Page 1

User’s Manual

www.extron.com

Extron Electronics, USA

1230 South Lewis Street

Anaheim, CA 92805

800.633.9876 714.491.1500

FAX 714.491.1517

Extron Electronics, Europe

Beeldschermweg 6C

3821 AH Amersfoort, The Netherlands

+800.3987.6673 +31.33.453.4040

FAX +31.33.453.4050

© 2008 Extron Electronics. All rights reserved.

Extron Electronics, Asia

135 Joo Seng Rd. #04-01

PM Industrial Bldg., Singapore 368363

+800.7339.8766 +65.6383.4400

FAX +65.6383.4664

Extron Electronics, Japan

Kyodo Building, 16 Ichibancho

Chiyoda-ku, Tokyo 102-0082

Japan

+81.3.3511.7655 FAX +81.3.3511.7656

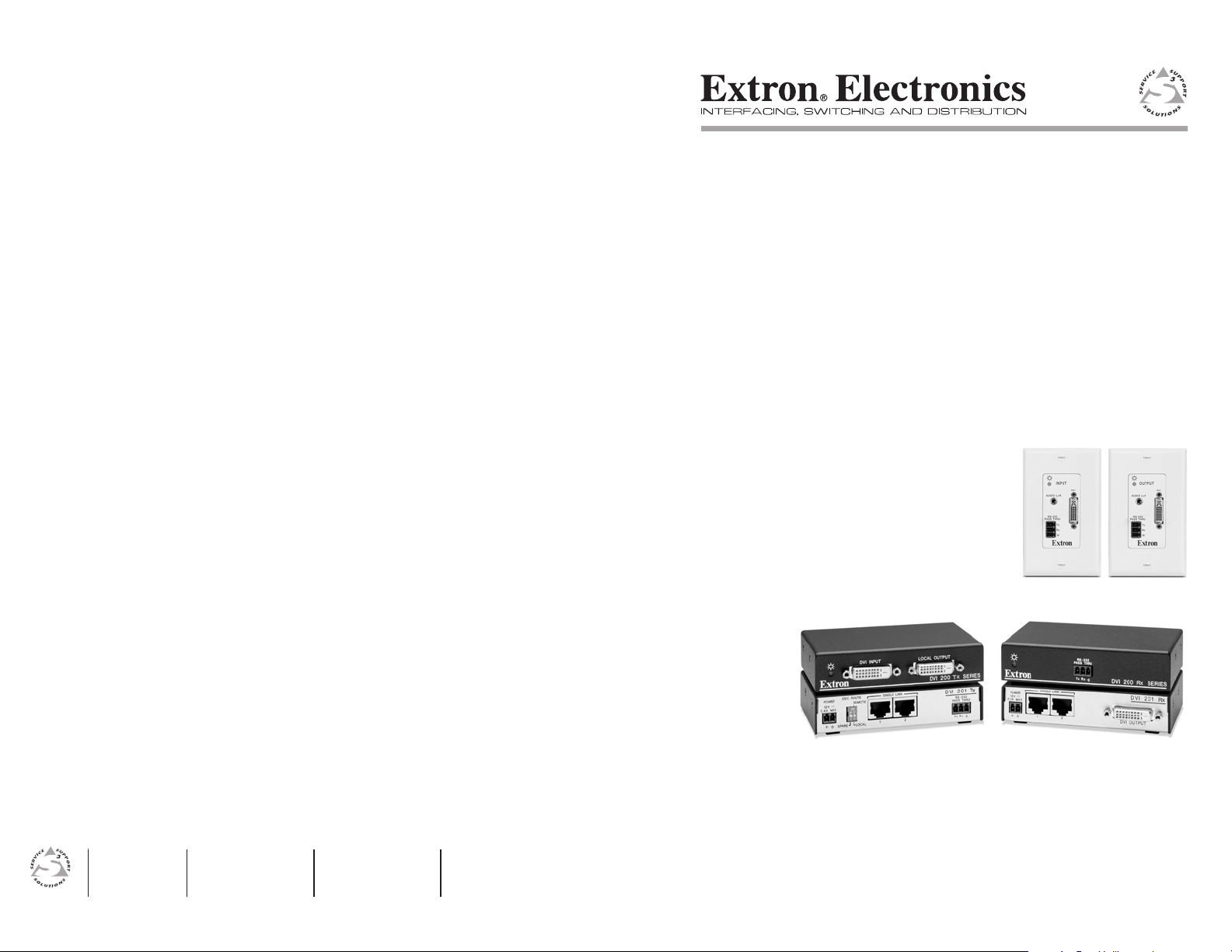

DVI 201 Tx/Rx

Digital Video Transmitter and Receiver

68-1034-02 Rev. A

01 08

Page 2

Precautions

Safety Instructions • English

This symbol is intended to alert the user of important

operating and maintenance (servicing) instructions in

the literature provided with the equipment.

This symbol is intended to alert the user of the

presence of uninsulated dangerous voltage within

the product’s enclosure that may present a risk of

electric shock.

Caution

Read Instructions • Read and understand all safety and operating

instructions before using the equipment.

Retain Instructions • The safety instructions should be kept for future

reference.

Follow Warnings • Follow all warnings and instructions marked on the

equipment or in the user information.

Avoid Attachments • Do not use tools or attachments that are not

recommended by the equipment manufacturer because they may be

hazardous.

Consignes de Sécurité • Français

Ce symbole sert à avertir l’utilisateur que la

documentation fournie avec le matériel contient des

instructions importantes concernant l’exploitation et

la maintenance (réparation).

Ce symbole sert à avertir l’utilisateur de la présence

dans le boîtier de l’appareil de tensions dangereuses

non isolées posant des risques d’électrocution.

Attention

Lire les instructions• Prendre connaissance de toutes les consignes de

sécurité et d’exploitation avant d’utiliser le matériel.

Conserver les instructions• Ranger les consignes de sécurité afi n de pouvoir

les consulter à l’avenir.

Respecter les avertissements • Observer tous les avertissements et consignes

marqués sur le matériel ou présentés dans la documentation utilisateur.

Eviter les pièces de fi xation • Ne pas utiliser de pièces de fi xation ni d’outils

non recommandés par le fabricant du matériel car cela risquerait de poser

certains dangers.

Sicherheitsanleitungen • Deutsch

Dieses Symbol soll dem Benutzer in der im

Lieferumfang enthaltenen Dokumentation

besonders wichtige Hinweise zur Bedienung und

Wartung (Instandhaltung) geben.

Dieses Symbol soll den Benutzer darauf aufmerksam

machen, daß im Inneren des Gehäuses dieses

Produktes gefährliche Spannungen, die nicht isoliert

sind und die einen elektrischen Schock verursachen

können, herrschen.

Achtung

Lesen der Anleitungen • Bevor Sie das Gerät zum ersten Mal verwenden,

sollten Sie alle Sicherheits-und Bedienungsanleitungen genau durchlesen

und verstehen.

Aufbewahren der Anleitungen • Die Hinweise zur elektrischen Sicherheit

des Produktes sollten Sie aufbewahren, damit Sie im Bedarfsfall darauf

zurückgreifen können.

Befolgen der Warnhinweise • Befolgen Sie alle Warnhinweise und

Anleitungen auf dem Gerät oder in der Benutzerdokumentation.

Keine Zusatzgeräte • Verwenden Sie keine Werkzeuge oder Zusatzgeräte,

die nicht ausdrücklich vom Hersteller empfohlen wurden, da diese eine

Gefahrenquelle darstellen können.

Instrucciones de seguridad • Español

Este símbolo se utiliza para advertir al usuario

sobre instrucciones importantes de operación y

mantenimiento (o cambio de partes) que se desean

destacar en el contenido de la documentación

suministrada con los equipos.

Este símbolo se utiliza para advertir al usuario sobre

la presencia de elementos con voltaje peligroso sin

protección aislante, que puedan encontrarse dentro

de la caja o alojamiento del producto, y que puedan

representar riesgo de electrocución.

Precaucion

Leer las instrucciones • Leer y analizar todas las instrucciones de operación y

seguridad, antes de usar el equipo.

Conservar las instrucciones • Conservar las instrucciones de seguridad para

futura consulta.

Obedecer las advertencias • Todas las advertencias e instrucciones marcadas

en el equipo o en la documentación del usuario, deben ser obedecidas.

Evitar el uso de accesorios • No usar herramientas o accesorios que no

sean especifi camente recomendados por el fabricante, ya que podrian

implicar riesgos.

Warning

Power sources • This equipment should be operated only from the power source

indicated on the product. This equipment is intended to be used with a main power

system with a grounded (neutral) conductor. The third (grounding) pin is a safety

feature, do not attempt to bypass or disable it.

Power disconnection • To remove power from the equipment safely, remove all power

cords from the rear of the equipment, or the desktop power module (if detachable),

or from the power source receptacle (wall plug).

Power cord protection • Power cords should be routed so that they are not likely to be

stepped on or pinched by items placed upon or against them.

Servicing • Refer all servicing to qualifi ed service personnel. There are no user-

serviceable parts inside. To prevent the risk of shock, do not attempt to service

this equipment yourself because opening or removing covers may expose you to

dangerous voltage or other hazards.

Slots and openings • If the equipment has slots or holes in the enclosure, these are

provided to prevent overheating of sensitive components inside. These openings

must never be blocked by other objects.

Lithium battery • There is a danger of explosion if battery is incorrectly

replaced. Replace it only with the same or equivalent type recommended by

the manufacturer. Dispose of used batteries according to the manufacturer’s

instructions.

