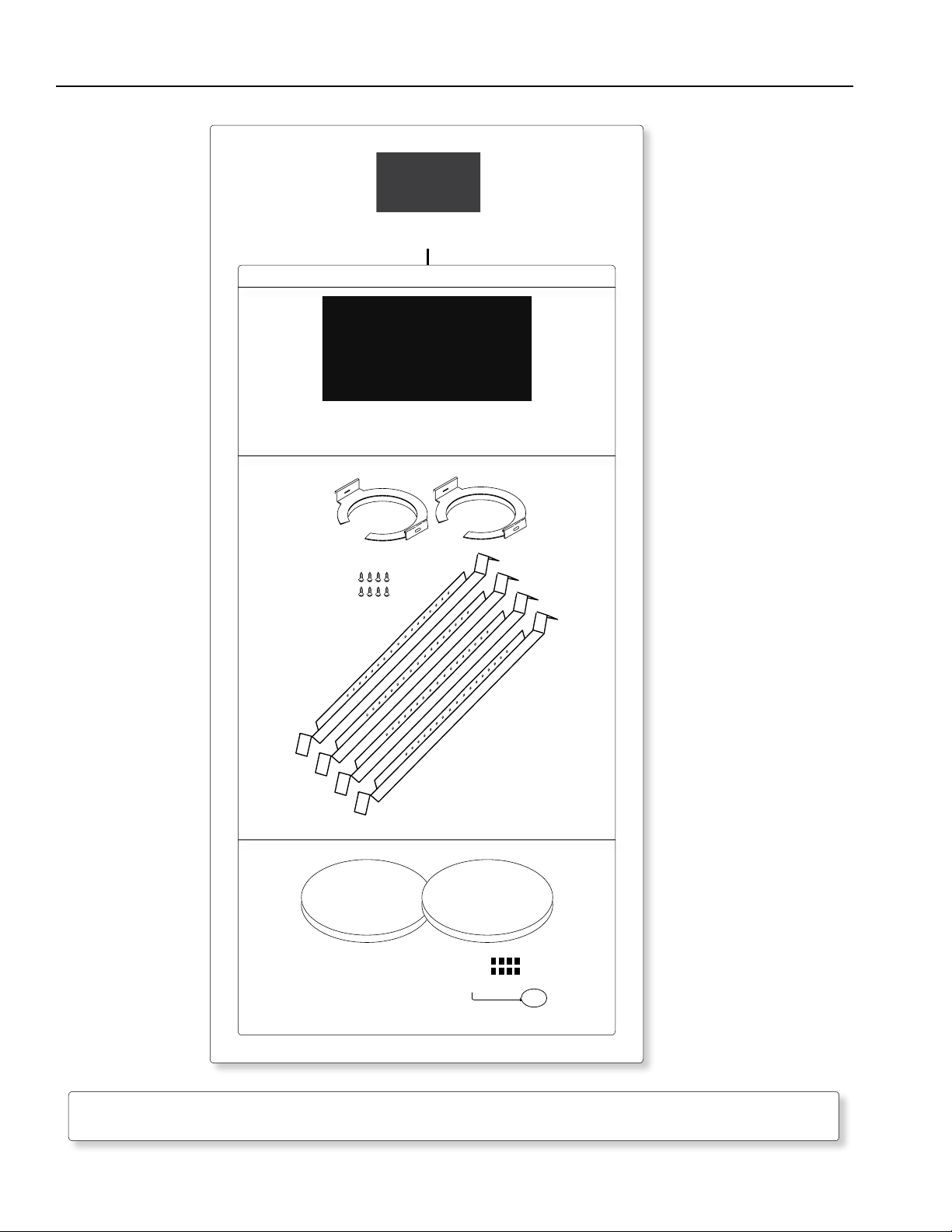

Introduction — Inventory Overview, cont’d

PV SI 3C LP

Speakers

PV SI 3C LP White

42-103-13

(2) C-rings

(8) C-ring attaching screws

(4) V-rails

(2) Speaker grills

(8 pcs) Grill putty

(1) Grill key

PV SI 3C LP

PoleVault System Ceiling Speakers

1-8

1-8

N

PoleVault Systems Installation • Introduction — Inventory Overview

If any items in the PoleVault System boxes are damaged or missing, contact the Extron Technical Hotline (see rear

cover for contact numbers).

Page 11

b. Items not included

The following items are not included. However, input and display devices are essential parts of the system, and at

any installation they may vary depending on their use. This list suggests various devices that may be used.

• Projector (or display device)

• Screen (and mounting hardware)

• Input devices, such as:

DVD/CD/VCR combo player (and cables)

Document camera (and cables)

PC or Mac (with keyboard, mouse, local monitor, VGA cables, RJ-45 network cables, power cords, and,

where desired, a P/2 DA2 or DA for PC signal to local monitor and projector)

• Installation hardware needed (may vary per installation):

Bolts for concrete structural ceilings where needed

Toggles (used for screen mounting on dry wall)

S-hooks for hanging the screen

Spare ceiling tiles in case of accidental damage during installation

Electrical box, where installation of a box on the PCM 240 is desired

Safety wire, lag eye bolts, and strain reliefs for installation and securing ceiling speakers

Heat shrink, extension cord

c. Optional items

The optional items suggested below can be added to or substituted for items in the standard PoleVault System.

• Optional accessories:

MLP 101 D (mic to line pre-amplier)

Wall mount speakers (e.g., SI 26) or extra ceiling speakers

MLC 104 IP Plus DV+ controller (includes DVD/VCR IR control)

MLC 104 IP Plus L controller (with lectern faceplate)

MLC 104 IP Plus AAP controller (with AAP opening)

PPC 25 Priority Page Controller

P/2 DA2

• Optional installation hardware:

FCMP (flat ceiling mount)

ACMP (angled ceiling mount)

SMB (surface mount boxes for installing the MLC on a podium or desk)

EWB (external wall boxes to mount devices for a surface raceway system)

MLM-WB+ (lockable metal wall box with ip-down 4U rack space)

• Optional A/V source inputs:

PVT CV AAP (composite video architectural adapter plate model)

PVT RGB AAP (RGB architectural adapter plate model)

PVT RGB (RGB rack mount model)

PVT SW RGB (RGB rack mount model with switching capabilities)

PVT CV (composite video rack mount model)

PVT RGB CV (RGB and composite video rack mount model)

• Optional speakers:

SI 3 (Compact Full-Range Surface Mount Speakers)

SI 26X (Two-Way Open Back Ceiling Speakers)

SI 26W (Two-Way-In-Wall Speakers with 6.5" Woofer)

SI 28W (Two-Way-In-Wall Speakers with 8" Woofer)

SI 26CT (Two-Way Ceiling Speakers with 8" Back Can and Transformer)

SI 26 (Two-Way Surface Mount Speakers with 6.5" Woofer)

PoleVault Systems Installation • Introduction — Inventory Overview

1-9

1-9

Page 12

Introduction — Inventory Overview, cont’d

d. Installation tools

To aid the professional installer, this checklist gives the tools recommended to complete the installation.

