Page 1

Installation Guide

CVC 300

Component Video and HDTV to RGB Converter

68-1541-01 Rev. B

12 08

Page 2

LAN

ACT

LINK

RESET

7

8

5

6

3

4

1

2

7

8

5

6

3

4

1

2

7

8

5

6

3

4

1

2

7

8

5

6

3

4

1

2

7

8

5

6

3

4

1

2

OUTPUTS

OUTPUTS

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

15

16

13

14

11

12

9

10

7

8

5

6

3

4

1

2

INPUTS

INPUTS

Matrix Switcher

Projector

RGBHV

Component

POWER

12V

3A MAX

CVC 300

OUTPUT

R

G B V

H/HV

PR/R

PB/B

Y/G

INPUT

DSS Receiver

or

or

Blu-ray Disc

Extron

CVC 300

Component Video

Converter

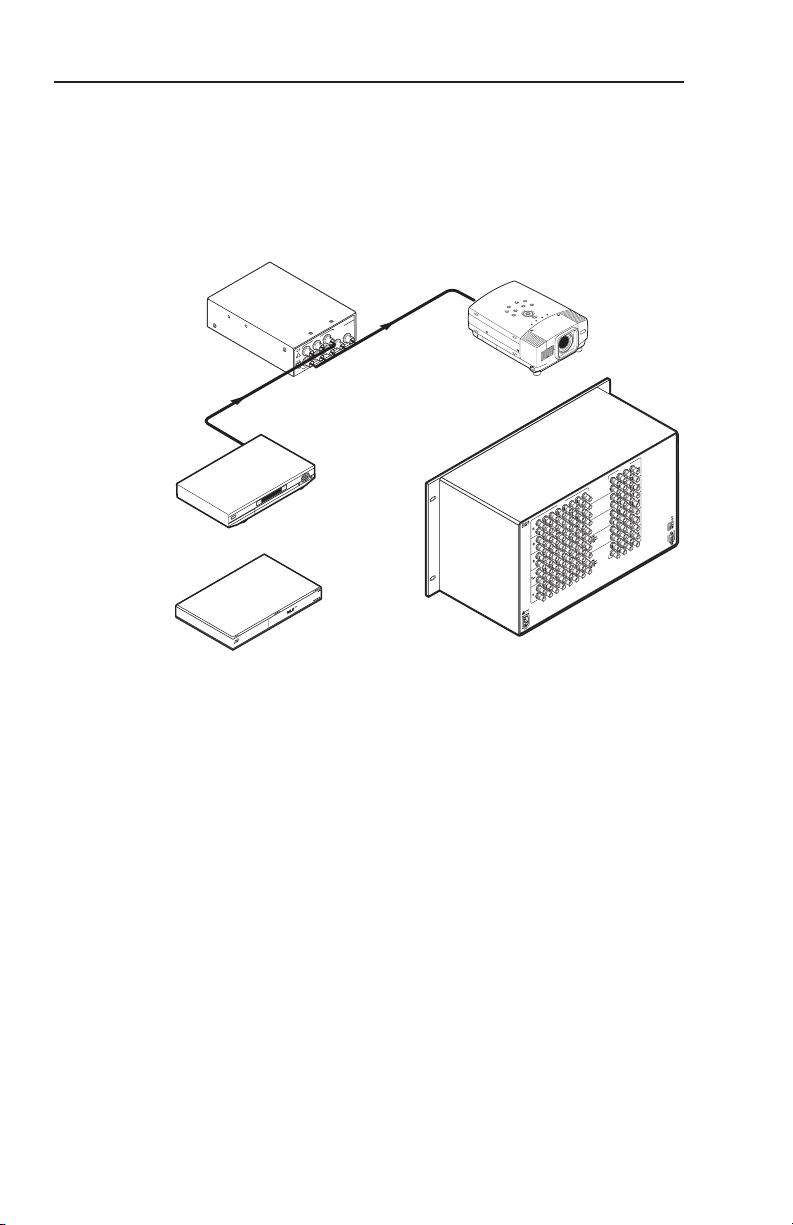

Introduction

The Extron CVC 300 Component Video Converter converts all

standard component video formats: NTSC/PAL, DVD, and

Betacam®, to RGBHV or RGBS; and converts SMPTE HDTV

component video to RGBHV. The CVC 300 can also strip

sync-on-green (SOG) from RGsB video. The converter outputs

RGBHV or RGBS video on BNC connectors. The figure below

shows a typical CVC 300 application.

