Page 1

DMP 64

Digital Matrix Processor

User Guide

Audio Products

Mixers and Processors

68-1790-01 Rev. C

04 13

Page 2

Safety Instructions

Safety Instructions • English

WARNING: This symbol, , when used on the product, is intended to

alert the user of the presence of uninsulated dangerous voltage within

the product’s enclosure that may present a risk of electric shock.

ATTENTION: This symbol, , when used on the product, is intended to alert

the user of important operating and maintenance (servicing) instructions in the

literature provided with the equipment.

For information on safety guidelines, regulatory compliances, EMI/EMF

compatibility, accessibility, and related topics, see the Extron Safety and

Regulatory Compliance Guide, part number 68-290-01, on the Extron

website, www.extron.com.

Instructions de sécurité • Français

AVERTISSEMENT: Ce pictogramme, , lorsqu’il est utilisé sur le

produit, signale à l’utilisateur la présence à l’intérieur du boîtier du

produit d’une tension électrique dangereuse susceptible de provoquer

un choc électrique.

ATTENTION: Ce pictogramme, , lorsqu’il est utilisé sur le produit,

signale à l’utilisateur des instructions d’utilisation ou de maintenance

importantes qui se trouvent dans la documentation fournie avec le

matériel.

Pour en savoir plus sur les règles de sécurité, la conformité à la

réglementation, la compatibilité EMI/EMF, l’accessibilité, et autres sujets

connexes, lisez les informations de sécurité et de conformité Extron, réf.

68-290-01, sur le site Extron, www.extron.fr.

Sicherheitsanweisungen • Deutsch

WARNUNG: Dieses Symbol auf dem Produkt soll den Benutzer darauf

aufmerksam machen, dass im Inneren des Gehäuses dieses Produktes

gefährliche Spannungen herrschen, die nicht isoliert sind und die einen

elektrischen Schlag verursachen können.

VORSICHT: Dieses Symbol auf dem Produkt soll dem Benutzer

in der im Lieferumfang enthaltenen Dokumentation besonders

wichtige Hinweise zur Bedienung und Wartung (Instandhaltung)

geben.

Chinese Simplified(简体中文)

警告: 产品上的这个标志意在警告用户该产品机壳内有暴露的危险

电 压 ,有 触 电 危 险 。

注意: 产品上的这个标志意在提示用户设备随附的用户手册中有

重要的操作和维护(维修)说明。

关于我们产品的安全指南、遵循的规范、EMI/EMF 的兼容性、无障碍

使用的特性等相关内容,敬请访问 Extron 网站 www.extron.cn,参见 Extron

安全规范指南,产品编号 68-290-01。

Chinese Traditional(繁體中文)

警告: 若產品上使用此符號,是為了提醒使用者,產品機殼內存在著

可能會導致觸電之風險的未絕緣危險電壓。

注意 若產品上使用此符號,是為了提醒使用者。

有關安全性指導方針、法規遵守、EMI/EMF 相容性、存取範圍和相關主題的詳細

資訊,請瀏覽 Extron 網站:www.extron.cn,然後參閱《Extron 安全性與法規遵

守手冊》,準則編號 68-290-01。

Japanese

警告: この記 号 が製品上に表示されている場合は、筐体内に絶縁されて

いない高電圧が流れ、感電の危険があることを示しています。

注意: この記号 が製品上に表示されている場合は、本機の取扱説明書に

記載されている重要な操作と保守(整 備)の指示についてユーザーの

注意を喚起するものです。

安全上のご注意、法規厳守、EMI/EMF適合性、その他の関連項目に

つ い て は 、エ ク スト ロン の ウェブ サ イト www.extron.comより

『Extron Safety and Regulatory Compliance Guide 』 (P/N 68-290-01) をご覧ください。

Weitere Informationen über die Sicherheitsrichtlinien, Produkthandhabung,

EMI/EMF-Kompatibilität, Zugänglichkeit und verwandte Themen finden Sie in

den Extron-Richtlinien für Sicherheit und Handhabung (Artikelnummer 68-290-

01) auf der Extron-Website, www.extron.de.

Instrucciones de seguridad • Español

ADVERTENCIA: Este símbolo, , cuando se utiliza en el producto,

avisa al usuario de la presencia de voltaje peligroso sin aislar dentro

del producto, lo que puede representar un riesgo de descarga

eléctrica.

ATENCIÓN: Este símbolo, , cuando se utiliza en el producto, avisa

al usuario de la presencia de importantes instrucciones de uso

y mantenimiento recogidas en la documentación proporcionada

con el equipo.

Para obtener información sobre directrices de seguridad, cumplimiento

de normativas, compatibilidad electromagnética, accesibilidad y temas

relacionados, consulte la Guía de cumplimiento de normativas y seguridad de

Extron, referencia 68-290-01, en el sitio Web de Extron, www.extron.es.

Korean

경고: 이 기호 , 가 제품에 사용될 경우, 제품의 인클로저 내에 있는

접지되지 않은 위험한 전류로 인해 사용자가 감전될 위험이 있음을

경고합니다.

주의: 이 기호 , 가 제품에 사용될 경우, 장비와 함께 제공된 책자에 나와

있는 주요 운영 및 유지보수(정비) 지침을 경고합니다.

안전 가이드라인, 규제 준수, EMI/EMF 호환성, 접근성, 그리고 관련

항목에 대한 자세한 내용은 Extron 웹 사이트(www.extron.co.kr)의

Extron 안전 및 규제 준수 안내서, 68-290-01 조항을 참조하십시오.

Page 3

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part15 of the FCC rules. The ClassA limits provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates,

uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause interference; the user must correct the interference at

his own expense.

NOTE: For more information on safety guidelines, regulatory compliances, EMI/EMF compatibility,

accessibility, and related topics, see the “Extron Safety and Regulatory Compliance

Guide” on the Extron website.

Copyright

© 2013 Extron Electronics. All rights reserved.

Trademarks

All trademarks mentioned in this guide are the properties of their respective owners.

The following registered trademarks

(R)

, registered service marks

RGBSystems, Inc. or Extron Electronics:

Registered Trademarks

AVTrac, Cable Cubby, CrossPoint, eBUS, EDID Manager, EDID Minder, Extron, Flat Field,GlobalViewer, Hideaway, Inline, IP Intercom, IP Link,

Key Minder, LockIt, MediaLink, PoleVault, PowerCage, PURE3, Quantum, SoundField, System Integrator, TouchLink, V-Lock, VersaTools, VNMatrix, VoiceLift, WallVault, WindoWall

Registered Service Mark

AAP, AFL (Accu-Rate Frame Lock), ADSP (Advanced Digital Sync Processing), AIS (Advanced Instruction Set), Auto-Image, CDRS (Class D

Ripple Suppression), DDSP (Digital Display Sync Processing), DMI (Dynamic Motion Interpolation), Driver Configurator, DSP Configurator, DSVP

(Digital Sync Validation Processing), FastBite, FOXBOX, IP Intercom HelpDesk, MAAP, MicroDigital, ProDSP, QS-FPC (QuickSwitch Front Panel

Controller), Scope-Trigger, SIS, Simple Instruction Set, Skew-Free, SpeedMount, SpeedNav, SpeedSwitch, Triple-Action Switching, XTP, XTP

Systems, XTRA, ZipCaddy, ZipClip

(SM)

: S3 Service Support Solutions

Trademarks (™

(SM)

, and trademarks

(®)

)

(TM)

are the property of

Page 4

Conventions Used in this Guide

Notifications

The following notifications are used in this guide:

DANGER: A danger indicates a situation that will result in death or severe injury.

WARNING: A warning indicates a situation that has the potential to result in death or

severe injury.

CAUTION: A caution indicates a situation that may result in minor injury.

ATTENTION: Attention indicates a situation that may damage or destroy the product or

associated equipment.

NOTE: A note draws attention to important information.

TIP: A tip provides a suggestion to make working with the application easier.

Software Commands

Commands are written in the fonts shown here:

^AR Merge Scene,,Op1 scene 1,1 ^B 51 ^W^C

[01] R 0004 00300 00400 00800 00600 [02] 35 [17] [03]

E X! *X1&* X2)* X2#* X2! CE}

NOTE: For commands and examples of computer or device responses mentioned

in this guide, the character “0” is used for the number zero and “O” is the capital

letter “o.”

Computer responses and directory paths that do not have variables are written in the font

shown here:

Reply from 208.132.180.48: bytes=32 times=2ms TTL=32

C:\Program Files\Extron

Variables are written in slanted form as shown here:

ping xxx.xxx.xxx.xxx —t

SOH R Data STX Command ETB ETX

Selectable items, such as menu names, menu options, buttons, tabs, and field names are

written in the font shown here:

From the File menu, select New.

Click the OK button.

Specifications Availability

Product specifications are available on the Extron website, www.extron.com.

Page 5

Contents

Introduction ................................................... 1

About This Guide ............................................. 1

About the DMP64 Digital Matrix Processor ..... 1

Features .......................................................... 2

DMP64 Application Diagram ........................... 4

Installation ..................................................... 5

Mounting the DMP64 ..................................... 5

Rear Panel Features and Cabling ..................... 5

USB Configuration Port (Front Panel) ........... 8

Hardware Operation ...................................... 9

DMP64 Operation........................................... 9

Front Panel Operation .................................... 10

Rear Panel Operation .................................... 11

Power Cycle .............................................. 11

Firmware Updates ..................................... 11

Reset Actuator and LED Indicator .............. 12

Digital I/O Ports ......................................... 13

DMPSoftware .............................................. 14

Software Control............................................ 14

Embedded Web Pages.................................. 15

Windows-based Program Control .................. 15

Installing the DSP Configurator Program .... 15

Install the USB Driver ................................. 17

DSP Configurator Program Basics ................. 18

Starting the Program ................................. 18

Using the Program ..................................... 18

Navigation ................................................. 20

Cut, Copy, or Paste Functions ................... 20

DSP Configurator Toolbar Menus ............... 22

Presets Drop-down ................................... 26

Mode Buttons ........................................... 26

Audio Level, Mix-point, Processing Blocks,

and Signal Chains ......................................... 27

Level Control Blocks .................................. 28

Processor Blocks....................................... 28

Mic/Line Input Signal Controls ....................... 30

Gain Control (GAIN) .................................. 30

Filter (FILT) ................................................ 31

Feedback Suppressor (FBS) ...................... 41

Dynamics (DYN)......................................... 45

Delay (DLY) ................................................ 50

Ducking (DUCK) ........................................ 51

Ducking Configuration .............................. 52

Ducker Tutorials ............................................. 54

Pre-mixer Gain (GAIN) ................................ 55

Line Output Channels .................................... 56

Loudness (LOUD) ...................................... 56

Delay Block (DLY) ..................................... 58

Filter Block (FILT) ....................................... 58

Dynamics Block (DYN) .............................. 58

Volume Control (VOL) ............................... 59

Virtual Bus Returns ........................................ 60

Filter (FILT) ................................................. 60

Dynamics (DYN)......................................... 60

Loudness (LOUD) ...................................... 60

Gain (GAIN) ............................................... 60

Primary Mix Matrix ......................................... 61

Mix-point Behavior: .................................... 62

Mix-point Examples ................................... 64

Secondary Mix Matrix .................................... 67

Group Masters .............................................. 69

Group Members ........................................ 69

Grouped Controls ...................................... 69

Configuring a Group Master ....................... 71

Deleting a Group Master ............................ 72

Viewing and Using a Group Master ............ 72

Add a Group .............................................. 72

Tools .......................................................... 73

Soft Limits ................................................. 74

Digital I/O Ports ............................................. 75

Reinitialize Digital I/O .................................. 76

Emulate Mode and Live Mode ....................... 76

Synchronizing ............................................ 76

Selecting Live Mode and

Pushing or Pulling Data ............................. 77

vDMP64 • Contents

Page 6

Presets .......................................................... 81

Previewing and Recalling a Preset ............. 81

Building a Preset ........................................ 82

Protected Configuration ................................. 84

Save Protected Configuration .................... 84

Recall Protected Configuration................... 84

Change PIN ............................................... 84

DSP Configurator Windows Menus ............... 85

Keyboard Navigation ................................. 85

Optimizing Audio Levels ................................ 88

About Setting Gain Structure ..................... 89

Setting Input Gain ...................................... 89

Setting a Nominal Output Level.................. 89

Adjusting Pre-mixer Gain ........................... 90

Setting Output Gain Structure .................... 90

Setting Mic/Line Input and Mix Levels ........ 91

Adjusting Trim ............................................ 91

Setting Volume Control for the

Amplifier Stage ......................................... 91

SIS Programming and Control ................... 92

Connection Options ....................................... 92

RS-232 Ports ............................................ 93

USB Port (Front Panel) ............................... 93

Ethernet (LAN) Port .................................... 93

Verbose Mode ........................................... 94

Host-to-device Communications ................... 95

DMP64-initiated Messages ....................... 95

Password Information ................................ 95

Error Responses ........................................ 96

Simple Control Port Commands -

Telnet and Web-browser Accessible ......... 97

Command and Response Table for

Basic SIS Commands .................................. 98

Command and Response Tables for

DSP SIS Commands .................................. 103

Symbol definitions ................................... 104

Special Characters ...................................... 104

HTML Operation ........................................ 120

Download the Startup Page ......................... 120

Status Tab ................................................... 122

System Status Page ................................ 122

Configuration Tab ........................................ 123

System Settings Page ............................. 123

Passwords Page...................................... 126

Firmware Upgrade Page .......................... 127

File Management Tab .................................. 131

File Management Page ............................ 131

Control Tab .................................................. 132

Audio Settings Page ................................ 132

Group Controls Page ............................... 134

Presets Page ........................................... 135

Special Characters ...................................... 135

Reference Information .............................. 136

Firmware Loader ......................................... 136

DMP64 Hardware Reset Modes ................. 138

Mounting the DMP64 ................................. 139

Tabletop Use ........................................... 139

UL Rack Mounting Guidelines .................. 139

Rack Mounting ........................................ 139

Furniture Mounting................................... 139

Table or Wall Mounting ............................. 139

DMP64 • Contents vi

Page 7

Introduction

This section describes this manual and the DMP64, including:

• About This Guide

• About the DMP64 Digital Matrix Processor

• Features

• DMP64 Application Diagram

About This Guide

This guide contains installation, configuration, and operating information for the

ExtronElectronicsDMP64ProDSP™ Digital Matrix Processor, software-controlled digital

audio processor.

In this guide, the DMP64 can also be referred to as “the mixer” or “device.”

About the DMP64 Digital Matrix Processor

The DMP64 is a standalone audio matrix processor with six microphone/line inputs and

four line outputs. Using high-quality 24-bit A/D converters sampling at 48kHz, input signals

are converted into the digital domain where Digital Signal Processing algorithms process

and mix the signals using Extron floating point ProDSP™ technology. The DMP64 uses

a dual-matrix design providing virtual processing busses, with audio signal processing

available in any of the input, virtual, and output signal paths. A dual matrix mixer with virtual

paths provides extremely flexible architecture, allowing for versatile processing, mixing, and

routing scenarios.