Tools should include, but are not confined to:

• Laser level, or two levels (large for screen installation, small for wall plates and projector mounts)

• Tape measure

• Stud nder

• Drill and drill bit set including a Unibit to cut through metal studs

• Extension drill bit (3/4" min., 4 to 8 foot length, to drill through re-breaks)

• Socket set

• Pipe strap or wrapped pipe wrench

• Lineman’s pliers and wire strippers

• Standard screwdriver set and Tweeker

• Cable cutters (to cut safety wire)

• Dry wall saw and hacksaw blade mounted on handle (for cutting ceiling tiles)

• Flashlight and safety goggles

• Razor knife

• 2" hole saw

• Painter's tape (to mark up walls), pencil, and marker pen

• RJ-45 crimpers and RJ-45 connectors

• Voltage tester

• Fish tape, pull string, and electrical tape (for taping sh tape to pull string)

• Zip ties

• Vacuum cleaner

• Heat gun

1-10

PoleVault Systems Installation • Introduction — Inventory Overview

Page 13

Installation OverviewInstallation Overview

This overview outlines the basic steps for installing the PoleVault System. Detailed description of these steps is given

in five sections, Stages One though Five.

N

Carefully check inventory of PoleVault system packages, input and output devices, any optional accessories, and

installation hardware before commencing.

Additional installation hardware is needed and should be supplied by the installer. See Introduction, “Items not

included”, for a list.

Optional accessories may be desired for this installation. See Introduction, “Optional items”, for a list, or

visit www.extron.com for details.

Refer to local building standards and codes to verify that the installation will meet all the regulatory requirements.

Observe all local and national building and safety codes, UL requirements, and ADA Accessibility Guidelines.

For details of the OSHPD approved method of installation (OPA-1782), consult the PCM 240 User’s Manual,

68-1180-01, Rev D.

Refer to the specifications on pages 2-31 through 2-33 for system hardware weights and dimensions.

Outline of installation steps

Stage One — Install the Screen and Projector.

c Mark the screen location (page 2-3).

c Install projector to verify location (page 2-3).

c Verify the image location (page 2-4).

c Cut the ceiling tile (page 2-5).

c Finish projector ceiling mount installation (page 2-5).

c Secure the projector ceiling mount to the ceiling (page 2-6).

c Install the screen (page 2-7).

Stage Two — Install the A/V Source Input Wall Plates and MLC 104 IP Plus.

c Install the mud rings (page 2-10).

c Pull cables (page 2-11).

c Install the wall plates (page 2-12).

c Install the MediaLink Controller (page 2-13).

Stage Three — Install the PV SI 3C LP Ceiling Speakers.

c Cut the ceiling tile (page 2-17).

c Install the speaker in the ceiling tile (page 2-17).

c Secure the speakers to the structural ceiling (page 2-18).

c Cable the speakers (page 2-18).

c Finish speaker installation (page 2-20).

Stage Four — Install the PMK 450 and the PVS 204SA.

c Pull the cables (page 2-22).

c Install the PMK 450 pole mount kit (page 2-22).

c Install the PVS 204SA switcher (page 2-23).

c Finish installing the pole mount kit (page 2-24).

Stage Five — Configuring the system.

c Congure the system (page 2-26).

c Test the system (page 2-28).

c Final installation (page 2-29).

Where possible in the following pages, line drawings and photos from an actual installation are used to clarify some

of the steps discussed in the text. Each image has a number corresponding to the particular step (e.g.,

) described.