Mounting

1

The component video input formats include SMPTE, HDTV

and Betacam component video. The RGsB video input can be

computer video or NTSC/PAL video.

The 1U high, quarter rack width, CVC 300 converter can be

mounted to a rack, under a desk or tabletop, or on a projector

bracket. It can be rack mounted using one-quarter of a 1U

Universal Rack Shelf, RSU 129 (part #60-190-01) or 1U Basic

UL rack mounting guidelines

Rack Shelf, RSB 129 (part #60-604-01).

The following Underwriters Laboratories (UL) guidelines

pertain to the installation of the CVC 300 into a rack.

Elevated operating ambient temperature — If the 1.

equipment is installed in a closed or multi-unit rack

assembly, the operating ambient temperature of the

rack environment may be greater than room ambient

temperature. Therefore, install the converter in an

environment compatible with the maximum ambient

temperature (Tma = +104 °F, +40 °C) specified by Extron.

CVC 300 • Installation

Page 3

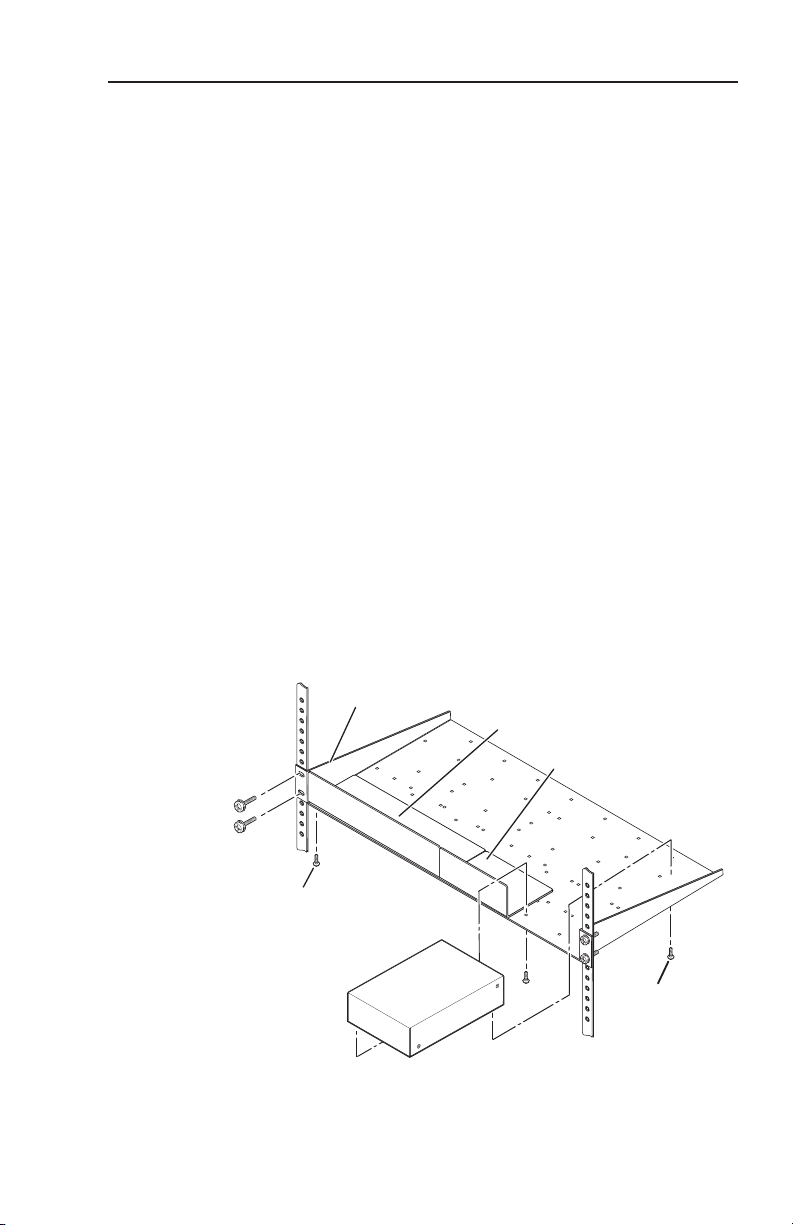

Use 2 mounting holes on

opposite corners.