The DMP64 is IP Link®-enabled, connecting to a host computer via the Ethernet port for

fast configuration and setup. Dual RS-232 ports on the rear panel, plus a USB port located

on the front panel provide convenient high-speed access. Six digital I/O ports permit

connection of switches and sensors to provide input to the system for triggering a variety of

actions within the device.

The DMP64 has no front panel controls therefore, all configuration is performed using

the Extron DSP Configurator™ program from a host computer connected by any of the

communication ports: RS-232, USB or Ethernet. Signal present and clip LEDs for the six

input channels and four output channels are provided on the front panel.

Two operational modes, Live and Emulate, allow a user to work offline from the device to

set up a configuration and create presets and group controls as needed before placing the

configuration in the DSP 64. DSP Configurator settings developed offline can be saved to

disk as a job file to be uploaded to the device at a later time, or can be transferred directly

to the device by switching to Live mode. Up to 32 full or partial presets and up to 32 group

master controls can be created, loaded into, and stored in the DMP64. The presets and

controls can then be recalled through DSPConfigurator, or a control system using Simple

Instruction Set(SIS™) commands. Control systems connected to the device either by RS232 or Ethernet can control a limited subset of DMP64 functions using SIS commands.

DMP64 • Introduction 1

Page 8

Features

• Consumer and professional audio compatibility — Input and output line level can

be set to consumer (–10dBV) or professional (+4dBu).

• Inputs — Six balanced or unbalanced mic/line on 3.5 mm, 3-pole captive screw

connectors.

• Outputs — Four balanced or unbalanced on 3.5 mm, 3-pole captive screw

connectors.

• ProDSP™ audio signal processing — Features 32- and 64-bit floating point

audio DSP processing providing wide dynamic range and maintaining audio signal

transparency while preventing DSP signal clipping and simplifying management of

gain staging.

• Pro-grade hardware — Studio grade 24-bit, 192 kHz analog-to-digital and

digital-to-analog converters sampling at 48 kHz.

• Low latency DSP processing — The DSP engine supports a large array of

concurrent audio processing within an audio channel and across multiple channels,

while maintaining extremely low latency from input to output.

• DSP Configurator software — Powerful, user-friendly PC-based software tool

for managing all audio operations of the DMP64. Enables complete setup and

configuration of digital audio processing tools on the ProDSP platform, as well as

routing and mixing.

• Intuitive graphical user environment — The DSP Configurator Software features

a Graphical User Environment with a clear view of all input and outputs, audio

processing blocks, routing, mix points, and virtual routing in a single window. This

allows a designer or installer to quickly view all audio activities without having to

access multiple windows or menus.

• SpeedNav keyboard navigation — SpeedNav enables user-friendly, keyboard-

based navigation of the DSP Configurator Software without the need for a mouse

or touchpad. Using keyboard navigation keys and shortcuts, a user can access any

input or output, mixing points, and all audio DSP tools. Using only the keyboard for

software access can help expedite audio system setup and commissioning while

on-site using laptop PCs.

• Copy and paste for processing blocks — To help speed audio system design

and setup, parameter settings can be quickly copied between individual processing

blocks or identical groups of blocks within the Graphical User Environment, using

conventional cut-and-paste commands.

• 32 DSP Configurator presets — Using the DSP Configurator software, parameters

for DSP processing, signal levels, or audio routing can be saved as presets. These

settings can be saved for the entire system, or any selected group of inputs, outputs,

mixing points, and DSP blocks.

• Six digital I/O ports for remote control or feedback — Six configurable digital I/O

ports are provided that enable the DMP64 to sense and respond to external triggers

such as mic activation and muting.

• Dual matrix design — The DMP64 employs a dual matrix design with substantial

flexibility to rout, mix, and process audio input sources. A primary matrix routes each

input to any or all four outputs. If desired, any of the six inputs can first be directed

into a secondary matrix, which routes the inputs to four virtual buses before being

mixed back to the outputs via the primary matrix. Virtual buses allow for inputs to be

grouped together and then processed with the same DSP settings and parameters,

simplifying system setup and control.

DMP64 • Introduction 2

Page 9

• Group masters — The DMP64 provides the capability to consolidate gain or mute

control throughout the system. Any gain or mute block within the Graphical User

Environment can be selected and added to a group master, which can then be

controlled by a single master fader and mute control. Each group master can have up

to 16 blocks, and up to 32 group masters can be created.

• Soft limits — Soft limits can be applied to group master faders. Minimum and

maximum limits can be specified and controlled via RS-232 serial control.

• Source signal presence and clipping LEDs — The DMP64 provides indicator

LEDs on the front panel for each input and output providing real-time monitoring of

signal presence. A separate set of LEDs illuminates as a warning when signal clipping

is detected.

• Flexible control options — The DMP64 can be controlled using the DSP

Configurator Software and a PC connection to the IP Link Ethernet port, the RS-232

serial port, or the USB 2.0 port on the front panel.

• Front panel USB configuration port — Enables configuration without having to

access the rear panel.

• RS-232 serial control port — Using serial commands, the DMP64 can be

controlled and configured via the Extron Windows®-based control program, or

integrated into third-party control systems using Extron Simple Instruction Set (SIS™)

commands. With two RS-232 serial ports plus the IP Link Ethernet port, the DMP64

offers possibilities for control in single and divisible room applications.

• Two RS-232 ports — The DMP64 is equipped with both primary and secondary

RS-232 serial ports for divided room applications.

• IP Link® Ethernet monitoring and control — Engineered to meet the needs

of professional A/V environments, IP Link enables the DMP64 to be proactively

monitored and managed over a LAN, WAN, or the Internet, using standard TCP/IP

protocols.

• Versatile mounting options — Rack-mountable 1U, half rack width metal

enclosure.

• Universal power supply — The 100-240 VAC, 50-60 Hz, international power supply

provides worldwide power compatibility.

DMP64 • Introduction 3

Page 10

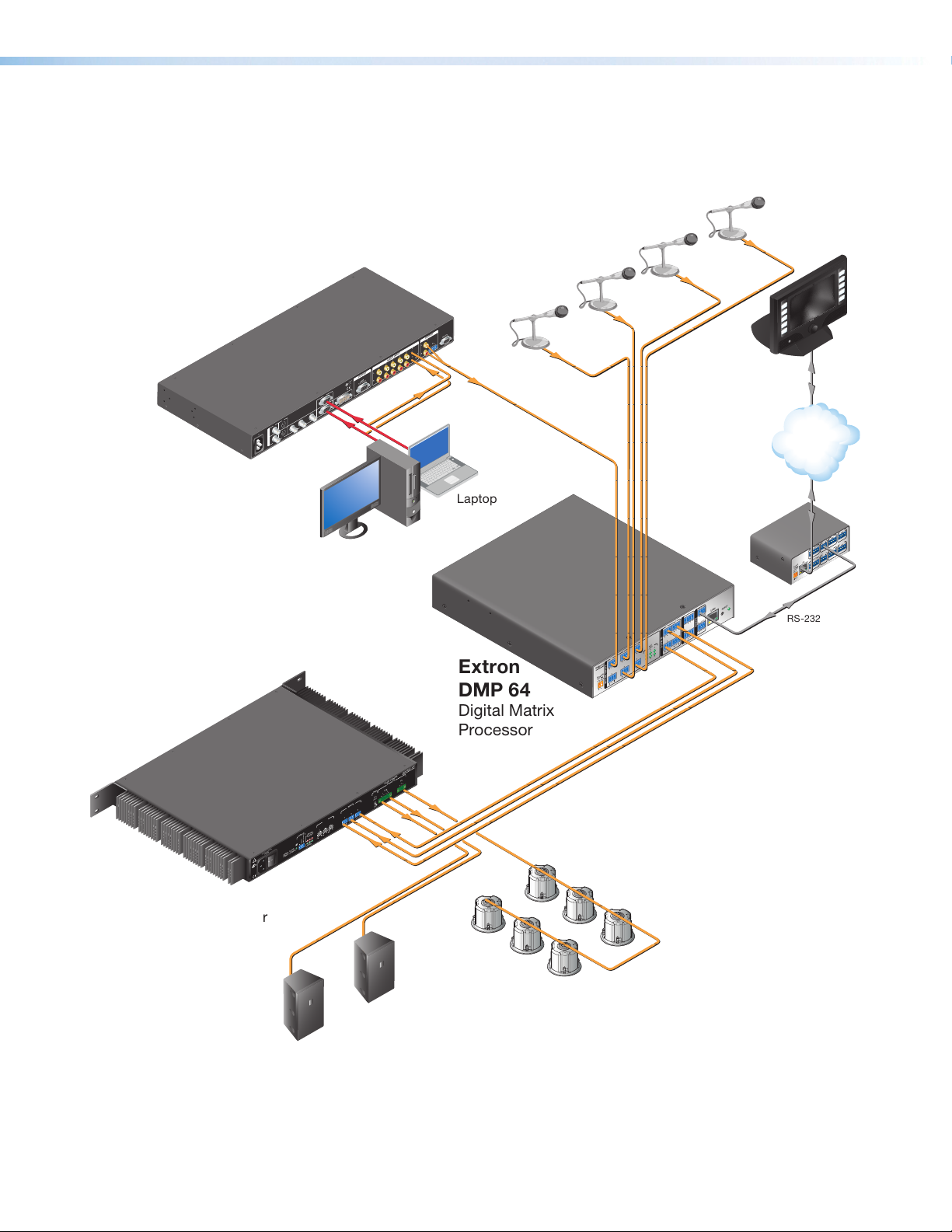

DMP64 Application Diagram

3

AUDIO INPUT

2

1

L

OUTPUT

R

RGB

LISTED

1T23

U S

I.T.E.

Y, B-Y, R-Y

C

6

8

DVI

RGB

7

RGB

3

YC

R-Y

1

VID

5

B-Y

I

Y

N

VID

100-240V 50-60Hz

4

P

U

2

Extron

IN1508

Scaling Presentation

Switcher

T

PC

Desk Microphones

VCR

DVD

DOC

CAM

LAPTOP

ON

OFF

DISPLAY

MUTE

SCREEN

UP

SCREEN

RS-232

OUTPUT

A

R

B

L

L

6

R

8

4 5

7

Extron

TLP 700TV

7" TouchLink

DOWN

™

PC

Ethernet

Tabletop

Touchpanel

TCP/IP

Network

Extron

IPL 250

Laptop

IP Link Ethernet

Control

Processor

2

RELAY

1

2

IR

1

COM 2

4

RELAY

TXRX

G S G

3

S

COM1

RT SC TS

IR

4

TXRX

3

COM 3

G

RX

S

TX

S G

INPUT

3 4

2

LAN

1

POWER

12V

500mA

MAX

RS-232 (1)

RESET

LAN

TxRx G

Extron

2

RS-232 (2)