Ñ

PoleVault Systems Installation • Installation Overview

2-1

Page 14

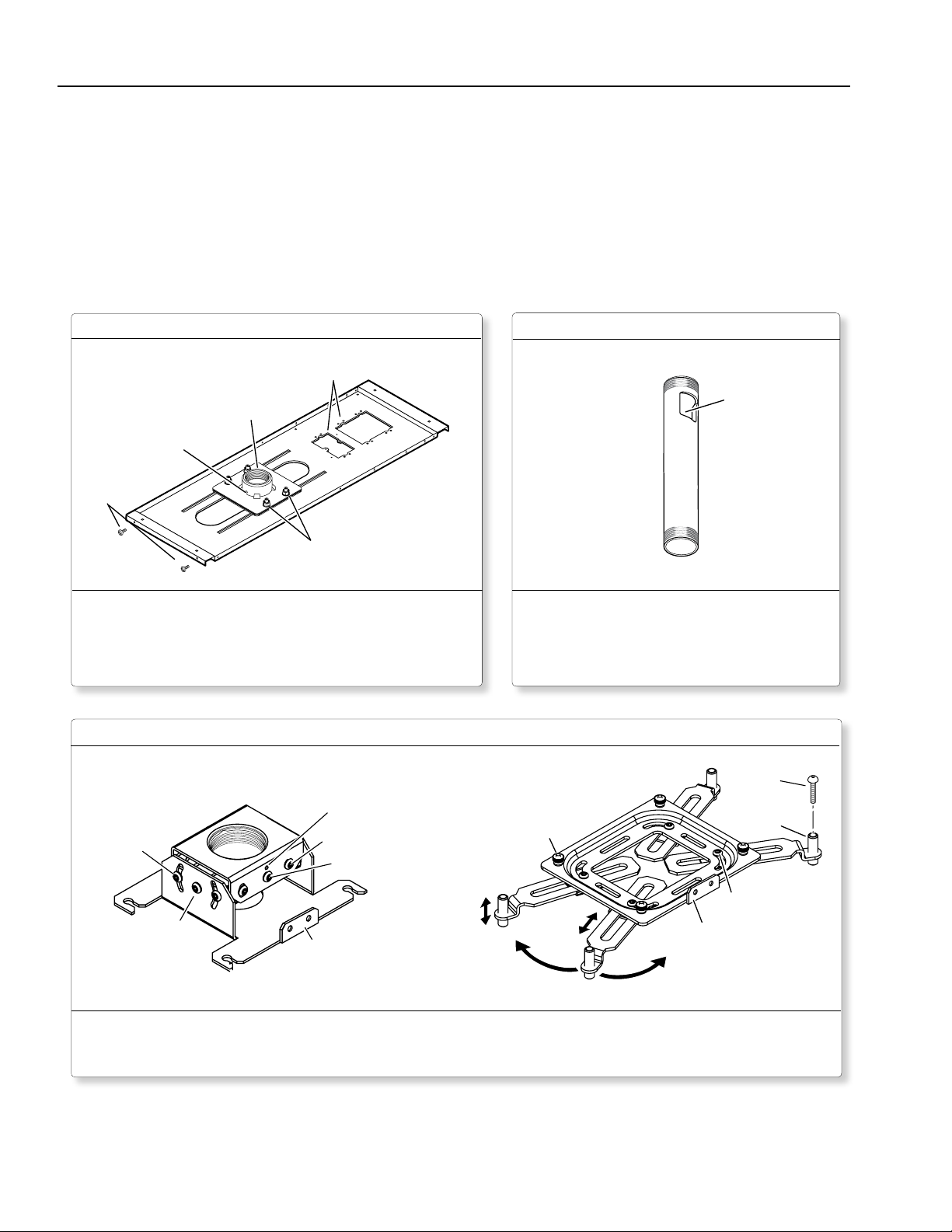

Stage One — Install the Screen and Projector

Cable

Access

Cutout

(install this

end uppermost)

Threaded at both

ends

T-bar

Securing

Screws (4)

Pipe Adapter Plate

Lock Nuts (4)

Pipe

Adapter

Pipe

Adapter

Set Screws (2)

1-gang and 2-gang Accessory

Mounting Points (e.g. power sockets)

360° Movement

Projector Securing

Screw

Threaded

Barrels (4)

Arm Adjustment

Screws (4)

Adjuster Plate

Locking Screws (4)

Security Flange

(on rear)

Projector Bracket

(Bottom Section)

Adjuster Plate

(Top Section)

Pivot Point screws (4)

Horizontal Angle

Adjustment Screws (4)

Set Screws (2)

Security Flange

(on rear)

Vertical Angle

Adjustment

Screws (4)

Pivot

Point

Screw

Stage 1

This stage involves installing the three pieces of hardware shown below.

PCM 240 Projector Ceiling Mount

Where it goes: Attaches to structural ceiling, rests on

suspended ceiling.

What it does: Holds PMP, Pole Mount Kit

(see Stage 4), and projector.

UPB 25 Universal Projector Bracket (shown separated into the two sections)

PMP Projector Mounting Pole

Where it goes: Screws up into PCM 240.

What it does: Holds Pole Mount Kit and

projector.

Where it goes: Adjuster plate screws onto base of PMP, and projector bracket attaches to projector.

What it does: Attaches projector to PMP. Allows projector orientation to be adjusted in three planes.

2-2

PoleVault Systems Installation • Installation — Stage 1

Page 15

Adjuster Plate

Locking Screws (4)

Projector

Bracket

Adjuster

Plate

Loosen the four Adjuster Plate

Locking Screws and slide the

Adjuster Plate away from the

Projector Bracket

a

b

Set Screws (2)

Minimum/Maximum

Throw Distance Marks

PCM

2b

1a

PMP installed

onto PCM 240

2c

2d

1. Mark screen location

a. Mark the center line and the outer edges of screen.

When marking the location of screens, devices, or site

T

for installing transmitters and MediaLink control

devices, use painters’ tape to avoid wall surface damage.

When marking the center line of the screen,

where possible, keep it aligned with the center of the

ceiling tile. This makes the projector installation and

alignment easier.

b. Mark any structural studs, utility pipes, conduits,

or fire-breaks before drilling the hardware holes.

Do not drill the holes at this time.

2. Install projector to verify location

a. Remove the ceiling tiles, and mark the maximum and

minimum throw distances on the T-frame.

b. Place the PCM 240 over the T-frame, between the two

marks. Lightly tighten the frame screws.

Mark the screen location

c. Back out the set screws on the PCM 240 adapter plate

and screw the PMP into the pipe adapter, with the cable

access hole closest to the ceiling. Turn it so the cable

access hole faces away from the screen.

Tighten the set screws.

d. Back out the set screws on the top portion (the adjuster

plate, see

onto the base of the PMP. Align it so the security flange

is at the rear. Tighten the set screw.

below) of the UPB 25, and screw the plate

a

Place the PCM 240 on the T-bar

Install the PMP

Screw the adjuster plate onto the PMP

PoleVault Systems Installation • Installation — Stage 1

2-3

Page 16

Installation — Stage One, cont’d

Projector

Center Line

Lens

Center Line

Measure the

horizontal offset

2f

2e

e. Using suitable screws, mount the projector onto the

lower portion of the UPB 25 (the projector bracket, see b

in step 2d’s drawing). Align it so the security flange is at

the rear. A minimum of three arms need to be attached

to the projector Adjust the arms to fit as needed. Lock

down the arm adjustment screws.

Adjust the threaded barrels at the end of each

T

arm to keep the bracket level.

f. Lift the projector up to the mount plate and slide it into

place. Tighten down the locking and pivot screws.

Attach the bracket to the projector

3. Verify the image location

a. Connect a power cable to the projector and turn it on.

b. Verify image size and location by loosening the

PCM 240 adapter plate locking nuts, and adjust the plate

(left-right) to center the image.

Remember to include the vertical and horizontal offsets

T

when aligning the projector. Refer to the projector

manual for information.

c. When satised lock down the plate locking nuts.

2-4

PoleVault Systems Installation • Installation — Stage 1

Slide and lock the projector onto the

adjuster plate

T Horizontal offset

Page 17

T-bar

X"

Y"

Minimum and

Maximum

Throw Distance Marks

4b

5d

4c

4. Cut the ceiling tile

a. Mark the location of the PCM 240 on the T-bar, before

removing it. This aids putting it back in the correct

location when the tile is replaced.

Mark the screen direction on back of the tile (e.g. with

T

an arrow or “to front”) to help orientation of tile when

replacing it after cutting.

b. Measure the distances X and Y (see gure) from the inner

vertical section of the front and left T-bar runners to the

center of the Pipe Adapter Plate.

c. Using these dimensions, mark and cut a hole for the

PMP in the ceiling tile.

Place the tile on a box, mark hole center on the

T

underside of the tile. Use a hole saw bit to start to cut

the hole by hand (turning bit counter clockwise) to

avoid damaging the tile. When the drill bit is through

the tile, turn the tile over and finish cutting from the

top side.

Take measurements with the PCM 240

on the T-bar

5. Finish Projector Ceiling Mount installation

a. Loosen the set screws and unscrew the UPB 25 from the

mounting pole. Do not remove the projector bracket

from the projector.

b. Loosen the PCM 240 ‘s set screw and remove the

mounting pole, then remove the PCM 240.

c. Replace the cut ceiling tile, checking the orientation to

align the hole with the PCM 240.

d. Replace the PCM 240 over the ceiling tile and screw

the mounting pole (with the access hole uppermost) up

through the hole into the mounting plate. Tighten the set

screws.