(2) 4-40 x 3/16"

Screws

1U Universal Rack Shelf

Both front false faceplates

use 2 screws.

QuarterRackStandardShelf

1/4 Rack Width Front False

Faceplate

1/2 Rack Width Front False

Faceplate

Mounting

Reduced air flow — Install the equipment in a rack so that 2.

the amount of air flow required for safe operation of the

equipment is not compromised.

Mechanical loading — Mount the equipment in the rack so 3.

that a hazardous condition is not achieved due to uneven

mechanical loading.

Circuit overloading — Connect the equipment to 4.

the supply circuit and consider the effect that circuit

overloading might have on overcurrent protection and

supply wiring. Appropriate consideration of equipment

nameplate ratings should be used when addressing this

concern.

Reliable earthing (grounding) — Maintain reliable 5.

grounding of rack-mounted equipment. Pay particular

attention to supply connections other than direct

connections to the branch circuit (e.g. use of power strips).

Mounting instructions

Rack mount the CVC 300 as follows:

Remove the feet from the CVC, if they were previously 1.

installed.

Mount the CVC 300 on the rack shelf, using two 2.

4-40 x 3/16" screws in opposite corners (under the shelf) to

secure the converter to the shelf (see below).

CVC 300 • Installation

2

Page 4

Cable Connection and Rate Selection

POWER

12V

1.0 A MAX

CVC 300

OUTPUT

R

GB V

H/HV

P

R

/R

P

B

/B

Y/G

INPUT

COMPONENT VIDEO CONVERTER

CVC 300

FORMAT

c

e

b

a

d

Y, PR, PB

Video

RGsB

(SOG)

Video

Y, B-Y, R-Y

Video

B-YR-Y

PR /R PB /BY/G

PR /R PB /BY/G

PR /R PB /BY/G

R G B

H/HV

V

RGBHV

Video

RGBS

Video

R G B H/HV V

Cable Connection and Rate Selection

See the illustrations below to identify the panel connections.

Power connector — Plug the external 12 VDC power supply

a

here using the included 2-pole captive screw connector

(See "Power supply wiring").

Input connectors — Connect a component (SMPTE, HDTV,

b

or Betacam) or RGsB video input device to these female BNC

connectors. Connect the input device as shown below.

Output connectors — Connect an RGBHV or RGBS display to

c

these female BNC connectors. Connect the display as shown

below.

Power LED — Green when power is applied and an active

d

video input is detected. Amber if power is available but no

input signal is present.

3

CVC 300 • Cable Connection

Page 5

Cable Connection and Rate Selection (Cont’d)