1 2 3 G

REMOTE

1

I/O

TxRx G

4

6 G

4 5

3

3

MIC

OUTPUTS

+48V

2

1 2 3

1

5 6

6

4

5

DMP 64

4

POWER

12V

1.0A MAX

MIC/LINE INPUTS

RS-232

DMP 64

Digital Matrix

XPA 2003C -70V

70V

3

CLASS 2 WIRING

OUTPUTS

4/8

2

HPF

1

CH 3

80 Hz

OFF

INPUTS

3

2

1

LEVEL

3

2

0

1

0

LIMITER/

0

REMOTE

PROTECT

TIMER DISABLE

STANDBY

SIGNAL

1.3A MAX

100-240V 50/60 Hz

GREEN - ACTIVE

AMBER - STANDBY

Listed

17TT

AUDIO/VIDEO

Extron

XPA 2003C 70V

Combo Power Amplier

APPARATUS

Extron

SI 28

Surface-Mount

Speakers

Processor

Extron

SI 26CT

Two-Way Ceiling

Speakers

DMP64 • Introduction 4

Page 11

Installation

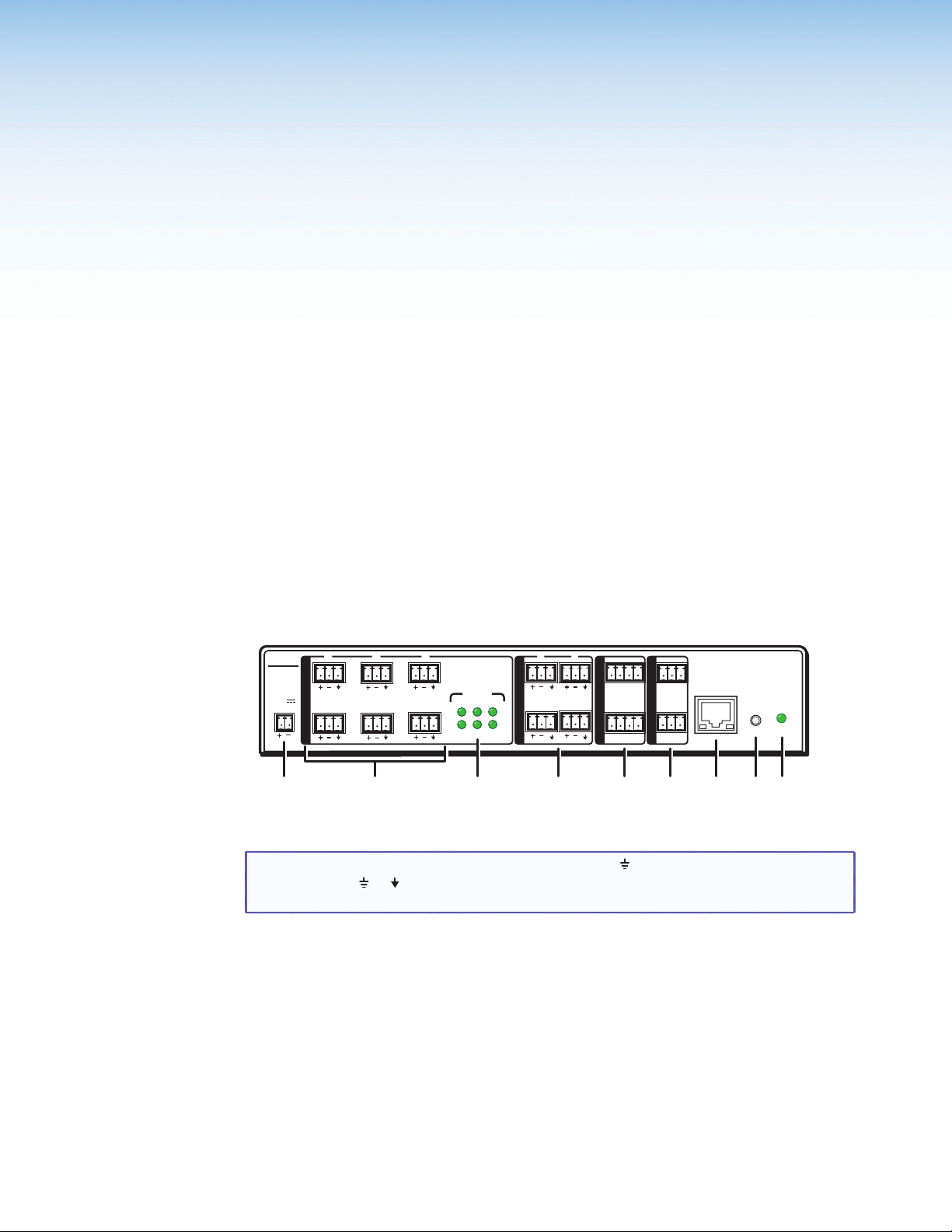

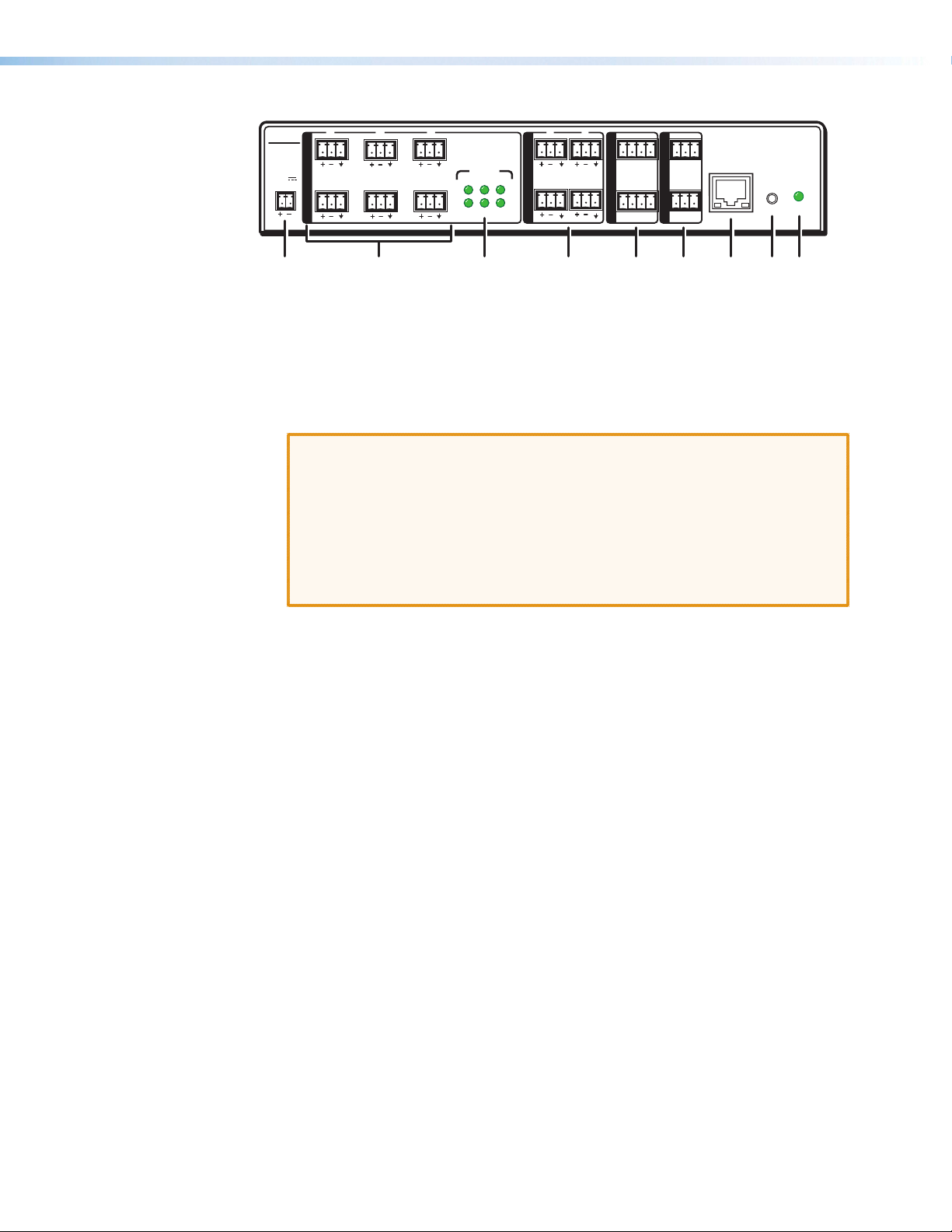

ab cdefghi

This section describes the installation of the DMP64, including:

• Mounting the DMP64

• Rear Panel Features and Cabling

Mounting the DMP64

The 1U high, half rack width, 9.5 inch deep DMP64 Digital Matrix Processor can be:

• Set on a table,

• Mounted on a rack shelf,

• Mounted under a desk or tabletop, or

• Mounted on a projector bracket.

For detailed mounting options and UL rack mounting guidelines (see Mounting the

DMP64 on page139).

Rear Panel Features and Cabling

DMP 64

POWER

12V

1.0A MAX

1

4

MIC/LINE INPUTS

2

5

Figure 1. DMP64 Rear Panel

NOTE: Control signal ground pins may be labeled as or “G”. Audio ground pins may

be labeled as or .

The wiring and function are the same, whichever way your product is labeled.

3

6

MIC

+48V

123

456

1

2

123 G

I/O

4

3

OUTPUTS

456 G

RS-232 (1)

Tx Rx G

RS-232 (2)

REMOTE

Tx Rx G

LAN

RESET

DMP64 • Installation 5

Page 12

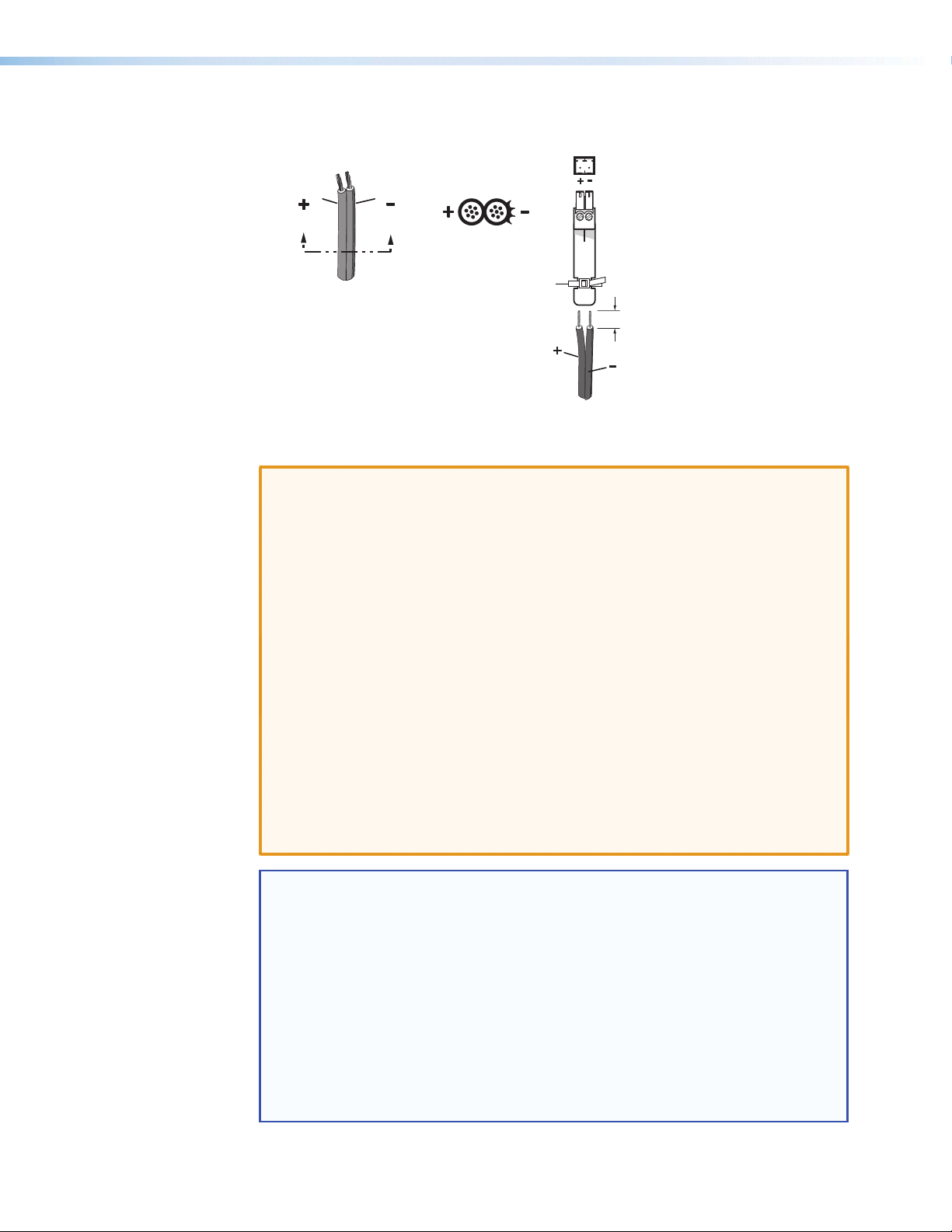

a Power connector — Connect the included 12 VDC external power supply into the

2-pole 3.5 mm captive screw connector. Be careful to observe the correct polarity.

Smooth

A

Ridges

A

Power Supply

Output Cord

SECTION A–A

Tie Wrap

Smooth

2-Pole Orange

Captive Screw

Connector

3/16”

(5 mm) Max.

Ridges

(12V)

Figure 2. Power Supply Wiring

Use the supplied tie-wrap to strap the power cord to the extended tail of the connector.

ATTENTION:

• The two power cord wires must be kept separate while the power supply is

plugged in. Remove power before wiring.

• Always use a power supply specified by Extron Electronics for the DMP64. Use

of an unauthorized power supply voids all regulatory compliance certification and

may cause damage to the supply and the DMP64.

• When connecting the power supply, voltage polarity is extremely important.

Applying power with incorrect voltage polarity could damage the power supply

and the DMP64. Identify the power cord negative (ground) lead by the ridges on

the side of the cord or a black heat shrink wrapping around it.

• Unless otherwise stated, the AC/DC adapters are not suitable for use in air

handling spaces or in wall cavities. The power supply is to be located within the

same vicinity as the Extron AV processing equipment in an ordinary location,

Pollution Degree 2, secured to the equipment rack within the dedicated closet,

podium or desk.

• The installation must always be in accordance with the applicable provisions of

National Electrical Code ANSI/NFPA 70, article 75 and the Canadian Electrical

Code part 1, section 16. The power supply shall not be permanently fixed to

building structure or similar structure.

NOTES:

• The length of the exposed (stripped) copper wires is important. The ideal length

is 3/16 in (5mm). Longer bare wires can short together. Shorter wires are not as

secure in the direct insertion connectors and could be pulled out.

• Do not tin the stripped power supply leads. Tinned wires are not as secure in the

captive screw connectors and could be pulled out.

• To verify the polarity before connection, check the no load power supply output

with a voltmeter.

• To avoid losing adjustments when configuring the DMP64 via SIS commands,

issue a 2FF or if using the Extron DSPConfigurator, select Tools > Save

changes to device to store the latest changes to the device. Wait several

minutes after saving the adjustments before disconnecting power.

DMP64 • Installation 6

Page 13

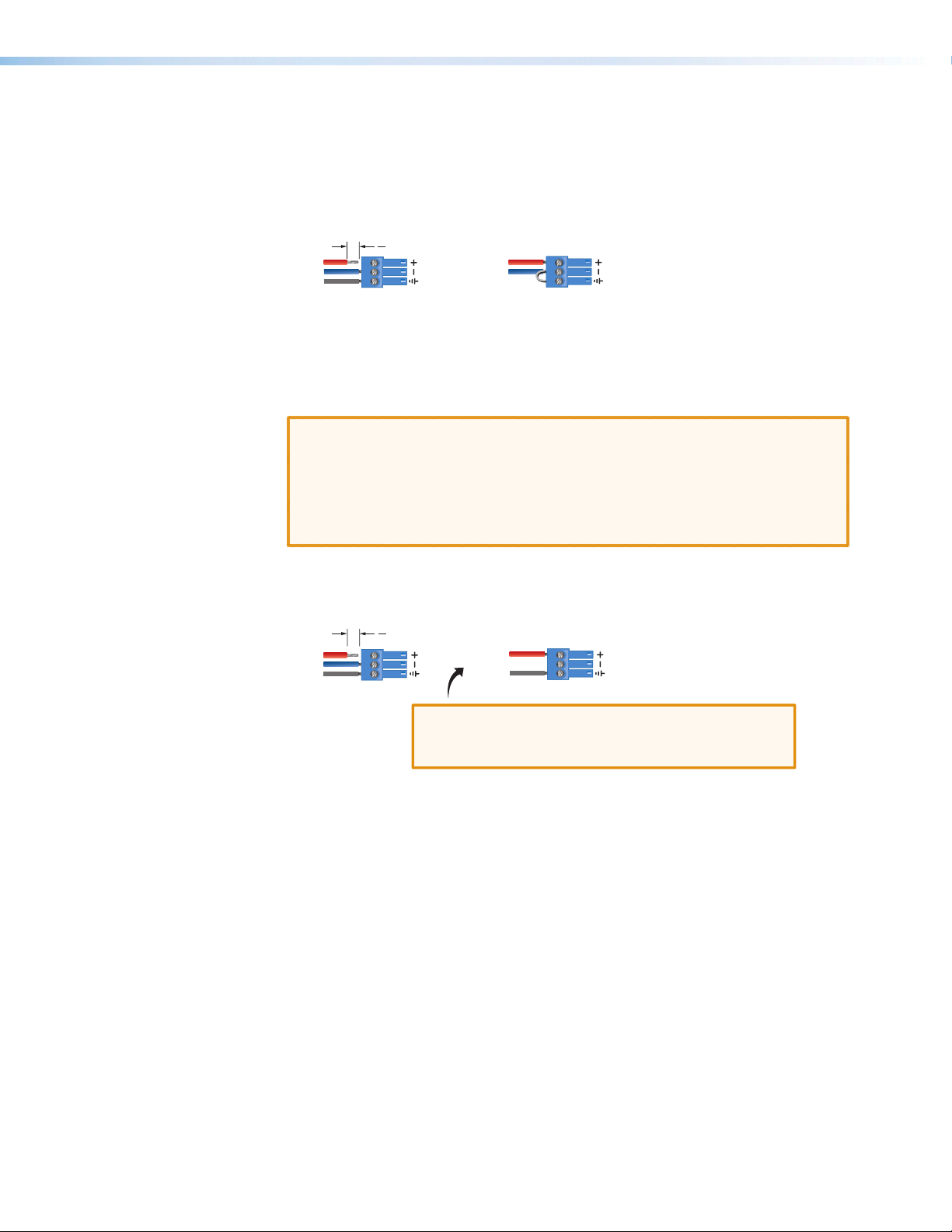

b Mic/Line 1-6 input connectors — 3-pole 3.5 mm double-stacked captive screw

"

(5 mm) MAX. (typ)

3

16

Audio INPUT Wiring

Balanced Input

Sleeve

Ring

Tip

Tip

Sleeve

Jumper

Unbalanced Input

connectors accept balanced or unbalanced mono mic or line level signals. Mic/line

inputs provide gain settings to accommodate consumer (–10dBV) and professional

(+4dBu) operating line level sources, plus microphone level sources. Up to six mono

microphones or line inputs, balanced and unbalanced in any combination can be

connected to these inputs. See the following diagram for wiring instructions.