Mark and start cutting the hole on the

underside. Finish on the top side.

Screw the PMP into the mounting plate

(viewed from below)

PoleVault Systems Installation • Installation — Stage 1

2-5

Page 18

Installation — Stage One, cont’d

6a

PCM

T-bar

Adjust the turnbuckles to take

up any slack in the hanging wire.

6e

6b

6. Secure the Projector Ceiling Mount to the ceiling

a. Attach the four turnbuckles to the mounting plate, one at

each corner.

C

N

b. Mark and drill holes at 10 degrees out from vertical.

Drill a fth hole directly centered above the PCM 240 for

the safety cable.

c. Install appropriate anchors or lag eye-bolts for the

structural ceiling into each drilled hole

d. Cut four equal lengths of the supplied hanging wire, and

loop the wire through the anchors or eye screws, and the

turnbuckles, then twist the wire around itself at least five

times tightly.

DO NOT rest or lean on the mounting plate or

suspended ceiling when attaching turnbuckles,

tie wire, or when drilling into the ceiling

For safest installation, insert the turnbuckle from

the outside so that it hooks inwards.

Attach turnbuckles at the corners

Mark structural ceiling for lag bolt

installation

e. Hand tighten the turnbuckles, and level the plate so it

just rests on the grid.

C

Do not overtighten the turnbuckles or the

T-bar assembly could be lifted, making the

suspended ceiling bowed and unsafe.

f. Tighten the four T-bar securing screws on the PCM 240.

g. Mark a point in the ceiling directly above the plate’s

center, drill a hole and install a ceiling anchor or eye

screw

2-6

PoleVault Systems Installation • Installation — Stage 1

The four hanging wires should be taut, taking

the full weight of the completed installation.

C DO NOT rest or lean on the plate or

suspended ceiling grid during

installation of safety cable, or during

installation and wiring of electrical

boxes, accessories, and projector.

Tighten the turnbuckles

Page 19

PMK 450

T-bar

PCM 240

(viewed from

above)

Install power outlet

in the 2-gang cutout

(RACO box installed)

Attach safety cable

to center holes and

secure with cable

clamps.

6i

h. Pass the safety cable through the anchor and attach it to

the center holes on either side of the plate. Ensure the

cable is of equal length on both sides of the anchor and

secure the cable using the cable clamps.

Install any optional power outlets in the 2 gang opening

T

on the mounting plate, towards the outside edge of the

mount, so it does not interfere with the PMK 450 when

installed.

Attach the safety cable to the PCM

C

For safety, all wiring of the electrical boxes and

accessories should be completed after the plate is

fully installed and secure.

7. Install the Screen

a. Following the screen manufacturers guidelines, continue

to install the screen mounting brackets and then hang the

screen.

T Power outlet installation on the

PCM 240

T

Use S-hooks to hang the screen from the brackets.

Bend the ends of the S-hooks so the screen does not fall

when it is rolled up.

PoleVault Systems Installation • Installation — Stage 1

2-7

Page 20

Stage Two — Install the Wall Plates and MLC 104 IP

AUDIO IN

L

R

VIDEO IN

Audio and

Video input

connectors

Audio and Video

output port (at rear)

PVT CV D

AUDIO IN

L

R

VIDEO IN

Mounting

screws (2)

Decora

Faceplate

COMPUTER IN

AUDIO IN

Audio and

Video input

connectors

Audio and Video

output ports (2* - at rear)

* Each RGB wall plate needs

2 output cables, A and B.

PVT RGB D

CONFIG

DISPLAY

VOLUME

MLC 104 IP PLUS

ON

VCR

DVD

PC

OFF

1

2

3

4

Mounting

screws (4)

1

2

3

GROUND

+12V OUT

CM

GROUND

IR OUT

GROUND

SCP

GROUND

Tx

Rx

DISPLAY

RS-232/IR

A B C D E

COMM LINK

LAN

PRESS TAB WITH

TWEEKER TO REMOVE

A B

MLS

RS-232

POWER

12V

DIGITAL

I/O

IR IN

Tx

GROUND

Rx

+12V IN

Right Side

Ethernet

port

Display/RS-232/IR

Comm. Link

Digital I/O,

MLS/RS-232

Power

RUN

100

00-05-A6-01-6B-F5

Location of

MAC address

Rear View

Captive screw connectors for:

Stage 2

This stage involves installing the devices shown below.

PVT CV D and PVT RGB D PoleVault A/V Source Input Wall Plates

Where it goes: Installs in a wall near input location.

What it does: Transmits an input’s composite or RGB video and audio signals to the switcher.

MLC 104 IP Plus MediaLink Controller

Where it goes: Installs in a wall at a location convenient to user.

What it does: Provides remote control of switcher and projector.

2-8

PoleVault Systems Installation • Installation — Stage 2

Page 21

MLC, PW/RS-232/VC, 50

’

IR SERIAL COMM, 50’

CAT5 Patch, 50’

PVT transmitter installation

• CAT 5 T568A signal transmission cables (connects

PVT’s to PVS 204SA switcher)

MLC 104 IP Plus installation

• MLC power and RS-232 control cable (connects

the MLC to the MLC/Power control port on the

PVS 204SA switcher)

• IR/RS-232 communications cable control cable

(connects the MLC to the projector via RS-232

or to an IR emitter)

• LAN network cables (not supplied - connects

the MLC to LAN)

Cables

PoleVault Systems Installation • Installation — Stage 2

2-9

Page 22

Stage Two — Install the Wallplates and MLC 104 IP Plus

Wall

Dogleg

Dogleg

Screw

Surface Mounting

Hole

Equipment Mounting

Holes

NOTE Rotate the dogleg out of

the way to insert the

mud ring into the wall.

Extron

Mud Ring

1d

N

The installation must conform to national and

local electrical codes, and UL requirements.

Refer to the devices’ user manuals for details.

1. Install mud rings

N

a. Mark the holes for the mud rings.

T

b. Cut out the material from the marked area.

c. Insert the mud ring into the opening. The mud ring’s

rear connectors should t easily into the opening. Bend

over the mud ring doglegs and secure with the screws

provided.

Repeat steps a to c for all the transmitters needing to be

installed.

These devices can be installed using the supplied

mud ring or a wall box. If installing a box, allow

enough depth for the plate, and the cables. The box

should be at least 2.5" (6.4 cm) deep to

accommodate the connectors and cables.

If a suitable wall box is already installed, follow

step 2 onwards.

Use a level when marking the holes.

d. At the desired location repeat steps a to c for the larger

MLC 104 IP Plus mud ring

2-10

PoleVault Systems Installation • Installation — Stage 2

1c Insert the mud ring.