Avertissement

Alimentations• Ne faire fonctionner ce matériel qu’avec la source d’alimentation

indiquée sur l’appareil. Ce matériel doit être utilisé avec une alimentation principale

comportant un fi l de terre (neutre). Le troisième contact (de mise à la terre) constitue

un dispositif de sécurité : n’essayez pas de la contourner ni de la désactiver.

Déconnexion de l’alimentation• Pour mettre le matériel hors tension sans danger,

déconnectez tous les cordons d’alimentation de l’arrière de l’appareil ou du module

d’alimentation de bureau (s’il est amovible) ou encore de la prise secteur.

Protection du cordon d’alimentation • Acheminer les cordons d’alimentation de

manière à ce que personne ne risque de marcher dessus et à ce qu’ils ne soient pas

écrasés ou pincés par des objets.

Réparation-maintenance • Faire exécuter toutes les interventions de réparation-

maintenance par un technicien qualifi é. Aucun des éléments internes ne peut être

réparé par l’utilisateur. Afi n d’éviter tout danger d’électrocution, l’utilisateur ne doit

pas essayer de procéder lui-même à ces opérations car l’ouverture ou le retrait des

couvercles risquent de l’exposer à de hautes tensions et autres dangers.

Fentes et orifi ces • Si le boîtier de l’appareil comporte des fentes ou des orifi ces, ceux-ci

servent à empêcher les composants internes sensibles de surchauffer. Ces ouvertures

ne doivent jamais être bloquées par des objets.

Lithium Batterie • Il a danger d’explosion s’ll y a remplacment incorrect de la batterie.

Remplacer uniquement avec une batterie du meme type ou d’un ype equivalent

recommande par le constructeur. Mettre au reut les batteries usagees conformement

aux instructions du fabricant.

Vorsicht

Stromquellen • Dieses Gerät sollte nur über die auf dem Produkt angegebene

Stromquelle betrieben werden. Dieses Gerät wurde für eine Verwendung mit einer

Hauptstromleitung mit einem geerdeten (neutralen) Leiter konzipiert. Der dritte

Kontakt ist für einen Erdanschluß, und stellt eine Sicherheitsfunktion dar. Diese

sollte nicht umgangen oder außer Betrieb gesetzt werden.

Stromunterbrechung • Um das Gerät auf sichere Weise vom Netz zu trennen, sollten

Sie alle Netzkabel aus der Rückseite des Gerätes, aus der externen Stomversorgung

(falls dies möglich ist) oder aus der Wandsteckdose ziehen.

Schutz des Netzkabels • Netzkabel sollten stets so verlegt werden, daß sie nicht im

Weg liegen und niemand darauf treten kann oder Objekte darauf- oder unmittelbar

dagegengestellt werden können.

Wartung • Alle Wartungsmaßnahmen sollten nur von qualifi ziertem Servicepersonal

durchgeführt werden. Die internen Komponenten des Gerätes sind wartungsfrei.

Zur Vermeidung eines elektrischen Schocks versuchen Sie in keinem Fall, dieses

Gerät selbst öffnen, da beim Entfernen der Abdeckungen die Gefahr eines

elektrischen Schlags und/oder andere Gefahren bestehen.

Schlitze und Öffnungen • Wenn das Gerät Schlitze oder Löcher im Gehäuse aufweist,

dienen diese zur Vermeidung einer Überhitzung der empfi ndlichen Teile im

Inneren. Diese Öffnungen dürfen niemals von anderen Objekten blockiert werden.

Litium-Batterie • Explosionsgefahr, falls die Batterie nicht richtig ersetzt

wird. Ersetzen Sie verbrauchte Batterien nur durch den gleichen oder einen

vergleichbaren Batterietyp, der auch vom Hersteller empfohlen wird. Entsorgen Sie

verbrauchte Batterien bitte gemäß den Herstelleranweisungen.

Advertencia

Alimentación eléctrica • Este equipo debe conectarse únicamente a la fuente/tipo

de alimentación eléctrica indicada en el mismo. La alimentación eléctrica de este

equipo debe provenir de un sistema de distribución general con conductor neutro

a tierra. La tercera pata (puesta a tierra) es una medida de seguridad, no puentearia

ni eliminaria.

Desconexión de alimentación eléctrica • Para desconectar con seguridad la acometida

de alimentación eléctrica al equipo, desenchufar todos los cables de alimentación

en el panel trasero del equipo, o desenchufar el módulo de alimentación (si fuera

independiente), o desenchufar el cable del receptáculo de la pared.

Protección del cables de alimentación • Los cables de alimentación eléctrica se deben

instalar en lugares donde no sean pisados ni apretados por objetos que se puedan

apoyar sobre ellos.

Reparaciones/mantenimiento • Solicitar siempre los servicios técnicos de personal

califi cado. En el interior no hay partes a las que el usuario deba acceder. Para evitar

riesgo de electrocución, no intentar personalmente la reparación/mantenimiento

de este equipo, ya que al abrir o extraer las tapas puede quedar expuesto a voltajes

peligrosos u otros riesgos.

Ranuras y aberturas • Si el equipo posee ranuras o orifi cios en su caja/alojamiento,

es para evitar el sobrecalientamiento de componentes internos sensibles. Estas

aberturas nunca se deben obstruir con otros objetos.

Batería de litio • Existe riesgo de explosión si esta batería se coloca en la posición

incorrecta. Cambiar esta batería únicamente con el mismo tipo (o su equivalente)

recomendado por el fabricante. Desachar las baterías usadas siguiendo las

instrucciones del fabricante.

Extron’s Warranty

Extron Electronics warrants this product against defects in materials and workmanship

for a period of three years from the date of purchase. In the event of malfunction during

the warranty period attributable directly to faulty workmanship and/or materials,

Extron Electronics will, at its option, repair or replace said products or components,

to whatever extent it shall deem necessary to restore said product to proper operating

condition, provided that it is returned within the warranty period, with proof of

purchase and description of malfunction to:

USA, Canada, South America, Europe, Africa, and the Middle East:

and Central America: Extron Electronics, Europe

Extron Electronics Beeldschermweg 6C

1001 East Ball Road 3821 AH Amersfoort

Anaheim, CA 92805, USA The Netherlands

Asia: Japan:

Extron Electronics, Asia Extron Electronics, Japan

135 Joo Seng Road, #04-01 Kyodo Building

PM Industrial Bldg. 16 Ichibancho

Singapore 368363 Chiyoda-ku, Tokyo 102-0082

Japan

This Limited Warranty does not apply if the fault has been caused by misuse, improper

handling care, electrical or mechanical abuse, abnormal operating conditions or nonExtron authorized modifi cation to the product.

If it has been determined that the product is defective, please call Extron and ask for an

Applications Engineer at (714) 491-1500 (USA), 31.33.453.4040 (Europe), 65.6383.4400

(Asia), or 81.3.3511.7655 (Japan) to receive an RA# (Return Authorization number). This

will begin the repair process as quickly as possible.

Units must be returned insured, with shipping charges prepaid. If not insured, you

assume the risk of loss or damage during shipment. Returned units must include the

serial number and a description of the problem, as well as the name of the person to

contact in case there are any questions.

Extron Electronics makes no further warranties either expressed or implied with respect

to the product and its quality, performance, merchantability, or fi tness for any particular

use. In no event will Extron Electronics be liable for direct, indirect, or consequential

damages resulting from any defect in this product even if Extron Electronics has been

advised of such damage.

Please note that laws vary from state to state and country to country, and that some

provisions of this warranty may not apply to you.

Page 3

安全须知 • 中文

这个符号提示用户该设备用户手册中

有重要的操作和维护说明。

这个符号警告用户该设备机壳内有暴

露的危险电压,有触电危险。

注意

阅读说明书 • 用 户使 用该 设备 前必 须阅 读并 理

解 所有 安全 和使 用说 明。

保存说明书 • 用户应保存安全说明书以备将来使

用。

遵守警告 • 用户应遵守产品和用户指南上的所有安

全和操作说明。

避免追加 • 不要使用该产品厂商没有推荐的工具或

追加设备,以避免危险。

警告

电源 • 该 设备 只能 使用 产品 上标 明的 电源 。 设备

必 须使 用有 地线 的供 电系 统供 电。 第 三条 线

( 地线 )是 安全 设施 ,不 能不 用或 跳过 。

拔掉电源 • 为安全地从设备拔掉电源,请拔掉所有设备后

或桌面电源的电源线,或任何接到市电系统的电源线。

电源线保护 • 妥善布线, 避免被踩踏,或重物挤压。

维护 • 所有维修必须由认证的维修人员进行。 设备内部没

有用户可以更换的零件。为避免出现触电危险不要自己

试图打开设备盖子维修该设备。

通风孔 • 有些设备机壳上有通风槽或孔,它们是用来防止

机内敏感元件过热。 不要用任何东西挡住通风孔。

锂电池 • 不正确的更换电池会有爆炸的危险。 必须使用与

厂家推荐的相同或相近型号的电池。 按照生产厂的建

议处理废弃电池。

FCC Class A Notice

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this

device may not cause harmful interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation. The Class A limits are designed to

provide reasonable protection against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and can radiate radio frequency energy

and, if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference, in which case the user will be required to correct the interference at his

own expense.

N

This unit was tested with shielded cables on the peripheral devices. Shielded cables must be used

with the unit to ensure compliance with FCC emissions limits.