3

"

(5 mm) MAX. (typ)

Tip

Ring

Sleeve

Balanced Input

16

Tip

Sleeve

Jumper

Unbalanced Input

Figure 3. Balanced or Unbalanced Mic and Line Input Wiring

c Phantom Power indicators — These green LED indicators light when +48V

phantom power is placed on the corresponding mic/line input. Phantom power is not

adjustable.

ATTENTION:

• Condenser microphones require phantom power. Dynamic microphones do

not require power.

• Never set an unbalanced dynamic microphone to 48 V. Doing so can

damage the microphone. For condenser mics, verify the microphone will

safely operate at +48 VDC.

d Mono output connectors — 3-pole 3.5 mm captive screw connectors provide

balanced or unbalanced connections for mono line level output signals.

3

"

(5 mm) MAX. (typ)

16

Tip

Ring

Sleeve

Balanced Output

ATTENTION:

the ground contact.

DO NOT connect the sleeve to the negative (−) contacts.

Figure 4. Output Connector Wiring

Tip

NO Ground Here

Sleeve

Unbalanced Output

For unbalanced audio, connect the sleeve to

DMP64 • Installation 7

Page 14

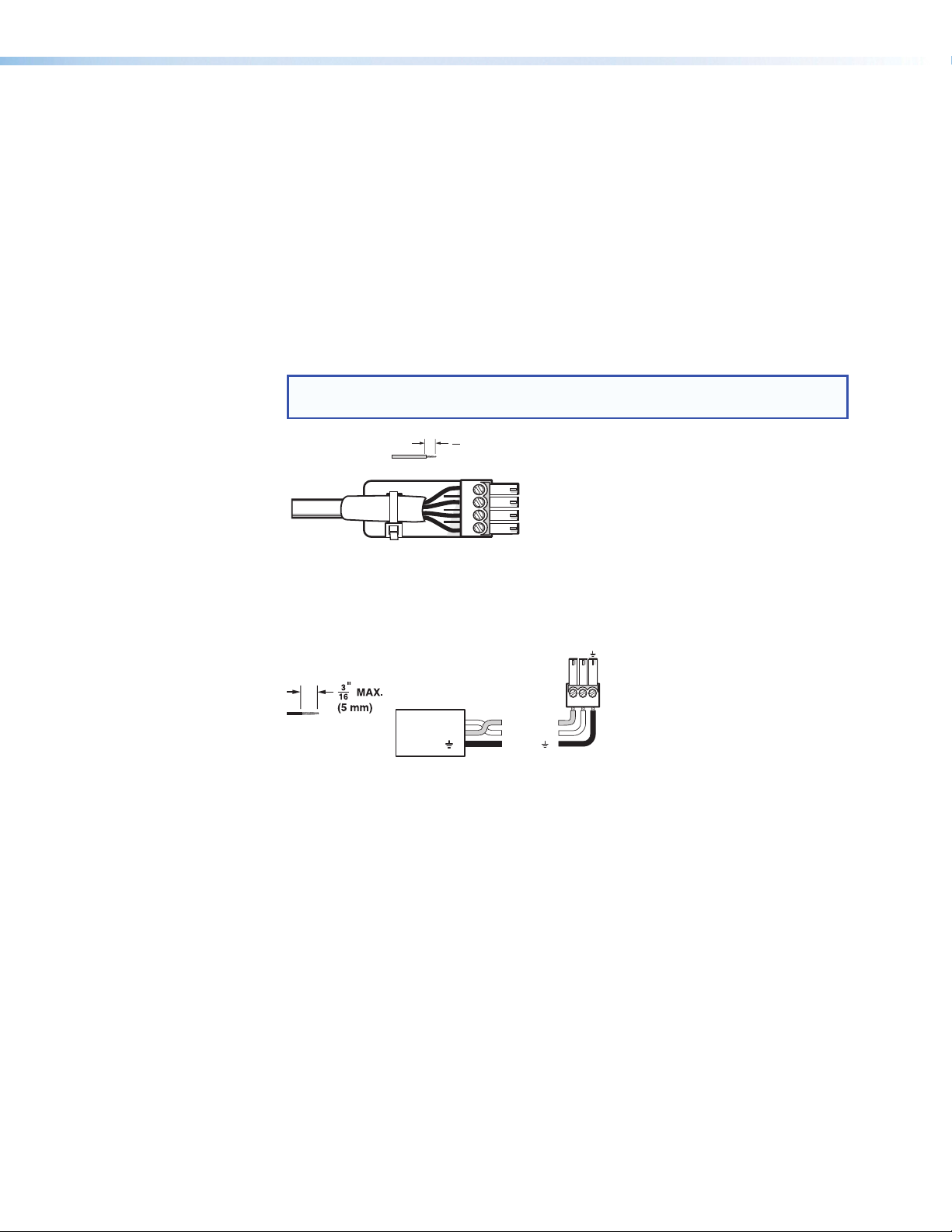

e Digital I/O output connectors — A double-stacked 4-pole 3.5 mm captive screw

RxTx

connector provides six configurable digital input or output ports allowing connection

to various devices such as motion detectors, alarms, lights, LEDs, buttons, photo

(light) sensors, or temperature sensors.

Digital I/O ports are used to monitor or drive TTL level digital signals. The inputs

can be configured to operate in one of two modes: digital input or digital output.

In OUTPUT mode, the device can source up to 250mA at +5 V. In INPUT mode,

voltages greater than 1 V indicate a logic 'high' signal while voltages less than 1 V

indicate a logic 'low'.

All digital I/O ports are tied to a common ground (one common ground for each

4-pole connector), but can be individually configured to operate in one of two modes:

digital input or digital output.

NOTE: These ports can be configured via the DSP Configurator (see Digital I/O

Ports on page75 for additional information).

3 "

(5 mm) MAX.

16

Do not tin the wires!

4

1

5

2

-or-

6

3

_

_

Figure 5. Digital I/O Wiring

f RS-232 connector — Two stacked 3-pole 3.5 mm captive screw connectors,

labeled RS-232 (1) and RS-232 (2), are available for bi-directional RS-232 (±5V) serial

control. Default baud rate is 38400.

RS-232

Device

Do not tin

the wires!

Transmit (Tx)

Receive (Rx)

Ground ( )

Bidirectional

Transmit (Tx)

Receive (Rx)

Ground ( )

Figure 6. RS-232 Wiring

g LAN (RJ-45) connector — A standard RJ-45 jack accepts an RJ-45 plug for

Ethernet connection.

• A yellow (ACT) LED indicates data activity on the connection.

• A green (Link) LED indicates the jack is connected properly to the network.

See SIS Programming and Control on page92 for additional information on

Ethernet cabling.

h Reset button — The reset button is used to return the DMP64 to different tiers of

default states and to place the unit into an event recording mode for troubleshooting

(see DMP64 Hardware Reset Modes on page138).

USB Configuration Port (Front Panel)

A front panel configuration port uses an Extron USB A Male to USB Mini B Male

Configuration Cable (part number 26-654-06) for connection to a PC computer and the

USB port (see Install the USB Driver on page17 for USB driver installation details).

DMP64 • Installation 8

Page 15

Hardware Operation

This section describes the the operation of the DMP64, including:

• DMP64 Operation

• Front Panel Operation

• Rear Panel Operation

DMP64 Operation

The DMP64 does not have physical controls. Configuration and operation are

accomplished using a PC running Windows XP or newer and the DSPConfigurator

software (available on the included disc or at www.extron.com), an embedded web

page using Windows Internet Explorer, or the Extron Simple Instruction Set (SIS™) using

hyper-terminal or DataViewer.

The DMP64 has several front and rear panel operational indicators described in the

following pages.

DMP64 • Operation 9

Page 16

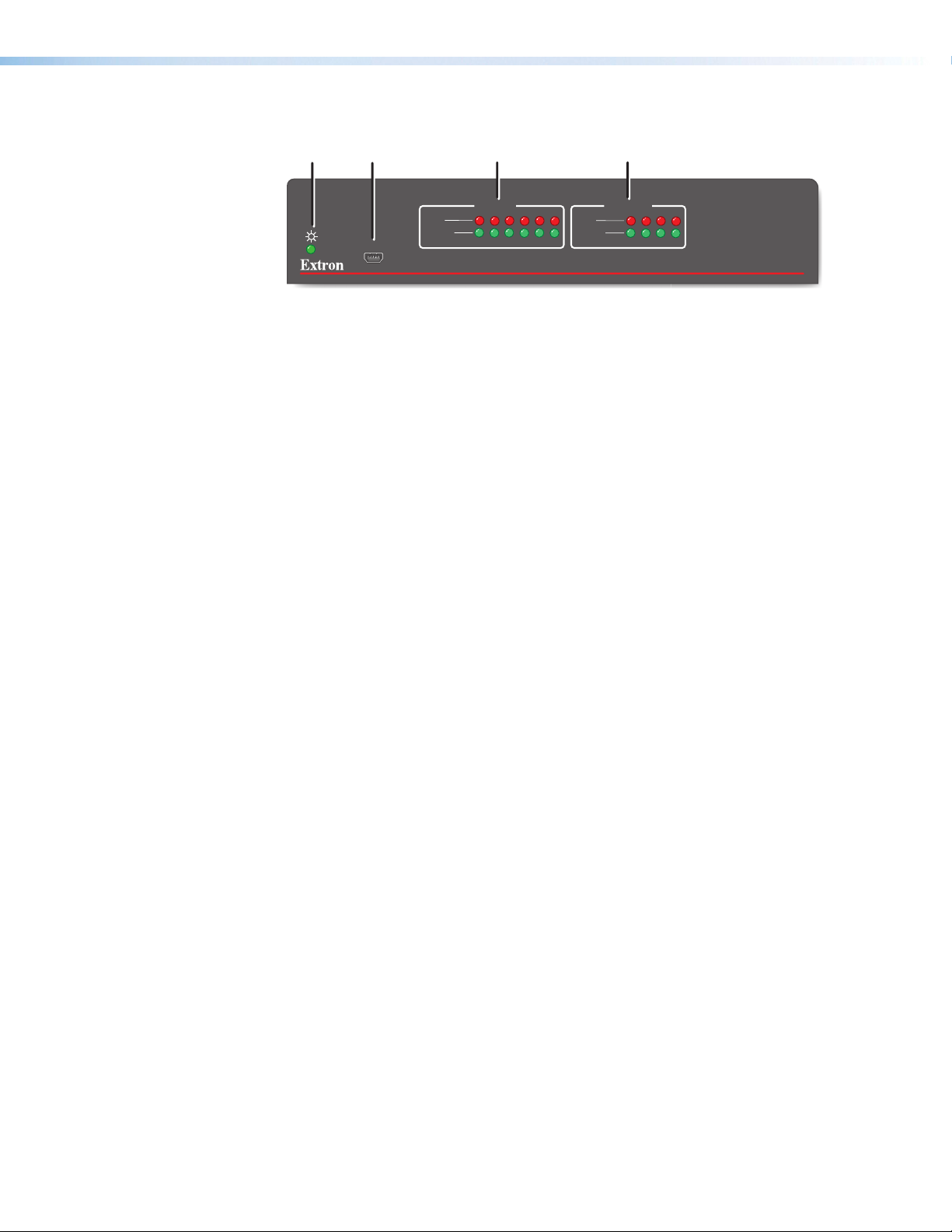

Front Panel Operation

bc da

CONFIG

CLIP

SIGNAL

INPUTS

123 456

CLIP

SIGNAL

OUTPUTS

1234

DIGITAL MATRIX PROCESSOR

DMP 64

Figure 7. DMP64 Front Panel

Power LED — The power indicator lights when the DMP64 is operational.

a

Configuration connector — The USB 2.0 port uses a mini type-B connector to

b

connect to a host computer for control. The DMP64 USB driver must be installed

prior to using the port (see Install the USB Driver on page17).

The DMP64 appears as a USB peripheral with bi-directional communication. The

USB connection can be used for software operation (see Windows-based Program

Control on page15), and SIS control (see Software Control on page14).

Input Indicators — Stacked red (signal clipping) and green (signal present) LEDs for

c

inputs 1 – 6 . Each column represents one input channel.

The green signal LED varies in brightness corresponding to the real-time input signal

level. It begins to light at – 60dBFS increasing in fifteen steps to full intensity as the

signal level increases. When the signal reaches – 3dBFS or above, the red clipping

LED lights and remains lit as long as the signal remains above – 3dBFS. When it falls

below that level, the red LED remains lit for 200 milliseconds, after which the display

resumes real-time monitoring of the signal level.

Output Indicators — Stacked red (signal clipping) and green (signal present) LEDs

d

for outputs 1 through 4. Each LED column represents one output channel.

The green signal LED varies in brightness corresponding to the output signal level. It

begins to light at – 60dBFS increasing to full intensity corresponding to signal level

increases. When the signal level reaches – 3dBFS or above, the red clipping LED

lights and remains lit as long as the signal remains above – 3dBFS. When it falls

below that level, the red LED remains lit for 200 milliseconds, after which the display

resumes real-time monitoring of the signal level.

DMP64 • Operation 10

Page 17

Rear Panel Operation

ab cdefghi

DMP 64

POWER

12V

1.0A MAX

MIC/LINE INPUTS

Figure 8. DMP64 Rear Panel

1

4

2

5

3

MIC

+48V

123

6

456

1

2

123 G

I/O

4

3

OUTPUTS

456 G

RS-232 (1)

Tx Rx G

RS-232 (2)

REMOTE

Tx Rx G

LAN

RESET

a b d e f

See Rear Panel Features and Cabling on page5 for details.

c Phantom Power indicators (MIC +48V) — These green LED indicators light solid

when +48 V phantom power is placed on the corresponding mic/line input. Phantom

power is not adjustable.

ATTENTION:

• Condenser microphones require phantom power. Dynamic microphones do

not require power.

• Never set an unbalanced dynamic microphone to +48V. Doing so can

damage the microphone. For condenser mics, verify the mic will safely

operate at +48 VDC.