Features for mud ring installation

Page 23

RGB #1A

NOTE Fasten the colored section to the cable first,

then wrap the clear section around it.

2b

2c

2. Pull cables

The following cables need to be installed:

• CAT 5 cables for signal transmission from the

A/V Wall plates to the PVS 204SA.

N

• CAT 5 cables for MLC network connection

• PoleVault switcher communication cable from the

MediaLink controller

• Projector communication cables from the

MediaLink controller.

a. Drill cable pathways through any obstructions

(e.g., wall caps, fire-breaks, or horizontal studs).

b. Label the CAT 5 signal cables at both ends with the

supplied labels. Refer to the PVS 204SA User’s Manual

for labeling details.

For PVT RGB D Wall plates, two CAT 5 signal

cables for each input are needed.

Maximum distance from the PVS 204SA to the

Wall plates is 100 feet. The optimum distance

is between 50 and 75 feet.

The CAT 5 cables supplied are terminated to the

TIA 568A standard. Other CAT 5 cables can

be used if they are TIA 568A or 568B standards

and terminated to the same standard at both ends.

Use the supplied labels for clear cable

identification during installation.

Signal Cable Label color

RGB 1A (Input 1 RGB) Orange

RGB 1 B (Input 1 RGB) Orange w/black stripe

RGB 2A (Input 2 RGB) Yellow

RGB 2B (Input 2 RGB) Yellow w/black stripe

Video 3 (Input 3 Composite Vid) Green

Video 4 (Input 1 Composite Vid) Red

c. Pull the cabling through the wall from the ceiling space

down to the location of the transmitters and other wall

devices, and out through the openings.

Secure cables with cable clamps to provide strain relief.

T

Trim back the outer foil shield to the point where the

cable exits the cable clamp, and insulate exposed cable

shields with heat shrink to reduce the chance of short

circuits.

Both braided and foil shields should be connected to an

equipment ground at the other end of the cable.

Pull the cables at each location.

PoleVault Systems Installation • Installation — Stage 2

2-11

Page 24

Installation — Stage Two, cont’d

Extron

Mud Ring

Decora

Faceplate

Extron

PVT RGB D

COMPUTER IN

AUDIO IN

RGB IN # 1

Faceplate

Label

3b

3c

3. Install wall plates

a. Connect the CAT 5 cables to the rear of the input devices

(for RGB devices, cable labeled A to port A, cable B to

port B).

b. Mount each device into the mud ring.

3a Connect the cables to the A/V source

input devices at each location.

c. Attach the supplied Decora faceplate.

d. Label the Decora plate with the supplied label, using the

appropriate input number. This makes inputs easier to

identify when configuring the switcher.

e. Repeat steps a-d for other wall plates.

2-12

PoleVault Systems Installation • Installation — Stage 2

Mount the PVT in the mud ring, then

attach

and label 3dthe Decora

faceplate.

Page 25

MLC's MLS and

Power ports

PWR

12V

MLS

RS-232

GROU ND

GROU ND

A B

Tx

Rx

+1 2V IN

Ground ( )

+12 VDC

Transmit (Tx)

B

Receive (Rx)

A

Transmit (Tx)

Heat Shrink

over Drain Wire

Receive (Rx)

B

A

NOTE If you use cable that has a drain wire, tie

the drain wire to ground at both ends.

Apply heat shrink cover to both ends of the

wire to avoid accidental grounding.

RS-232/MLC/IR

PVS 204SA

Switcher's rear panel

RS-232/MLC/IR port

ABCDE

Tx Rx IR

+12V

Ground ( )

Heat Shrink

over Drain Wire

4a

Wire Bared

3/16"

(5 mm)

Max.

7/8"

(22 mm)

Heat Shrink on

Outer Jacket to

Inner Conductor

Transition

Heat Shrink on

Drain Wire

4. Install MediaLink Controller

Before cabling and installing the MLC 104 IP Plus,

T

locate and write down the MAC address of the device

for configuring the IP address. The 12 character

alphanumeric address (e.g., 00-05-A6-03-9G-H4)

can be found on a label on the rear of the controller.

The length of exposed wire is critical to avoid

T

transmission problems. Ensure the lengths given

here are adhered to when stripping the cables for

connection.

N

If a drain wire is used, both ends of the

wire must be covered by heat shrink to

avoid accidental grounding.

a. Connect the MLC power and RS-232 control cable as

shown.

N

The MLC 104 IP Plus is powered from the

PVS 204SA. DO NOT connect an external

power supply to the MLC 104 IP Plus unless

installing an optional secondary control panel.

From MLC 104 IP Plus

terminal

A - (Rx on the MLS port) White A - (Tx on the RS-232 port)

B - (Tx on the MLS port) Violet B - (Rx on the RS-232 port)

MLS RS-232 Ground Drain wire

Power Ground Black

12 V In Red E - +12 V

T Wire stripping lengths

Wire color To PVS 204SA terminal

D - Ground

D - Ground

Connecting the MLC to the switcher

PoleVault Systems Installation • Installation — Stage 2

2-13

Page 26

Installation — Stage Two, cont’d

4b

123

GRO UND

+12 V O UT

CM

GRO UND

IR OUT

GRO UND

SCP

GRO UND

Tx

Rx

DISPLAY

RS-232/IR

A B C D E

COMM LINK

LAN

PRESS TAB WITH

TWEEKER TO REMOVE

A B

MLS

RS-232

POWER

12V

DIGITAL

I/O

IR IN

Tx

GRO UND

Rx

+12 V I N

MLC 104 IP Plus Right Side Panel

TCP/IP

Network

CAT 5 Cable

4c

MLC 104 IP Plus

Right Side Panel

Ground ( )

Receive (Rx)

Transmit (Tx)

GRO UND

IR OU T

Tx

Rx

DISPLAY

RS-232/IR

RS-232 to projector

RS-232 connection

+1 2V OU T

PW R S NS

GRO UN D

GRO UN D

GRO UN D

Tx

Rx

HOST/

CONFIG

PROJECTOR

RS-232/IR

Tx /IR

Rx

N White, Violet, an

d

Shield Not Used

Red

Black

Projector

MLC IR/RS-232

Comm Cable

IR Emitter

Connecting IR Cable

White

(or striped)

Black

Red

Black

9-Pin Female

White

Violet

Shield

+1 2V OU T

PW R S NS

GRO UN D

GRO UN D

GRO UN D

Tx

Rx

HOST/

CONFIG

PROJECTOR

RS-232/IR

Tx /IR

Rx

MLC 104 IP Plus

N Red and Black

Not Used

Connecting RS-232 Cable

Projector

MLC 104 IP Plus

Right Side Panel

To projector

Ground ( )

IR Signal

Unidirectional IR Output

via White Striped Wire

IR Emitter

100'

(30.5 m)

GRO UND

IR OU T

Tx

Rx

DISPLAY

RS-232/IR

IR connection

Black

Black

Red

b. Connect the IR/RS-232 projector communication cable as

shown for either RS-232 or IR projector control.