Page 4

i

Table of Contents

Chapter One • Introduction .................................................... 1-1

About this Manual ....................................................................1-2

About the DVI 201 Transmitters and Receivers ............... 1-2

TP cable advantages .............................................................. 1-4

Control communications .......................................................1-4

Transmission distance ............................................................ 1-4

Features ........................................................................................1-5

Chapter Two • Installation and Operation ................... 2-1

Mounting the Tx/Rx.................................................................. 2-2

Non-Decora unit mounting ................................................... 2-2

Tabletop placement ................................................................2-2

Rack mounting ........................................................................2-2

Under-furniture mounting .....................................................2-4

Through-furniture mounting .................................................2-5

Projector mounting ................................................................2-6

Decora unit mounting .........................................................2-11

UL/Safety Requirements ......................................................2-11

Preparing the site and installing the wall box ...................2-11

Final installation ...................................................................2-14

Connections ............................................................................... 2-15

Transmitter connections ...................................................... 2-15

Receiver connections ........................................................... 2-19

Pin assignments and wiring ................................................ 2-22

DVI connector pin assignments ...........................................2-22

TP cable termination ............................................................2-23

Power supply wiring ............................................................2-25

RS-232 connector wiring ......................................................2-26

Operation ................................................................................... 2-27

Transmitter control and indicator ....................................... 2-29

Receiver indicator ................................................................2-29

System operation ................................................................. 2-29

Technical Points for Digital Video and Content

Protection Encryption ............................................................. 2-30

Troubleshooting ....................................................................... 2-31

Application Examples ............................................................. 2-32

Audio conversion ................................................................. 2-32

Modulated IR pass through ................................................. 2-33

DVI 201 Tx/Rx • Table of Contents

i

Page 5

Table of Contents, cont’d

Appendix A • Reference Information ..............................A-1

Specifications ..............................................................................A-2

Part Numbers ..............................................................................A-6

Transmitter/receiver pair part numbers ...............................A-6

Included parts .........................................................................A-6

Mounting accessories ............................................................A-7

Cables ......................................................................................A-8

Adapters .................................................................................A-8

Decora Template Dimensions ................................................A-9

DVI 201 Tx/Rx

Chapter One

1

68-1034-02 Rev. A

All trademarks mentioned in this manual are the properties of their respective owners.

ii

DVI 201 Tx/Rx • Table of Contents

Introduction

About this Manual

About the DVI 201 Transmitters and Receivers

Features

01 08

Page 6

DVI 201 Tx/Rx • Introduction

Introduction

DVI 201 Tx/Rx • Introduction

1-2

1-3

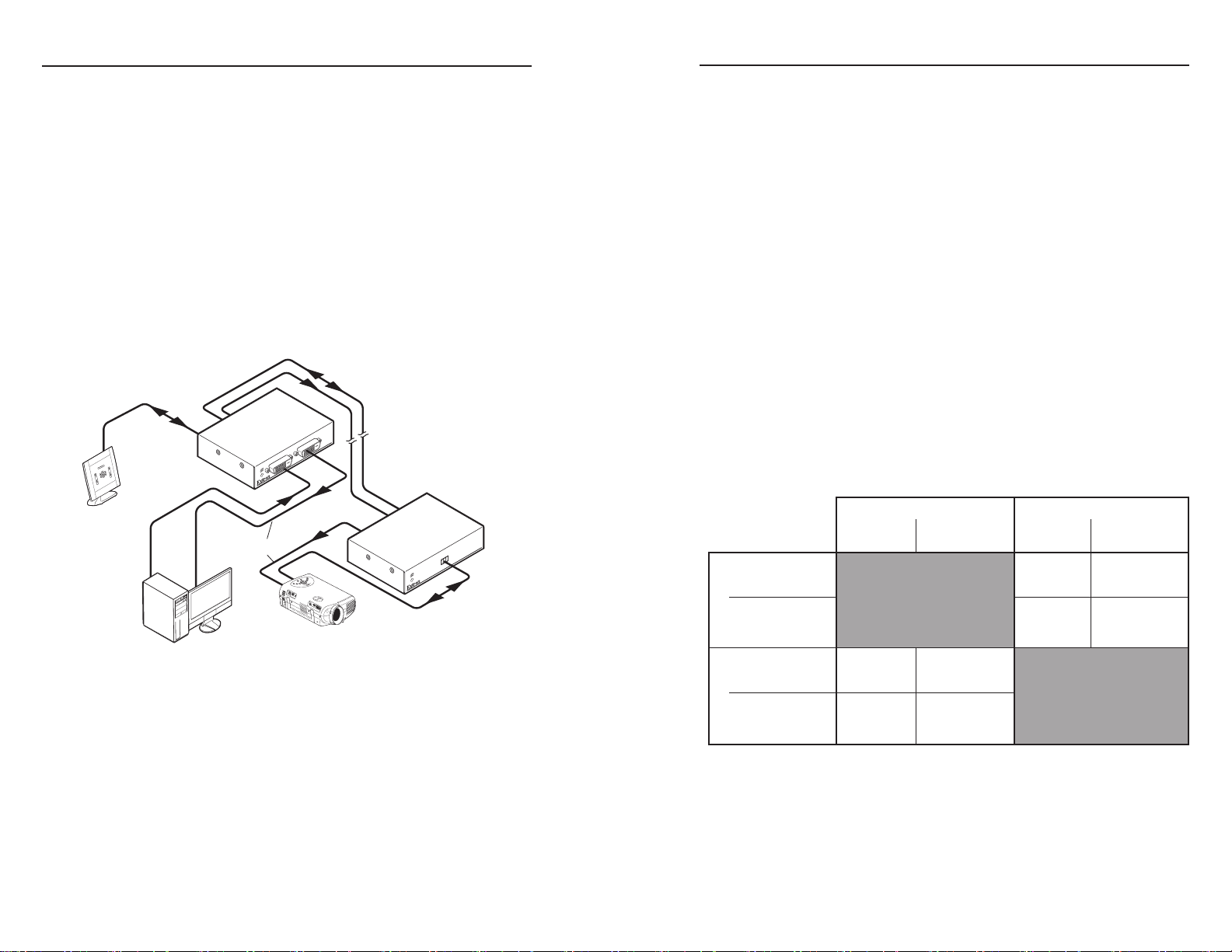

DVI 201 Tx

non-Decora

Transmitters

TransmittersReceivers

Receivers

DVI 201 Tx

non-Decora

DVI video

Control

DVI video

Control

DVI 201 A D Tx

non-Decora

DVI 201 Rx

non-Decora

DVI 201 A D Rx

non-Decora

DVI 201 A D Tx

Decora

DVI 201 Rx

non-Decora

DVI 201 A D Rx

Decora

DVI video

Control

DVI video

Control

Audio (pass)

DVI video

Control

DVI video

Control

DVI video

Control

DVI video

Control

Audio (pass)

D

V

I

2

0

0

T

X

S

E

R

I

E

S

L

O

C

A

L

O

U

T

P

U

T

D

V

IN

P

U

T

Multimedia

PC

Projector

Extron

DVI 201 Tx

Transmitter

Extron

DVI 201 Rx

Receiver

DVI Cable

D

V

I

2

0

0

R

S

-

2

3

2

P

A

S

S

T

H

R

U

T

x

R

x

RS-232

Control

CAT 5/5e /6 UTP up to 200’

RS-232

About this Manual

This manual contains information about the Extron

DVI 201 family of Digital Visual Interface (DVI) video

transmitters (Tx) and receivers (Rx), including how to install,

operate, and configure them.

About the DVI 201 Transmitters and Receivers

The Extron DVI 201 is a family of DVI transmitters and

receivers, in enclosures that support different mounting options.

A transmitter and receiver pair extends the usable distance of

DVI digital video and RS-232 control signals over two Category

(CAT) 5/5e/6 unshielded twisted pair (UTP) or shielded twisted

pair (STP) cables. The DVI 201 A D transmitter and receiver also

route audio, but not on the TP link. The video and control (and

audio, if applicable) signals can be transmitted up to 200' (60 m).

There are two subsets of transmitters and receivers in two

different enclosures or form factors:

• DVI 201 Tx/Rx — These units are housed in quarter rack

width metal enclosures. They can be set on a tabletop

or mounted in a rack, under or through furniture, or to a

projector pole. The transmitter in this form factor has a

local monitor output.

N

The non-Decora® models do not input, transmit, receive,

or output audio.

• DVI 201 A D Tx/Rx — These units are housed in

enclosures that can be mounted in UL standard wall boxes

with Decora-style face plates. These units also convert

computer level audio to balanced or unbalanced stereo

audio.

N

• A non-Decora transmitter or receiver is partially

compatible with a Decora receiver or transmitter.

A mixed form factor system can transmit and receive

•

video and RS-232 communications.

A mixed form factor system cannot handle audio,

•

as the non-Decora models do not input, transmit,

receive, or output audio.

Figure 1-1 — Typical transmitter and receiver application

A DVI 201 system consists of a transmitter (Tx) and a receiver

(Rx). The pair can handle a single link of DVI-D digital video

and a bi-directional RS-232 link. The DVI 201 A D also converts

a computer audio input into balanced or unbalanced stereo

audio output.

The units can be purchased as a pair (of the same form factor)

or individually. Each purchased pair and each individual

transmitter is shipped with a single external desktop 12 VDC

power supply that accepts 100 to 240 VAC, 50 Hz or 60 Hz input.

A single power supply connected to either the transmitter or the

receiver can power both units through one of the TP cables that

link the units.

Page 7

DVI 201 Tx/Rx • Introduction

Introduction, cont’d

1-4

DVI 201 Tx/Rx • Introduction

1-5

N

In this manual, the terms "DVI 201," "DVI 201 Tx,"

"DVI 201 Rx," "transmitter," and "receiver" refer to the

applicable unit(s) in either form factor, unless otherwise

specified.

TP cable advantages

Twisted pair cable is much smaller, lighter, more flexible, and

less expensive than coaxial or DVI cable. These transmitter and

receiver twisted pair (TP) products make cable runs simpler

and less cumbersome. Termination of the cable with RJ-45

connectors is simple, quick, and economical.