• When a line level source is connected, be certain the +48V phantom power

is off (unchecked).

g LAN — The LAN connector has a green LED that lights solid to indicate proper

connection to an active LAN and a yellow LED that blinks to indicate data activity.

h Reset — The reset actuator initiates system resets (see Reset Actuator and LED

Indicator on page12).

i Power/Reset LED — The green LED indicator adjacent to the reset button

duplicates the front panel LED operation (see Reset Actuator and LED Indicator

on page12).

Power Cycle

Current mixing and audio processor settings (the current state of the device) are saved

in nonvolatile memory. When the unit is powered off, all settings are retained. When the

unit is powered back on, it recalls settings from the nonvolatile memory. If a configuration

was in process during the power down, these saved mix, audio level, and audio DSP

processor settings become active.

On power up the unit performs a self-test. The front and rear power indicator LEDs flash

during the test, then light solid when the unit is available for operation or programming.

Firmware Updates

The firmware of the DMP64 can be updated through Ethernet, USB, or RS-232

connection. The user can obtain new firmware from the Extron website, or from an Extron

Applications Engineer via e-mail. After obtaining the new firmware, upload it to the unit

via the served web pages (see HTML Operation on page120), using the Firmware

Loader in the DSPConfigurator program (see DMPSoftware on page14), or using

the Extron standalone FirmwareLoader software application available on the included disc

or at www.extron.com.

DMP64 • Operation 11

Page 18

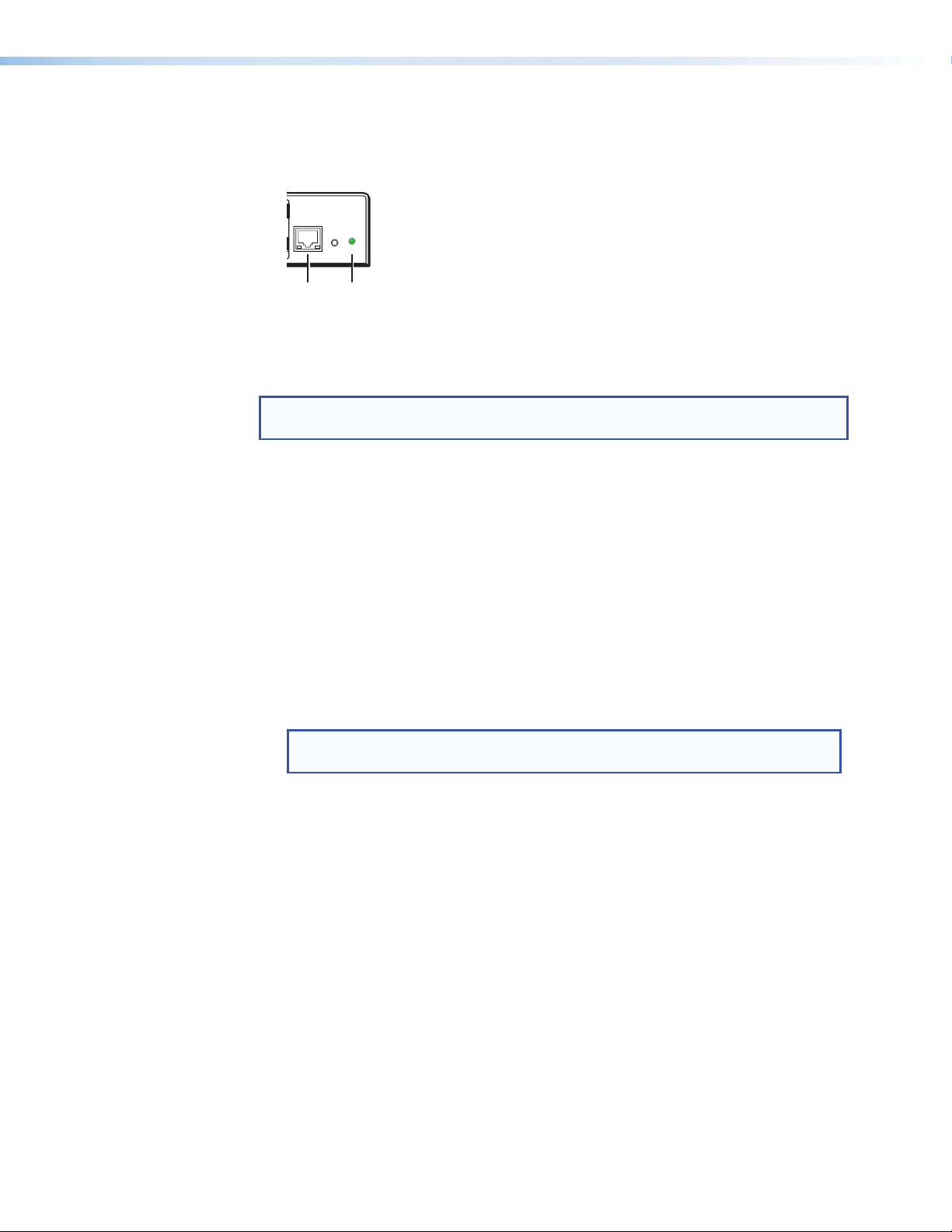

Reset Actuator and LED Indicator

Rear Panel

hi

A recessed button (h) on the rear panel initiates several reset modes. The rear panel LED

(i) blinks to indicate the reset mode.

LAN

RESET

Figure 9. Reset button and LED

Hardware Reset Modes:

NOTE: The reset modes listed below will close all open IP and Telnet connections,

and close all sockets.

The reset modes have separate and distinct functions. Additional information is available

(see DMP64 Hardware Reset Modes on page138).

Each reset LED flash lasts for 0.25 seconds.

MODE 1 — Firmware reset:

1. Disconnect power to the DMP64.

2. Press and hold the reset button.

3. Apply power to the device while holding the reset button.

Mode 1 will:

• Return the firmware to the version shipped with the unit from the factory. This

allows recovering a unit with incorrect or corrupt firmware.

• Maintain all user files and settings.

NOTE: Some user web pages may not work correctly if returning the unit to an

earlier firmware release.

MODE 3 — Events reset:

1. Apply power to the DMP64.

2. Press and hold the reset button until the reset LED blinks once (~3 seconds).

Release the reset button,

3. Within one(1) second press the reset button again to toggle events on or off,

depending on the current state.

• If event logging is currently stopped, following the momentary (<1 sec.) press,

the reset LED will flash twice indicating events logging has started.

• If any events are currently running, following the momentary press, the reset

LED will flash three times indicating that events logging has stopped.

If a momentary press does not occur within 1 second, the events logging status

before entering reset will remain.

DMP64 • Operation 12

Page 19

MODE 4 — IP Address reset:

1. Apply power to the DMP64.

2. Press and hold the reset button about 6seconds until the reset LED blinks twice.

Release the reset button.

3. Within (1) second, press the reset button again to reset the IP settings.

If a momentary press does not occur within 1 second, the reset will be ignored.

Mode 4 will:

• Enable ARP program capability

• Set the IP address back to factory default (192.168.254.254)

• Set the Subnet back to factory default (255.255.0.0)

• Set the Gateway back to factory default (0.0.0.0)

• Set the Digital I/O Port mapping back to factory default

• Turn DHCP off

• Turn Events logging off

MODE 5 — Factory default reset:

1. Apply power to the DMP64.

2. Press and hold the reset button until the reset LED blinks 3 times (~9 seconds),

then release.

3. Momentarily (<1 second) press the reset button to return the DMP64 to factory

default conditions.

If a momentary press does not occur within 1 second, the reset is exited.

The default (reset) state of the device is:

• All mix-points set to 0dB gain and muted.

• All outputs active (unmuted, 100% volume).

• No inserted or active DSP processing.

• All audio inputs are set to 0dB gain and muted.

• All preset and group master memory is clear (empty).

Digital I/O Ports

The dual 4-pin Digital I/O ports monitor or drive TTL level digital signals. The ports consist

of two banks of three I/Os with the fourth pin used as a ground, providing six ports total.

The DSP Configurator software provides selection from a list of scripts, that can be loaded

to the DMP64. The scripts provide pre-configured sets of functions.

From the main structure menu, click Tools > Configure Digital IO to access the scripts

(see Digital I/O Ports on page75).

DMP64 • Operation 13

Page 20

DMPSoftware

This section describes the control software for the DMP64, including:

• Software Control

• Embedded Web Pages

• Windows-based Program Control

• DSP Configurator Program Basics

• Audio level, Mix-point, Processing Blocks, and Signal Chains

• Mic/Line Input Signal Controls

• Ducker Tutorials

• Line Output Channels

• Virtual Bus Returns

• Primary Mix Matrix

• Secondary Mix Matrix

• Group Masters

• Digital I/O Ports

• Emulate Mode and Live Mode

• Presets

• Protected Configuration

• DSP Configurator Windows Menus

• Optimizing Audio Levels

Software Control

The DMP64 can be controlled using the DSPConfigurator software, SIS commands

through hyper terminal or DataViewer, or using embedded WebPages. IPLink functions

will be available through network connection including global viewer functionality.

The DMP64 has the following connection options:

• RS-232 — One single stack 3-pole, 3.5 mm captive screw connector is used for

• LAN — 10 Mbps, 100 Mbps, halfduplex, full duplex connections are supported. Two

• USB 2.0 — A Mini B-type USB connector located on the front panel provides

bi-directional RS-232 (±5 V) serial control.

See Rear Panel Features and Cabling on page5, for additional details on

connecting the RS-232 port.

LEDs indicate connection and activity status. The device has the following default

Ethernet configurations:

IP Address: 192.168.254.254 Default Gateway: 0.0.0.0

Subnet Mask: 255.255.0.0 DHCP: OFF

See Rear Panel Features and Cabling on page5, and Connection Options

on page92 for additional details on connecting the LAN.

high-speed USB 2.0 connectivity to a host computer, backward compatible to 1.0.

DMP64 • Software Control 14

Page 21

Embedded Web Pages

The embedded web pages, accessible by LAN using a web browser, include the following

information, available in a tabbed interface.

• System Status — The opening web page, displaying a report of system status

parameters.

• Configuration — This tab contains the following menu items.

• System Settings. Contains IP address and date/time settings.

• Passwords. Enter/re-enter admin and user password fields to set up password

protected access.

• Firmware Upgrades. Browse/upload firmware to the device.

• File Management — Delete or upload files

• Control — Contains the following menu items:

• Audio Settings. Includes mix matrix, input and output gain control.

• Group Controls. Provides access-only to the group controls.

• Presets. Used to save new presets created on Audio Settings page.

See HTML Operation on page120 for further details.

Windows-based Program Control

The DSP Configurator Control Program is compatible with Windows 2000, WindowsXP,

and Vista, and provides remote control of the input gain/attenuation, output volume

output adjustment, and other features.

DSP Configurator can control the DMP64 using any of the three control ports, RS-232,

USB, or LAN.

Updates to this program can be downloaded from the Extron website at

www.extron.com.

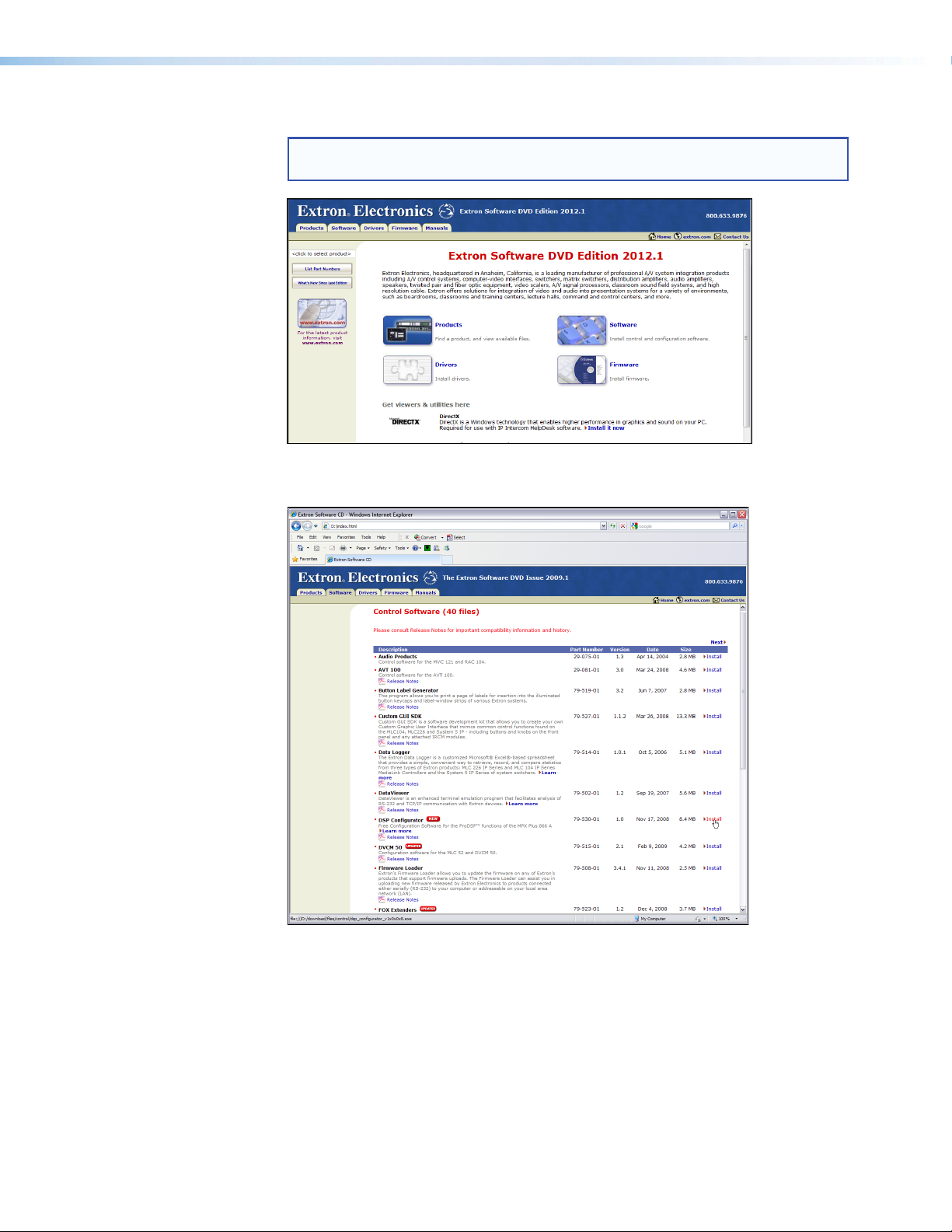

Installing the DSP Configurator Program

The program is contained on the Extron Software Products disk.

Install the software as follows:

1. Insert the disk into the drive

DMP64 • Software Control 15

Page 22

2. Click the Software tab or software icon.

NOTE: If the DVD setup program does not start automatically, run Launch.exe

from the DVD ROM directory using Windows “My Computer”.