Terminal RS-232 Cable color Pin

Tx White 2

Rx Violet 3

Ground Shield 5

Terminal IR/RS-232

IR Cable color

Cable color

Ground

IR Signal Red White/Black

Black Black

Connect the MLC to the projector with

an RS-232 cable or IR emitter cable, as

appropriate.

c. Connect a CAT 5, 5e, or 6 straight through cable to the

MLC ‘s RJ-45 jack.

W

2-14

DO NOT connect the MLC’s RJ-45 jack

to the PVS 204SA twisted pair inputs.

PoleVault Systems Installation • Installation — Stage 2

Connect to the LAN using a CAT 5 cable

Page 27

Extron

MLC 104 IP Plus

Rotate locking arm

and insert into wall

opening.

OFF

ON

OFF

ON

Extron

CONFIG

DISPLAY

MLC 104 IP Plus

VOLUME

1

2

3

4

ON

OFF

VCR

DVD

PC

Extron

MR 200

Modular Mud Ring

4e

123

GRO UND

+12 V O UT

CM

GRO UND

IR OUT

GRO UND

SCP

GRO UND

Tx

Rx

DISPLAY

RS-232/IR

A B C D E

COMM LINK

LAN

PRESS TAB WITH

TWEEKER TO REMOVE

A B

MLS

RS-232

POWER

12V

DIGITAL

I/O

IR IN

Tx

GRO UND

Rx

+12 V I N

LR

AUX/MIX IN

1B

1A

I

N

P

U

T

S

O

U

T

P

U

T

S

2B2A4

3

RS-232 MLC/IR

DC VOL

4/8

Ohms

AMPLIFIED OUTPUTS

VOL/MUTE

Tx

ABC

Rx IR 12V

10V

POWER

12V

3A MAX

US

LISTED

17TT

AUDIO/VIDEO

APPARATUS

®

RGB

VIDEO RGB

VIDEO

STEREO

ON

DUAL

MONO

HIGH

PASS

FILTER

OFF

ON

MLC 104 IP Plus Right Side Panel

PVS 204SA Switcher Rear Panel

Projector

RS-232

and Power

TCP/IP

Network

4c

4a

4b

RS-232 Control

CAT 5 Cable

Plenum Rated UL 2043

Suitable for Use in Air-Handling Spaces

III IIIIII IIIII IIIIII IIIII

S/N A024ERD56 E 235411 WO564871-12

PVS 204SA PoleVault Switcher

DO NOT GROUND

OR SHORT

SPEAKER OUTPUTS

The connections between the MLC 104 IP Plus

and the PVS 204SA switcher should look like this.

e. Sliding the cables into the opening, secure the

MLC 104 IP Plus to the mud ring with the provided

machine screws

Connections made to the MLC 104 IP Plus

Secure the MLC 104 IP Plus to the

mud ring

PoleVault Systems Installation • Installation — Stage 2

2-15

Page 28

Stage Three — Install the PV SI 3C LP Ceiling Speakers

Seismic Tab

Plenum Cover

Doglegs (4)

Speaker

Grills (2)

PV SI 3C LP Speakers (2)

V-rails (4)

Fitting

screws (8)

C-Rings (2)

V-rails Tabs

SPK 18, 25’

Stage 3

This stage involves installing the devices shown below.

PV SI 3C LP Ceiling Speakers

Where it goes: Installs in ceiling tiles at predetermined location for best acoustics. Connects to switcher.

What it does: Receives and outputs audio signal from PVS 204SA switcher

Speaker Installation:

• Speaker cable (connects ceiling speakers to the PVS 204SA switcher)

Cables

2-16

PoleVault Systems Installation • Installation — Stage 3

Page 29

1b

2c

Loosen the screws and

remove the plenum cover.

2a

2b

Bend Tabs

Upwards

N

The installation must conform to national and

local electrical codes, and UL requirements.

Refer to the device’s user manual for details.

1. Cut ceiling tile

If installing PV SI 3C LP speakers, do the following:

a. Remove the ceiling tiles where the speakers are to be

installed.

For ease of working on the speaker when it is replaced

T

on the T-bar, remove an adjacent tile(s).

b. Locate the tile center, and using the supplied template,

trace and cut the hole for the speaker.

Place an empty box under the tile for support and to

T

collect the waste.

Measure and mark the center point of the tile and align

the cross marks with those on the supplied template.

Use a fine hacksaw blade to cut the tile without

damaging the face.

2. Install the speaker in the ceiling tile

a. Lay two supplied speaker V-rails across the tile on either

side of the hole.

b. Remove the C-ring from the speakers and attach it to the

center of the V-rails with the supplied hardware.

At the ends of each V-rail, bend the tabs upwards.

T

This makes it easier when replacing the tile back on the

T-bars. When installation is complete, bend the V-tabs

down onto the T-bars

Mark the tile and cut the hole

Place the V-rails on either side of the

hole, insert and

attach the C-ring

c. Remove the plenum cover from the speaker terminals

d. Insert the speaker into the ceiling tile from the face side.

Bend the end tabs upwards.

Remove plenum cover

PoleVault Systems Installation • Installation — Stage 3

2-17

Page 30

Installation — Stage Three, cont’d

A

B

2e

3b

Attach the Conduit or Cable

to the Terminal Cover

Mark, drill a hole, and insert a lag

eyebolt in the structural ceiling.

Attach hanging wire

to the speaker

(seismic tab) and

to the eye bolt.

3c

4b

e. Loosen the four screws on the front baffle (counter

clockwise) 1/2 turn (see figure, A) and turn the doglegs

to lock onto the C-ring. Tighten down the front screws

(see gure, B).

Use a handheld screwdriver, as a powered screwdriver

T

may slip and damage the speaker.

f. Repeat steps a through e for each speaker that is to be

installed.

3. Secure speakers to structural ceiling

a. Replace each tile and speaker on the T-bar frame

b. Bend down the V-rail tabs to hold it in place and give

added support.

Turn and lock down the four dog legs

on the C-ring

c. Drill a hole into the structural ceiling and install a lag eye

bolt at a suitable location over the speaker.

d. Attach a hanging wire to the speaker seismic tab.

4. Cable the speakers

a. Cut the included speaker cable (SPK 18) to length and

run the cable from the PVS 204SA to the first speaker in

the speaker system being installed.

b. If not using conduit, insert a ½" clamp into the terminal

(plenum) cover knockout and pass the cable through the

knockout. Clamp the cable or conduit to the cover.