N

N

The transmitter and receiver pair works with unshielded

twisted pair (UTP) or shielded twisted pair (STP)

cables; but, to ensure FCC Class A and CE compliance,

STP cables are recommended.

Do not use Extron’s UTP23SF-4 Enhanced Skew-

Free™ A/V UTP cable to link the transmitter and

receiver. Skew-free A/V cable was designed for most

Extron TP transmitter/receiver applications, but the

DVI 201 Tx/Rx does not work properly with this cable.

Control communications

The RS-232 and/or infrared (IR) communications are via a

passive pass-through only; the transmitter and receiver do not

generate or respond to these signals.

Transmission distance

The maximum transmission distance is determined by the

resolution of the signal and the TP cable that is used.

With CAT 5/5e/6 UTP cable, the Tx/Rx pair can transmit and

receive 720p and 1080i HDTV or XGA video signals up to

200' (60 m) and 1080p HDTV or UXGA video up to 100' (30 m).

With CAT 5/5e/6 STP cable, the Tx/Rx pair can transmit and

receive 720p and 1080i HDTV or XGA video signals up to

200' (60 m) and 1080p HDTV or UXGA video up to 125' (38 m).

N

The transmission distance varies greatly, depending on

the signal resolution, type of cable used, graphics card,

and display used in the system.

Features

Transmits single link DVI-D signals over two CAT 5/5e/6

cables — Standard twisted pair cables provide an

economical, easily installed cable solution.

Long distance transmission —

CAT 5/5e/6 UTP cable — Accommodates 720p and

1080i HDTV or XGA video over 200' (60 m), and

1080p HDTV or UXGA (1600 x 1200) over 100' (30 m).

CAT 5/5e/6 STP cable — Accommodates 720p and

1080i HDTV or XGA video over 200' (60 m), and

1080p HDTV or UXGA (1600 x 1200) over 125' (38 m).

Local monitor output (DVI 201 Tx [non-Decora] only) —

The DVI 201 Tx transmitter features a DVI-D output for

connection to a local monitor.

Supports DDC and HDCP copy protection transmission —

The Tx/Rx pairs fully support long distance transmission

of the DDC and HDCP signals.

DDC routing to local or remote display — At the DVI 201 Tx

[non-Decora], the DDC or HDCP signal is directed to

either the local display or the remote display, depending

on which is more critical in receiving the signal.

Remote powering of transmitter or receiver — Only one power

supply is necessary to power both devices.

Control communications pass-through — Bidirectional RS-232

or IR control signals can be transmitted alongside the

DVI or HDMI signal, so that the remote display can be

controlled without the need for additional cabling.

Audio routing — The DVI 201 A D Tx/Rx also routes

unbalanced stereo audio, when both units are the Decora

form factor.

Supports CEC signal transmission

1" high, quarter rack width, metal enclosures (DVI 201 Tx

and DVI 201 Rx [non-Decora] only) — With low profile

enclosures, the transmitter and receiver can be discreetly

installed in locations such as behind a plasma or LCD

flat-panel display.

Wall-mountable enclosures (DVI 201 A D Tx and

DVI 201 A D Rx [Decora] only)

External 100 VAC to 240 VAC, 50/60 Hz, international power

supply (part #70-055-01) — Included with units sold as a

paired system and with transmitters

Page 8

Introduction, cont’d

DVI 201 Tx/Rx

Chapter Two

2

1-6

Installation and Operation

Mounting the Tx/Rx

Connections

Operation

Technical Points for Digital Video and Content Protection Encryption

Troubleshooting

Application Examples

DVI 201 Tx/Rx • Introduction

Page 9

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation

DVI 201 Tx/Rx • Installationand Operation

2-2

2-3

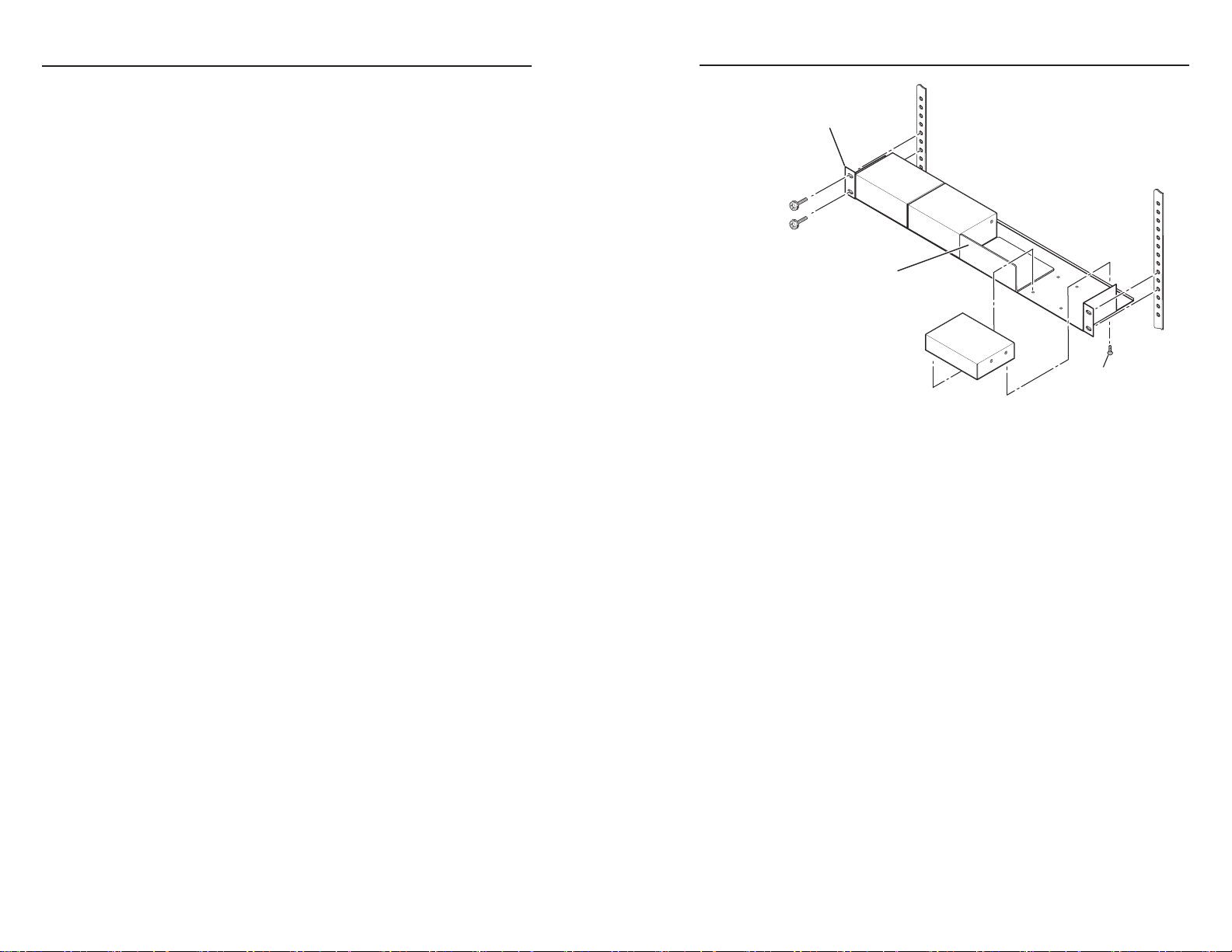

(2) 4-40 x 3/16"

Screws

Use 2 mounting holes on

opposite corners.

VersaTools Rack Shelf

1/4 Rack Width Front

False Faceplate

Mounting the Tx/Rx

Installation and service must be performed by

authorized personnel only.

installed in a closed or multi-unit rack assembly, the

operating ambient temperature of the rack environment

may be greater than room ambient. Therefore, consider

installing the equipment in an environment compatible

with the +122 °F (+50 °C) maximum ambient temperature

(Tma) specified by Extron.

should be such that the amount of air flow required for

safe operation of the equipment is not compromised.

the rack should be such that a hazardous condition is not

achieved due to uneven mechanical loading.

the connection of the equipment to the supply circuit and

the effect that overloading of the circuits might have on

overcurrent protection and supply wiring. Appropriate

consideration of equipment nameplate ratings should be

used when addressing this concern.

of rack-mounted equipment should be maintained.

Particular attention should be given to supply connections

other than direct connections to the branch circuit (such as

the use of power strips).

Non-Decora unit mounting

Tabletop placement

Rack mounting

C

The 1" high, quarter rack width DVI 201 (non-Decora)

transmitters and receivers can be placed on a tabletop, mounted

on a rack shelf, or mounted under a desk or tabletop. The

receiver can be mounted on a projector bracket.

Affix the four included rubber feet to the bottom of the unit and

place it in any convenient location.

UL requirements

The following Underwriters Laboratories (UL) requirements

pertain to the installation of the transmitter or receiver into or

onto a rack (figure 2-1).

1. Elevated operating ambient — If the equipment is

2. Reduced air flow — Installation of the equipment in a rack

3. Mechanical loading — Mounting of the equipment in

4. Circuit overloading — Consideration should be given to

5. Reliable earthing (grounding) — Reliable earthing

Figure 2-1 — Mounting the transmitter or receiver

unit on a VersaTools rack shelf

Rack mounting instructions

For optional rack mounting, mount the transmitter or receiver

on any of the following rack shelves:

• RSF 123 3.5" deep 1U VersaTools® rack shelf kit

(part #60-190-20) (figure 2-1)

• RSB 123 3.5" deep 1U VersaTools rack shelf (part #60-604-20)

• RSU 126 6" deep 1U universal rack shelf kit

(part #60-190-10)

• RSB 126 6" deep 1U basic rack shelf (part #60-604-10)

• RSU 129 9.5" deep 1U universal rack shelf kit

(part #60-190-01) (figure 2-2 on the next page)

• RSB 129 9.5" deep 1U basic rack shelf (part #60-604-01)

On the non-VersaTools rack shelves, the transmitter or receiver

unit can be mounted in the front or the rear of the rack.