Figure 10. DVD Software Menu

3. Scroll to the DSP Configurator program and click the Install text to its right.

Figure 11. DVD Control Software Menu

4. Follow the on-screen instructions. By default, the installation creates a

C:\Program Files\Extron\DSP_Configurator folder for the DSPConfigurator

program.

5. When the DSP Configurator installation is complete, the USB Installer starts

automatically (see Install the USB Driver on page17). Extron recommends the

USB drivers be installed whether they are used immediately or not.

DMP64 • Software Control 16

Page 23

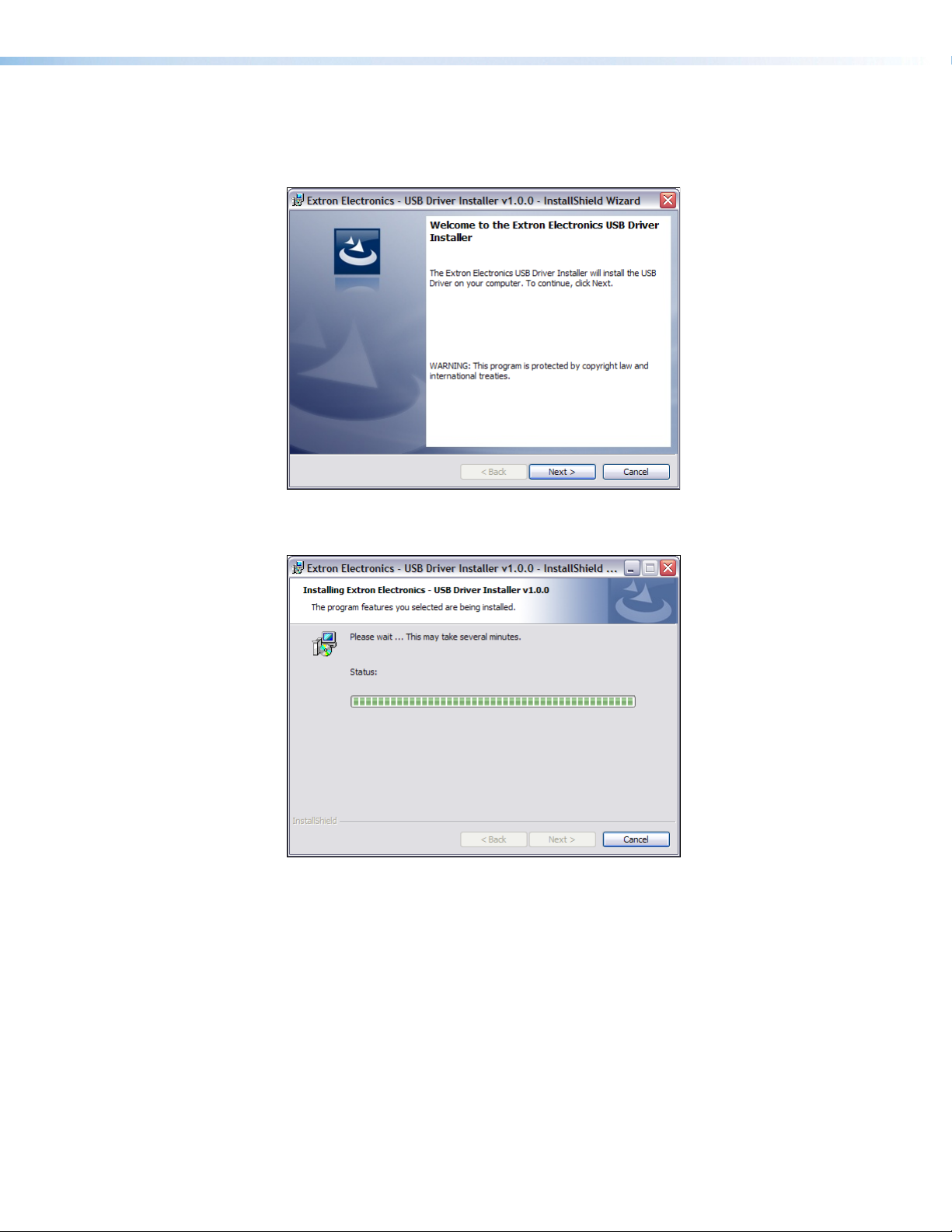

Install the USB Driver

When the USB installer begins, follow these instructions.

1. When the driver installation window appears (see figure 12), click Next to proceed.

Figure 12. USB Installer Splash Screen

2. The driver installer launches (see figure 13).

Figure 13. USB Driver Installation

DMP64 • Software Control 17

Page 24

3. When the installer has completed the installation of the USB drivers, the following

screen appears (see figure 14):

Figure 14. Successful USB Driver Installation

4. Click Finish.

USB driver installation is complete.

DSP Configurator Program Basics

Starting the Program

NOTE: Extron recommends connection via the Ethernet LAN port for running the

DSPConfigurator program.

Using the Program

To run the DSP Configurator Program, click

Start > Programs > Extron Electronics > DSP Configurator > DSP

Configurator.

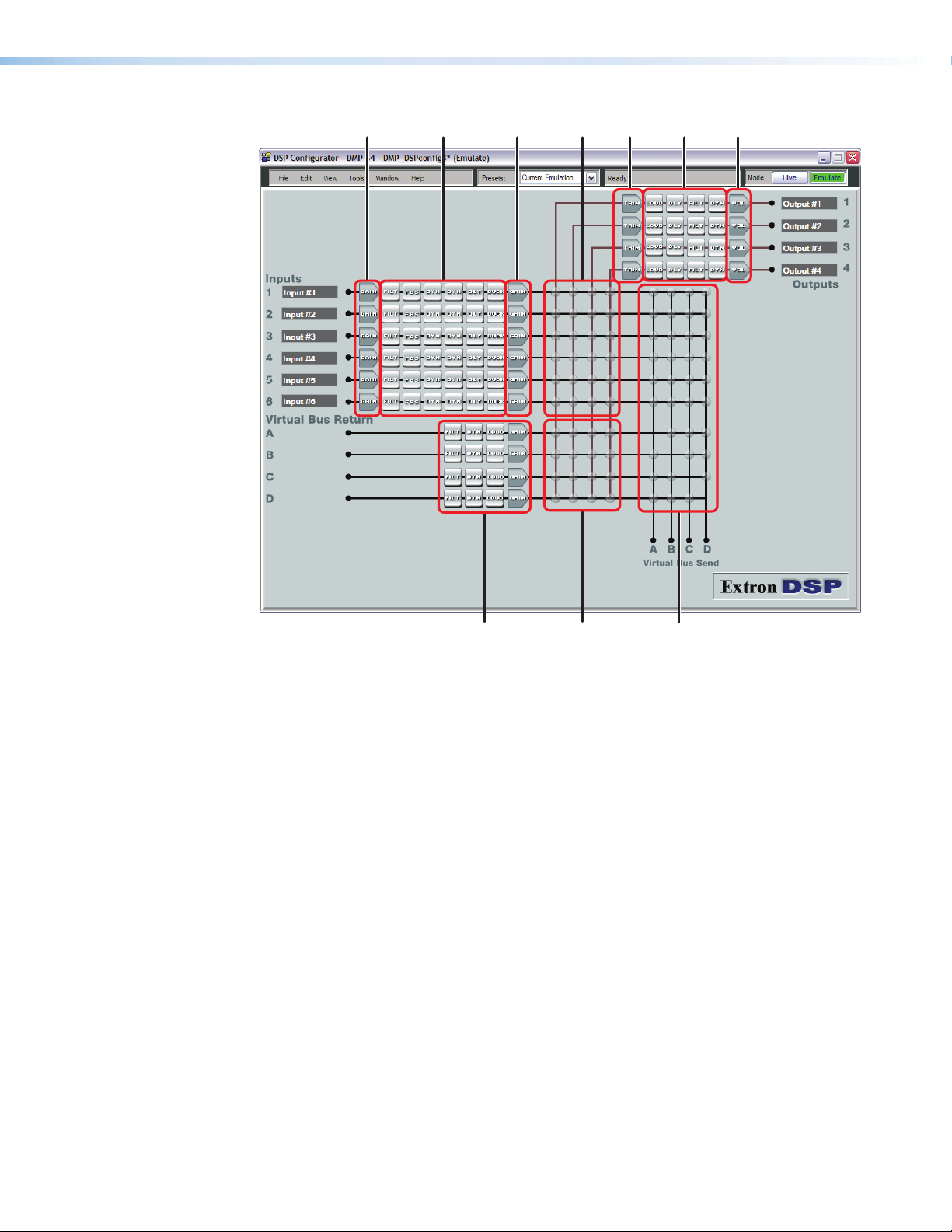

The DSP Configurator program starts in Emulate mode (see figure 15, next page). Also

(see Emulate Mode and Live Mode on page76) for details of mode operation.

In Emulate mode, audio parameters can be selected, then transferred to the DMP64

by switching to Live mode (while connected to a DMP64). Audio settings can also be

tailored while connected to the DMP64 which allows real-time auditioning of the audio

output as adjustments are made (see Emulate Mode and Live Mode on page76).

DMP64 • Software Control 18

Page 25

abcd

jhi

fge

Figure 15. DMP64 Configurator Program

The DSP Configurator program window consists of an input and virtual return signal

processor chain, the main mixer, virtual send and receive (secondary) mixers, and an

output signal processing chain.

a Mic/Line Input Gain control f Output signal processor chain

b Mic/line input signal processor chain g Output volume control

c Mic/Line input pre-mixer gain h Virtual Bus signal processor chain

d Primary Mix-points i Virtual Bus Return (primary) mix-points

e Output trim control (post-mixer trim) j Virtual Bus Send (secondary) mix-points

DMP64 • Software Control 19

Page 26

Navigation

There are two methods of navigation around the interface:

• Keyboard • Mouse

One element in the user interface always retains focus. When a new DSP Configurator file

is opened, the upper left element (Input #1 Gain) is focused by default.

Keyboard Navigation

All user interface elements, including mix-points, have the ability to receive focus using

the tab and arrow keys or using the arrow keys following a single left-click. For additional

details (see Keyboard Navigation on page85).

Mouse Navigation

Left-click. A single click brings focus to a processor block, as well as other interface

elements such as tabs, sliders, check boxes. Other left-click actions follow the Windows

standard.

Right-click. A single right-click brings up a context menu specific to the processor block

right-clicked. Other right-click actions follow the Windows standard.

Double-click. A double-click opens a dialog window from either the focused or

unfocused state of an element.

Cut, Copy, or Paste Functions

The user can cut, copy, or paste a processor. The actions can be performed from a:

• Context menu accessed by a right-click of the processor,

• Using the Edit menu,

• Using standard Windows keystrokes:

• <Ctrl+X> = cut

• <Ctrl+C> = copy

• <Ctrl+V> = paste

Multiple elements can be acted upon but the blocks copied must be compatible with

the desired paste blocks. A highlighted group of elements can be cut or copied to a

clipboard. The clipboard contents can then be pasted, but only succeeds if there is an

exact one-to-one relationship between the clipboard contents and the block or blocks

pasted.

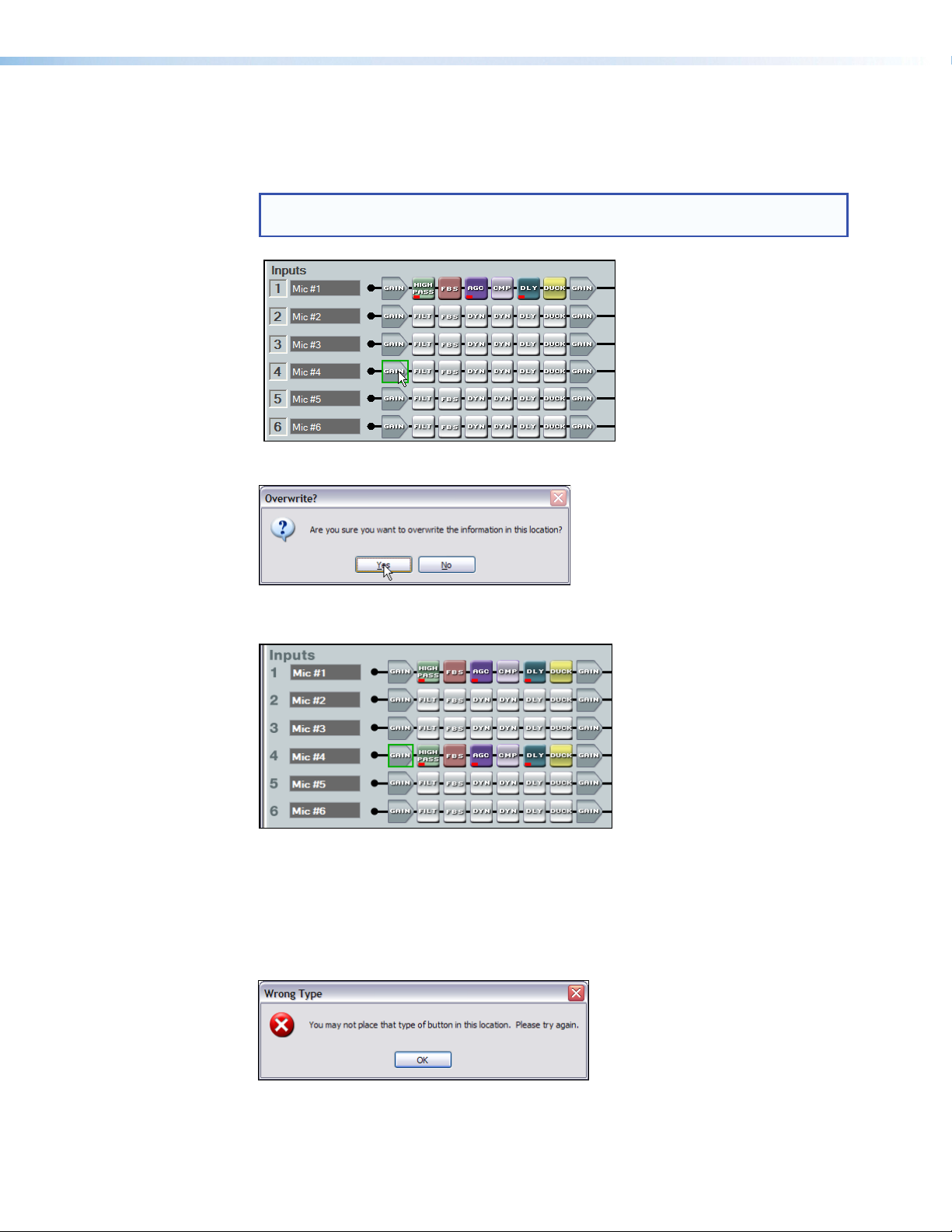

In the following example, the Mic #1 input signal path is copied to Mic #5. First, click the

mouse and drag it across the entire signal path. The selected blocks are highlighted in

green. Press <Ctrl+C>, or use the Edit > Copy menu selection to copy the blocks.