PoleVault Systems Installation • Installation — Stage 3

2-18

Replace tile and bend V-rail tabs down

Attach hanging cable to seismic tab

Attach conduit to terminal cover

Page 31

4c

PVS Switcher

Rear Panel

Speaker 1 Speaker 2

4-pole Captive

Screw Connector

LR

4/8

Ohms

AMPLIFIED OUTPUTS

4-pole Captive

Screw Connector

Audio output

to speakers

8 Ohm Load

Stereo R–

Stereo R+

Stereo L–

LR

8 Ohms

AMPLIFIED OUTPUTS

Stereo L+

8 Ohm Load

LR

8 Ohms

AMPLIFIED OUTPUTS

Mono –

Mono +

Mono –

Mono +

4 Ohm Total Load4 Ohm Total Load

Two 8 ohm speakers

wired in parallel

equal a 4 ohm load.

LR

4/8 Ohms

AMPLIFIED OUTPUTS

Mono –

or

Stereo R-

8

ohms

8

ohms

Mono +

or

Stereo R+

Mono –

or

Stereo L-

Mono +

or

Stereo L+

8

ohms

8

ohms

c. To terminate the cable, strip the end of the cable 0.2" (5

mm) and secure the wires into the supplied

4-pole captive screw connector.

d. Plug the 4-pole connector into the speaker terminal and

replace and secure the plenum cover

N

The correct speaker impedance loading must be

observed when setting up a speaker system

See figures below for examples.

Stereo output

Speaker

Wire color

Red Positive (+)

Black Negative (-)

To PVS 204SA terminal

(Left and Right)

Wire the captive screw connector.

Dual mono output

Stereo or Dual Mono output using parallel speaker wiring

PoleVault Systems Installation • Installation — Stage 3

2-19

Page 32

Installation — Stage Three, cont’d

Apply 4 pieces of black putty

(supplied), equally spaced 90°

apart, to the upper inside edge

of the grille.

5a

5. Finish speaker installation

a. Install/replace the speaker grill on the front of the

speaker, using the supplied adhesive tabs (putty) to

secure it in place.

b. Repeat cabling and final installation steps for all

speakers, connecting the speakers according to the

system preferred (e.g in parallel, see page 2-19)

Apply putty to speaker grill.

2-20

PoleVault Systems Installation • Installation — Stage 3

Page 33

LR

AUX/MIX IN

1B

1A

I

N

P

U

T

S

O

U

T

P

U

T

S

2B

2A

4

3

RS-232 MLC/IR

DC VOL

4/8

Ohms

AMPLIFIED OUTPUTS

VOL/MUTE

Tx

ABC

Rx IR 12V

10V

POWER

12V

3A MAX

US

LISTED

17TT

AUDIO/VIDEO

APPARATUS

®

RGB

VIDEO RGB

VIDEO

STEREO

ON

DUAL

MONO

HIGH

PASS

FILTER

OFF

ON

1A

32A

1A

32A

1B

42B

PVT RGB D

Input

Power Supply

Connector

PVT CV D

Input

RGB

Output

Video

Output

Speaker

Output

MLC Control

Port

Aux/Mix

Input

Plenum Rated UL 2043

Suitable for Use in Air-Handling Spaces

III IIIIII IIIII IIIIII IIIII

S/N A024ERD56 E 235411 WO564871-12

PVS 204SA PoleVault Switcher

DO NOT GROUND

OR SHORT

SPEAKER OUTPUTS

PVS 204SA

POLEVAULT SWITCHER

INPUTS

12

RGB

MIN/MAX CLIP

CONFIG

AUX/MIX

LEVEL

3 4

VIDEO

AUTO SW

LOCKOUT

AUDIO

Pipe Collar (1) with

Set Screws (4)

Security Screws (2)

AC Power Cord

Access Slot

Plate

Screws (2)

Bottom Plate (1)

Filler Plate (1)

Front Plate (1)

Rear Plate (1)

Top Plate (1)

Power Supply and Cable

MVGA M-M, 3’

V RCA, 3’

Stage Four — Install the PMK 450 and the PVS 204SA

Stage 4

This stage covers installing the devices shown below.

PMK 450 Pole Mount Kit

Where it goes: Attaches to PMP around cable access hole, above the projector.

What it does: Supports and hides the installed PVS 204SA switcher, power supply, and any installed optional

accessories.

PVS 204SA PoleVault Switcher

Rear View

Where it goes: PVS 204SA and power supply install on the base plate of the PMK 450.

What it does: Receives input video and audio signals from A/V source input wall plates, outputs and switches

VGA cable (connects to RGB output and projector)

the signals to projector and ceiling speakers.

Cables

RCA cable (connects to video output and projector)

PoleVault Systems Installation • Installation — Stage 4

2-21

Page 34

Installation — Stage Four, cont’d

PMK 450

Top Plate

PMP

Projector pipe

Cable access

hole

Slide the top cover upwards until it is located

just above the cable access hole.

Front

(towards screen)

1c

1d

1

1

1 2

3

4

4

5

6

1

3

4

4

2 5 6

To Pr ojector

To PVS 204SA

Cables from

PVS 204SA

Cables from A/V wall plates, MLC 104 IP Plus,

and SI 3CT LP speakers.

1

1

1

3

4

SI 3CT LP speaker cables

MLC 104 IP Plus switcher control cable

A/V wall plate cables, RGB (2), Video (1)

2

MLC 104 IP Plus projector control cable

5

6

VGA cable

Video cable

Cables to Projector

Cables to PVS 204SA

2b

N

The installation must conform to national and local

electrical codes, and UL requirements. Refer to the

device’s user manual for details.

1. Pull the cables

a. Loosen the PCM 240 set screws and remove the PMP.

b. Gather all the cables from the speakers, A/V wall plates,

MLC 104 IP Plus controller, and any optional devices

installed that have been run to the projector location,

and pull them down through the hole in the ceiling tile.

These cables are:

the MLC power/RS-232 cable,

the CAT 5 input cables from the wall plates,

the speaker cables,

the MLC to projector IR/Serial comms cable,

any optional device cables (e.g. PPC 25 sensor)

c. Gather the cables together below the suspended ceiling

and pass them down the PMP.

d. Screw the PMP back up into position and tighten the set

screws on the PCM 240.

2. Install the PMK 450 Pole Mount kit

a. Remove the front and rear plates from the PMK 450,

remove the side screws, and slide the top plate forward

and away from the base plate lugs.

b. Slide the PMK 450’s top plate up the projector pole until

it is located just above the cable access hole.