1. Remove the feet from the bottom of the transmitter or

receiver unit, if they are installed.

2. Mount the transmitter or receiver unit using two

4-40 x 3/16" screws in opposite (diagonal) corners to

secure the transmitter or receiver to the shelf.

3. Install false faceplate(s) or other unit(s) to the rack shelf.

Page 10

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-4

DVI 201 Tx/Rx • Installation and Operation

2-5

Use 2 mounting holes on

opposite corners.

(2) 4-40 x 3/16"

Screws

1U Universal Rack Shelf

1/4 Rack Width

Front False

Faceplate

1/2 Rack Width

Front False

Faceplate

Both front false faceplates

use 2 screws.

Figure 2-3 — Under-desk mounting

Figure 2-2 — Mounting the transmitter or receiver

unit on a standard rack shelf

Under-furniture mounting

The unit can be mounted under a horizontal surface using an

optional MBU 125 under-desk mounting kit (part #70-077-01).

Mount the unit under a desk or table as follows:

1. Secure the under-desk mounting brackets to the

2. Hold the transmitter or receiver with attached brackets

3. Drill 1/4" (6.4 mm) deep, 3/32" (2 mm) diameter pilot

4. Insert the four wood screws into the pilot holes. Fasten

5. Align the installed screws with the slots in the mounting

6. Slide the transmitter or receiver slightly forward or back,

transmitter or receiver with the four machine screws

provided in the mounting kit (figure 2-3).

against the underside of the desk or other furniture. Mark

the location of holes for screws on the desk.

holes in the table or desk at the marked screw locations

from the underside or inside (the concealed side) of the

furniture, where the transmitter or receiver will be located.

each screw into the installation surface until just less than

1/4" of the screw head protrudes.

brackets, and place the transmitter or receiver against the

surface, with the screws through the bracket slots.

then tighten all four screws to fasten it in place.

Through-furniture mounting

The transmitter or receiver can be mounted through a desk or

other furniture using an optional Extron MBD 129 through-desk

mounting kit, part #70-077-02. Mount the transmitter or receiver

through a desk or table as follows (figure 2-4):

Figure 2-4 — Through-desk mounting

Page 11

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-6

DVI 201 Tx/Rx • Installation and Operation

2-7

Extron

PMK 300

Multi-product Projector Mount Kit

U-Bolt

Front Mounting

Plate

Side Mounting

Plate

Extron

DVI 201 or HDMI 201

Receiver

Power Supply

Bracket

Brace

1. Loosely attach the mounting brackets to the transmitter

or receiver using the four machine screws and washers

supplied with the mounting kit.

2. Hold the transmitter or receiver against the inside of the

surface through which it will be mounted. Mark the four

screw holes on the inside of the surface to which you are

mounting the device.

3. Drill four pilot holes, each 3/32" in diameter by 1/4" deep,

where you made marks.

4. Using the provided four wood screws, secure the brackets

to the mounting surface.

5. Slide the transmitter or receiver up and down in the

mounting brackets until the face of the transmitter or

receiver is at the desired height. Tighten the screws that

secure the brackets in place.

If the screws are inaccessible to a screwdriver:

a. Mark the location of the brackets relative to the screws.

b. Remove the transmitter or receiver from inside the

furniture.

c. Tighten the screws.

d. Replace the unit inside the surface (step 4).

Projector mounting

The receiver can be mounted on a projector bracket using either

of the following optional Extron projector mounting kits:

• PMK 300 projector mounting kit (part #70-374-01)

• PMK 350 low profile projector mounting kit

(part #70-563-02 [black] or part #70-563-03 [white])

PMK 300 mounting

Mount the receiver to a PMK 300 bracket as follows:

1. If necessary, remove the feet from the bottom of the

receiver.

2. Mount the receiver to one of the bracket’s three mounting

plates using two of the supplied 4-40 x 3/16" screws in

opposite (diagonal) corners to secure the device to the

bracket. It can be vertically mounted facing either up or

down (figure 2-5).

N

On the side mounting plates, the device is typically

mounted on the outside of the bracket.

On the front mounting plate, the device is typically

mounted on the inside of the bracket.

Figure 2-5 — PMK 300 projector mounting a receiver

3. If the power supply is connected to the receiver, use the

two included tie wraps to strap the power supply to one of

the brackets.

Page 12

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-8

DVI 201 Tx/Rx • Installation and Operation

2-9

U-Bolt

Extron

PMK 300

Multi-product Projector

Mount Kit

Bracket

Brace

Extron

PMK 350

Multi-product Projector

Mounting Kit

Cover Sheet

Front Plate

Rear Plate

U-bolt

L-shaped

Bracket

Contoured

Base

Extron

Power Supply

Extron

Quarter-rack

Sized Product

N

The PMK 300 has a hole in the bottom plate that

allows the projector pole to be inserted through the

center of the plate (figure 2-6), rather than outside of

the plate (figure 2-5). To install the PMK 300 in this

configuration, slide the bracket up from the bottom of the

pole before the projector is installed on the pole.

Figure 2-6 — Projector pole on the inside

4. Place the contoured bracket brace against the pole and

opposite the back plate. The pole should fit snugly into the

depression in the center of the bracket brace.

5. Place the U-bolt around the ceiling pole. Insert the

two legs of the U-bolt through the round holes on the

contoured bracket brace and then through the slotted holes

on the bracket’s mounting plate.

N

The supplied U-bolt fits a typical (1.5" to 2.0" diameter)

ceiling pole.

6. Secure the bracket to the U-bolt with the included hex

nuts, washers, and lock washers. Tighten the hex nuts just

enough that they can be loosened by hand.

PMK 350 mounting

Mount the receiver to a PMK 350 bracket as follows:

1. Remove the front and rear plates from the PMK 350

(figure 2-7), using an Extron Tweeker or a #2 Philips

screwdriver. Retain the screws to reattach the plates when

you are finished.

Figure 2-7 — PMK 350 projector mounting a receiver

2. If necessary, remove the feet from the bottom of the

receiver.

3. Secure the receiver to one side of the mounting tray,

using two of the supplied 4-40 x 3/16" screws in opposite

(diagonal) corners.

4. If power supply is connected to the receiver, use the

two included tie wraps to strap the power supply to the

bracket.

5. Place the PMK 350 around the projector ceiling mounting

pole (figure 2-7).

Page 13

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-10

DVI 201 Tx/Rx • Installation and Operation

2-11

U-bolt

Slotted Hole

in PMK Tray

L-shaped

Bracket

L-shaped

Bracket Screws

Contoured

Base

Ceiling

Pole

Mount Plate

Flange

6. Assemble the U-bolt and the following parts in the

following order (figure 2-8):

a. Pass the legs of the U-bolt through the slotted holes on

the mount plate flange.

b. Place the legs around the projector pole.

c. Pass the legs through the holes in the contour base.

N

The pole fits snugly into the depression in the

center of the contoured base.

d. Pass the legs through the holes in the L-shaped bracket.

N

The supplied U-bolt fits a typical (1.5" to 2.0"

diameter) ceiling pole.

Figure 2-8 — Hanging the tray on the pole

7. Align the two slotted holes in the bottom of the L-shaped

bracket with the two slotted holes in the base of the tray.

Secure the L-bracket to the base by inserting two provided

6-32 x 5/16" screws through the aligned slots.

8. Move the PMK 350 up to the desired location on the ceiling

pole, as close to the ceiling as desired.

9. Secure the L-shaped bracket to the U-bolt using the

included hex nuts, washers, and lock washers. Tighten the

hex nuts securely.

N

Be sure to tighten the hex nuts securely enough that the

PMK 350 does not slide down the ceiling pole. A socket

10. Secure the front and rear plates to the mounting tray with

wrench is recommended to tighten the hex nuts.

four of the included #6 screws.

11. If desired, choose one of the provided four sizes of selfadhesive cover sheets, and apply it to the underside of the

mounting tray.

Decora unit mounting

The DVI 201 A D (Decora) transmitter and receiver can be

installed in a one-gang electrical wall box with a Decora wall

plate cover (supplied).

The installation must conform to national and local electrical

codes and to the wall plate’s size requirements.

UL/Safety Requirements

The following Underwriters Laboratories (UL) requirements

pertain to the installation of the Decora transmitters and

receivers into a wall or furniture.

1. These units are not to be connected to a centralized DC

power source or used beyond their rated voltage range.

2. These units must be installed in UL listed junction boxes.

3. These units must be installed with conduit in accordance

with National Electrical Code.

Preparing the site and installing the wall box

Choose a location that allows cable runs without interference.

Allow enough depth for both the wall box and the cables. The

box should be at least 2.5" (6.4 cm) deep to accommodate the

connectors and cables. Install the cables into the wall, furniture,

or conduits before installing the wall plate.

N

The Decora units are very deep and have connectors

on the back side (figure 2-9 on page 2-12). Extron

recommends its 1-gang or 2-gang junction boxes

(part #s 980130 or 980084), which have a depth of

2.5" (6.4 cm).