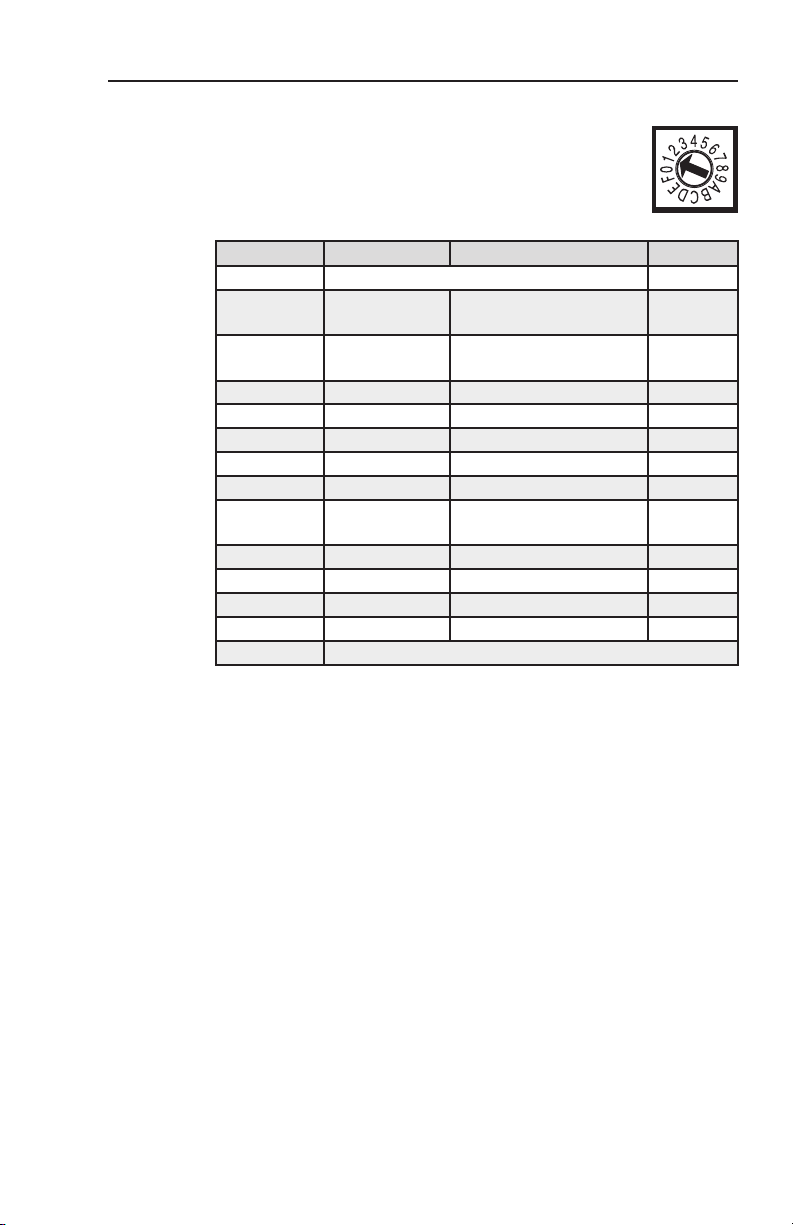

Input Format rotary switch — Use an Extron

e

Tweeker or other small screwdriver to set the Format

rotary switch to match the video input format. The

following table shows switch settings and their

assigned input video formats.

Position Input Resolutions Output

Position 0 Reserved for future use

Position 1

(Default):

Position 2: RGsB

Position 3: YUVi 480i, 576i RGBHV

Position 4: RGsB HD 720p, 1080i, 1080p RGBHV

Position 5: Betacam 50 480i, 576i RGBHV

Position 6: Betacam 60 480i, 576i RGBHV

Position 7: YUVp 480p, 576p RGBS

Position 8 RGsB

Position 9: YUVi 480i, 576i RGBS

Position A: RGsB HD 720p, 1080i, 1080p RGBS

Position B: Betacam 50 480i, 576i RGBS

Position C: Betacam 60 480i, 576i RGBS

D, E and F Reserved for future use

Input Format Table (Rotary Switch)

YUVp/HD

480p, 576p, 720p,

1080i, 1080p

480i/p, 576i/p,

640x480 to 1920x1200

480i/p, 576i/p,

640x480 to 1920x1200

RGBHV

RGBHV

RGBS

CVC 300 • Rate Selection

4

Page 6

Power Supply Wiring

Captive Screw Connector

SECTION A–A

Power Supply

Output Cord

Ridges

A

Smooth

A

Tie Wrap

+ _

3

5

Power supply wiring

N

Wire the supplied male power connector (plug) as shown below.

This product is intended to be powered by a UL Listed

power supply with an output rated at 12 VDC, 2 A.

C

N

To verify the polarity before connection, plug in the power

supply with no load and check the output with a voltmeter.

W

As an alternative, an Extron PS 123 Universal 12 VDC Power

Supply, part #60-814-01, can power multiple Extron 12 VDC

devices using only one AC power connector.

Insert the wired plug into the power connector on the rear

panel, then connect AC power.

Power supply voltage polarity is critical. Incorrect

polarity can damage the power supply and the product.

Identify the power cord negative lead by the ridges on the

side of the cord.

The length of the exposed (stripped) copper wires is

important. The ideal length is 3/16” (5 mm). Longer bare

wires can short together. Shorter wires are not as secure in

the captive screw connectors and could be pulled out.

Do not tin the stripped power supply leads. Tinned wires

are not as secure in the captive screw connectors and could

be pulled out.

The two power cord wires must be kept separate while

the power supply is plugged in. Remove power before

wiring.