Gather the cables, pass them down

the PMP and

screw it into place.

c. Level the plate and secure it in place with the four set

screws located on the collar, ensuring that a minimum

of three set screws are tightened firmly against the pole.

Rotate the pipe if necessary to achieve this.

d. Pull the CAT 5 cables from the wall plates, the speaker’s

cable, and the MLC control cable through the access hole,

ready for connection to the switcher. Leave the MLC to

projector serial communications cable to hang out of the

bottom of the pipe.

e. Insert the output video signal cables (VGA and RCA)

into the access hole and pull them down the pipe so

one end hangs out the pipe with the MLC to projector

communication cable. These cables connect to the

2-22

projector later.

PoleVault Systems Installation • Installation — Stage 4

Slide the top plate up onto the pole

Switcher and projector cable overview

Page 35

LR

AU

X

/M

IX

IN

1B

1A

I

N

P

U

T

S

O

U

T

P

U

T

S

2B

2A

4

3

RS-2

32 M

LC

/I

R

D

C

VO

L

4/8

O

hm

s

A

M

PLIF

IED

O

U

TPUT

S

V

OL

/M

U

TE

Tx

ABC

RxIR 12V

10V

POWER

12V

3A

MAX

US

LIS

TE

D

17

TT

AU

D

IO

/V

ID

E

O

A

P

P

A

R

A

TU

S

®

RGB

VIDEO

RGB

VIDEO

STEREO

H

IG

H

PA

S

S

FIL

T

ER

O

N

O

FF

D

UA

L

M

O

NO

PMK 450

Bottom Plate

Extron

Power

Supply

Extron

PVS 204SA

PoleVault

Switcher

™

Front

(towards screen)

Secure to PMK

with Screws (2)

Secure to PMK

with Velcro pads

Power Supply

Output Cord

2-pole Captive

Screw

Connector

SECTION A–A

Ridges

Smooth

A

A

Tie Wrap

3

L R

AUX/MIX IN

1B

1A

I

N

P

U

T

S

O

U

T

P

U

T

S

2B

2A

4

3

RS-232 MLC/IR

DC VOL

4/8

Ohms

AMPLIFIED OUTPUTS

VOL/MUTE

Tx

AB C

Rx IR 12V

10V

POWER

12V

3A MAX

US

LISTED

17TT

AUDIO/VIDEO

APPARATUS

®

RGB

VIDEO RGB

VIDEO

STEREO

ON

DUAL

MONO

HIGH

PASS

FILTER

OFF

ON

1A

32A

1A

32A

1B

42B

Power Supply

Connector

Dual DIP

Switch

III IIIIII IIIII IIIIII IIIII

S/N A024ERD56 E 235411 WO564871-12

PVS 204SA PoleVault Switcher

Plenum Rated UL 2043

Suitable for Use in Air-Handling Spaces

DO NOT GROUND

OR SHORT

SPEAKER OUTPUTS

3a

3c

3d

3. Install the PVS 204SA switcher

a. Pass two 4-40 x 3/16" screws up through the PMK’s

bottom plate into the holes in the base of the switcher,

and secure it in place at the left front of the bottom plate.

N

b. Install the power supply on the right rear of the

PMK 450 bottom plate and secure it using velcro.

c. Attach the supplied 2-pole male captive screw connector

to the cord of the supplied power source and connect the

power cord to the rear of switcher.

Do not install the rubber feet on the switcher

when installing the device in the PMK.

Install the switcher and power supply

onto the base plate of the PMK 450

Insert the extra captive screw connectors into any

T

ports which are not going to be used at this time. This

keeps the connectors handy for any future system

modifications.

d. Set the DIP switches on the rear panel of the

PVS 204SA to Dual Mono and high pass lter off.

Refer to the PVS 204SA User’s Manual for details.

Wire the captive screw connector for

the power supply

PoleVault Systems Installation • Installation — Stage 4

e. Install any other optional devices, such as the Extron

Priority Page Sensor Kit on the PMK 450, following the

installation steps in the devices’ user’s manuals. See the

“Optional Accessory Installation — PPC-25” section in

this manual for an overview.

Set the DIP switches as desired

2-23

Page 36

Installation — Stage Four, cont’d

L R

AUX/MIX IN

1B

1A

I

N

P

U

T

S

O

U

T

P

U

T

S

2B

2A

4

3

RS-232 MLC/IR

DC VOL

4/8

Ohms

AMPLIFIED OUTPUTS

VOL/MUTE

Tx

ABC

Rx IR 12V

10V

POWER

12V

3A MAX

US

LISTED

17TT

AUDIO/VIDEO

APPARATUS

®

RGB

VIDEO RGB

VIDEO

STEREO

ON

DUAL

MONO

HIGH

PASS

FILTER

OFF

ON

1A

32A

1A

32A

1B

42B

PVT RGB D Input

(2 cables, A and B)

RGB output

to projector

RGB #1A

PVT CV D

Input

VIDEO #4

Ground ( )

+12 VDC input

External

Power Supply

(12 VDC, 3 A max.)

Power source

Tie Wrap

Video output

to projector

RGB #1B

MLC104 IP Plus

RS-232 input

4-pole Captive

Screw Connector

Audio output

to speakers

VGA Connector

RCA Connector

5-pole Captive

Screw Connector

2-pole Captive

Screw Connector

CAT 5 cable

with RJ-45

connector

CAT 5 cables

with RJ-45

connectors

d

e

b

a

f

c

a

B

A

+12 VDC

Ground ( )

Transmit (Tx)

Receive (Rx)

Ground ( )

Plenum Rated UL 2043

Suitable for Use in Air-Handling Spaces

III IIIIII IIIII IIIIII IIIII

S/N A024ERD56 E 235411 WO564871-12

PVS 204SA PoleVault Switcher

DO NOT GROUND

OR SHORT

SPEAKER OUTPUTS

4a

4. Finish installing the Pole Mount kit

a. Lift the bottom plate (complete with the PVS 204SA

and power supply installed) up to base of the pole and

connect the cables as follows:

CAT 5 cables according to the cable labels

a

Control/power cable from the MLC 104 IP Plus

b

Speaker cables

c

VGA and e RCA cables

d

Power supply cable. Do not apply

f

power yet.

N

Do not thread the power cable through the

projector pipe. Threading the power cable through

the pipe violates national electrical regulations.

Connect the cables to the switcher

Speaker

Wire color

Red Positive (+)

Black Negative (-)

To PVS 204SA terminal

(Left and Right)

MLC Wire

color

White A - (Tx on the RS-232 port)

Violet B - (Rx on the RS-232 port)

Drain wire

Black

Red E - +12 V

To PVS 204SA

terminal

D - Ground

D - Ground

2-24