Page 14

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-12

DVI 201 Tx/Rx • Installation and Operation

2-13

2.50 [63.5mm]

1.51 [38.48mm]

1.85 [47mm]

Junction Box

TP Cable

(no boot)

TP Cable

(no boot)

Captive

Screw

Connectors

Signal

Output

Cable

Cable

Clamp

Wall Stud

Screws

or Nails

Wall Stud

Cable

Clamp

Screws

or Nails

Signal

Output

Cable

Figure 2-10 — Installing the wall box

Figure 2-9 — Decora unit depth profile

To install a new wall box, perform steps 1 through 9 below. If a

suitable wall box is already installed, perform steps 6 through 9

below. UL listed wall boxes are recommended.

1. If a wall box is not available to use for a template, use the

dimensions on page A-9 to create a template. If installing

directly into furniture, cut out the center portion of your

template.

2. Place the wall box (or your template) against the

installation surface, and mark the opening guidelines.

3. Cut out the material from the marked area.

4. Insert the wall box into the opening. The box or the wall

5. Secure the wall box with nails or screws, leaving the front

plate’s rear connectors should fit easily into the opening.

Enlarge or smooth the edges of the opening if needed.

edge flush with the outer wall or furniture surface. See

figure 2-10.

N

If attaching the wall box to wood, use four #8 or #10

screws or 10-penny nails. A minimum of 0.5" (1.3 cm)

of screw thread must penetrate the wood.

If attaching the wall box to metal studs or furniture,

use four #8 or #10 self-tapping sheet metal screws or

machine bolts with matching nuts.

6. Feed the twisted pair cables and, if applicable, the audio

and power cables through the opening and through the

wall box punch-out holes, securing them with cable clamps

to provide strain relief.

N

In order to fit in the junction box, the TP cables and

RJ-45 connectors should not have a boot installed.

N

One power supply can power both the transmitter and

the receiver, so only one unit needs a power supply.

7. Trim back and/or insulate exposed cable shields with heat

shrink to reduce the chance of short circuits.

To prevent short circuits, the outer foil shield can be cut

back to the point where the cable exits the cable clamp.

8. Connect the cables to the rear of the unit. See

"Connections", later in this manual, for connector wiring

details.

9. Connect front panel devices (see "Connections", later in

this manual, for connector details), restore the power

supply, and test the transmitter/receiver system. Make

any cabling adjustments before final installation, as the

cables will be inaccessible afterwards.

Page 15

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-14

DVI 201 Tx/Rx • Installation and Operation

2-15

Wall opening

is flush with

edge of box.

Wall Box

Decora

Faceplate

Extron

DVI 201 A D

D

V

I

A

U

D

I

O

I

N

IN

P

U

T

T

x

R

x

R

S

-

2

3

2

P

A

S

S

T

H

R

U

DVI 200 Tx Series

DVI INPUT LOCAL OUTPUT

DVI 201 Tx Front Panel

DVI 201 A D Tx Front Panel

INPUT

Rx

Tx

RS-232

PASS THRU

DVI

AUDIO L+R

4

21

1

3

Final installation

After testing and making any adjustments, do the following:

1. At the power outlet, unplug the power supply.

N

2. Mount the transmitter or receiver into the wall box, and

Figure 2-11 — Mounting the transmitter or receiver

One power supply can power both the transmitter and

the receiver, so only one unit needs a power supply.

attach the supplied Decora faceplate to the unit, as shown

in figure 2-11.

Connections

Transmitter connections

The rack-mountable transmitter is in a quarter rack width

enclosure. The wall-mountable transmitter is in an enclosure

that can be mounted in UL standard wall boxes with Decora®style face plates.

Figure 2-12 shows the front panel of both DVI 201 Tx models.

Figure 2-13 shows the rear panel of both models.

3. At the power outlet, reconnect the power supply. This

powers up both units.

Figure 2-12 — DVI 201 Tx front panel connectors

Page 16

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-16

DVI 201 Tx/Rx • Installation and Operation

2-17

POWER

12V

0.4A MAX

DVI 201 Tx

RS-232

PASS THRU

Tx Rx

DDC ROUTE

1 2

REMOTE

SPARE LOCAL

POWER

12V

0.4A MAX

L

AUDIO

OUTPUT

R

DO NOT

CONNECT

TO LAN

1

2

DVI 201

A D Tx

O

U

T

P

U

T

S

5 6 4

7

DVI 201 Tx Rear Panel

DVI 201 A D Tx Rear Panel

6

5

Tip (L+) Sleeve (Gnd)

Tip (L+)

Ring (R+)

Sleeve (Gnd)

N

In a system where the local output is not used, ensure

that you power up the end display first before the video

source. Route the DDC to the remote end (see the

DDC Route DIP switch [item b, in "Operation", on

page 2-29]).

Audio input (DVI 201 A D Tx [Decora] only) — Connect an

c

unbalanced stereo audio source to this 3.5 mm mini stereo jack

for unbalanced audio input. Figure 2-14 shows how to wire the

audio plug.

Figure 2-14 — Audio input connector wiring

RS-232 connector — Connect a serial communications port to

d

this 3.5 mm, 3-pole captive screw connector for bidirectional

RS-232 communication. See "RS-232 connector wiring," on

page 2-26, to wire the connector.

N

The RS-232 connector can also transmit one-way

modulated infrared (IR) signals. See "Modulated IR

pass through" on page 2-33.

Figure 2-13 — DVI 201 Tx rear panel connectors

DVI input connector — Connect a DVI cable between this port

a

and the DVI output port of the digital video source. See "DVI

connector pin assignments," on page 2-22, for pin assignments.

Local output (DVI 201 Tx ([non-Decora] only) — If desired,

b

connect a DVI monitor for local monitoring of the input digital

image. See "DVI connector pin assignments," on page 2-22, for

pin assignments.

DC power input connector — Plug the included external

e

12 VDC power supply into either this connector or the power

input connector on the receiver (item k on page 2-20). See

"Power supply wiring," on page 2-25, to wire the connector.

Transmitter output connector — Connect one end of two

f

separate TP cables to these RJ-45 female connectors on the

transmitter.

C

Do not connect these devices to a computer data or

telecommunications network.

N

In order to fit in the junction box, the TP cables and

RJ-45 connectors should not have a boot installed.

Connect the free ends of the same TP cables from the transmitter

to the receiver’s Input RJ-45 female connectors (item h on

page 2-21).

Page 17

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-18

DVI 201 Tx/Rx • Installation and Operation

2-19

Unbalanced Output Balanced Output

Do not tin the wires!

L

AUDIO

OUTPUT

R

Tip

Sleeve (s) Sleeve (s)

Tip

NO GROUND HERE.

NO GROUND HERE.

Tip

Tip

Ring

Ring

L

AUDIO

OUTPUT

R

POWER

12V

0.4A MAX

DVI 201 Rx

1 2

DVI OUTPUT

DVI 201 Rx Rear Panel

POWER

12V

0.4A MAX

L

AUDIO

INPUT

R

DO NOT

CONNECT

TO LAN

1

2

DVI 201

A D Rx

I

N

P

U

T

S

DVI 201 A D Rx Rear Panel

11 8 9

10

8

11

N

Connect transmitter output 1 to receiver input 1.

Connect transmitter output 2 to receiver input 2.

N

If necessary, test for proper cable connection (output 1 to

input 1, output 2 to input 2) as follows:

1. Plug both TP cables into the powered unit.

2. Momentarily connect either of the cables on the

opposite end into the unpowered unit‘s “2” connector.

If the unpowered unit’s Power LED is lit, the

connection is correct.

If the unpowered unit’s Power LED is not lit,

unplug the connector on the unpowered end and

connect the other cable to the “2” connector.

See "TP cable termination," on page 2-23, to properly wire the

RJ-45 connectors.

Audio Output connector (DVI 201 A D Tx [Decora] only) —

g

Connect one end of a 5-wire audio cable to this 3.5 mm, 5-pole

direct insertion connector.

Connect the free end of the same cable from the transmitter to

any compatibly wired unit, such as a switcher, an amplifier, or a

DVI 201 A D Rx (Decora) receiver.

Figure 2-15 shows how to wire the captive screw audio

connector. Insert the wires into the appropriate openings in the

direct insertion connector. Tighten the screws on the side to

fasten the wires.

Receiver connections

The rack-mountable receiver is in a quarter rack width

enclosure. The wall-mountable receiver is in an enclosure that

can be mounted in UL standard wall boxes with Decora®-style

face plates.

Figure 2-16 shows the rear panel of both DVI 201 Rx models.

Figure 2-17 shows the front panel of both models.

Connect the sleeve to ground (Gnd). Connecting

Figure 2-15 — Captive screw connector wiring for

transmitter audio output

C

the sleeve to a negative (–) terminal will damage the

audio output circuits.

Figure 2-16 — DVI 201 Rx rear panel connectors

Page 18

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-20

DVI 201 Tx/Rx • Installation and Operation

2-21

DVI 201 Rx Front Panel

DVI 201 A D Rx Front Panel

DVI 200 Rx Series

RS-232

PASS THRU

Tx Rx

OUTPUT

Rx

Tx

RS-232

PASS THRU

DVI

AUDIO L+R

12

12

9

13

Tip

Sleeve

Sleeve

Tip

Unbalanced Input Balanced Input

Do not tin the wires!

Sleeve (s)

Tip

Tip

Ring

Ring

L

AUDIO

OUTPUT

R

L

AUDIO

OUTPUT

R

N

If necessary, test for proper cable connection (output 1 to

input 1, output 2 to input 2) as follows:

1. Plug both TP cables into the powered unit.

2. Momentarily connect either of the cables on the

opposite end into the unpowered unit‘s “2” connector.

If the unpowered unit’s Power LED is lit, the

connection is correct.

If the unpowered unit’s Power LED is not lit,

unplug the connector on the unpowered end and

connect the other cable to the “2” connector.