DMP64 • Software Control 20

Page 27

As shown below, the starting point for the paste, (the upper, leftmost element), must first

be focused by left-clicking the mouse on it. Note the green focus outline that appears on

the Mic #4 Gain block. The clipboard elements are pasted using the context menu Paste

command, the Edit>Paste command, or <Ctrl+V>.

NOTE: A cut and copy of elements can be pasted to multiple locations. To copy the

clipboard to an additional location, click on the leftmost block and paste again.

The program warns that all settings in the section being pasted to will be overwritten:

After clicking Yes, the entire Mic #4 input path is now identical to the Mic #1 input path

including signal levels, parameter settings, and mute/bypass selections.

Any single processor block can be copied, then pasted to a similar processor block in the

same or different input, virtual or output signal path. Mix-point gains can be copied from

one to another; however, input gain, pre-mixer gain, post-mixer trim, and output volume

cannot. Mix-point settings can be freely copied between mix-points. The user is always

asked whether they want to overwrite the existing information. If an attempt is made to

copy a processor block setting to an incompatible block, the user is advised the action

cannot be completed.

DMP64 • Software Control 21

Page 28

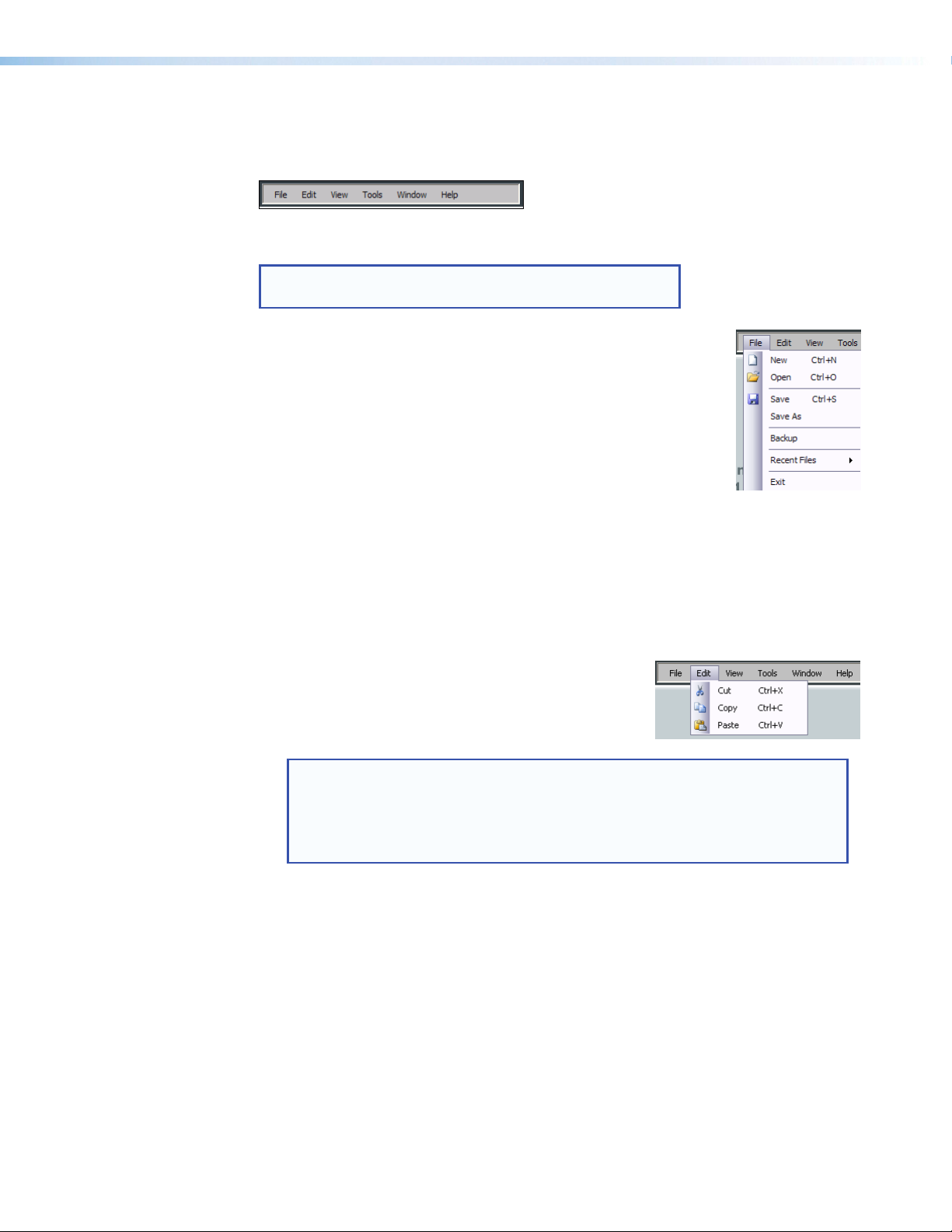

DSP Configurator Toolbar Menus

The DSP Configurator contains the following structural menus, arranged horizontally

below the title bar:

File

NOTE: New, Open, and Recent Files are unavailable in Live

mode.

• New — Discards the current DSP configuration (after prompting to

save any changes) and opens a blank configuration file.

• Open — Loads and activates a previously saved DSP

configuration file.

• Save — Saves all changes to the current DSP configuration file

under the current file name. If the file has not previously been

saved, prompts for a file name.

• Save As — Saves all changes to the current DSP configuration

file under a new file name.

• Backup — Transfers all partial presets plus the current configuration to a DSP

configuration file within the DSP Configurator program.

• Recent Files — Opens a list of recently opened or saved DSP configuration files.

• Exit — Closes the DSP Configurator Program.

Edit

• Cut — Removes all parameters of a selected

processor block or set of selected blocks to the

clipboard. If not followed by a Paste command to a

different block, the parameters are restored.

NOTE: Processor blocks are not removed from the processor stream after a

Cut and a subsequent Paste operation. Only the parameters are moved.

Processor blocks and their parameters can be pasted only into another block of

the same type. For example, the input 1 filter block and all of its parameters can

be copied to the input 2 filter block but not to the input 1 delay block.

• Copy — Copies all of the parameters of a selected processor block, gain block, or

set of selected blocks to the clipboard.

• Paste — Inserts processor blocks and their parameters from the clipboard into the

selected location.

DMP64 • Software Control 22

Page 29

View

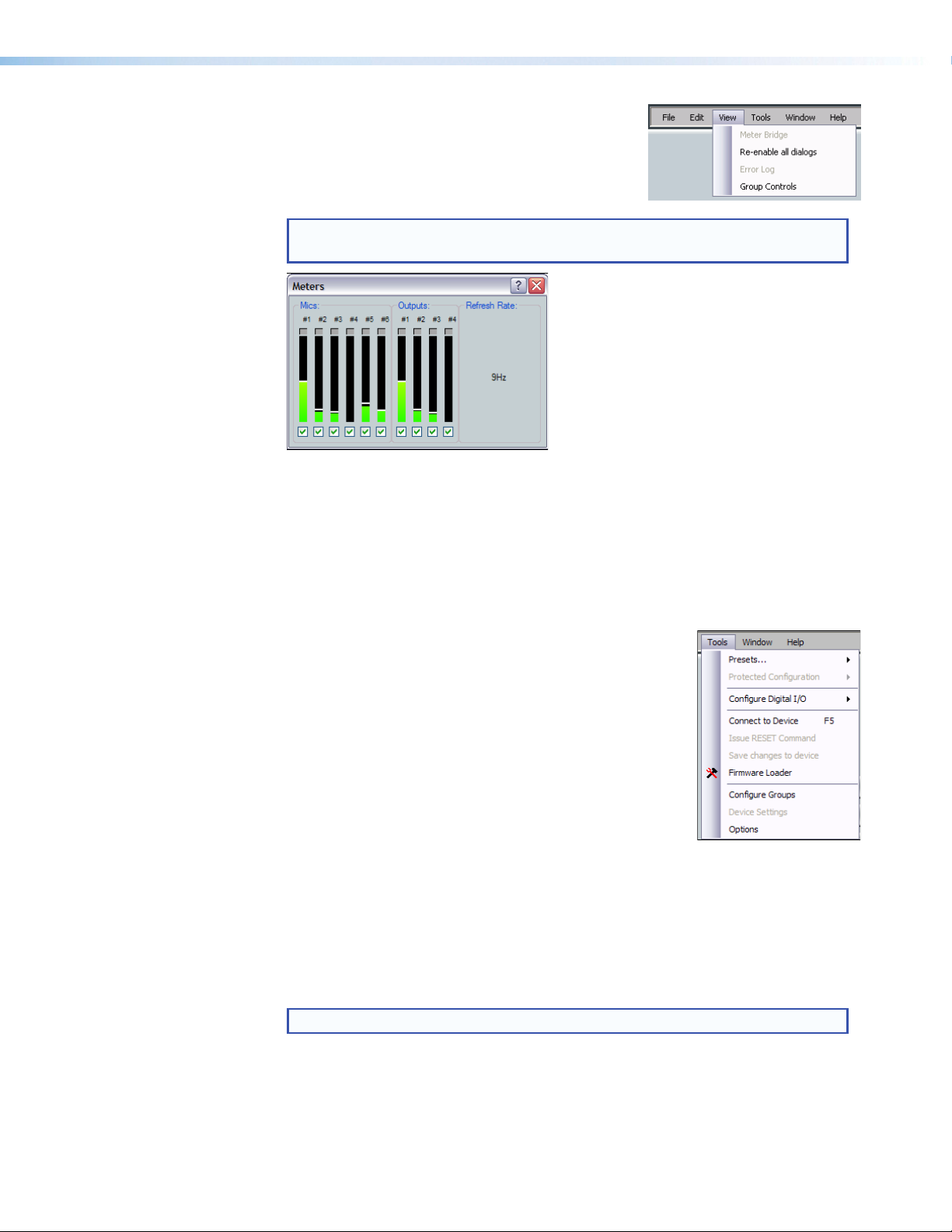

• Meter Bridge — Opens a Meters dialog box with

real-time meters that monitor signal levels at each

input and output.

NOTE: Meter Bridge is available in Live mode only while connected using

the LAN port.

Figure 16. Meter Bridge

• Re-enable all dialogs — Re-enables all dialog boxes, the pop-up windows

that allow changes to block parameters.

• Error log — Lists error messages as a troubleshooting tool.

• Group Controls — Opens the Group Controls dialog box (see Group Masters on

page69).

Tools

The Tools menu contains the following items and sub-menu:

• Presets — Provides three options:

• Mark All Items — Mark (select) all parts of the

• Protected Configuration — Live mode only. Allows a user (typically the

current configuration (excluding presets), including

processors and mix-points to save as a partial preset.

• Save Preset — Save the currently marked

processors, and mix-points as a partial preset.

• Clear Marked Items — Unmark (deselect) all parts

of the current configuration (excluding presets), including

processors and mix-points.

installer) to save and recall a protected configuration. The protected configuration

is useful to establish parameters and values (with the exception of the device

IP address) in a known state, either as a troubleshooting tool or as a baseline

configuration. A protected configuration, once saved in the device, is always present

and cannot be overwritten without entering a user-defined Personal Identification

Number (PIN) password. The protected configuration is restored without a PIN.

NOTE: The default PIN is 0000.

• Save — Save the current configuration (excluding presets), including processors

and mixes as a password protected configuration. The DSPConfigurator

program prompts for a PIN to save.

• Recall — Recall the protected configuration.

• Change PIN — Change the PIN associated with the protected configuration.

DMP64 • Software Control 23

Page 30

• Configure Digital I/O Ports — Live mode only. Opens a utility to configure

digital I/O ports. The DMP64 provides six digital I/O ports that can be used to trigger

external events from DMP64 actions, or for external events to trigger DMP actions

(see Digital I/O Ports on page75).

• Connect to/Disconnect from Device (depending on Emulate or Live

mode) — Performs the same functions as the Mode Emulate and Mode Live

buttons.

• Issue RESET Command — Initializes and clears the following: mix-points, presets,

processor blocks, and gain blocks. This reset is identical to the E ZXXX} SIS

command (see SIS Programming and Control on page92).

• Save changes to device — Live mode only. Saves configuration changes

made in the DSPConfigurator program to the DMP64.

• Firmware Loader — Calls the Firmware Loader program, which allows updates

without taking the DMP64 out of service (see Firmware Loader on page136).

• Configure Groups — Opens the configure groups dialog box (see Group

Masters on page69).

• Device Settings — Live mode only. Opens a dialog box providing a means to

change the IPaddress, set administrator and user passwords, and select the serial

port baud rate.

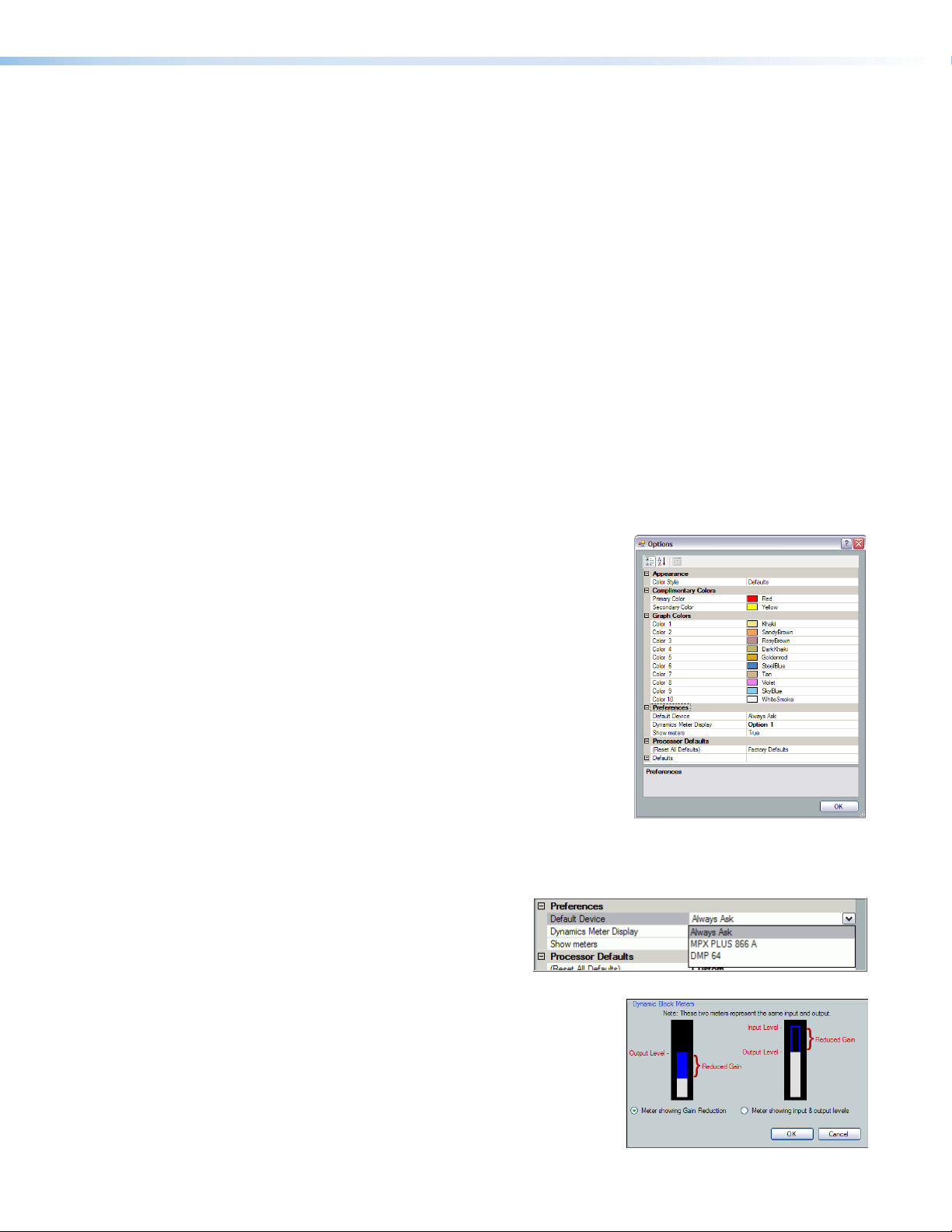

• Options — Opens a tabbed dialog box to customize the DSPConfigurator

appearance and operation.