CVC 300 • Power Supply Wiring

5

Page 7

Specifications

Video input

Number/signal type ..................... 1 component video [HDTV

(Y, PR, PB), SMPTE (Y, R-Y, B-Y), or

Betacam® (Y, R-Y, B-Y)] or RGsB

Connectors ..................................... 3 BNC female

Nominal level ................................ 1 Vp-p for Y of component video and

for G of RGsB

0.7 Vp-p for PB, PR, R-Y and B-Y of

component video, and for R and B of RGsB

Minimum/maximum levels ........ 0 V to 1.5 Vp-p with no offset

Impedance ...................................... 75 ohms

Horizontal frequency .................... 15 kHz to 100 kHz according to selected

mode

Vertical frequency .......................... 50 Hz to 120 Hz

Resolution range ........................... 640x480 to 1920x1200, 480i/p, 576i/p,

720p, 1080i/p

Return loss ...................................... <-35 dB @ 10 MHz

Video output

Number/signal type ..................... 1 RGBHV, RGBS

Connectors ..................................... 5 BNC female

Nominal level ................................ 0.7 Vp-p for RGB

Minimum/maximum levels ........ RGB: 0.0 V to 0.7 Vp-p

Impedance ...................................... 75 ohms

Return loss ...................................... <-45 dB @ 10 MHz

Vertical frequencies ....................... Locked to the detected input rate

Sync

Input type ....................................... RGsB; YUV; Y, R-Y, B-Y

Output type .................................... RGBHV, RGBS

Standards ........................................ SMPTE 170M (NTSC), SMPTE 274M

(1080i/p), SMPTE 293M (480p), SMPTE

296M (720p)

Input level ...................................... 0.3 V to 1.0 Vp-p (sync + video)

Output level ................................... 0.0 V to 5.0 Vp-p

Input impedance ........................... 75 ohms (on Y or Gs connector)

Output impedance ........................ 75 ohms (on H/HV and V connectors)

CVC 300 • Specications

6

Page 8

Extron USA - West

Headquarters

+800.633.9876

Inside USA / Canada Only

+1.714.491.1500

+1.714.491.1517 FAX

Extron USA - East

+800.633.9876

Inside USA / Canada Only

+1.919.863.1794

+1.919.863.1797 FAX

Extron Europe

+800.3987.6673

Inside Europe Only

+31.33.453.4040

+31.33.453.4050 FA X

Extron Asia

+800.7339.8766

Inside Asia Only

+65.6383.4400

+65.6383.4664 FAX

Extron Japan

+81.3.3511.7655

+81.3.3511.7656 FAX

Extron China

+400.883.1568

Inside China Only

+86.21.3760.1568

+86.21.3760.1566 FAX

Extron Middle East

+971.4.2991800

+971.4.2991880 FAX

Specifications (Cont’d)

General

External power supply ................. 100 VAC to 240 VAC, 50-60 Hz, external;

to 12 VDC, 2 A, regulated

Power input requirements ........... 12 VDC, 1.0 A

Temperature/humidity ................ Storage: -40 to +158 °F (-40 to +70 °C) /

10% to 90%, noncondensing

Operating: +32 to +104 °F (0 to +40 °C) /

10% to 90%, noncondensing

Cooling ........................................... Convection, no vents

Mounting

Rack mount ........................ Yes, with optional 1U, 9.5" deep rack shelf

(RSU 129, #60-190-01; RSB 129, 60-604-01);

or 1U, 6" deep rack shelf (RSU 126,

#60-190-10; RSB 126, 60-604-10)

Furniture mount ................ Yes, with optional MBU 125 Under

Desk Mount kit (70-077-01) or MBU 129

Through Desk Mount kit (70-077-02)

Enclosure type ............................... Metal

Enclosure dimensions ................... 1.7" H x 4.3" W x 6.0" D (1U high, quarter

rack wide)

(4.3 cm H x 10.9 cm W x 15.2 cm D)

(Depth excludes connectors.)

Product weight .............................. 0.8 lbs (0.4 kg)

Shipping weight ............................ 2 lbs (1 kg)

Vibration ......................................... ISTA 1A in carton (International Safe

Transit Association)

Regulatory compliance

Safety ................................... CE, CUL, UL

EMI/EMC .......................... CE, C-tick, FCC Class A, ICES,

VCCI Class A

MTBF ............................................... 30,000 hours

Warranty ......................................... 3 years parts and labor

N

N

All nominal levels are at ±10%.

Specifications are subject to change without notice.

© 2008 Extron Electronics. All rights reserved.

Loading...

Loading...