See "TP cable termination," on page 2-23, to properly wire the

RJ-45 connectors.

DVI Output connector — Connect a DVI monitor or projector

i

for display of the transmitted direct digital image. See "DVI

connector pin assignments," on page 2-22, for pin assignments.

Audio Input connector (DVI 201 A D Rx [Decora] only) —

j

Connect one end of a 5-wire audio cable to this 3.5 mm, 5-pole

direct insertion connector.

Connect the free end of the same cable to any compatibly

wired audio source unit, such as a switcher's output or a

DVI 201 A D Tx (Decora) transmitter.

Figure 2-18 shows how to wire the captive screw audio

connector. Insert the wires into the appropriate openings in the

direct insertion connector. Tighten the screws on the side to

fasten the wires.

Figure 2-17 — DVI 201 Rx front panel connectors

Do not connect these devices to a computer data or

In order to fit in the junction box, the TP cables and

RJ-45 connectors should not have a boot installed.

Connect transmitter output 1 to receiver input 1.

Receiver input connector — Connect one end of the two

h

separate TP cables from the transmitter output connectors (item

on page 2-17) to these RJ-45 female connectors.

f

C

N

N

Connect transmitter output 2 to receiver input 2.

telecommunications network.

Figure 2-18 — Captive screw connector wiring for

receiver audio output

DC power input connector — Plug the included external

k

12 VDC power supply into either this connector or the power

input connector on the transmitter (item e on page 2-17). See

"Power supply wiring," on page 2-25, to wire the connector.

Page 19

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-22

DVI 201 Tx/Rx • Installation and Operation

2-23

Pin Signal

1

TMDS data 2–

TMDS data 2+

TMDS data 1–

TMDS data 1+

DDC clock +5 V power

DDC data TMDS clock+Ground (+5 V)

CEC control* TMDS clock–Hot Plug Detect

TMDS data 0–

TMDS data 0+

Spare

Spare

Spare

Spare

Spare

Spare

TMDS data 2

shield

TMDS data 1

shield

TMDS data 0

shield

TMDS clock

Shield

Pin PinSignal Signal

2

9

10

17

4 12 20

5 13 21

6 14 22

7 15 23

Spare SpareSpare

C1 C3 C5

Spare Spare

C2 C4

8

* CEC control on pin 8 is a proprietary usage,

not the industry standard.

16 24

18

3 11 19

1

9

8

17 24

C3 C4

C1 C2

C5

5

Pin

1

2

3

6

7

8

4

N Terminate both ends of both cables identically, in accordance with

either the TIA/EIA T 568A or the TIA/EIA T 568B wiring standard.

Wire color

White-green

Green

White-orange

White-blue

Orange

White-brown

Brown

Blue

Data 0+

Data 0–

Data 1–

ID Clock–

Data 2+

Data 2–

Wire color

White-green

Green

White-orange

White-blue

Orange

White-brown

Brown

Signal

TIA/EIA T

586 A

TIA/EIA T

586 B

RJ-45 #1

ID Clock+

Data 1+Blue

CEC

HPD

RS-232

TX

+12 V

RS-232

RX

DDC data

Ground

RJ-45 #2

DDC Clk

Side

1234 56 78

Insert

Twisted

Pair Wires

Pins:

RJ-45

Connector

RS-232 connector — Connect a serial communications port to

l

this 3.5 mm, 3-pole captive screw connector for bidirectional

RS-232 communication. See "RS-232 connector wiring," on

page 2-26, to wire the connector.

N

The RS-232 connector can also transmit one-way

modulated infrared (IR) signals. See "Modulated IR

pass through" on page 2-33.

Audio output connector (DVI 201 A D Tx [Decora] only) —

m

Connect a stereo audio device to this 3.5 mm mini stereo jack to

receive the unbalanced audio output. Figure 2-14 on page 2-17

shows how to wire the audio plug.

Pin assignments and wiring

DVI connector pin assignments

Figure 2-19 defines the pinout for the DVI protocol.

Figure 2-19 — DVI connectors

TP cable termination

N

RJ-45 termination with CAT 5, CAT 5e, or

CAT 6 cable must comply with the TIA/EIA T 568A or

TIA/EIA T 568B wiring standard for all connections.

Figure 2-20 details the recommended termination of TP cables

with RJ-45 connectors in accordance with either the

TIA/EIA T 568A or the TIA/EIA T 568B wiring standard.

Figure 2-20 — TP cable termination

N

Do not use Extron’s UTP23SF-4 Enhanced Skew-Free™

A/V UTP cable to link the transmitter and receiver.

Skew-free A/V cable was designed for most Extron

TP transmitter/receiver applications, but the

DVI 201 Tx/Rx will not work properly with this cable.

N

In order to fit in the junction box, the TP cables and

RJ-45 connectors should not have a boot installed.

N

If necessary, test for proper cable connection (output 1 to

input 1, output 2 to input 2) as follows:

1. Plug both TP cables into the powered unit.

2. Momentarily connect either of the cables on the

opposite end into the unpowered unit‘s “2” connector.

If the unpowered unit’s Power LED is lit, the

connection is correct.

If the unpowered unit’s Power LED is not lit,

unplug the connector on the unpowered end and

connect the other cable to the “2” connector.

Page 20

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-24

DVI 201 Tx/Rx • Installation and Operation

2-25

Peel back shield and

fold back.

Aluminum Tape

Wrap tape around folded foil shielding.

Slightly overlap.

Cut and save the excess tape

for other connectors.

Crimped Connector

Power Supply

Output Cord

Orange Captive

Screw

Connector

Non-Decora units

SECTION A–A

Ridges

Smooth

A A

Ferrite Bead

DC Power Cord

(between power supply

and DVI unit

power connector)

Tie Wrap

3

5

Terminating shielded cable

N

The transmitter and receiver pair works with unshielded

twisted pair (UTP) or shielded twisted pair (STP) cables;

but, to ensure FCC Class A and CE compliance, STP

cables are recommended.

The Tx/Rx includes four shielded RJ-45 connectors and a length

of self-adhesive shielded tape that you can use to make the STP

cables that connect the transmitter and receiver.

N

Extron supplies the connectors and the shielded tape.

You must supply the CAT 5, 5e, or 6 STP cable.

Terminate the STP cable as follows:

1. Peel back the cable shielding (figure 2-21) from the

end of the cable the length of the RJ-45 connector body

(approximately 7/8" [2.2 cm]) and fold it back.

Figure 2-21 — Peeling back the cable shielding

2. Cut away and discard the clear cellophane inner wrapper

from the end of the cable back to the folded-over cable

shielding.

3. Peel the backing off the self-adhesive shielded aluminum

tape and wrap it around the folded-over cable shielding,

slightly overlapping the beginning of the tape

(figure 2-22).

Figure 2-23 — Crimped RJ-45 connector

Power supply wiring

N

• Only one power supply is required. A single power

supply connected to either unit in the pair powers

both units.

• A single power supply is included with systems

packaged as a pair.

• A power supply is also included with each

individually-packaged transmitter.

Figure 2-24 shows how to wire the connector.

C

Power supply voltage polarity is critical. Incorrect

voltage polarity can damage the power supply and

the transmitter or receiver. Identify the power cord

negative lead by the ridges on the side of the cord

(figure 2-24).

To verify the polarity before connection, plug in the power

supply with no load and check the output with a voltmeter.

Figure 2-22 — Wrapping the shielded tape

4. Cut the unused portion of the shielded tape and retain for

shielding other RJ-45 connectors.

5. Crimp the RJ-45 cable in the normal manner, folding the

tangs at the end of the connector over the shielded tape

(figure 2-23).

Figure 2-24 — Power connector wiring

W

The two power cord wires must be kept separate

while the power supply is plugged in. Remove

power before wiring.

Page 21

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-26

DVI 201 Tx/Rx • Installation and Operation

2-27

Ground

Receive

Transmit

Connected RS-232

Device Pins

Tx/Rx

Pins

Rx

Tx

DVI 200 Tx SERIES

DVI INPUT LOCAL OUTPUT

POWER

12V

0.4A MAX

DVI 201 Tx

RS-232

PASS THRU

Tx Rx

DDC ROUTE

1 2

REMOTE

SPARE LOCAL

2

1

DVI 201 Tx Transmitter Rear Panel

DVI 201 Tx Transmitter Front Panel

C

The length of the exposed (stripped) copper wires

is important. The ideal length is 3/16" (5 mm).

Longer bare wires can short together. Shorter wires

are not as secure in the connector and could be

pulled out.

N

Do not tin the power supply leads before installing in

the connector. Tinned wires are not as secure in the

connector and could be pulled out of the connector.

Use the supplied tie-wrap to strap the power cord to the

extended tail of the connector.

N

Your transmitter/receiver pair may have shipped with a

blue captive screw connector. This blue connector can be

plugged into either a blue or an orange power receptacle.

The blue connector does not have the extended tail or the

included tie-wrap.

Snap the provided ferrite bead onto the DC power cable,

between the power supply and the DVI unit’s connector.

RS-232 connector wiring

Figure 2-25 shows how to wire the RS-232 connector for serial

communications.

N

The RS-232 connector can also transmit one-way

modulated infrared (IR) signals. See "Modulated IR

pass through" on page 2-33.

Operation

Figure 2-26 shows the DDC control and power indicator on the

non-Decora transmitter. Figure 2-27 shows the power indicator

on the Decora transmitter.

N

Figure 2-26 — Non-Decora control and indicator

Both receiver models have power indicators in the same

location as on the related transmitter model.

Figure 2-25 — RS-232 connector wiring

C

N

The length of the exposed (stripped) copper wires

is important. The ideal length is 3/16" (5 mm).