• Colors — Tailor the appearance of

the various graphs and dialog boxes.

Appearance uses a selected color scheme

for the complimentary and graph colors.

Complimentary Colors allows custom

selection of colors used with the various

graphs and dialog boxes. Graph colors

change the row colors containing the

information and descriptions of the graphs

seen in the processor blocks.

• Preferences — The startup splash screen contains options to select the

device to connect to, or to “Always ask” on startup.

The selection can be changed using Default Device.

• If Show Meters is set to True, Dynamic

Block Meters is used to tailor the

appearance of the dynamics meters to

use the full meter to show input and gain

reduction, or to show the level based on the

output and gain reduction.

DMP64 • Software Control 24

Page 31

• Processor Defaults,

Reset All Defaults —

Returns the DMP64 processor

and level control blocks to factory

default settings. Each processor

and gain/volume/trim block also

has an individual default reset.

• Processor Defaults,

Defaults

— Individually selects the default

parameters for the various

processor, trim, and gain blocks.

Each row item contains default

settings customized for the

processor, filter, trim, or gain block

it represents.

Gain and volume blocks can be

initially muted, while filter and

dynamics processor blocks can

be initially bypassed.

NOTE: The bypass function is labeled Enable.

• To view the individual processor defaults, press the + button on the name of the

processor, trim, gain or meter device.

Window Menu

• Cascade — Rearranges all open DSP Configurator program

windows, including dialog boxes, in a cascading array.

• Close All Windows — Closes all open dialog boxes.

• Individual Windows — Brings the associated dialog box to the front of the desktop.

Help selection

The Help menu contains the following elements:

• Contents — Opens the Help file at the Contents tab.

• Search — Opens the Help file at the Search tab.

• About... — Displays the name of the application, the current version number, and

copyright information.

NOTE: Help can be activated by pressing the <F1> key from the main screen.

When a dialog box is open the <F1> key opens context-specific help. .

DMP64 • Software Control 25

Page 32

Presets Drop-down

Displays a list of up to 32 presets. Select a preset from the list to

display it in the window and either activate it (Recall), abort the

selection without either recalling or deleting it (Cancel), or delete it

(Delete).

NOTE: An asterisk in the drop-down list indicates a partial preset exists only in

the DMP64 and has not been uploaded to the DSPConfigurator.

Mode Buttons

Provides selection between Live mode and Emulate mode. See

Emulate Mode and Live Mode on page76 for more information.

Backup

When in Live mode (connected to a DMP64), if presets exist in the DMP64 that are not

present in the DSPConfigurator program (indicated by an asterisk next to the preset

name), the function halts and prompts the user to run a backup.

Backup (File>Backup) transfers all partial presets plus the current configuration from

the DMP64 to a DSP configuration (.edc) file within the DSP Configurator program and

then displays a prompt to save the file to the hard drive. Backup is unavailable when the

DSPConfigurator program is in Emulate mode.

DMP64 • Software Control 26

Page 33

abcd

fge

Figure 17. Control Blocks and Processor Chains

Audio Level, Mix-point, Processing Blocks, and Signal Chains

Outlined in red above (see figure 17), all control blocks on the main DSP user interface

have one of three main functions in the overall signal chain:

• Level control (gain, trim, and volume),

• Mix-point (signal routing), or

• Signal processing (filter, feedback, dynamics, delay, duck, and loudness).

The signal chain varies depending on whether it is in the input, output, or virtual bus stage.

The input chain begins with a level control (GAIN), filter (FILT), feedback suppression

(FBS), two dynamics (DYN) and a delay (DLY) processor, followed by ducking (DUCK) and

a pre-mixer gain (GAIN) control. The output chain begins with a level control (post-mixer

trim [TRIM]), loudness (LOUD), delay (DLY), filter (FILT), and dynamics (DYN) processing

blocks, and an output volume control (VOL). Each virtual bus chain has a filter (FILT), a

dynamic processing block (DYN), loudness (LOUD), and output trim control (GAIN). All

mix-points have a gain control.

Each of the three signal processing chains; Input (a, b, c), Output(e,f,g),

and Virtual (h) (see figure 17), consist of a series of control blocks of two

basic types specific to that chain: level control (gain, trim, and volume

control), and signal processors (frequency filters, feedback suppression, dynamics, delay,

ducking, and loudness). Both types of control blocks are always present in the chains.

Gain controls default to unmuted and processor blocks are bypassed upon insertion.

Gain, trim and volume blocks can be muted and processor blocks (after being inserted)

can be bypassed for signal comparison. Mutes and bypasses are shown by a red

indicator in the lower left of the block.

Figure 18. Input Gain Control Muted, Dynamics Processor Bypassed

DMP64 • Software Control 27

Page 34

Level Control Blocks

Double-click the

To access a gain, trim or volume control to view a setting, make a change, or observe a

live audio meter (input gain and output volume blocks only), double-click the gain block

icon (see figure 19). This action opens a dialog box that contains the fader for that control.

Double-click a gain,

trim, or volume control.

A dialog box opens,

containing the full

fader control.

NOTE: In Emulate mode (the

startup mode), the meter is

not operational.

Figure 19. Accessing a Typical Gain Control Dialog Box

Processor Blocks

Each processor block represents a menu of one or more processors that can be inserted

into the audio stream. For blocks that provide more than one processor, only one can be

selected. Each block can be inserted by a double-click or right-click>Insert then selecting

the desired processor (see figure 20). When a block is inserted, the selected processor

is displayed in the block and the block changes color. Processor blocks default to

bypassed. To have them default to “not bypassed,” see Tools on page23.

processor block.

Click the desired

-orRight-click the

processor block.

processor.

Click insert.

Figure 20. Selecting a Processor Block

The selected processor is displayed in the

block.

To change processor variables, double-click the

block again to open the processor dialog box.

Click to select the

desired processor.

DMP64 • Software Control 28

Page 35

Once a processor is inserted, to view associated parameters that define the selected

processor (such as a frequency curve) or to remove the bypass, double-click on the

processor block. This action opens a new window with a dialog box that contains

parameters for the processor (see figure21).

Figure 21. Sample Processor Dialog Box

• The Set Defaults button discards all custom settings and

reloads the default parameters.

• The Bypass button temporarily suspends the processing without

without removing the processor block. Red indicates the processor is

bypassed.

By default, each processor block is bypassed when inserted (the Bypass button in the

processor dialog box is red). This can be changed for each processor block type, see

Tools>Options and the specific defaults for the processor types.

NOTE: Figure 21 is an example of one type of dialog box. Contents and appearance

of each dialog box are unique to the processor type.

The block can be removed from the signal chain by selecting it with a single mouse click

and pressing the keyboard <Delete> key or by right-clicking and selecting Delete.

DMP64 • Software Control 29

Page 36

Mic/Line Input Signal Controls

The input signal processor chain allows adjustments to program or microphone audio

material before input to the main mixer.

Gain Control (GAIN)

The gain control provides a single long-throw fader with a range of –18dB to +80dB,

adjustable in 1 dB increments with the fader, or in 0.1dB increments using direct entry

in the input signal level readout below the fader. The

peak reading meter holds the peak level for one second,

displaying it numerically in the box below the meter. The

default setting is unity gain (0.0dB).

The Phantom Power checkbox, accessible in the

dialog box, toggles the +48 VDC phantom power on

and off. Phantom power is typically used to power a

condenser microphone.

The Mute button, accessible in the dialog box, silences

the input.

The Polarity button, accessible in the dialog box,

allows the polarity of the wires connected to the audio

connectors (+/tip and –/ring) to be flipped to correct for

miswired connectors.

Fader Handle

Input

Signal Level

Readout

DMP64 • Software Control 30

Page 37

Filter (FILT)

Each filter block allows a total of five filters. The first filter is inserted from a processor list

that appears when the block is double-clicked or from a context window that shows a

processor list when the block is right-clicked.

Figure 22. Insert Filter Menu

Once inserted, double-click the processor block to change parameters of the filter. After

the first filter is inserted, up to four additional filters can be added to the filter block using

the dialog box. Select the desired filters from the following list using the drop-down boxes:

• High pass filter — A high pass filter passes a band of frequencies extending from a

specified cutoff frequency (greater than zero) up toward the high end of the frequency

spectrum. All frequencies above the specified cutoff frequency are allowed to pass,

while all frequencies below are attenuated.

The default cutoff is 100 Hz.

• Low pass filter — A low pass filter passes a band of frequencies extending from a

specified cutoff frequency (less than infinite) towards the lower end of the frequency

spectrum. All frequencies below the specified frequency are allowed to pass, while all

frequencies above are attenuated.

The default cutoff is 10 kHz.

• Bass and treble filters — Also known as shelving or tone controls, the separate

bass and treble filters provide the ability to cut or boost gain linearly above or below a

specific frequency, with the end-band shape giving the visual appearance of a shelf.

The bass default frequency is 100 Hz and the treble default is 8 kHz.

• Parametric equalizer filter — The parametric filter is a frequency equalizer that

offers control of all parameters, including amplitude (the amount of gain/boost or

gain reduction/cut applied), center frequency (frequency), and range of affected

frequencies (Q) around the center frequency.

DMP64 • Software Control 31

Page 38

Figure 23. Filter Block Dialog Box

Additional filters are inserted using the open filter block dialog box, and selecting a filter

type from the drop-down filter selection list. All filter parameters are modified using

the Filter block dialog box. Each filter is loaded with all applicable default parameters

displayed to the right of each drop-down filter selection list.

DMP64 • Software Control 32

Page 39

Figure 24. Filter Dialog Box, Filters Added

Within the dialog box, a filter is focused when a filter type is inserted, or is focused by

clicking the filter number to the left of the filter selection drop-down list. Note how box3

(see figure 24) is highlighted in yellow, indicating it is the filter in focus. When bypassed,

the results of the filter in focus (independent of other filters) will show in the graph as a

dotted line the same color as its filter row. When active (not bypassed), the line is solid.

When multiple filters are enabled, the graph indicates the focused filter result (independent

of other filters) in the color of the filter row in the type/parameters table below the graph.

The composite response of all filters is displayed in red.

DMP64 • Software Control 33

Page 40

Figure 25. Filter Dialog Box, Filter Not Bypassed

Above the graph, each filter has a "handle" (circled in red above for the parametric

EQ filter) placed directly above the cutoff or center frequency. The handle number

corresponds to the filter number (also outlined in red). Clicking a handle or clicking the

table row brings focus to that filter. <Click+hold+dragging> the handle horizontally

changes the cutoff or center frequency to a new position on the x axis.

The table below shows each filter type with default parameter settings. The table

immediately following shows the range for each parameter.

Type Frequency Parameter 1 Parameter 2

Parametric 1000.0 Hz Boost/Cut: 0.0dB Q: 1.0

High Pass 100.0 Hz Slope: 6dB N/A

Low Pass 10000.0 Hz Slope: 6dB N/A

Bass (Tone) 100.0 Hz Boost/Cut: 0.0dB Slope: 6dB

Treble (Tone) 8000.0 Hz Boost/Cut: 0.0dB Slope: 6dB

Filter Parameter Settings Range

Frequency 20Hz to 20kHz

Tone (Boost/Cut) -24dB to +24dB

Q (Parametric EQ only) 0.707 to 15.000

Slope (HP & LP filters only) 1st Order (6dB) and 2nd Order (12dB)

DMP64 • Software Control 34

Page 41

High Pass

The high pass filter allows frequencies below the specified frequency to pass

unattenuated. All frequencies below the cutoff are attenuated.

The default cutoff is 100Hz.

Figure 26. High Pass Filter Response Curve

All frequencies lower than the specified frequency (in this example,100 Hz) are attenuated

leaving the upper frequency response flat. Also note that at the specified frequency

(100Hz) the signal is 3dB down, typical operation for high pass filters. The 3dB down

point will remain constant regardless of the slope setting. Only the steepness of the

frequency attenuation curve changes.

DMP64 • Software Control 35

Page 42

Low Pass

The low pass filter is the opposite of the High Pass filter. All frequencies above the

specified frequency are attenuated allowing lower frequencies to pass.

Figure 27. Low Pass Filter Response Curve

Here, the frequencies higher than the specified frequency, 10 kHz, are attenuated leaving

the lower frequency response flat.

DMP64 • Software Control 36

Page 43

Bass and Treble Shelving

Bass and treble shelving can be added to the filter. Also known as shelving or tone

controls, the separate bass and treble filters provide the ability to cut or boost gain

linearly above or below a selected frequency, with the end-band shape giving the visual

appearance of a shelf.

Adding the filter automatically inserts both a bass and a treble control row. If only a bass

or only a treble filter is required, either bypass the unneeded control or set it to Unused in

the selection box (see row 3, row 4, and row 5 in figure 28).

Figure 28. Bass and Treble Shelving

The corner frequency of the controls can be selected to 0.1 Hz accuracy. Two slopes,

6and 12dB/octave are selectable along with the ability to boost or cut the signal up

to24dB.

DMP64 • Software Control 37

Page 44

Parametric (Equalizer)

The parametric filter is a frequency equalizer that offers control of all parameters, including

amplitude (the amount of gain [boost], or gain reduction [cut] applied), center frequency

(frequency), and range of affected frequencies (Q) around the center frequency.