Longer bare wires can short together. Shorter wires

are not as secure in the connector and could be

pulled out.

Do not tin the power supply leads before installing in

the connector. Tinned wires are not as secure in the

connectors and could be pulled out of the connector.

Page 22

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-28

DVI 201 Tx/Rx • Installation and Operation

2-29

INPUT

Rx

Tx

RS-232

PASS THRU

DVI

AUDIO L+R

1

DVI 201 A D Tx Transmitter Front Panel

Figure 2-27 — Decora power indicator

Transmitter control and indicator

Power LED —

a

DVI 201 Tx (non-Decora) — This front panel LED lights green

to indicate that the unit is receiving power:

DVI 201 A D Tx (Decora) — This two-color front panel LED

lights to indicate signal and power status as follows:

Amber — The unit is receiving power.

Green — The unit is receiving power and a signal is present on

the DVI input.

DDC Route switch (DVI 201 Tx ([non-Decora] only) —

b

This rear panel switch selects either the remote or local DVI

display as the route of the display resolution data (the display

data channel [DDC]) and HDCP copyright decoding keys.

Receiver indicator

N

Power LED —

a

DVI 201 Rx (non-Decora) — This front panel LED lights green

to indicate that the unit is receiving power:

DVI 201 A D Rx (Decora) — This two-color front panel LED

lights to indicate signal and power status as follows:

Amber — The unit is receiving power.

Both receiver models have power indicators in the same

location as on the related transmitter model.

Green — The unit is receiving power and a signal is present on

the TP input.

System operation

After the transmitter, the receiver, and their connected devices

are powered up, the system is fully operational. If any problems

are encountered, ensure all cables are routed and connected

properly.

N

Ensure that the video source and display selected for the

DDC are properly connected to the transmitter/receiver

pair, and that the transmitter, the receiver, and the

display have power applied before power is applied to

the video source. If all other devices are not turned on

before the video source, the image may not appear.

Page 23

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-30

DVI 201 Tx/Rx • Installation and Operation

2-31

Technical Points for Digital Video and Content Protection Encryption

• Digital Visual Interface (DVI) is a digital video format

that was created by the computer industry in 1999.

• High Definition Multimedia Interface (HDMI™) is a

multimedia format that was created by the consumer

video industry in 2003.

The HDMI format is built onto the DVI format,

adding digital audio and control while reducing the

size of the connector.

The HDMI format is likely to replace the DVI format

in the near future.

With passive adapters, the HDMI format is backward

compatible with the DVI format.

• With Extron adapters and/or cables, the DVI 201 fully

supports either format, regardless of the connector

type on the video source and display. See appendix A,

"Reference Information," for part numbers.

• High-bandwidth Digital Content Protection (HDCP) is

an encryption method that protects copyrighted digital

entertainment material that uses DVI video.

HDCP is generated by video player hardware,

enabled by the video content.

The HDCP key is transmitted with the Display Data

Channel (DDC).

The DDC signal line was designed for the DDC’s low

data rate; the HDCP key rate is much higher.

♦ Without active buffering, an HDCP key signal

can travel only a short distance. The display

may properly receive the digital video signal, but

not the HDCP key. Without the key, the display

cannot decrypt the video signal. Symptoms of

undecrypted video may include a flashing black

or blue screen or “snow”.

♦ With active buffering, an HDCP key signal can

travel as far as other signals to ensure proper

decryption.

♦ The DVI 201 actively buffers the HDCP key.

Troubleshooting

DVI signals run at a very high frequency and are especially

susceptible to bad video connections, too many adapters,

or cables that are too long. To avoid the loss of an image or

introduction of image jitter, follow these guidelines:

• The DVI cable on the input to the transmitter or

the output of the receiver should not exceed 10' (3 m).

• Use only cable designed for DVI signals.

• Limit or avoid the use of adapters.

• If the display exhibits a flashing black or blue screen,

snow, or other distortion, a non-HDCP compliant display

may be receiving an HDCP-encrypted signal.

Check for an HDCP problem by ejecting the DVD from

the player. If the display distortion stops and the DVD

menu or screen saver image is clear, the problem is

HDCP-related.

• Always power the display before the DVI video source in

order for the source to retrieve the DDC from the display.

Page 24

DVI 201 Tx/Rx • Installation and Operation

Installation and Operation, cont’d

2-32

DVI 201 Tx/Rx • Installation and Operation

2-33

POWER

12V

0.4A MAX

DVI 201 RX

1 2

DVI OUTPUT

POWER

12V

0.4A MAX

L

AUDIO

OUTPUT

R

DO NOT

CONNECT

TO LAN

1

2

DVI 201

A D Tx

O

U

T

P

U

T

S

INPUT

Rx

Tx

RS-232

PASS THRU

DVI

AUDIO L+R

DVI-D In

Source

Audio

TP 1

TP 2

Balanced Audio Out

Balanced Audio

Wiring

Audio System

DVI 201 A D Tx Front DVI 201 A D Tx Rear

DVI 201 Rx

Projector

R+

R-

L+

L-

TP 1

TP 2

INPUT

Rx

Tx

RS-232

PASS THRU

DVI

AUDIO L+R

DVI 200 RX SERIES

RS-232

PASS THRU

Tx Rx

IR Emitter

Ground

Control

Modulated IR

DVI 201 Rx

DVI 201 A D Tx

Flat Panel Display

w/ IR Control

Application Examples

Audio conversion

Figure 2-28 shows a standard installation with DVI video and an

audio input. The DVI 201 A D Tx converts the video input into

two proprietary TP outputs. The Tx outputs the audio directly

on a captive screw connector.

Modulated IR pass through

Figure 2-29 shows an installation in which the Tx/Rx pair sends

a modulated infrared (IR) signal across the link. On the TX side,

control system is connected to the Tx pin (the modulated IR

signal) and the Gnd (signal ground) on the transmitter. An IR

emitter is connected to the Tx and Gnd receiver output.

Figure 2-28 — Typical installation

Figure 2-29 — Installation routing modulated IR

Page 25

Installation and Operation, cont’d

DVI 201 Tx/Rx

Appendix A

A

2-34

Reference Information

Specifications

Part Numbers

Decora Template Dimensions

DVI 201 Tx/Rx • Installation and Operation

Page 26

DVI 201 Tx/Rx • Reference Information

Reference Information

DVI 201 Tx/Rx • Reference Information

A-2

A-3

Specifications

Video input and loop-through — transmitters

Number/signal type ..................... 1 DVI-D/HDMI* input, 1920x1200

@ 60 Hz max. resolution

1 DVI-D/HDMI* local loop-through

Connectors

DVI 201 Tx/Rx................... 2 DVI-D female

DVI 201 A D Tx/Rx ........... 2 DVI-I female

Interconnection between transmitter and receiver

Connectors ..................................... 2 RJ-45 per unit for 2 CAT 5/5e/6 or

STP (shielded twisted pair) cables

connecting the transmitter and receiver

Termination standards.................. TIA/EIA T 568A or T 568B. Pin

configurations for each standard are

available in the manual’s installation

chapter.

Bit rate ............................................. 5 gigabits/second total (1.65 gigabits/

second/color)

Signal transmission distance

1920x1200 @ 60 Hz (the highest resolution of the single link DVI

standard)

STP (shielded twisted pair cable)

125' (38 m)

CAT 5/5e/6 cable ...... 100' (30 m)

HDTV (1080i or 720p) or 1024x768 @ 60 Hz

CAT 5/5e/6 or STP (shielded twisted pair) cable

200' (60 m)

Audio — DVI 201 A D Tx/Rx

Gain ................................................ Unbalanced output: 0 dB;

balanced output: +6 dB

Frequency response ..................... 20 Hz to 20 kHz, ±0.05 dB

THD + Noise ................................. 0.10% @ 1 kHz at nominal level

S/N ................................................. >85 dB at maximum output (unweighted)

Stereo channel separation ........... >86 dB @ 1 kHz

Audio input — DVI 201 A D Tx/Rx

Number/signal type

DVI 201 A D Tx .................. 1 stereo, unbalanced

DVI 201 A D Rx .................. 1 stereo, balanced/unbalanced

Connectors

DVI 201 A D Tx .................. (1) 3.5 mm mini audio jack (tip, ring,

sleeve)

DVI 201 A D Rx .................. (1) 3.5 mm captive screw connector, 5 pole

Impedance

DVI 201 A D Tx .................. >10k ohms unbalanced, DC coupled

DVI 201 A D Rx .................. >18k ohms unbalanced, 14k ohms

balanced, DC coupled

Nominal level

DVI 201 A D Tx .................. -10 dBV (316 mVrms)

DVI 201 A D Rx .................. +4 dBu (1.23 Vrms)

Maximum level

DVI 201 A D Tx .................. +11 dBu, unbalanced at 1% THD+N

DVI 201 A D Rx .................. +16.8 dBu, unbalanced at 1% THD+N

N

0 dBu = 0.775 Vrms, 0 dBV = 1 Vrms, 0 dBV ≈ 2 dBu

N

The transmission distance varies greatly depending on the signal

resolution and on the type of cable, graphics card, and display used in

the system.

Video output — receivers

Number/signal type ..................... 1 DVI-D/HDMI*, 1920x1200 @ 60 Hz max.

resolution

Connectors

DVI 201 Tx/Rx................... 2 DVI-D female

DVI 201 A D Tx/Rx ........... 2 DVI-I female

Audio output — DVI 201 A D Tx/Rx

Number/signal type

DVI 201 A D Tx .................. 1 stereo, balanced/unbalanced

DVI 201 A D Rx .................. 1 stereo, unbalanced

Connectors

DVI 201 A D Tx .................. (1) 3.5 mm captive screw connector, 5 pole